Don't wanna be here? Send us removal request.

Text

Singhal Industries Pvt. Ltd.: Leading Polypropylene Sheet Manufacturer

Polypropylene (PP) sheets have become a staple in various industries due to their versatility, durability, and excellent chemical resistance. Singhal Industries Pvt. Ltd. is a premier manufacturer of high-quality polypropylene sheets, offering innovative solutions that cater to the diverse needs of its clients. This article explores the capabilities, advantages, and applications of Singhal Industries' polypropylene sheets.

Excellence in Polypropylene Sheets

Singhal Industries Pvt. Ltd. has established itself as a leader in the manufacturing of polypropylene sheets, recognized for their exceptional quality and performance. These sheets are widely used across industries such as packaging, automotive, construction, and agriculture due to their strength, flexibility, and resistance to moisture and chemicals.

Advanced Manufacturing Capabilities

Singhal Industries operates a state-of-the-art manufacturing facility equipped with advanced technology and machinery. This enables the company to produce polypropylene sheets with precision and consistency, adhering to stringent quality control measures. The facility is designed to handle large-scale production while ensuring superior product performance.

Uncompromising Quality Assurance

Quality assurance is a cornerstone of Singhal Industries' operations. The company maintains rigorous quality control at every stage of the manufacturing process, from raw material sourcing to the final inspection of finished polypropylene sheets. Each sheet undergoes comprehensive testing to ensure it meets the highest standards of durability, dimensional stability, and chemical resistance.

Singhal Industries uses virgin-grade polypropylene resin and employs advanced processing techniques to achieve uniform thickness and excellent mechanical properties in their sheets. This commitment to quality has earned the company certifications and accolades, solidifying its reputation as a trusted manufacturer.

Customization Options

Recognizing the diverse needs of their clients, Singhal Industries offers extensive customization options for polypropylene sheets. Clients can specify dimensions, thicknesses, colors, and additional features such as UV stabilization or flame retardancy based on their specific application requirements. This flexibility allows businesses to optimize their operations and enhance product performance.

Sustainability and Environmental Responsibility

Singhal Industries is dedicated to sustainable manufacturing practices. The company utilizes recyclable materials and energy-efficient processes in the production of polypropylene sheets, minimizing environmental impact. By promoting eco-friendly products, Singhal Industries supports sustainable development goals and meets the growing demand for environmentally responsible solutions.

Applications of Polypropylene Sheets

1. Packaging

Polypropylene sheets are widely used in the packaging industry due to their strength, flexibility, and moisture resistance. They are ideal for creating boxes, containers, and protective packaging materials.

2. Automotive

In the automotive industry, polypropylene sheets are used for interior components, such as door panels, dashboards, and trunk liners, due to their durability and resistance to chemicals and heat.

3. Construction

Polypropylene sheets are utilized in the construction sector for applications such as wall panels, flooring, and roofing. Their resistance to moisture and chemicals makes them suitable for harsh environments.

4. Agriculture

In agriculture, polypropylene sheets are used for creating greenhouse panels, irrigation systems, and protective coverings due to their durability and UV resistance.

Leading Provider of High-Quality Polypropylene Sheets

Singhal Industries Pvt Ltd is a prominent PP Sheets Manufacturer, specializing in producing high-quality polypropylene sheets for a variety of industrial applications. These PP sheets are known for their excellent durability, chemical resistance, and ease of fabrication. Singhal Industries Pvt Ltd utilizes advanced manufacturing techniques and stringent quality control processes to ensure that their PP sheets meet the highest standards of performance and reliability, making them ideal for sectors such as packaging, automotive, and construction.

Innovating Durable and Versatile Solutions

As one of the leading Polypropylene Sheet Manufacturers, Singhal Industries Pvt Ltd excels in creating durable and versatile sheet solutions tailored to meet diverse industry needs. Their polypropylene sheets are designed to withstand harsh environmental conditions, providing superior chemical resistance and thermal stability. By leveraging state-of-the-art technology and adhering to rigorous quality standards, Singhal Industries Pvt Ltd delivers polypropylene sheets that offer exceptional performance and longevity, making them suitable for a wide range of applications including industrial equipment, consumer goods, and signage.

Standardized Sheets for Broad Applications

Singhal Industries Pvt Ltd offers Polypropylene Sheets 4x8 size, providing a reliable and versatile solution for various industrial and commercial applications. These 4x8 polypropylene sheets are manufactured using high-quality materials and advanced production processes, ensuring consistent thickness and superior mechanical properties. The 4x8 size is particularly popular for its convenience and adaptability, making it ideal for applications such as wall cladding, chemical containment, and furniture. With Singhal Industries Pvt Ltd's commitment to quality and customer satisfaction, their 4x8 polypropylene sheets are a preferred choice for businesses seeking efficient and effective material solutions.

Conclusion

Singhal Industries Pvt. Ltd. exemplifies excellence in the manufacturing of polypropylene sheets, driven by innovation, quality, and customer satisfaction. With advanced manufacturing capabilities, stringent quality control processes, and a commitment to sustainability, the company offers reliable and customizable solutions for diverse industrial applications. For businesses seeking durable and versatile polypropylene sheets, Singhal Industries provides unparalleled expertise and reliability.

FAQs

1. What are the key properties of Singhal Industries' polypropylene sheets?

Singhal Industries' polypropylene sheets are known for their strength, flexibility, chemical resistance, and dimensional stability. These properties make them suitable for a wide range of industrial applications where durability and reliability are essential.

2. How does Singhal Industries ensure the quality of its polypropylene sheets?

Singhal Industries implements stringent quality control measures throughout the production process. This includes rigorous testing of raw materials, continuous monitoring of production parameters, and thorough inspection of finished sheets to ensure adherence to high-quality standards.

3. Can Singhal Industries provide customized polypropylene sheet solutions?

Yes, Singhal Industries offers extensive customization options for polypropylene sheets. Clients can specify dimensions, thicknesses, colors, and additional features to meet specific application requirements, ensuring optimal performance and functionality.

4. Are Singhal Industries' polypropylene sheets environmentally friendly?

Singhal Industries is committed to sustainability and uses recyclable materials and energy-efficient processes in the manufacturing of polypropylene sheets. This eco-friendly approach reduces environmental impact and supports sustainable development practices.

5. What industries commonly use polypropylene sheets from Singhal Industries?

Singhal Industries' polypropylene sheets are widely used across industries such as packaging, automotive, construction, agriculture, and electronics. They serve various applications including packaging materials, automotive components, construction barriers, agricultural liners, and more.

0 notes

Text

Singhal Industries Pvt Ltd: Your Reliable Source for Rockshield Products

Rockshield, an essential component in pipeline construction, provides crucial protection against damage caused by external factors. Singhal Industries Pvt Ltd is a trusted manufacturer of high-quality rockshield products, offering durable solutions to safeguard pipelines in various environments. This comprehensive guide explores the features, benefits, applications, and why Singhal Industries Pvt Ltd is the preferred choice for rockshield products.

Understanding Rockshield

Rockshield, also known as pipeline padding or pipeline protection mesh, is a protective layer installed around pipelines to shield them from damage caused by rocks, debris, and external forces. Typically made from high-density polyethylene (HDPE) or polypropylene (PP), rockshield effectively absorbs impact and minimizes the risk of abrasion and puncture.

Features of Singhal Industries Pvt Ltd's Rockshield Products

High-Quality Material: Our rockshield products are crafted from premium-grade HDPE or PP material, ensuring superior strength and durability.

Impact Resistance: Designed to withstand heavy impacts from rocks, boulders, and debris, providing reliable protection for pipelines.

Flexibility: The flexible nature of our rockshield products allows for easy installation around pipelines, even in challenging terrains.

Chemical Resistance: Resistant to chemicals, acids, and alkalis, ensuring long-term performance and stability in various environments.

UV Stabilization: Treated with UV stabilizers, our rockshield products offer excellent resistance to sunlight exposure, extending their lifespan.

Benefits of Singhal Industries Pvt Ltd's Rockshield Products

Pipeline Protection: Provides essential protection against damage, including abrasion, puncture, and impact, ensuring the integrity and longevity of pipelines.

Cost-Effectiveness: By reducing the need for costly repairs and maintenance, our rockshield products offer significant cost savings over the long term.

Easy Installation: Lightweight and flexible, our rockshield products are easy to handle and install, minimizing installation time and labor costs.

Versatility: Suitable for a wide range of pipeline diameters and terrains, our rockshield products offer versatile solutions for various projects.

Environmental Sustainability: Made from recyclable materials and manufactured using sustainable practices, our rockshield products support environmental conservation efforts.

Applications of Singhal Industries Pvt Ltd's Rockshield Products

Oil and Gas Pipelines: Used to protect oil and gas pipelines from damage during construction, transportation, and operation.

Water Pipelines: Employed in water pipeline projects to prevent damage caused by rocks, debris, and soil movement.

Utility Pipelines: Installed around utility pipelines, including sewer, drainage, and electrical conduits, to enhance their durability and lifespan.

Infrastructure Projects: Integrated into infrastructure projects, such as roadways, railways, and bridges, to protect pipelines passing through these areas.

Environmental Remediation: Used in environmental remediation projects to protect remediation systems, such as groundwater extraction wells and monitoring wells.

Why Choose Singhal Industries Pvt Ltd for Rockshield Products?

Quality Assurance: Our rockshield products undergo rigorous quality control measures to ensure they meet the highest standards of performance and reliability.

Customization Options: We offer customization options, including size, thickness, and material composition, to meet specific project requirements.

Technical Expertise: With years of experience in the industry, our team of experts provides technical support and guidance to ensure the success of your projects.

Timely Delivery: We prioritize timely delivery to ensure that your project timelines are met without delays.

Customer Satisfaction: At Singhal Industries Pvt Ltd, customer satisfaction is our top priority, and we are committed to providing exceptional products, service, and support to our valued customers.

Singhal Industries Pvt. Ltd. introduces top-of-the-line Rock Shield for Pipeline in challenging terrains. Our rock shields are meticulously engineered to provide robust protection against abrasion, impact, and external pressures, ensuring the integrity and longevity of your pipelines. Whether for oil, gas, water, or other fluids, our rock shields offer unparalleled durability and reliability, giving you peace of mind in even the harshest environments.

As premier Rock Shield Manufacturer, Singhal Industries Pvt. Ltd. takes pride in delivering innovative solutions that meet the highest industry standards. Our rock shields are crafted with precision using high-quality materials and advanced manufacturing techniques, guaranteeing exceptional performance and longevity. With a commitment to excellence and customer satisfaction, we strive to exceed expectations and establish ourselves as leaders in the field of pipeline protection.

Singhal Industries Pvt. Ltd. is a trusted name among Rock Shield Manufacturers, renowned for our dedication to quality and reliability. Our rock shields are meticulously crafted to provide superior protection against external threats, ensuring the safety and integrity of pipelines in diverse applications. With a focus on innovation and continuous improvement, we remain committed to delivering rock shield solutions that meet the evolving needs of our customers worldwide.

Conclusion

Singhal Industries Pvt Ltd is your trusted partner for high-quality rockshield products that provide essential protection for pipelines in various industries and environments. With our premium materials, customization options, versatility, and commitment to customer satisfaction, we deliver reliable solutions that meet your specific project needs. Choose Singhal Industries Pvt Ltd for rockshield products that offer unmatched durability, performance, and peace of mind.

FAQs

1. Can Singhal Industries Pvt Ltd customize rockshield products to fit specific pipeline diameters?

Yes, we offer customization options to ensure that our rockshield products fit the specific diameter and requirements of your pipelines.

2. Are Singhal Industries Pvt Ltd's rockshield products suitable for use in environmentally sensitive areas?

Yes, our rockshield products are designed to meet environmental regulations and standards, making them suitable for use in environmentally sensitive areas.

3. How can I request a quotation for rockshield products from Singhal Industries Pvt Ltd?

You can request a quotation by contacting our sales team directly via phone, email, or through our website. Please provide details such as product specifications, quantity, and any specific customization requirements for an accurate quotation.

4. Are Singhal Industries Pvt Ltd's rockshield products recyclable?

Yes, our rockshield products are made from recyclable materials, supporting environmental sustainability and conservation efforts.

5. What industries commonly use rockshield products from Singhal Industries Pvt Ltd?

Our rockshield products are commonly used in industries such as oil and gas, water utilities, infrastructure development, environmental remediation, and construction, among others, to protect pipelines and infrastructure from damage.

0 notes

Text

Vacuum Form Plastic Sheets: Essential Materials for Versatile Applications

Vacuum forming is a popular plastic fabrication process used to create a variety of products, from packaging to automotive parts. Vacuum form plastic sheets are the primary material used in this process, offering numerous benefits such as versatility, durability, and cost-effectiveness. This article explores the features, benefits, and applications of vacuum form plastic sheets and highlights Singhal Industries Pvt Ltd as a leading manufacturer of these essential materials.

Understanding Vacuum Form Plastic Sheets

Vacuum forming involves heating a plastic sheet until it becomes pliable, then stretching it over a mold and applying vacuum pressure to form the desired shape. Various types of plastic sheets are used in this process, including ABS (Acrylonitrile Butadiene Styrene), HIPS (High Impact Polystyrene), PETG (Polyethylene Terephthalate Glycol), and PVC (Polyvinyl Chloride).

Features of Vacuum Form Plastic Sheets

Thermoformability: These plastic sheets can be easily heated and shaped over molds, making them ideal for vacuum forming processes.

Durability: Vacuum form plastic sheets are resistant to impact, weathering, and chemicals, ensuring long-lasting performance.

Versatility: Available in various materials, thicknesses, and colors, these sheets can be customized to meet specific requirements.

Lightweight: Despite their strength, plastic sheets used in vacuum forming are lightweight, making them easy to handle and transport.

Recyclability: Many vacuum form plastic sheets are recyclable, contributing to environmental sustainability.

Advantages of Vacuum Form Plastic Sheets

Cost-Effectiveness: Vacuum forming is a relatively low-cost production method, and the plastic sheets used are affordable, making it a cost-effective solution for producing large volumes of products.

Design Flexibility: Vacuum form plastic sheets can be molded into complex shapes with fine details, offering great design flexibility for various applications.

Quick Production: The vacuum forming process is efficient and quick, allowing for rapid production of parts and products.

Consistency: This process ensures consistent quality and uniformity in the produced parts, essential for mass production.

Customizability: Plastic sheets can be tailored in terms of thickness, color, texture, and material properties to suit specific application needs.

Applications of Vacuum Form Plastic Sheets

Vacuum form plastic sheets are used in a wide range of industries and applications, including:

Packaging: Used to create custom packaging solutions, such as blister packs and clamshells, for protecting and displaying products.

Automotive: Used to manufacture interior and exterior components, including dashboards, door panels, and protective covers.

Consumer Goods: Applied in producing items such as toys, appliance housings, and electronic enclosures.

Medical: Utilized for creating medical trays, equipment housings, and orthotic devices.

Signage and Displays: Used in producing durable, eye-catching signs, displays, and point-of-purchase stands.

Industrial: Applied in making machine guards, panels, and other industrial components.

Singhal Industries Pvt Ltd: Your Trusted Vacuum Form Plastic Sheets Manufacturer

As a leading manufacturer of plastic materials, Singhal Industries Pvt Ltd offers high-quality vacuum form plastic sheets designed to meet the specific needs of various industries. Our commitment to quality, innovation, and customer satisfaction sets us apart in the market.

Singhal Industries Pvt Ltd offers premium-quality Vacuum Form Plastic Sheets designed for a variety of industrial and commercial applications. These sheets are made from high-grade materials, ensuring excellent durability, flexibility, and uniform thickness. Ideal for creating detailed and precise molded parts, Singhal Industries' vacuum form plastic sheets are suitable for use in sectors such as packaging, automotive, and consumer goods. Their commitment to quality and innovation ensures that each sheet meets rigorous performance standards, providing reliable and high-quality results.

Singhal Industries Pvt Ltd produces plastic sheets specifically designed for use with Vacuum Forming Machine Plastic Sheets. These sheets are crafted to deliver consistent heating and molding characteristics, making them perfect for producing complex shapes and detailed components. Available in various materials and thicknesses, Singhal Industries' vacuum forming machine plastic sheets offer excellent versatility for different manufacturing needs. Their products ensure optimal performance and precision, making them the preferred choice for businesses seeking high-quality plastic sheets for their vacuum forming operations.

Singhal Industries Pvt Ltd specializes in Vacuum Forming Plastic Sheets that cater to a wide range of applications, from product packaging to automotive components. These sheets are known for their exceptional strength, flexibility, and ability to form intricate shapes with precision. Whether for prototype development or large-scale production, Singhal Industries' vacuum forming plastic sheets deliver superior quality and performance. With a focus on customer satisfaction and product excellence, they provide reliable and versatile plastic sheets that meet the highest industry standards, ensuring consistent and optimal results for every project.

Why Choose Singhal Industries Pvt Ltd?

Quality Assurance: Our vacuum form plastic sheets undergo rigorous quality control checks to ensure they meet the highest standards of performance and reliability.

Customization Options: We offer a wide range of customization options, including different materials, thicknesses, colors, and textures, to suit various applications and design requirements.

Technical Expertise: With extensive experience in the industry, our team provides valuable technical support and guidance to help customers select the best materials for their projects.

Sustainability Commitment: We prioritize environmental responsibility by offering recyclable plastic sheets and adopting sustainable manufacturing practices.

Conclusion

Vacuum form plastic sheets are essential for a wide range of applications, offering versatility, durability, and cost-effectiveness. As a leading manufacturer, Singhal Industries Pvt Ltd is dedicated to delivering high-quality, customizable vacuum form plastic sheets that meet the specific needs and requirements of our clients, ensuring superior performance and satisfaction.

FAQs

1. What are vacuum form plastic sheets, and what materials are commonly used?

Vacuum form plastic sheets are materials used in the vacuum forming process to create various products. Common materials include ABS, HIPS, PETG, and PVC, each offering specific properties such as strength, flexibility, and durability.

2. What are the benefits of using vacuum form plastic sheets?

Vacuum form plastic sheets offer several benefits, including cost-effectiveness, design flexibility, quick production, consistency, and customizability. They are ideal for producing a wide range of products with complex shapes and fine details.

3. In which industries are vacuum form plastic sheets commonly used?

Vacuum form plastic sheets are used in industries such as packaging, automotive, consumer goods, medical, signage and displays, and industrial applications. They are used to create custom packaging, automotive components, consumer products, medical trays, signs, and industrial parts.

4. Can vacuum form plastic sheets be customized?

Yes, vacuum form plastic sheets can be customized in terms of material, thickness, color, texture, and other properties to meet specific application needs. Manufacturers like Singhal Industries Pvt Ltd offer a wide range of customization options.

5. Why should I choose Singhal Industries Pvt Ltd as my vacuum form plastic sheets manufacturer?

Singhal Industries Pvt Ltd offers high-quality, customizable vacuum form plastic sheets designed to meet specific industry needs. With a focus on quality assurance, extensive customization options, technical expertise, and a commitment to sustainability, we provide reliable and efficient material solutions for our clients.

0 notes

Text

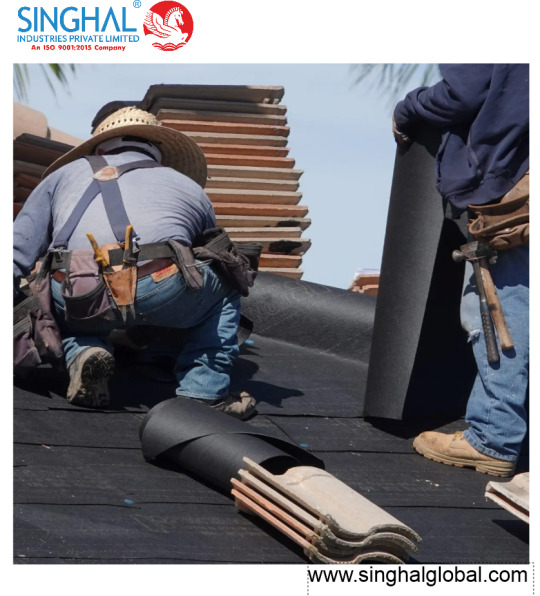

Exploring Roofing Underlayment: Enhancing Roof Protection and Longevity

Roofing underlayment is a critical component of any roofing system, providing an additional layer of protection against moisture, wind-driven rain, and other environmental elements. In recent years, synthetic roofing underlayment has gained popularity due to its durability, ease of installation, and superior performance compared to traditional materials. This article provides an overview of roofing underlayment, the benefits of synthetic options, and highlights a leading manufacturer in the industry.

Understanding Roofing Underlayment

Roofing underlayment, often referred to as felt paper or roofing felt, is installed directly onto the roof deck before the final roofing material, such as shingles or tiles, is applied. Its primary function is to serve as a secondary barrier against water infiltration, protecting the roof structure and interior of the building.

Importance of Roofing Underlayment

Waterproofing: Roofing underlayment acts as a waterproof barrier, preventing water from penetrating the roof deck and causing damage to the underlying structure, insulation, and interior of the building.

Weather Protection: In addition to water, underlayment also provides protection against wind-driven rain, snow, and ice dams, helping to maintain a dry and comfortable indoor environment.

Enhanced Longevity: By minimizing the risk of moisture-related issues such as rot, mold, and mildew, roofing underlayment helps extend the lifespan of the roof and reduces the need for costly repairs and replacements.

Types of Roofing Underlayment

Asphalt-Saturated Felt: Traditional roofing felt made from organic or fiberglass material saturated with asphalt. While cost-effective, it can be prone to tearing and degradation over time.

Synthetic Roofing Underlayment: Made from advanced synthetic materials such as polyethylene or polypropylene, synthetic underlayment offers superior durability, tear resistance, and UV protection. It is lightweight, easy to handle, and less prone to wrinkling and tearing during installation.

The Rise of Synthetic Roofing Underlayment

Synthetic roofing underlayment has revolutionized the roofing industry with its numerous advantages over traditional felt paper. Some key benefits include:

Durability: Synthetic underlayment is highly resistant to tears, wrinkles, and degradation, offering long-lasting protection even in extreme weather conditions.

Water Resistance: Unlike felt paper, synthetic underlayment does not absorb water, ensuring consistent performance and preventing moisture-related issues.

UV Stability: Many synthetic underlayment products are UV-stabilized, allowing them to withstand prolonged exposure to sunlight without deteriorating.

Ease of Installation: Synthetic underlayment is lightweight and easy to handle, making installation quicker and more efficient compared to traditional felt paper.

Versatility: Synthetic underlayment can be used with a wide range of roofing materials, including asphalt shingles, metal, and tile, making it a versatile choice for various roofing projects.

Singhal Industries Pvt Ltd: Your Trusted Roofing Underlayment Manufacturer

As a leading manufacturer of construction materials, Singhal Industries Pvt Ltd is committed to providing high-quality roofing underlayment solutions tailored to the needs of our customers. Our synthetic roofing underlayment products offer superior performance, durability, and ease of installation, ensuring maximum protection for residential and commercial roofing projects.

Elevating Roofing Integrity with Singhal Industries Pvt Ltd

Singhal Industries Pvt Ltd stands at the forefront of Roofing Underlayment solutions, setting industry standards with their commitment to quality and innovation. Their roofing underlayment products serve as a vital shield against moisture and weather-related damages, fortifying roofs for enduring protection. With Singhal Industries, customers can trust in superior materials engineered for seamless installation and long-term resilience, ensuring peace of mind and longevity for every structure they safeguard.

Pioneering Solutions

Experience the next generation of Synthetic Roofing Underlayment technology with Singhal Industries Pvt Ltd's synthetic offerings. Crafted with precision and durability in mind, their synthetic underlayments redefine performance expectations in the roofing industry. Engineered to resist tears, UV degradation, and harsh environmental conditions, these advanced solutions provide unparalleled defense for roofs, ensuring optimal longevity and reliability. Trust Singhal Industries to deliver synthetic roofing underlayments that elevate both protection and peace of mind.

Unrivaled Expertise

Singhal Industries Pvt Ltd emerges as a trusted leader in the realm of Roofing Underlayment Manufacturer. With an unwavering dedication to excellence, they bring decades of expertise and innovation to every product they create. Their comprehensive range of underlayment solutions caters to diverse roofing needs, offering superior performance, ease of installation, and exceptional durability. When it comes to securing the integrity of roofs, Singhal Industries sets the standard as a manufacturer committed to quality, reliability, and customer satisfaction.

Why Choose Singhal Industries Pvt Ltd?

Premium Quality: Our roofing underlayment products are manufactured using the finest materials and advanced production techniques, ensuring exceptional quality and reliability.

Innovative Solutions: We continually invest in research and development to create innovative roofing underlayment products that meet the evolving needs of the industry.

Customer Satisfaction: At Singhal Industries Pvt Ltd, customer satisfaction is our top priority. We strive to exceed our customers' expectations by delivering superior products and excellent service.

Environmental Responsibility: We are committed to sustainability and environmental responsibility. Our roofing underlayment products are manufactured using eco-friendly materials and processes wherever possible.

Conclusion

Roofing underlayment plays a crucial role in protecting roofs and buildings from water damage and other environmental hazards. Synthetic roofing underlayment offers numerous advantages over traditional materials, including enhanced durability, water resistance, and ease of installation. As a leading manufacturer of construction materials, Singhal Industries Pvt Ltd is proud to offer high-quality roofing underlayment solutions that provide superior protection and longevity for residential and commercial roofing projects.

FAQs

1. What is roofing underlayment, and why is it important?

Roofing underlayment is a secondary barrier installed onto the roof deck before the final roofing material. It provides additional protection against water infiltration, wind-driven rain, and other environmental elements, helping to extend the lifespan of the roof and protect the interior of the building.

2. What are the benefits of synthetic roofing underlayment?

Synthetic roofing underlayment offers superior durability, tear resistance, water resistance, and UV stability compared to traditional felt paper. It is lightweight, easy to handle, and compatible with various roofing materials, making it an excellent choice for both residential and commercial roofing projects.

3. How does synthetic roofing underlayment compare to traditional felt paper?

Synthetic roofing underlayment is more durable, water-resistant, and UV-stable than traditional felt paper. It is less prone to tearing, wrinkling, and degradation, offering long-lasting protection and peace of mind for homeowners and contractors.

4. Can synthetic roofing underlayment be used with any type of roofing material?

Yes, synthetic roofing underlayment is compatible with a wide range of roofing materials, including asphalt shingles, metal, tile, and cedar shakes. It is suitable for use in both residential and commercial roofing applications.

5. Why choose Singhal Industries Pvt Ltd for roofing underlayment?

Singhal Industries Pvt Ltd is a trusted manufacturer of construction materials, known for delivering high-quality products and excellent customer service. Our synthetic roofing underlayment products offer superior performance, durability, and ease of installation, making them the ideal choice for roofing projects of any size or complexity.

0 notes

Text

Revolutionizing Packaging Solutions: The Role of Plastic Carry Bags

Introduction: Plastic carry bags have become an integral part of modern life, serving as convenient and versatile packaging solutions for a wide range of products. Singhal Industries Pvt Ltd, a prominent player in the packaging industry, is dedicated to manufacturing high-quality plastic carry bags that meet the diverse needs of consumers and businesses alike. In this blog, we will explore the significance of plastic carry bags, the innovative solutions offered by Singhal Industries, and their impact on the packaging landscape.

The Evolution of Plastic Carry Bags: Plastic carry bags have evolved significantly since their inception, transitioning from simple, single-use bags to more durable and environmentally-friendly options. Today, plastic carry bags come in various shapes, sizes, and designs, catering to different packaging requirements. From grocery shopping to retail purchases, plastic carry bags offer unmatched convenience and reliability.

Singhal Industries: Leading the Way in Plastic Carry Bag Manufacturing: Singhal Industries has established itself as a leading manufacturer of plastic carry bags in India, with a strong presence in Gujarat. The company's commitment to quality, innovation, and customer satisfaction sets it apart in the competitive packaging market. With state-of-the-art manufacturing facilities and a dedicated team of professionals, Singhal Industries produces plastic carry bags that adhere to the highest standards of excellence.

Customized Solutions for Every Need: One of the key strengths of Singhal Industries is its ability to offer customized solutions tailored to the unique requirements of its customers. Whether you need plastic carry bags for retail packaging, promotional events, or grocery stores, Singhal Industries can provide customized bags in various sizes, colors, and designs. The company's flexible manufacturing process ensures that each order is tailored to meet specific customer demands.

Environmental Considerations: While plastic carry bags offer undeniable convenience, there is growing concern about their environmental impact. Singhal Industries recognizes the importance of sustainability and is committed to minimizing the environmental footprint of its products. The company explores eco-friendly alternatives and encourages responsible disposal and recycling of plastic carry bags to reduce environmental harm.

Innovative Features and Benefits: Singhal Industries' plastic carry bags boast several innovative features that enhance their functionality and appeal. From reinforced handles for added strength to customizable printing options for branding and marketing, these bags offer unmatched versatility and utility. Singhal Industries continually invests in research and development to introduce new features and materials that improve the performance and sustainability of its plastic carry bags.

Meeting Global Demands with Quality Solutions

In India, carry bags plastic exporters play a crucial role in meeting the global demand for plastic packaging solutions. These exporters, such as Singhal Industries Pvt Ltd, specialize in producing high-quality plastic carry bags that are durable, versatile, and eco-friendly. With advanced manufacturing facilities and stringent quality control measures, Carry Bags Plastic Exporters in India ensure that their products meet international standards and specifications. By collaborating with carry bags plastic exporters in India, businesses worldwide can access reliable and cost-effective packaging solutions that enhance convenience and sustainability in their operations.

Providing Convenient Solutions for Modern Consumers

In India, online carry bag manufacturers cater to the needs of modern consumers by offering convenient and customizable solutions for packaging and carrying goods. These manufacturers, including companies like Singhal Industries Pvt Ltd, specialize in producing a wide range of carry bags that are available for purchase through online platforms. With user-friendly interfaces and efficient delivery systems, Online Carry Bag Manufacturers in India enable customers to order customized bags tailored to their specific requirements. By leveraging digital technologies and responsive customer service, online carry bag manufacturers in India provide seamless shopping experiences for businesses and individuals seeking packaging solutions.

Promoting Sustainable Packaging Practices

In Gujarat, plastic shopping bag exporters play a significant role in promoting sustainable packaging practices by offering eco-friendly and recyclable products. These exporters, such as Singhal Industries Pvt Ltd, specialize in producing plastic shopping bags that are designed to minimize environmental impact while providing convenience and durability. By utilizing biodegradable materials and adopting responsible manufacturing practices, Plastic Shopping Bag Exporters in Gujarat ensure that their products meet the growing demand for sustainable packaging solutions. By collaborating with plastic shopping bag exporters in Gujarat, businesses can access environmentally friendly alternatives to traditional plastic bags, contributing to efforts to reduce plastic waste and promote a circular economy.

Conclusion: In conclusion, plastic carry bags continue to play a vital role in modern packaging, offering convenience, versatility, and reliability for various applications. Singhal Industries Pvt Ltd stands at the forefront of plastic carry bag manufacturing, providing innovative solutions that meet the evolving needs of consumers and businesses. With a focus on quality, customization, and sustainability, Singhal Industries is shaping the future of packaging with its plastic carry bags.

FAQ:

Are Singhal Industries' plastic carry bags recyclable? Yes, Singhal Industries' plastic carry bags are made from recyclable materials and can be recycled to reduce environmental impact.

Can I order plastic carry bags with custom printing for my business? Absolutely! Singhal Industries offers customizable printing options to help businesses promote their brand and enhance their marketing efforts.

What sizes are available for plastic carry bags? Singhal Industries provides plastic carry bags in a variety of sizes to suit different packaging needs, from small retail bags to large grocery bags.

Do plastic carry bags from Singhal Industries meet industry safety standards? Yes, Singhal Industries' plastic carry bags comply with all relevant industry safety and quality standards to ensure customer satisfaction and product safety.

How does Singhal Industries ensure the durability of its plastic carry bags? Singhal Industries utilizes advanced manufacturing techniques and high-quality materials to produce plastic carry bags that are durable, tear-resistant, and reliable for everyday use.

0 notes

Text

Unveiling the Versatility of PP Multifilament Yarn: A Comprehensive Exploration

Unveiling the Versatility of PP Multifilament Yarn: A Comprehensive Exploration

Polypropylene (PP) multifilament yarn stands as a cornerstone in the textile industry, offering a myriad of applications and benefits. In this in-depth exploration, we delve into the characteristics, uses, manufacturing process, and innovative advancements of PP multifilament yarn, shedding light on its pivotal role in various sectors.

Understanding PP Multifilament Yarn: Characteristics and Composition

PP multifilament yarn is composed of multiple continuous filaments of polypropylene, intricately spun together to form a durable and flexible thread. Known for its high tensile strength, abrasion resistance, and low moisture absorption properties, PP multifilament yarn exhibits excellent performance in diverse applications. With a range of deniers and filament counts available, manufacturers can tailor the yarn to meet specific requirements and preferences.

Exploring the Applications of PP Multifilament Yarn

PP multifilament yarn finds extensive use across various industries:

Textiles: Used in the production of fabrics, ropes, cords, and webbings for apparel, home furnishings, and technical textiles.

Geotextiles: Employed in geotextile applications such as erosion control, soil stabilization, and drainage systems for civil engineering projects.

Packaging: Utilized for manufacturing flexible packaging materials, industrial bags, and woven sacks for the packaging and transportation of goods.

Automotive: Integrated into automotive components such as seat belts, airbags, and upholstery for enhanced safety and durability.

Sports and Outdoor Equipment: Incorporated into sports equipment, camping gear, and outdoor apparel for its lightweight and resilient properties.

The Manufacturing Process of PP Multifilament Yarn

The production of PP multifilament yarn involves several key stages:

Polymer Extrusion: Polypropylene polymer pellets are melted and extruded through spinnerets to form continuous filaments.

Quenching: The extruded filaments are rapidly cooled to solidify them and prevent sticking together.

Drawing: The filaments are stretched to align the polymer molecules and improve strength and uniformity.

Annealing: The stretched filaments are heated to relieve internal stresses and enhance dimensional stability.

Winding: The treated filaments are wound onto bobbins or spools to create the final yarn product.

Leveraging Innovations in PP Multifilament Yarn

Recent advancements in polymer technology and yarn spinning techniques have led to innovations in PP multifilament yarn production. These innovations include:

Enhanced Strength and Durability: Improved polymer formulations and spinning processes result in yarn with higher tensile strength and abrasion resistance.

Specialized Finishes and Treatments: Surface treatments and coatings are applied to the yarn to impart specific properties such as UV resistance, antistatic properties, and flame retardancy.

Recyclability: Developments in recycling technology enable the production of eco-friendly PP multifilament yarn from recycled polypropylene materials, contributing to sustainability efforts in the textile industry.

Leading the Industry: Multifilament Yarn Suppliers in India

India boasts a thriving textile industry, supported by a network of multifilament yarn suppliers catering to diverse market demands. These suppliers offer a wide range of multifilament yarn options, including polypropylene (PP) multifilament yarn, to meet the needs of various sectors such as textiles, packaging, and industrial applications. With a focus on quality, reliability, and customer satisfaction, Multifilament Yarn Suppliers in India play a pivotal role in driving the growth and innovation of the textile industry nationwide.

Exporting Excellence: Polypropylene Multifilament Yarn Exporters in Ahmedabad

Ahmedabad, a prominent industrial city in Gujarat, serves as a hub for polypropylene multifilament yarn exporters, leveraging its strategic location and robust infrastructure to meet global market demands. These exporters specialize in supplying high-quality PP multifilament yarn to customers worldwide, offering a diverse range of yarn options tailored to specific applications and requirements. With a commitment to excellence in product quality, packaging, and timely delivery, Polypropylene Multifilament Yarn Exporters in Ahmedabad contribute significantly to the international textile trade and Gujarat's reputation as a textile manufacturing hub.

Innovating Excellence: PP Multifilament Yarn Manufacturer in Gujarat

Gujarat, known for its entrepreneurial spirit and manufacturing prowess, hosts several leading PP multifilament yarn manufacturers driving innovation and excellence in the industry. These manufacturers utilize advanced technology, state-of-the-art machinery, and quality assurance processes to produce PP multifilament yarn of superior quality and consistency. With a focus on research and development, PP Multifilament Yarn Manufacturer in Gujarat continuously strive to enhance product performance, expand product offerings, and meet the evolving needs of customers in domestic and international markets.

Conclusion: Harnessing the Power of PP Multifilament Yarn

In conclusion, PP multifilament yarn stands as a versatile and indispensable material in the textile and manufacturing sectors. With its exceptional properties, diverse applications, and continuous innovations, PP multifilament yarn continues to play a vital role in enhancing product performance, efficiency, and sustainability across industries. As technology advances and demand grows, PP multifilament yarn remains poised to shape the future of textiles and beyond.

Frequently Asked Questions About PP Multifilament Yarn

What are the key advantages of PP multifilament yarn compared to other textile materials? PP multifilament yarn offers several advantages, including high tensile strength, abrasion resistance, low moisture absorption, and affordability. These properties make it suitable for a wide range of applications across industries.

Can PP multifilament yarn be dyed or colored? Yes, PP multifilament yarn can be dyed or colored using various dyeing techniques and pigments. However, it is essential to consider the specific properties of PP and the desired colorfastness requirements for the intended application.

Is PP multifilament yarn suitable for outdoor applications? Yes, PP multifilament yarn is commonly used in outdoor applications due to its resistance to UV radiation, moisture, and chemicals. It is frequently employed in products such as outdoor furniture, camping gear, and marine ropes.

How does the denier of PP multifilament yarn affect its performance? The denier of PP multifilament yarn refers to the thickness or diameter of the individual filaments composing the yarn. Higher denier yarns typically offer increased strength and durability, making them suitable for heavy-duty applications such as industrial ropes and geotextiles.

Are there any environmental considerations associated with PP multifilament yarn? PP multifilament yarn is recyclable and can be reused or repurposed into new products after its lifecycle. Additionally, advancements in recycling technology enable the production of eco-friendly PP multifilament yarn from recycled materials, contributing to sustainability efforts in the textile industry.

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

Mastering Biaxial Geogrids: The Ultimate Guide to Reinforcing Soil and Ensuring Stability

Biaxial geogrids are a type of geosynthetic material used in civil engineering and construction projects to reinforce soils and provide stability to various structures. These grids consist of intersecting ribs or strands that form a grid-like pattern, typically made from high-density polyethylene (HDPE) or polyester. Biaxial geogrids are designed to distribute loads evenly and improve the bearing capacity of soils, making them suitable for applications such as road construction, retaining walls, embankments, and slope stabilization.

Importance of Biaxial Geogrids

Biaxial geogrids play a crucial role in enhancing the performance and longevity of civil engineering projects by providing reinforcement to weak or unstable soils. By confining soil particles within the grid structure, biaxial geogrids improve soil stability, prevent erosion, and reduce the risk of settlement or deformation under heavy loads. Additionally, biaxial geogrids help to minimize the use of traditional construction materials such as stone aggregates, reducing project costs and environmental impact.

Types of Biaxial Geogrids

There are several types of biaxial geogrids available, each with specific characteristics and performance properties:

HDPE Biaxial Geogrids: Made from high-density polyethylene, these geogrids offer high tensile strength, durability, and resistance to chemical and biological degradation. HDPE biaxial geogrids are suitable for a wide range of soil reinforcement applications, including road construction, pavement rehabilitation, and landfill liners.

Polyester Biaxial Geogrids: Polyester biaxial geogrids are manufactured from high-tenacity polyester fibers, offering excellent tensile strength and modulus properties. These geogrids are commonly used in applications where high tensile strength and long-term durability are required, such as reinforced soil slopes, retaining walls, and bridge abutments.

Composite Biaxial Geogrids: Composite biaxial geogrids combine the benefits of different materials, such as polyethylene and polyester, to achieve enhanced performance characteristics. These geogrids may feature a combination of high tensile strength, flexibility, and chemical resistance, making them suitable for demanding soil reinforcement applications in challenging environmental conditions.

Properties of Biaxial Geogrids

Biaxial geogrids exhibit several key properties that make them effective for soil reinforcement:

High Tensile Strength: Biaxial geogrids have a high tensile strength, allowing them to withstand significant loads without deformation or failure.

Flexibility: Biaxial geogrids are flexible and conformable, enabling them to adapt to irregular soil surfaces and contours.

Puncture Resistance: Biaxial geogrids offer excellent puncture resistance, protecting against damage during installation and service life.

Chemical Resistance: Biaxial geogrids are resistant to chemical degradation from acids, alkalis, and other environmental factors, ensuring long-term performance in harsh conditions.

Benefits of Using Biaxial Geogrids

The use of biaxial geogrids offers several benefits for civil engineering and construction projects:

Improved Soil Stability: Biaxial geogrids provide reinforcement to soils, increasing their bearing capacity and stability under heavy loads.

Reduced Construction Costs: By minimizing the need for traditional construction materials and simplifying installation, biaxial geogrids help to reduce project costs and construction time.

Enhanced Durability: Biaxial geogrids are resistant to degradation from environmental factors, ensuring long-term performance and durability in various applications.

Versatility: Biaxial geogrids can be used in a wide range of soil reinforcement applications, offering versatility and flexibility in design and construction.

Installation of Biaxial Geogrids

The installation of biaxial geogrids involves several key steps to ensure proper performance and effectiveness:

Site Preparation: Prepare the site by clearing vegetation, removing debris, and compacting the soil to the required specifications.

Placement of Geogrid: Place the biaxial geogrid on the prepared soil surface, ensuring proper alignment and overlap between adjacent rolls or panels.

Anchoring: Anchor the geogrid securely to the ground using stakes, pins, or other anchoring devices to prevent movement during installation and service life.

Covering: Cover the geogrid with a layer of soil or aggregate material to protect it from damage and provide additional stability.

Compaction: Compact the soil or aggregate material over the geogrid to achieve the desired density and ensure adequate contact between the geogrid and soil layers.

Maintenance of Biaxial Geogrids

Proper maintenance is essential to maximize the performance and longevity of biaxial geogrids:

Regular Inspection: Inspect the geogrid periodically for signs of damage, such as tears, punctures, or deformation, and repair any issues promptly.

Vegetation Management: Control vegetation growth on or around the geogrid to prevent root penetration and damage.

Surface Cleaning: Keep the surface of the geogrid free from debris, sediment, and vegetation to maintain optimal performance.

Monitoring: Monitor the performance of the geogrid over time, especially in areas prone to heavy traffic or environmental stresses, and take corrective action as needed.

Empowering Infrastructure: Geogrid Manufacturers in India

Geogrids, essential components of modern infrastructure projects, find their roots in the manufacturing prowess of India. Geogrid manufacturers across the country specialize in producing these geosynthetic materials engineered to enhance soil stability, reinforce structures, and mitigate the effects of erosion. With cutting-edge technology and stringent quality control measures, Geogrid Manufacturers in India ensure the production of high-performance materials that meet international standards and cater to the diverse needs of civil engineering projects, transportation networks, and environmental conservation initiatives.

Engineering Excellence: Geogrid Manufacturers in Ahmedabad

Ahmedabad, a vibrant industrial city in Gujarat, stands as a prominent hub for geogrid manufacturing in India. Manufacturers in Ahmedabad leverage the city's robust infrastructure, skilled workforce, and strategic location to produce a wide range of geogrids tailored to various applications. From soil reinforcement to slope stabilization, Geogrid Manufacturers in Ahmedabad uphold a legacy of engineering excellence, delivering innovative solutions that bolster the resilience and longevity of infrastructure projects across the nation.

Supporting Progress: Geogrid Supplier in India

Within India's expansive geotechnical industry, geogrid suppliers serve as vital links connecting manufacturers with end-users. These suppliers play a crucial role in distributing geogrids to construction firms, engineering consultants, government agencies, and infrastructure developers across the country. By offering a comprehensive range of products, timely delivery, and technical support, Geogrid Supplier in India contribute significantly to the advancement of civil engineering projects, transportation networks, and environmental conservation efforts nationwide.

Conclusion

In conclusion, biaxial geogrids are essential materials in civil engineering and construction projects, providing reinforcement and stability to soils in various applications. With their high tensile strength, flexibility, and durability, biaxial geogrids offer a cost-effective and sustainable solution for soil stabilization, erosion control, and slope reinforcement. By understanding the types, properties, benefits, installation, and maintenance of biaxial geogrids, engineers and contractors can make informed decisions to achieve successful project outcomes and long-term performance.

FAQs (Frequently Asked Questions)

Q: Can biaxial geogrids be used for slope stabilization? A: Yes, biaxial geogrids are commonly used for slope stabilization to prevent erosion, soil movement, and slope failure by providing reinforcement and stability to the soil structure.

Q: What is the lifespan of biaxial geogrids? A: The lifespan of biaxial geogrids varies depending on factors such as material quality, environmental conditions, and installation techniques. Generally, high-quality biaxial geogrids can last 20 years or more with proper installation and maintenance.

Q: Are biaxial geogrids environmentally friendly? A: Biaxial geogrids are considered environmentally friendly as they help to reduce the use of traditional construction materials, minimize soil erosion, and promote sustainable land development practices.

Q: Can biaxial geogrids be recycled? A: Yes, biaxial geogrids made from recyclable materials such as HDPE or polyester can be recycled through specialized recycling programs or facilities that accept plastic materials.

Q: Are there any regulations or standards for biaxial geogrids? A: While there are no specific regulations for biaxial geogrids, they are typically manufactured and tested according to industry standards such as ASTM and ISO to ensure quality, performance, and durability.

0 notes

Text

0 notes