Don't wanna be here? Send us removal request.

Text

Revolutionary Breakthrough in Golf Ball Technology: The Science Behind Enhanced Performance

Golf, a sport steeped in tradition, has seen a dynamic evolution in its equipment over the years. At the heart of this evolution lies the golf ball, a seemingly simple sphere that has undergone a remarkable transformation through groundbreaking scientific advancements.

Innovation in Flight Dynamics:

The breakthrough that forever changed the trajectory of golf balls was the discovery of dimples. Early golf balls were smooth, limiting their distance and accuracy. The concept of adding dimples to the surface, inspired by the aerodynamics of aeronautical designs, revolutionized their flight dynamics. These indentations create a turbulent boundary layer of air that reduces drag, enabling the ball to achieve greater distances and maintain stable flights.

Material Matters:

The materials used in modern golf balls are carefully chosen to achieve specific performance characteristics. Rubber cores provide the initial compression, while advanced materials like ionomer and urethane are employed for the outer layers. This layered construction enables manufacturers to fine-tune aspects such as spin, feel, and control.

The Science of Compression:

Golf ball compression is a critical factor in determining how the ball interacts with the clubface. Lower compression balls are more forgiving and suitable for players with slower swings, allowing them to achieve greater distance. On the other hand, higher compression balls offer better control and are favored by those with faster swings.

Personalization and Customization:

Advances in manufacturing technology have not only enhanced performance but also allowed for greater personalization. Golfers can now customize their balls with specific play numbers, logos, and text. This personal touch not only adds a sense of identity but also reflects the growing synergy between technology and individual preferences.

Looking Ahead:

The golf ball industry shows no signs of slowing down its pursuit of excellence. Brands continue to invest in research and development, seeking new ways to optimize ball design, aerodynamics, and overall performance. As golfers demand balls that cater to their unique styles, this commitment to innovation ensures that the game's essential element—the golf ball—continues to evolve, enhancing players' experiences and pushing the boundaries of what's possible on the course.

The golf ball's journey from its humble beginnings to its current state is a testament to human curiosity, ingenuity, and the relentless pursuit of improvement. Groundbreaking scientific discoveries, combined with cutting-edge manufacturing techniques, have transformed the golf ball into a high-performance marvel. As players tee off with these technological marvels, they are not just hitting a ball—they are wielding the result of a scientific revolution that's propelling the sport to new heights.

1 note

·

View note

Text

Injury Prevention and Management: Safeguarding Athletes in the World of Sports

Participating in sports offers numerous physical and mental benefits, but the risk of injuries is an inherent aspect that cannot be ignored. Implementing effective injury prevention strategies and understanding proper management techniques are essential for safeguarding athletes and ensuring their long-term well-being.

The Importance of Injury Prevention:

Minimizing Risk: Injury prevention aims to reduce the likelihood of injuries occurring in the first place. This includes addressing common causes such as inadequate warm-ups, overtraining, and improper techniques.

Preserving Performance: Preventing injuries ensures athletes can consistently perform at their best. An injury-free athlete is more likely to achieve their potential and maintain a higher level of performance.

Long-Term Health: Avoiding injuries contributes to an athlete's long-term physical health. Chronic injuries can have lasting effects on joints, muscles, and overall mobility if not managed properly.

Effective Injury Prevention Strategies:

Proper Warm-Up and Cool-Down: A thorough warm-up routine prepares muscles and joints for activity, reducing the risk of strains. Cool-down exercises help alleviate post-exercise muscle soreness.

Balanced Training: Athletes should follow well-structured training programs that include a mix of cardiovascular, strength, and flexibility exercises to prevent overuse injuries.

Technique Mastery: Coaches should emphasize correct form and technique to minimize the risk of injuries caused by improper movements.

Appropriate Equipment: Wearing well-fitting, protective gear and using suitable footwear can significantly reduce the risk of impact-related injuries.

Managing Injuries:

Immediate Response: Treating acute injuries promptly is crucial. Employing the RICE (Rest, Ice, Compression, Elevation) protocol within the first 24-48 hours helps manage pain and swelling.

Professional Consultation: Seeking medical attention is vital for accurate diagnosis and appropriate treatment. Medical professionals can guide rehabilitation plans and recovery timelines.

Structured Rehabilitation: Rehabilitation programs, often overseen by physical therapists, focus on restoring strength, mobility, and functionality after an injury.

Gradual Return: Athletes should follow a structured plan when returning to their sport after recovering from an injury. Rushing the process can lead to setbacks.

Creating a Culture of Safety:

Education: Athletes, coaches, and parents should be educated about injury prevention techniques and the importance of reporting discomfort promptly.

Open Communication: Athletes must feel comfortable communicating any pain or discomfort to coaches and parents. Ignoring warning signs can exacerbate injuries.

Rest and Recovery: Adequate rest between intense training sessions is crucial. Athletes need time to recover and allow their bodies to heal.

Injury prevention and management are vital components of a safe and successful athletic journey. By implementing proactive strategies, promoting a culture of safety, and ensuring proper rehabilitation, athletes can minimize the risk of injuries, perform at their best, and enjoy the benefits of sports for years to come.

1 note

·

View note

Text

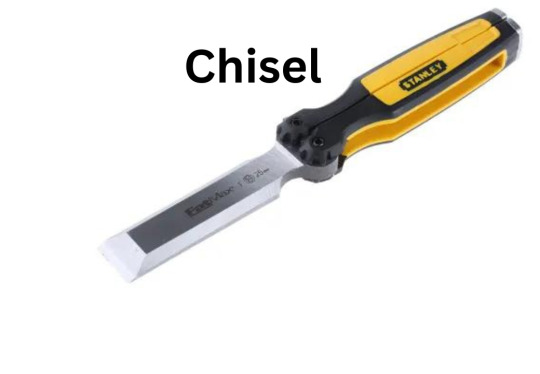

How do you sharpen a chisel?

A chisel is an essential tool for woodworking and is used to shape, cut, and carve wood. However, like all cutting tools, a chisel becomes dull with use and needs to be sharpened regularly to maintain its effectiveness. Sharpening a chisel can seem intimidating at first, but it is a straightforward process that can be accomplished with a few simple tools.

The first step in sharpening a chisel is to gather the necessary tools. You will need a honing guide, a sharpening stone, and a lubricant. Honing guides are designed to hold the chisel at the correct angle, ensuring a consistent sharpening angle across the entire blade. Sharpening stones come in a variety of materials, including diamond, ceramic, and natural stones. A lubricant such as water, oil, or a specialized honing fluid is used to reduce friction and prevent clogging of the sharpening stone.

To begin sharpening, secure the chisel in the honing guide, making sure it is set at the desired angle. The angle at which you sharpen your chisel will depend on the intended use of the chisel. A general-purpose chisel is usually sharpened at a 25-30 degree angle, while a chisel used for heavy-duty work may be sharpened at a steeper angle of 35-40 degrees.

Next, apply lubricant to the sharpening stone. Place the honing guide with the chisel attached onto the stone and begin sharpening the chisel by moving it back and forth across the stone. Keep the blade perpendicular to the stone and ensure that the entire beveled edge of the chisel is in contact with the stone. Continue sharpening until a burr, or wire edge, forms on the opposite side of the chisel blade.

Once a burr has formed, turn the chisel over and repeat the process on the opposite side of the blade. After sharpening both sides, remove the burr by lightly honing the chisel on a fine-grit stone or by stropping the edge on a leather strop.

Finally, remove the chisel from the honing guide and test its sharpness on a piece of scrap wood. If the chisel still feels dull, repeat the sharpening process until the desired level of sharpness is achieved.

In conclusion, sharpening a chisel is a simple process that can be accomplished with a few basic tools. By following the steps outlined above and taking the time to maintain your chisels, you can ensure that they remain sharp and effective for years to come.

1 note

·

View note

Text

What are some common applications of a band saw in various industries?

A band saw is a type of saw that has a long, continuous blade with teeth on one edge, which runs around two or more wheels to create a cutting motion. It is a versatile cutting tool that is used in many industries, including woodworking, metalworking, and meat processing. Here are some of the most common applications of a band saw in various industries.

Woodworking Band saws are commonly used in woodworking to cut wood into different shapes and sizes. They can be used to make straight cuts, curved cuts, and irregular cuts. They are also used for resawing, which is the process of cutting a thick board into thinner boards. Band saws can handle larger pieces of wood than other types of saws, making them ideal for cutting logs or large boards.

Metalworking Band saws are also used in metalworking to cut metal into different shapes and sizes. They can be used to cut metal pipes, bars, and sheets. They are ideal for cutting metal because they produce less heat and friction than other types of saws, which can cause the metal to warp or distort. Band saws are also more precise than other types of saws, making them ideal for cutting intricate shapes and designs.

Meat processing Band saws are commonly used in meat processing plants to cut large pieces of meat into smaller pieces. They are used to cut through bone and tough connective tissue. The blades of band saws used in meat processing are made of stainless steel, which is easy to clean and resists corrosion. The saws are designed to be easy to clean and sanitize, which is important in the food industry.

Automotive industry Band saws are also used in the automotive industry to cut metal parts and components. They are used to cut exhaust pipes, chassis components, and other metal parts. Band saws are ideal for cutting metal in the automotive industry because they produce clean, precise cuts that are essential for maintaining the quality of the finished product.

Construction industry Band saws are used in the construction industry to cut a wide range of materials, including wood, metal, and concrete. They are used to make precise cuts in framing lumber, to cut metal pipes and rods, and to cut concrete blocks and bricks. Band saws are ideal for construction because they can handle a variety of materials and are capable of making clean, precise cuts.

In conclusion, band saws are versatile cutting tools that are used in many industries. They are ideal for cutting a wide range of materials, including wood, metal, and meat. They produce clean, precise cuts that are essential for maintaining the quality of the finished product. Whether you are in the woodworking, metalworking, meat processing, automotive, or construction industry, a band saw is an essential tool for any cutting job.

1 note

·

View note

Text

What are the different types of band saws available?

Vertical Band Saw

The vertical band saw, also known as a contour saw, is the most common type of band saw used in the industry. It has a stationary table and a vertical blade that moves up and down, allowing it to cut curves, angles, and other shapes into materials like wood and metal. Vertical band saws are typically used for intricate cutting and shaping tasks, such as cutting curves into furniture legs or making jigsaw puzzles.

Horizontal Band Saw

The horizontal band saw, also known as a metal-cutting saw, is designed to cut metal in a straight line. It features a horizontal blade that moves back and forth across a stationary workpiece, providing more control and accuracy than other types of saws. Horizontal band saws are commonly used in metalworking applications, such as cutting metal bars, tubes, and pipes.

Portable Band Saw

A portable band saw, as its name suggests, is a lightweight and compact saw that can be easily transported from one job site to another. It features a handheld design and a small blade, making it ideal for cutting through small materials like PVC pipes and sheet metal. Portable band saws are commonly used in plumbing, electrical, and HVAC applications.

Benchtop Band Saw

A benchtop band saw is a smaller version of the vertical band saw, designed for use on a workbench or tabletop. It features a stationary blade and a tilting table that allows for angled cuts, making it ideal for cutting small pieces of wood or metal. Benchtop band saws are commonly used in woodworking, jewelry making, and other crafting applications.

Resaw Band Saw

A resaw band saw is designed for cutting large pieces of wood or other materials into thinner, more manageable pieces. It features a wide blade and a high-powered motor that allows it to cut through thick materials quickly and easily. Resaw band saws are commonly used in woodworking applications, such as cutting veneers and laminates.

Dual Column Band Saw

A dual column band saw is a heavy-duty saw designed for cutting thick and heavy materials, such as steel beams and large logs. It features two columns on either side of the blade that provide additional support and stability, allowing for precise and accurate cuts. Dual column band saws are commonly used in industrial and manufacturing applications.

In conclusion, there are several types of band saws available, each with unique features and benefits. Choosing the right type of band saw depends on the specific cutting tasks you need to perform and the materials you will be working with. By understanding the different types of band saws and their uses, you can make an informed decision and choose the right tool for your job.

1 note

·

View note

Text

What materials are axes typically made from?

Axes are one of the oldest and most useful tools known to humanity. They have been used for centuries for various tasks such as chopping wood, clearing forests, and even as weapons. Axes are typically made from a variety of materials, each with its own advantages and disadvantages. In this article, we will discuss the most common materials used to make axes.

Steel: Steel is one of the most popular materials used for making axe heads. It is strong, durable, and holds an edge well. Steel axe heads are typically made from high carbon steel, which is heat-treated to increase its strength and durability. Steel axe heads can be heavy, making them ideal for heavy-duty chopping and splitting.

Carbon Fiber: Carbon fiber is a relatively new material used in axe production. It is lightweight, strong, and durable. Carbon fiber axe heads are ideal for backpacking and camping trips, as they are lightweight and easy to carry.

Titanium: Titanium is a lightweight and strong material that is commonly used in aerospace and military applications. Titanium axe heads are incredibly durable, and they can withstand extreme conditions. However, titanium is also an expensive material, making it less commonly used in axe production.

Aluminum: Aluminum is a lightweight and corrosion-resistant material that is commonly used in the construction of axe handles. Aluminum axe handles are lightweight and comfortable to use, but they can also be less durable than other materials, particularly when subjected to heavy use.

Wood: Wood is the traditional material used in the construction of axe handles. Wooden axe handles are comfortable to use and provide a natural grip that can be customized to the user's hand. Wood also has the advantage of being relatively lightweight, which can help reduce fatigue during extended use.

Fiberglass: Fiberglass is a synthetic material that is commonly used in the construction of axe handles. It is strong, durable, and lightweight, making it an ideal material for heavy-duty axes. Fiberglass handles also have the advantage of being resistant to moisture, which can help prevent rot and decay over time.

In conclusion, axes can be made from a variety of materials, each with its own advantages and disadvantages. Steel is the most popular material used for axe heads, while wood and fiberglass are the most common materials used for axe handles. The choice of material will depend on the intended use of the axe, as well as personal preference and budget.

1 note

·

View note

Text

What are some safety precautions to take when using an axe?

An axe is a powerful and versatile tool, but it can also be dangerous if not used properly. To ensure your safety when using an axe, it is important to take some safety precautions. Here are some of the most important safety precautions to take when using an axe:

Wear protective gear: When using an axe, it is important to wear protective gear, such as gloves, eye protection, and a hard hat. Gloves can protect your hands from blisters and cuts, eye protection can prevent eye injuries from flying debris, and a hard hat can protect your head from falling branches or other objects.

Choose the right work area: Choose a work area that is clear of any obstacles or debris that could interfere with your swings. Make sure you have plenty of space to move around and swing the axe without hitting anything or anyone.

Inspect the axe before use: Before using an axe, inspect it to make sure that it is in good condition. Check the head to make sure it is securely attached to the handle, and check the handle for any cracks or splinters. Make sure the blade is sharp and free of any nicks or chips.

Use the proper grip: When using an axe, grip the handle firmly with both hands. Your dominant hand should be at the bottom of the handle, while your other hand should be near the top of the handle for better control.

Stand in the proper position: Stand with your feet shoulder-width apart and your dominant foot slightly forward. This will help you maintain your balance and provide better control when swinging the axe.

Never swing an axe over your head: Never swing an axe over your head or behind your back. This can cause you to lose control of the axe and can result in serious injury.

Use proper chopping technique: When chopping wood, aim for the center of the log and use a downward chopping motion. Alternate your swings from the left side to the right side to prevent the axe from becoming stuck in the wood.

Use caution and be aware of your surroundings: Always use caution when using an axe and be aware of your surroundings. Make sure there are no people or objects within your swinging range. Never use an axe when you are tired or distracted.

Keep the axe sharp: A dull axe is more dangerous than a sharp one. A sharp axe is more efficient and requires less force to chop wood, reducing the risk of injury.

Store the axe properly: After use, clean the axe and store it in a dry, safe place. Store the axe with the blade covered to prevent damage or injury.

In conclusion, taking safety precautions when using an axe is crucial to avoid injury and ensure a successful outcome. By following these safety precautions, you can use an axe safely and effectively for a variety of tasks. Remember to always wear protective gear, choose the right work area, inspect the axe before use, use the proper grip and position, never swing the axe over your head, use proper chopping technique, be aware of your surroundings, keep the axe sharp, and store the axe properly.

1 note

·

View note

Text

What is the proper way to use an axe?

An axe is a powerful tool that can be used for a variety of tasks, such as chopping wood, felling trees, and clearing brush. However, it is important to use an axe safely and correctly to avoid injury and damage to the tool. Here are some guidelines for using an axe properly:

Choose the right axe for the job: There are different types of axes that are designed for different tasks. For example, a felling axe is used for cutting down trees, while a splitting axe is used for splitting logs. Make sure you choose the right axe for the task at hand.

Inspect the axe before use: Before using an axe, inspect it to make sure that it is in good condition. Check the head to make sure it is securely attached to the handle, and check the handle for any cracks or splinters. Make sure the blade is sharp and free of any nicks or chips.

Use the proper grip: When using an axe, it is important to grip the handle firmly with both hands. Your dominant hand should be at the bottom of the handle, while your other hand should be near the top of the handle for better control.

Stand in the proper position: Stand with your feet shoulder-width apart and your dominant foot slightly forward. This will help you maintain your balance and provide better control when swinging the axe.

Swing the axe properly: When swinging the axe, start with the axe head close to the ground and swing it up and over your head in a controlled motion. Aim for the target, and make sure you follow through with the swing to maximize the force of the blow.

Use proper chopping technique: When chopping wood, aim for the center of the log and use a downward chopping motion. Alternate your swings from the left side to the right side to prevent the axe from becoming stuck in the wood.

Use caution and be aware of your surroundings: Always use caution when using an axe and be aware of your surroundings. Make sure there are no people or objects within your swinging range. Never use an axe when you are tired or distracted.

Store the axe properly: After use, clean the axe and store it in a dry, safe place. Store the axe with the blade covered to prevent damage or injury.

In conclusion, using an axe properly requires proper technique, caution, and awareness of your surroundings. By following these guidelines, you can use an axe safely and effectively for a variety of tasks. Remember to always choose the right axe for the job and inspect it before use to ensure that it is in good condition.

0 notes

Text

What are the maintenance requirements for an angle grinder?

Angle grinders are versatile power tools that are used for grinding, cutting, and polishing various materials. Like any power tool, angle grinders require regular maintenance to ensure optimal performance and longevity. Here are the key maintenance requirements for an angle grinder:

Clean the tool regularly: Angle grinders should be cleaned after every use to prevent dust and debris from building up inside the tool. Use a brush or compressed air to remove debris from the motor and other components.

Check the power cord: The power cord should be checked regularly for any signs of damage or wear. If the cord is damaged, it should be replaced immediately.

Inspect the grinding wheel: The grinding wheel should be inspected before each use to ensure that it is not cracked or damaged. If the wheel is damaged, it should be replaced immediately.

Lubricate moving parts: The moving parts of the angle grinder, such as the bearings and gears, should be lubricated regularly to prevent friction and wear. Follow the manufacturer's instructions for lubrication.

Check the carbon brushes: The carbon brushes are an important part of the motor and should be checked regularly for wear. If the brushes are worn, they should be replaced.

Store the tool properly: When the angle grinder is not in use, it should be stored in a dry, cool place. Keep the tool away from moisture and extreme temperatures.

Follow manufacturer's instructions: Always follow the manufacturer's instructions for use and maintenance of the angle grinder. This will help ensure the tool operates safely and efficiently.

In conclusion, maintaining an angle grinder is crucial to ensure it operates safely and effectively. By following these maintenance requirements, you can extend the lifespan of your tool and minimize the risk of accidents or damage.

0 notes

Text

What is the difference between an angle grinder and a cut-off tool?

Angle grinders and cut-off tools are both handheld power tools that can be used for cutting and grinding applications. While they share some similarities, there are a few key differences that distinguish these two tools.

The primary difference between an angle grinder and a cut-off tool is the type of cutting wheel or disc that they use. Angle grinders typically use abrasive cutting discs, while cut-off tools use thin, reinforced cutting wheels.

Angle grinders are versatile tools that can be used for a wide range of applications, including cutting, grinding, and sanding. They are available in a variety of sizes, with the most common being 4.5 inches and 7 inches. Angle grinders can be used with a range of cutting discs, including abrasive discs, diamond discs, and wire brushes. These tools are commonly used for cutting and shaping metal, concrete, and stone.

Cut-off tools, on the other hand, are designed specifically for cutting through metal. They are typically smaller than angle grinders, with a cutting wheel diameter ranging from 2 inches to 4 inches. Cut-off tools use a thin, reinforced cutting wheel that is designed to slice through metal with precision and speed. These tools are commonly used in automotive repair, metalworking, and construction applications.

Another difference between angle grinders and cut-off tools is the speed at which they operate. Angle grinders typically operate at higher speeds than cut-off tools, with speeds ranging from 5,000 to 11,000 RPM. Cut-off tools, on the other hand, typically operate at speeds between 10,000 and 15,000 RPM.

In terms of safety, both angle grinders and cut-off tools can be dangerous if not used properly. It's important to wear appropriate

personal protective equipment, such as safety glasses and gloves, when using either tool. It's also important to follow the manufacturer's instructions and to never exceed the maximum RPM rating of the tool or cutting wheel.

In conclusion, while angle grinders and cut-off tools share some similarities, they are designed for different purposes and use different cutting wheels. Angle grinders are versatile tools that can be used for a range of applications, while cut-off tools are designed specifically for cutting through metal. Understanding the differences between these tools can help you select the right tool for your specific cutting or grinding application.

0 notes

Text

What is the maximum speed of an angle grinder?

An angle grinder is a versatile tool that can be used for a variety of cutting, grinding, and polishing applications. One of the key features that determines the performance and effectiveness of an angle grinder is its maximum speed. The maximum speed of an angle grinder is an important factor to consider when selecting the right tool for a specific task.

The maximum speed of an angle grinder is usually expressed in revolutions per minute (RPM). This refers to the number of times the disc rotates around its central axis in one minute. The maximum speed of an angle grinder varies depending on the size and type of the tool. Generally, smaller angle grinders have a higher maximum speed than larger ones.

For example, a typical 4.5-inch angle grinder will have a maximum speed of around 11,000 RPM, while a larger 9-inch grinder may have a maximum speed of only 6,000 RPM. It's important to note that the maximum speed of an angle grinder should not be exceeded, as this can result in damage to the tool, the disc, or even personal injury.

When selecting an angle grinder, it's important to choose one with a maximum speed that is appropriate for the task at hand. For example, if you're working with a thick metal plate, a high-speed grinder with a smaller disc may be the best choice. However, if you're working with a softer material like wood or plastic, a slower speed grinder with a larger disc may be more suitable.

It's also important to take into account the type of disc you'll be using with your angle grinder. Different types of discs are designed to operate at different speeds, so it's important to select a disc that is compatible with your tool's maximum speed. If you use a disc that is rated for a lower speed than your tool's maximum speed, it may not be able to withstand the stress and may break apart, posing a safety hazard.

In conclusion, the maximum speed of an angle grinder is a critical factor to consider when selecting the right tool for your job. It's important to choose a tool with a maximum speed that is appropriate for the task at hand and to always use compatible discs that are rated for your tool's maximum speed. By doing so, you can ensure that your angle grinder operates safely and effectively, delivering the results you need.

0 notes

Text

What are the uses of an angle grinder?

Angle grinders are versatile tools that can be used for a wide range of applications, from cutting and grinding metal to polishing and sanding surfaces. In this article, we will discuss the different uses of angle grinders and their applications.

Cutting Metal: Angle grinders are commonly used for cutting metal, including steel, aluminum, and copper. They can cut through thick metal sheets, pipes, and bars quickly and easily, making them an essential tool for metal fabrication and construction.

Grinding Metal: Angle grinders can also be used for grinding metal surfaces, such as welds, rust, and burrs. They are often used to smooth rough edges or to remove unwanted material from metal surfaces, such as in automotive repair and metalworking.

Polishing and Sanding: Angle grinders can be fitted with polishing and sanding attachments, which makes them suitable for polishing and sanding surfaces, such as wood, metal, and stone. They are often used in furniture making, woodworking, and DIY projects.

Cutting Concrete and Masonry: Angle grinders fitted with diamond cutting discs can be used for cutting concrete, masonry, and other hard materials. They are often used in construction and renovation projects, such as cutting and shaping concrete blocks and pavers.

Sharpening Tools: Angle grinders can be used for sharpening a variety of tools, such as knives, axes, and garden tools. They are often used by professional tradespeople and DIY enthusiasts for maintaining and sharpening their tools.

Removing Paint and Rust: Angle grinders fitted with wire brushes or abrasive discs can be used for removing paint, rust, and other coatings from metal surfaces. They are often used in automotive repair and metalworking, as well as in restoration projects.

In conclusion, angle grinders are versatile tools that can be used for a wide range of applications. Whether you are a professional tradesperson or a DIY enthusiast, an angle grinder is an essential tool for cutting, grinding, polishing, and sanding a variety of materials. When using an angle grinder, it is important to follow proper safety precautions, such as wearing appropriate safety gear and using the tool in a well-ventilated area.

0 notes

Text

What are the different types of angle grinders?

Angle grinders are versatile tools that are used in a wide range of applications, from cutting and grinding metal to polishing and sanding surfaces. There are several different types of angle grinders available, each with its own unique features and benefits. In this article, we will discuss the different types of angle grinders and their applications.

Electric Angle Grinders: Electric angle grinders are the most common type of angle grinder, and they are powered by an electric motor. They are available in different sizes and power ratings, ranging from small handheld models for light-duty tasks to larger, more powerful models for heavy-duty applications.

Pneumatic Angle Grinders: Pneumatic angle grinders are powered by compressed air, and they are typically lighter and more compact than electric models. They are often used in industrial settings, such as metal fabrication and automotive repair.

Cordless Angle Grinders: Cordless angle grinders are powered by rechargeable batteries, which makes them portable and convenient to use in remote locations. They are available in various sizes and power ratings, but they may not be as powerful as electric or pneumatic models.

Mini Angle Grinders: Mini angle grinders are small and lightweight, making them ideal for use in tight spaces and for precision work. They are available in electric and cordless models, and they typically have smaller discs or wheels.

Variable Speed Angle Grinders: Variable speed angle grinders allow the operator to adjust the speed of the disc or wheel, which makes them versatile and suitable for a wide range of applications. They are available in electric and cordless models, and they are often used in metalworking, woodworking, and construction.

Angle Grinders with Dust Collection: Angle grinders with dust collection are designed to capture dust and debris as they are created, which makes them ideal for use in environments where dust and debris are a concern, such as construction sites and workshops.

In conclusion, there are several different types of angle grinders available, each with its own unique features and benefits. Choosing the right type of angle grinder depends on the application, the size of the workpiece, and the level of power and control required. Whether you are a DIY enthusiast or a professional tradesperson, there is an angle grinder that is suitable for your needs.

0 notes

Text

How to use a Band saw?

Band saws are an essential tool in many woodworking, metalworking, and fabrication shops. These versatile machines can cut through a wide variety of materials, including wood, metal, plastic, and more. While band saws may seem intimidating at first, with a little bit of knowledge and practice, you can learn how to use them effectively and safely. In this blog post, we'll cover the basics of how to use a band saw.

Step 1: Safety First

Before you begin using a band saw, it's crucial to prioritize safety. Band saws can be dangerous if not used properly, so make sure to follow these safety guidelines:

Always wear eye protection and hearing protection when using a band saw.

Keep your fingers and loose clothing away from the blade at all times.

Make sure the blade is properly tensioned and tracking correctly before use.

Keep the workpiece firmly in place using a clamp or vise.

Do not force the material through the blade, as this can cause the blade to break or become damaged.

Keep the band saw clean and well-maintained.

Step 2: Adjust the Blade and Guides

Before you begin cutting, you'll need to adjust the blade and guides. The blade should be tensioned properly, with the correct amount of blade deflection. The guides should be adjusted so that they are just a hair away from the blade, without touching it. This will help prevent the blade from wandering during the cut.

Step 3: Set the Fence

If your band saw has a fence, you'll want to set it up before you begin cutting. The fence will help ensure that your cuts are straight and consistent. The fence should be positioned just a hair away from the blade, so that the material can slide through without rubbing against it.

Step 4: Make the Cut

Now it's time to make the cut! Turn on the band saw and slowly feed the material into the blade, using a steady and even pressure. Keep your fingers and hands away from the blade, and let the saw do the work. If you need to make a curved cut, you can adjust the angle of the material as you feed it through the blade.

Step 5: Finishing

Once you've finished the cut, turn off the band saw and wait for the blade to come to a complete stop before removing the material. If you need to make additional cuts, repeat the process starting from step 2.

In conclusion, using a band saw requires some practice, but with these simple steps, you should be able to safely and effectively use a band saw to make straight and curved cuts in a variety of materials. Remember to always prioritize safety, adjust the blade and guides, set the fence, make the cut, and finish the process safely. With time, you'll become more comfortable and confident using this versatile and powerful tool.

0 notes

Text

How to use a chisel?

How to Use Chisel: A Beginner's Guide

Chisel is a hardware design language that is used to describe digital circuits. It is a powerful tool that can help you create complex circuits with ease. If you are new to Chisel, you may be wondering how to use it. In this article, we will walk you through the steps of using Chisel to create digital circuits.

Step 1: Installing Chisel The first step to using Chisel is to install it on your system. Chisel requires the Scala programming language, so you will need to install that first. Once you have installed Scala, you can install Chisel by following the instructions on the Chisel website.

Step 2: Creating a Basic Circuit Once you have installed Chisel, you can start creating circuits. The easiest way to get started is to create a basic circuit that performs a simple operation, such as adding two numbers. To create a basic circuit, you will need to define the inputs and outputs of the circuit using Chisel syntax.

Step 5: Testing the Circuit Once you have created your circuit, you can test it to make sure it works as expected. To test your circuit, you can use the Chisel tester. The Chisel tester allows you to write tests in Scala that simulate the behavior of your circuit.

In conclusion, Chisel is a powerful tool for creating digital circuits. By following these steps, you can use Chisel to create and test your own digital circuits. With practice and experience, you can use Chisel to create complex circuits that meet your design requirements.

1 note

·

View note