Don't wanna be here? Send us removal request.

Text

Sheet Metal Cutting Tools That Every Roofer Should Have

If you’re someone who’s been working on roofs for a long time, you probably have developed your own method. Though the end result is always the same, each individual roofer has a different process. Each step of the process requires a different tool. Just like how the method itself varies from worker to worker, so will the preference in tools.

The tools will also vary depending on the specific job and material that you’re working with. For example, a slate roofer will need certain tools such as slate rippers, cutters, hammers, and hooks. The tools are specially designed to install slate roofs. If you’re working with sheet metal roofs you’ll need things like sheet metal benders, hammers, edge folding tools, seamers, and last but certainly not least, sheet metal cutters.

Different types of Sheet Metal Cutters

Nibblers Nibblers are excellent sheet metal cutting tools. They are made so that you can easily remove a piece of metal from the shear so that there is minimal waviness or distortion. TRUMPF Nibblers are well-made, high-quality cutters. They are highly maneuverable and can handle angled cuts and radii much easier than some other cutters.

The battery is excellent as well. It has a run-time that is higher than other similar tools on the market. Don’t worry about carrying unnecessarily heavy tools around either. This cutter is lightweight, weighing in at a little over 3 pounds. Vibrations are minimized allowing you to cut edges with ease. It’s a lightweight, smooth tool with a long charge. What’s not to love?

Drill Attachment Shears Drill attachments are always handy enhancements. They allow you to get specific jobs done right, without having to go out and buy an entirely new tool. Not only are drill attachment shears inexpensive, but you can find quality versions that will cut sheet metal effortlessly.

The Malco Turbo Shear HD drill attachment is one of the best that you’ll find. It’s very useful to have because it can be used for many different things. Obviously, it excels when it comes to sheet metal roofing, bt it is also good for metal ductwork and stone-coated shingles as well. The blades are sturdy and durable, so you won’t have to worry about throwing them out after a single-use.

Slitters Slitters are a very unique sheet metal cutting tools. Many roofers will use handheld slitters that have cutting wheels or discs. By pulling across coil stock you can make clean cuts with these easy to use tools. A hand slitter is an especially good sheet metal cutter when it comes to pulling across coil stock and making precise cuts.

If you are looking for a sheet metal cutter for your next roofing job the best place to get one is stortz.com. Their website is a convenient one-stop-shop that has all the roofing tools that you’ll need for the job. Whether you’re looking for a slitter, a shear drill attachment, or a nibbler, Stortz has you covered for all your sheet metal needs.

0 notes

Text

How Important Are Metal Roofing Snow Guards For My Home

In general, when you think about winter, you think about snow and what it does to your property. You want to keep the ice pack from avalanching off of your roof—further damaging property, people, and plants below. No matter how you feel about snow, it will always be inevitably part of winter and the only way around it, especially if you have a metal roof or living in an area prone to snow, you may want to think about putting snow guards on your metal roofing to retain snow from falling.

Snow Guards are rooftop devices that aid in snow slides, the threatening movement of snow and ice, by letting melt completely or fall off on a small scale. Snow guards hold equally dispersed snow and ice at rest on your metal roof. Metal roofing snow guards are also referred to as, snow stops, snow-guards, snow blocks, snow brackets, or snowbirds and are commonly installed on commercial metal roof buildings.

Everyone will benefit from safer roofs, fewer complaints of avalanching snow and ice, less harm to roof vents, and overall tranquility during the winter season. Metal roofing snow guard is a feasible, economical addition to any sloped metal roof in winter climates.

Does My Home Need Snow Guards? If you currently reside in an area prone to snowfall during the winter months, it is highly advised that you begin installing a metal roofing snow guard. As snow piles up, ice packs form, massive snow gets heavier, and your metal roof will likely collapse.

Snow guards are designed to keep your roof and the objects below it safe. So, if you’ve ever experienced ice or snow falling off your roof, wrecking your property, then you most definitely need snow guards!

How Are They Installed? When installing snow guards to your metal roofing, you have to carefully refer to the installation guides provided by the manufacturer. Normally, snow guards can be fixed on a metal roof in two different two ways: with an adhesive or fastened with a clamp. A clamp method is highly recommended by most manufacturers though, this is to avoid any avoidable impaling to your metal roof. Different snow guards are designed for different types of metal roofs, they could be corrugated or standing steam and many others. It is rather crucial that you follow the instructions specific to your metal roof.

Falling ice and snow can cause wreckage to a homeowner's property. This not only damages your roof and gutters but also plants or people below. Snow guards help shield your home and property from these possible damages. It is a good idea to install snow guards before the winter season comes or if it's already here for some to avoid the problems mentioned above.

If you have any questions about snow guards for your metal roof, get in touch with your trusted roofing specialist today, or you can also take a look at some of the metal roofing snow guards available at stortz.com for your snow guards needs.

0 notes

Text

Do I Need to Use Metal Roof Snow Guards?

Let's try to unpack some of the questions you might have regarding metal roof snow guards. Whether you are a professional in the industry looking to expand your skill set into metal roofing and snow retention, or you are a homeowner improving your property bit by bit, this is useful information to have. By the time we are done here, you should feel more confident about metal roof snow guards and determining when they should be installed in a property.

What Are Metal Roof Snow Guards For? Snow guards make up a form of snow retention system for roofing, meaning they are used to help manage the amount of snow that falls onto rooftops. When rooftops are overloaded with compacted snow, the chances of an avalanche falling increases greatly. Small amounts of snow do not cause too much trouble, but a steady stream of compacted snow and ice build-up can have dangerous consequences. For one thing, it can fall and hit whatever lies underneath it. This concern goes even further when you consider the potential of someone being in the way of the roof avalanche. Metal roof snow guards help you to manage that concern by catching onto the snow and preventing it from falling down where you would not want it to. After some time passes, the snow remaining on the roof will melt away and pour out gently and safely. Essentially, metal roof snow guards help you control how the snow on your roofing falls over the edge.

Does My Home Need Them? Now we can move on to determine if your property would benefit from having metal roof snow guards in place. This is something that you should seriously consider if your home has metal roofing installed with sloped sides. That is setting yourself up for a difficult situation in the winter if the precipitation slides off of your roof. The metal does not provide enough friction for the snow to slowly fall off on its own at a moderate pace. Instead, snow and ice remain where they settle on the roof and build up until an avalanche occurs. This is especially dangerous if you live in an area where the winter snowfall is heavy and steady. You may have seen this already throughout the winters past. If that’s the case, then you will want to count your blessings that no one and no things were hurt. You will also want to consider installing metal roof snow guards if there are children or physically impaired people in your home since they may be caught up under a rooftop avalanche. It is best for everyone's safety if snow guards were in place to prevent such accidents.

All of this information should have helped you develop a better understanding of when to install snow guards onto a roof. Generally, any home with metal roofing in an area that receives snowfall would benefit from having snow guards in place as a preventive measure. Take a look at some of the metal roof snow guards available at stortz.com to learn more about them and to stock up when you are ready to install.

0 notes

Text

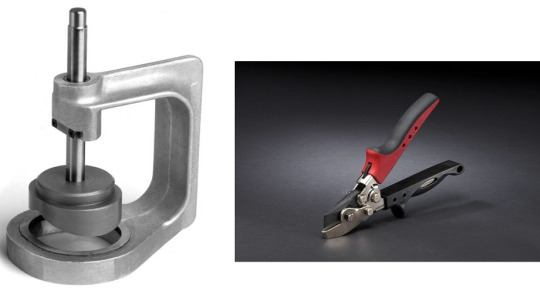

Best Portable Alternatives to a Sheet Metal Brake

When working with sheet metal that needs to be bent, cut, or manipulated in some way or another, one of the first tools people often think of is the sheet metal brake. It is great for use on a wide range of metals in different gauges and can make fairly precise bends to the measure you think. They are great tools to have in your back pocket if you do metal roofing or perform any other projects with large amounts of sheet metal. The issue with them is that they are not the most practical tools to have around. A sheet metal brake is large and difficult to transport, so you might find it frustrating bringing one with you every time. For many projects, brakes are also overkill since you only need to bend smaller, more flexible segments of sheet metal. While they are great to have around if you really need them, you might also want to look at some other tools that are smaller and more convenient to use. Let's briefly go over a few examples from least to most precise.

PVC Hammers PVC or rubberized hammers might be categorized as forming tools, meaning they are not meant to give you precise, defined bends like a sheet metal brake would, but they do help you get your metal to the general shape that you want. The PVC or rubberized head is an important aspect of these hammers because it will help keep your metal from becoming scuffed or scratched, thereby protecting the integrity of the material. These are quite simple to use and mainly rely on the amount of force you choose to use for the given project.

Roller Benders Roller bender tools are great for anyone who has to work with sheet metal regularly for various projects. They are able to handle different types of metal and give you clean, accurate bends. A high-quality roller bending tool should also be able to perform the task without causing any damage to the metal either. This is a good option if you are looking for something that can handle lots of different tasks easily, while still being small and portable.

Hand Seamers This is where precision reaches its peak. Hand seamers and pliers are the tools you want to reach for when you want to make small, precise bends like for finishing work on edges. You can create very defined, incremental bends with a hand seamer that you will have a hard time creating on a sheet metal brake.

It is really up to you to determine which are the best tools for you to work with based on how often you work with sheet metal and what you need to do with it. But now that you have an idea of your options, you can make an informed decision of which tools you want in your supply. While you are looking for handheld tools as alternatives to a sheet metal brake, you will want to visit stortz.com. They have a great selection of high-quality tools for working with sheet metal, so you will be able to find what you need there.

0 notes

Text

Malco Tools for Roofing. 3 Essential Tools for The Job Site

By now, those who work in the roofing or HVAC industry know the story of Mark W. Keymer. He started his own tool-making business when he came up with his revolutionary pipe crimper. A few years later, the brand Malco Tools was associated with time-saving tools by contractors and workers from all over the country.

This tool crafting tradition continues after 70 years as Malco regularly introduces new hand and powered tools for our industry.

As metal roof installers, we have a set of favorite Malco tools that we can´t live without and we wanted to go over some of them today.

Our favorite Malco Tools for Metal Roof Installation Corrugated metal sheets are a favorite for those who appreciate durability and affordability. If you´re installing sheets of corrugated metal, you can´t go out without Malco´s TSCM turboshear. It boasts a universal drill clamp, and its rotating head allows for enough clearance for cutting hard-to-reach edges. It is extremely versatile as it can easily cut through corrugated metal sheets, always leaving a rust-resistant sealed edge. I personally love how it can be used for detail work, like curved or square edges for easy duct and vents installation.

Its sister, the TSHD Turboshear, is better for flat metal panels, especially when you want to create standing seams out of a flat metal panel. It cuts through heavy gauges like butter and offers the same maneuverability as the TSCM.

Our tool belt is never complete unless we carry a sturdy set of hand snips. We usually go with any brand, but we recently gave Malco snips a try and we could feel their strength right away. We are particularly fond of their offset hand snip which allows us to notch tight standing seams, and create foldable grip edge flaps on metal panels with real ease.

Now, when the time comes to fold those flaps, you need to give them a clean and crisp bend. Many like to use hand seamers for the hob, but it takes too long, and uniformity quickly becomes an issue. For this job, we got us the 3-station edge rollers a few months ago and getting straight standing seams has never been easier. It lets you accurately measure the bend´s depth, so you will have a completely uniform bend along the entire length of the panel´s edge. Moreover, you can retract the 2 external stations leaving the middle one free to create curved bends with ease. A total delight.

Those are our three favorite Malco tools for roof installation and repair. They make metalwork a breeze. Of course, there are many more useful tools to carry on your truck, but they are more project-dependent. I recommend you visit stortz.com to check out what they have. Stortz has prided itself on providing high-quality roofing tools for many years. They have been a trusted brand and business for over 100 years now. Visit their site today to get a cutting tool that can make your job a little easier.

0 notes

Text

3 Gutter Tools You Need in Your Kit

Before you head over to the next job site to install or repair gutters, you want to double check your equipment to make sure that you have all the right tools in your kit. Here is a list of three helpful gutter tools that can change the way you do your job. If you somehow do not have these tools in your kit already, you should definitely consider picking up some new items.

1. Gutter Clamp A gutter clamp is a great tool that can make your job much easier. It can clamp onto two separate pieces where you are working so that they can stay in place as you work and move around. With the two separate pieces of gutter held in place, you can move around more easily and free up one of your hands to continue working. It is incredibly easy to use, even intuitive, so you do not need to have much experience to work with these gutter tools either. Even beginners will be able to work with these simple tools. The fact that they are so small and lightweight makes them even better because it makes them so much easier to transport and carry with you as you are working along the edge of a roof. You do not have to struggle to bring out your gutter clamps and quickly hold two pieces in place.

2. Gutter Bracket Bender Gutter bracket benders are great tools to have when manipulating your materials to fit into the project better. Just as the name implies, bracket benders are used to bend gutter brackets to whatever measurement you need. With the brackets at the right angle, it is much easier to fit your hanging gutters into the space comfortably and securely. While bracket benders are not quite as small as the clamps, they are also very easy to use with a simple leverage motion.

3. Downspout Expander Downspout expanders are fantastic gutter tools to have when you need to add new downspouts to handle overflowing. You will have to expand the gutter so that it will be able to fit in the new downspout easily. The downspout expander widens the gutters so they fit everything well, making your work there much easier. It also makes the final result look better because you do not have to fight the materials to fit properly. A sign of a good craftsman is being able to leave the final project looking clean and polished.

With all of these gutter tools in your kit, you should be ready to tackle any project with absolute confidence that you have what you need to get the job done in good time. Each of these tools greatly helps to make your job easier and more efficient so you can work faster and run into fewer problems along the way. They help you do your work more smoothly and with better results so that you and the client are both satisfied. To get your kit fully prepared, you can shop for any of these gutter tools over at stortz.com where they offer high-quality professional tools and equipment to support you through all of your projects.

0 notes

Text

What to Know Before Buying Your Paint Scraper

Before you go online and purchase the first paint scraper listing you see, you should take the time to explore your options for this tool and how you want to perform. Let’s take a quick look at paint scrapers and what you should know before buying one.

What They Are Used For A paint scraper is a fairly simple tool in design, but can be used on many occasions to work with different materials. As long as you know what you are doing and have a good, sturdy paint scraper in your toolkit, you will probably find that it will help you out on many occasions. Of course we know that they are meant to scrape paint off of various surfaces like doors, walls, door frames, or other indoor structures. They make it easy and efficient to remove paint without damaging the material underneath. You can just scrape through the older material, potentially using the help of an item like a heat gun to gently work the paint off.

What to Look For Since this is a tool that you will likely come to rely on over time, you will want to shop for something high-quality right out the gate. You want something that will last for years even after being used so often on various projects. Look for a paint scraper with a strong, sturdy handle and a good grip so it will feel natural to hold onto consistently and the handle will not loosen up and break off over time. You especially want a tool that can easily be sharpened repeatedly as needed so that the blades remain sharp and effective. Try to find reviews or descriptions of the products you are looking at to see if they claim the scraper tool does not leave a large amount of dust behind so you can work cleanly.

Shapes of Paint Scrapers

Rounded Rounded paint scrapers are ideal for working around curved, concave surfaces that would ordinarily be challenging. Their shape allows you to move them around curves and bends easily so that you will be able to do your work quickly, and without bothering your hands or wrists too much. Paint scrapers could be entirely rounded like ovals, or they could be more angular shapes with a rounded corner to work with.

Rectangular or Triangular Rectangular paint scraper tools are great for covering larger surface areas at a time. They allow you to work quickly and efficiently on large, flat surface areas. Triangular ones are similar because of their flat sides, but come with the added benefit of their distinct corners which can work into sharp, difficult corners or edges.

Regardless of which shapes you prefer working with, you can find some great options for paint scrapers that will hold up to steady use at stortz.com. Their tools are known for being well-crafted and high-quality so you can be sure they will stand up to the work you put them through. Their shop has paint scrapers in all shapes and sizes, so all that is left is to decide which ones are best suited for your needs.

0 notes

Text

Different Kinds of Tin Snips Needed for A Sheet Metal Roofing Job

Sheet metal roofing is a job that requires multiple tools to complete the job, or at least get it done correctly in a timely manner. These metal roofing tools range from metal benders, whether they be used in a shop or portable benders used at the job site, to smaller tools like tinner’s hammer. Today we’re going to talk about a tool that can fit right into your toolbox, but that is also a bit more complex than some may know, and that is tin snips

Tin Snips can be a sheet metal roofer’s best friend if he has the correct pair. There are so many different roofing tool brands and types of snips to choose from, that if it may be difficult to choose the right one for each particular job even for a roofing professional. One website that has a vast variety of snips for sale, is stortz.com. Let’s talk about each kind of snips that they have to offer.

Circular Snips Circular Snips are a very popular kind of snips when it comes to sheet metal roofing. They are used for circular cuts thanks to the circular blade. They are especially handy for standing seam detail work when it comes to eave trimming. Stubai is the most popular brand of snips when it comes to roofing and they make excellent circular snips that can be found right on Stortz’s site.

Pelican Snips Pelican snips are an excellent choice when it comes to making long, straight cuts. There are two major brands that are trusted when it comes to these snips: Stubai and Freund. Both of their pelican snips have a 3” blade depth. Freund’s are made from high alloy steel, but when it comes to their pelican snips, a right-handed person may find it difficult to see the cutting line without left-cut snips.

Offset Snips Offset snips are great when it comes to straight cuts or angles. Klenk makes an amazing pair of snips that can handle angles and circles with ease. This makes it simple to cut round pipe. It can leave both ends completely clean. The handles are up and away from the metal of the snips making it easy to protect your hands. They can make a cut of 1 ⅜” even though the handles are 5” apart.

Other Important Roofing Tools Safety should be your number one priority when using any metal roofing tool. Because of this, there are Sheet metal craftsman gloves available so that you don’t cut your hand. Snips may not seem as dangerous as a power tool or other bigger and sharper roofing tools, but when not in the hands of a roofing expert it is easy to chop a finger off if you’re not careful.

There are plenty of other options available like the Masc Nibbler and Combination Tin Snips but you can find out more about them on Stortz’s site. All the snips options you could ever dream of are available on one convenient site. Visit stortz.com for all of your sheet metal roofing tool needs.

0 notes

Text

Three Brands of Sheet Metal Benders That Every Roofer Should Be Aware Of

If you’re a roofer that’s used to working with sheet metal you probably understand the importance of having high-quality tools. Having proper tools can take hours off the time it would take you to a job without them. Not to mention, it can alleviate some of the stress and back-breaking labor you have to do. Obviously, roofing is a physically demanding job regardless of the tools at your disposal, but having dated or obsolete tools only make the job that much more difficult.

One tool that no sheet metal roofing professional can do without is a sheet metal bender. In all honestly, you may even need more than one depending on the size of the job. Luckily there are plenty of excellent options available online when it comes to metal benders. Several roofing tool companies produce metal benders worthy of an expert roofer. Some of those would be Stortz, Freund, and Wuko. Each brand has metal benders available on Stortz.com, but let’s go into detail on what makes each brand unique.

Stortz Sheet Metal Benders John Stortz & Son is a roofing tool business that has been making quality hand tools since 1853. You have to be a very innovative and productive business to continue producing the quality products that they have been for all these years. Their sheet metal benders are just as efficient as the rest of the tools that they produce.

Stortz perfect benders come in various different sizes, ranging from their pocket bender to their popular XL-150. The pocket bender is extremely convenient. It’s a simple bender that is especially useful when bending to the corners. The XL-150 bender and its counterpart the S-150 bender are both made of stainless steel to be used in any weather condition. They can both be paired with roller hemming tools as well.

Freund Metal Benders Freund is a company that makes some amazing portable bending options. When it comes to seamless bends, they have options available to get the job done right whether you’re working with straight sheets or curved sheets. They have radius rollers, disc rollers, and premium benders available. Each of these are quality products that offer convenience and will make it so you’re able to bend sheet metal directly at the job site rather than going to a shop.

Wuko Metal Benders Last, but definitely not least, we have Wuko. Anyone who has ever worked with sheet metal in any architectural manner likely knows the quality associated with the Wuko brand name. Their benders are able to form panel profiles or flanges on sheet metal, straight and curved alike. Both their singular benders and their combos are reviewed very highly by roofing experts. They have a wide variety of premium-level benders available.

Get all of these sheet metal benders and more on stortz.com. They have a wide variety of roofing tools for all of your sheet metal needs. Buying roofing online tools online has been made easier than ever with everything you can need on the job available in one spot. Visit Stortz’s website today and see the vast selection they have available.

0 notes

Text

Must-Have Sheet Metal Tools

Sheet metal roofs are gaining popularity and are often chosen over slate. When it comes to working on that sheet metal, the job requires much different tools and techniques than when working with slate.

All roofers know that having reliable, durable tools is important. No one wants to be halfway through a job and have a tool stop working for them. It ruins a worker’s momentum and motivation leaving them frustrated and ready to quit. Some must-haves for roofers when working on a sheet metal roof are snips, sheet metal benders, tin hammers and more.

Snips Snips are a very important sheet metal tool. If you find yourself replacing snips more often than you should be, it is most likely because you are buying the wrong pair of snips. Being aware of the cut orientation, hardness, and blade type needed will allow you to purchase a pair of snips that is right for you.

When buying snips you may want a pair that is spring-loaded like the MASC Nibbler. As long as you’re able to cut continuous slots while avoiding slits then you should be in business. A good pair of nibblers shouldn’t tear the metal easily and be able to work easily with Zinc and other materials. Depending on the job, circular tin snips as well.

Sheet Metal Benders Sheet metal benders have become an essential part of every professional sheet metal roofers’ arsenal. With a metal bender, you can bend up to 90 degrees directly onsite without having to rely on a heavy brake. This has made sheet metal roofing much easier and was absolutely revolutionary to the industry as a whole.

Stortz, Wuko, and Freund all make excellent sheet metal benders for the modern roofing professional. There are different sizes and types of benders, so be sure to know what you’re looking for before you make your decision. On Stortz’s website, you can actually find benders from all three of these amazing brands. Get an individual sheet metal bender or a combo package.

Standing Seamers Standing seam roofs are certainly on the rise and you’ll notice more of them being installed now than ever before. It is all a matter of preference when it comes to seamers. If you are looking for a classic, first stage, or second stagehand seamer there are plenty of options that can get the job done correctly. One of the best brands for hand seamers are ESE. They also offer finish hand seamers available for a double lock.

You may be more interested in a power seamer. Once again there are plenty of options on the market, but one of the best is Stortz’s Accuseamer. This sheet metal tool can save you time and effort and is one of the best investments you can make as a roofer. This innovative product will allow you to do single and double locks with ease.

If you are looking for any of these sheet metal tools or brands, they can be all be found at stortz.com. Whether it’s a power seamer or a tinner’s hammer, you can visit their site for anything you’d need for a sheet metal or slate roofing job. Check out the amazing deals and products they have available.

0 notes

Text

Choose a Shingle Remover That Is Better by Design

There is not one single tool that any given roofer needs to have before ascending the ladder. It all comes down to the medium that the roofer is working with and what the job at hand entails. However, for those that work with wood or stone shingles, such as slate, a shingle remover is one of the more important tools among them.

Specialized hammers, shears, benders and marking tools are all important for roofers, some of them for sheet metal and others for stone, but a shingle remover that is purpose built for performance is a boon for any roofer that specifically works with shingle roofs.

Some shingle tools are poorly specialized and some roofers may take to less-than-specialized opinions for prying up shingles for removal. However, when you want to preserve the underlying roofing material or the shingles themselves, a well-designed tool will go a long way.

Consider a tool like the Stortz Slate Ripper, that you can find online at Stortz.com, and while you’re shopping, don’t let the name fool you. This “slate ripper” is useful for far more than just removing and replacing slate shingles - although it is tops for that.

The Stortz Slate Ripper shingle remover features one piece forged construction and a thin, spring tempered blade that is durable, tough, and ideal for sliding underneath shingles and shakes. When used properly, this tool can be used to remove shingles and shakes without breaking or damaging adjoining pieces.

This tool is also simple to use and highly effective. It’s designed to be slid underneath a shingle or a shake; the spring-tempered blade has a divot that can be seated against the nail that secures the shingle. Once seated, the handle of the tool can be struck with a hammer to easily and cleanly remove the nail. The entire tool features simple construction and the reinforced handle is intended to stand up to a lifetime of hard use, although you can also get replacement handles and replaceable blades for some of their models.

The blade also has notches on the trailing edge of the blade that can be used to remove loose nails or pull them out once the nail has been unseated. The tool is ergonomic, features simple construction, and is rock solid. Like everything else available at John Stortz & Son, this tool is built with the intention of being a lifetime investment. There’s not much you can do to make a simple tool like this flinch, and it’s equally effective on wood shakes and shingles as it is on stone shingles.

It is also only one of the specialty tools that Stortz.com provides for its customers with respect to shingle and tile roofing. Their collection also contains a variety of other styles of shingle removal tools and slate rippers, along with many other specialized tools for both slate and sheet metal roofers.

Visit their website, Stortz.com, to learn more about what they provide and the specifics of their products. You can also get in touch with them at 888-847-3456.

1 note

·

View note

Text

How to Transform a Piece of Stone with a Brick Hammer

You’re probably familiar with an all-purpose hammer or a claw hammer. It’s a simple striking tool with a head featuring a flat face for driving nails and spikes. Specialized hammers may have a claw on the head opposite the striking face that can be used to pry out nails once they have been driven.

These types of tools, general as they are, belong to a class of much broader striking tools and specialized hammers that are meticulously engineered to provide very precise functions in the hands of skilled users. One of these is a brick hammer, which may also be called a mason’s hammer.

Brick hammers, like claw hammers, have a flat striking face, just like claw hammers. However, at the opposite end of the head, in place of a prying claw, they have a flattened, chisel shaped striking head. This is used to make precise cuts and alterations in pieces of stone or brick, in a surprisingly accurate fashion.

Not to suggest that there isn’t a significant amount of skill involved in the process, because there is, but the manner in which cuts and alterations can be made to a piece of stone or brick can be pretty succinctly described. You’ll need a piece of the same (brick or stone) and you’ll also need a brick or mason hammer to accomplish this.

First, plan out in your mind the piece of the stone that you wish to remove from the stock. Then, taking the chiselled face of the mason hammer, and using a sharp, abrupt movement, make small marks in the stone. Create a series of marks around the stone that you intend to remove from the stock, girdling the stone. The idea here is to remove very small pieces or chips of stone from the stock, creating a natural boundary along which a fracture will travel when the stone is struck.

Once you have completely encircled the section of the stone you wish to remove, turn the hammer around and orient the flat face toward the stone. Using a sharp but powerful stroke, hit the stone squarely along the boundary. It should break cleanly along the outline you have created using the chiselled face.

Of course, it could take a few, or many, tries before you can get this right. Masons and bricklayers spend their whole lives becoming proficient in the use of mason tools like these. That is the basic process for making alterations to a piece of stone or brick as specified, but don’t expect it to be easy!

For those of you looking for the tool itself rather than a blank tutorial on how to use it, you’ll find quality awaiting you at Stortz.com. John Stortz & Son has been providing high quality, specialized tools to its customers for over a hundred and fifty years, including but not limited to masonry tools like brick hammers. Visit their website listed above to see what they offer, and if you have any questions on any of their products, give them a call at 888-847-3456.

0 notes

Text

What is a Metal Bender Used For?

For anyone setting themselves up with only the most versatile, useful tools they need to keep a kit fully functioning, a good metal bender has to come into the picture at some point. It is a really handy device for a wide range of projects in roofing, automotive work, construction, etc. As simple as its basic purpose is, you may be a bit unsure before purchasing one because of the different types you see available. Generally you will find there to be two types of metal benders that you will want to consider using. For those who know a fair amount about metal bending and are simply weighing their options, consider this a quick little rundown of what you should keep in mind when shopping. And if metal bending sounds more like a superpower to you than a construction tool, just keep reading. We’ll make things a bit more simple.

What is a metal bender?

A metal bender is a tool used to manipulate metal and bend it at an angle so that it is easier to work with for certain projects. Metal benders ideally should be precise, consistent throughout the material, and able to operate smoothly without damaging the material.

Portable Benders

A smaller, handheld metal bender is the less expensive option out of the two types and the most easy to manage since it is so easy to carry with you on-site as needed. This especially comes in handy when roofing. The main drawback is that it cannot work on certain types of metal, but for someone who works with softer materials or does not need to use it too often, that should not become an issue.

Sheet Metal Brake

A sheet metal brake is a larger device used to bend metal of a wide range of gauges at higher tensile strength. This is the stronger, more heavy duty option for bending metal and is very useful when it is something that you need to do quite regularly. It also comes at a higher price point than the smaller counterpart, making it more of an investment. It is larger and more stationary, making it more difficult to move around with you. With this device, you are truly committing to metal bending frequently and want a tool to make it much easier the whole way through.

Just as promised, that was a pretty simple and clean breakdown of the two types of metal benders you may want to add to your life. You can get the smaller, more portable tool, or the larger, more heavy duty brake to get the job done. If you are still on the fence about which metal bender is best for your purposes, or you have a good idea of which one you want to go with, you should visit John Stortz & Son online. They not only have metal benders available to purchase, but also additional information on the uses of metal benders. Take your time looking over some of their resources to learn more about this type of equipment.

0 notes

Text

Alternatives to Using a Sheet Metal Brake

You probably already know what a sheet metal brake is used for if you have spent any amount of time in fields like roofing and construction. A sheet metal brake is a somewhat large device used to bend sheets of metal for various projects. While a bending brake is great for certain purposes like dealing with higher gauges of metal, it also comes with its fair share of drawbacks as well. Bending brakes are stationary, take up a great deal of space and generally lack flexibility for the user.

You may have become familiar with the name and simply accepted it as the main tool you would want to use for bending metal. However, you should know that it is not the only option in metal bending tools, and it is certainly not the best choice in many circumstances. You should keep in mind that there are plenty of other metal benders on the market that are much more practical to use than just a sheet metal brake. You will likely find that using any of these metal bending tools will actually be the better call.

Hand Seamers This is what you will probably want to choose if you need to bend metal ever so carefully in small increments at a time. Hand seamers are very small, handheld tools that largely resemble pliers. The difference is in the metal tips. Hand seamers give you a great amount of manual control, so they are good for doing detailed precision work with metal. They come in handy especially if you have to work in a tight, confined space or on a small surface. As an added incentive, hand seamers are less expensive than many other devices you could use including metal brakes.

Rollers This type of metal bender is more versatile than the previous one mentioned. Handheld roller benders give you a great amount of control over the bend of many different types of metal. A good one will allow you to bend metal, quickly and easily without leaving any scratches or scuff marks on the material. This is a real workhorse of benders because they are so useful and can be easily brought onsite with you to a job. This is the bender you want to bring with you to work on a roof.

Take a good look over these bending tools to see if there is any one that will fill an empty space in your work supplies. Of course there will still be times when a sheet metal brake is the best metalworking tool to use, but not all the time and probably not for most of the times you will need to bend metal. For all of the many other occasions, one of these alternatives will work just fine. You really do not need to weigh yourself down with a large, cumbersome piece of machinery in your work vehicle, when a small, handheld tool will do the trick. You can take your pick of any of these alternatives over at John Stortz & Son, where they have plenty of options for each type of product mentioned here.

0 notes

Text

3 Manual Metal Cutting Tools Should You Own

As you build out your equipment for construction work, you will run into quite a few different types of specialized tools all used for metalwork. Each tool has its own purpose and its benefits to you as the user for any of the work you might like to have them around for. Whether you do professional work, or consider yourself quite the handyman yourself, you will want a selection of high quality manual metal cutting tools to get you by in all of your projects. A few well-selected tools can cover a wide range of purposes and give you an easy time using them. At the very least, here are a few metal cutting tools you will want to keep by your workbench.

Shears or Snips Tin snips or shears are some of the most useful handheld metal cutting tools you could own. They are, as the names imply, much like scissors, which snip and cut the sheet metal you are working with. They are inexpensive and durable, while still being a tool you reach for often, making them incredibly practical to keep around. They are able to cut through materials in curves or straight lines, since they work like scissors, so you are able to manipulate them as you wish. You can use them for just about any material that is not too thick, otherwise you will want to upgrade to something else.

Hacksaws Hacksaws are great for picking up where shears or snips leave off. Unlike shears, hacksaws can handle much thicker gauges to cut through. But very similarly, they are also very easy to use and fairly inexpensive. They work well for cutting materials away from your workbench, when the position of the material might not be laid out as evenly as you would normally prefer. One of the only drawbacks is the amount of effort you need to put in, in order to use this tool for an extended period of time. However, if you can accept that, then one is for you. The hacksaw is likely one of, if not, the first of the metal cutting tools you considered purchasing for yourself. It’s hard to go wrong with having this one on standby.

Punchers Punchers are less likely to be thought of when making a list of metal cutting tools, but still come highly recommended. These versatile tools can handle quite the range of use in metalwork from fully piercing the metal to intentionally only leaving a dent. You can use punchers to press a small hole into metal in order to create a place to bring something like a bolt, nail, or dowel through. Another way to use punches is to make an indentation in your metal to serve as a marker for your plans as you go. Much like the other metal cutting tools listed above, punches are quite durable, versatile, affordable, and easy to use, making them a wise choice to have in your arsenal.

Next time you are shopping for tools, make sure to add these to the list so you won’t forget. Then visit John Stortz & Son for whatever quality hand tools you need, including your new go-to metal cutting tools.

0 notes

Text

Comparing Tin Snips: Serrated Jaws Vs. Straight Edge Jaws

Do you own a pair of tin snips? If you do, go get it and take a close look at the jaws. Now take a closer look at the jaws, along the edge where they come together. Do you see anything noteworthy? Would it help if we were more specific?

We’re not asking you to look for a spot of rust or something odd like that. We’re asking you to take a look at whether your tin snips have straight-edged or serrated jaws. Believe it or not, this is not simply a cosmetic alteration. There are very real reasons that these features are worked into the design of sheet metal shears and some other cutting tools.

There’s a reason that snips (sometimes called aviation snips), which are remarkable, versatile tools for fitting into tight spaces and making precise cuts to aluminum, copper and steel, sometimes have teeth.

You see, straight-edged snips, those that lack teeth along the blade edges, are ideal for cutting softer materials like aluminum and copper. These metals are softer than steel and the jaws are less prone to struggling to grip the surface. Smooth-edged snips are designed to cut through these easily.

By contrast, cutting snips with serrated steel blades are more effective at cutting harder materials like stainless steel. The serrations in the blades are better at gripping the material and there is less likelihood that the jaws will slip or twist which diminishes their ability to separate the sheet metal. The serrations also help to concentrate the force. One thing to remember about serrated snips is that it’s important to buy and use only properly heat treated snips, preferably those that have been made with a high carbon steel. Low grade steels and poor heat treatments will cause the serrations to deform or wear prematurely.

There’s a little more to this picture, however. Tin snips that have serrated jaws are very effective, but there is a little caveat to their use. Predictably, serrated jaws create small serrations along the edge of the material they are used to cut. These little serrations, however, create tiny stress risers in the metal that can crack or tear over time if the metal is stressed.

Therefore, it is safer to use straight-edged shears for making cuts if this is a concern. It’s also safer to use straight-edged shears to cut softer materials like copper or aluminum, since these are more prone to tearing under stress.

If you’re looking for a collection of the highest quality tin snips for making both straight cuts and curved cuts, look no farther than John Stortz & Son. for well over a hundred years, Stortz has been a provider of the highest quality tools for roofers and other tradesmen around the country. Visit their website, Stortz.com, to learn more about the tools they sell and the industries they serve.

Call them up even if you only want to learn more about the differences between the many variations of snips that are out there. They’ll quickly become your preferred resource - get in touch with them at 888-847-3456.

0 notes

Text

Floor Scraper 101

Have an upcoming home renovation project but still figuring out all of the tools you need? Yeah it’s understandable. There is a lot that goes into creating a sturdy, well-made home before a single piece of furniture ever walks in through that door. The wiring, the roofing, the walls and flooring all add up to a whole host of trouble. So where do you even begin? Well, pick a part of the house, figure out what you need to do to it, and get the materials you need to achieve that. Let’s start with the floor. If you want to redo the flooring, then there is at least one tool you will need before a single tile drops. A floor scraper.

What is a floor scraper? A floor scraper is a small handheld tool with a flat, wide metal blade attached to the handle. The blade is somewhat sharp since it is used on tough materials. Seeing as it is a simple tool by nature, it does not vary much by way of design.

What is it used for? It is used for removing old and unwanted materials off of the floor so that it is smooth and prepared for something new to be put in its place. It can remove substances like paint, tile, carpeting, and carpet glue. It might also be used to remove carpet nails, but that can do damage to the scraper. Although it is most known for flooring, as the name suggests, a floor scraper can also be a handy tool for removing paint, wallpaper or even excess mortar from walls.

What makes a good floor scraper? You know what it is, but you want to know how to pick out a good one to make your home renovation process easier. The main thing you will want from the scraper is a strong blade that can hold up to the pressure you will be putting it through. Some substances are much softer and easier to scrape off of the floor than others. That is only some of the substances. Floors can be very tricky to work on because they are not always smooth and clear under a light layer of materials. When scraping floors, there is a chance that you will try to run over difficult patches where something sticks out from the floor like a nail or carpet staple and your blade will either stop on the spot or hit the mark and spring off of it. As fun as it is to move along without thinking once you get into a rhythm, you have to keep your eyes sharp on any obstacles that may appear. You wouldn’t want to damage the tool right out the gate.

So there you have a quick rundown on one of the tools you will need to rework the flooring of your property. This should be enough information to help you pick out a floor scraper for yourself and get ready to tackle that floor head on. A good place to turn to is stortz.com where they have floor scrapers and a bunch of other tools for renovation projects.

0 notes