Stratgem is a diversified and innovative company that offer the best solutions in the field of Powder Handling Automation and Air Pollution Control Solutions.

Don't wanna be here? Send us removal request.

Text

Telescopic Chute Manufacturer in India | StratGem Projects

Stratgem is a top telescopic chute manufacturer in Pune, India. We offer bulk material handling systems, loading spouts, & dust control solutions.

StratGem was incorporated in 2014, with the purpose of serving Industries for environmental and engineering solutions and with the aim to cater and bring difference in the field of powder handling and air pollution control.

Speak with Our Expert:

Email: [email protected]

Landline: +91 020 46028762

Phone: +91 9175673483

Corporate Office: Office No. 20, 4th Floor, B Wing, City Vista Kolte Patil Downtown, Fountain Road, Kharadi, Pune. MH, India 411014

0 notes

Text

Fume Extractor Manufacturers: Boosting Operational Safety and Efficiency

When it comes to industrial and laboratory reactor systems, maintaining clean air and preventing exposure to hazardous fumes is crucial. StratGem’s Fume Extractor in Reactor Systems offers cutting-edge air purification, designed to ensure safety, operational efficiency, and compliance with stringent regulations. From capturing toxic fumes to enhancing air quality in industrial settings, StratGem is at the forefront of fume extraction technology.

StratGem was incorporated in 2014, with the purpose of serving Industries for environmental and engineering solutions and with the aim to cater and bring difference in the field of powder handling and air pollution control.

Speak with Our Expert:

Email: [email protected]

Landline: +91 020 46028762

Phone: +91 9175673483

Corporate Office: Office No. 20, 4th Floor, B Wing, City Vista Kolte Patil Downtown, Fountain Road, Kharadi, Pune. MH, India 411014

#fume extraction systems#fume exhaust system#Reactor Fume Extractor#Industrial Air Purification#Welding Fume Extractor#Laser Welding Fume Extractor#Plasma Welding Extraction

0 notes

Text

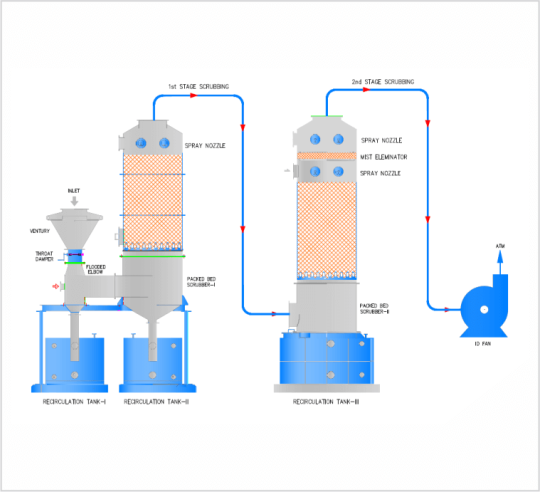

Wet Scrubber Air Pollution Control System Manufacturer in Pune, India

Industrial air pollution is a critical global concern, and effective emission control is essential for environmental and regulatory compliance. Stratgem Projects, a trusted name among wet scrubber manufacturers in India, specializes in cutting-edge wet scrubber systems and pollution control equipment to help industries meet strict emission norms.

StratGem was incorporated in 2014, with the purpose of serving Industries for environmental and engineering solutions and with the aim to cater and bring difference in the field of powder handling and air pollution control.

Speak with Our Expert:

Email: [email protected]

Landline: +91 020 46028762

Phone: +91 9175673483

Corporate Office: Office No. 20, 4th Floor, B Wing, City Vista Kolte Patil Downtown, Fountain Road, Kharadi, Pune. MH, India 411014

#wet scrubber#wet scrubber manufacturers#wet scrubber manufacturers in India#wet scrubber system#scrubber system#water scrubber#pollution control equipment

0 notes

Text

Screw Conveyors/Auger Feeders

Screw Conveyors Manufacturer & Supplier for Material Conveying: StratGem

Bulk materials are handled by means of screw conveyors, which are highly adaptable mechanical apparatuses. They are generally used in the construction, mining, food processing, and agricultural industries for the horizontal or mildly inclined transportation of materials.

Stratgem develops and manufactures Screw Conveyors/Auger Feeders based on the needs and specifications of the customer for the material handling. Food, chemicals, pharmaceuticals, plastics, polymers, and breweries are just a few of the industries we serve.

We also provide other powder/material handling products. To know more about Powder Handling Automation Products please feel free to connect us!

#Screw Conveyors#positive push conveyors#U Trough Screw Conveyor#positivepushconveyors#screwconveyormanufacturer#augerconveyor#screwFeeder

0 notes

Text

Pulse Jet Bag Filter or Bag House Dust Collector Supplier in Pune, India

A pulse jet bag filter also known as a baghouse dust collector, pulse jet dust collector is a filtration and cleaning equipment. The pulse jet cleaning system dislodges and removes the particulate matter and dust from the surface of the filter fabric(bag) with the pulse of high-pressure compressed air. Pulse jet bag filters are the most common and advanced type of particulate air pollution control equipment installed in industries to meet environmental compliances and maintain better work area quality and safety of the workplace. The name Pulse Jet is given on the basis that the cleaning of filter bags is done by the pulse of compressed air passed on to the filter bags.

#bag filter#pulse jet bag filter#jet pulse#bag house#Baghouse dust collector#bag filter supplier#dust collector filter bags#industrial dust collector#bag filter manufacturer#air pollution control products

0 notes

Text

Dust Extraction Systems

The Dust Extraction System is basically developed and manufactured for the removal, and extraction the dust from the industrial area. The dust particles produced during the manufacturing process are totally removed ensuring a safe and healthy working environment by preventing the release of pollutants into the atmosphere.

If you're considering and willing to implement a Dust Extraction System in your industrial facility, StratGem Projects is here to help with your significant application with the best Dust Extraction System Manufacturers India. Contact us today to discuss your specific needs and explore the best dust extraction solution for your industry, factory, business, etc.

#dust extraction system#Dust Extraction System Manufacturers#Dust Extraction System Manufacturers India#dust collector machine#machine dust collector#dust collector#dust collector system#dust extraction#industrial dust collector#dust collector filter#dust collector filter bag#dust extractor machine#bag filter#dust remover#bag filter dust collector#dust collector bags#bag house filter#industrial dust extractor manufacturers#bag filtration#dust extraction system manufacturer#high efficiency particulate air filter#cyclone separator#rotary air lock valve

0 notes

Text

A vacuum powder transfer system is a specific type of powder transfer system that uses the vacuum created by a vacuum pump to transfer powder materials. It usually consists of a vacuum pump, a conveying line or tube, and a collection vessel.

A vacuum powder transfer system offers many advantages. First, it allows efficient and dust-free transfer of powder materials, reducing the risk of contamination and ensuring product integrity. In addition, it enables precise control of the transfer process, facilitates accurate dosing, and minimizes material loss.

The closed system design also enhances safety by preventing operators from coming into contact with potentially hazardous substances.

#vacuum#vacuumpowdertransfer#powdertransfersystem#powderhandlingsystems#VacuumConveying#PowderConveyingSystem#vacuumtransfersystems#powderhandlingequipments#industrialmachinery#industry#Manufacturing#vacuumtransfersystem#industrialequipments#startgemprojects#industrialautomation

0 notes

Text

A spot filter is a compact and small bag filter that is designed for the removal of dust from conveyors, elevators, and bunkers. Depending on the type of equipment, a spot filter can be installed horizontally or vertically. This dust removal filter works by using a series of filter bags that are placed inside the unit. As air and dust enter the spot filter, the filter bags capture the dust particles and prevent them from being released into the surrounding environment. The clean air is then released back into the equipment or into the atmosphere. It means it is extremely efficient at capturing dust and other particulate matter. For more detailed information Please visit www.stratgemprojects.com/spotfilter.html . Stratgem develops and manufactures Spot Filter, a dust remover, based on the needs and specifications of the customer. To know more please contact us.

#Dust Remover System#small bag filter#dust removal filter#filter bags#low-maintenance Dust Remover System#low-maintenance Spot Filter#Spot Filter for Pneumatic Conveying System#Centrifugal fan#Spotfiltermanufacturer#Spotfiltermanufacturerindia#Spotfilterproviders#dustremovalmanufacturerindia#Dustremoversystemprovider#Stratgem’s Spot Filter#centralized dust extraction system#Compact design Spot Filter#grainsindustry#pharmaceuticalsindustry#plastics industry#mineralsindustry

0 notes

Text

A spot filter is a compact and small bag filter that is designed for the removal of dust from conveyors, elevators, and bunkers. Depending on the type of equipment, a spot filter can be installed horizontally or vertically. This dust removal filter works by using a series of filter bags that are placed inside the unit. As air and dust enter the spot filter, the filter bags capture the dust particles and prevent them from being released into the surrounding environment. The clean air is then released back into the equipment or into the atmosphere. It means it is extremely efficient at capturing dust and other particulate matter. Stratgem develops and manufactures Spot Filter, a dust remover, based on the needs and specifications of the customer. To know more please contact us.

#spotfilter#DustRemoverSystem#smallbagfilter#dustremovalfilter#filterbags#low-maintenanceDustRemoverSystem#low-maintenanceSpotFilter#Spot FilterforPneumaticConveyingSystem#Centrifugalfan#Spotfiltermanufacturerindia#Spotfiltermanufacturer#Spotfilterproviders#dustremovalmanufacturerindia#Dustremoversystemprovider#Stratgem’sSpotFilter#centralizeddustextractionsystem#CompactdesignSpotFilter#airpollutioncontrolsystem#foodindustry#chemicalsindustry#grainsindustry#pharmaceuticalsindustry#plasticsindustry#mineralsindustry

0 notes

Text

Dilute phase conveying system or Lean phase conveying system is described as the process of (pressure) pushing or (vacuum) pulling particles suspended in air from one location to another.

#dilutephaseconveyingsystem#leanphaseconveyingsystem#powderconveyingsystem#dilutephase#leanphase#powderhandlingsystem#pneumaticconveying#powderhandlingmachines#powderhandlingequipment#powderhandlingsystemprovider#pneumaticconveyingsystem#silo#stratgemprojects#powderhandlingsystemmanufacturerinindia

0 notes

Text

Dilute phase conveying system

Dilute phase conveying system or Lean phase conveying system is described as the process of (pressure) pushing or (vacuum) pulling particles suspended in air from one location to another. Basically Dilute Phase conveying systems are a mode of transporting powders generally through a positive displacement blower, side channel blowers or vacuum pumps. It is a simple system used for various powders that doesn’t have any specific quality requirements for degradation or loss of material properties.

For more information https://www.stratgemprojects.com/Lean-Dilute-Phase-Conveying-System.html

#dilutephaseconveyingsystem#leanphaseconveyingsystem#powderconveyingsystem#dilutephase#leanphase#pneumaticconveyingsystem#powderhandlingsystemprovider#powderhandlingequipment#powderhandlingmachines#powderhandlingsystem#powderhandlingsystemmanufacturerinindia#silo#stratgemprojects

0 notes

Text

A bulk bag, also known as a FIBC (Flexible Intermediate Bulk Container), is a large bag made of woven polypropylene material. It is designed to hold and transport dry bulk materials in a safe and efficient manner. Bulk bags are available in various sizes and configurations, ranging from small bags with a capacity of a few hundred pounds to large bags that can hold several tons of material. Stratgem Projects provides all sizes of bulk bags for various purposes.

#bulkbag#fibcbags#bulkbagdischarger#jumbobag#bag#bulkbagunloader#bulkbagunloadingsystem#jumbobagdischargesystem#bulkbagdischargesystem#fibc#bulkbagdischargesystemmanufacturer#bigbagdischarger#bulkconveyor#wholesalebags#bulk#startgemprojects

0 notes

Text

Dense phase Pressure conveying system

Dense phase conveying system comprises pressure vessel with various valves and instrumentation for the automation. The system can be operated in auto mode through a PLC, and it can also be integrated with SCADA depending on the customer’s automation requirements. The dense phase conveying system (pressure) is a dust-tight operation with emission-free conveying that ensures a high pressure range of 0.5 bar (g) to 7 bar (g). The gas velocities in these systems are decided based on the type of product, which can vary between 1 and 10 m/s.

For more information visit https://www.stratgemprojects.com/Dense-Phase-Pneumatic-Conveying-Systems.html

#Dense phase pneumatic conveying systems#Dense phase conveying systems#Pressure conveying system#Dense phase pressure conveying systems#material handling equipment#powder conveying system#pneumaticconveyingsystemmanufacturer#densephase

0 notes

Text

A Bulk Bag, also known as a FIBC (Flexible Intermediate Bulk Container), is a large bag made of woven polypropylene material. It is designed to hold and transport dry bulk materials in a safe and efficient manner. Bulk bags are available in various sizes and configurations, ranging from small bags with a capacity of a few hundred pounds to large bags that can hold several tons of material.

#bulkbagdischargers#bulkbagunloadingsystem#bulkbag#bagunloader#jumbobagdischargesystem#bulkmaterialsorpowders#bulkbagdischarges

0 notes

Text

sascscscscscscscsacsacsacsacsacsa

0 notes