#“DTH drill bits”

Text

The Impact of DTH Drill Bits in Mining and Construction

Introduction:

When it comes to drilling in mining and construction, getting the job done efficiently is the name of the game. That's where Down-the-Hole (DTH) drill bits come into play, offering a game-changing solution for drilling through tough materials with precision and speed. Let's take a closer look at how DTH drill bits are revolutionizing the industry.

Understanding the Technology:

AG-DRILLs DTH drill bits are like the rock stars of the drilling world, working alongside DTH hammers to penetrate rocks, soil, and more. Unlike traditional methods, where the hammer is at the end of the drill string, DTH drilling flips the script, placing the hammer behind the drill bit. This tweak in design packs a punch, delivering better energy transfer and faster, straighter drilling.

How They Work:

Picture this: compressed air or fluids pumped down the drill string actuate the piston inside the hammer, which then hammers away at the back of the drill bit. It's this constant percussion action that pulverizes rock formations, making way for efficient drilling, no matter how challenging the conditions.

Advantages That Matter:

DTH drill bits aren't just another tool in the box; they're the MVPs of drilling operations. Their versatility shines through in various formations, from hard rocks to soft soils, ensuring consistent performance across the board. Plus, they're not picky about angles or depths, making them a go-to choice for everything from mining to construction projects.

Speed and Precision:

Speed demons, rejoice! DTH drill bits boast impressive penetration rates, meaning projects get done quicker and with fewer headaches. And let's talk precision – maintaining hole straightness is a breeze with DTH drilling, perfect for those projects where accuracy is non-negotiable.

Built to Last:

When it comes to durability, DTH drill bits are in it for the long haul. Crafted from top-notch materials like tungsten carbide and hardened steel, these bad boys can take a beating and keep on drilling. That means fewer replacements, less downtime, and more money saved in the long run.

Environmental Friendliness:

But it's not all about performance – DTH drill bits also have a softer side. Their efficient drilling process means less disruption to the environment, making cleanup a breeze once the project's done. Plus, they're quieter and produce fewer vibrations, making them a neighbor-friendly option for urban drilling projects.

In Conclusion:

In a world where time is money, DTH drill bits are the ultimate investment. Their unmatched efficiency, precision, and durability make them a staple in mining, construction, and beyond. As technology continues to advance, expect DTH drilling to lead the charge, driving progress and productivity in drilling operations worldwide.

Resource : https://penzu.com/p/de3d28645f906121

0 notes

Text

Our hot insertion technology for R32 button bits, steel material 45CrNiMoV, tungsten carbide buttons grade YK05 or T6.

WhatsApp: +8615965516086

E-mail: [email protected]

Skype: rockdrillingtool

#dth drill#dth bits#button bits#threaded button bits#dth button bits#retrac button bit#rock bits#drill bits#r32 button bits

2 notes

·

View notes

Text

http://www.kgrindustries.co.in/button-bits/button-bits-manufacturers.php

KGR Industries Button Bits Manufacturers are pioneers in business captivated as suppliers and exporters of Button Bits in India. We make utilization of just the best quality materials really taking shape of these Button Bits that gives us a chance to offer our customers with an immaculate extent of high performing Button Bits. Throughout the assembling methodology of the Button Bits, the amalgam steel experiences the radio realistic and ultrasonic tests after which the items are high temperature treated in the most exceptional and most recent techniques.

0 notes

Text

What Is DTH Drilling

DTH drilling, also known as Down-The-Hole drilling, is a technique used in mining, construction, and exploration projects to drill holes in hard rock formations. It is a percussion drilling method that utilizes a pneumatic or hydraulic hammer, often referred to as a DTH hammer, to deliver powerful blows to the drill bit.

Here's how the DTH drilling process typically works:

Rig Setup: A drilling rig is set up at the desired location. The rig consists of a drill string, which includes drill pipes, a DTH hammer, and a drill bit. The rig is positioned vertically or at a suitable angle for the drilling operation.

Hammer Assembly: The DTH hammer is connected to the bottom end of the drill string. The hammer contains a piston that strikes the back of the drill bit, transmitting energy to the bit for breaking the rock.

Air or Fluid Supply: Compressed air or drilling fluid (usually water-based) is pumped down the drill string to the hammer. The air or fluid serves multiple purposes, including removing drill cuttings from the hole and providing the necessary force to operate the hammer.

Drilling Operation: When the air or fluid reaches the DTH hammer, it enters the hammer's internal chamber and applies pressure to the piston. The piston reciprocates rapidly, delivering powerful blows to the drill bit. The impact energy fractures the rock, while the cuttings are carried to the surface through the annular space between the drill string and the hole wall.

Hole Advancement: As the drilling progresses, the rig applies downward force to the drill string, allowing the bit to penetrate deeper. The process continues until the desired depth is reached.

DTH drilling offers several advantages, including high drilling efficiency, accurate hole straightness, and the ability to drill in various rock types. It is commonly used in applications such as mining exploration, quarrying, foundation drilling, water well drilling, and geotechnical investigations.

Visit : rotary cum dth drilling rig india to knowmore

4 notes

·

View notes

Text

DTH Drilling Solutions and Types of Down-the-Hole Drills

Down-the-hole (DTH) drilling solutions have emerged as a game-changer in modern drilling technologies, revolutionizing how various industries extract valuable resources from the Earth. These ingenious tools are designed to provide efficient and cost-effective dth drilling solutions across diverse applications. This blog post will explore the different types of DTH drills and how they cater to specific drilling needs.

Conventional DTH Drills:

Conventional Down the hole drills are the foundation of down-the-hole drilling technology. They consist of a hammer and bit assembly, where the hammer delivers powerful percussive forces to the bit while air circulates to clear debris from the hole. These drills are known for their simplicity, ruggedness, and ability to penetrate various rock formations. They find mining, quarrying, construction, and water well drilling applications.

Reverse Circulation (RC) DTH Drills:

RC DTH drills address the challenges of collecting accurate geological samples while drilling. They incorporate a dual-wall drill string that enables the collection of rock cuttings through a separate inner tube, preventing contamination. This design facilitates better analysis of subsurface formations and is widely used in mineral exploration and geotechnical investigations.

Oilfield DTH Drills:

In the oil and gas industry, DTH drilling solutions have been adapted to suit the specific demands of offshore and onshore exploration. Oilfield DTH drills are engineered to withstand harsh environments, high pressures, and challenging drilling conditions. These drills are crucial in wellbore construction, geothermal drilling, and other energy-related applications.

Symmetric and Eccentric DTH Drills:

Symmetric and eccentric DTH drills are specialized variations of conventional DTH drills. Symmetric designs ensure balanced wear on the bit's face, providing uniform drilling performance. On the other hand, eccentric designs intentionally create uneven bit wear, leading to faster penetration rates in certain rock formations. The choice between these two designs depends on the specific geological characteristics of the drilling site.

High-Frequency DTH Drills:

High-frequency DTH drills utilize advanced technology to deliver rapid and efficient drilling. By increasing the impact frequency, these drills can achieve faster penetration rates while maintaining bit longevity. High-frequency DTH drills are commonly used in large-scale mining operations where productivity is a top priority.

Auger DTH Drills:

Auger Down the Hole drills combine the principles of DTH drilling with auger systems. They are ideal for drilling in loose or unconsolidated soil conditions, such as sandy or clayey terrains. The auger attachment aids in removing drilled material, while the DTH hammer provides the necessary impact force. Auger DTH drills are frequently employed in environmental and geotechnical drilling.

Compact DTH Drills:

In scenarios where limited space is a challenge, compact DTH drills come to the rescue. These drills are designed to be highly maneuverable and can access tight spaces without compromising drilling efficiency. Their versatility makes them suitable for urban construction projects, infrastructure development, and tunneling operations.

Innovation in DTH drilling solutions is a testament to human ingenuity and the constant quest

for improvement. As industries evolve and new challenges arise, engineers and manufacturers will likely develop even more specialized DTH drill types to address these demands. These might include drills optimized for deep-sea exploration, drills that integrate real-time data analytics for on-the-fly adjustments, and eco-friendly drills with reduced environmental impact.

The journey of the Down the Hole drill is far from over, and the ongoing pursuit of enhanced performance, efficiency, and sustainability promises an exciting future for the field and the industries it serves.

Conclusion

The world of down-the-hole drilling solutions is diverse and dynamic, with various DTH drill types catering to specific drilling needs across industries. From conventional drills that power through rock formations to specialized designs for accurate sample collection and oilfield exploration, the evolution of DTH technology has transformed how we tap into the Earth's resources. As technology advances, we expect further innovations in DTH drilling solutions, contributing to more efficient and sustainable resource extraction processes.

3 notes

·

View notes

Text

DTH Button Bits Manufacturing

In the dynamic world of drilling and excavation, the role of high-quality equipment cannot be overstated. Among the essential tools in this sector are DTH (Down-The-Hole) button bits, which are critical for efficient and precise drilling in challenging environments. KGR Industries has distinguished itself as a leading manufacturer in this niche, setting benchmarks for performance, durability, and technological innovation.

A Legacy of Excellence

KGR Industries has built a robust reputation over the years, driven by a commitment to quality and cutting-edge technology. Their DTH button bits are crafted using advanced manufacturing techniques and the highest quality materials, ensuring superior performance in various drilling conditions. These bits are designed to handle the rigorous demands of mining, construction, and geological exploration, where reliability and efficiency are paramount.

Superior Engineering and Design

What sets KGR Industries apart in the competitive landscape of DTH button bits manufacturing is their focus on precision engineering. Each button bit is meticulously designed to offer exceptional drilling efficiency, characterized by optimal penetration rates and minimal wear. The company's dedication to research and development allows them to incorporate the latest technological advancements into their products, enhancing their performance and longevity.

Quality Control and Innovation

KGR Industries’ commitment to quality is reflected in their stringent quality control processes. Every DTH button bit undergoes rigorous testing to ensure it meets the highest industry standards before it reaches the market. This attention to detail not only guarantees reliability but also reduces downtime and operational costs for their clients. Innovation is at the heart of KGR Industries’ approach, with continuous improvements and adaptations to meet the evolving needs of the drilling industry.

Customer-Centric Approach

Understanding the diverse needs of their clientele, KGR Industries offers a range of DTH button bits tailored to various drilling applications. Their customer-centric approach includes providing technical support and expertise to help clients select the most suitable products for their specific requirements. This personalized service, combined with their high-quality offerings, has earned KGR Industries a loyal customer base and a solid reputation in the industry.

A Trusted Partner

In the competitive field of DTH button bits manufacturing, KGR Industries stands out as a trusted partner for professionals seeking reliable and high-performance drilling solutions. Their dedication to excellence, coupled with their focus on innovation and customer satisfaction, positions them as a leader in the industry. For those looking to enhance their drilling operations with top-tier equipment, KGR Industries remains a premier choice, reflecting their unwavering commitment to quality and performance.

0 notes

Link

DTH Drilling tools | DTH Bits High Quality, Competitive Price, Problems Solve Ability, Fast Delivery Time。

0 notes

Text

Button Bits Suppliers In Hyderabad

Step into a world of exciting possibilities with the most trusted and performance-driven button bits supplier in Hyderabad. Founded by a team of highly accomplished industry professionals in 1992, we are backed by a rich history of innovation, engineering excellence, and top-notch customer satisfaction. We take great pride in being a global leader when it comes to providing solid drilling solutions for a wide range of requirements for our clients. Our portfolio of high-performance drilling equipment includes tractor-mounted rigs, blast hole drilling rigs, core drilling rigs, friction welded drill pipe, DTH hammers button bits, etc.

Our mission as a leading button bits supplier in Hyderabad is simple and profound; empower our partners with unmatched drilling capabilities that will enhance performance, safety, and sustainability. We invest heavily in R&D projects to develop new technology and reinvent the drilling industry. We also ensure that our production line follows the most rigorous quality control measures starting from selection of materials, to design, development, and production. We conform to ISO 9001:2008 quality regulations coupled with requirements based on clients’ specifications. Our pride and glory is the massive 20,000 sq. mtr. production facility where the magic takes place while helping redefine the drilling sector with every effort.

0 notes

Text

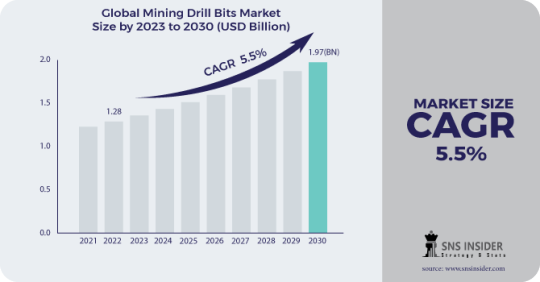

Understanding the Scope: Mining Drill Bits Market Analysis and Forecast for 2031

Global Mining Drill Bitsmarket research provides a comprehensive overview of fundamental data on market volume, industry growth potential, and business structure. All this contributes to the growth of the market. In addition, the study provides details on technology investments over the projected time horizon and a unique perspective on global demand in many of the categories studied. Mining Drill Bits market research helps clients better understand industry challenges and opportunities. Based on geography, global market research provides up-to-date information on consumer technology advances and growth potential.

Ask For Sample Report Here @ https://www.snsinsider.com/sample-request/1091

The study on global Mining Drill Bitsmarket provide in-depth analysis of future technologies, RDD projects, and new products. The study looks at all the major innovations and breakthroughs that are expected to have a significant impact on global market growth in the coming years. Likewise, the studies look at all sectors in different geographic areas and provide a cross-sectional analysis of the global economy in terms of demand forecasts. It also describes the many variables, constraints and opportunities in the market that will almost certainly impact business growth over the next few years.

Segmentation View

BY TYPE

Rotary bits

Fixed cutter bits

Roller cones bits

DTH Hammer bits

Others

BY MATERIAL

PDC Diamond

Tungsten carbide

Steel

Others

BY SIZE

Below 8 inches

8 to11 inches

Above 11 inches

BY APPLICATION

Surface mining

Underground Mining

By Company

The major key players are Rockmore International, Western Drilling Tools Inc, CATTERPILLAR INC., Robit Plc,Epiroc AB, Sandvik AB, Brunner & Lay Inc., Xiamen Prodrill Equipment Co. Ltd., Mitsubishi Materials Corporation, MICON-Drilling GmbH, Boart Longyear, DATC Group, Changsha Heijingang Industrial Co., Ltd.

The segmentation analysis section of the Mining Drill Bits market research focuses on past and future industry dynamics, business development, and challenges faced by the global vendors and consumers. Based on a comprehensive model of primary research and distribution, this article explores global markets at the national and regional levels, focusing on the major global suppliers. Mining Drill Bits market research and regional retail and distribution assessments using state-of-the-art methods.

Competitive Scenario

The report provides detailed industry competitive research and an overview of Porter's Five Forces model to help clients understand the competitive environment of leading global vendors in the Mining Drill Bitsmarket. This lengthy publication also provides a comprehensive review and summary of each research chapter. In order to provide viewers of this survey with an accurate picture of the global Mining Drill Bits industry, this report provided a highly competitive environment and product offerings from major vendors spread across multiple locations. The survey includes the latest analysis of the market forecast for the forecast period.

The Mining Drill Bitsresearch report explores four levels of detail, including market share analysis of major companies, business analysis (industry trends), supply chain analysis, and brief industry profiles. The study also provides an overview of the business environment, high growth markets, and high growth countries, differences in relevant industry, business factors and constraints.

Buy This Report Here @ https://www.snsinsider.com/checkout/1091

Report Conclusion

The report will help market participants to revisit their strategies and make necessary changes to stay in firm position in the competitive market.

0 notes

Text

Exploring Rama Mining Tools: Innovations in Mining Equipment

Rama Mining Tools stands at the forefront as a premier manufacturer, exporter, and wholesale supplier of mining tools, catering to the dynamic needs of the mining industry worldwide. Let’s dive into the diverse range of mining equipment offered by Rama Mining Tools.

Mining Tools Overview

Rama Mining Tools provides an extensive selection of mining tools meticulously crafted to enhance efficiency, safety, and productivity in mining operations. These tools include:

Sinker Drill

The sinker drill, a cornerstone in mining operations, is adept at drilling holes for explosive charges, facilitating efficient rock fragmentation and excavation.

Jackleg / Pusherleg Drill

This versatile drill, designed for underground mining, offers maneuverability and precision, making it ideal for tunneling and shaft sinking applications.

Stoper Drill

The stoper drill is engineered for stoping operations, enabling miners to extract ore from underground deposits with precision and efficiency.

Pneumatic Drifter

The pneumatic drifter delivers high-impact energy to the drill bit, enabling rapid drilling in hard rock formations, enhancing drilling performance in challenging geological conditions.

Simba Junior

The Simba Junior, a compact and agile drilling rig, is designed for small-scale mining operations, offering versatility and maneuverability in confined spaces.

DTH Hammer

The Down-the-Hole (DTH) hammer is employed for drilling blast holes in hard rock formations, delivering high penetration rates and efficiency in mining and quarrying applications.

Wagon Drill

The wagon drill, mounted on a movable carriage, offers flexibility and mobility in drilling operations, catering to both surface and underground mining requirements.

Jackleg / Pusherleg

Rama Mining Tools provides jackleg and pusherleg options, essential tools for supporting and stabilizing drilling operations in underground mines.

Loaders

Rama Mining Tools offers a range of loaders tailored to meet the loading and hauling needs of mining operations, enhancing productivity and efficiency in material handling tasks.

Wire Saw Machine

The wire saw machine utilizes diamond wire technology to cut through hard rock formations, providing precision cutting solutions for mining and quarrying applications.

Slim Drill

The slim drill, with its compact design, is ideal for narrow vein mining, offering maneuverability and precision in accessing ore deposits in confined spaces.

Crawler Drill

The crawler drill, equipped with tracks for mobility, is suitable for rugged terrains and challenging environments, ensuring uninterrupted drilling operations in remote mining sites.

Importance of Quality Mining Tools

In the mining industry, the quality and reliability of tools are paramount to operational success and safety. Investing in high-quality mining tools ensures optimal performance, durability, and safety standards, ultimately driving productivity and profitability in mining operations.

Rama Mining Tools' Commitment to Excellence

Rama Mining Tools is dedicated to delivering innovative and reliable mining tools that meet the highest industry standards. With a focus on technological advancement and customer satisfaction, Rama Mining Tools continues to redefine excellence in the mining equipment sector.

Conclusion

In conclusion, Rama Mining Tools emerges as a trusted partner for mining professionals, offering a diverse portfolio of high-quality tools engineered for optimal performance and reliability. With a relentless commitment to innovation and customer-centric approach, Rama Mining Tools remains at the forefront of the mining equipment industry, driving progress and efficiency in mining operations worldwide.

0 notes

Text

Drilling Deeper: AG-DRILL's Expertise in DTH Drill Bits

In the realm of drilling technology, Direct-to-Hole (DTH) drill bits stand as a pinnacle of innovation and efficiency. These cutting-edge tools have revolutionized various industries, from mining and quarrying to construction and well drilling. At the forefront of this evolution stands AG-DRILL, a professional manufacturer and supplier of superior rock drilling tools. Let's delve into the world of DTH drill bits and discover how AG-DRILL is shaping the landscape of drilling technology

0 notes

Text

GT60 3660mm 4265mm MF Rods

#dth drill#dth bits#button bits#threaded button bits#dth button bits#gt60#gt60 button bits#GT60 DRILL RODS

2 notes

·

View notes

Text

ATR Drills: Pioneering Excellence in Drilling Equipment Supply

Embark on a journey of innovation and reliability with ATR Drills, a trailblazer in the drilling equipment supply arena. Discover cutting-edge solutions, a comprehensive product lineup, and a customer-centric approach that sets ATR Drills apart. Join us in exploring the unparalleled world of drilling where excellence meets innovation.

In an age where precision reigns supreme, the need for trustworthy drilling equipment is more critical than ever. ATR Drills emerges as a beacon of excellence, redefining standards in the drilling equipment supply sector. Let’s delve into what distinguishes ATR Drills as a leader in this field.

Exploring ATR Drills Unique Advantages:

1. Technological Brilliance:

ATR Drills thrives on the latest drilling technologies, emphasizing innovation for enhanced performance. The integration of cutting-edge features ensures unmatched efficiency across diverse drilling applications.

2. Diverse Product Range:

From DTH Hammers to Drilling Fluid, ATR Drills offers an extensive product line. High-quality drilling fluid, rotary drill bits, and pipes make ATR Drills the go-to solution for a wide array of drilling needs.

3. Quality Spare Parts:

ATR Drills prioritizes uninterrupted operations by providing top-tier OEM spare parts, drill rig spare parts, and rock drill spare parts. The unwavering commitment to quality guarantees durability and minimal downtime.

4. Specialized Services:

Beyond equipment supply, ATR Drills offers specialized services like foundation drilling tools and geotechnical consumables, catering to the unique demands of various drilling projects.

Why ATR Drills Stands Out:

1. Industry Expertise:

ATR Drills’ wealth of experience positions it as an industry leader. Clients benefit from the team’s proficiency in understanding drilling challenges and delivering tailored solutions.

2. Customer-Centric Approach:

The ‘About Us’ page introduces the team behind ATR Drills, highlighting certifications and achievements. This transparency instills trust in clients, emphasizing ATR Drills’ commitment to customer satisfaction.

3. Validated by Case Studies:

Real-world success stories, presented as case studies, further validate ATR Drills’ capabilities. These testimonials showcase the positive impact of ATR Drills’ equipment in diverse drilling scenarios.

Conclusion:

ATR Drills is not just a supplier; it’s a trendsetter in the drilling equipment landscape. With a focus on innovation, a comprehensive product range, and unwavering customer dedication, ATR Drills charts the course for excellence in drilling equipment supply. Join us in exploring the future of drilling, where ATR Drills is not just meeting expectations but surpassing them. In the realm of drilling, ATR Drills stands tall — where excellence seamlessly merges with innovation!

#atr drill#mining and quarrying drill tools#top hammer rock drilling tools#drilling equipment supplier

0 notes

Text

Beaver Tracks: Premier Crawler Drill Exporter

When searching for the top Crawler Drill Exporter, look no further than Beaver Tracks

Beaver Tracks is distinguished by its extensive range of products, including Pole Erection Equipment, Water Well Drilling Rigs, DTH Hammers, Button Bits, Drill Rods, and more. Our drills and hammers are engineered to operate as a cohesive unit, ensuring optimal drilling performance. Our dedicated team comprises highly skilled engineers, service personnel, and technical experts, all of whom bring deep knowledge and expertise to deliver superior products.

Commitment to Quality

As a leading Crawler Drill Exporter, Beaver Tracks adheres to stringent quality standards. We are ISO 9001:2008 certified, reflecting our commitment to maintaining world-class manufacturing practices. Our state-of-the-art warehouse is meticulously organized, featuring distinct sections for easy access and safe storage of our products.

Why Choose Beaver Tracks?

Our dedication to delivering high-quality products has earned us a reputation for excellence. We proudly serve a diverse clientele, including notable organizations such as AED, the Central Ground Water Board, Groundwater Surveys, and various development agencies. Our focus on customer satisfaction drives us to provide cost-effective, reliable, and efficient solutions tailored to meet specific requirements.

Our team of highly skilled engineers collaborates closely with clients to customize products according to their needs, ensuring that we meet and exceed expectations. Beaver Tracks' unwavering commitment to excellence has solidified our position as the premier Crawler Drill Exporter.

FAQs about Crawler Drills

Which company is good for drill machines?

Beaver Tracks is renowned for its high-quality drill machines, offering a variety of options suited to mining, construction, and exploration needs.

What is a crawler drilling machine?

A crawler drilling machine is a type of heavy equipment designed for drilling tasks in various terrains. It features a crawler track system that provides stability and mobility, making it ideal for challenging environments.

0 notes

Text

Unlock the full potential of DTH Drilling with SVE Drilling's exceptional tools and technology. Our state-of-the-art DTH hammers and bits are designed for precision, ensuring accurate boreholes and minimized hole deviation. With a proven track record in the drilling industry, SVE Drilling delivers reliability and efficiency in every project. Our customer-centric approach means that our DTH Drilling solutions are tailored to your specific needs, providing unmatched performance and cost-effectiveness. Experience the future of drilling with SVE Drilling's cutting-edge DTH Drilling tools.

0 notes