#304 buttweld fittings supplier

Text

Building with Strength: Why SPP Metal and Alloys is Your Partner for 304 Buttweld Fittings in Mumbai

Mumbai, the heart of India's commercial panorama, flourishes on strong infrastructure and reliable additives. When it comes to developing steady piping structures, 304 buttweld fittings reign best. But navigating a sea of suppliers may be hard. Here's where SPP Metal and Alloys steps in, presenting fantastic 304 buttweld fittings in Mumbai.

What are 304 Buttweld Fittings?

304 buttweld fittings are everlasting pipe connectors used to create seamless connections in piping systems. Manufactured from grade 304 chrome steel, they offer a completely unique combo of power, corrosion resistance, and affordability. These fittings are permanently joined to pipes using a welding method, creating a sturdy and leak-proof connection.

Key Specifications of 304 Buttweld Fittings:

Material: Grade 304 stainless-steel (SS304)

Chemical Composition: Primarily chromium and nickel, presenting fantastic corrosion resistance.

Applications: Suitable for numerous industries, inclusive of:

Chemical processing

Food and beverage

Pharmaceuticals

Oil and Gas

Construction

Standards: Manufactured to fulfill enterprise requirements like ASTM A234, ASME B16.Nine

Why Choose SPP Metal and Alloys for Your 304 Buttweld Fittings?

When it comes to your assignment, choosing the proper dealer is paramount. Here's why SPP Metal and Alloys stands proud:

Unmatched Quality: SPP Metal and Alloys prioritizes fine. They source their 304 buttweld fittings from reputable producers and cling to stringent best control procedures. Mill test certificates are without difficulty to be had, ensuring the fittings meet exact requirements and fabric composition.

Diverse Product Range: They provide a complete choice of 304 buttweld fittings in numerous shapes, sizes, and schedules. This ensures you discover the appropriate fitting for any application, from elbows and tees to reducers and caps.

Technical Expertise: The group at SPP Metal and Alloys possesses in-intensity know-how of 304 buttweld fittings and their applications. They can offer precious advice on choosing the right fittings on your precise task requirements, optimizing your design and making sure device integrity.

Customer Focus: SPP Metal and Alloys understands the importance of notable customer service. They offer spark off prices, well timed deliveries, and responsive assist at some stage in the buying procedure. Their dedication to consumer satisfaction ensures a clean and a successful project.

Beyond the Basics: Value-Added Services

SPP Metal and Alloys is going the greater mile to help your undertaking needs:

Inventory Management: They preserve a properly-stocked stock to meet your orders promptly, minimizing venture delays.

Custom Solutions: For specific necessities, they are able to help in sourcing or even custom production fittings to meet your specific challenge needs.

Competitive Pricing: SPP Metal and Alloys offers competitive pricing on their 304 buttweld fittings, ensuring you get exceptional price for your funding.

Conclusion

Building a sturdy piping system in Mumbai requires dependable partners. By choosing SPP Metal and Alloys on your 304 buttweld fittings, you gain right of entry to super merchandise, technical know-how, and notable customer service. Their commitment to exceptional, various product variety, and value-introduced services make them the best companion in your task fulfillment. Remember, making an investment in wonderful 304 buttweld fittings supplier from SPP Metal and Alloys interprets to long-term sturdiness, protection, and fee-effectiveness for your piping system.

0 notes

Text

Long Stub End Buttweld Fitting Exporters in India

Nutech Overseas areFittings or ANSI B 16.9 Stub End, Stub End Buttweld Fittings close to you with most limited time transport or free instance of Stub End Racket 2642. Call us or mail to [email protected] for Most recent and Refreshed regard Rundown of Stub End Buttweld Fittings and EN 1092-1 Stub End.

Nutech Overseas is most irrefutable Stub End manufacturers in India. We keep up most recognizable store of Stainless Steel Stub End Pipe Fittings. We stock vastest degree of Carbon Steel Stub End Fittings, Stub End Buttweld Fittings in different sizes. We are standard trained professional and suppliers of ANSI B 16.9 Stub End, most very smart arrangement, cost as we are one of the most astonishing suppliers and vendor of Stub End EN 1092-1 Sort 36 in India. We are most huge Manufacturers of Stub End Noise 2642 mentioned by Saudi Aramco. We pass on Stub End Jis 10k, EN 1092-1 Stub End, Stub End 304 and Mss Type B Stub End at humble rate because of sensible virtuoso hours in India and amazing store of top notch Stub End Carbon Steel, most very smart arrangement, cost open in Mumbai, India.

Nutech Overseas are manufacturers of ASME B16.9 Stub End and deftly top notch Stainless Steel Stub End Pipe Fittings offer you the best costs keeping watch. The Stub End Stainless Steel are made in all Stub End Aspects. Our important Stub End Type A, Stub End Buttweld Fittings are endeavored and checked for strength, precision and exactness. ANSI B 16.9 Stub End are incredibly utilized in pipe works and are utilized in joint various kinds of Pipes & Tubes.

Stub End Fittings are mechanical joints that wires two districts: The Stub End, which in a general sense a short length of line, which has one end that is radiated outwards and the far edge made to be welded to line of near Ostensible Line Gauge (NPS), material and of an essentially hazy divider thickness. Laid out Steel Stub End slide direct over the line and are generally regularly used with stub end fittings. A line is normally welded to the Carbon Steel Stub End and the Lap Joint line rib is allowed to turn the stub end. The upside of lap joint stubend fittings is that there won't be any issues with paralyze opening plan.

For More Information:

Visit Our Website - https://nutechoverseas.com/long-stub-end-buttweld-fitting-manufacturers-exporters-suppliers-stockists.html

Call Us: +91-9769056671

E-mail: [email protected]

#Lap Joint Stub End Buttweld Fitting Manufacturers#Lap Joint Stub End Buttweld Fitting Suppliers#Lap Joint Stub End Buttweld Fitting Stockists

10 notes

·

View notes

Text

Supplier of MS Fittings in Rajasthan

Company Overview:

Rahul Steel India is an approved Manufacturer and Supplier of MS Fittings in Rajasthan, India.

MS Fittings, or Mild Steel Fittings, essentially consist of carbon steel fittings categorized into low, high, and mild carbon steel fittings.

Various fittings like MS Line Elbow can be manufactured using mild carbon steel materials.

MS Pipe Fittings are available in nominal sizes ranging from ½ inches to 12 inches.

Schedules for different fittings, such as MS Buttweld Tee, range from Sch10s to 80s, providing options based on specific requirements.

MS Fittings serve different functional purposes based on their design and specifications.

Product Specifications:

Supplier of premium-quality stainless steel investment casting fittings, manufactured under expert guidance.

Fittings undergo rigorous quality checks at all production stages to ensure high quality.

All investment casting fittings are pressure tested with air underwater to ensure superior quality.

Key products and regular stock items include stainless steel 202 IC fittings, 304 IC fittings, and 316 IC fittings.

Investment casting screwed or threaded fittings are available in various shapes like Elbow, Tee, Union, Cross, Coupling, Cap, Bushing, Plug, and Nipple.

Grades include AISI 202, 201, 304, 316, 304L, and 316L (CF8, CF8M).

Sizes range from 1/8 inch to 4 inches.

Standards comply with ASTM A-351 and ANSI B16.3, with threads to ANSI B2.1 specifications.

Thread types include NPT, BSPT, and BSP.

Pressure rating conforms to ANSI Class 150 standards.

Rahul Steel India is a Supplier of MS Fittings in Rajasthan Including Ajmer, Alwar, Anupgarh, Balotra, Banswara, Baran, Barmer, Beaware, Bharatpur, Bhilwara, Bikaner, Bundi, Chittorgarh, Churu, Dausa, Deeg, Dholpur, Didwalna-Kuchaman, Dudu, Dungarpur, Ganganagar, Gangapur City, Hanumangarh, Jaipur, Jaipur, Jaisalmer, Jalore, Jhalawa, Jhunjhunu, Jodhpur, Jodhpur, Karauli, Kekri, Kherthal-Tijara, Kota, Kotputli-Behror, Nagaur, Pali, Phalodi, Pratapgarh, Rajsamand, Salumbar, Sanchore, Sawai Madhopur, Shahpura, Sikar, Sirohi, Tonk, Udaipur.

For further inquiries or to discuss customization options, please feel free to contact us.

Read the full article

#Ajmer#Alwar#Anupgarh#Balotra#Banswara#Baran#Barmer#Beaware#Bharatpur#Bhilwara#Bikaner#Bundi#Chittorgarh#Churu#Dausa#Deeg#Dholpur#Didwalna-Kuchaman#Dudu#Dungarpur#Exporter#Ganganagar#GangapurCity#Hanumangarh#India#Jaipur#Jaisalmer#Jalore#Jhalawa#Jhunjhunu

0 notes

Text

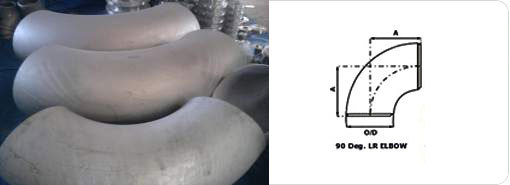

Elbow 90 Manufacturers

Elbow 90 Degree Buttweld Pipe Fittings, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers, Elbow 90 Degree Buttweld Pipe Fittings Suppliers, Elbow 90 Degree Buttweld Pipe Fittings Exporters, Elbow 90 Degree Buttweld Pipe Fittings Stockists.

Elbow 90 Degree Buttweld Pipe Fittings in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Suppliers in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Exporters in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Stockists in Mumbai.

Elbow 90 Degree Buttweld Pipe Fittings in India, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers in India, Elbow 90 Degree Buttweld Pipe Fittings Suppliers in India, Elbow 90 Degree Buttweld Pipe Fittings Exporters in India, Elbow 90 Degree Buttweld Pipe Fittings Stockists in India.

90° ELBOW

We have earned presumed name in making of Elbow (90°) which is developed with the best of the materials accessible in the business sector. Stainless steel, composite steel and carbon steel and so forth are utilized for manufacturing this elbow. We give these funnel fittings at business sector driving ratesSPECIFICATION

Size:

1/2"NB TO 48"NB IN

Schedule:

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Type:

Seamless

ERW

Welded

Fabricated.

Material Type:

Stainless Steel

Alloy Steel

Carbon Steel

Nickel Alloys

Duplex

Grades :

Nickel Alloy:

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Stainless Steel:

ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel :

ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760.

Alloy Steel :

ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91.

Carbon Steel:

ASTM / ASME A 234 WPB, WPC

ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

0 notes

Text

Stainless Steel Bars Manufacturer

Luvana Metal Corporation are Manufacturer, Exporter and Supplier of Stainless Steel Bars in Thane, Maharashtra.

We are an ISO 9001:2015-certified corporation headquartered in Ankleshwar and Pune, India.

We specialize in SS coils, sheets, plates, bars, rods, wires, valves, pipes, fittings, channels, angles, buttweld fittings, flanges, and fasteners.

Adhering to Indian and International standards like ASME, ASTM, ANSI, AISI, etc., we meticulously manufacture pipes and seamless tubes.

Our Stainless Steel Round Bars, solid cylindrical bars crafted from stainless steel, are a core focus of our offerings.

Regulated by PLC, our Stainless Steel Round Bars, made from stainless steel, meet production needs for medium and small enterprises.

We manufacture and supply custom-sized Stainless Steel Round Bars, catering to the unique industrial requirements of our customers.

These bars, renowned for robust corrosion resistance and weldability, excel in acidic settings, offering pitting corrosion resistance.

Our experienced team, employing advanced machining technology, manufactures our Stainless Steel Round Bars.

We conduct rigorous quality checks, inspecting each bar to ensure the highest standards, reflecting our commitment to customer satisfaction.

Specifications:

Dimensions: ASTM, ASME, API.

Thickness: 5 mm To 500 mm

Size: from 2.00mm to 6.35mm (0.078″ to 0.25″) dia.

Finish: Bright, Black, Polish

Form: SS Bars, SS Wires, S Rods

Condition: Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished

Other Services: Machining (CNC), Centreless Grinding (CG), Heat Treatment, Annealing, Pickling, Polish, Rolling, Forging, Cutting, Bending, Minor Fabrication

Stainless Steel Grades: AISI 202, 301, 302, 303, 304, 304L, 310, 316, 316L, 317, 321, 347, 410, 416, 420, 430, 431, F51, F53, F55, F44, UNS S21800, Alloy 20, 904L,

PH13-8Mo, 17-4ph, 15-5ph, 17-7ph, Ph15-7 Mo, 254Smo, Al-6Xn, 654SMO, duplex 2205, duplex 2507, nitronic ferralium 255.

Luvana Metal Corporation is Supplier of Stainless Steel Bars in Thane, Maharashtra serves diverse locations such as Ahmednagar, Akola, Amravati, Aurangabad,

Bhandara, Bhusawal, Buldhana, Chandrapur, Daulatabad, Dhule, Jalgaon, Kalyan, Karli, Kolhapur, Mahabaleshwar, Malegaon, Matheran, Mumbai, Nagpur, Nanded,

Nashik, Osmanabad, Pandharpur, Parbhani, Pune, Ratnagiri, Sangli, Satara, Sevagram, Solapur, Thane, Ulhasnagar, Vasai-Virar, Wardha, Yavatmal.

0 notes

Text

What are stainless steel 304 pipe fittings?

Stainless Steel 304 pipe fittings are components used to connect, control, and divert the flow of liquids or gases within a piping system. These fittings are specifically crafted from Stainless Steel 304 to harness its remarkable properties. As the leading Stainless Steel 304 Pipe Fittings Manufacturer, Supplier, Stockist, and Exporter globally, Bullion Pipes & Tubes LLP takes pride in offering a diverse range of top-notch stainless steel 304 pipe fittings to cater to the varied needs of industries worldwide.

In this blog post, we will delve into the characteristics, benefits, and common uses of stainless steel 304 pipe fittings.

Understanding Stainless Steel 304 Pipe Fittings:

Stainless Steel 304 is a grade of stainless steel that is composed of 18% chromium and 8% nickel, making it highly resistant to corrosion and oxidation. This particular grade is known for its excellent formability, weldability, and strength, making it a preferred material for a wide range of industrial and domestic applications.

Key Characteristics of Stainless Steel 304 Pipe Fittings:

Corrosion Resistance:

Stainless steel 304 pipe fittings exhibit remarkable resistance to corrosion, making them suitable for applications where exposure to harsh chemicals or corrosive elements is common. This feature ensures longevity and reliability in diverse industrial settings.

High-Temperature Strength:

The high-temperature strength of stainless steel 304 is a crucial factor in its suitability for pipe fittings. These fittings can withstand elevated temperatures, making them suitable for applications in industries such as petrochemicals, chemical processing, and oil and gas.

Versatility:

Stainless steel 304 pipe fittings offer versatility in design and functionality. They are available in various shapes and sizes, allowing for customization to meet specific project requirements. This versatility makes them adaptable to a wide range of applications in plumbing and industrial systems.

The Array of Stainless Steel 304 Pipe Fittings:

At Bullion Pipes & Tubes LLP, we go beyond the ordinary, presenting an extensive range of Stainless Steel 304 Pipe Fittings designed to meet the highest standards of quality and performance. Our offerings include:

SS 304 Buttweld Fittings:

Crafted with precision, our SS 304 Buttweld Fittings ensure a seamless and robust connection, enhancing the integrity of your piping system.

SS 304 Butt Weld Tee:

The SS 304 Butt Weld Tee offers a three-way connection, ensuring optimal flow distribution and structural stability in your piping network.

SS 304 Buttweld Cross:

Engineered for versatility, the SS 304 Buttweld Cross facilitates the convergence of multiple pipes with precision and reliability.

SS 304 Reducer:

Our SS 304 Reducer provides a seamless transition between pipes of different diameters, ensuring a smooth and efficient flow in your system.

SS 304 Stub End:

The SS 304 Stub End is designed to optimize the alignment of pipes, contributing to the overall efficiency and longevity of your piping infrastructure.

SS 304 Pipe Bend:

Offering flexibility in design, our SS 304 Pipe Bend ensures that your piping system can navigate corners and obstacles seamlessly.

Stainless Steel 304 Pipe Fittings Specification

Standard

ASTM A403 / ASME SA403

Dimensions

ANSI B16.9, B16.25, B16.28, MSS-SP-43, MSS-SP-48, MSS-SP-59

Size

1/8" NB TO 48" NB

Type

Seamless / Welded(100% X-Ray Welded) / Fabricated

Schedule

SCH 5S, 10S, 10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160 & XXS

Bending Radius

R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Equivalent Grades of A403 Stainless Steel 304 Buttweld Fittings

STANDARD

WERKSTOFF NR.

UNS

JIS

BS

GOST

AFNOR

EN

SS 304

1.4301

S30400

SUS 304

304S31

08X18H10

Z7CN18-09

X5CrNi18-10

Stainless Steel 304 Pipe Fittings Chemical Properties

Grade

C

Mn

Si

P

S

Cr

Mo

Ni

N

SS 304

0.08 max

2 max

0.75 max

0.045 max

0.030 max

18 – 20

-

8-11

-

SS 304 Buttweld Pipe Fittings Mechanical Properties

Density

Melting Point

Tensile Strength

Yield Strength (0.2%Offset)

Elongation

8.0 g/cm3

1400 °C (2550 °F)

Psi – 75000 , MPa – 515

Psi – 30000 , MPa – 205

35 %

Benefits of Stainless Steel 304 Pipe Fittings:

Longevity and Durability:

Stainless steel 304 pipe fittings are known for their longevity and durability. Their resistance to corrosion and rust ensures a longer lifespan, reducing the need for frequent replacements and maintenance.

Hygienic Properties:

In industries where sanitation is paramount, such as the food and pharmaceutical sectors, stainless steel 304 pipe fittings are preferred for their hygienic properties. They are easy to clean and maintain, making them suitable for applications where cleanliness is a priority.

Cost-Effective:

While stainless steel 304 is a premium material, its long-term benefits, including durability and low maintenance costs, make it a cost-effective choice for pipe fittings.

Applications of Stainless Steel 304 Pipe Fittings

The versatility of Stainless Steel 304 pipe fittings makes them indispensable in various industries:

Chemical Processing Industry

Food and Beverage Industry

Oil and Gas Industry

Pharmaceutical Industry

Water Treatment Plants

Pulp and Paper Industry

Automotive Industry

Aerospace Industry

Construction and Architecture

Power Generation

Marine Industry

Renewable Energy

Textile Industry

Other Applications

Final Words!

The choice of Stainless Steel 304 Pipe Fittings is a critical decision in ensuring the success of your projects. At Bullion Pipes & Tubes LLP, we not only offer a diverse range but also stand out as a global leader in the industry. Our commitment to quality, competitive pricing, and customer satisfaction makes us your ideal partner. As a leading Stainless Steel 304 Pipe Fittings Exporter, we have established our presence across the globe. Our products are trusted and utilized in countries including India, Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, and Russia. This global recognition is a testament to the reliability and quality of our offerings.

0 notes

Text

Stainless Steel Buttweld Fittings to ASME B16.9 - Metal Forge India

Stainless Steel Buttweld Fittings to ASME B16.9

In the realm of piping systems, selecting the right fittings is crucial to ensure seamless operation and durability. At Metal Forge India, we take immense pride in being the premier manufacturer, supplier, stockist, and exporter of top-notch stainless steel buttweld fittings conforming to the ASME B16.9 Standard. Our commitment to excellence extends beyond stainless steel, encompassing a diverse range of materials and grades such as Alloy 20, SMO 254, UNS N06600, Hastelloy C276, Stainless Steel 904L, and Inconel 600 Buttweld Fittings. Our comprehensive selection caters to varied project needs, offering a perfect fit for every requirement.

This blog post sheds light on the significance of stainless steel buttweld fittings manufactured in accordance with the ASME B16.9 standard.

Understanding Stainless Steel Buttweld Fittings to ASME B16.9

Stainless steel buttweld fittings to ASME B16.9 are essential components in various industries. These fittings offer exceptional corrosion resistance and durability, making them ideal for demanding environments. Let's explore the key features of these fittings:

Precision Engineering: Stainless steel buttweld fittings are designed with precision to ensure a secure and leak-free connection between pipes. This engineering precision reduces the risk of leaks and enhances overall system integrity.

Diverse Applications: These fittings find application in industries such as oil and gas, petrochemical, chemical processing, and more. Their versatility makes them suitable for both high-pressure and high-temperature environments.

Material Options: The buttweld fittings are available in different grades, such as Stainless Steel 304, 316, 304L, 316L, 317, Alloy 20 Buttweld Fittings, SMO 254 Buttweld Fittings, UNS N06600 Buttweld Fittings, Hastelloy C276 Buttweld Fittings, Stainless Steel 904L Buttweld Fittings, and Inconel 600 Buttweld Fittings, each offering specific properties. This variety allows engineers to choose fittings that align with the requirements of their projects.

ASME B16.9 Compliance: ASME B16.9 is a standard that outlines the requirements for factory-made wrought buttwelding fittings. Stainless steel buttweld fittings that adhere to this standard ensure consistent dimensions and reliable performance.

The Advantages of Using Stainless Steel Buttweld Fittings

Stainless steel buttweld fittings offer numerous advantages, making them a preferred choice for many industries. Here's a look at some of their key benefits:

Corrosion Resistance: Stainless steel is known for its exceptional resistance to corrosion, rust, and oxidation. This property ensures the longevity of buttweld fittings, even in harsh environments.

Strength and Durability: Stainless steel possesses impressive mechanical properties, including high tensile strength and toughness. These qualities contribute to the overall durability and reliability of the fittings.

Hygienic Properties: In industries like food and beverage and pharmaceuticals, stainless steel's hygienic properties are crucial. The smooth surface of stainless steel buttweld fittings prevents the accumulation of contaminants and ensures the integrity of the fluid being transported.

Ease of Maintenance: Stainless steel fittings are relatively low-maintenance, requiring minimal upkeep to retain their appearance and functionality. This factor adds to their cost-effectiveness over the long term.

Standards & Specifications of Buttweld Pipe Fittings

Size

1/8” NB – 48” NB

Standards

ASME/ANSI and DIN

Schedules

5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS with NACE Certifications

Types

45 Degree elbow, 90 Degree elbow & 180 Degree elbow, Cross, Caps, Tee, Concentric Reducers, Eccentric and Stub End

Materials

Stainless Steel & Alloy 20 Steel, Monel, Inconel, Hastelloy, Duplex Steel, Super Duplex Steel, and 254 SMO

Forms

Seamless, Welded & Fabricated

Grades

Stainless Steel 304, 316, 304L, 316L, 317, Alloy 20 Buttweld Fittings, SMO 254 Buttweld Fittings, UNS N06600 Buttweld Fittings, Hastelloy C276 Buttweld Fittings, Stainless Steel 904L Buttweld Fittings, and Inconel 600 Buttweld Fittings

Selecting the Right Stainless Steel Buttweld Fittings

Choosing the appropriate stainless steel buttweld fittings for a project involves considering various factors. Let's explore the key considerations when selecting these fittings:

Fluid Compatibility: Different grades of stainless steel are suitable for different types of fluids. Understanding the fluid's corrosiveness and temperature will help in selecting the right grade of stainless steel.

Pressure and Temperature: Stainless steel buttweld fittings are designed to withstand specific pressure and temperature ranges. Ensuring that the fittings can operate safely within the intended conditions is crucial.

Size and Configuration: The size and configuration of fittings play a significant role in their compatibility with existing piping systems. Accurate measurements and fittings that match the piping system are essential.

Quality and Compliance

Opting for stainless steel buttweld fittings from reputable Stainless Steel Buttweld Fittings manufacturers like Metal Forge India ensures quality and compliance. Look for certifications such as Material Test Certificates (MTC) in accordance with EN 10204 3.1 and EN 10204 3.2, along with Test Certificates certifying NACE MR0103 and NACE MR0175. These certifications guarantee traceability and adherence to industry standards.

Project Budget: While stainless steel buttweld fittings offer numerous advantages, it's important to consider budget constraints. Balancing the benefits of stainless steel with project costs is key.

Installation and Maintenance of Stainless Steel Buttweld Fittings

Proper installation and maintenance practices are essential to ensure the optimal performance and longevity of stainless steel buttweld fittings. Here's a guide on installing and maintaining these fittings:

Preparation: Before installation, ensure that all components are clean and free from contaminants. Proper preparation prevents issues such as leaks and faulty connections.

Welding Techniques: Stainless steel buttweld fittings are typically welded to the pipes. Utilizing appropriate welding techniques, such as TIG or MIG welding, is crucial to maintaining the fittings' integrity.

Inspection and Testing: After installation, perform thorough inspections and pressure tests to identify any potential leaks or defects. Timely detection and rectification of issues are essential to prevent system failures.

Regular Maintenance: While stainless steel requires minimal maintenance, periodic inspections are still recommended. Check for signs of corrosion, wear, or damage, and replace fittings as needed.

The Future of Stainless Steel Buttweld Fittings in Industry

Stainless steel buttweld fittings continues to evolve in response to changing industry needs. Here's a glimpse into the future trends and innovations in this field:

Advancements in Materials: Ongoing research and development are leading to the creation of new stainless steel alloys with enhanced properties, opening up new possibilities for fittings in extreme conditions.

Digitization and Automation: Industry 4.0 trends are making their way into fitting manufacturing. Digitized processes and automation are improving precision and efficiency in production.

Sustainability: As environmental concerns grow, manufacturers are exploring ways to make stainless steel production and usage more sustainable, aligning with global green initiatives.

Final Words!

The stainless steel buttweld fittings offered by Metal Forge India meet ASME B16.9 standards and cater to a wide range of project needs. Furthermore, We do also export our ASME B16.9 Stainless steel buttweld fittings to various countries, including the United Arab Emirates, the USA, Germany, South Korea, Russia, Singapore, France, Thailand, Turkey, Vietnam, and Indonesia. Our worldwide delivery capabilities ensure that customers around the world can benefit from our high-quality products.

0 notes

Text

The fundamentals of metalworking.

All of the metal parts that we use have been created in some way. You can imagine how busy the firm is given the many processes required for manufacturing to provide custom shapes, sizes, and finishes.

0 notes

Text

The application is perfect in any situation

Today the stainless steel has reached high levels and grades that are very much used in various domestic as well as industrial applications. When it comes to stainless steel fittings, it should be of the highest quality and processed using the state-of-art technology in compliance with the international standards. Even the stainless steel 202 buttweld fittings are made considering the China Stainless Steel Austenitic Pipe applications and the strength needed for the application. There is a wide range of fittings and buttweld fittings that are customized according to the need of the clients. The requirements are different and so most of the manufacturers are ready to provide various specifications and features needed by the client. Buttweld fittings pipe fittings The buttweld fittings are designed to weld on site at the ends so that the pipes connect each other and thus the change of flow takes place.

The direction, the diameter, ending and branching out takes place due to the buttweld fittings. There are various types of butt weld fittings manufactured like the seamless butt weld pipe fittings. You can find advantages of butt weld fittings as well. They provide greater freedom in the designing of the layout and also use less space. They are more compact in the design and also come with greater strength and ability. The application is perfect in any situation and thus provides greater durability. The stainless steel 304 buttweld fittings too are popular in its application in various fields. One can find them at various dealers of buttweld pipe. Features Stainless steel buttweld fittings come in various grades and standards and that is why you see there are features that are different as well. Stainless steel is resistant to corrosion and is safe to use in water.

The durability is increased due to the high quality involvement of alloys. Thus, it is used in heavy industries and small scale industries on a large scale. Manufacturers The manufacturer of the pipe fittings meets certain specification during production. You also have to be certain about the supplier who is involved in the process. Exporters are also in need of only the best quality fittings that meet the international standards. The physical properties are checked along with the materials that are used during production and the pressure, corrosion ability, and abrasion. Besides, the temperature resistance is also noted for the particular application. This is due to the fact that its application varies and is necessary to reach the best performance that is also acceptable to the costs. The engineers are liable to take the responsibilities of the materials that go into buttweld fitting pipes. The designing and the production is looked by them so that the strength too is apt.

1 note

·

View note

Photo

Nufit Piping Solutions - Manufacturer, exporter & supplier of Stainless Steel Buttweld Pipe Fittings Seamless and Welded ASTM A403/ASME SA403 WP 304 304L 316 316L Elbow/Tee/Cross/Reducer/Cap/Stubend available according to dimension standards ASME B16.9 Above fitting is Stainless Steel Seamless Buttweld Elbow, ASTM A403 WP316L, 90 Deg, LR, R=1.5D, ASME B16.9 Size DN 50 x SCH 80 exported to our client in Dubai, UAE For more details, kindly visit us at https://fittingsmanufacturer.com For your requirement, mail us at [email protected] #ssfittings #stainlessteeelfittings #ss316Lfittings #ss316fittings #astma403fittings #asmesa403fittings #ss316l #stainlesssteel #elbow #90degelbow #45degelbow #lrbend #longbend #sselbow #buttweldfittings #seamleselbow #marinefittings #manufacturer #exporter #fittingsmanufacturer #fittingsexporter #astmfitting #asmefitting #nufit #nufitpipingsolutions #india #ınstagood #newpost (at Nufit Piping Solutions) https://www.instagram.com/p/Cjm0JppLwpG/?igshid=NGJjMDIxMWI=

#ssfittings#stainlessteeelfittings#ss316lfittings#ss316fittings#astma403fittings#asmesa403fittings#ss316l#stainlesssteel#elbow#90degelbow#45degelbow#lrbend#longbend#sselbow#buttweldfittings#seamleselbow#marinefittings#manufacturer#exporter#fittingsmanufacturer#fittingsexporter#astmfitting#asmefitting#nufit#nufitpipingsolutions#india#ınstagood#newpost

0 notes

Text

The Metals Factory

The Metals Factory is an ISO certified and PED approved professional and international manufacturer, supplier and exporter of stainless steel, aluminium, nickel alloys, carbon steel and alloy steel products. With a collective experience of over 30 years, we have emerged as one of the largest just in time exporter of steel and aluminum products. Our range of products includes steel plates, rods, bars, angle, channels, steel pipe and tube, forged flange and fittings, elbow, tee, reducer, stub end, gaskets, fasteners, valves etc. We are devoted to provide the best solutions for steel materials and industrial equipment for our respected customers. We have manufacturing set up, sales and export offices in both India and China to meet the immediate and long term steel and aluminium product requirements across the globe.

Our stainless steel pipe and carbon steel pipe products are designed and manufactured in compliance with international standards and are appreciated for their sturdiness, precise dimensions, durability, finish and corrosion resistance. They are available in distinguished sizes, dimensions and thicknesses to cover the requirements of various industries like power plants, automobile, heavy engineering, offshore and chemical.

In addition to being a manufacturer of seamless pipes and welded steel pipes, we are also one of the biggest stainless steel plate and aluminum plate processing center in India. We are a leading stockholder, processor and supplier of high quality stainless steel plates, stainless steel sheets, stainless steel coils, stainless steel strips, alloy steel plates, special alloy plates, mild steel plates, mild steel coils, hot rolled coils, hot rolled plates, cold rolled coils.

We supply not only commonly used carbon steel and stainless steel materials (SS304/L, SS316/L, SS321), but also duplex and super duplex steel 1.4547, 1.4462, 1.4410 (S31254, S31803, S32750, S32760), and special austenite stainless steel such as 310S, 347H, 317L, 904L.

Some of our important & key products include the following:

1) Aluminium sheets, plates and coils in size range of 0.2mm to 350mm in Alloys 1050, 1060, 1070, 1080, 1100, 1200, 3003, 3105 and 8011. We are also one of the leading suppliers of 5052, 5083, 5086, 6061, 6082 and 7075 plate, and sheet products. Other products available in Aluminium alloys include bar and rods, seamless tubes, buttweld fittings, flanges and aluminium blocks for CNC machining.

2) Stainless steel sheets, plates and coils in size range of 0.2mm to 80mm in SS 304/L, SS316/L, SS321, duplex and super duplex steel, 310S, 347H, 317L, 904L. We offer stainless steel products in various forms including stainless steel pipes, stainless steel rods, stainless steel forgings, stainless steel large diameter pipes, stainless steel pipe fittings and flanges.

3) Carbon steel plates are available for sale in size range of 6mm to 200mm in custom widths and lengths, especially boiler quality plates, pressure vessel steel plates, abrasion resistant steel plates, and high tensile plates.

4) Stainless steel flexible hose pipes and bellows in sizes from 1/4” to 12” in custom lengths with various types of end connections such as flanges, female or male nuts, nipples, adaptors, camlock couplings, quick release couplings etc.

5) Carbon steel seamless pipes available in size range of 1/2’’~24’’NB, carbon steel ERW pipes available in sizes 1/2’’~40’’NB, while LSAW and Spiral welded steel pipes are available in size range of 18’’~72’’NB

6) Stainless steel pipes are available in various grades such as SS 304/L, SS316/L, SS321, duplex and super duplex steel, 310S, 347H, 317L, 904L, Stainless steel seamless pipes are available in size range of 1/2’’~24’’NB, while stainless steel ERW and Fabricated pipes are available in sizes 1/2’’~40’’NB.

Various piping system related pipes fittings, fasteners, gaskets and flanges are available in carbon steel, stainless steel, nickel alloys and alloy steel grades. We manufacture and supply buttweld pipe fittings, forged fittings and flanges in size ½” to 60”.

1 note

·

View note

Text

SSP Alloys, the top choice for butt-weld fittings in India, specializes in manufacturing

SSP Alloys: Leading Manufacturer of Butt-weld and Socket Weld Fittings, Specializing in 304 & 316 Weld Fittings. Trusted Supplier of Socket Weld Tube Fittings and Manufacturer of Welded Tubes SS409. We serving major cities like Mumbai, Delhi, Bangalore, Karnataka, Hyderabad, Andhra Pradesh, Pune, Faridabad, Aurangabad, Tamil Nadu, Ankleshwer, Punjab, and Chennai.

#304 buttweld fittings manufacturer#Buttweld 304 fittings stockiest#Buttweld Fitting 316 stockist#Welded Tubes SS409 Manufacturer#socket weld tube fittings supplier

0 notes

Text

C276 suppliers in India

C276 Round Suppliers in India

C276 Round Suppliers in India (by and large called Branch Connection Fittings or Outlet Fittings) which give an outlet from a more prominent funnel to a humbler one (or one of a near size).

C276 Round Suppliers in India are fanning fittings made by biggest producers of metal fittings like us. C276 Round Suppliers in India offer a substitute technique for interfacing into the essential run and don't require fortress or fortification. Krishna Steel & Alloys are pre-formed to the twist of the run pipe. Level based weldolets are open for interfacing with pipe tops and vessel heads.

The chief channel onto which the branch association is welded is generally called the Run or Header measure gauge. The funnel to which the branch alliance or affiliation gives a channel is known as the Branch or Outlet measure. Branch associations are in all sizes, sorts, types, bores, and classes, in an expansive arrangement of treated steel, chrome-molly, and particular amalgams mixes.

C276 Round Suppliers in India are for the most part used for stretching on high weight and high temperature applications. Most extreme acceptable weight of a fitting is same concerning associated straight steady or consistent run channel of proportionate material.

C276 Round Suppliers in India uses Materials and Grades (Weldolets, Threadolets, Sockolets)

1) Stainless Steel Olet Fittings - ASTM/ASME SA 182F GR. 304, 304L, 304H, 304N, 304LN, 316, 316L, 316H, 316N, 316LN, 309L, 310, 317, 317L, 321, 321H, 347, 347H AND UNS 31254 (254SMO)

2) Carbon Steel Olet Fittings - ASTM/ASME A105/A350 LF2, ASME SA105, A694 - F42, F46, F52, F60, F65, F70, A36, A516 GR. 70, 60

3) Alloy Steel Fittings - ASTM/ASME A182 GR. F1/F5/F9/F11/F22/F91

4) Duplex Steel Fittings - ASTM/ASME SA 182F GR. F44, F45, F51, F53, F55, F60, F61.WERKSTOFF NO. 1.4462

5) Nickel Alloy Steel FittFlangeings - ASTM/ASME SB 256 GR. NICKEL ALLOY 200, NICKEL ALLOY 20, MONEL ALLOY 400, INCONEL ALLOY 600, INCONEL ALLOY 625, INCOLOY ALLOY 800, INCOLOY ALLOY 800H, INCOLOY ALLOY 800HT, INCONEL ALLOY 825, ALLOY 20, HASTELLOY C-276, HASTELLOY C-4, HASTELLOY C-22, ALLOY 6XN

6) Low Temperature Pipe Fittings- A/SA 350 LF2, LF3

C276 Round Suppliers in India is Fittings are likewise accessible in other metal like titanium, aluminum, bronze, Lead, tantalum, zinc, metal and so on.

Application or Uses of Krishna steel & Alloys are are utilized in wide scope of businesses. Some of them are :

· Force Plants

· Water Pipelines

· Treatment facilities

· Nourishment and Beverages

· Pharmaceuticals

· Materials

· Railroads

· Petrochemicals

· Atomic Plants

· Sugar factories

Types of our Products:

1) Brazolet - Brazolet is utilized for the most part and for the most part to interface or partner the continued fittings. Brazolet is same like a weldolet, and is a marvelous fitting for metal channels, copper tubing and iron funnels pipes with metal.

2) Coupolet - Coupolet fittings are gotten ready for use in fire/fire assurance sprinkler structures and other low weight diverting applications.

3) Elbolet - Elbolet is utilized on 90° Long Radius Elbows (can be conveyed for Short Radius Elbows) for thermo well and instrumentation affiliations

4) Flexolet - Flexolets take after weldolets with a minor refinement for example flexolet has straight bore while weldolet has lessened bore.

5) Insert Weldolet - Insert Weldolet is the most extensively seen of all branch affiliations, and is welded onto the outlet pipe.

6) Latrolet - Latrolets are a variety of weldolets. You have to relate it in same manner, anyway these Latrolets make a 45-degree relationship with the standard channel as opposed to a 90 degree.

7) Nipolet - Nipolets is only a blend of olets with pipe areolas. These olets work like the weldolets or threadolets, yet are with areola.

8) Sockolet - Sockolets are in a general sense like weldolets and threadolets; close to the course that in Sockolets there is unique association fit welding.

9) Sweepolet - Sweepolet is a framed, essentially continued; butt-weld branch relationship with a low pressure elevating part for low loads and long consumption or depletion life.

10) Threadolet - Threadolets look like various olets; the essential contrast is that this olet is equipped with female strung affiliation.

11) Weldolet - Weldolets or welding olets or welding branch affiliation fittings are the most comprehended among all the olets. These are for the most used and organized as buttweld fittings, as these are welded into the branch pipe.

Assembling Standards

ASTM A182 - ASME SA182 - Standard Specification

ASME B16.11 - Forged Fittings Socket - Welding and Threaded

1 note

·

View note

Photo

Stainless Steel Erw Pipe Manufacturer India

https://www.coppernickelpipefittings.com/stainless-steel-erw-pipe-manufacturer-india.html

Manisha Steel Centre is one of the largest Stainless Steel Erw Pipe Manufacturer India and Stainless Steel 316 Erw Pipe Suppliers. We export Stainless Steel 304 Erw Pipe & tube, SS 304 pipe buttweld fittings used in extreme applications. Check Ss Erw Pipe and Erw Stainless Steel Pipe Price

For more details:

https://www.coppernickelpipefittings.com/

9819868540

Gala No.2, 162, T.P Street,(6th Kumbharwada), Cooper Compound, Mumbai-400 004.

1 note

·

View note

Video

Korus Steels | Sheets Plates & Coils | SS 304 HR Coil |

About Us

Korus Steels is one of the leading Stainless Steel Manufacturer, Supplier, Exporter, Dealer in India and many international cities. We deal in Buttweld Fittings, Forged Fittings, Fasteners, Bars, Sheets Plates & Coils, Shim Sheets, etc.

For more details:

Website: https://korussteels.com/

Product: https://korussteels.com/stainless-steel-304-hr-coil-manufacturer-india/

0 notes

Text

PIPE FITTING COLLAR

COLLAR PIPE FITTINGS TUBING, COLLAR PIPE FITTINGS EXPORTER, CARBON STEEL COLLAR PIPE FITTINGS, SS 310/310S COLLAR PIPE FITTINGS, STAINLESS STEEL 316/316S COLLAR FITTINGS, ANSI B16.9 BUTTWELD COLLAR FITTINGS, COLLAR PIPE FITTINGS WITH FERRULE FITTINGS SUPPLIER, COLLAR PIPE FITTINGS CONNECTOR, ASME B16.9 BUTT WELD COLLOR, COLLAR PIPE FITTINGS STOCKIST, ALLOY STEEL COLLAR PIPE FITTINGS EXPORTER, SS 304/304L COLLAR FITTINGS, SS 904L COLLAR FITTINGS, NICKEL ALLOY COLLAR PIPE FITTINGS, COLLAR PIPE FITTINGS INSTRUMENTATION PIPE FITTING,LEADING COLLAR PIPE FITTINGS MANUFACTURER, INCONEL 600/601/625 COLLAR FITTINGS, STAINLESS STEEL COLLAR PIPE FITTINGS STOCKIST, HASTELLOY C22/C276 COLLAR FITTINGS.

We have specialization to manufacture customized ANSI/ASME B16.9 Butt Weld Collar per customers’ specifications, we welcome small quantity order.

Mcneil Instruments Inc (India) is Manufacturer, Stockists & Supplier of premium quality range of ANSI/ASME B16.9 Butt Weld Collar, Stainless Steel Flanges & Other Stainless Steel Pipe fittings that are manufactured under the expert guidance of our diligent workforce. we are highly experienced company in ANSI/ASME B16.9 Butt Weld Collar & other pipe fittings. our ANSI/ASME B16.9 Butt Weld Collar & Other Fitting products are manufactured using quality material and go through a rigorous quality check at all stages of production to ensure quality. Designed in compliance with international quality standards, these ANSI/ASME B16.9 Butt Weld Collar are corrosion resistance, sturdy and durable. we also supply ANSI/ASME B16.9 Butt Weld Collar & other pipe fittings Flanges in customized size. Our Product Supply Division offers a broad portfolio of Steel Flanges and ANSI/ASME B16.9 Butt Weld Collar. When you place an order with Mcneil Instruments Inc (India), you will receive the products that will stand up in service from people that will stand behind their product.

Checkout Technical Specification & Material of Construction — http://www.mcneilinstruments.com/collar-pipe-fitting.html

Copyright 2021 Mcneil Instruments — http://www.mcneilinstruments.com/

#plumber#fitting#pipe#industrial#valve#valveman#valvesupplier#pipeline#elbw#tee#vessel#chemical#contractor#waterplant

0 notes