#316L Equal Tee

Text

Supplier of SS Butt Weld Pipe Fittings in Chhattisgarh

Company Overview:

We Rahul Steel India are a premier organization for the development of the stainless steel and metal industry.

Rahul Steel India is High quality Stockiest and Supplier of SS Butt Weld Pipe Fittings in Chhattisgarh, India.

Also known as seamless pipe fittings, ERW pipe fittings, buttweld ERW pipe fittings, and buttweld seamless pipe fittings.

Designed to be welded on-site at their ends to connect pipes together, allowing changes in direction or pipe diameter, branching, or ending.

Product Specifications:

Butt weld fittings are the simplest form of welded fittings, requiring no cutting, and allowing the material to be welded into any desired shape.

Types include 90 Degree Elbow (Long Radius/Short Radius), Equal Tee, 45 Degree Elbow (Long Radius/Short Radius), Reducing Tee, Round Cap, Concentric Reducer, Eccentric Reducer, and Stubend.

Offered in various grades of stainless steel (ASTM A403 WP304/304L/304H/316/316L/317/317L/321/310/347/904L) and carbon steel (ASTM A234 WPB/A420 WPL3/A420 WPL6/MSS-SP-75 WPHY 42/46/52/56/60/65/70).

Metals offered for making butt-weld pipe fittings include Monel, Nickel, Inconel, Hastalloy, Copper, Brass, Bronze, Titanium, Tantalum, Bismuth, Aluminium, High-Speed Steel, Zinc, and Lead.

Butt weld pipe fittings manufactured from alloys such as carbon or stainless steel offer many advantages compared to socket weld fittings.

Used for various industrial applications, these fittings are durable and possess high strength, ensuring long-lasting functioning.

Size: Available in sizes ranging from 1/8" NB to 48" NB (Seamless and Welded).

Applications:

Petrochemical and Chemical Processing

Oil and Gas Refining

Power Generation

Pharmaceutical and Biotechnology

Food and Beverage Processing

Water and Wastewater Treatment

HVAC (Heating, Ventilation, and Air Conditioning)

We Provide Supplier of SS Butt Weld Pipe Fittings in Chhattisgarh Including Raipur, Bhilai, Bilaspur, Korba, Durg, Rajnandgaon, Raigarh, Jagdalpur, Ambikapur, Kawardha, Mahasamund, Bhatapara. Dhamtari, Baloda Bazar, Balod, Mungeli, Pandariya, Takhatpur, Bhilai Charoda, Kumhari, Bemetara, Basna, Chirmiri, Dongargarh, Khairagarh, Pithora.

For additional information, please feel free to contact us.

Read the full article

#Ambikapur#Balod#BalodaBazar#Basna#Bemetara#Bhatapara.Dhamtari#Bhilai#BhilaiCharoda#Bilaspur#ButtWeldPipeFittings#Chhattisgarh#Chirmiri#Dongargarh#Durg#Exporter#India#Jagdalpur#Kawardha#Khairagarh#Korba#Kumhari#Mahasamund#Manufacturer#Mungeli#Pandariya#Pithora#Raigarh#Raipur#SSButtWeldPipeFittings#StockiestofofSSButtWeldPipeFittings

0 notes

Text

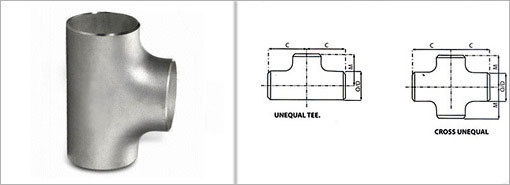

Unequal Tee and Unequal Cross Suppliers in India

UNEQUAL TEE & CROSS UNEQUAL

We offer Unequal Tees and Unequal Cross, which are generally favored by clients because of their precise elasticity, consumption and scraped area safe and astounding completion. These unequal tees fittings and unequal crosses fittings require immaterial support. Our scope of unequal tees are suitable for use in high, and in addition in low temperature. The unequal crosses discover application crosswise over differing commercial ventures, too, attributable to their consistence to industry characterized

principles.SPECIFICATION

Size:

1/2"NB TO 48"NB IN

Schedule:

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Form :

Equal Tee, Reducing Tee, Barred Tee , Lateral Tee.

Test Certificate :

Mill Test Certificate as per EN 10204 / 3.1B

Type:

Seamless

ERW

Welded

Fabricated.

Services:

Hot Dip Galvanizing

Epoxy Coating

Electro polish

Grades :

Nickel Alloy:

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Stainless Steel:

ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Carbon Steel:

ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel:

ASTM A420 WPL3 / A420WPL6.

Alloy Steel:

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 .

Duplex Steel:

ASTM A 815 UNS NO S 31803 , S 32205.

For More Information:

Visit Our Website: https://www.chhajedpipefittings.com/

Contact No: + 022- 2386 1894 / 2389 3666

Email I'd: [email protected]

#Unequal Tee and Unequal Cross in Mumbai#Unequal Tee and Unequal Cross Manufacturers in Mumbai#Unequal Tee and Unequal Cross Suppliers in Mumbai#Unequal Tee and Unequal Cross Exporters in Mumbai#Unequal Tee and Unequal Cross Stockists in Mumbai.

0 notes

Text

Types of Buttweld Fittings Explained

Buttweld fittings play a critical role in piping and plumbing systems. These fittings play a vital role in ensuring the seamless flow and structural integrity of your projects. As a frontrunner in the industry, Metal Forge India takes pride in being the premier Buttweld Fittings Manufacturer, Supplier, Stockist, and Exporter in India. Our diverse range of buttweld fittings, encompassing elbow 45, 90, & 180-Degree, Cross, Caps, Tee, Concentric, Eccentric Reducer, and Stub End, empowers our customers to cherry-pick fittings that impeccably align with their project prerequisites.

In this comprehensive guide, we'll delve into the various types of buttweld fittings available, each designed to suit different project requirements.

Understanding Buttweld Fittings

Before we dive into the specifics, let's understand the basics. Buttweld fittings are essential components that facilitate the connection of pipes, allowing for fluid flow and structural continuity. These fittings are meticulously designed to withstand varying pressures, temperatures, and corrosive environments. Their primary goal is to ensure a secure, leak-free, and efficient flow of liquids and gases within industrial setups.

Common Types of Buttweld Fittings

Elbows: Directing Flow with Precision:

Elbows are the workhorses of piping systems, responsible for changing the direction of flow at crucial junctures. Available in angles of 90°, 45°, and 180°, these fittings find applications in diverse industries, from oil and gas to chemical processing. A 90° elbow, for instance, efficiently redirects flow around tight corners, while a 45° elbow offers a gentler turn, ideal for nuanced applications.

Tees: Branching Out for Versatility:

When branching connections are needed, tees step in. Equal tees create three-way connections while reducing tees allows for different-sized pipes to merge seamlessly. Industries dealing with distribution and diversion, such as water treatment and pharmaceuticals, benefit greatly from the functionality of tees.

Reducers and Expanders: Adapting to Change:

Pipelines often need to transition between different diameters. Reducers and expanders are the solutions to this challenge. Concentric reducers maintain center alignment, ensuring a smooth transition, while eccentric reducers are perfect for applications where precise alignment isn't crucial, like drain lines.

Caps and Stub End: Sealing and Connecting:

Caps serve as protective covers for pipe ends, preventing debris and contaminants from entering. Stub ends, on the other hand, provide an alternative to welding when connecting pipes to flanges, offering versatility and ease of maintenance.

Crosses and Laterals: Navigating Complex Pathways:

For intricate systems involving intersecting or branching pipelines, crosses and laterals prove invaluable. Cross fittings create four-way connections, while laterals are perfect for splitting flow in multiple directions, making them essential in industries with intricate distribution needs.

Couplings and Olets: Ensuring Structural Integrity:

Couplings provide a straightforward way to connect pipes of the same diameter, often used in repairs or retrofitting. Olets, including weldolets and sockolets, offer a reliable means of creating branch connections without compromising the overall integrity of the system.

Standards & Specifications of Buttweld Pipe Fittings

Size

1/8” NB – 48” NB

Standards

ASME/ANSI and DIN

Schedules

5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS with NACE Certifications

Types

45 Degree elbow, 90 Degree elbow & 180 Degree elbow, Cross, Caps, Tee, Concentric Reducers, Eccentric and Stub End

Materials

Stainless Steel & Alloy 20 Steel, Monel, Inconel, Hastelloy, Duplex Steel, Super Duplex Steel, and 254 SMO Fittings

Forms

Seamless, Welded & Fabricated

Grades

Stainless Steel 304, 316, 304L, 316L, 317, Alloy 20 Buttweld Fittings, SMO 254 Buttweld Fittings, UNS N06600 Buttweld Fittings, Hastelloy C276 Buttweld Fittings, Stainless Steel 904L Buttweld Fittings, and Inconel 600 Buttweld Fittings

Applications of Buttweld Fittings

Buttweld Fittings are commonly used to connect pipes and tubing sections, providing a secure and leak-free connection. Here are some of the key applications of buttweld fittings:

Oil and Gas Industry

Chemical Processing

Power Generation

Water Treatment

Food and Beverage

Pharmaceuticals

Pulp and Paper Industry

Mining Industries

Construction and Infrastructure

Marine and Shipbuilding

Agriculture Industry

Automotive and Transportation

Aerospace:

Renewable Energy

Medical and Healthcare

Other Applications

Final Words!..

Selecting the ideal butt weld fittings is a pivotal stage in ensuring the accomplishment and dependability of your industrial piping system. At the forefront of the industry, Metal Forge India emerges as a reliable source for a diverse range of butt weld fittings. As a distinguished Buttweld fittings Supplier, Manufacturer, Stockist, and Exporter in India, we offer an extensive assortment including Alloy 20 Buttweld Fittings, SMO 254 Buttweld Fittings, UNS N06600 Buttweld Fittings, Hastelloy C276 Buttweld Fittings, Stainless Steel 904L Buttweld Fittings, and Inconel 600 Buttweld Fittings. Our product lineup encompasses elbow fittings, crosses, caps, tees, reducers, and stub ends, catering comprehensively to an array of project prerequisites. This guarantees peak performance, longevity, and meticulousness in every application. By opting for Metal Forge India, you're not simply acquiring a product; you're initiating a partnership with excellence in the realm of butt weld fittings.

0 notes

Text

All you need to know about Butt Weld Fittings

Butt weld fittings are essential components used in various industries to join and connect pipes or tubes seamlessly. These fittings play a crucial role in creating a robust and leak-free piping system. As a leading butt weld fittings manufacturer and supplier, stockist, and exporter in India. Bullion Pipes & Tubes LLP offers an extensive range to suit various project needs. Our fittings are available in different sizes, specifications, material grades, and types, ensuring you find the perfect fit for your specific application.

In this comprehensive guide, we will delve into all you need to know about butt weld fittings and how they cater to the needs of different applications.

What Are Butt Weld Fittings?

Butt weld fittings are designed to have smooth inner surfaces, ensuring minimal friction and pressure drop in the flow of fluids. This characteristic makes them ideal for applications where flow velocity and efficiency are critical factors. Additionally, the absence of crevices or threads in butt weld fittings prevents the accumulation of debris, reducing the chances of contamination and facilitating easy cleaning and maintenance.

Comprehensive Range of Butt Weld Fittings

We take pride in offering a comprehensive range of buttweld pipe fittings, including

Butt Weld Elbows: Available in 45-degree, 90-degree, and 180-degree angles, providing flexibility in directing the flow of fluids.

Butt Weld Crosses: Ideal for intersecting pipelines, ensuring smooth fluid flow in multiple directions.

Butt Weld Caps: Used to seal the end of a pipe, protecting it from contaminants and preventing leakage.

Butt Weld Tees: Available as equal and unequal tees, facilitating even or uneven flow distribution.

Butt Weld Reducers: Both concentric and eccentric reducers for smooth transitions between pipes of different diameters.

Butt Weld Stub Ends: Facilitating easy flange connections without welding.

Advantages of Butt Weld Fittings

Excellent Structural Integrity: Butt weld fittings create a continuous and strong joint that enhances the structural integrity of the entire piping system. This is especially important in applications where safety and reliability are paramount.

Smooth Inner Surface: The absence of internal disruptions such as threads or flanges ensures a smooth inner surface, minimizing turbulence and pressure loss during fluid flow.

Strong and Reliable Joints: The welding process used to join the pipes ensures a permanent and robust connection, reducing the risk of leaks or failures.

Suitable for High-Pressure and High-Temperature Applications: Butt weld fittings are capable of withstanding extreme pressures and temperatures, making them suitable for critical and demanding industries.

Disadvantages of Butt Weld Fittings

Skilled Labor for Welding: Proper welding requires skilled labor, which may increase the installation cost compared to other types of fittings that do not require welding.

Slightly More Expensive: Butt weld fittings can be slightly more expensive than other fittings due to the welding process and the need for precision manufacturing.

Materials & Grades we offer - Buttweld Fittings

Stainless Steel Buttweld Fittings

SS 904L

SS 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347, 446

Titanium Buttweld Fittings

Titanium Alloy Gr 2

Titanium Alloy Gr 5

Monel Buttweld Fittings

Monel K500

Monel 400

Carbon Steel Buttweld Fittings

Inconel Buttweld Fittings

Inconel 718

Inconel 600

Inconel 601

Inconel 625

Alloy Steel Buttweld Fittings

Alloy Steel P5

Alloy Steel P9

Alloy Steel P11

Alloy Steel P12

Alloy Steel P22

Alloy Steel P91

Aluminium Buttweld Fittings

Nickel Buttweld Fittings

Nickel Alloy 200/201

SMO 254 Buttweld Fittings

Duplex Steel Buttweld Fittings

Duplex UNS S32205

Duplex UNS S31803

Hastelloy Buttweld Fittings

Hastelloy C22, Hastelloy B2

Hastelloy C276

Super Duplex Steel Buttweld Fittings

Super Duplex Steel S32750

Super Duplex Steel S32760

Incoloy Buttweld Fittings

Incoloy 800/800H/800HT

Incoloy 825

Alloy 20 Buttweld Fittings

Applications of Buttweld Fittings

Buttweld fittings are a type of pipe fittings used to connect pipes or tubes with a butt welding process. They are widely used in various industries for a range of applications due to their structural integrity and reliability. Some of the common applications of buttweld fittings include:

Plumbing and Water Supply

Oil and Gas Industry

Chemical Processing

Petrochemical Industry

Power Generation

Pharmaceutical Industry

Food and Beverage Industry

HVAC Systems

Shipbuilding

Construction

Nuclear Power Plants

Other Application

How to Select the Right Butt Weld Fitting?

Choosing the right butt weld fitting is essential to achieve an efficient and reliable piping system. Consider the following factors during selection:

Project Requirements: Understand the specific needs of your project, such as fluid type, pressure, temperature, and flow rate.

Material Compatibility: Ensure that the material of the fitting is compatible with the material of the pipes to prevent corrosion and ensure longevity.

Fitting Dimensions: Select fittings with dimensions that match the pipe size to achieve a secure and leak-free joint.

Industry Standards and Codes: Adhere to industry-specific standards and codes to maintain the quality and safety of the piping system.

Installation and Welding Process of Buttweld Fittings

Proper installation and welding are critical to ensuring the effectiveness of buttweld pipe fittings. Follow these steps for a successful installation:

Preparation: Clean the pipe ends and fittings thoroughly to remove any dirt, grease, or debris that could affect the quality of the weld.

Alignment: Ensure precise alignment of the pipes and fittings before welding to create a strong and reliable connection.

Welding: Employ the appropriate welding method, such as TIG or MIG, to create a robust and leak-proof joint.

Inspection: Thoroughly inspect the welds for defects using non-destructive testing methods to ensure the integrity of the joints.

Leak Testing: Before putting the system into service, conduct a leak test to verify the integrity of the joints and prevent potential leaks.

Final Thoughts!..

Butt weld fittings are vital components in creating strong and reliable connections within piping systems. Bullion Pipes & Tubes LLP stands at the forefront as the leading butt weld fitting supplier, manufacturer, stockist, and exporter in India. With an extensive range of fittings and a commitment to quality, we cater to diverse industrial needs across India and various countries as well including Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, and Russia. Our buttweld pipe fittings offer exceptional strength, leak resistance, and versatility, making them the ideal choice for critical applications. When selecting the right fitting, consider the specific project requirements, material compatibility, and adherence to industry standards.

Choose Bullion Pipes & Tubes LLP for all your butt weld fitting needs, and experience excellence in quality and service. Contact us today to explore our vast range of fittings and find the perfect solution for your piping requirements.

0 notes

Text

Stainless Steel, Carbon Steel, Alloy Steel Socket Weld :- *Equal Tee*

Price :- 300/--Per Nos

Brand :-Ramco

Size : 1/8″~4″ (DN6~DN100)

Standards : ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Pressure Class : 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS

Type : Socket Weld

Specifications : ASTM A 182 / SA 182

Grades : F304/ 304L/ 304H/316/ 316L/ 317/ 317L/ 321/ 310/ 347/ 904L/ ETC.

Types : Elbow 90 Degree, Elbow 45 Degree, Tee, Cross, Union, Coupling, Half Coupling, Cap, Boss, Reducer, Outlet, Long Stub-end, Short Stub-end Welding Outlet, Insert etc.

Applications:- Pipeline Engineering

Oil, Gas, Pharma, Chemical and Petrochemical

Power Industries

Food Processing

www.ramcosteel.com

1 note

·

View note

Text

How You can Get Best Results with Steel Pipe Fittings?

Butt weld fittings made of stainless steel 304 offered by Seamless Steel Tube manufacturers in India are tiny fittings used for sealing tube ends. It is a phrase that refers to the procedure of butt welding fittings made of 304 stainless steel material in tubes/pipes to avoid leaks. These fittings of SS Seamless Pipe manufacturer in Indiaare relatively affordable and offer excellent resistance to air corrosion. According to industry demand, Hastelloy C276 Plate is made in a range of forms, sizes, grades, and standards.

Fittings of various types:

Though many companies create fittings to the needs of the industries to which they service, other small-scale firms prefer to develop some common fittings that are commonly utilised. The size of the same might range from 1" and 48". These are some important examples of frequent kinds:

45 degree elbow – widely used in the paper, brewing, agricultural, electronics, and food processing sectors.

90 degree elbow – widely used in the oil and gas pipeline, chemical plants, plumbing, and general purpose applications. You can contact with Stainless Steel ERW Pipe manufacturers in Indiafor more information.

Equal Tee - Used in power plants, breweries, and the sugar industry

Concentric reducer - Used in the plumbing and car industries

Inconel 600 Plate fittings are extremely dependable. Stainless Steel 304 has a greater chromium percentage and a lower carbon content. Welding produces less chromium carbide due to lower carbon levels. This steel of SS Square Pipe manufacturer in Indiahas as little as 0.03% carbon, making it less susceptible to intergranular corrosion. This steel can withstand prolonged exposure to temperatures of around 1500°F without deterioration.

Welding a fitting to a pipe with Stainless Steel Conduit Pipe Manufacturers in Indiamakes it permanently leak proof.

The regular metal structure shaped between the fitting and pipe of Duplex Pipe Manufacturers in India adds strength to the system.

A flat and smooth surface and progressive direction changes reduce pressure losses as well as turbulence and minimise the action of corrosion and erosion.

Flanges made of Hastelloy C276

Off-Shore Oil Drilling Companies

Power Generation

Petrochemicals

Gas Processing

Specialty Chemicals

Pharmaceuticals

Pharmaceutical Equipment

Chemical Equipment

Heat Exchangers

Equipment for Sea Water

Condensers

Pulp and Paper Industry

316L stainless steel

Monel 400 Tube Fittings Used in Chemical Procedures

Stainless Steel Pipes of SS Tube Manufacturers In IndiaUsed in the Medical Field

Stainless Steel Tube Fittings Used in Pharmaceutical Plants

Hastelloy C276 Tube Fittings Used in Food Processing Plants

Stainless Steel Pipe Fittings Used during Aviation Engine Components

Because austenitic stainless steel has a low permeability, it is also known as a nonmagnetic material. Steel with a stable sleeve structure, such as 0Cr20Ni10 or 0Cr25Ni20, won't be magnetic although if treated with a considerable quantity of end greater than 80%.

There are several additional applications for Monel 400 Pipe Fittings of Stainless steel heat exchanger manufacturer in Indiain various sectors. You can get suggestions from professional manufacturers and get best option for your industry.

0 notes

Link

ASME B16.9 ASTM A403 WP316L Equal Tee 3/8 Inch SCH80

FOB Price USD 1 - 1,900/Piece

Port Ningbo or Shanghai Port

MOQ 1 Piece

Supply Ability 1000 Pieces Per Day

Payment Terms L/C,T/T,Western Union,MoneyGram

Packaging Seaworthy plywood cases or pallets

Delivery 2 - 10 days

1

Detailed descriptionQuick Details

Material:316L

Technics:Forged

Type:Equal Tee

Place of Origin:Zhejiang, China (Mainland)

Model Number:Equal Tee

Brand Name:Yaang

Connection:Welding, Weld

Shape:Equal

Head Code:Round

Packaging & Delivery

Packaging Detail:Plywood case or fumigation woodern case

Delivery Detail:Usually 2-10 days depend on the quantity

Specifications

ASME B16.9 ASTM A403 WP316L Equal Tee 3/8 Inch SCH80

1) Size: 3/8" (DN10)

2) THK: SCH80

3) Material: 316L

ASME B16.9 ASTM A403 WP316L Equal Tee, like all pipe tees, is in the shape of T with two ends of equal size and the third one slightly smaller. In other words, 316 smls Equal tee is a type of pipe fitting in which the branch port size is smaller than the ports of the run. This type of pipe fitting can also consider size reduction from one of the run ports to the other.

China Equal Tee Manufacturer Yaang supplies ASME B16.9 ASTM A403 WP316L Equal Tee, 3/8 Inch, SCH80.

Composition ranges for 316L grade of stainless steels

Type

WP316L Equal Tee

Size

SMLS Tee: 1/2"~12" (DN15 - DN300)

Welded Tee: 1/2"~48" (DN15 - DN1200)

Wall thickness

sch10, sch20, sch30, std, sch40S, sch60,

xs, sch80, sch100, etc

Standards

ASME, ASTM, DIN, JIS, etc

Material

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Stainless Steel: ASTM A182 F304/304L/316/316L, etc

Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc.

Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc

Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800,

Hastelloy C276, Hastelloy C22, Hastelloy B1/B2/B3, Alloy 20, etc

Cu-Ni: 90/10,70/30, etc

Surface treatment

Transparent oil, rust-proof black oil or hot galvanized

Applications

Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc

ASME B16.9 ASTM A403 WP316L Equal Tee

1. They are manufactured to be used in flow lines for gases, fluids in industrial processes, medical, construction and many other specialized applications.

2. The 316L Equal Tee is constructed of heavy materials for rigid applications like extreme high/low temperature resistance etc.

3. The 316L Equal Tee is specifically designed for use on process and control systems, instrumentation, and equipment used in chemical, petroleum, fluid power, electronic and pulp and paper plants.

ASME B16.9 ASTM A403 WP316L Equal Tee's Packing & Shipping

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps , pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request .

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality ASME B16.9 ASTM A403 WP316L Equal Tee.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry about products, please feel free to contact us [email protected]

Related products:

More>>

Alloy 20 Eccentric Reducer

Staninless Steel Pipe Fittings Reducer

ASTM A420 WPL6 ELBOW 90DEG,SEAMLESS,BW,ASME B16.9

ASTM B16.11 A182 F53 GR2507 45 Degree SW Elbow DN50 CL3000

0 notes

Text

JSS PIPES AND FITTINGS TRADING LLC

JSS Pipes and Fittings Trading LLC is one of the largest stockist n UAE (United Arab Emirates) Headquartered in Dubai. They specialize in the following products:

Pipes Fittings such as

Elbow Pipe (90 degree elbow and 45 degree elbow),Pipe end caps ranging from ½” – 24”,Eccentric Reducer.Concentric Reducer,Equal Tee,Unequal Tee and Reducing Tee

Pipe Flanges such as Weldneck Flange,Slipon Flange,Socktweld Flange,Threaded Flange,Blind Flange

Forge Fittings such as ,Weldolet,Sockolet,Reducer Bushing,Hex Nipple,Sockolet,Threadolet,Union,SW Elbow, Threaded Elbow

Seamless pipe such as carbon steel pipe (cs pipe) , stainless steel pipe (ss pipe) in grades astm a53, api 5l , astm a106, asme b36 10, astm 312 316l, api 5l x52, astm a333

Carbon steel pipe is also known as black steel pipe. We also supply galvanized steel pipe. For more information visit www.jsspipes.com

1 note

·

View note

Text

General Explanation of Stainless Steel Pipe Fittings

Stainless steel pipe fittings belong to one kind of pipe fittings, it is made of stainless steel material so called stainless steel pipe fittings, it includes: stainless steel elbow, stainless steel tee, stainless steel tee, stainless steel four-way, stainless steel different diameter pipe, stainless steel pipe cap, according to the connection method can be divided into socket stainless steel pipe fittings, threaded stainless steel pipe fittings, Four types of steel pipe fittings and welded stainless steel pipe fittings. Stainless steel elbows are used where the fittings turn; flanges are used where the tubes and pipes are connected to each other, at the end of the pipe; stainless steel tee pipes are used where the three pipes converge; stainless steel tee pipes are used where the four pipes converge; and stainless steel pipes with different diameters are used where the two pipes are connected. Main stainless steel material: 304, 304L, 316, 316L

Current standards

GB/T10752–1995 marine pipe pair welding head

Flexible interface cast iron pipes and fittings for GB/T12772–1999 drainage

Hot oven test method for injection moulded rigid polyvinyl chloride (PVC-U), chlorinated polyvinyl chloride (PVC-C), acrylonitrile-butadiene-styrene terpolymer (ABS) and Acrylonitrile-Styrene-Acrylate terpolymer (ASA) threaded pipe fittings

GB/T 8802–2001 thermoplastic pipes and fittings VEKA determination of softening temperature

GB/T 18251–2000 determination of pigment or carbon black dispersion in polyolefin pipes, fittings and mixtures

Test method for crosslinking degree of GB/T 18474–2001 cross linked polyethylene (PE-X) pipes and fittings

Classification and nomenclature of materials for thermoplastic pressure pipes and fittings

GB/T 18742.3–2002 cold and hot water polypropylene piping system third parts: fittings

GB/T 18991–2003 thermoplastic pipes and fittings for cold and hot water systems

GB/T 18993.3–2003 chlorinated polyvinyl chloride (PVC-C) piping system for hot and cold water third parts: fittings

GB/T 18998.3–2003 industrial chlorinated polyvinyl chloride (PVC-C) piping system third parts: fittings

Rubber O type sealing ring for GB/T 19228.3–2003 stainless steel card fittings

General terms and definitions of GB/T 19278–2003 thermoplastic pipes, fittings and valves

GB/T 19473.3–2004 hot and hot water polybutene (PB) piping system third parts: fittings

Seamless butt welded pipe made of GB/T 12459–2005 steel

GB/T 19712–2005 plastic pipe and fittings polyethylene (PE) saddle bypass impact test method

GB 15558.2–2005 gas buried polyethylene (PE) piping system second parts: fittings

GB/T 13663.2–2005 water supply polyethylene (PE) piping system second parts: fittings

Extrusion stripping test of GB/T 19806–2005 plastic pipe and pipe PE electrical fusion module

Preparation of GB/T 19807–2005 plastic pipes and fittings, polyethylene pipes and electric fusion fittings

TENSILE PEELING TEST OF POLYETHYLENE ELECTROMELTED COMPONENTS WITH NORMAL EXTERNAL DIAMETERS OF PLASTIC PIPES AND FITTERS greater than or equal to 90 mm

Preparation of Hot Melt Butt Assembly for Plastic Pipe and Tube Fittings Polyethylene (PE) Pipe/Tube or Tube/Tube Fittings

Determination of tensile strength and failure mode of GB/T 19810–2005 polyethylene (PE) pipes and fittings welded joints

Butt welded pipe made of GB/T 13401–2005 steel plate

GB/T 19993–2005 hot water Thermoplastics piping system piping and fittings combination system thermal cycling test method

GB/T 5836.2–2006 rigid polyvinyl chloride (PVC-U) pipe fittings for building drainage

Test methods and technical requirements for susceptibility of polyethylene (PE) pipes for irrigation to environmental stress cracking caused by insertion fittings

GB/T 20201–2006 polyethylene (PE) pressure pipe mechanical connection pipe for irrigation

GB/T 20207.2–2006 acrylonitrile butadiene styrene (ABS) pressure piping system second parts: fittings

GB/T 20674.2–2006 plastic pipe and fittings polyethylene system welding equipment second parts: Electrofusion connection

GB/T 20674.1–2006 plastic pipe and fittings polyethylene system welding equipment first part: hot melt butt joint

Test method for falling of GB/T 8801–2007 rigid polyvinyl chloride (PVC-U) pipe fittings

Determination of the opacity of GB/T 21300–2007 plastic pipes and fittings

GB/T 21409–2008 general rules for inspection, installation and use of glass equipment, pipes and fittings

GB/T 21408–2008 Universality and interchangeability of 15mm-150mm diameter pipes and fittings for glass equipment, pipes and fittings

GB/T 14383–2008 forging socket welding and threaded fittings

GB/T 13295–2008 ductile iron pipes, fittings and accessories for water and gas pipelines

Graphical symbols for piping system in GB/T 6567.3–2008 technical drawings

GB/T 22051–2008 cross linked polyethylene (PE-X) pipe with sliding tight jacket cold expansion fittings

Graphic Symbols for Pipeline Systems — Axonometric Drawing of Pipelines, Fittings and Valves

GB/T 11618.1–2008 copper pipe joint first parts: brazed fittings

GB/T 12772–2008 drained flexible interface cast iron pipes, fittings and accessories

GB/T 3420–2008 grey cast iron malleable iron pipe fittings

GB/T 11618.2–2008 copper pipe joint second parts: card pressure fittings.

GB/T 23241–2009 basic parameters and technical requirements for plastic pipes and fittings for irrigation

Requirements, design and installation of GB/T 23682–2009 refrigeration system and heat pump hose fittings, isolation pipes and expansion joints

Chlorinated polyvinyl chloride (PVC-C) pipes and fittings for sewage discharge and waste water (high and low temperature) in buildings

GB/T 17457–2009 ductile iron pipe and fittings cement mortar lining

GB/T 24596–2009 polyurethane coating for ductile iron pipes and fittings

GB/T 24672–2009 thin wall pipe and fittings for sprinkler irrigation

GB/T 5135.19–2010 sprinkler system nineteenth parts: plastic pipes and fittings

GB/T 26002–2010 stainless steel corrugated hose and fittings for gas transportation

GB/T 26120–2010 low pressure stainless steel threaded fittings

GB/T 26081–2010 ductile iron pipes, fittings and accessories for sewage

0 notes

Text

SS Buttweld Fittings

Stockists, Suppliers, and Exporters of high integrity Buttweld Pipe Fittings, buy Steel Buttweld Pipe Fittings in all Dimensions

We are manufacturing Stainless Steel buttweld fittings in seamless or welded form, it proudly caters the needs of our customers in Oil & Gas, Power Generation, Petrochemical, and Industrial Construction, inclusive of Upstream, Midstream, and Downstream sectors. Our offered Buttweld Pipe Fittings is being developed and designed in accordance by means of the international quality of standards at our infrastructure facility for to attain the highest scales of quality. Buy comprehensive Variety of Butt weld fittings in Stainless Steel, Carbon Steel, Alloy Steel, Hastelloy, Monel, Inconel, Titaniun, Duplex Steel, Super Duplex Steel, Incoloy, Alloy 20, 254 SMO, Copper Nickel Materials.

WHAT IS A BUTTWELD PIPE FITTINGS

A buttweld pipe fittings is designed to be welded on site at its end(s) to connect pipe(s) together and allow change in direction or pipe diameter, or branching or ending.

This fitting then becomes part of a system for transporting fluids (oil, gas, steam, chemicals, …) in a safe and efficient manner, over short or long distances.

Buttweld Pipe Fittings are most commonly available in carbon steel, stainless steel, nickel alloy, aluminum and high yield material. High yield butt weld carbon steel pipe fittings are available in A234-WPB, A234-WPC, A420-WPL6, Y-52, Y-60, Y-65, Y-70. All WPL6 pipe fittings are annealed and are NACE MR0157 and NACE MR0103 compatible.

Buttweld Fittings Types:

• 2 Halve Fittings• Cap

• Customised Fittings• Dairy Fittings

• Elbow LR & SR• Mitered Bend

• Nipple Swage• Reducer Eccentric & Concentric

• Return Bends• Stubend Long & Short

• Tee Equal & Barred

Radical Steel & Alloys is counted as one of the privileged manufacturers, stockists, and exporters of an admirable range of buttweld Pipe Fittings. We offer the same in different forms such as Stainless Steel, Carbon Steel, Alloy Steel, Duplex Steel, Super Duplex Steel, and many more.

We are manufacturing buttweld fittings in seamless or welded form, it proudly caters the needs of our customers in Oil & Gas, Power Generation, Petrochemical, and Industrial Construction, inclusive of Upstream, Midstream, and Downstream sectors. Our offered Buttweld Pipe Fittings is being developed and designed in accordance by means of the international quality of standards at our infrastructure facility for to attain the highest scales of quality.

Specifications:Size : 1/8"NB TO 48"NB IN

Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Type : Seamless / ERW / Welded / Fabricated

Form : Elbow, Tee, Reducer, Cap, Stubend, Bends, Nipple etc. Long radius bends of 2.5 D / 3 D / 5D / 10 D /20D & 22 D for piglaunching steam & General purpose fittings. STAINLESS STEEL BUTT WELD FITTINGS: Range : 1/2"NB TO 48"NB IN SCH: 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75

Type

SEAMLESS / WELDED/ FABRICATED

Form

Elbows in Long & Short Radius in 45 deg, 90 Deg, 180 deg.

Equal, Unequal Tee & Barred Tee.

Eccentric Reducer & Concentric Reducer.

Caps & Crosses.

Long & Short Stub End.

Swage Nipple & Barrel Nipple.Standard : ASTM / ASME A/SA 403 GR WP "S" / "W" / " WX"

Grade : 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L

Value Added Services: Electro Polish

Test Certificate: Manufacturer Test Certificate as per EN 10204 / 3.1B| Top |DUPLEX STEEL BUTT WELD FITTINGS:Range : 1/2"NB TO 48"NB IN SCH: 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75

Type

SEAMLESS / WELDED/ FABRICATED

Form

Elbows in Long & Short Radius in 45 deg, 90 Deg, 180 deg.

Equal, Unequal Tee & Barred Tee.

Eccentric Reducer & Concentric Reducer.

Caps & Crosses.

Long & Short Stub End.

Swage Nipple & Barrel Nipple..Standard: ASTM / ASME SA 815

Grade: UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760

Test Certificate: Manufacturer Test Certificate as per EN 10204 / 3.1B| Top |CARBON STEEL BUTT WELD FITTINGS:Range : 1/2"NB TO 60"NB IN SCH: 20, 30, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75.

Type : SEAMLESS / WELDED/ FABRICATED

Form :

Elbows in Long & Short Radius in 45 deg, 90 deg, 180 deg.

Equal, Unequal Tee & Barred Tee.

Eccentric Reducer & Concentric Reducer.

Caps & Crosses.

Long & Short Stub End.

Swage Nipple & Barrel Nipple.Standard : ASTM A234 WPB / MSS-SP-75, ASTM / ASME A 860, ASTM A 420 WPL6 Type :

Grade : WPB, WPC, WPBW, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.Value Added ServicesHot Dipped Galvanizing

Epoxy Coating

Sand BlastingTest Certificate: Manufacturer Test Certificate as per EN 10204 / 3.1B| Top |ALLOY STEEL BUTT WELD FITTINGS:Range : 1/2"NB TO 48"NB IN SCH: 20, 30, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75

Type : SEAMLESS / WELDED/ FABRICATED

Form

Elbows in Long & Short Radius in 45 deg, 90 deg, 180 deg.

Equal, Unequal Tee & Barred Tee.

Eccentric Reducer & Concentric Reducer.

Caps & Crosses.

Long & Short Stub End.

Swage Nipple & Barrel Nipple.Standard: ASTM / ASME A/SA 234

Grade: WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91

Test Certificate: Manufacturer Test Certificate as per EN 10204 / 3.1B

Value Added Services: Hot Dipped Galvanizing , Sand Blasting | Top |NICKEL ALLOY BUTT WELD FITTINGS:Range : 1/2"NB TO 48"NB IN SCH: 20, 30, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75

Type : SEAMLESS / WELDED/ FABRICATED

Form

Elbows in Long & Short Radius in 45 deg, 90 deg, 180 deg.

Equal, Unequal Tee & Barred Tee.

Eccentric Reducer & Concentric Reducer.

Caps & Crosses.

Long & Short Stub End.

Swage Nipple & Barrel Nipple.Standard : ASTM / ASME SB 336

Grade : UNS 2200 (NICKEL 200 Elbow) , UNS 2201 (NICKEL 201 Elbow) , UNS 4400 (MONEL 400 Elbow) , UNS 8020 (ALLOY 20 / 20) CB 3 , UNS 8825 INCONEL (825 Elbow) , UNS 6600 (INCONEL 600 Elbow) , UNS 6601 (INCONEL 601 Elbow) , UNS 6625 (INCONEL 625 Elbow) , UNS 10276 (HASTELLOY C 276 Elbow)

Test Certificate: Manufacturer Test Certificate as per EN 10204 / 3.1B| Top |COPPER ALLOY BUTT WELD FITTINGS:Range : 1/2" OD TO 6" OD IN x 18swg, 16swg, 14swg, 12swg, 10swg

Type : SEAMLESS / WELDED

Copper Buttweld Pipe Fittings

Form

Elbows in Long & Short Radius in 45 deg, 90 deg, 180 deg.

Equal, Unequal Tee

Bend

Reducer

Caps

Long & Short Stub End.

Swage Nipple & Barrel Nipple. Copper Butt Weld Pipe Fitting

Grade : De-oxidized & Electrolytic 99.9% Copper

Standard: ASTM / ASME SB 111 , ASTM / ASME SB 466

Grade: UNS NO.C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600, C 71500.UNS NO.C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30)

Standard: ASTM / ASME SB 111 / 466 Grade: UNS NO. C 10100, 10200, 10300, 10800, 12000, 12200, 70600 ( CU -NI- 90/10), 71500( CU -NI- 70/30).

Test Certificate: Manufacturer Test Certificate as per EN 10204 / 3.1B| Top |MILD STEEL BUTT WELD FITTINGS:Materials : Mild SteelSize : 15 NB to 150 NB, 200 NB to 500 NBClass & Thickness : ‘B’ Class & ‘C’ Class & 6.35mm to 12.7mm ThkType : SEAMLESS / WELDED/ FABRICATED FormElbows in Long & Short Radius in 45 deg, 90 deg, 180 deg.

Equal, Unequal Tee & Barred Tee.

Eccentric Reducer & Concentric Reducer.

Caps & Crosses.

Long & Short Stub End.

Swage Nipple & Barrel NippleValue Added ServicesHot Dipped Galvanizing

Sand Blasting

Threading (As per Gauge)Test Certificate: Manufacturer Test Certificate as per IS standards| Top |GALVANIZED STEEL BUTT WELD FITTINGS:Materials: Mild Steel with Hotdipped Galvanized

Size: 15 NB to 150 NB, 200 NB to 500 NB

Class & Thickness: ‘B’ Class & ‘C’ Class & 6.35mm to 12.7mm Thk

Type: SEAMLESS / WELDED/ FABRICATED

Form

Elbows in Long & Short Radius in 45 deg, 90 deg, 180 deg.

Equal, Unequal Tee & Barred Tee.

Eccentric Reducer & ConcentricReducer.

Caps & Crosses.

Long & Short Stub End.

Swage Nipple & Barrel NippleValue Added Services

Hot Dipped Galvanizing

Sand Blasting

Threading (As per Gauge)Test Certificate: Manufacturer Test Certificate as per IS standards

#ss buttweld fittings#SS Flanges#manufacturers in india#exporters#stainless steel forged fittings#ss 304#ss316#ss316l#ss309#ss 409

0 notes

Photo

STAINLESS STEEL FITTINGS

From the years of commencement, we are engaged in offering a huge assortment of quality approved Stainless Steel Fittings to our clients. This Stainless Steel Fittings is manufactured by the team of experience members using latest equipments at precisely designed manufacturing unit. Our offered range of products is flawlessly finished during the whole manufacturing process.we provied stainless steel fittings in various sizes and in different grades like 202, 303, 304, 309, 310, 316, 316L, 316TI, 420, 430, 440C, 904L etc.We also provide stainless steel fitting in various types such as Buttweld Fittings,Forged Fittings,Screw Fittings,Pipe Fittings and in different forms i.e Eccentric Reducer,Elbow,Concentric Reducer,Equal Tee,Unequal Tee,Full Coupling,Half Coupling,Cross Tee,Reducing Coupling, Long Stub Bend, Pipe Cap,etc.

#stainlesssteel#fittings#ssfitting#stainlesssteelfittings#buttweldfittings#forgedfittings#pipefittings#steelpipe#pipe#reducer#equaltee#stud#pipecap#tee#coupling#exporter#manufacturer#trader#supplier.

0 notes

Text

Seamless Buttweld Fitting Manufucture - Suraj Group

Suraj manufacture stainless seamless buttweld pipe fittings according to ANSI/ASME. Our stock includes from 1/2 in. to 12 in. and range includes schedule 10S to Schedule XXS.

We manufacture finest quality of buttweld pipe fittings in diverse shapes like Elbows, Tees, Crosses, Reducers, Stub ends and Caps at affordable market rates.

Our quality system is certified and approved for ISO 9001 : 2008 , AD 2000 – Merkblatt / W0 , and PED – 97 / 23/ EC and has been developed and implemented to ensure that all the customer requirements is satisfied.

All Suraj’s buttweld fittings are acc. to ASME B16.9, annealed and quenched, bevelled ends acc. to ASME B16.25, hardness acc. to NACE MR0175.

Suraj’s ASME buttweld fittings are certified acc. to EN 10204/3.1 and also available with on-site inspection..

Type :

* Elbow 45°, 90°, 180° [LR and SR]

* Tee [Equal and Unequal]

* Crosses [Equal and Unequal]

* Reducers [Eccentric and Concentric]

* Stub ends [Long and Short]

* Caps

Size: 1/2″ in to 12” [10mm to 300mm] Seamless

Schedules: 5s. 10S, 20S, 30S, 40S, 60S, 80S, 100S, 120S, 140S, 160S, STD, XS, XXS.

Standards : ASME/ANSI B16.9, ASME B16.25.

Grades: TP304/304L, 304H, TP316/316L,316Ti, TP317/317L, TP321/321H, TP347/347H, SS31803, S32550, S32750, S32760.

I am manager of Suraj Group Ltd professional recommendation on uses and applications of steel. We are providing Specific and wide range of Stainless Steel Heat Exchanger Tube. For more visit look:

www.surajgroup.com

0 notes

Text

Unequal and Unequal Cross Manufacturer

We offer Unequal Tees and Unequal Cross, which are generally favored by clients because of their precise elasticity, consumption and scraped area safe and astounding completion. These unequal tees fittings and unequal crosses fittings require immaterial support. Our scope of unequal tees are suitable for use in high, and in addition in low temperature. The unequal crosses discover application crosswise over differing commercial ventures, too, attributable to their consistence to industry characterized principles.

SPECIFICATION

Size:

1/2"NB TO 48"NB IN

Schedule:

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Form :

Equal Tee, Reducing Tee, Barred Tee , Lateral Tee.

Test Certificate :

Mill Test Certificate as per EN 10204 / 3.1B

Type:

Seamless

ERW

Welded

Fabricated.

Services:

Hot Dip Galvanizing

Epoxy Coating

Electro polish

Grades :

Nickel Alloy:

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Stainless Steel:

ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Carbon Steel:

ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel:

ASTM A420 WPL3 / A420WPL6.

Alloy Steel:

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 .

Duplex Steel:

ASTM A 815 UNS NO S 31803 , S 32205. .

For More Information:

Visit our website-https://https://chhajedpipefittings.com/unequal-tee-and-unequal-cross-manufacturers-suppliers-exporters-stockists.html

Call Us: +91 98215 13630 / 93211 13630

E-mail: [email protected]

0 notes

Text

Butt Weld Fittings and Types of Butt Weld Fittings by Metal forge India

Butt Weld Fittings and Types of Butt Weld Fittings by Metal forge India

Butt weld fittings are commonly used in piping systems to connect pipes or tubes of different sizes or shapes. They are designed to fit seamlessly into the system, ensuring a smooth flow of fluids or gasses. Butt weld fittings are commonly used in industries such as oil and gas, chemical, and petrochemical, among others.

In this article, we will discuss butt weld fittings, their types, and how Metal Forge India manufactures high-quality butt weld fittings.

Definition:

Butt weld fittings are a type of pipe fittings that are used to connect two or more pipes or tubes. They are used in piping systems to change the direction of flow, reduce or increase the diameter of the pipe, or connect different components of the system. Butt weld fittings are welded to the pipes or tubes, creating a strong and leak-proof joint.

Types of Butt Weld Fittings

Butt weld fittings come in different types and sizes, each designed for specific purposes. The following are the most common types of butt weld fittings:

Buttweld Elbows fittings

Elbows are used to alter the direction of flow in a piping system. They come in different angles, such as 45 degrees, 90 degrees, and 180 degrees, and can be either a long or short radius. Long-radius elbows are used in low-pressure applications, while short-radius elbows are used in high-pressure applications.

Buttweld Tees Fittings

Tees are used to connect three pipes or tubes in a piping system. They have a T-shaped design, with one inlet and two outlets. Tees are available in equal or reduced sizes, depending on the application.

Buttweld Reducers Fittings

Reducers are used to connect pipes or tubes of different sizes in a piping system. They have a conical shape and can either be eccentric or concentric.

Eccentric reducers are used when the centerline of the piping system needs to be aligned, while concentric reducers are used when maintaining the same centerline is not necessary.

Buttweld Caps Fittings

Caps are used to close the end of a pipe or tube in a piping system. They are designed to be welded onto the end of the pipe, creating a strong and leak-proof seal.

Buttweld Stub Ends Fittings

Stub ends are used in piping systems that require frequent dismantling. They are designed to be welded to the pipe, while the other end is connected using a lap joint flange. This allows for easy removal and replacement of components in the system.

Buttweld Collars Fittings

Buttweld collar fittings are a type of pipe fitting that is used to connect pipes or tubes in a piping system. They consist of a collar or ring-shaped component that is welded to the end of a pipe or tube, and a matching collar that is welded to the end of another pipe or tube.

Buttweld Inserts Fittings

Buttweld insert fittings are a type of pipe fitting used to join pipes or tubes with a buttweld connection. They are typically used in high-pressure applications and are designed to provide a smooth transition between different diameters of pipe or tubing.

Metal Forge India's Butt Weld Fittings

As Metal Forge India is a renowned manufacturer, supplier, stockiest, and exporter of butt weld fittings in India. They provide a broad selection of butt weld fittings in different sizes, materials, and grades, including Stainless Steel and Alloy Steel. The Stainless Steel grades available include 304, 316, 304L, 316L, 317, and so on. Alloy Steel consists of Monel, Inconel, Hastelloy, Duplex Steel, Super Duplex Steel, and 254 SMO.

Buttweld fittings can also be made of Carbon Steel and Special Grade Steel. Metal Forge India's butt weld fittings are acknowledged for their exceptional quality and durability, rendering them suitable for use in demanding applications.

Metal Forge India's butt weld fittings are manufactured using advanced technology and equipment, ensuring precise dimensions and a perfect fit. They undergo strict quality control measures to ensure that they meet the highest standards of quality and performance.

Application of Buttweld Fittings

Buttweld fittings can be utilized in a multitude of industries to modify, divide, or halt the flow of fluids. These industries include waste treatment plants, oil processing, breweries, chemical and petrochemical industries, cryogenic plants, paper and pulp production, gas processing, and even nuclear power plants. The extensive variety of applications reveals the durability of buttweld fittings and how commonly this particular type of fitting is utilized.

Conclusion

Butt weld fittings are essential components of piping systems, used to connect pipes or tubes of different sizes or shapes. They come in different types, each designed for specific purposes, such as changing the direction of flow, reducing or increasing the diameter of the pipe, or connecting different components of the system.

Moreover, Metal Forge India is also an of high-quality Butt weld fittings in India, is proud to announce its export services to countries such as Brazil, South Africa, the UAE, Bahrain, Italy, Indonesia, Malaysia, the United States, Mexico, China, Peru, Nigeria, Kuwait, Jordan, Dubai, Thailand (Bangkok), Venezuela, Iran, Germany, the UK, Canada, Russia, Turkey, Australia, New Zealand, Sri Lanka, Vietnam, South Africa, Kazakhstan, and Saudi Arabia.

Explore High-Quality Buttweld Weld Fittings with Metal Forge India!

0 notes

Link

ASME B16.9 ASTM A403 WP316L Equal Tee 1-1/4 Inch SCH10S

FOB Price USD 1 - 1,900/Piece

Port Ningbo or Shanghai Port

MOQ 1 Piece

Supply Ability 1000 Pieces Per Day

Payment Terms L/C,T/T,Western Union,MoneyGram

Packaging Seaworthy plywood cases or pallets

Delivery 2 - 10 days

Quick Details

Material:316L

Technics:Forged

Type:Equal Tee

Place of Origin:Zhejiang, China (Mainland)

Model Number:Equal Tee

Brand Name:Yaang

Connection:Welding, Weld

Shape:Equal

Head Code:Round

Packaging & Delivery

Packaging Detail:Plywood case or fumigation woodern case

Delivery Detail:Usually 2-10 days depend on the quantity

Specifications

ASME B16.9 ASTM A403 WP316L Equal Tee 1-1/4 Inch SCH10S

1) Size: 1 1/4" (DN32)

2) THK: SCH10S

3) Material: 316L

ASME B16.9 ASTM A403 WP316L Equal Tee, like all pipe tees, is in the shape of T with two ends of equal size and the third one slightly smaller. In other words, 316 smls Equal tee is a type of pipe fitting in which the branch port size is smaller than the ports of the run. This type of pipe fitting can also consider size reduction from one of the run ports to the other.

China Equal Tee Manufacturer Yaang supplies ASME B16.9 ASTM A403 WP316L Equal Tee, 1-1/4 Inch, SCH10S.

Composition ranges for 316L grade of stainless steels

Type

WP316L Equal Tee

Size

SMLS Tee: 1/2"~12" (DN15 - DN300)

Welded Tee: 1/2"~48" (DN15 - DN1200)

Wall thickness

sch10, sch20, sch30, std, sch40S, sch60,

xs, sch80, sch100, etc

Standards

ASME, ASTM, DIN, JIS, etc

Material

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Stainless Steel: ASTM A182 F304/304L/316/316L, etc

Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc.

Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc

Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800,

Hastelloy C276, Hastelloy C22, Hastelloy B1/B2/B3, Alloy 20, etc

Cu-Ni: 90/10,70/30, etc

Surface treatment

Transparent oil, rust-proof black oil or hot galvanized

Applications

Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc

ASME B16.9 ASTM A403 WP316L Equal Tee

1. They are manufactured to be used in flow lines for gases, fluids in industrial processes, medical, construction and many other specialized applications.

2. The 316L Equal Tee is constructed of heavy materials for rigid applications like extreme high/low temperature resistance etc.

3. The 316L Equal Tee is specifically designed for use on process and control systems, instrumentation, and equipment used in chemical, petroleum, fluid power, electronic and pulp and paper plants.

ASME B16.9 ASTM A403 WP316L Equal Tee's Packing & Shipping

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps , pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request .

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality ASME B16.9 ASTM A403 WP316L Equal Tee.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry about products, please feel free to contact us [email protected]

Related products:

More>>

ASTM A420 WPL6 ELBOW 90DEG,SEAMLESS,BW,ASME B16.9

ASTM B16.11 A182 F53 GR2507 45 Degree SW Elbow DN50 CL3000

ASTM A403 MSS-SP43 Type A WP316L Lap Joint Stub End SCH10S DN400

OD273MM 10inch Steel Elbow

0 notes

Link

ASME B16.9 ASTM A403 WP316L SMLS CON RED 3 Inch x 2-1/2 Inch SCH10S

FOB Price USD 1 - 1,900/Piece

Port Ningbo or Shanghai Port

MOQ 1 Piece

Supply Ability 1000 Pieces Per Day

Payment Terms L/C,T/T,Western Union,MoneyGram

Packaging Seaworthy plywood cases or pallets

Delivery 2 - 10 days

Quick Details

Material: 316L (UNS S31603)

Technics: Cold Formed

Type: SMLS CON RED

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Yaang

Connection: Welding

Shape: Equal

Head Code: Round

Packaging & Delivery

Packaging Detail:Plywood case or fumigation woodern case

Delivery Detail:Usually 2-10 days depend on the quantity

Specifications

ASME B16.9 ASTM A403 WP316L SMLS CON RED

1. Size: 3" - 2 1/2" (DN80 - DN65 )

2. Wall thickness: SCH10S

3. Material: 316L (UNS S31603)

Composition ranges for 316L grade of stainless steels

Size:2-1/2" - 2" (DN65 - DN50)

Material:

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Stainless Steel: ASTM A182 F304/304L/316/316L, etc

Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc.

Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc

Super Duplex Stainless Steel: S32750/2507, UNS32760, etc

Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800,

Hastelloy C276, Hastelloy C276, Hastelloy B1/B2/B3, Alloy 20, etc

Cu-Ni: 90/10,70/30, etc

Standard: ASME/DIN/ISO/, etc

Connection: Welding

Wall thickness:SCH40S

Finish: Mirror polish, semi bright etc

NPSO.D.

DO.D.

D1Len

H

3*2½88.97389

CON RED

ASME B16.9 ASTM A403 WP316L SMLS CON RED is used to join pipes or tubes sections on the same axis. They provide an in-line conical transition between pressurized pipes of differing diameters. A WP316L SMLS CON RED can be a single diameter change or a multiple diameter change. The pipes cannot recognize what the outside configuration of the pipe reducer looks like. The pipe flow is affected by the inside diameter conical transition configuration which can be axially moved and externally reconfigured to provide for more economical reducer fittings. Thus, WP316L SMLS CON RED connects pipes of unequal size but have a common centerline. In other words, it is a type of pipe fitting with different size ends to join pipes of different diameter that joins pipe sections on the same axis.

WP316L SMLS CON RED is designed with the small and large diameters on opposite ends and joined by a cone shaped transition section. They are available in both seamless and welded construction.

Use of WP316L SMLS CON RED is as follows:

WP316L SMLS CON RED will transition gracefully between the piping and the pump.

The WP316L SMLS CON RED helps in transporting slurries or abrasive liquids.

They are useful in services where cavitation is present.

When transporting between flanges or pipes of different ratings and wear protection is necessary, concentric reducers are ideal.

WP316L SMLS Concentric reducers are used in discharge of the pump.

Application range: Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc

If any inquiry, please feel free to contact by email [email protected]

Related products:

More>>

ASTM B366 UNS N10665 Hastelloy B2 45 Degree Elbow

Stainless steel 304 304L 316 316L Swage Nipple

buttwelded pipe elbows

ASTM A182 UNS32750 GR2507 SMLS Equal Tee 100NB SCH40S

0 notes