#APQP Process

Explore tagged Tumblr posts

Text

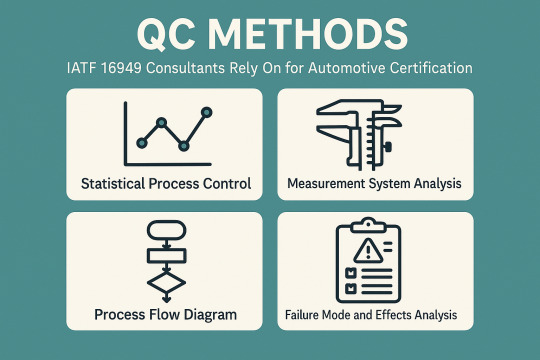

QC Methods IATF 16949 Consultants Rely On for Automotive Certification

In the competitive world of automotive manufacturing, quality is not something to strive for; it is imperative. Based on customer expectations, we must also ensure safety, reliability, and compliance with regulations. That’s where a globally recognized quality management standard designed specifically for the automotive sector comes into play in the form of IATF 16949.

IATF 16949 is more than a certification; it embodies a culture of continual improvement and process excellence. Becoming certified, though, is a labyrinth of requirements, documents, and audits. Here is where the role of IATF 16949 Consultants becomes crucial, as they help organizations navigate the process with their knowledge and clear insights.

Fundamentals of IATF 16949 in UAE

IATF 16949 is based on the fundamentals of ISO 9001, but with many automotive-specific requirements that are required for product development, production, and servicing. The main goal of IATF 16949 Certification in Abu Dhabi is to create a quality management system that promotes continual improvement, focuses on defect prevention, and reduces variation and waste in the automotive supply chain.

Main Goals of the Certification:

Maintain the quality of the products

Enhance customer satisfaction

Increase productivity in the manufacturing process

Create a culture of continual improvement

Benefits of the Certification:

Increased reliability and performance of the product

It increases the credibility in the market, and also the customers start trusting the product.

Easier access for global automotive supply chains

Lower operational costs and recall costs

As IATF 16949 Certification Consultants, your role is to ensure organizations meet the exacting standards of IATF 16949, thereby enhancing their organizational processes.

The IATF 16949 standard process can be lengthy and requires a lot of documentation, internal audits, and compliance reviews. Enter consultants to the rescue.

Benefits of Hiring a Consultant:

Quicker: It reduces the process of implementation and certification.

Quality: Prevents costly mistakes and unsuccessful audits.

Risk Mitigation: You are prepared to meet compliance and customer expectations

Widely-used QC Tools in IATF 16949

To get the correct products, organizations implement Quality Control (QC) tools. IATF 16949 Consultants in Dubai are essential to help solve problem diagnosis, process control, and decision-making.

Significant QC Tools:

Cause-and-Effect Diagram (Fishbone or Ishikawa): Assists in determining the root causes of quality and performance problems.

Collects Real-time data for analysis, check Sheet

Control Chart: Control charts are used to test process stability.

Histogram: Shows how the data is distributed to identify variability.

Pareto Chart: Emphasizes significant problems through the 80/20 rule.

Scatter Diagram: This shows the correlation between two different variables.

Process Diagram: Charting out process steps, using this step to identify; Also helps identify dead ends or redundancies

Tools Related to Advanced Quality Planning (Core Tools):

APQP (Advanced Product Quality Planning): A framework for product and process design.

PPAP (Production Part Approval Process): Verifies that a product meets the customer needs of design needs before bulk production.

Failure Mode and Effects Analysis (FMEA): Assesses potential risks in products and processes.

MSA (Measurement System Analysis): Evaluates the accuracy and precision of the measurement systems.

Statistical Process Control (SPC): Utilizes statistical techniques to monitor and control processes.

The Role of QC Tools in the Quality Systems:

Resolution: If the issue is recurring, trace back the roots and take preventive measures

Maintain Consistency: Process control

Decision-Making: Focus your actions on objective data and trends.

Continuous Improvement: This principle involves the concept of constant improvement.

Tools for Quality Control Implementation of IATF 16949

It is also worth noting that the above QC tools are not just theoretical but are embedded in the DNA of IATF 16949 Certification in Dubai.

How do QC Tools Help Compliance?

FMEA reinforces risk-based thinking, which is a fundamental requirement.

Ongoing validation and monitoring of process: Control Charts and SPC

Corrective actions based on the data based on Pareto Charts and Histograms

APQP and PPAP are structured for the planning and validation of a product.

Example Scenarios:

One of the quality suppliers identifies repetitive defects in a certain part by Pareto analysis and resolves it by Fishbone diagrams and FMEA.

MSA and SPC data are used by an organization during PPAP submission to demonstrate process capability and measurement reliability.

Consultant's Role:

Based on certain challenges, recommend tools.

Develop templates, offer training, and provide software solutions.

Tools must be used effectively and in compliance with expectations.

While the benefits are numerous, many organizations struggle with certification.

Common Obstacles:

A failure to understand the requirements.

Documentation that is incomplete or poorly maintained.

Inconsistent use of QC tools.

Resistance to change or continuous improvement at the community level.

Mistakes in using QC tools or the wrong tools used:

Tools that do audits but are not used for decision-making.

Data that has been collected but not processed or acted on.

Staff was trained never to read charts and metrics

How IATF 16949 Consultants Help in Dealing with Challenges?

Analyze requirements, discover commonalities, and factor them into incremental steps.

Educate staff on how to use the tools correctly.

Get them involved and make it real with workshops and real-world scenarios.

Develop a sense of quality across the organization.

Conclusion

The IATF 16949 is not only a badge but a testament to excellence, consistency, and customer satisfaction in the automotive industry. Expert guidance and practical tools are needed in order to reach and maintain this standard.

IATF 16949 Consultants in UAE know what has gone wrong in the past and the strategies, processes, and ways of thinking that will help a company successfully implement the standard and prepare for and respond to audits. On the other hand, QC tools are the eyes and ears of your quality management system, detecting problems and informing decisions.

Collectively, they enable automotive suppliers to raise the bar in the industry. Investing in expert consultants and embracing QC tools is not just smart—it's essential for any organization seeking sustainable growth and operational excellence.

0 notes

Text

Revolutionize Your Quality Journey: Ditching Excel for a SaaS APQP/PPAP Solution

In today’s fast-paced manufacturing landscape, ensuring product quality from conception to launch is paramount. Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) are critical frameworks that guide this journey, minimizing risks and guaranteeing customer satisfaction. While many organizations still rely on traditional, manual methods like Excel spreadsheets, the limitations of such approaches are becoming increasingly apparent. It’s time to embrace the future of quality management with a robust SaaS APQP/PPAP solution.

The Shackles of the Excel Spreadsheet: Why Manual is No Longer Enough

For years, Excel has been the go-to tool for managing various business processes, including APQP and PPAP. Its familiarity and perceived low cost often make it seem like an easy choice. However, beneath its seemingly simple interface lie significant limitations that can hinder efficiency, accuracy, and ultimately, product quality:

Error-Prone Manual Processes

Lack of Real-time Insights

Limited Collaboration and Communication

Poor Data Integration and Management

Lack of Traceability and Auditability

Scalability Challenges

Benefits of an APQP/PPAP SaaS Solution

Moving to a dedicated SaaS APQP/PPAP solution addresses these challenges head-on, offering a multitude of benefits that streamline processes, enhance quality, and drive efficiency. Based on the capabilities often found in such solutions, including those highlighted on the Smart Factory India website, here’s what you can expect:

Improved Visibility and Enhanced Collaboration

Increased Accuracy and Efficiency

Data-Driven Decision Making:

Enhanced Compliance and Risk Management

Scalability and Flexibility

Switch from Excel Spreadsheet Solution to APQP/PPAP SaaS Solution Today!

The benefits of moving from a manual, Excel-based approach to a dedicated SaaS APQP/PPAP solution are clear and compelling. Smart Factory India’s APQP Management Software offers a robust platform designed to streamline your product quality planning, enhance collaboration, reduce errors, and ensure compliance. Don’t let outdated manual processes hold back your product development and quality initiatives. Embrace the power of digitalization to achieve greater efficiency, improved quality, and ultimately, enhanced customer satisfaction.

0 notes

Text

Top Online Courses and Certifications for IATF 16949 Training

The automotive industry is fast-paced, complex, and constantly evolving—making quality management a top priority for OEMs and suppliers alike. One of the most respected standards in this space is the IATF 16949 standard, which blends ISO 9001 principles with specific automotive industry requirements.

But here’s the challenge: understanding and applying the iatf 16949 standard with examples isn’t something you can pick up overnight. It requires structured learning, real-life case studies, and ongoing training. That’s why online IATF 16949 courses and certifications have become essential tools for professionals, organizations, and quality managers aiming to ensure compliance and stay competitive.

💡 Want to learn how core tools support the IATF journey? Check out our blog: 🔗 What Are Automotive Core Tools and How to Use Them?

📞 Need help choosing the right training for your team? Talk to our certification consultants to get expert guidance.

Why Training Matters in IATF 16949 Implementation

The IATF 16949 standard is not just a tick-box exercise. It involves building a culture of risk-based thinking, customer-specific requirements, supplier management, and more.

While most companies implement the standard with the help of a consultant or internal team, training enhances internal understanding, accelerates adoption, and supports long-term compliance. Plus, it empowers your employees to use quality tools confidently and make informed decisions on the production floor.

Key Topics Covered in IATF 16949 Training

Good IATF 16949 training should help learners:

Understand the structure and clauses of the standard

Interpret real-world examples of implementation

Learn how to apply Automotive Core Tools like FMEA, APQP, PPAP, etc.

Grasp customer-specific requirements (CSRs)

Apply risk-based thinking to process and product design

Prepare for third-party certification audits

Top Online IATF 16949 Courses & Certification Options

Here are some of the most recommended online platforms and certification programs that offer IATF 16949 training:

1. 4C Consulting – IATF 16949 Awareness Training

Best For: Beginners, engineers, and SMEs Features:

Affordable price

Real-world examples

Designed by industry experts

Immediate certification upon completion

Includes modules on automotive core tools and audit preparedness

This course is ideal for those looking for an Indian training provider with localized case studies and affordable pricing.

📞 Contact 4C Consulting to schedule training for your team or explore advanced modules.

2. AIAG (Automotive Industry Action Group)

Best For: Tier 1 & Tier 2 suppliers in the global supply chain Highlights:

Recognized by global OEMs

In-depth training on PPAP, FMEA, MSA, SPC

Certification courses aligned with North American CSRs

AIAG also provides e-learning bundles that combine standard training with case-based learning.

3. 4C Consulting Global

Best For: Engineers & Quality Managers Benefits:

Access to certified trainers

Industry-focused case studies

Advanced modules on process auditing & failure prevention

Often bundled with ISO 9001 updates

4. Training Academy

Best For: Global automotive suppliers Course Features:

IATF 16949 internal auditor and lead auditor certifications

Delivered live online or self-paced

Detailed guidance on risk-based thinking and context of the organization

Who Should Enroll in IATF 16949 Online Courses?

Quality Managers & Engineers: To lead the QMS implementation

Production & Process Engineers: For better integration of quality in operations

Internal Auditors: To ensure continual improvement

Suppliers/Vendors: To meet OEM requirements

Students & Freshers: To boost employability in the automotive sector

Benefits of Taking Online IATF 16949 Training

✔️ Flexible Learning

Learn at your own pace from anywhere—ideal for working professionals.

✔️ Cost Effective

Online certifications are often more affordable than in-person training, especially for teams.

✔️ Immediate Certification

Most platforms offer downloadable certificates that can be used for audits or resume-building.

✔️ Practical & Relevant

Look for platforms that use iatf 16949 standard with examples, not just theory.

Final Thoughts: Invest in Learning to Stay Ahead

Whether you’re a startup entering the automotive supply chain or a seasoned Tier 1 supplier, training is non-negotiable. The IATF 16949 standard is rigorous, but with the right online course, it becomes manageable and even transformative.

Explore platforms like 4C Consulting, AIAG, and SAE to find a course that fits your team’s goals and technical level. Make sure to prioritize training that includes real-world examples and access to experts.

🔍 And if you're unsure where to begin, we're here to help. Reach out to us to get personalized recommendations based on your current QMS maturity.

Don’t Miss This:

🔗 What Are Automotive Core Tools and How to Use Them? – This blog complements any IATF training by explaining the five essential tools for implementation success.

0 notes

Text

Omnex Systems offers cutting-edge Advanced Product Quality Planning (APQP) solutions that streamline product development and ensure quality from concept to production. Our APQP tools help organizations manage risk, improve collaboration, and meet customer and regulatory requirements efficiently. With integrated modules for FMEA, control plans, PPAP, and process flow diagrams, our software centralizes quality planning to boost transparency and accountability. Designed for industries like automotive and manufacturing, Omnex Systems’ APQP solution supports consistent quality outcomes, faster time-to-market, and continuous improvement. Empower your teams with structured, data-driven planning that ensures every product meets the highest standards of quality and performance.

For more info visit us https://www.omnexsystems.com/products/apqp-ppap-manager-software

0 notes

Text

Chapter 16: Advanced Quality Planning: Supplier Quality Management

Abstract: Advanced Quality Planning” (APQP) in the context of Supplier Quality Management refers to a structured process used to proactively plan and manage the quality of products and services delivered by suppliers, ensuring they meet all necessary standards and customer requirements throughout the design and development stages, before mass production begins ; it involves close collaboration…

View On WordPress

0 notes

Text

Comprehensive Guide to IATF 16949 Training with 4C Consulting

In today’s competitive automotive industry, maintaining high standards for quality and performance is crucial. The International Automotive Task Force (IATF) 16949 standard provides a robust framework for quality management systems specifically designed for the automotive sector. For organizations seeking to enhance their quality management systems and achieve IATF 16949 certification, effective training is essential. This blog will provide a comprehensive understanding of IATF 16949 training, its importance, and an overview of the training process, concluding with why 4C Consulting is your ideal partner for this journey.

Understanding IATF 16949 Training

Framework and Objectives: IATF 16949 training aims to educate participants about the requirements of the IATF 16949 standard. It covers the framework, principles, and specific objectives of the standard, ensuring that trainees understand the comprehensive scope and purpose of the quality management system.

Scope of Training: The training includes detailed sessions on the structure and requirements of the IATF 16949 standard. It covers all clauses, including context of the organization, leadership, planning, support, operation, performance evaluation, and improvement.

Key Concepts and Terminology: Trainees gain a solid understanding of the key concepts and terminology used in IATF 16949. This includes familiarization with terms such as APQP (Advanced Product Quality Planning), PPAP (Production Part Approval Process), FMEA (Failure Mode and Effects Analysis), and MSA (Measurement Systems Analysis).

Implementation Strategies: The training provides practical guidance on how to implement the IATF 16949 standard within an organization. This includes strategies for developing and maintaining documentation, managing processes, and ensuring compliance with the standard’s requirements.

Importance of IATF 16949 Training

Enhanced Quality Management: IATF 16949 training is essential for enhancing the overall quality management system within an organization. It ensures that employees are knowledgeable about quality management principles and practices, leading to improved product quality and customer satisfaction.

Compliance and Certification: Proper training helps organizations achieve and maintain compliance with the IATF 16949 standard. It prepares employees for internal and external audits, increasing the likelihood of successful certification.

Continuous Improvement: Training promotes a culture of continuous improvement by educating employees about the importance of ongoing process optimization. This leads to better efficiency, reduced waste, and higher productivity.

Risk Management: Understanding the requirements of IATF 16949 enables organizations to identify and manage risks effectively. Training helps employees recognize potential risks and implement preventive measures to mitigate them.

IATF 16949 Training Process

Needs Assessment: The training process begins with a needs assessment to identify the specific requirements of the organization. This involves evaluating current practices, identifying gaps, and determining the training needs of employees.

Customized Training Programs: Based on the needs assessment, a customized training program is developed. This program is tailored to the specific requirements of the organization, ensuring that all relevant aspects of the IATF 16949 standard are covered.

Interactive Training Sessions: The training sessions are designed to be interactive and engaging. They include a combination of lectures, discussions, case studies, and practical exercises to ensure that participants understand and can apply the concepts learned.

Practical Application: The training emphasizes practical application, providing participants with the skills and knowledge needed to implement the IATF 16949 standard in their organization. This includes guidance on developing documentation, managing processes, and conducting audits.

Assessment and Evaluation: To ensure the effectiveness of the training, participants are assessed through quizzes, tests, and practical exercises. This helps to gauge their understanding and identify areas where further training may be needed.

Follow-Up Support: Post-training support is provided to help organizations implement the IATF 16949 standard effectively. This includes ongoing consultation, additional training sessions, and assistance with audits and certification processes.

Why Choose 4C Consulting

Choosing 4C Consulting for IATF 16949 training ensures that your organization receives expert guidance and support throughout the training and implementation process. Our team of experienced consultants is dedicated to helping you achieve and maintain compliance with the IATF 16949 standard, promoting a culture of continuous improvement and excellence within your organization. With 4C Consulting, you can be confident that you are partnering with a leader in quality management systems, committed to delivering the highest standards of service and support.

IATF 16949 training is a vital component for any organization in the automotive sector striving to enhance its quality management system and achieve certification. By understanding the framework, importance, and training process, organizations can effectively implement the IATF 16949 standard and reap the benefits of improved product quality, compliance, and continuous improvement. With 4C Consulting as your partner, you can navigate the complexities of IATF 16949 with confidence and achieve your quality management goals. Contact us now.

0 notes

Text

Optimizing Manufacturing with Advanced Product Quality Planning and Asset Calibration Software

In today’s competitive manufacturing landscape, Advanced Product Quality Planning (APQP) and reliable Asset Calibration and Maintenance Software play pivotal roles in ensuring high-quality outcomes and streamlined processes. Businesses striving for excellence leverage these tools to meet regulatory standards, enhance efficiency, and minimize operational risks.

https://trackmedium.stck.me/post/612015/Optimizing-Manufacturing-with-Advanced-Product-Quality-Planning-and-Asset-Calibration-Software

0 notes

Text

Quality Management System: Solutions Which Are Build For Future

In today’s competitive landscape, product quality, and customer satisfaction are necessary for any business striving for excellence. White traditional quality management systems often fall short due to inefficiencies and fragmented processes that hinder progress. Quality management systems fill the vacuum with their cutting-edge features.

What is a Quality Management Solution?

A Quality Management Solution is a comprehensive system or software designed to oversee and improve the quality of an organization’s processes, products, and services. It comes with a set of tools, methodologies, and best practices that ensure consistent quality, compliance with industry standards, and continuous improvement within an organization. These solutions are tailored for business leaders seeking robust, integrated tools. Quality management software easily blends advanced methodologies with user-friendly features to drive your projects toward success.

The Benefits of Adopting Quality Management Software

Implementing quality management solutions offers a multitude of advantages that extend beyond mere compliance. Here’s how your business can thrive with this comprehensive quality management system:

Enhanced Efficiency Streamline your workflows with automated processes that reduce manual effort and eliminate redundancies. Quality management solution maximizes productivity, allowing your team to focus on what truly matters — innovating and delivering exceptional products.

Improved Collaboration Facilitate seamless communication across departments and teams. With these solutions, everyone stays aligned, fostering a collaborative environment that accelerates project timelines and enhances overall performance.

Superior Quality Control Mitigate risks and ensure product reliability through integrated Failure Modes and Effects Analysis (FMEA) and Production Part Approval Process (PPAP). Proactive risk management translates to higher-quality products and increased customer trust.

Time Savings Accelerate your project timelines with ready-to-use templates and automated notifications. These solutions help you meet deadlines consistently, ensuring timely delivery without compromising on quality.

Regulatory Compliance Stay ahead of industry standards and regulations with built-in compliance features. Quality management software ensures that your processes are always aligned with the latest requirements, avoiding costly compliance issues.

Real-Time Insights Gain actionable insights into project progress and resource utilization with advanced reporting and analytics tools. Make informed decisions swiftly, backed by accurate and up-to-date data.

Features of Quality Management Systems

Quality management software is packed with features meticulously designed to address the multifaceted challenges of quality management:

Integrated FMEA and PPAP Seamlessly combine FMEA and PPAP with Process Flow and Control Plans. This integration ensures streamlined product development, robust documentation, and unwavering compliance with industry standards.

Project Planning and Control Effectively manage new product development projects through streamlined resource allocation and enhanced risk management. These solutions simplify timeline tracking, keeping your projects on course and within scope.

APQP Status Reporting and Revision Management Track project phases, milestones, and overall progress with customizable status reporting templates. Maintain version control and simplify change management with efficient revision management tools.

Automation for Efficiency Automate the generation of FMEA analyses and PPAP documentation. Reduce manual effort, minimize errors, and ensure consistency across all project documentation.

Reporting and Analytics Utilize advanced reporting tools to generate performance metrics, monitor progress, and ensure compliance documentation is accurate and accessible. Real-time analytics empower you to optimize your processes continuously.

Enhanced Risk Mitigation Identify potential failure modes and establish proactive control plans with integrated FMEA and Control Plan capabilities. Quality management software enables effective risk mitigation, reducing errors and enhancing product reliability.

Ready-to-Use APQP Templates Accelerate your project timelines with pre-designed templates that are easy to implement within your manufacturing workflows. Save time and ensure consistency across all projects.

Seamless Integration Integrate quality management software with your existing systems to create a unified New Product Development (NPD) ecosystem. Enhance data flow and ensure all your tools work in harmony.

Conclusion

In an era where quality and efficiency define business success, these solutions offer the ultimate solution for forward-thinking companies. By integrating essential quality management processes with intuitive project management tools, organizations can deliver superior products, exceed customer expectations, and maintain a competitive edge in the market.

Take the Next Step Toward Excellence

Ready to elevate your quality management processes and drive your business to new heights? Reach out to Smart Factory Solutions today to discover how SmartAPQP can be tailored to meet your specific needs. Our team is eager to provide personalized recommendations and demonstrate how our solutions can propel your business forward. Contact us now and take the first step towards achieving exceptional quality and customer satisfaction.

0 notes

Text

'Design for Manufacturability’ (DFM) and ‘Design for Testability'

In the competitive landscape of electronics manufacturing, the ability to produce high-quality, reliable products efficiently is key to success. At inYantra, we understand that achieving this requires more than just state-of-the-art manufacturing processes—it begins with thoughtful, strategic design. That’s why we place a strong emphasis on two critical aspects of product development: Design for Manufacturability (DFM) and Design for Testability (DFT).

The Importance of DFM and DFT

DFM and DFT are crucial features of any new product. By integrating these principles early in the design process, inYantra ensures that products are not only easier to manufacture and test but also more cost-effective and reliable. This proactive approach provides our customers with a distinct advantage in the marketplace, enabling the creation of the highest quality products possible.

Design for Manufacturability (DFM)

DFM focuses on designing products that are easy and cost-effective to manufacture. It involves evaluating product designs to identify and eliminate potential manufacturing issues before they arise, thereby optimizing production time, resources, and costs.

At inYantra, DFM is not just a one-time activity—it’s a continuous process that follows your product from development through to production and even into redevelopment. This ensures that improvements can be made from one product generation to the next, consistently enhancing manufacturing productivity and product quality.

Design for Testability (DFT)

DFT, on the other hand, ensures that a product is designed in a way that makes it easy to test during manufacturing and in the field. Effective DFT allows for early detection of defects, which reduces the risk of costly post-production issues and simplifies maintenance and repair processes.

By incorporating DFT into the design process, inYantra helps guarantee more efficient diagnosis and repair, providing more accurate diagnostics down to the part and pin level. This not only improves product reliability but also lowers both initial and life cycle costs.

inYantra’s Advanced Capabilities

Our commitment to DFM and DFT is backed by our advanced capabilities in test bench development, rapid prototyping, and document management. Here’s how we support your product’s success:

High-End Test Bench Development: We have the capability to develop sophisticated test benches using technologies like PLC, SCADA, and LABView. These advanced testing systems ensure that your products are thoroughly evaluated for performance and reliability.

Rapid Prototyping: Our rapid prototyping capabilities allow us to quickly develop and refine product designs, enabling faster iterations and more efficient product development.

Dedicated Document Management (DMS) and Change Management: We have separate verticals for document handling and change management, ensuring that all documentation is meticulously managed and any changes are carefully tracked and implemented.

Advanced System Integration in NPI: We integrate advanced methodologies such as APQP (Advanced Product Quality Planning), PFMEA (Process Failure Modes and Effects Analysis), and TGR/TGW (Things Gone Right/Things Gone Wrong) into our New Product Introduction (NPI) process. These tools help us identify and mitigate potential risks early in the development cycle, ensuring a smoother transition from design to production.

The Benefits of inYantra’s DFM & DFT Services

By partnering with inYantra for your DFM and DFT needs, you unlock a range of benefits that can significantly enhance your product’s success:

Enhanced Manufacturing Productivity: Our DFM and DFT processes streamline manufacturing, reducing production time and increasing output efficiency.

Improved Product Quality and Reliability: By designing with manufacturability and testability in mind, we help you deliver products that meet the highest standards of quality and reliability.

Reduced Maintenance and Cost-Effectiveness: DFM and DFT address cost and maintenance issues at the conceptual design stage, leading to lower manufacturing and lifecycle costs.

Decreased Time to Market: Faster, more efficient production and testing processes help you bring your products to market sooner, giving you a competitive edge.

Increased Customer Satisfaction: Reliable products with fewer defects and easier maintenance translate to higher customer satisfaction.

Conclusion

At inYantra, DFM and DFT are integral to our operational processes, providing our customers with the tools they need to succeed in a competitive market. By focusing on manufacturability and testability from the very beginning, we ensure that your products are not only of the highest quality but also cost-effective, reliable, and efficient to produce. Trust inYantra to help you design and manufacture products that exceed expectations, generation after generation.

0 notes

Text

Unlock Flawless Product Launches with APQP Management Software

In today’s fiercely competitive manufacturing landscape, bringing new products to market successfully isn’t just about innovation — it’s about precision, collaboration, and meticulous planning. Delays, quality issues, and cost overruns can sink even the most promising ventures. This is where APQP (Advanced Product Quality Planning) Management Software becomes your strategic advantage. If you’re constantly striving for excellence in product development, you’re in the right place. At Smart Factory Solutions, we understand the challenges you face, and our APQP Management Software is engineered to transform your product launch process.

What is APQP Software?

APQP software is a specialized digital solution designed to streamline, standardize, and optimize the entire Advanced Product Quality Planning process. Think of it as your central command center for all new product development activities, guiding your team through each critical phase from concept to launch and beyond. It ensures that quality is built into your product from day one, rather than being an afterthought.

How APQP Software Can Transform Your Business

APQP software isn’t just a tool; it’s a catalyst for operational excellence. It transforms your business by:

Minimizing Risks & Ensuring Compliance

Accelerating Time-to-Market

Boosting Collaboration & Communication

Improving Product Quality & Reliability

Reducing Costs & Waste

Key Features of Smart Factory Solutions’ APQP Management Software:

Our APQP software is packed with intuitive features designed for the modern manufacturer:

Integrated Project Planning & Tracking

Risk Management & FMEA Integration

Document & Version Control

Real-time Collaboration & Communication

Supplier Quality Management

Automated Workflow & Notifications

Reporting & Analytics Dashboards

Customizable Forms & Checklists

Benefits:

Reduced product development cycle times

Improved new product introduction (NPI) success rates

Enhanced cross-functional teamwork and accountability

Higher product quality and fewer customer complaints

Significant cost savings due to error prevention

Better visibility and control over all APQP phases

Simplified auditing and compliance adherence

Why Smart Factory Solutions?

We understand the unique complexities of manufacturing. Our APQP Management Software is not just a generic tool; it’s built with a deep understanding of industry best practices and the specific challenges faced by manufacturers. We offer:

Industry Expertise

Tailored Solutions

Comprehensive Support

Scalable & Future-Proof

Conclusion

In the fast-paced world of manufacturing, achieving flawless product launches is no longer a luxury — it’s a necessity. Smart Factory Solutions’ APQP Management Software provides the framework, tools, and insights you need to build quality into every product from inception.

0 notes

Text

5 Features of APQP Manager Software

Omnex Systems' APQP Manager Software streamlines the Advanced Product Quality Planning (APQP) process, ensuring efficient and compliant product development. Designed for automotive and manufacturing industries, it offers robust tools for planning, risk management, document control, and cross-functional collaboration. The software centralizes all APQP elements—FMEA, control plans, and PPAP—into a unified platform, enabling real-time updates, automated workflows, and seamless communication among teams. With intuitive dashboards and detailed reporting, organizations gain full visibility into project status and compliance. Omnex Systems’ APQP Manager helps reduce errors, accelerate timelines, and enhance product quality from concept to launch, supporting continuous improvement and customer satisfaction.

For more info visit us https://www.omnexsystems.com/products/apqp-ppap-manager-software

1 note

·

View note

Text

https://aurosks.com/the-best-ways-to-use-auros-for-product-development/

Explore the best ways to utilize Auros Knowledge Systems for product development. This page details how Auros supports Agile processes, APQP, design reviews, engineering standards, CAD design, knowledge-based engineering, regulatory compliance, systems engineering, and virtual build assessment. Learn how Auros can streamline workflows, improve collaboration, and enhance efficiency in your product development efforts.

For more details, visit Auros Knowledge Systems.

#enterprise knowledge management software#manufacturing engineering#software for knowledge management#manufacturing project management software#engineering knowledge management#knowledge based engineering

0 notes

Text

Optimizing Manufacturing with Advanced Product Quality Planning and Asset Calibration Software

In today’s competitive manufacturing landscape, Advanced Product Quality Planning (APQP) and reliable Asset Calibration and Maintenance Software play pivotal roles in ensuring high-quality outcomes and streamlined processes. Businesses striving for excellence leverage these tools to meet regulatory standards, enhance efficiency, and minimize operational risks.

https://www.taskade.com/d/ohbY2F4rYV2jCdK8?share=edit&edit=ohx1WYUJYxh3vd2x&as=list

0 notes

Text

Driving Excellence: Automotive Core Tools Certification Guidance by 4C Consulting

Unlocking excellence in automotive quality management is made simpler with Automotive Core Tools Certification Consultants from 4C Consulting. With a rich legacy of empowering over 2000 clients and delivering more than 10,000 hours of ISO Training, our consultants specialize in guiding automotive organizations through the intricacies of Automotive Core Tools certification. From APQP to PPAP, FMEA to SPC, and MSA, our consultants offer expert guidance on implementing these core tools effectively, ensuring compliance with industry standards and driving continuous improvement.

By partnering with our Automotive Core Tools Certification Consultants, automotive companies gain access to a wealth of expertise and experience tailored to their unique needs. Our consultants provide personalized support to navigate the certification process seamlessly, helping organizations enhance product quality, optimize processes, and mitigate risks effectively. With our proven track record and commitment to excellence, we empower automotive businesses to achieve certification with confidence and unlock new levels of operational excellence.

Experience the difference of working with Automotive Core Tools Certification Consultants from 4C Consulting. Gain the assurance of compliance, the confidence to innovate, and the competitive edge to thrive in the dynamic automotive industry. Let our consultants be your trusted partners on the journey to achieving Automotive Core Tools certification and driving sustainable success. Contact us for more information.

0 notes