#Alloy 20 Mechanical Properties

Text

Alloy 20 / UNS N08020

Austenitic alloy – Alloy 20 is based on nickel, iron, and chromium and has high corrosion resistance in settings including sulfuric acid and other hostile fluids. This alloy is stabilized with niobium to stop intergranular corrosion. When carefully compared to higher nickel-based alloys, Alloy 20 may offer possible cost savings while outperforming regular stainless steels.

Alloy 20 Chemical Composition:

ElementContent (%)Iron, Fe35Nickel, Ni32-38Chromium, Cr19-21Copper, Cu3-4Manganese, Mn≤2Molybdenum, Mo2-3Niobium, Nb≤1Silicon, Si≤1Carbon, C≤0.07Phosphorous, P≤0.045Sulfur, S≤0.035

Alloy 20 Physical Properties:

PropertiesMetricImperialDensity8.05 g/cm30.291 lb/in3

Alloy 20 Mechanical Properties:

PropertiesMetricImperialTensile strength (annealed)620 MPa89900 psiYield strength (annealed)300 MPa43500 psiElongation at break (annealed)41%41%

Nickel Alloy 20 Thermal Properties:

PropertiesMetricImperialThermal expansion co-efficient (@20-100°C/68-212°F)14.7 µm/m°C8.17 µin/in°FThermal conductivity12.3 W/mK85.4 BTU.in/hrft².°F

Industries and Applications:

Alloy 20 distinctive attributes find resonance in a multitude of industries. From chemical processing to pharmaceuticals, this alloy proves its mettle in various applications. We unravel the sectors that have harnessed the power of Alloy 20 and delve into specific use cases that highlight its adaptability and reliability.

Resistance to Corrosion:

One of Alloy 20 most remarkable features is its unparalleled resistance to corrosion. Delving into the alloy’s molecular structure, we uncover the mechanisms that empower Alloy 20 to withstand the harsh environments of chemical compounds, particularly those containing sulfuric acid. Through real-world examples and scientific insights, we illustrate how Alloy 20 stands as a stalwart guardian against the corrosive forces that can compromise other materials.

Fabrication and Heat Treatment:

The journey from raw materials to the final Alloy 20 product involves intricate fabrication techniques and carefully orchestrated heat treatments. We dissect the fabrication process, highlighting the steps that shape Alloy 20 into its final form.Furthermore, we investigate the impact of heat treatment in improving the mechanical characteristics of the alloy and ensuring that it fits the requirements of diverse applications.

It is possible to cold-work or hot-work alloy 20 using conventional techniques. Prior to forging, hot forged material should be heated to a temperature between 2100°F and 2250°F with rigorous temperature management to ensure that the material does not drop below 1800°F. After hot working, anneal the material by raising its temperature to between 1725°F and 1850°F for at least 30 minutes per inch of thickness, and then quench it in water.

When stress relief is sought, heat to a temperature below 1000°F and then quench with water once the appropriate time has passed at the temperature. Alloy 20 should be annealed at a temperature of 1725°F to 1850°F for 30 minutes per inch of thickness. By heating to 2100°F, a reduced hardness can be achieved, although this may not be good for the alloy’s ability to stabilize.

Alloy 20 is often welded using TIG, MIG, and submerged arc welding (SAW), with the appropriate filler metal (ER320LR for TIG, MIG, and SAW, and E320LR for SAW). When welding to higher-grade alloys like C276 and Alloy 22, or to dissimilar alloys like 316, AWS ERNiCrMo-3 may be used for TIG and MIG, whereas ENiCrMo-3 can be used for SAW.

Other Designations – Equivalent:

ASME SB-462 – SB-464

ASME SB-468

ASTM B 462 – B 464

ASTM B 468

ASTM B 472 – B 474

ASTM B 751

#Alloy 20#UNS N08020#Alloy 20 Chemical Composition#Alloy 20 Physical Properties#Alloy 20 Mechanical Properties#Nickel Alloy 20 Thermal Properties

0 notes

Text

Did you know Steel is one of the strongest materials in the world ?

Steel Facts By Virat Steels … Steel is one of the most valuable materials in the history of our planet, but few people know about the facts of versatile material.

Steel can be 1000 times stronger than Iron and When liquid iron is converted into steel ,it reaches temp up to 1700 degree centigrade , literally hotter than a Volcanic lava. There are more than 3500 grades of steel with its unique physical , mechanical , chemical properties designed for its specific applications & “approximately 75% of modern steels have been developed in the past 20 years.”

Looking for Steel in every Indian city and abroad ? Learn More About steel at Virat Steel & its Supply

Now that you’re knowledgeable about the strongest metals around, you’re one step closer to choosing the right metal for your next project.

Product List

DIE STEEL ( HH 370 - 410 BHN ) (DIN-1.2714 / AISI L6 )

HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

Have queries? Virat Steels can help.

🌐https://viratsteels.com 📨 [email protected] 📞 +91 098140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#HighSpeedSteels#ColdWorkSteels#HCHCr#SteelTrades#MetalIndustry#H13Steel#D2Steel#SteelFacts

2 notes

·

View notes

Text

Duplex Steel S32205 Wire Exporters in India

Duplex Steel S31803/S32205 Wire, which is alloyed with tungsten correspondingly as copper. Duplex S31803 Wire takes its name from its two-make microstructure out of ferrite and austenite in approx. looking at degrees. Duplex S31803 Circle Wire contains more than 20 % chromium and around 5 % nickel, and it is a spot of the party of set up gets ready.

In Duplex S31803 Wound Wire, the base chromium, molybdenum, and nitrogen substances have been extended to move out of other materials. Duplex S31803 Wire safeguards their ideal properties with a reasonable ferrite-austenite part of around 50/50. Move out of the austenitic set plans, Duplex S31803 Wire contains less nickel (approx. 4 % to 8 %), which brings about an ordinarily stunning lift for cash.

Duplex S32205 Wire might be utilized in the temperature relax between - 40 Degree C and 280 Degree C. The standard piece of Duplex S32205 Wire is depicted with 25 % chromium, 7 % nickel, 4 % molybdenum and 0.25 % nitrogen. Duplex S32205 Wire is similarly saw by its broad security from setting, opening and stress use part, and an extra advancement in its mechanical quality credits.

Duplex S32205 Wire is now the widest social affairs and is seen by magnificent application properties and by high responsiveness in all the fitting thing plots.

DUPLEX STEEL S31803/S32205 WIRE SPECIFICATIONS

Specifications: ASTM A276 ASME SA276

Dimensions: ASTM, ASME

Thickness: 10mm to 100mm

Diameter: 100 mm To 6000 mm

Specialize: Wire, Filler Wire, Coil Wire

For More Information :

Visit Our Website: https://sankalpalloys.com

Contact No: 91-8828369483

E-Mail ID: [email protected]

7 notes

·

View notes

Text

Alloy Steel F11Forged Fittings Exporters in India

INTRODUCTION:

Manilaxmi Industrial, a prominent name in the manufacturing, supplying, and exporting of Alloy Steel F11 Forged Fittings, brings forth an array of high-quality forged fittings suitable for diverse industrial applications. Renowned for their exceptional block limit, mechanical properties, and weldability, Alloy Steel F11 fittings are the go-to choice for industries requiring robust and reliable components.

DESCRIPTION:

Alloy Steel F11, characterized by its excellent formability and superior resistance to harsh conditions, is widely used in the production of forged fittings. This steel variant, with its austenitic structure enriched with chromium and molybdenum, offers outstanding resistance to corrosion and mechanical stress. These properties make Alloy Steel F11 suitable for applications in extreme environments, ensuring durability and performance.

BENEFITS:

Superior Mechanical Properties: Alloy Steel F11 exhibits high tensile and yield strength, making it capable of withstanding significant mechanical stress.

Exceptional Weldability: The alloy's excellent weldability allows for easy fabrication using standard welding techniques.

Resistance to Corrosion: The chromium and molybdenum content provide enhanced resistance to oxidation and corrosion, even in aggressive environments.

Versatile Applications: Suitable for a range of applications, including the petrochemical, food management, oil and gas, and pharmaceutical industries.

High-Temperature Performance: Maintains structural integrity and strength at temperatures ranging from 600 to 900 degrees Celsius.

SPECIFICATIONS:

Standards: ASTM A182 / ASME SA182

Specifications: ASME B16.11, MSS SP-79, 83, 95, 97, BS 3799

Size Range: NPS 1/8″- 4″ (DN 6~100)

Rating Pressure:

Threaded End: 2000/3000/6000 LBS

Socket weld End: 3000/6000/9000 LBS

Type: Socket Weld, Screwed, BSP Threaded & NPT Threaded

Equivalent Grades:

WERKSTOFF NR.: 1.7338

UNS: K11597

Trade Name: 1-1/4Cr-1/2Mo

Chemical Composition:

C: 0.15 max

Mn: 0.3-0.6

Si: 0.5-1

P: 0.03 max

S: 0.030 max

Cr: 1-1.5

Mo: 0.044-0.65

Mechanical Properties:

Tensile Strength: 415 MPa

Yield Strength (0.2% Offset): 205 MPa

Elongation: 20%

PRODUCT OVERVIEW:

Manilaxmi Industrial produces an extensive range of Alloy Steel F11 Forged Fittings, including but not limited to:

Forged Socket Weld Equal Tee

Threaded Fittings

Forged Threaded 90° Elbow

Socket Weld Fittings

Forged Threaded Union

Plug and Hex Bushing

High-Pressure Forged Pipe Fittings

These fittings are meticulously manufactured to meet both domestic and international standards, ensuring reliability and quality. Available in various dimensions, these products cater to the specific requirements of different industrial applications.

CONCLUSION:

Manilaxmi Industrial stands out as a trusted manufacturer and supplier of Alloy Steel F11 Forged Fittings, delivering products that exemplify quality, durability, and performance. With a commitment to maintaining high standards and continuous innovation, Manilaxmi Industrial ensures that its fittings meet the evolving needs of various industries.

For inquiries or to place an order, contact us via email at [email protected] or call us at +91-7710800415. Visit our website at www.manilaxmifittings.com for more information.

0 notes

Text

ASTM B473 Alloy 20 Round Bar Supplier & Stockist | Anand steels

In the area of commercial substances, excessive-performance alloys are essential, especially in environments that call for superb corrosion resistance and mechanical strength. Among these, Alloy 20, distinct underneath ASTM B473, is a standout desire for lots programs. Anand Steel, a leading dealer and stockist, is well-identified for imparting top-first-rate ASTM B473 Alloy 20 Round Bars, Alloy 20 Hexagonal Bars, and other high-overall performance alloys. This blog delves into the advantages, programs, and specifics of those substances, along side the exceptional services presented with the aid of Anand Steel.

Understanding ASTM B473 Alloy 20

What is Alloy 20?

Alloy 20, also called Carpenter 20, is a nickel-iron-chromium austenitic alloy designed more often than not for maximum resistance to acid attack, particularly sulfuric acid. This alloy is a part of the superalloy category and is surprisingly valued for its fantastic resistance to pitting, chloride ion corrosion, and sulfuric acid.

Key Properties

- Corrosion Resistance: Alloy 20 is mainly proof against sulfuric acid, making it a top desire for chemical processing industries.

- Mechanical Strength: This alloy continues top notch mechanical houses in high-temperature environments.

- Fabrication Ease: Alloy 20 can be fabricated and welded using traditional techniques, including its versatility.

ASTM B473 20 Alloy Round Bar

Overview of ASTM B473

ASTM B473 is a specification that covers nickel-iron-chromium-molybdenum-copper alloy (UNS N08020) bar and twine. These materials are in particular designed to be used in exceptionally corrosive environments.

Applications

- Chemical Processing: Utilized in warmth exchangers, blending tanks, and technique piping that handle sulfuric acid and other harsh chemicals.

- Food and Pharmaceutical Industries: Used in system and machinery wherein excessive ranges of sanitation and corrosion resistance are required.

- Power Generation: Suitable for use in warmness exchangers and other components uncovered to harsh working conditions.

ASTM B473 Alloy 20 Hexagonal Bars

Features and Uses

ASTM B473 Alloy 20 Hexagonal Bars provide the same top notch corrosion resistance and mechanical homes as spherical bars however are often utilized in programs wherein particular geometric shapes are required for meeting or structural functions.

Key Applications

- Construction: Used in frameworks and assist systems requiring high corrosion resistance.

- Marine Environments: Ideal for components exposed to seawater and other marine situations.

- Petrochemical Industry: Utilized in components that handle chemical reactions and excessive-temperature tactics.

Comparing ASTM B473 Alloy 20 and ASTM B408 Inconel Round Bars

What is ASTM B408 Inconel?

ASTM B408 Inconel Round Bars covers nickel-iron-chromium alloys (Inconel), recognized for his or her excessive power and resistance to oxidation and corrosion at high temperatures.

Inconel UNS N08 718 Round Bars

- Composition: Inconel 718 is a nickel-chromium alloy with additions of molybdenum and niobium, which give excessive energy and correct corrosion resistance.

- Applications: Primarily utilized in aerospace, gas generators, and different excessive-temperature business packages.

Key Differences

- Corrosion Resistance: While each alloys offer incredible corrosion resistance, Alloy 20 is advanced in sulfuric acid environments, while Inconel is more suited for excessive-temperature oxidizing situations.

- Temperature Stability: Inconel 718 can face up to better temperatures in comparison to Alloy 20, making it perfect for packages concerning severe heat.

Anand Steel: Your Trusted Supplier and Stockist

A reputable supplier and stockist of excessive-performance alloys, which includes ASTM B473 Alloy 20 Round Bars and ASTM B408 Inconel Round Bars. Here are some reasons why Anand Steel is a preferred preference:

- Quality Assurance: Ensures that all products meet stringent exceptional standards and specs, presenting reliability and overall performance.

- Extensive Inventory: They hold a complete stock of Alloy 20 and Inconel bars, making sure of quick availability and prompt transport.

- Technical Expertise: Group possesses deep technical know-how, offering professional recommendation and solutions tailor-made to purchaser wishes.

- Customer Support: They offer incredible customer support, from product selection to after-sales support, making sure an unbroken and fine experience.

Applications of Products

- Chemical Plants: Utilized in critical additives like reactors, piping systems, and heat exchangers to handle corrosive chemicals.

- Oil and Gas Industry: Employed in drilling devices, pipelines, and processing flora exposed to harsh environments.

- Aerospace: Inconel round bars are used in turbine engines and other components that require excessive-temperature resistance and durability.

Conclusion

ASTM B473 Alloy 20 Round Bars and ASTM B408 Inconel Round Bars are important substances in industries requiring excessive corrosion resistance and mechanical electricity. Alloy 20, with its superior resistance to sulfuric acid and different harsh chemical substances, is a crucial cloth for chemical processing and related industries. In assessment, Inconel 718 is right for excessive-temperature programs in the aerospace and strength era.

Anand Steel stands proud as a leading provider and stockist of those high-performance alloys in Saudi Arabia. Their dedication to nice, full-size inventory, technical expertise, and excellent customer support lead them to the pass-to preference for all your alloy wishes. Whether you're in the chemical processing enterprise, oil and fuel area, or aerospace, you need the right solution for your precise requirements. By choosing Anand Steel, you ensure that your tasks are ready with the great materials, contributing to their achievement and durability.

#ASTM B473 20 Alloy Round Bar#ASTM B473 Alloy 20 Hexagonal Bars#ASTM B408 inconel round bars#Inconel UNS N08 718 round bars

0 notes

Text

2.4683Sheet

2.4683 Sheet in India, 2.4683 Sheet Importers in India, 2.4683 Sheet Suppliers in India, 2.4683 Sheet Exporter in India, 2.4683 Sheet Stockists in India.

2.4683 / Alloy 188, commonly known as Haynes 188 or UNS R30188, presents itself as a cobalt-nickel-chromium-tungsten alloy renowned for its exceptional resistance to oxidizing environments, enduring temperatures up to 1095°C. Exhibiting remarkable high-temperature resilience, it serves as a stalwart companion for long-term usage, showcasing impeccable resistance to hot corrosion caused by sulfate deposits. Ease of manufacturing through conventional techniques further enhances its allure.

This alloy boasts a spectrum of significant properties, including outstanding resistance to molten chloride salts and commendable resilience against gaseous sulfidation. The moniker UNS R30188 underscores its cobalt-based superalloy nature, coupled with favorable forming and welding attributes. Its inherent ductility allows for facile cold working, albeit requiring caution due to rapid work-hardening, necessitating periodic intermediate annealing for intricate component formation.

Critical to note is the imperative of annealing all hot or cold worked parts followed by rapid cooling to achieve equilibrium. The welding process, both manual and automatic, is viable for this alloy. Solution heat treatment at temperatures ranging from 1163 to 1191°C, followed by rapid cooling or water quenching, optimizes its properties. Annealing at temperatures below the solution heat treatment threshold may precipitate carbides, affecting material properties.

The versatile properties of 2.4683 / Alloy 188 / Haynes 188 render it apt for various fabrication component applications within the aerospace industry. It finds extensive utility in military and commercial gas turbine engines, particularly in combustion boxes, transition ducts, and afterburner components. Furthermore, it emerges as a preferred choice in novel engine programs, exemplifying its adaptability and efficacy in demanding operational environments.

Superalloy Overview:

Group: Cobalt Base

W.Nr.: 2.4683

US: R30188

Brand Name: Conicro 4023 W

Specifications: CoCr22NiW

Explanation: Heat resistant cobalt base alloy with nickel and chromium. Exhibits excellent mechanical properties up to 1150°C. Also known as Alloy 188 or Haynes 188.

Chemical Composition (2.4683 / Alloy 188 / Haynes 188):ElementMinimum (%)Maximum (%)C0.050.15And0.200.50Mn-1.25P-0.02S-0.015Cr20.024.0In20.024.0W13.016.0CoRemainder-Fe-3.00The0.020.12

Note: The provided information serves as an explanation and does not guarantee material properties.

Forms and Dimensions:

SAC (Cold Rolling):

Thickness (mm): 0.5 - 8

Width (mm): ≤ 300

Length (mm): ≤ 3000

SAC (Hot Rolling):

Thickness (mm): 9 - 30

Width (mm): Production width

Length (mm): Production length

Strip:

Thickness (mm):

0.10 - 0.5

0.50 - 1.2

1.2 - 8.0

Width (mm):

15 - 250

20 - 250

20 - 270

KANGAL I.D. (mm):

≤ 125, 175, 300

≤ 300, 400

500

Coil Weight (kg):

Max. 250

Max. 500

Max. 800

Rod:

Print (mm): 10 - 350

Length (mm): 1000 - 5000

For more information:

Visit our website: https://www.aluminiumwala.com/

Email I'd: [email protected]

Contact no: 916 734 7029

0 notes

Text

Reliable Overseas - Leading Supplier of Stainless Steel 446 Round Bars

Reliable Overseas stands as a premier supplier of stainless steel 446 round bars, providing high-quality materials for a range of industrial applications. The significance of stainless steel 446 lies in its exceptional resistance to oxidation and sulfidation, making it a preferred choice for environments subjected to high temperatures and corrosive elements.

Company Overview

History and Establishment

Reliable Overseas was established in 2010, with a mission to deliver top-notch steel products to various industries. Over the years, the company has built a reputation for reliability and excellence in the supply chain.

Core Values

Quality Assurance: Committed to providing only the best quality products.

Customer Satisfaction: Focused on building long-term relationships with clients.

Innovation: Continuously improving and adapting to market needs.

Market Reach

With a global footprint, Reliable Overseas serves clients across multiple continents, ensuring timely delivery and robust after-sales support.

Product Specifications

Material Composition

Stainless steel 446 is an alloy primarily composed of:

Iron (Fe)

Chromium (Cr): 23-27%

Molybdenum (Mo): Enhances corrosion resistance

Physical Properties

Density: 7.7 g/cm³

Melting Point: 1425-1510°C

Thermal Conductivity: 26 W/m·K at 100°C

Mechanical Properties

Tensile Strength: 485 MPa

Yield Strength: 275 MPa

Elongation: 20%

Applications

Industrial Uses

Stainless steel 446 round bars are ideal for:

High-Temperature Furnaces: Due to their excellent heat resistance.

Chemical Processing Equipment: Resistant to aggressive chemicals.

Petrochemical Industry: Withstands corrosive environments.

Construction

Used in the construction of:

Bridges and Structures: For durability and longevity.

Architectural Applications: Provides a sleek and modern aesthetic.

Benefits of Stainless Steel 446

Corrosion Resistance

Stainless steel 446 offers superior resistance to oxidation and sulfidation, extending the lifespan of components exposed to harsh conditions.

Heat Resistance

Capable of withstanding high temperatures, it is suitable for applications involving extreme heat.

Longevity and Durability

The material's robust nature ensures a longer lifespan, reducing the need for frequent replacements and maintenance.

Quality Assurance

Certification

Reliable Overseas adheres to international quality standards, including:

ISO 9001: Ensuring consistent quality management.

ASTM Standards: Compliant with ASTM A276 and A479 specifications.

Testing and Inspection

Each batch undergoes rigorous testing, including:

Chemical Analysis: Verifying material composition.

Mechanical Testing: Ensuring strength and durability.

Visual Inspection: Checking for surface defects.

Customer Testimonials

Case Study 1: Chemical Plant

A leading chemical plant reported a significant increase in equipment lifespan after switching to stainless steel 446 round bars supplied by Reliable Overseas, highlighting the material's superior performance.

Case Study 2: Heat Treatment Facility

A heat treatment facility praised the high-temperature resistance of the stainless steel 446 round bars, noting improved operational efficiency and reduced downtime.

Expert Insights

Metallurgist's Perspective

Dr. John Doe, a renowned metallurgist, emphasizes the advantages of stainless steel 446 in high-temperature applications, citing its stable microstructure and resistance to thermal fatigue.

Industry Analyst

Jane Smith, an industry analyst, notes the growing demand for high-performance materials like stainless steel 446 in emerging markets, driven by advancements in industrial technologies.

Conclusion

Reliable Overseas is your trusted partner for high-quality stainless steel 446 round bars. With a commitment to excellence and a focus on customer satisfaction, they provide materials that meet the highest standards of performance and reliability.

#Stainless Steel 422 Bright Bars#Stainless Steel 316L Round Bars#Stainless Steel 304 Round Bars#Stainless Steel 446 Round Bars#Super Duplex Steel UNS S32760 Round Bars#Monel 400 Round Bars#Inconel 600 Round Bars#Hastelloy C276 Round Bars#Stainless Steel 446 Tubes#Stainless Steel 446 Sheets and Plates

0 notes

Text

Alloy Steel Astm A691 1CR Seamless Pipes Exporters In India

Introduction

Alloy Steel ASTM A691 1CR Seamless Pipes fall within the scope of the A691 specification, which covers both alloy steel pipes and carbon steel pipes fabricated through fusion welding with filler materials. As Manufacturers, Suppliers, Stockists, and Exporters, Metinox Overseas provides a wide range of ASTM A691 pipes to meet diverse industrial requirements.

Description

Metinox Overseas offers a comprehensive range of Alloy Steel ASTM A691 1CR seamless pipes. These pipes are meticulously engineered to meet the rigorous requirements of various industrial sectors, including power generation, oil and gas, petrochemicals, and chemical processing. The 1CR designation signifies the alloy's chromium content, which imparts excellent mechanical properties and resistance to high temperatures and corrosion.

Alloy Steel Astm A691 1CR Seamless Pipes Specifications

GradeAlloy Steel ASTM A691 Cl22, A691 GRADE 1 CR, GRADE 1/2 CR, GRADE 1 1/4 CR, GRADE 2 1/4 CR, GRADE 3 CR, GRADE 5 CR, GRADE 9 CR, GRADE 91, CM 65, CM 70, CM 75Size1/2” NB to 36” NBThickness3-12mmSchedulesSCH5, SCH10, SCH10S, SCH20, SCH30, SCH40, SCH40S, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXSClass DesignationClass 10, 11, 12, 13, 20, 21, 22, 23, 30, 31, 32, 33, 34, 40, 41, 42, 43, 50, 51, 52, 53, 60, 61, 62, 63, 70, 71, 72, 73ASTM A691 GradesASTM A691 Gr 11, ASTM A691 Gr.91, ASTM A691 9cr, ASTM A691 5cr, ASTM A691 1 1/4cr Cl22, ASTM A691m, ASTM A691 Gr.5cr Cl22, ASTM A691 Cm70, ASTM A691 Class 22, ASTM A691 Class 42, ASTM A691-91, ASTM A691 Grade 2.1/4cr, ASTM A691 11/4cr Cl22OriginEuropean, Japanese, Korean, US, Russian, Indian (Strictly No Chinese Material)ToleranceCold drawn pipe: +/-0.1mm Cold rolled pipe: +/-0.05mmCraftCold rolled and Cold drawnTypeSeamless / ERW / Welded / Fabricated / LSAW Pipesavailable in Form ofRound, Square, Rectangular, Hydraulic Etc.LengthStandard Double & In Cut length also.EndPlain End, Beveled End, TreadedSpecialized inLarge Diameter ASTM A691 PipeAdditional TestingNACE MR 0175, NACE TM0177, NACE TM0284, HIC TEST, SSC TEST, H2 SERVICE, IBR, etc.ApplicationSeamless Ferritic Alloy-Steel Pipe for High-Temperature Service

Benefits

The Alloy Steel ASTM A691 1CR seamless pipes from Metinox Overseas provide a multitude of advantages, such as:

Exceptional Strength: These pipes are designed to endure high-pressure environments, making them suitable for critical applications.

Corrosion Resistance: The chromium content enhances the pipes' resistance to oxidation and corrosive elements, ensuring longevity and reliability.

High-Temperature Stability: These seamless pipes maintain their mechanical integrity even at elevated temperatures, ideal for high-heat applications.

Versatility: Available in various sizes and specifications, these pipes can be customized to meet diverse industrial requirements.

Cost-Effective: The durability and low maintenance needs of these pipes lead to significant cost savings over their lifespan.

Product Overview

Alloy Steel ASTM A691 1CR Seamless Pipes

Grade 1CR pipes are distinguished by their composition, which includes 1% chromium. This specific alloying element enhances the pipes' mechanical properties, making them suitable for high-temperature and high-pressure applications. These pipes are widely utilized in industries such as power plants, oil refineries, and chemical processing facilities, where superior performance under harsh conditions is crucial.

Conclusion

Metinox Overseas is a leading exporter of Alloy Steel ASTM A691 1CR seamless pipes in India, dedicated to providing high-quality products that adhere to international standards. By focusing on customer satisfaction and maintaining a robust product portfolio, Metinox Overseas ensures that clients receive dependable and durable solutions tailored to their specific needs.

For more information or to place an order, contact Metinox Overseas at:

Phone: +91-98199 80997 / +91-70212 61928

Experience the unparalleled quality and performance of Alloy Steel ASTM A691 1CR seamless pipes with Metinox Overseas, your reliable partner in industrial solutions.

0 notes

Text

Titanium Gr 9 Sheets & Plates Stockists In India

Navneet Metal Corporation needs a dependable load of the brilliant thought of Titanium Gr 9 Sheets and Plates that we have given from one side of the world to the other. This thing is basically versatile. As such, they are appropriate for any sort of progress that will be finished by the basics of our clients. It very well may be related to its size, perspective, shape, plan, finish, thickness, and so on. In any case, they are all around used in the arrangement of explicit planes and flight body parts. Other than that, they are referenced in different sections of business and present-day business regions.

In any case, with its pocket-obliging nature, it also advances towards the family or nearby purposes. Titanium Gr 9 Sheets and Plates can be helped through an assortment of hardness ranges such as hard, delicate, half-hard, quarter-hard, spring-hard, and so on. Besides, it appears in a variety of types, like plain sheets, shim sheets, checkered plates, pads, and so forth. Besides, it also stays aware of the arrangement of completing abilities such as hot-moved plates, cold-moved sheets, 2B, 2D, BA, Silk, and so forth.

Grade 9 has enormous applications in sugar associations, oil and gas attempts, petrochemicals, and power plant experiences. It is really usable, and as such, it is similarly found in the space of composts, substance processors, drugs, food, and dairy associations. Also, they are not abandoned in thermal energy stations.

This thing has an extension area of up to 20%. They comparably have a moderate degree of both sensibleness and yield strength. Its moulding point is 1665 degrees Celsius (or 3030 Fahrenheit). There are managing rules for the competent focal points concerning substance as well as certifiable properties. Those are ASTM A265 and AMSE SB 265. The alloy arrangement of this tempered steel grade is piled up with parts like carbon, nitrogen, oxygen, hydrogen, titanium, and ferrous iron. Oxygen and iron, being the basic partners in creation, give it unprecedented oxidising obstruction and solidifying credits. Titanium Gr 9 Sheets and Plates also present the documentation as PMI reports, fumigation test reports, 100 percent radiography test checks, 100 percent unadulterated rough substance articulations, designed mechanical appraisal reports, and so forth.

0 notes

Text

Alloy 20 Flanges Stockists In India

Introduction: In the intricate tapestry of industrial infrastructure, Alloy 20 Flanges stand out as essential components, revered for their exceptional corrosion resistance, durability, and versatility. Within India's dynamic manufacturing landscape, numerous stockists specialize in providing high-quality Alloy 20 Flanges, catering to the diverse needs of industries worldwide. With an unwavering commitment to quality assurance, reliability, and customer satisfaction, these stockists fortify India's reputation as a premier exporter of alloy steel products.

Benefits of Alloy 20 Flanges: Alloy 20 Flanges offer a myriad of benefits that make them indispensable in various industrial applications. Renowned for their exceptional resistance to corrosion, particularly in acidic and corrosive environments, these flanges ensure longevity and reliability in critical operations. Their superior mechanical properties, including high tensile strength and impact resistance, make them suitable for demanding conditions such as chemical processing, pharmaceuticals, and petrochemicals. Additionally, Alloy 20 Flanges exhibit excellent weldability and formability, facilitating easy fabrication and installation. Their compatibility with a wide range of fluids and chemicals further enhances their versatility and suitability for diverse industrial settings.

Countries Importing Alloy 20 Flanges from India: India's expertise in manufacturing Alloy 20 Flanges has positioned it as a preferred supplier for countries worldwide. Importers from nations including the United States, United Kingdom, Germany, United Arab Emirates, and Singapore recognize the superior quality and reliability offered by Indian stockists. These countries rely on India's robust manufacturing infrastructure, stringent quality control measures, and competitive pricing to fulfill their industrial requirements. With India's unwavering commitment to continuous improvement and customer satisfaction, Alloy 20 Flanges stockists contribute significantly to global supply chains, fostering mutually beneficial trade relationships and driving industrial growth.

Conclusion: In conclusion, Alloy 20 Flanges stockists in India play a pivotal role in supplying top-quality components to industries worldwide. With a focus on excellence, reliability, and customer-centric solutions, these stockists uphold India's reputation as a dependable exporter of alloy steel products. As industries continue to prioritize corrosion resistance, durability, and versatility in their infrastructure projects, Alloy 20 Flanges stockists remain poised to meet their needs with steadfast dedication and expertise.

For more details

Email: [email protected]

Contact: 8779038854

If any enquiries please contact us our support team will connect you as soon as possible.

#Alloy 20 Flanges Manufacturers#Alloy 20 Flanges Suppliers#Alloy 20 Flanges Stockists#Alloy 20 Flanges Exporters#Alloy 20 Flanges Manufacturers In India#Alloy 20 Flanges Suppliers In India#Alloy 20 Flanges Stockists In India#Alloy 20 Flanges Exporters In India

0 notes

Text

Alloy 20 Sheets And Plates Exporters In India

INTRODUCTION:-

Shasan Piping Solution is a dependable Manufacturers, Exporters, and Suppliers of the a wide range of mechanically utilized items. We are giving the awesome nature of Alloy 20 Sheets and Plates to our regard benefactors for fulfilling their various requests. We are the client's aggressive industry that is giving something similar to our clients at various principles, details, sizes, wall thickness, surface gets done, and shapes.

BENEFITS:-

Alloys is the material that is chromium, nickel, and iron-based austenitic compound. It is made for guaranteeing the higher protection from the corrosive assaults, especially to the sulfuric corrosive. This material is having excellent opposition capacity to the overall consumption, cleft erosion and pitting too. Likewise, it opposes sulfuric corrosive, phosphoric corrosive, and nitric corrosive. Likewise, it is containing niobium for the adjustment against the sharpening.

SPECIFICATION:-

Alloy 20 Sheets and Plates Specification : ASTM B463 / ASME SB463

Dimension Standard : JIS, AISI, ASTM, GB, DIN, EN, etc

Width : 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length : 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Thickness : 0.3 mm to 120 mm

Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc.

Surface Finishing : Hot rolled plate (HR), Cold rolled sheet (CR),2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, Chequered, embossed, hair line, sand blast, Brush, etching, SATIN (Met with Plastic Coated) etc.

PRODUCT OVERVIEW:-

The produced scopes of Alloy 20 Sheets and Plates are having numerous great properties to offer in view of which it has turned into an ideal fit for various purposes. The properties found in it are high elasticity, great layered precision, predominant surface completions, rough development, high strength, long usefulness, non-destructive body, endure high temperature, and so on.

CONCLUSION:-

Today Alloy 20 Sheets and Plates are widely utilized in numerous modern applications. It resembles heat exchangers, condensers, mash and paper industry, petrochemicals, drugs, specialty synthetics, substance industry, oil and gas handling, seawater applications, cars, building, and developments.

Alloy 20 Sheets and Plates are completely quality tried before dispatched from our industry. The tests are significantly finished for really looking at the item strength. The tests are pitting erosion tests, strength tests, positive material ID tests, and so on. The bundling of the equivalent is finished in wooden beds for more secure transportation.

CONTACT US:-

+91 22-6651 8642

EMAIL ID: [email protected]

WEBSITE: https://www.shasanpiping.com/alloy-20-sheets-and-plates-manufacturers-exporters-suppliers-stockists.html

#"Alloy 20 Sheets and Plates Manufacturers#Alloy 20 Sheets and Plates Suppliers#Alloy 20 Sheets and Plates Stockists

0 notes

Text

Did you know that what is Die Steel?

Die steel, also known as tool and die steel, is a specialized type of steel designed for use in the production of dies, molds, and other tooling used in manufacturing processes. Dies and molds are used to shape, cut, or form materials such as metals, plastics, and ceramics in various industrial applications. Die steel needs to have specific properties to withstand the harsh conditions of these processes.

Key characteristics of die steel include:

Hardness: Die steel is typically hardened to resist wear and deformation. This is crucial because dies and molds are subjected to repeated cycles of stress, pressure, and friction during manufacturing processes.

2. Toughness: In addition to hardness, die steel must also possess toughness to resist cracking or chipping under high impact loads. This is important for maintaining the integrity and longevity of the dies.

3. Heat resistance: Many manufacturing processes involve high temperatures, so die steel must be able to withstand elevated temperatures without losing its hardness or other mechanical properties.

4. Wear resistance: Die steel should have good wear resistance to maintain its shape and effectiveness over time, especially when used in high-volume production settings.

5. Corrosion resistance: Although not always a primary concern, some die steels may also be designed to resist corrosion, especially when used in environments where exposure to moisture or corrosive substances is a concern.

Die steels are often classified based on their intended use and specific properties, and different grades of die steel may be chosen based on the requirements of a particular application. The selection of the appropriate die steel is crucial for achieving high-quality and cost-effective manufacturing processes.

VIRAT SPECIAL STEELS is leading Tool Steel & Die Steel Importer, Exporter, Stockiest, Distributor and Supplier in India.

Product List

HOT WORK STEEL ( HH 370 - 410 BHN ) (DIN-1.2714 / AISI L6 )

HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

For more information visit

https://www.viratsteels.com/

Any further queries feel free to contact us :

Email: [email protected] or Call: +91 98140 21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#diesteels#diesteelsuppier#diesteel#die steels#diemouldsteels#db6 steel#h13steel#h11steel#p20steels#p20

2 notes

·

View notes

Text

Advantages and disadvantages of alloy steel and high carbon steel

1. in industrial production, high carbon steel and alloy steel are two commonly used metal materials, they each have unique performance characteristics. High carbon steel is widely used in various fields because of its low cost and good processing performance. However, the hardenability of high carbon steel is relatively poor, especially when water quenching is performed, and its critical quenching diameter is usually between 15 and 20 mm. This means that for large parts with a diameter of more than 20 mm, even using the water quenching process, it is difficult to ensure uniform mechanical properties across the section. Therefore, high carbon steel may not be the best choice when manufacturing large parts with high requirements. In contrast, alloy steel, due to its excellent hardenability, can be used to produce large sections and complex shapes to meet the more demanding industrial requirements.

2. in the high temperature environment, the performance of high carbon steel will also be limited. Specifically, when high carbon steel is used at temperatures above 200 degrees Celsius, its strength and hardness rapidly decrease, which limits its application in high temperature conditions. After the alloy steel is tempered, not only the stability is better, but also the red hardness has been significantly improved, so that it can maintain the working performance at higher temperatures.

3. high carbon steel in the pursuit of comprehensive performance also has limitations. For example, when trying to balance strength and toughness by tempering treatment, it is often difficult to achieve the desired results. If higher strength is to be guaranteed, it may lead to reduced toughness; On the contrary, if the pursuit of better toughness, the strength may be insufficient. This phenomenon is mainly due to the poor tempering stability of high carbon steel. In contrast, alloy steel can obtain better comprehensive properties of strength and toughness through reasonable alloying element ratio and heat treatment process.

4. In addition, high carbon steel is not as good as alloy steel in terms of special properties. For example, for applications requiring high temperature hardness, tensile strength, oxidation resistance, corrosion resistance or special electromagnetic properties, high carbon steel often cannot meet these special requirements, and must rely on alloy steel to achieve. Nevertheless, high carbon steel still has its advantages, such as by adjusting the carbon content and appropriate heat treatment, many properties required for industrial production can be obtained. Due to its low price, easy production and good processing properties, high carbon steel is still one of the most widely used steel materials in industry, accounting for more than 80% of the total steel consumption.

The selection principle of alloy steel and high carbon steel is to make up for the lack of high carbon steel, by adding specific alloying elements on the basis of high carbon steel, a variety of alloy steel with the required properties can be developed. Although alloy steel has many excellent and even special properties that make it a very important steel class that can meet the needs of many applications, there are also some disadvantages of alloy steel. The main disadvantages include: the addition of alloying elements makes the smelting and processing properties of steel relatively complicated, and the cost is high. Therefore, under the principle of reasonable material selection, if high carbon steel can meet the requirements of use, priority should be given to the use of high carbon steel.

We have a deeper understanding of the differences between alloy steel and high carbon steel, advantages and disadvantages, and selection principles. Because a variety of different metal elements can be added to alloy steel, making it far more functional than high-carbon steel, alloy steel is more common in practical applications. For example, cutting tools such as drills, taps, reamers, etc., are usually made of high carbon steel with a carbon content of 0.90% to 1.00%. In general, alloy steel and high carbon steel have their own strengths, there is no absolute advantages and disadvantages, the key is to choose the most appropriate material according to the specific conditions and environment.

0 notes

Text

Top Features Of Forged Fittings You Should Look For

Forged fittings are crucial to ensuring your piping systems will last long. These components play a vital role in connecting and securing pipes, determining the overall efficiency and reliability of your industrial or plumbing setup. At Bullion Pipes & Tubes LLP, we take pride in being the leading manufacturer, supplier, stockist, and exporter of forged fittings globally. Our extensive range, available in various sizes, specifications, standards, grades, materials, and types, empowers you to select fittings tailored to your project needs.

This blog post will explore the top features you should look for in forged fittings to ensure optimum performance and durability.

Forged Fittings

Forged fittings are components used in piping systems that are manufactured by shaping solid steel or alloy billets under high pressure and heat. This process enhances the fittings' strength and durability, making them suitable for high-pressure applications in industries such as oil and gas, chemical, and power generation. Common types include forged elbows, tees, unions, and many more. The forging method ensures better mechanical properties and dimensional accuracy compared to cast fittings, making forged fittings highly reliable and resilient in demanding environments.

Here are the top features of forged fittings you should look out for!

Material Quality:

The foundation of any reliable forged fitting lies in its material composition. Opt for fittings crafted from high-quality materials such as Stainless Steel, Titanium, Carbon Steel Forged Fittings, Inconel Forged Fittings, Alloy Steel Forged Fittings, Aluminium forged fittings, Nickel Forged Fittings, SMO 254 Forged Fittings, Duplex Steel Forged Fittings, Hastelloy Forged Fittings. Super Duplex Steel forged Fittings, Incoloy Forged Fittings, and Alloy 20 Forged Fittings. These materials not only provide excellent corrosion resistance but also ensure the fittings can withstand extreme temperatures and pressures, making them ideal for a wide range of applications.

Precision Manufacturing for Reliability:

Our forged fittings undergo advanced forging techniques to guarantee precision in manufacturing. This results in fittings with dimensional accuracy and consistency, providing a secure and reliable connection. The tight fit minimizes the risk of leaks, contributing to the overall structural integrity of your piping system.

Threaded or Socket Weld Options:

Choose forged fittings that offer flexibility in installation. Threaded and socket weld options are popular, each catering to specific requirements. Threaded fittings are easy to install and dismantle, while socket weld fittings provide a more robust connection, ideal for high-pressure applications. Assess your project needs to determine which type of fitting suits your requirements best.

Pressure and Temperature Ratings:

Different applications demand varying pressure and temperature requirements. Ensure the forged fittings you select are designed to handle the specific conditions of your project. Manufacturers provide detailed specifications regarding pressure and temperature ratings, helping you make an informed decision based on your system's operational parameters.

Corrosion Resistance:

Corrosion can significantly compromise the longevity of a piping system. Opt for forged fittings with excellent corrosion resistance properties, especially if your application involves exposure to harsh chemicals or corrosive environments. Stainless steel fittings, for example, are renowned for their corrosion resistance, making them a popular choice in diverse industrial settings.

Strict Adherence to Industry Standards:

We understand the importance of quality and reliability in your projects. That's why our forged fittings conform to industry standards such as ASME, ASTM, and ANSI. This commitment to compliance ensures that you receive fittings that meet the highest quality benchmarks in the industry.

Applications of Forged Fittings

Forged fittings are essential components in various industries due to their strength, durability, and reliability. These fittings are created by shaping metal through localized compressive forces, typically involving heat and mechanical processes. Here are some applications of forged fittings:

Oil and Gas Industry

Chemical Processing Plants

Power Generation

Shipbuilding

Aerospace Industry

Petrochemical Industry

Automotive Sector

Construction and Infrastructure

Mining Industry

Nuclear Power Plants

Other Applications

Final Words!

Choosing the right forged fittings is a critical decision that impacts the efficiency and longevity of your piping systems. At Bullion Pipes & Tubes LLP, we offer a comprehensive range of forged fittings designed to meet the unique demands of your projects. With premium materials, precision manufacturing, and a commitment to industry standards, our fittings are your guarantee of a resilient and high-performing piping infrastructure.

Moreover, we are also a well-known forged fittings Exporter all across the globe in various countries like Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, Russia, and many other regions at the most reasonable price in the market. Contact us today at [email protected] or [email protected] for excellence in every fitting.

0 notes

Text

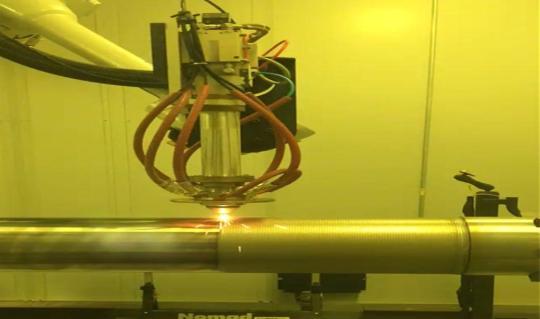

Laser Cladding Unlimited Guide

What Is Laser Cladding?

Laser cladding, also known as laser metal deposition, is a process for depositing one material on top of another. A stream of metallic powder or wire is fed into a melt pool formed by a laser beam as it scans across the target surface, producing a coating of the desired material.

The laser cladding method improves the surface properties of a part, such as wear resistance, and allows for the restoration of damaged or worn surfaces. One of the most accurate welding procedures is used to create this mechanical link between the base material and the layer.

Read More : Laser Cladding Powder Feeding Method Guide

Why is laser cladding an important manufacturing technology today?

By producing protective layers against wear and corrosion, laser cladding improves the performance of industrial items. Engineers may design parts with generic base metal alloys, which helps preserve natural resources. The component is then locally laser clad with a high alloyed material to provide the appropriate performance characteristics.

Laser cladding is also a method that is used to restore and remanufacture high-value components into their original shape. In addition to just fixing the shape of a part, choosing an additive material with superior wear characteristics than the original component improves service life and performance.

Arc Welding

Thermal Spray

Hard-Chrome Plating

Laser Cladding

Heat Input

High

Low

N/A (chemical process)

Low

Dilution Rate

10 – 40%

N/A(mechanical bonding)

No metallurgical bond

<5%

Hardness (HV)

Relatively Low

<1000

800 – 1000

>1000

Distortion

High

Low

N/A

Low

Heat Affected Zone

Large and wide

Low

N/A

Low

Quality

Less durable

Full of pores and less durable

Prone to chipping and delamination

Highly dense and Long life

Pre/Post Treatments

Many

Many

Many

Few

Automation

Difficult

Difficult

Difficult

Easy

Coat Thickness

>0.020”

0.020” – 0.040”

0.002” – 0.006”

>0.020”

Read More : Laser Cladding VS Thermal Spray

Advantages Of Laser Cladding

When compared to traditional coating methods, laser cladding has various benefits. The benefits of laser cladding include higher quality coating material (including high bond strength and integrity) with less distortion and dilution, as well as improved surface quality. These benefits include:

low laser exposure duration and depth

layer and basic material metallurgical relationship

Thermal spray coatings are less durable than layers.

good surface quality and little warpage, with virtually no post-processing required

High energy economy, quick laser cladding process duration

Can be utilized with a wide range of materials as both the substrate and the layer, including custom alloys or metal matrix composite (MMC) designs.

Within the deposits, there is little to no porosity (>99.9% density).

A narrow heat affected zone (EHLA as low as 10m) derives from a relatively low heat input.

The necessity for corrective machining is reduced when the substrate has little deformation.

Laser Cladding Classifications

There are many variations of laser cladding and laser cladding technology.

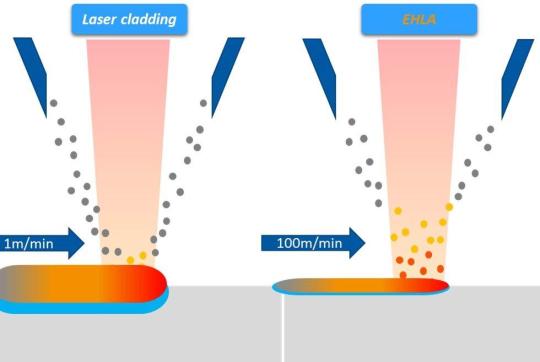

The powder is supplied into the path of the focussed laser beam above the substrate during the EHLA process. This ensures that the deposited material is already molten before making contact with the substrate; however, a very shallow melt pool remains on the substrate, allowing the deposited material to cool and solidify in contact with the underlying material, reducing the amount of heat reaching the component below as well as the depth of the dilution and heat effects.

This tiny dilution allows for the production of significantly thinner coatings (20-300m) that attain the necessary chemistry within 5-10m. This is also the foundation of EHLA’s high traversal speeds, which may surpass 100m/min.

Laser Cladding Target Materials

Laser cladding is possible with a range of metals, including:

Target Material

Typical Hardness (HV)

Thermal Stability (°C)

Application

High Strength Steels (M2, H13)

550 – 650

450 – 500

Tool repair

Rockit™

900 – 1100

–

Excellent substitution for hard chrome, high abrasion resistance at ambient temperature

SS309, SS316L

250 – 300

–

Used as root layer/build up, relatively good general corrosion resistance

SS420, SS431

550 – 600

500 – 550

Reasonable wear resistance

Stellite-6

550 – 600

500 – 550

Excellent galling, wear, erosion, and cavitation protection over a wide temperature range

Stellite-21

400 – 450

500 – 550

Superior thermal and mechanical shock resistance, relatively high resistance to galling and cavitation

Inconel-625

250 – 300

900 – 1000

Applied in extremely high corrosive environments, used as buffer layer

Inconel-718

400 – 450

600 – 650

Age hardenable, high temperature stability and corrosion protection, ideal for hot forging punch

NiCrSiB-65%WC

1500 – 2500

600 – 650

Extremely high abrasion/erosion resistance and excellent for part-to-part sliding wear due to relatively low friction coefficient

Colmonoy 69 (NiCrMoCu)

600 – 650

500 – 550

Excellent resistance to aluminum liquid erosion used in high pressure die cast

Ni80Cr20

300 – 350

1000 – 1100

Hot oxidation resistance

Aluminum-Bronze

200 – 300

350 – 400

Excellent galling resistance for cold forming tolls, good general corrosion resistance

Because of the variety of materials available, laser cladding may be utilized for a wide range of industrial applications, including quick manufacturing, component repair, and surface improvement. Tungsten carbide, for example, in an MMC, provides durability, making it perfect for coating applications requiring exceptional wear resistance.

Read More : Laser Cladding Powder Unlimited Guide

Application Of Laser Cladding

Laser cladding is useful for a wide range of industrial applications. These uses range from agriculture and aerospace to drilling, mining, and power generation.

Flanges

Seats

Wear Sleeves

Pumps

Glass Molds

Seal/Bearing Journals

Impellers

Rotor Shafts

Pump Shafts

Compressor Wheels

Gearbox Housing

Propeller Shafts

Exhaust Valves

Rolls

Crank Shafts

Engine Components

Mandrels

Drilling tools

High-performance drilling instruments are required for the development of oil and gas reserves. These are subjected to extreme stress and would not have extended lifespans if not protected against wear. That is why, for some time now, special coatings, which are increasingly being achieved with laser coating technology, have become the norm.

Learn More

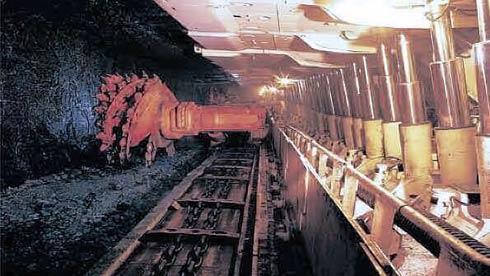

Coating of hydraulic cylinders for the mining industry

Laser coating of hydraulic cylinders in technological mining operations such as coal extraction is a rising business. The cylinder’s coating corrodes fast in the local climate, resulting in leaks, thus a replacement or fresh coating will be required.

Until recently, chromium plating was the dominant approach, but laser coatings will gradually replace it because of their greater endurance. The particular improvement in durability cannot yet be defined, although current data reveal a higher than 100% increase in lifespan.

Learn More

Cutting Tools

Layers of laser clad materials can be utilized to protect saw blades, counter blades, disc harrows, and other cutting instruments from wear and corrosion while also offering enhanced cutting properties. Because of the lack of distortion in this technique, these tools remain straight while variable coating thicknesses may be obtained to meet needs. These coated tools may be used in a variety of industries, including construction and agriculture.

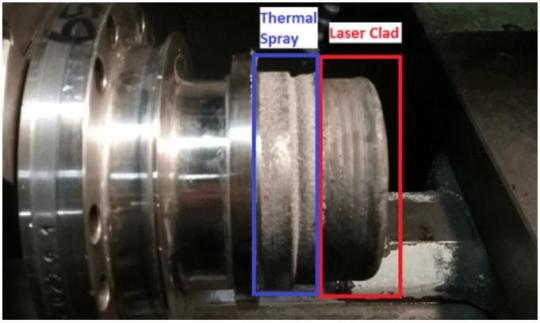

Proven Solution for Hot Mill Rolls used in Steel Making Industry

Rolling steel is a procedure that pushes the performance boundaries of the rolling equipment’s components. Roller and other component failures can be caused by abrasion wear, heat stress, and galling, resulting in downtime and quality concerns. Because of the wide temperature range, a high hardness, low friction solution is required.

Haitian Laser Machinery provides a tried-and-true solution for increasing the service life of hot mill rollers. Customers who have used our laser cladded carbide-based overlays have experienced a 6x increase in service life when compared to thermal spray or arc welding, resulting in decreased operating costs and downtime.

Learn More

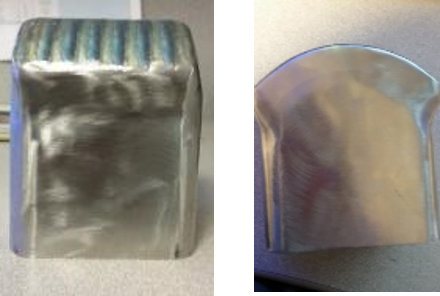

Bottom Punch/Magnet Dies

When producing magnets for motors, the magnet material is blended in a slurry and placed in a die. The slurry is then forced into the magnet die, forcing all of the water/contaminants out. These punches must have non-magnetic tips to avoid interfering with the polarity of the magnet. Furthermore, the dies are vulnerable to significant metal-to-metal wear.

Stellite 6 was traditionally applied to the top surface using GTAW. The dilution line between the base material (W2 steel) and the substrate (Stellite 6) was, however, choppy, and the manual procedure was time intensive (about 1 hour each punch).

To boost efficiency, HaiTian developed an automated approach. A coaxial powder feed laser head was employed in the solution, and bespoke programming was used to map the clad/layer routes.

HaiTian was able to construct a Stellite 6 buildup with a very clear dilution line between the parent and clad material, as well as a cladding in 15-20 minutes rather than 1 hour. As a result, this automated approach significantly increased quality and efficiency.

Wind Turbine Centrifuge Hubs/Shafts

Wind turbine hubs and shafts wear owing to load fluctuation caused by changes in wind speed/intensity. Because of this wear, gearboxes might break early, resulting in expensive replacement costs.

HaiTian used laser cladding on worn hubs, journals, and shafts before machining them to original design specifications. Stainless steels (410 SS, 420 SS, 440 SS) were used as base materials. 420 stainless steel was used as the primary cladding material. Controlling the preheat and process conditions carefully guaranteed that the clad material was defect-free and had similar/improved characteristics to the base material.

Steel Mill Rods

Steel mill rods are components that are frequently worn. Typically, the wear is minimal yet sufficient to render the rod unusable. IBC Coatings Technologies coat worn rods with lasers. The base material was a high strength steel (4140), and the overlay was 431SS martensitic stainless steel to increase the wear resistance of the substrate.

What Type of Laser Is Used in Laser Cladding?

1. Fiber Lasers

Fiber lasers, which use optical fibers to create laser beams, are well-known for their efficiency and dependability.

2. Diode Lasers

Diode lasers are a type of laser that produces laser radiation via a semiconductor. Diode lasers, which vary in wavelength, power, and fiber type, are used in two types of prostatectomy procedures

3. CO2 Lasers

Carbon dioxide lasers, often known as CO2 lasers, generate laser beams using a gas mixture and are ideal for cladding greater regions.

4. Nd:YAG Lasers

Solid-state crystals are used to create laser beams in neodymium-doped yttrium aluminum garnet lasers. They are adaptable to a variety of cladding applications.

1 note

·

View note

Text

Alloy 20 Flanges and Fittings: Unveiling the Excellence of ASTM

Alloy 20 Flanges and Fittings: Unveiling the Excellence of ASTM B564 UNS N10276 and ASTM B366 WPNC

In the elaborate international of business materials, Alloy 20, also referred to as Carpenter 20, emerges as an immoderate-performance alloy celebrated for its first rate corrosion resistance and flexibility. The deployment of Alloy 20 in crucial packages necessitates stringent requirements for its additives, and amongst those, ASTM B564 UNS N10276 and ASTM B366 WPNC stand out, defining the specifications for Alloy 20 flanges and fittings. This alloy, famed for its potential to resist corrosive environments, finds its excellence manifested in these standards, making sure reliability and durability in quite a few industries.

A Corrosion-Resistant MarvelAlloy 20

Alloy 20 is a nickel-chromium-molybdenum chrome steel alloy with brought copper and niobium. This particular aggregate of factors imparts fantastic resistance to corrosion, particularly in sulfuric acid and phosphoric acid environments.

Precision Forging for Flanges: ASTM B564 UNS N10276

This specification delineates the requirements for nickel-molybdenum-chromium-iron alloy forgings, specifically for flanges, fittings, valves, and exceptional additives applied in corrosive environments. The UNS N10276 designation indicates the precise alloy composition, making sure that the flanges synthetic underneath this preferred meet stringent criteria for chemical composition, mechanical components, and corrosion resistance.

The precision forging process specified in ASTM B564 UNS N10276 effects in flanges with uniform properties, ensuring steady overall performance in important packages.

ASTM B366 WPNC: Excellence in Fittings for Alloy 20:

Complementary to ASTM B564 for flanges, ASTM B366 is the same old specification for Alloy 20 fittings. Within this standard, WPNC in particular denotes Alloy 20 fittings. ASTM B366 WPNC fittings cover a complete range of types, such as elbows, tees, reducers, caps, and extra. These fittings play a vital position within the seamless assembly and connection of Alloy 20 piping structures, making sure leak-loose and dependable operations.

Applications across Industries:

The application spectrum for Alloy 20 flanges and fittings ruled by means of ASTM B564 UNS N10276 and ASTM B366 WPNC is considerable and numerous. In the chemical processing industry, wherein exposure to corrosive chemical compounds is commonplace, Alloy 20 flanges and fittings offer a sturdy solution for building piping systems that call for reliability and durability.

Quality Assurance and Testing:

Both ASTM B564 UNS N10276 and ASTM B366 WPNC emphasize rigorous quality assurance and checking out protocols. These requirements mandate diverse assessments, such as chemical evaluation, mechanical assets trying out, and non-unfavourable examinations, to ensure that the synthetic flanges and fittings meet or exceed the required necessities.

Conclusion:

In conclusion, Alloy 20 flanges and ASTM B366 Fittings, governed by ASTM B564 UNS N10276 and ASTM B366 WPNCMC, epitomize the pinnacle of corrosion-resistant answers for critical packages. The precision engineering, material excellence, and stringent first-class manage measures described in those standards make certain the reliability and sturdiness of Alloy 20 components in industries where corrosive environments pose substantial challenges. As industries hold to evolve, Alloy 20, guided by means of those requirements, remains a stalwart preference for those searching for excellence in corrosion-resistant substances for their piping structures.

0 notes