#Aluminium Honeycomb Core

Text

#aluminium composite panel#Honeycomb Panels#Aluminium Honeycomb Panels#Aluminium Honeycomb Core#Lightweight Honeycomb Panels

0 notes

Text

Ecocomb Aluminium Honeycomb Core India refers to the production of aluminium honeycomb core material in India. Ecocomb Aluminium honeycomb core is a key component in the manufacture of composite panels and structures, offering high strength-to-weight ratio, stiffness, and resistance to damage. The aluminium honeycomb core production in India provides a range of products and services, including custom-made honeycomb core structures, to meet the specific needs of its customers. The use of aluminium honeycomb core has become widespread in the aerospace, transportation, and building construction industries, due to its unique properties and versatility.

0 notes

Text

Aluminium Honeycomb Sheet: Know Its Benefits & Applications

An aluminium honeycomb sheet can be depicted as a sandwich plate that comes with a honeycomb structure at its core. It is inspired by the hexagonal shape of a natural honeycomb. This special structure makes its weight way lighter than other materials of the same volume. What is more, the overall stability and stiffness are also very good. Let us find out more about the honeycomb sheet in the following passages.

Benefits of Aluminium Honeycomb Sheet

Fire Resistance:

These panels are non-melting type and non-combustible with a fire rating of FR grade A2+. There is a hexagonal design honeycomb sheet in the core that prevents the fire from spreading rapidly.

Lightweight

Since the honeycomb sheet comes with a hollow core, it is of low density. Also, that is why the overall weight of the panel is light which makes it useful especially in aerospace engineering, metro coaches, as well as theatres.

Highly Efficient

The hexagonal honeycomb core connects with the aluminium skin on the top and bottom which makes an I-beam structure. This particular feature makes the panel highly durable and enables high-impact stress resistance.

Recyclable Material

The honeycomb panel is made with 100% recyclable and reusable aluminium alloy.

Hassle-free Installation

As these panels are lightweight and thin, they are easy to install. These can be easily installed with rivets and nuts as wall panels or in other applications.

Key Applications Of Honeycomb Sheet

These honeycomb sheets are suitable for installation in ceilings, Metro coaches, railway stations, facades, airports, etc. Suitable for both interior and exterior installation these are highly efficient and aesthetic.

Final Words

If you want to buy the best quality aluminium honeycomb sheet at the best prices, always deal with a trusted supplier. Only they offer premium quality products at competitive prices ensuring the best return on your investment.

2 notes

·

View notes

Text

The Cost-Effectiveness of Honeycomb Aluminium Sheets in Construction Projects

In the world of modern construction and architecture, material innovation plays a crucial role in pushing the boundaries of design and functionality. One such innovative material is the honeycomb aluminium sheet. At Alucobond India, we understand the importance of combining strength, lightweight properties, and aesthetic appeal in building materials. This blog explores the benefits and applications of honeycomb aluminium sheets, making them an ideal choice for various architectural and industrial projects.

Lightweight Yet Strong

Honeycomb aluminium sheets are designed with a core structure that mimics the natural honeycomb pattern, providing exceptional strength while keeping the material lightweight. This dual benefit allows for easier transportation and handling on construction sites, reducing labor costs and equipment requirements.

Reduced Material Costs:

Compared to solid aluminium sheets, honeycomb aluminium sheets require less raw material due to their hollow core design. This not only lowers the overall cost of the sheets but also contributes to a reduction in the overall weight of the structure, leading to potential savings in foundational and structural supports.

Energy Efficiency and Sustainability

Honeycomb aluminium sheets offer excellent thermal insulation properties, which can contribute to energy savings in buildings. Additionally, aluminium is a recyclable material, making honeycomb sheets an environmentally friendly choice that aligns with sustainable construction practices.

Lower Maintenance Costs

The durability and corrosion resistance of honeycomb aluminium sheets ensure that they maintain their structural integrity over time, reducing the need for frequent repairs or replacements. This long-term reliability translates into lower maintenance costs, making them a cost-effective option in the long run.

Versatility in Application

These sheets can be used in a wide range of construction applications, from facades and roofing to interior partitions and flooring. Their versatility allows for innovative design solutions while keeping costs under control, as one material can serve multiple functions within a project.

Conclusion

Honeycomb aluminium sheets represent a perfect blend of innovation, strength, and sustainability. Their wide range of applications, from architectural facades to the transportation industry, showcases their versatility and importance in modern construction. At Alucobond India, we are proud to offer high-quality honeycomb aluminium sheets that contribute to building the future, one project at a time.

For more information on our products or to discuss your project requirements, feel free to contact us at Alucobond India. Let’s build something extraordinary together!

To Know More https://alucobond.in/

0 notes

Text

Aluminium Honeycomb Panels: Lightweight Giants of Modern Engineering

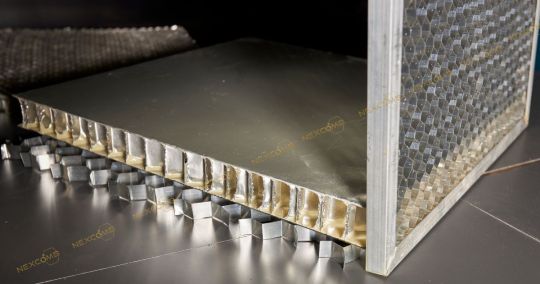

Aluminium honeycomb panels are a marvel of engineering, combining lightweight construction with remarkable strength and durability. These panels consist of a core made of hexagonal aluminium honeycomb cells sandwiched between two thin layers of aluminium sheets. While they might seem simple in design, their applications and benefits are vast and varied.

Unmatched Strength-to-Weight Ratio

One of the most striking features of aluminium honeycomb panels is their exceptional strength-to-weight ratio. The honeycomb structure provides incredible strength while keeping the overall weight of the panel relatively low. This makes them ideal for applications where weight reduction is crucial without sacrificing structural integrity.

Applications in Aerospace

In the aerospace industry, where every ounce matters, aluminium honeycomb panels are widely used in aircraft construction. They are utilized in aircraft interiors for wall panels, flooring, ceiling panels, and other structural components. Their lightweight nature helps reduce fuel consumption while maintaining the structural integrity necessary for flight safety.

Architectural Marvels

Beyond aerospace, aluminium honeycomb panels have found their way into architectural designs, revolutionizing the construction industry. Their versatility allows architects and designers to create innovative structures that are both visually stunning and structurally sound. From exterior cladding to interior partitions, these panels offer endless possibilities for modern architecture.

Energy Efficiency and Sustainability

Aluminium honeycomb panels also contribute to energy efficiency and sustainability in construction. Their lightweight nature reduces the load on buildings, resulting in lower energy consumption for heating, cooling, and transportation during construction. Additionally, aluminium is highly recyclable, making these panels an eco-friendly choice for green building projects.

Versatility in Transportation

In addition to aerospace applications, aluminium honeycomb panels are utilized in various transportation sectors, including automotive and marine industries. In automobiles, they are used for interior components, such as door panels, floors, and trunk liners, contributing to improved fuel efficiency. In marine applications, they offer lightweight solutions for boat hulls, decks, and bulkheads, enhancing performance and fuel economy.

Fire Resistance and Safety

Safety is paramount in any application, and aluminium honeycomb panels excel in this regard as well. Their inherent fire-resistant properties make them suitable for use in environments where fire safety is a concern, such as building interiors and transportation vehicles. Additionally, their high strength ensures structural integrity even under extreme conditions, providing peace of mind to architects, engineers, and occupants alike.

Cost-Effective Solutions

Despite their advanced engineering and superior performance, aluminium honeycomb panels offer cost-effective solutions for various industries. Their long lifespan, low maintenance requirements, and energy-efficient properties translate to significant cost savings over the lifetime of a project. Moreover, their lightweight nature reduces transportation and installation costs, further enhancing their cost-effectiveness.

Conclusion

Aluminium honeycomb panels represent the pinnacle of modern engineering, offering a perfect blend of strength, durability, versatility, and sustainability. From aerospace to architecture, transportation to construction, these panels have transformed industries and opened doors to endless possibilities. As technology advances and new innovations emerge, aluminium honeycomb panels are sure to remain at the forefront of modern design and engineering, shaping the world we live in for generations to come.

Stay informed about the latest advancements in rail technology by following our updates on Tumblr and visiting MetaCor Rail Applications.

0 notes

Text

Honeycomb core manufacturers India specialize in the production of honeycomb structures that are widely used in various industries for their lightweight, high strength, and excellent structural integrity. Honeycomb cores are typically made from materials such as aluminum, paper, or thermoplastics, and feature a series of hexagonal cells arranged in a honeycomb pattern.

0 notes

Text

Aluminium Honeycomb Composite Panel is a type of sandwich panel consisting of two thin aluminium sheets bonded to an aluminium honeycomb core. This combination results in a lightweight and strong panel with excellent thermal and acoustic insulation properties. Ecocomb Aluminium honeycomb composite panels are commonly used in the construction, aerospace, and transportation industries due to their durability, stability, and resistance to corrosion. The panels can be customised in terms of size, shape, and color to meet the specific requirements of various applications. They are also easy to install and maintain, making them a popular choice for various structures, partitions, and cladding systems.

0 notes

Text

EMI Shielding Aluminium Honeycomb suppliers

Kinetic Polymers is a foremost manufacturer, supplier of EMI Shielding Aluminium Honeycomb in India, Hyderabad. Our EMI shielding products are made from Aluminium Honeycomb mounted into a frame. We are specialize in aluminium honeycomb cores and aluminium honeycomb panels to several Industry. We offers high levels of shielding with a minimum resistance to air flow. Honeycomb vent panels are used where there is a necessity for high level airflow and EMI Shielding concert. Laminated honeycomb panels provide important strength-to-weight ratio, and many industries are advancing from this technology. Our EMI Shielding products are designed for use in various electronic industries where good air flow is mandatory for cooling and drying but where EMC obedience must be ensured.

EMI SHIELDING PRODUCTS

Our EMI Shielding Aluminium Honeycomb can be supplied in several configurations to suit different EMI Shielding performance requirements.Our company are pride in creative design, customer satisfaction and quality workmanship. Our engineers develop new and advanced products often in close co-operation with selected partners in the private industry. An extensive range of aluminium extrusion mounting frames are available from stock contributing a choice of mounting methods and sizes.

https://www.kineticpolymers.com/emi-shielding/emi-shielding-aluminium-honeycomb.php

0 notes

Text

What Are The Advantages of ACP Sheet

ACP(aluminum composite sheet) is a new material that uses aluminum honeycomb core or foamed aluminum or solid aluminum plate as the base material, and composites PVC, PET film, solid wood skin, stone, cloth, leather and other common finishes on the surface of the solid aluminum plate like pre painted aluminium coil. What are its advantages?

1. Lightweight and high strength

Composite aluminum…

View On WordPress

0 notes

Text

Discovering the Characteristics of the Honeycomb Sheet - Eurobond ACP

Eurobond's honeycomb sheet is a specialized form of Aluminum Composite Panel designed to enhance specific properties such as strength, rigidity, and lightweight characteristics. The honeycomb structure consists of hexagonal cells resembling a honeycomb, and this design imparts unique mechanical and thermal properties to the panel.

1. Material Composition:

The honeycomb sheet from Eurobond typically comprises three main layers – two outer layers of aluminum and a central core made of aluminum honeycomb. The outer layers are usually made of high-quality aluminum sheets, while the honeycomb core is created by bonding together aluminum hexagons. This structure results in a lightweight yet strong and rigid panel.

2. Strength and Rigidity:

The honeycomb structure in the core significantly improves the strength-to-weight ratio of the panel. This makes it an excellent choice for applications where high strength and rigidity are essential but minimizing weight is also a priority. Construction projects, especially those where structural integrity is crucial, benefit from the use of Eurobond's honeycomb sheets.

3. Lightweight Construction:

One of the key advantages of Eurobond's honeycomb sheet is its lightweight nature. This feature is particularly beneficial in construction applications where reducing the overall weight of the structure is desired without compromising on strength and durability. Lightweight materials can contribute to easier handling, transportation, and installation.

4. Thermal Performance:

The honeycomb structure also offers good thermal insulation properties. The air pockets within the honeycomb cells act as insulators, reducing the transfer of heat through the panel. This can contribute to energy efficiency in buildings, helping to maintain a comfortable interior temperature while potentially reducing heating and cooling costs.

5. Versatility in Applications:

Eurobond's honeycomb sheets find applications in a variety of industries. They are commonly used in the construction of facades, partitions, ceilings, and interior panels. The versatility of these panels allows architects and builders to explore innovative design possibilities while ensuring structural integrity.

6. Aesthetic Appeal:

In addition to their functional benefits, Eurobond's honeycomb sheets are available in various finishes and colors, contributing to the aesthetic appeal of architectural projects. The ability to choose from a range of colors and finishes enables designers to create visually striking and customized facades.

7. Durability and Weather Resistance:

Like other Eurobond ACP products, honeycomb sheets are designed to withstand harsh weather conditions, UV radiation, and environmental factors. The use of high-quality materials and advanced manufacturing processes ensures the durability of the panels over an extended period.

Conclusion:

Eurobond's honeycomb sheet represents a sophisticated solution for industries that require a balance of strength, rigidity, and lightweight characteristics in their construction materials. Whether used in commercial buildings, residential projects, or industrial applications, these panels offer a combination of structural integrity and design flexibility. Architects and builders looking for reliable and versatile composite panels often turn to Eurobond's honeycomb sheets to meet the evolving demands of modern construction. Always refer to the latest product specifications and recommendations from Eurobond for the most accurate and up-to-date information.

[honeycomb sheet, Eurobond honeycomb sheet, Aluminium honeycomb sheet]

1 note

·

View note

Text

Core Material Market Global Industry Share & Size Analysis

Core Material Market, By Type (Foam, Honeycomb, and Balsa), End-use Industry (Wind Energy, Aerospace & Defense, Marine, Automotive & Transportation, Construction, and Industrial) and Geography (North America, Europe, Asia-Pacific, Middle East and Africa and South America)

Market Overview

Global Core Material market is anticipated to reach USD 1.5 billion in 2021 growing at a CAGR of 13.8% during the forecasting period, 2021-2028.

Core material are made from paper, polymeric foam, or woods like materials which are highly inflammable. These materials are fully covered with insulated materials and are thus not directly exposed to fire. Aluminium core used for covering will make the core material initially unaffected to fire but will eventually melt down.

Due to surge in demand form wind energy industry and use of composites in aerospace industry are some of the factors that have supported long-term expansion for Core Material industry.

Request Sample Pages of Report: https://www.delvens.com/get-free-sample/core-material-market-trends-forecast-till-2028

Key Findings

Global Core Material market is segmented into Type, End-use Industry and geography.

Type segment is segmented into Foam, Honeycomb, and Balsa

End-use Industry segment is segmented into Wind Energy, Aerospace & Defense, Marine, Automotive & Transportation, Construction, and Industrial

Geographically, global Core Material market is sub segmented into North America, Europe, Asia-Pacific, Middle East and Africa and South America and insights are provided for each region and major countries within the regions

To Grow Your Business Revenue, Make an Inquiry Before Buying at: https://www.delvens.com/Inquire-before-buying/core-material-market-trends-forecast-till-2028

Competitive Landscape

Key players in global Core Material market are 3A Composites (Switzerland), Diab Group (Sweden), Gurit (Switzerland), Hexcel Corporation (US), Armacell International S.A. (Luxembourg), Euro-Composites S.A. (Luxembourg), Changzhou Tiansheng New Materials Co. Ltd. (China), and The Gill Corporation (US) among others.

Reasons to Acquire

Increase your understanding of the market for identifying the best and suitable strategies and decisions on the basis of sales or revenue fluctuations in terms of volume and value, distribution chain analysis, market trends and factors

Gain authentic and granular data access for Core Material market so as to understand the trends and the factors involved behind changing market situations

Qualitative and quantitative data utilization to discover arrays of future growth from the market trends of leaders to market visionaries and then recognize the significant areas to compete in the future

In-depth analysis of the changing trends of the market by visualizing the historic and forecast year growth patterns

Purchase the Report: https://www.delvens.com/checkout/core-material-market-trends-forecast-till-2028

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Read Industry Related Reports:

Contact Us:

UNIT NO. 2126, TOWER B,

21ST FLOOR ALPHATHUM

SECTOR 90 NOIDA 201305, IN

+44-20-8638-5055

The Core Material Market report answers a number of crucial questions, including:

Which companies dominate the Core Material Market?

What current trends will influence the market over the next few years?

What are the market's opportunities, obstacles, and driving forces?

What predictions for the future can help with strategic decision-making?

What advantages does market research offer businesses?

Which particular market segments should industry players focus on in order to take advantage of the most recent technical advancements?

What is the anticipated growth rate for the market economy globally?

0 notes

Text

Ecocomb Aluminium Honeycomb Core Manufacturers refers to the production of aluminium honeycomb core material manufacture in India. Ecocomb Aluminium honeycomb core is a key component in the manufacture of composite panels and structures, offering high strength-to-weight ratio, stiffness, and resistance to damage.

0 notes

Text

Green Non Stick Wok Pan

One pot is multi-purpose, frying, frying, boiling, stewing, easy to handle a variety of dishes.

3 coats, PFOA free. 5mm thick pot bottom, faster heat conduction, less oily smoke, more energy-saving.

Anti-scalding and anti-slip handle, the whole pot body is die-cast, no dead angle, easy to clean. The vented glass lid lets you see the cooking process at a glance.

Specification of Green Non Stick Wok Pan

Color

Green

Package Dimensions

50.8 x 30.48 x 8.89 cm

Capacity

7 Liters

Material

Aluminium

Item Weight

1.27 kg

Features of Green Non Stick Wok Pan

1

More durable and scratch-resistant than other non-stick surfaces, you only need half the usual oil for frying, frying, grilling, boiling, and stewing.

Features of Green Non Stick Wok Pan

2

Adopt innovative honeycomb texture cooking surface to enhance heat distribution.

Features of Green Non Stick Wok Pan

3

Made of durable heavy gauge aluminum core, free of heavy metals. Features a comfortable heat-resistant silicon-coated handle and a magnetized base for induction hobs.

0 notes

Text

Design Flexibility Meets Durability: Innovations in Honeycomb Aluminum Sheet Technology

In the ever-evolving world of construction and architecture, materials that offer both aesthetic appeal and structural integrity are highly sought after. Alucobond India is at the forefront of this innovation, introducing advanced honeycomb aluminum sheet technology that combines design flexibility with unparalleled durability.

The Evolution of Building Materials

The construction industry has witnessed a significant transformation over the past few decades. Traditional materials like wood, stone, and steel, while reliable, often come with limitations in terms of weight, maintenance, and versatility. Enter aluminum—a material that offers a perfect balance of strength, lightweight properties, and resistance to environmental factors. Taking this a step further, the integration of honeycomb structures within honeycomb aluminium sheet has revolutionized the industry.

What is Honeycomb Aluminum Sheet Technology?

Honeycomb aluminum sheets consist of two layers of aluminum enclosing a honeycomb core, usually made from aluminum or a similar material. This design mimics the natural geometry of a honeycomb, known for its optimal strength-to-weight ratio. The core’s hexagonal cells are engineered to provide maximum rigidity with minimal material usage, making these sheets incredibly strong yet lightweight.

Key Benefits of Honeycomb Aluminum Sheets

Exceptional Strength and Durability: The honeycomb structure distributes stress evenly across the surface, providing high resistance to compression and impact. This makes the sheets ideal for both load-bearing and non-load-bearing applications.

Lightweight: Despite their strength, honeycomb aluminum sheets are remarkably light, reducing the overall weight of structures. This translates to easier handling, lower transportation costs, and reduced structural load.

Thermal and Acoustic Insulation: The air-filled cells within the honeycomb core act as insulators, offering excellent thermal and sound insulation properties. This makes these sheets suitable for both exterior facades and interior partitions.

Corrosion Resistance: Aluminum's natural oxide layer provides resistance to corrosion, ensuring longevity and reducing maintenance costs. This is particularly beneficial in harsh weather conditions or coastal environments.

Design Flexibility: Honeycomb aluminum sheets can be easily cut, shaped, and finished to meet specific design requirements. They are compatible with various finishes, including paint, anodizing, and laminates, offering architects and designers a broad palette of options.

Applications in Modern Architecture

Alucobond India's honeycomb aluminum sheets are versatile and can be used in a wide range of applications:

Exterior Cladding

The lightweight yet robust nature of honeycomb aluminum sheets makes them perfect for exterior cladding systems. They can withstand harsh weather conditions while providing a sleek, modern appearance.

Interior Design

In interior spaces, these sheets can be used for partitions, ceilings, and decorative elements. Their ability to be customized in terms of color and finish allows designers to create unique and visually appealing environments.

Furniture and Fixtures

Honeycomb aluminum sheets are also making their way into furniture design, offering lightweight and durable alternatives for tables, shelves, and other fixtures.

Transport and Aerospace

The aerospace and automotive industries benefit from the high strength-to-weight ratio of honeycomb aluminum sheets, utilizing them for components that require durability without adding excessive weight.

Sustainability and Environmental Impact

Alucobond India is committed to sustainable practices. Honeycomb aluminum sheets are recyclable, aligning with global efforts to reduce carbon footprints and promote eco-friendly building practices. The durability of these materials also means less frequent replacement, contributing to long-term sustainability.

Conclusion

As the construction and design industries continue to evolve, the demand for materials that offer both aesthetic flexibility and structural durability will only increase. Alucobond India's honeycomb aluminum sheet technology stands at the intersection of these demands, providing innovative solutions that push the boundaries of what’s possible in modern architecture and design.

Whether you’re an architect looking to create stunning exteriors or a designer aiming to craft innovativeinteriors, Alucobond India’s honeycomb aluminum sheets offer the perfect blend of form and function. Explore the future of construction materials with Alucobond India and discover how honeycomb aluminum sheets can transform your projects.

To know more: https://alucobond.in/all-products

0 notes

Text

What Are the Different Types of Core Materials Used in ACP?

Aluminum Composite Panel (ACP) is a popular material for building exteriors, interiors, and signage. The sandwich panel consists of two aluminium sheets bonded to a non-aluminium core, which provides rigidity, insulation, and lightweight properties. The core material used in ACP plays a crucial role in its overall performance and characteristics. This article will discuss the different types of core materials used in ACP.

What is ACP?

ACP is a flat panel of two thin aluminium sheets bonded to a non-aluminium core. The thickness of the aluminium sheets can vary from 0.2mm to 0.5mm, while the core material thickness can range from 2mm to 6mm. The most common ACP thickness is 4mm. ACP offers advantages over traditional building materials like masonry, wood, and steel. These include low weight, ease of installation, cost-effectiveness, weather resistance, and design versatility.

Why is Core Material Important in ACP?

The core material used in ACP significantly affects its mechanical and physical properties, such as rigidity, strength, fire resistance, and thermal insulation. The choice of core material also determines the panel's response to heat and fire. Therefore, choosing the right type of core material for your application is crucial.

Types of Core Materials Used in ACP

Polyethene (PE) Core

PE core is the most widely used core material in ACP due to its cost-effectiveness, lightweight, and ease of processing. The core material is made of low-density polyethene, which is a highly flammable material. PE core ACP is suitable for applications that do not require high fire resistance, such as signage, cladding, and interior decoration. However, it is not recommended for high-rise buildings or areas with strict fire safety regulations.

Fire Retardant (FR) Core

FR core ACP is designed to improve fire resistance and prevent the spread of fire. The core material is treated with fire-retardant additives, such as magnesium or aluminium hydroxide, to reduce flammability and smoke emission. FR core ACP is suitable for areas with strict fire safety regulations, such as hospitals, schools, and high-rise buildings.

Mineral Core

Mineral core ACP comprises non-combustible minerals, such as magnesium oxide or aluminium hydroxide, that provide excellent fire resistance and thermal insulation. The core material is bonded to the aluminium sheets using a unique adhesive that can withstand high temperatures. Mineral core ACP is ideal for applications that require high fire resistance, such as façade cladding, tunnels, and airports.

Aluminium Honeycomb Core

Aluminium honeycomb core ACP comprises hexagonal cells of aluminium foil bonded together to form a lightweight and robust core material. The core material offers excellent rigidity and compression strength while maintaining a low weight. Aluminium honeycomb core ACP is suitable for applications that require high mechanical strength, such as transportation, marine, and aerospace industries.

Polystyrene (PS) Core

Polystyrene core ACP comprises expanded polystyrene foam that offers lightweight and thermal insulation properties. The core material is bonded to the aluminium sheets using an adhesive. Polystyrene core ACP is suitable for applications that require insulation, such as cold rooms, refrigeration trucks, and sound barriers.

A2/B1 FR Core

A2/B1 FR core ACP is a new type of fire-resistant core material that complies with the European fire safety standard EN13501-1. The core material comprises non-combustible minerals, such as magnesium hydroxide and aluminium trihydroxide, that offer excellent fire resistance and smoke emission control. A2/B1 FR core ACP is suitable for high-fire resistance applications, such as high-rise buildings, hospitals, and airports.

Conclusion

The choice of core material in ACP is a crucial factor that can significantly affect the performance and safety of the final product. The core materials used in ACP are PE core, FR core, mineral core, aluminium honeycomb core, polystyrene core, and A2/B1 FR core. Each type of core material has its unique advantages and disadvantages, and the selection of suitable core material depends on the application's specific requirements.

Are you looking for the best company for ACP works in Coimbatore?

If you implement an ACP in your place, ‘Aysh Groups’ are always the best choice.

‘Aysh Groups’ make the process easy and convenient to order your aluminium composite panel (ACP) and get it installed on time.

We are the prominent and best Glass interiors, exteriors, partitions, and ACP work with high-quality materials in Chennai, Coimbatore, Trichy and Madurai.

For more information about the aluminium composite panel-related queries, do contact us via (Phone: 9884450095 or Website: https://ayshgroups.com/)

1 note

·

View note

Text

Can you discuss any recent advancements or innovations in Aluminium Honeycomb Core technology?

Structural Superiority: The Aluminium Honeycomb Core Revolution

In the world of construction and manufacturing, materials that offer a unique blend of strength, durability, and versatility are highly sought after. Aluminium honeycomb panels stand out as a prime example of such materials, offering a range of benefits that make them an ideal choice for various applications. Let's delve into the properties, uses, and advantages of aluminium honeycomb panels, and explore why they are gaining popularity in the industry.

Understanding Aluminium Honeycomb Panels:

Aluminium honeycomb panels are composite structures composed of two thin aluminium sheets bonded to a lightweight core made of hexagonal honeycomb-shaped cells. The core provides strength and rigidity to the panel while keeping its weight to a minimum. This unique construction gives aluminium honeycomb panels exceptional mechanical properties, making them suitable for a wide range of applications in construction, transportation, aerospace, and marine industries.

The Advantages of Aluminium Honeycomb Panels:

Strength and Durability: Aluminium honeycomb panels are renowned for their strength-to-weight ratio, making them incredibly strong yet lightweight. The honeycomb core structure distributes load evenly across the panel, providing excellent resistance to bending, compression, and shear forces. This inherent strength and durability make aluminium honeycomb panels suitable for demanding applications where structural integrity is essential.

Lightweight Construction: The lightweight nature of aluminium honeycomb panels offers several advantages in terms of transportation, installation, and overall efficiency. Compared to solid aluminium or steel panels, aluminium honeycomb panels are significantly lighter, reducing the structural load on buildings, vehicles, and other structures. This weight reduction translates to lower fuel consumption, easier handling, and reduced installation costs, making aluminium honeycomb panels a preferred choice for projects where weight savings are critical.

Thermal and Acoustic Insulation: Aluminium honeycomb panels offer excellent thermal and acoustic insulation properties, enhancing the comfort and efficiency of buildings and vehicles. The honeycomb core acts as a barrier to heat transfer and sound transmission, helping to regulate indoor temperatures and reduce noise levels. This thermal and acoustic insulation makes aluminium honeycomb panels suitable for applications where comfort, energy efficiency, and noise reduction are priorities.

Corrosion Resistance: Aluminium honeycomb panels exhibit high resistance to corrosion, making them suitable for outdoor and marine applications where exposure to harsh environments is a concern. The aluminium sheets are typically coated with protective finishes or anodized to further enhance corrosion resistance, ensuring long-term durability and performance in challenging conditions.

Design Flexibility: Aluminium honeycomb panels offer design flexibility, allowing architects, designers, and engineers to create innovative and aesthetically pleasing structures. The panels can be easily cut, shaped, and formed into various sizes and shapes to meet specific design requirements. Additionally, aluminium honeycomb panels are available in a wide range of colors, finishes, and surface textures, offering endless possibilities for customization and creativity.

Applications of Aluminium Honeycomb Panels:

Architectural Cladding and Façades: Aluminium honeycomb panels are widely used in architectural cladding and façade systems, providing a lightweight yet durable solution for exterior building envelopes. The panels offer superior weather resistance, thermal insulation, and design versatility, making them suitable for both new construction and renovation projects.

Transportation Interiors: In the transportation industry, aluminium honeycomb panels are used for interior applications in aircraft, trains, buses, and marine vessels. The lightweight construction of the panels helps reduce fuel consumption and increase payload capacity, while their strength and durability ensure passenger safety and comfort.

Industrial and Manufacturing Applications: Aluminium honeycomb panels find applications in various industrial and manufacturing sectors, including machinery enclosures, equipment housings, and cleanroom partitions. The panels provide structural support, vibration damping, and thermal insulation, making them ideal for demanding environments where precision and performance are critical.

Furniture and Product Design: Aluminium honeycomb panels are also utilized in furniture manufacturing and product design, where lightweight construction and aesthetic appeal are important considerations. The panels can be used to create stylish and functional furniture pieces, partitions, and decorative elements for residential, commercial, and hospitality settings.

Conclusion:

In conclusion, aluminium honeycomb panels offer a winning combination of strength, durability, and versatility that makes them a preferred choice for a wide range of applications in construction, transportation, aerospace, and manufacturing industries. Their lightweight construction, thermal and acoustic insulation properties, corrosion resistance, and design flexibility make them a valuable solution for architects, designers, engineers, and manufacturers seeking innovative materials that meet the highest standards of performance and reliability. As industries continue to prioritize efficiency, sustainability, and design excellence, aluminium honeycomb panels are poised to play a key role in shaping the future of construction and manufacturing.

0 notes