#Ammonia level control with indicator

Explore tagged Tumblr posts

Text

Ammonia level control with indicator| Ammonia level control with indicator supplier, Manufacturer in Pune, Mumbai, India

Asha Enterprises, is best Ammonia level control with indicator supplier, Manufacturer Company in Pune, Mumbai, Thane, Navi Mumbai, Kolhapur, Ratnagiri, Raigad, Nashik, Solapur, Latur, Aurangabad, Sindhudurg, Sangli, Solapur, Ahmednagar, Satara and Maharashtra.

#Asha Enterprises#Asha Enterprises in Pune#Asha Enterprises in India#Ammonia level control with indicator#Ammonia level control with indicator supplier#Ammonia level control with indicator manufacturer#Ammonia level control with indicator in Pune#Ammonia level control with indicator in Mumbai#Ammonia level control with indicator in Thane#Ammonia level control with indicator in Navi Mumbai#Ammonia level control with indicator in Kolhapur#Ammonia level control with indicator in Ratnagiri#Ammonia level control with indicator in Raigad#Ammonia level control with indicator in Nashik#Ammonia level control with indicator in Solapur#Ammonia level control with indicator in Latur#Ammonia level control with indicator in Aurangabad#Ammonia level control with indicator in Sindhudurg#Ammonia level control with indicator in Sangli#Ammonia level control with indicator in Ahmednagar#Ammonia level control with indicator in Satara#Ammonia level control with indicator in Maharashtra#Ammonia level control with indicator supplier in Pune#Ammonia level control with indicator supplier in Mumbai#Ammonia level control with indicator supplier in Thane#Ammonia level control with indicator supplier in Navi Mumbai#Ammonia level control with indicator supplier in Kolhapur#Ammonia level control with indicator supplier in Ratnagiri#Ammonia level control with indicator supplier in Raigad#Ammonia level control with indicator supplier in Nashik

1 note

·

View note

Text

OTD in 1969, The Iconic XB-70 Valkyrie Mach 3 Super Bomber Made Its Last Flight

February 4, 2021 Military Aviation, Military History

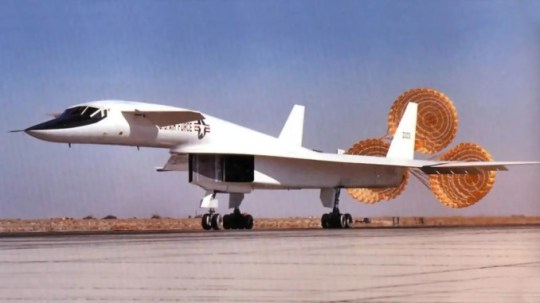

Three drag chutes were needed to slow down the landing roll of the XB-70. (Image credit: Reddit edit The Aviationist)

The massive XB-70 Valkyrie is the largest and heaviest airplane ever to fly at Mach 3.

The North American XB-70 Valkyrie was the most ambitious super-bomber project of the Cold War. The massive six-engine bomber was slated to be the ultimate American high-altitude, high-speed, deep-penetration manned nuclear bomber designed to fly high and fast, so as to be safe from Soviet interceptors.

Two Valkyrie prototypes were been built at North American Aviation before the Kennedy Administration cancelled the program as a consequence of the doubts that surrounded the future of manned bombers believed to be obsolete platforms. The threat posed by Soviet SAMs (Surface-to-Air Missiles) put the near-invulnerability of the strategic bomber at high altitudes in doubt. In low-level penetration role, the B-70 offered little performance improvement over the B-52 it was designed to replace (!) and it was much more expensive with shorter range.

Some fascinating variants of the aircraft were proposed. Some envisaged the B-70 carrying an Alert Pod, or flying as a Supersonic Refueler or as a Recoverable Booster Space System (RBSS). You can find all the details about these crazy concepts in this story we have posted last year.

Ezoic

The B-70 program was canceled in 1961 and development continued as part of a research program to study the effects of long-duration high-speed flight with the two XB-70A.

XB-70A number 1 (62-001) made its first flight from Palmdale to Edwards Air Force Base, CA, on Sept. 21, 1964. The second XB-70A (62-207) made its first flight on Jul. 17, 1965. The latter differed from the first prototype for being built with an added 5 degrees of dihedral on the wings as suggested by the NASA Ames Research Center, Moffett Field, CA, wind-tunnel studies.

While the 62-001 made only one flight above Mach 3, because of poor directional stability experienced past Mach 2.5, the second XB-70, achieved Mach 3 for the first time on Jan. 3, 1966 and successfully completed a total of nine Mach 3 flights by June on the same year.

Photo of the XB-70 #1 cockpit, which shows the complexity of this mid-1960s research aircraft. On the left and right sides of the picture are the pilot’s and co-pilot’s control yokes. Forward of these, on the cockpit floor, are the rudder pedals with the NAA North American Aviation trademark. Between them is the center console. Visible are the six throttles for the XB-70’s jet engines. Above this is the center instrument panel. The bottom panel has the wing tip fold, landing gear, and flap controls, as well as the hydraulic pressure gages. In the center are three rows of engine gages. The top row are tachometers, the second are exhaust temperature gages, and the bottom row are exhaust nozzle position indicators. Above these are the engine fire and engine brake switches. The instrument panels for the pilot left and co-pilot right differ somewhat. Both crewmen have an airspeed/Mach indicator, and altitude/vertical velocity indicator, an artificial horizon, and a heading indicator/compass directly in front of them. The pilot’s flight instruments, from top to bottom, are total heat gage and crew warning lights; stand-by flight instruments side-slip, artificial horizon, and altitude; the engine vibration indicators; cabin altitude, ammonia, and water quantity gages, the electronic compartment air temperature gage, and the liquid oxygen quantity gage. At the bottom are the switches for the flight displays and environmental controls. On the co-pilot’s panel, the top three rows are for the engine inlet controls. Below this is the fuel tank sequence indicator, which shows the amount of fuel in each tank. The bottom row consists of the fuel pump switches, which were used to shift fuel to maintain the proper center of gravity. Just to the right are the indicators for the total fuel top and the individual tanks bottom. Visible on the right edge of the photo are the refueling valves, while above these are switches for the flight data recording instruments. (Image credit: NASA)

A joint agreement signed between NASA and the Air Force planned to use the second XB-70A prototype for high-speed research flights in support of the American supersonic transport (SST) program.

However, on June 8, 1966, the XB-70 62-207 was involved in one of the most famous and tragic accidents in military aviation when it collided with a civilian registered F-104N while flying in formation as part of a General Electric company publicity photo shoot over Barstow, California, outside the Edwards Air Force Base test range in the Mojave Desert. The aircraft were flying in formation with a T-38 Talon, an F-4B Phantom II, and a YF-5A Freedom Fighter.

North American XB-70A Valkyrie just after collision. Note the F-104 is at the forward edge of the fireball and most of both XB-70A vertical stabilizers are gone. (U.S. Air Force photo)

As explained in a previous post here at The Aviationist:

Towards the end of the photo shooting NASA registered F-104N Starfighter, piloted by famous test pilot Joe Walker, got too close to the right wing of the XB-70, collided, sheared off the twin vertical stabilizers of the big XB-70 and exploded as it cartwheeled behind the Valkyrie. North American test pilot Al White ejected from the XB-70 in his escape capsule, but received serious injuries in the process. Co-pilot Maj. Carl Cross, who was making his first flight in the XB-70, was unable to eject and died in the crash.

The root cause of the incident was found to be wake turbulence: wake vortices spinning off the XB-70’s wingtip caused Walker’s F-104N to roll, colliding with the right wingtip of the huge XB-70 and breaking apart. As explained in details in this post, wingtip vortices form because of the difference in pressure between the upper and lower surfaces of a wing. When the air leaves the trailing edge of the wing, the air stream from the upper surface is inclined to that from the lower surface, and helical paths, or vortices, result. The vortex is strongest at the tips and decreasing rapidly to zero nearing midspan: at a short distance from the trailing edge downstream, the vortices roll up and combine into two distinct cylindrical vortices that constitute the “tip vortices.

Although research activities continued with the first prototype with a first NASA flight on April 25, 1967, the last one was on Feb. 4, 1969.

The only remaining XB-70 Valkyrie super bomber in on display at the National Museum of the U.S. Air Force at Wright-Patterson AFB in Dayton, Ohio. In October last year, it had to briefly moved outside for display maintenance. Here you can watch a video of the monumental move.

A view of the six massive afterburners on the XB-70 Valkyrie as the aircraft is towed out of its display hangar temporarily for museum maintenance. (Photo: National Museum of the U.S. Air Force via YouTube)

About David Cenciotti

David Cenciotti is a journalist based in Rome, Italy. He is the Founder and Editor of “The Aviationist”, one of the world’s most famous and read military aviation blogs. Since 1996, he has written for major worldwide magazines, including Air Forces Monthly, Combat Aircraft, and many others, covering aviation, defense, war, industry, intelligence, crime and cyberwar. He has reported from the U.S., Europe, Australia and Syria, and flown several combat planes with different air forces. He is a former 2nd Lt. of the Italian Air Force, a private pilot and a graduate in Computer Engineering. He has written five books and contributed to many more ones.

@TheAviationist via X

22 notes

·

View notes

Text

I mostly write about organisms and not the principles of fishkeeping. However people often ask me about two related phenomena, cycling and stocking. Aquariums are safe for fish and other animals because of the nitrogen cycle. This is what determines, moreso than the water volume, the carrying capacity of the tank. But many people seem to be confused - what is the nitrogen cycle?

'Cycling' refers to the cycle by which the toxin ammonia, which is excreted as waste by organisms, before it is turned to nitrite and then to nitrate by biological actors. In aquarist parlance 'cycling' refers to the process and duration of time, during which the nitrogen cycle becomes established and stable. Properly the cycle continues throughout the operation of the aquarium.

Ammonia, which contains nitrogen, is the principal excretory product of living animals, and they void it because it is a toxic byproduct of their own metabolic processes. Human urination is an example of a way in which animals lose excess ammonia, but other kinds of animal may excrete ammonia by means of different methods.

Fortunately other organisms can find a positive use for ammonia, which animals don't want. Their own metabolisms create nitrite from the ammonia they intake, by breaking it down and adding oxygen to the nitrogen. Then yet more microscopic organisms convert the nitrite to the similarly named and chemically related nitrate, which must also be maintained at low levels, but is far less harmful. Traces of nitrate are in fact beneficial to some aquarium organisms.

The nitrogen cycle originates from the decomposition of amino acid, and this is why test kits are available to test for dissolved organics, which are not themselves inherently harmful, but their buildup indicates strain upon the system. How much strain is acceptable depends on the kinds of animals that are living in the aquarium. There isn't really a single standard as to when there are too many dissolved organics, or even nitrate. But regular and sensibly proportionate water changes, help to keep both under control.

Because it involves the processes of different organisms, the nitrogen cycle is very obviously an ecological, as well as a chemical phenomenon. Both the natural processes of the cycle, and the technology by which the effects of the benign organisms are maximised, are known as biological filtration, or biofiltration. It is different from physical and chemical filtration, although the functions of filter media may overlap.

The good bacteria that are involved, colonise available surfaces throughout the aquarium. They are present on rocks and on substrates such as sand and gravel. Similarly they colonise sponges and various proprietary items such as 'bio balls'. At this point, I wish to explain the introductory principles of biofiltration, not to cover its different expressions. It is however worth pointing out, the more the better.

Stocking levels are problematic principally because the living animals themselves create strains upon the biofiltration. Furthermore they require inputs of food, excesses of which contribute to dissolved organics, and therefore the nitrogen cycle, when they are uneaten - thus, messy feeders create more bioload than other organisms, lowering the carrying capacity of the aquarium system.

Feeding behaviors thus determine the 'footprint' animals have on the biofiltration in their aquarium, moreso than their size. It is also the mass of an animal that contributes to its output of wastes, moreso than any single dimension, such as its total length. Another determinant is the metabolic rate of the animal in question, which determines the speed at which its wastes are generated and churned out into the water.

The nitrogen cycle is also why overfeeding is bad, because excess food must inevitably decompose. By definition, the aquarist can't be overfeeding, from the perspective of the nitrogen cycle, when the supplied food is being eaten; overfeeding as in overeating is a different problem. However if feeding your livestock and keeping them healthy begins to stress the cycle, then you have too much bioload in your aquarium.

Often in marine aquariums, 'live rock' and 'live sand' are mentioned. These terms mystify many people, although they are relevant to filtration. The rocks and sand in question are substrates already colonised by microscopic organisms, as play a role in the nitrogen cycle. All items already this colonised are thus 'live' biofiltration media.

Unfortunately there is a misconception that 'live' rock needs transporting from the sea. Such rock is shipped damp but emersed, killing benign and desirable organisms, and necessitating a period called 'curing' in which photosynthesizers are denied an energy source, and further mortality and decomposition ensues. The result is that only 'tough as boots' organisms survive, and some of these species are harmful to corals and such.

Clearly despite the appeal of 'live rock' as a ready made, natural reef, it's use is problematic and self defeating. A distinction just be made, between the use of 'living' filtration media, and the importation of artificially depauperate microenvironments for aquariums. It is better to take rock and sand from an established reef tank instead, to avoid unwanted guests. Although even impoverished live rock can introduce interesting and useful 'friends', these can arrive also from established, nuisance-free tanks

A counterpart to the use of live rock and sand in reef aquariums, is the Walstad style of freshwater aquarium. The Walstad type of tank is one in which living plants and soil substrates are employed instead of artificial filtration; more common than a strict Walstad setup, is a hybrid system that employs both naturalistic and 'normal' approaches in its running.

Sometimes it is said that planted tanks do not cycle, or that adding plants stops the cycle. Nothing could be further from the truth. True aquatic plants and the organisms called algae, play a role in the cycle, which is why algae bloom during the cycling period of a new aquarium, when the lighting is switched on. Adding plants to freshwater tanks, and macroalgae to marine aquariums, should be thought of as assisting the stabilisation of the nitrogen cycle.

#nitrogen cycle#ammonia#nitrite#nitrate#biological filtration#biofiltration#stocking level#overfeeding#dissolved organics#live rock#live sand#algae#plants#Walstad method#planted tanks#macroalgae

2 notes

·

View notes

Text

What difference between glass tube level gauge and glass plate level gauge

1. Glass tube level gauge

The glass tube liquid level gauge can have various forms according to the requirements of use. If the requirements are not high, it can be simple and self-made. The liquid level of the precision container can be a smoother and thicker glass tube (to reduce the capillary phenomenon) plus a more precise cursor Scale to read.

A floating magnetic steel (also called float) is installed in the glass tube communicating with the container. Reed relays are installed on the upper and lower ends of the glass tube. As such, when the float is close to the thousand reed relay, the relay generates a switching action. The upper and lower limits of the liquid level can be controlled or alarmed.

Glass tube liquid level gauge is suitable for direct indication of lower pressure, open or sealed container liquid level.

2.Glass plate level gauge

Its structure is to open a thin groove on the thick tempered glass plate, the lower end is connected to the measured liquid of the container with a metal tube, the upper end is connected to the space above the liquid surface of the container with a metal tube, and a valve is connected to the container for operation.

The glass plate level gauge can withstand high pressure (up to 40 kgf/cm2) and can measure the liquid level of various media (such as water, weak alkali, ammonia, various oils, copper propyl, benzene, isopropyl) Drunk, etc.), if you want to measure the liquid level from a larger range, such as 3-4 meters, you can connect several sections of glass plate to form a meter that has a larger range and is resistant to higher pressures. .

In order to prevent the liquid from flowing out of the container when the glass breaks, steel balls are installed in the upper and lower valves connected to the glass level gauge and the container. When the glass breaks, the steel ball can automatically seal under the pressure of the container to prevent the liquid from flowing out.

Because viscous and dark-colored media can stain glass and form sound readings, glass level gauges are not suitable for the measurement of viscous and dark-colored media.

Glass type liquid level gauge is characterized by simple structure, low price, no external energy required, simple installation, suitable for places without energy and requiring explosion-proof, so even if the reading is inconvenient, it is still widely used.

0 notes

Text

Understanding Gas Detection: Why Every Industry Needs It

Gas detection plays a crucial role in industrial safety, environmental monitoring, and personal protection. Whether in manufacturing plants, refineries, chemical industries, or confined spaces, hazardous gases pose serious risks to human health and infrastructure. Without proper gas detection systems, leaks and exposures can lead to life-threatening incidents.

In this article, we will explore the importance of gas detection, the role of portable gas monitors, and the significance of gas transmitters in ensuring workplace safety and environmental security.

What is Gas Detection?

Gas detection is the process of identifying hazardous gases in the environment to prevent accidents such as explosions, fires, and health hazards. These gases include carbon monoxide (CO), hydrogen sulfide (H₂S), methane (CH₄), ammonia (NH₃), and other volatile organic compounds (VOCs). Gas detection systems are designed to alert personnel before gas concentrations reach dangerous levels.

Importance of Gas Detection in Various Industries

Industrial Safety: Many industries, such as oil and gas, chemical processing, and manufacturing, deal with hazardous gases. Proper gas detection systems help prevent workplace accidents.

Environmental Monitoring: Detecting gas leaks helps in maintaining air quality and reducing environmental pollution.

Confined Space Safety: Areas like tunnels, mines, and storage tanks may have insufficient oxygen or toxic gases. Gas detection ensures a safe working environment.

Residential and Commercial Use: Gas detection is vital in homes and commercial spaces to prevent carbon monoxide poisoning and natural gas leaks.

Portable Gas Monitor: A Flexible Safety Solution

A portable gas monitor is a handheld device that provides real-time gas detection and alerts users of potential hazards. These devices are ideal for professionals working in confined spaces or hazardous environments where gas leaks are a concern.

Features of Portable Gas Monitors

Multi-Gas Detection: Many models can detect multiple gases simultaneously, such as CO, H₂S, and oxygen levels.

Real-Time Alerts: Equipped with alarms, vibration alerts, and visual indicators, ensuring immediate response to gas leaks.

Compact and Lightweight: Designed for easy portability, allowing workers to carry them conveniently.

Long Battery Life: Many portable gas monitors offer extended battery life, making them reliable for long working hours.

Data Logging: Some advanced models store historical data for safety audits and compliance monitoring.

Benefits of Portable Gas Monitors

Immediate Threat Detection: Helps workers identify hazards instantly and take necessary action.

Worker Safety Compliance: Meets industry safety standards and regulations.

Versatile Application: Useful in various industries, including oil refineries, underground mining, and fire safety operations.

Gas Transmitters: The Backbone of Fixed Gas Detection Systems

While portable gas monitors provide mobility, gas transmitters serve as permanent installations in workplaces. Gas transmitters continuously monitor and transmit gas concentration data to a control system.

Features of Gas Transmitters

Continuous Monitoring: Works 24/7 to detect gas levels in critical areas.

Integration with Control Systems: Sends real-time data to central control units for immediate action.

Durability: Designed to withstand harsh industrial environments.

Multiple Gas Detection Capability: Can detect gases like methane, carbon monoxide, and hydrogen sulfide.

Wireless Connectivity: Some advanced gas transmitters come with IoT integration for remote monitoring.

Benefits of Gas Transmitters

Enhanced Safety: Provides real-time monitoring and prevents hazardous gas accumulation.

Cost-Effective: Reduces long-term risks, lowering maintenance and accident-related costs.

Regulatory Compliance: Ensures compliance with safety regulations and industry standards.

Choosing the Right Gas Detection System

Selecting the right gas detection system depends on factors like the type of gases present, the work environment, and industry-specific needs. Consider the following:

Workplace Conditions: Industries with confined spaces may require both portable gas monitors and gas transmitters.

Type of Gas: Identify the specific hazardous gases in your workplace before choosing a detection system.

Budget & Maintenance: Consider long-term maintenance costs and reliability when investing in gas detection devices.

Regulatory Compliance: Ensure the equipment meets national and international safety standards.

Conclusion

Gas detection is a fundamental aspect of workplace safety, environmental protection, and industrial operations. Whether using portable gas monitors for individual protection or gas transmitter for continuous monitoring, reliable gas detection technology ensures the well-being of workers and prevents catastrophic incidents. Investing in high-quality gas detection solutions helps industries stay compliant, protect employees, and maintain operational efficiency.

By incorporating the right gas detection devices, businesses can create a safer and healthier work environment while preventing potential gas-related hazards.

0 notes

Text

kidney failure in dogs

Introduction Kidney failure, or renal failure, is a serious health condition affecting dogs of all ages and breeds. The kidneys play a vital role in filtering waste, regulating hydration, and maintaining electrolyte balance. When they fail, toxins build up in the bloodstream, leading to life-threatening complications. This article explains the types, causes, symptoms, and management of kidney failure in dogs, tailored for U.S. pet owners. Insights from organizations like the American Veterinary Medical Association (AVMA) and the American Kennel Club (AKC) are included to ensure credible guidance.

What Is Kidney Failure? Kidney failure occurs when the kidneys lose their ability to function properly. It is categorized into two types:

Acute Kidney Injury (AKI): Sudden onset, often due to toxins, infections, or trauma. Potentially reversible with prompt treatment.

Chronic Kidney Disease (CKD): Gradual, irreversible loss of function over months or years, common in older dogs.

Common Causes of Kidney Failure

Acute Causes:Toxins (e.g., antifreeze, grapes/raisins, lilies, certain medications like NSAIDs).Severe dehydration or heatstroke.Infections (e.g., leptospirosis, prevalent in some U.S. regions).Urinary blockages (e.g., bladder stones).

Chronic Causes:Age-related degeneration (most common in dogs over 7 years).Congenital conditions (e.g., polycystic kidney disease in breeds like Bull Terriers).Untreated dental disease (bacteria can spread to kidneys).

Signs and Symptoms Early detection is critical. Watch for:

Increased thirst and urination (early sign of CKD).

Loss of appetite and weight loss.

Vomiting or diarrhea (often with a foul odor).

Lethargy or weakness.

Bad breath (ammonia-like smell from toxin buildup).

Pale gums or mouth ulcers.

Dehydration (check for dry gums or skin tenting).

Note: Symptoms of CKD may develop slowly, while AKI often causes sudden, severe illness.

Diagnosis and Testing Veterinarians use a combination of:

Blood tests: Elevated BUN and creatinine levels indicate kidney dysfunction.

Urinalysis: Dilute urine or protein loss may suggest CKD.

Imaging: Ultrasound or X-rays to check kidney size/structure.

Blood pressure measurement: Hypertension is common in CKD.

Treatment Options Treatment depends on the type and severity:

Acute Kidney Injury:Hospitalization with IV fluids to flush toxins.Medications to control vomiting or infections.Addressing the underlying cause (e.g., antidotes for antifreeze poisoning).

Chronic Kidney Disease:Dietary management: Prescription low-protein, low-phosphorus diets (e.g., Hill’s k/d).Subcutaneous fluids: Administered at home to maintain hydration.Medications: Phosphate binders, anti-nausea drugs, or blood pressure regulators.Supplements: Omega-3 fatty acids or potassium supplements.

Prevention Tips

Keep toxins (antifreeze, human medications, toxic plants) out of reach.

Provide fresh water daily to prevent dehydration.

Schedule regular vet check-ups, especially for senior dogs.

Vaccinate against leptospirosis in high-risk areas.

Conclusion Kidney failure is a daunting diagnosis, but early intervention can extend your dog’s quality of life. Advances in veterinary care, including specialized diets and at-home treatments, offer hope for managing both acute and chronic cases. U.S. pet owners have access to resources like board-certified veterinary internal medicine specialists and pet insurance plans (e.g., Trupanion, Healthy Paws) to offset costs. Always consult your veterinarian if you notice concerning symptoms—proactive care saves lives.

For more updates …Click Here…

Frequently Asked Questions (FAQ)

Q1: Can kidney failure in dogs be cured? A: Acute kidney injury may be reversible with immediate treatment. Chronic kidney disease is incurable but manageable with lifelong care.

Q2: How long can a dog live with kidney failure? A: Survival varies. Dogs with well-managed CKD often live 1–3 years post-diagnosis. AKI survival depends on the cause and timeliness of care.

Q3: Is kidney failure painful for dogs? A: While CKD is not inherently painful, symptoms like nausea or mouth ulcers can cause discomfort. Pain management is part of treatment.

Q4: What foods should I avoid for a dog with kidney disease? A: Avoid high-sodium, high-phosphorus, or protein-rich foods. Never feed grapes, raisins, or onions.

Q5: Are certain breeds more prone to kidney failure? A: Yes. Breeds like Cocker Spaniels, Bull Terriers, and Samoyeds have higher genetic risks.

Q6: How much does treatment cost? A: Costs vary widely. AKI hospitalization may cost 1,500–1,500–5,000. CKD management (monthly) ranges from 100–100–300 for medications and diet.

#kidney disease#kidney stone specialist#kidney diet#kidneyhealth#kidney transplant#book blog#kidneys miserable taste#healthcare#medicine#authors

0 notes

Text

youtube

Checkout my blog post for more information on why duckweed is the ultimate plant for filterless, zero water change aquariums - https://glassboxdiaries.com/duckweed-plant/

Duckweed: The Ultimate Plant For Filterless, Zero Water Change Aquariums!

Filterless, zero-water-change aquariums are becoming increasingly popular, and in this video, I explore why duckweed is arguably the best plant for this type of setup. While regular duckweed (Lemna minor) gets a bad reputation for being difficult to manage, Giant Duckweed offers many of the same benefits with far less hassle, making it a great alternative for aquarists who want to enjoy the advantages without the maintenance headaches.

Duckweed is a powerhouse plant, known for its ability to reduce nitrogen compounds like ammonia, nitrite, and nitrate. Research even shows it can help lower toxic ammonia and nitrite levels, which are often challenging to manage in filterless setups. Additionally, duckweed excels at absorbing heavy metals, such as copper, which can be harmful to shrimp and other sensitive aquatic life. With absorption rates ranging from 70% to over 99%, this plant provides a natural way to keep your tank water safer for your fish, shrimp, and snails.

One common concern in zero-water-change tanks is rising Total Dissolved Solids (TDS). Many aquarists believe TDS will continue to climb as water evaporates and leaves dissolved solids behind. However, duckweed, along with beneficial bacteria, helps manage TDS by removing nitrogen compounds, heavy metals, and even some other contaminants. Studies have shown duckweed can reduce TDS in high-contamination water by 41% in just 15 days—an impressive feat when applied to aquariums with lower TDS levels.

Duckweed also reduces algae growth by absorbing excess nutrients and phosphorus, which are key contributors to algae blooms. Its thick canopy blocks light penetration, preventing algae from thriving, while still allowing low-light aquatic plants to grow. For filterless setups, which often rely on natural balance, this can significantly reduce the risk of algae overtaking the tank.

Another incredible benefit of duckweed is its ability to improve dissolved oxygen levels. By absorbing nitrogen compounds, duckweed reduces the workload on nitrifying bacteria, lowering the tank's chemical oxygen demand. Additionally, it controls algae growth, preventing oxygen depletion caused by decaying algae. Research indicates duckweed can reduce chemical oxygen demand by up to 70% and biological oxygen demand by 75%, freeing up oxygen for your fish, shrimp, and snails.

However, duckweed isn’t without its challenges. Its rapid growth can lead to overcrowding, which blocks gas exchange at the water’s surface. To avoid this, I recommend removing excess duckweed weekly, keeping it to around 25% of your tank’s surface area. Managing duckweed can be made easier by using a simple tool like a hair comb to skim off the excess. If you’re worried about duckweed taking over your tank, Giant Duckweed or Water Lettuce are excellent alternatives with similar benefits and easier maintenance.

Another common issue is that some aquarists struggle to grow duckweed, often due to high water flow or the presence of certain snails and fish that eat it. Adjusting flow and choosing compatible tank mates can solve these issues. For example, Goldfish and Apple Snails are known to eat duckweed, while shrimp, smaller snails, and peaceful community fish tend to coexist well with it.

#aquarium#fishtank#plantedtank#plantedaquarium#duckweed#aquariumplants#aquaticplants#walstad#walstadmethod#naturalaquariums#Youtube

1 note

·

View note

Text

Laboratory Chemical Suppliers in India: The Backbone of Scientific Research and Industry

In India, the role of laboratory chemical suppliers is crucial across a wide range of industries, from research and development to pharmaceuticals, food safety, and environmental testing. These suppliers provide a comprehensive range of chemicals, reagents, solvents, and other essential materials that are used in laboratories for a variety of purposes. With India being a hub for scientific advancement and innovation, the need for high-quality, reliable chemical suppliers has never been more significant.

What Do Laboratory Chemical Suppliers Do?

Laboratory chemical suppliers provide a wide array of chemicals that are critical to laboratory processes. They ensure the availability of the right chemicals in the right quantities and purity levels. This includes everything from basic reagents used in chemical reactions to advanced specialty chemicals needed for complex research projects.

The role of these suppliers goes beyond just providing chemicals. They are also responsible for ensuring the safety, proper handling, and storage of hazardous substances. Most reputable suppliers comply with industry regulations and standards, ensuring that the chemicals they supply meet the highest safety and quality requirements.

Why Are Laboratory Chemical Suppliers Important?

Support for Research and Innovation: India is home to numerous research institutions, universities, and laboratories that rely heavily on a constant supply of quality chemicals. Whether it’s for testing, analysis, or experiments, a steady supply chain of chemicals is essential for the progress of scientific research.

Contributing to the Pharmaceutical Industry: The pharmaceutical sector in India is one of the largest and most advanced in the world. Laboratory chemical suppliers play a key role in the development of medicines by providing chemicals needed for the synthesis of active pharmaceutical ingredients (APIs), excipients, and other components required for drug formulation.

Food and Beverage Safety: In the food and beverage industry, chemicals are used for quality control, preservation, and testing for contaminants. Suppliers that provide food-grade chemicals ensure that these substances meet strict regulatory standards to protect consumer health.

Environmental Testing: The growing emphasis on environmental protection means that more laboratories are conducting tests to monitor air, water, and soil quality. Laboratory chemical suppliers provide essential chemicals needed for these environmental assessments, helping to identify pollutants and safeguard public health.

Ensuring Consistency and Reliability: One of the biggest challenges for laboratories is maintaining consistency in their results. Reliable laboratory chemical suppliers ensure that chemicals are consistent in terms of quality, concentration, and shelf life. This reliability is critical for obtaining accurate and reproducible results in experiments and tests.

Key Chemicals Supplied by Laboratory Chemical Suppliers

Laboratory chemicals can be categorized into several groups, each serving a unique function in laboratory experiments. Some of the most common chemicals supplied by laboratory suppliers include:

Acids and Bases: These are fundamental reagents used in a variety of chemical reactions and processes. Examples include hydrochloric acid, sulfuric acid, sodium hydroxide, and ammonia.

Solvents: These are used to dissolve other substances, and some common solvents are water, ethanol, acetone, and methanol. Solvents play an essential role in many organic and inorganic reactions.

Buffers: These chemicals maintain the pH level of a solution, which is vital for many biochemical processes. Examples include phosphate buffer and tris buffer.

Reagents for Analysis: These include substances used in analytical procedures, such as indicators, titrants, and reagents for spectroscopy and chromatography.

Specialty Chemicals: These are more complex chemicals used in specialized applications, such as in pharmaceuticals or biotechnology. These can include catalysts, enzymes, and reagents for genetic research.

Choosing the Right Laboratory Chemical Supplier in India

When selecting a laboratory chemical supplier, there are several factors to consider:

Quality and Purity: The quality of the chemicals is paramount, as impurities can affect the results of experiments. Reliable suppliers provide certificates of analysis (COA) and ensure that their chemicals meet international standards.

Compliance with Safety Regulations: It’s essential to choose a supplier that adheres to safety regulations and provides the necessary safety data sheets (SDS) for their chemicals. This helps laboratories follow proper safety protocols when handling potentially hazardous substances.

Reputation and Experience: Established suppliers with a good track record are more likely to provide consistent, high-quality products. Look for companies with years of experience and positive reviews from customers in relevant industries.

Availability and Timeliness: A supplier with a fast and reliable delivery system ensures that laboratories don’t face any delays in receiving the chemicals they need. Timeliness is crucial, especially when working with perishable or time-sensitive materials.

Cost-Effectiveness: While price should not be the only factor, it’s important to balance quality with affordability. A reputable supplier will offer competitive prices without compromising on the quality of the chemicals they provide.

Conclusion

Laboratory chemical suppliers in India are essential partners in the fields of research, manufacturing, testing, and development. They provide the necessary materials to drive innovation and support various industries, from pharmaceuticals to food safety and environmental protection. Whether you’re involved in scientific research, quality control, or production, choosing the right supplier is crucial to ensuring that your work is accurate, efficient, and safe. By considering factors like quality, reliability, compliance, and experience, laboratories can find a trusted chemical supplier that meets their needs and supports their long-term goals.

#Laboratory chemical supplier india#scientific discovery#lab#chemicals#scifi#lab chemicals#science#lab instruments#laboratory chemicals#setting up a new lab

0 notes

Text

[ad_1] Paromita Das GG News Bureau New Delhi, 31st Jan. In a recent escalation of tensions, former Delhi Chief Minister and Aam Aadmi Party (AAP) leader Arvind Kejriwal has found himself at odds with the Election Commission of India (ECI) following his contentious claim that the Haryana government is “poisoning” the Yamuna River—a critical water source for the national capital. The ECI has issued a notice to Kejriwal, seeking clarification and evidence to substantiate his allegations, which have been criticized for potentially inciting public discord. ECI’s Demand for Evidence On January 30, the ECI formally requested that Kejriwal provide concrete evidence supporting his assertion that Haryana is contaminating the Yamuna River. The Commission’s notice emphasized the gravity of the allegations, highlighting concerns over promoting disharmony and public unrest. Kejriwal was instructed to submit detailed information, including the type and quantity of the alleged poison, detection methods employed by Delhi Jal Board engineers, and specific locations of contamination, by 11 a.m. on January 30. The ECI warned that failure to comply would result in appropriate action. ECI responds to AAP national convener Arvind Kejriwal to not mix issues of increased ammonia in Yamuna with his serious allegations of Yamuna poisoning with mass genocide, equating with an act of war between two nations. pic.twitter.com/rnu4mRmOlE — ANI (@ANI) January 30, 2025 Kejriwal’s Defiant Response In response, Kejriwal held a press conference where he launched a personal attack on Chief Election Commissioner Rajeev Kumar, accusing him of engaging in politics to secure a post-retirement position. He criticized the ECI for allegedly overlooking blatant instances of monetary inducements in Delhi and claimed that the Commission’s actions have tarnished its reputation. Expressing his readiness to face imprisonment, Kejriwal stated, “I know they will put me in jail within two days. Let them. I am not afraid.” Political Repercussions and Legal Actions Kejriwal’s allegations have elicited strong reactions from political adversaries. Both the Bharatiya Janata Party (BJP) and the Congress have filed complaints with the ECI, accusing him of making unfounded and inflammatory statements. On January 29, the Haryana government lodged a First Information Report (FIR) against Kejriwal under sections of the Disaster Management Act for spreading misinformation and creating public panic. Haryana’s Revenue and Disaster Management Minister, Vipul Goel, condemned Kejriwal’s remarks as irresponsible and asserted that the people of Delhi would soon reject his leadership. Historical Context of Yamuna Pollution The issue of Yamuna River pollution has been a longstanding concern, with various administrations pledging to address it. Notably, during Kejriwal’s tenure as Chief Minister, the pollution levels in the Yamuna reportedly doubled over eight years. Data from the Delhi Pollution Control Committee indicated a significant increase in Biological Oxygen Demand levels, a key indicator of water quality, at various monitoring points along the river. This data suggests that despite previous commitments, effective measures to mitigate pollution have been lacking. Kejriwal’s recent allegations against the Haryana government raise critical questions about political accountability and the responsible dissemination of information. While concerns over water quality are valid and warrant thorough investigation, making unsubstantiated claims can exacerbate inter-state tensions and undermine public trust. It is imperative for political leaders to engage in constructive dialogue, supported by evidence, to address environmental challenges collaboratively. Conclusion The confrontation between Arvind Kejriwal and the Election Commission underscores the delicate balance between political advocacy and responsible governance. As the situation unfolds, it remains essential for all parties involved to prioritize

factual accuracy and cooperative problem-solving to ensure the well-being of the populace and the preservation of vital natural resources like the Yamuna River. The post Arvind Kejriwal’s ‘Yamuna Poisoning’ Allegation Sparks Clash with Election Commission appeared first on Global Governance News- Asia's First Bilingual News portal for Global News and Updates. [ad_2] Source link

0 notes

Text

[ad_1] Paromita Das GG News Bureau New Delhi, 31st Jan. In a recent escalation of tensions, former Delhi Chief Minister and Aam Aadmi Party (AAP) leader Arvind Kejriwal has found himself at odds with the Election Commission of India (ECI) following his contentious claim that the Haryana government is “poisoning” the Yamuna River—a critical water source for the national capital. The ECI has issued a notice to Kejriwal, seeking clarification and evidence to substantiate his allegations, which have been criticized for potentially inciting public discord. ECI’s Demand for Evidence On January 30, the ECI formally requested that Kejriwal provide concrete evidence supporting his assertion that Haryana is contaminating the Yamuna River. The Commission’s notice emphasized the gravity of the allegations, highlighting concerns over promoting disharmony and public unrest. Kejriwal was instructed to submit detailed information, including the type and quantity of the alleged poison, detection methods employed by Delhi Jal Board engineers, and specific locations of contamination, by 11 a.m. on January 30. The ECI warned that failure to comply would result in appropriate action. ECI responds to AAP national convener Arvind Kejriwal to not mix issues of increased ammonia in Yamuna with his serious allegations of Yamuna poisoning with mass genocide, equating with an act of war between two nations. pic.twitter.com/rnu4mRmOlE — ANI (@ANI) January 30, 2025 Kejriwal’s Defiant Response In response, Kejriwal held a press conference where he launched a personal attack on Chief Election Commissioner Rajeev Kumar, accusing him of engaging in politics to secure a post-retirement position. He criticized the ECI for allegedly overlooking blatant instances of monetary inducements in Delhi and claimed that the Commission’s actions have tarnished its reputation. Expressing his readiness to face imprisonment, Kejriwal stated, “I know they will put me in jail within two days. Let them. I am not afraid.” Political Repercussions and Legal Actions Kejriwal’s allegations have elicited strong reactions from political adversaries. Both the Bharatiya Janata Party (BJP) and the Congress have filed complaints with the ECI, accusing him of making unfounded and inflammatory statements. On January 29, the Haryana government lodged a First Information Report (FIR) against Kejriwal under sections of the Disaster Management Act for spreading misinformation and creating public panic. Haryana’s Revenue and Disaster Management Minister, Vipul Goel, condemned Kejriwal’s remarks as irresponsible and asserted that the people of Delhi would soon reject his leadership. Historical Context of Yamuna Pollution The issue of Yamuna River pollution has been a longstanding concern, with various administrations pledging to address it. Notably, during Kejriwal’s tenure as Chief Minister, the pollution levels in the Yamuna reportedly doubled over eight years. Data from the Delhi Pollution Control Committee indicated a significant increase in Biological Oxygen Demand levels, a key indicator of water quality, at various monitoring points along the river. This data suggests that despite previous commitments, effective measures to mitigate pollution have been lacking. Kejriwal’s recent allegations against the Haryana government raise critical questions about political accountability and the responsible dissemination of information. While concerns over water quality are valid and warrant thorough investigation, making unsubstantiated claims can exacerbate inter-state tensions and undermine public trust. It is imperative for political leaders to engage in constructive dialogue, supported by evidence, to address environmental challenges collaboratively. Conclusion The confrontation between Arvind Kejriwal and the Election Commission underscores the delicate balance between political advocacy and responsible governance. As the situation unfolds, it remains essential for all parties involved to prioritize

factual accuracy and cooperative problem-solving to ensure the well-being of the populace and the preservation of vital natural resources like the Yamuna River. The post Arvind Kejriwal’s ‘Yamuna Poisoning’ Allegation Sparks Clash with Election Commission appeared first on Global Governance News- Asia's First Bilingual News portal for Global News and Updates. [ad_2] Source link

0 notes

Text

How to Choose the Best Hydrated Lime Manufacturers

Understanding the Importance of Hydrated Lime

Hydrated lime, also known as calcium hydroxide, is an essential chemical used across various industries, including construction, agriculture, water treatment, and more. The demand for high-quality hydrated lime makes it crucial to partner with reliable manufacturers who can deliver consistent quality and performance. Choosing the right manufacturer can be challenging, especially when considering the growing number of suppliers in the market. Here is a comprehensive guide to help you select the best Hydrated lime manufacturers for your business needs.

Identifying Your Specific Needs

Before you start your search, it's essential to identify your specific needs. Different industries require hydrated lime for various applications. In construction, it is used in soil stabilization and as a key ingredient in mortars and plasters. In agriculture, it enhances soil quality by neutralizing acidity. For water treatment, hydrated lime removes impurities and adjusts pH levels. Understanding your requirements will help you evaluate manufacturers based on their ability to meet your unique specifications.

Evaluating Industry Experience

Experience matters when selecting a hydrated lime manufacturer. Companies with years of experience in the industry tend to have better production processes, quality control systems, and expertise in meeting diverse customer needs. Established manufacturers often have a proven track record and a wide client base, reflecting their reliability.

Assessing Product Quality

The quality of hydrated lime can vary significantly between manufacturers. High-quality hydrated lime should have consistent chemical composition, purity, and performance. Request a sample from potential suppliers and conduct quality tests to ensure the product meets your standards. Reliable manufacturers, including Aluminium sulphate manufacturers, should adhere to international quality standards and certifications, such as ISO certifications. Their commitment to quality reflects their capability to deliver products that meet stringent industrial requirements.

Checking Production Capacity

If your business requires large quantities of hydrated lime, it is essential to assess the manufacturer’s production capacity. Ensure they can meet your demand consistently without compromising on quality. Additionally, inquire about their ability to scale production if your requirements grow over time.

Considering Versatility in Chemical Manufacturing

Leading chemical manufacturers often produce a wide range of related products, which can be an added advantage. For instance, manufacturers who also produce sodium sulphate, anhydrous ammonia, aluminium sulphate, and sodium metabisulfite demonstrate versatility and expertise in the chemical industry. This versatility may indicate their capability to maintain high-quality standards across multiple products, making them a reliable partner for your chemical needs.

Ensuring Supply Chain Efficiency

A reliable supply chain ensures timely delivery of products, which is critical for maintaining uninterrupted operations. When evaluating hydrated lime manufacturers, ask about their logistics and distribution capabilities. Do they have a robust network to deliver products on time? Are they equipped to handle international shipments if required? Efficient supply chain management is a hallmark of a dependable manufacturer.

Prioritizing Sustainability

Sustainability is becoming an increasingly important factor in the chemical industry. Choose manufacturers who prioritize eco-friendly production processes and minimize their environmental impact. Companies that adhere to sustainable practices not only contribute to a greener future but also help you align your business with environmental standards and regulations.

Evaluating Customer Support and Service

Excellent customer service is a key aspect of a successful partnership. Reliable manufacturers, including Sodium metabisulfite manufacturers, should provide prompt responses to inquiries, technical support for product usage, and assistance with documentation, such as safety data sheets and certifications. A manufacturer’s willingness to address your concerns and provide ongoing support reflects their commitment to customer satisfaction and long-term collaboration.

Researching Reputation and Reviews

Research the manufacturer’s reputation in the market. Look for customer reviews, testimonials, and case studies to gauge their reliability and performance. A company with positive feedback from long-term clients is more likely to deliver consistent quality and service.

Balancing Costs and Value

While cost is an important factor, it should not be the sole criterion for selecting a manufacturer. Focus on the value offered, which includes product quality, reliability, customer service, and long-term partnership benefits. A slightly higher upfront cost for a reliable manufacturer can save you from potential losses due to substandard products or inconsistent supply.

Partnering with Versatile Suppliers

Working with a manufacturer that supplies a broad range of chemicals can streamline your procurement process. For instance, companies that are also established sodium sulphate manufacturers, Anhydrous ammonia manufacturers, aluminium sulphate manufacturers, and sodium metabisulfite manufacturers can become your one-stop solution for multiple chemical needs. This reduces the complexity of dealing with multiple suppliers and ensures consistent quality across your chemical supplies.

Conclusion

Choosing the best hydrated lime manufacturers requires careful evaluation of their expertise, product quality, production capacity, supply chain efficiency, and commitment to sustainability. By partnering with a reliable and versatile manufacturer, you can ensure consistent supply, superior quality, and long-term benefits for your business. Keep in mind that manufacturers who also excel as Sodium sulphate manufacturers, anhydrous ammonia manufacturers, aluminium sulphate manufacturers, and sodium metabisulfite manufacturers demonstrate a level of expertise and versatility that can significantly enhance your operations. Take your time to research and make an informed decision to secure a successful and enduring partnership.

#Sodium Sulphate Manufacturers#Anhydrous Ammonia Manufacturers#Aluminium Sulphate Manufacturers#Hydrated Lime Manufacturers#Sodium Metabisulfite Manufacturers

0 notes

Text

Asha Enterprises | Ammonia valves, Ammonia refrigeration compressors, Ammonia solenoid valves, Ammonia weldable valves Pune, India

Asha Enterprises is best Ammonia valves, Ammonia refrigeration compressors, Ammonia solenoid valves, Ammonia weldable valves, Ammonia level control with indicator, Ice plant equipment, Ice cans, Refrigeration compressor spare parts, Ammonia compressor spare parts, Ammonia IBT Coil, Ammonia condensers, Ammonia receiver storage tanks supplier, Manufacturer Company in Pune, Mumbai, Thane, Navi Mumbai, Kolhapur, Ratnagiri, Raigad, Nashik, Solapur, Latur, Aurangabad, Sindhudurg, Sangli, Solapur, Ahmednagar, Satara and Maharashtra.

#Asha Enterprises#Asha Enterprises in Pune#Asha Enterprises in India#Ammonia valves#Ammonia refrigeration compressors#Ammonia solenoid valves#Ammonia weldable valves#Ammonia level control with indicator#Ice plant equipment#Ice cans#Refrigeration compressor spare parts#Ammonia compressor spare parts#Ammonia IBT Coil#Ammonia condensers#Ammonia receiver storage tanks#Pune#Mumbai#Thane#Navi Mumbai#Kolhapur#Ratnagiri#Raigad#Nashik#Solapur#Latur#Aurangabad#Sindhudurg#Sangli#Ahmednagar#Satara and Maharashtra.

0 notes

Text

Hair care solution

1. Understand Your Hair Type

Your hair type dictates your care routine. Hair can be:

Oily: Scalp produces excess oil; hair feels greasy.

Dry: Scalp lacks oil; hair appears dull or brittle.

Normal: Balanced moisture and oil levels.

Combination: Oily roots and dry ends.

How to Determine:

After washing,(https://e-commerceexpressindia.store/) check how your scalp feels by the end of the day.

Use products specifically designed for your hair type.

2. Cleansing: Shampooing the Right Way

Frequency: Avoid over-washing as it strips natural oils. Wash 2-3 times a week unless you sweat heavily or have an oily scalp.

Technique:

Wet hair thoroughly.

Use a small amount of shampoo, focusing on the scalp.

Gently massage with fingertips (not nails) to boost circulation.

Avoid Hot Water: It dries out the scalp. Use lukewarm water and finish with cold water to seal cuticles.

3. Conditioning for Moisture and Shine

How to Use:

Apply conditioner only on the mid-lengths to ends of your hair (not the scalp).

Leave for 2-3 minutes before rinsing.

Deep Conditioning:

Use a deep conditioner or mask weekly to repair damage and restore hydration.

4. Pre-Wash Hair Oiling

Why Oil?

Oils nourish the scalp, promote growth, and prevent dryness.

Best Oils for Hair:

Coconut Oil: Deeply penetrates hair shafts.

Argan Oil: Adds shine and reduces frizz.

Castor Oil: Promotes hair growth.

Almond Oil: Strengthens hair.

How to Apply:

Warm the oil slightly.

Massage into the scalp for 5-10 minutes.

Leave it on for at least 1 hour or overnight.

5. Avoiding Damage: Heat, Styling, and Chemicals

Minimize Heat Tools: Blow-dry, straighten, and curl sparingly.

Use Heat Protectants: Always apply before heat styling.

Chemical Treatments: Avoid frequent coloring, bleaching, or perming. Use ammonia-free dyes and herbal henna as alternatives.

6. Protecting Hair from Environmental Damage

Sun Protection: Wear hats or use hair sunscreen sprays.

Pollution: Cover your hair with a scarf in polluted areas.

Swimming: Wet hair before entering the pool to reduce chlorine absorption, and rinse hair immediately after.

7. Diet and Hydration for Healthy Hair

Key Nutrients:

Biotin: Found in eggs, nuts, and bananas for growth.

Omega-3: Found in fish, walnuts, and flaxseeds for hydration.

Proteins: Strengthen hair; include chicken, tofu, and dairy.

Iron and Zinc: Prevent hair fall; include spinach, beans, and lentils.

Stay Hydrated: Drink at least 8-10 glasses of water daily.

8. Special Hair Treatments

DIY Hair Masks:

For Dry Hair: Blend banana, honey, and coconut oil.

For Oily Hair: Mix yogurt, lemon juice, and aloe vera.

For Damage Repair: Use avocado, olive oil, and honey.

Protein Treatments: Strengthen weak strands with keratin-enriched masks.

9. Trimming and Maintenance

Frequency: Trim hair every 6-8 weeks to prevent split ends.

Combing: Use a wide-tooth comb to detangle. Start from the ends and work upwards.

10. Scalp Care: The Foundation of Healthy Hair

Exfoliate: Use a gentle scalp scrub once a month to remove dead skin cells and buildup.

Massage Regularly: Stimulates blood flow and enhances hair growth.

Anti-Dandruff Care:

Use shampoos with zinc pyrithione or ketoconazole.

Natural remedy: Massage with tea tree oil mixed with a carrier oil.

11. Night-Time Hair Care

Silk Pillowcases: Reduces friction, preventing breakage and frizz.

Protective Hairstyles: Opt for loose braids or buns to avoid tangling.

Overnight Masks: Apply nourishing treatments overnight for extra hydration.

12. Signs You Need Extra Attention

Hair Loss: Excessive shedding may indicate stress, nutritional deficiencies, or hormonal imbalances.

Breakage: Look into strengthening treatments or consult a dermatologist.

Scalp Issues: Persistent itching or dandruff may require medicated products.

By combining these practices, you can maintain strong, healthy, and shiny hair. Would you like guidance on specific concerns like dandruff, hair fall, or frizz control?

0 notes

Text

Fisheries: Common Winter Diseases in Fish and How to Prevent Them

Overview of Winter Fisheries Challenges The Value of Recognizing Seasonal Hazards Fish growers have particular difficulties throughout the winter. Due to weakening immune systems and environmental stresses, fish are more vulnerable to illnesses when temperatures decrease.

Why Fish Are More At Risk During the Winter Fish have a lower ability to fight diseases in colder climates because their metabolism slows down and they eat less. Furthermore, wintertime tends to see a decline in water quality, which exacerbates health problems.

Wintertime Common Fish Illnesses Yellow Spot Disease (Ichthyophthirius) Reasons and Signs A protozoan parasite is the cause of "Ich," or white spot disease. White patches on the body and gills, fatigue, and constant rubbing against objects are some of the symptoms.

Therapy and Avoidance Anti-parasitic drugs and a little increase in water temperature are two treatment options. Keeping the water at ideal levels and putting new fish in quarantine are two aspects of prevention.

The causes and symptoms of cotton wool disease, or columnaris Growths on the skin, fins, or gills that resemble cotton are the result of this bacterial illness. Poor water conditions are ideal for it, especially when oxygen levels are low.

Therapy and Avoidance Enhance water quality, separate contaminated fish, and provide antibiotics or antifungal medications. Making sure the water is clean and oxygen-rich is the main goal of prevention.

Swim Bladder Disorder: Signs and Causes It is difficult for fish in this state to stay buoyant. Poor water quality, bacterial illnesses, or constipation are frequently the causes.

Therapy and Avoidance The fish are fed peas to ease constipation and are fasted for a day or two as treatments. A healthy diet and routine tank maintenance are preventative measures.

Reasons for Fungal Infections and Their Signs White or grayish areas on the fish's body are frequently the result of fungal infections, which typically happen after stress or injury.

Therapy and Avoidance Apply antifungal treatments and enhance the water's quality. Reducing stress and taking quick care of injuries are examples of preventive strategies.

Fish diseases in winter are caused by a number of factors, including decreased metabolism. Fish that experience cold temperatures are less active and more susceptible to illnesses.

Inadequate Water Quality Because filtration is less effective in the winter, ammonia and nitrite levels tend to increase, stressing fish and raising the risk of illness.

Strain and Crowding Overcrowding in tanks or ponds can cause stress, more competition, and a quicker spread of illnesses.

Winter Fish Health Prevention Strategies: Preserving Water Quality and Temperature Control In severe weather, stabilize the temperature by using heaters or varying the water depth.

Frequently Scheduled Water Changes Regular water changes support the maintenance of oxygen levels and the removal of dangerous pollutants.

Healthy Eating Give fish winter diet that is easy to digest and of high quality to help boost their immune systems.

The right stocking density Follow suggested stocking densities to prevent overcrowding and lessen stress and disease transmission.

Protection of Fresh Fish Before adding new fish to the main pond or tank, keep them isolated for a few weeks to watch for illness symptoms.

The function of surveillance and early warning indicators Watch for odd behaviors such as fatigue, appetite loss, or obvious lesions. With early discovery, epidemics can be avoided.

Resources for Tracking the Health of Fish Measure things like oxygen levels, pH, and ammonia with water testing kits. Examining fish visually on a regular basis is also essential.

Disease Prevention's Benefits for Fisheries: Increased Yield Healthy fish, whether raised for meat or as ornaments, develop more quickly and output more.

Decreased Operating Expenses Disease prevention lowers treatment costs and decreases losses.

Improved Well-being of Fish Stress levels are lower in healthy fish, which improves their general health and lowers their death rates.

In conclusion, Fish farmers face particular difficulties during the winter, but with effective management, disease risks may be greatly decreased. A profitable and stress-free winter season in your fishery may be guaranteed by preserving water quality, feeding fish a balanced diet, and keeping an eye on their health.

0 notes

Text

Essential Guide to Florida Keys Aquarium Maintenance: Tips for an Optimum Marine Ecosystem

Owning an aquarium that reflects the stunning aquatic life of the Florida Keys is a rewarding endeavor, but it comes with unique challenges. The warm, tropical environment of the Keys is home to diverse marine species, each with specific needs. To successfully recreate and sustain this ecosystem in an aquarium, regular and thoughtful maintenance is required. Whether you are setting up a saltwater tank or maintaining one, understanding the essential aspects of Florida Keys aquarium maintenance can ensure a healthy environment for your aquatic life.

The Critical Role of Water Quality

Water quality is arguably the most important factor in maintaining a thriving aquarium. By offering Florida Keys aquarium maintenance services, professionals recreate a carefully balanced aquarium and take care to address key parameters like salinity, pH, ammonia, nitrites, and nitrates; carefully monitors and adjusts them as necessary. Saltwater aquariums, especially those replicating the Keys' environment, require a stable salinity level that mirrors ocean water—typically around 1.025 specific gravity.

Filtration and Water Circulation Systems

In the Florida Keys, the movement of water plays an integral role in maintaining the health of its marine life. Similarly, effective filtration and water circulation are essential for aquarium maintenance. Proper filtration helps remove organic waste and other toxins, keeping the water clean and clear. In saltwater aquariums, protein skimmers are especially beneficial as they remove organic matter before it can break down into dangerous compounds, reducing the load on your filtration system.

Proper Lighting and Temperature Control

Lighting is another critical aspect of Florida Keys aquarium maintenance, especially for tanks with live coral and other photosynthetic species. Corals and marine plants rely on light for photosynthesis, so providing the right type of lighting is essential. LED lighting systems with adjustable color temperatures and intensity can simulate the natural sunlight found in the Florida Keys, promoting healthy coral growth and the development of symbiotic relationships with algae.

Ongoing Maintenance and Observation

Consistent maintenance is a vital part of keeping an aquarium healthy over time. In addition to testing water quality, you should regularly clean the substrate, trim any overgrown plants, and inspect all equipment to ensure everything is functioning properly. Filters should be cleaned, protein skimmers maintained, and powerheads checked for any blockages. Routine observation of your aquarium’s inhabitants is also necessary to spot any signs of stress, disease, or poor health, which can often be early indicators of underlying issues with water quality or the aquarium's ecosystem

Overall, Florida Keys aquarium maintenance requires commitment, attention to detail, and a clear understanding of the delicate balance that sustains marine life. By keeping a close eye on water quality, filtration, lighting, and temperature, and committing to regular upkeep, you can create and maintain an aquarium that mirrors the vibrant and thriving ecosystems of the Florida Keys. Whether you're replicating a small reef tank or a larger marine setup, the right maintenance practices will help ensure your aquarium remains a beautiful and healthy home for your aquatic life.

0 notes

Text

Housing for beef cattle: The importance of finding the right structure

Taking steps to ensure the health and productivity of beef cattle is essential for any livestock owner. Proper housing for beef cattle plays an important role in this regard by providing a safe, healthy environment that supports growth and welfare. A well-designed structure goes beyond basic shelter and significantly affects cattle health, productivity, and overall farm efficiency.

With studies indicating a mortality rate of up to 30% in calves due to respiratory disease, paying attention to key factors like climate control and ventilation are crucial in maintaining a stable environment for livestock.

In this blog post, let’s find out more information to understand the relationship between structure, ventilation, and climate control vital for livestock owners.

The role of structure in cattle health

The design and structure of housing for beef cattle have a profound impact on the welfare and productivity of the herd. Proper structural design not only ensures that cattle have sufficient space but also provides protection from environmental factors such as wind, rain, and extreme temperatures.

Inadequate housing can lead to common health problems. For example, structures that lack sufficient ventilation can trap harmful gases like ammonia, contributing to respiratory diseases. Additionally, overcrowded spaces can lead to stress and aggressive behaviour among cattle, which negatively impacts their overall health and growth. A well-structured housing system, by contrast, promotes easy movement, reduces stress, and ensures that cattle remain safe and comfortable.

A strong structural design also simplifies day-to-day operations. Tasks like feeding, cleaning, and animal monitoring are made easier, reducing labour costs and improving efficiency on the farm.

The importance of ventilation

Ventilation is critical to maintaining the health of beef cattle. Proper air circulation ensures that humidity and ammonia levels remain low, preventing the development of respiratory illnesses. High humidity encourages the growth of harmful bacteria, while ammonia build-up from cattle manure can irritate the respiratory systems of both cattle and humans.

Good ventilation also plays a significant role in reducing heat stress. During hot weather, beef cattle can suffer from elevated body temperatures, which reduce feed intake and slow their growth. A well-ventilated space allows heat to escape, keeping cattle cooler and more comfortable. Systems that incorporate open-sided structures, ridge ventilation, or mechanical fans ensure adequate airflow, which helps maintain a stable and healthy environment for cattle throughout the year.

Building the future of housing for beef cattle

Focusing on key elements like structural design, ventilation, and climate control is the best way to ensure that livestock is housed in structures optimising their living conditions. These factors are essential in promoting cattle health, boosting productivity, and reducing operational costs. Investing in high-quality housing is not just an expense but a long-term investment that will pay off in healthier, more productive herds. By staying compliant with regulations and adopting best practices, livestock owners can ensure that their cattle are sheltered in livestock housing with optimal conditions, leading to greater profitability and success in their farming operations.

0 notes