#Animal feed exporters from india

Text

Innovative Approaches to Animal Feed Export: Brinda Feeds' Best Practices

Discover how Brinda Feeds aligns with international standards to meet the diverse needs of global markets. You can get best animal feed suppliers in india. Want now Get now

#animal feed suppliers in india#animal feed manufacturers in india#animal feed export from india#Animal Feed Suppliers

0 notes

Text

We are one of India's major manufacturers, exporters and suppliers of agricultural products and other commodities. Dhanraj Enterprise is a leading supplier of oil seeds, spices, dry fruits, pulses & grains, herbs, animal feeds, coconuts products etc. Established in 2008, we are able to supply you finest quality products from the most reliable pre-screened sources. We have well trained & experienced staff having efficient knowledge of global trade.

#Desiccated coconut exporter#Desiccated coconut Manufacturer#Desiccated coconut producer#Desiccated coconut supplier#Animal feed products manufacturer and exporter from india#Indian dry red chilli manufacturer and exporters

0 notes

Text

India's Dairy Industry Sees Surge in Milk Production Amid New Challenges

The dairy industry has always been a vital part of India’s agricultural sector, and recent developments indicate that it is poised for even more growth. With increasing demand for milk and dairy products both domestically and globally, the industry is taking significant steps to boost production and ensure sustainability. India remains the largest producer of milk in the world, with its dairy sector contributing significantly to the livelihoods of millions of farmers across the country. However, as the market continues to grow, new challenges are emerging that require attention from policymakers and industry leaders.

One of the most notable trends in dairy industry news is the increase in Indian milk production over the past year. According to recent reports, India’s milk output has grown by nearly 6% annually, reaching approximately 220 million metric tons in 2023. This surge is largely attributed to the adoption of advanced dairy farming techniques, improved animal husbandry, and better feed management practices. The government has also played a crucial role by introducing schemes aimed at modernizing dairy infrastructure, enhancing cold chain facilities, and providing financial assistance to small and marginal farmers.

Despite the increase in Indian milk production, the industry faces several challenges. One pressing issue is the rising cost of fodder and feed, which has put pressure on the profitability of dairy farmers. Climate change is another growing concern, as unpredictable weather patterns and extreme temperatures are affecting livestock health and milk yields. Furthermore, the industry is grappling with the need for more efficient logistics and distribution systems, especially in rural areas where access to quality refrigeration and storage facilities remains limited.

In response to these challenges, industry stakeholders are advocating for greater investment in research and development to enhance dairy farming practices and make them more resilient to climate change. Additionally, there is a growing focus on expanding export opportunities for Indian dairy products, particularly in Southeast Asia and the Middle East, where demand for high-quality milk products is on the rise.

Overall, while the Indian dairy industry continues to experience impressive growth, addressing these challenges will be critical to ensuring its long-term sustainability. As the sector evolves, it remains a crucial component of India’s economic fabric, supporting the livelihoods of millions and contributing to the nation’s food security.

0 notes

Text

Starch Manufacturers in India | Gujarat Ambuja Exports Limited

Gujarat Ambuja Exports Limited (GAEL) is a famous name in the starch manufacturing industry in India. Founded in 1991, GAEL has become one of the largest producers of corn starch and maize starch, supplying high-quality products to various industries. Starch, a versatile carbohydrate, plays an essential role in numerous sectors, from food processing to pharmaceuticals. GAEL’s contribution to the starch industry underscores its commitment to innovation, quality, and sustainability.

Understanding Starch

Starch is a naturally occurring carbohydrate found in plants like corn, maize, and potatoes. Chemically, it is a polysaccharide composed of glucose molecules linked together. There are different types of starch, with corn starch and maize starch being among the most commonly used. Corn starch is widely used in food processing, while maize starch finds applications in industries like textiles and pharmaceuticals.

Who are the Biggest Starch Producers in India?

India has several major players in the starch industry. GAEL stands out as one of the largest manufacturers of starch. These companies have established a strong presence in the domestic and international markets, contributing significantly to the country's starch production.

Who is the Manufacturer of Starch in India?

GAEL is a leading starch manufacturer in India, producing high-quality starch products. They specialise in corn starch derivatives and soya derivatives, catering to various industries such as food, textiles, pharmaceuticals, and agro-processing. With advanced manufacturing facilities and a focus on sustainable practices, GAEL has earned its reputation as a trusted starch producer in India.

Gujarat Ambuja Exports Limited: Company Profile

Founded in 1991, GAEL began its journey with a vision to become a leader in agro-processing. The company focuses on producing corn starch derivatives, soya derivatives, and animal feed products. With advanced technology and a dedicated team, GAEL has grown to become one of the largest starch producers in India. Their emphasis on innovation, quality control, and sustainable practices has allowed them to maintain a competitive edge in the market.

The Role of Starch in Various Industries

Starch is a critical ingredient in several industries. In the food industry, it is used as a thickener, stabilizer, and emulsifier. The pharmaceutical sector utilizes starch in the production of tablets and capsules, where it acts as a binder. In the feed industry, starch is used as an energy source in animal feed. The versatility of starch makes it an indispensable component in modern manufacturing, and GAEL’s products serve these diverse sectors efficiently.

Corn Starch and Maize Starch Manufacturing

GAEL specializes in the production of both corn starch and maize starch. The manufacturing process begins with the extraction of starch from corn kernels, followed by purification and drying. Corn starch is primarily used in the food industry, while maize starch is used in textiles, adhesives, and pharmaceuticals. GAEL's manufacturing facilities are equipped with cutting-edge technology that ensures the highest quality products, meeting industry standards.

Major Players in the Indian Starch Industry

GAEL stands out due to its comprehensive product range, high production capacity, and focus on sustainable practices. While other companies also contribute to the starch market, GAEL’s emphasis on quality and innovation sets it apart.

GAEL’s Commitment to Quality and Sustainability

GAEL places a strong emphasis on quality control throughout its production processes. From sourcing raw materials to final packaging, stringent measures are taken to ensure product purity and consistency. In addition to quality, GAEL is committed to sustainability. The company adopts eco-friendly practices, such as reducing water and energy consumption, recycling waste, and using renewable energy sources in its manufacturing processes.

Customer Base and Market Reach

GAEL’s customer base spans a wide range of industries, including food processing, pharmaceuticals, textiles, and animal feed. The company’s products are in high demand both in India and internationally. GAEL’s extensive market reach and ability to cater to diverse customer needs make it a dominant force in the starch industry.

Conclusion

Gujarat Ambuja Exports Limited has cemented its position as a leading starch manufacturer in India, providing high-quality products that serve various industries. Starch plays a crucial role in food, pharmaceuticals, textiles, and agro-processing, making it an essential commodity in today’s industrial landscape. GAEL’s commitment to quality, innovation, and sustainability ensures that it will continue to be a driving force in the industry for years to come.

For more information or inquiries about GAEL’s products, visit our website or contact at +91-79-61556677. You can also reach them via email at [email protected] for further assistance.

0 notes

Text

🌾 Green Millet & Pearl Millet: Premium Quality from India 🌾

Looking for a reliable supplier of Green Millet and Pearl Millet (Bajra)? Greenx Industries is your go-to partner for premium-grade millets, perfect for human consumption, poultry feed, and animal feed.

Why Choose Greenx Industries?

As leading exporters from India, we specialize in providing high-quality, nutrient-rich millets that are carefully processed to meet international standards. Whether for food production, animal nourishment, or bird feed, our millets are packed with energy and essential nutrients.

Applications of Green Millet (Bajra):

🌾 High-energy food source for human consumption

🐦 Ideal for bird and poultry feed

🐄 Excellent as animal and cattle feed

Our commitment to quality and customer satisfaction makes us a trusted name in global trade. Let’s work together to bring the best of Indian agriculture to the world!

Contact Us Today:

🌐 Web: www.greenxindustries.com

📧 Email: [email protected]

📞 Phone: +91 78020 20364

#GreenMilletSupplierIndia #PearlMilletExporterIndia #BajraSuppliersIndia #GreenMilletExportersIndia #MilletsForAnimalFeed #PoultryFeedSuppliersIndia #PearlMilletTraderIndia #IndianAgricultureExport #BajraForHumanConsumption #PremiumMilletsIndia #MilletExportBusinessIndia #HighQualityMilletsIndia #MilletsForGlobalMarket #IndianMillets #GreenMilletsExporterFromIndia #PearlMilletsSupplierFromIndia #BajraSupplierExporterTraderFromIndia #PearlMilletExportersIndia #PremiumBajraSupplierIndia #GreenMilletExportersIndia #TopMilletSuppliersFromIndia #BestPearlMilletExporterIndia #BajraExportersFromIndia #GreenMilletPoultryFeedSupplierIndia #PearlMilletForAnimalFeed #BajraForBirdFeedIndia #IndianMilletsSupplierAndExporter #GreenMilletTraderFromIndia #BajraExportQualityIndia #MilletExportBusinessIndia #MilletSuppliersForGlobalMarket #BajraSupplierForAnimalFeed #HighQualityMilletsFromIndia #MilletExportExpertsIndia

#GreenMilletSupplierIndia#PearlMilletExporterIndia#BajraSuppliersIndia#GreenMilletExportersIndia#MilletsForAnimalFeed#PoultryFeedSuppliersIndia#PearlMilletTraderIndia#IndianAgricultureExport#BajraForHumanConsumption#PremiumMilletsIndia#MilletExportBusinessIndia#HighQualityMilletsIndia#MilletsForGlobalMarket#IndianMillets#GreenMilletsExporterFromIndia#PearlMilletsSupplierFromIndia#BajraSupplierExporterTraderFromIndia#PearlMilletExportersIndia#PremiumBajraSupplierIndia#TopMilletSuppliersFromIndia#BestPearlMilletExporterIndia#BajraExportersFromIndia#GreenMilletPoultryFeedSupplierIndia#PearlMilletForAnimalFeed#BajraForBirdFeedIndia#IndianMilletsSupplierAndExporter#GreenMilletTraderFromIndia#BajraExportQualityIndia#MilletSuppliersForGlobalMarket#BajraSupplierForAnimalFeed

0 notes

Text

India to buy soybeans to help farmers reeling from losses NEW DELHI, Sept 11 (Reuters) - India will buy soybeans from farmers of the central state of Madhya Pradesh at state-set support prices to help growers reeling from a crash in domestic rates for the oilseed, a government statement said on Wednesday. India uses soybeans to manufacture soyoil, which helps the country cut its hefty edible oil imports, while the by-product soymeal is used for animal feed and exported mainly to Southeast Asia and the Middle East. Farmers plant soybeans during the monsoon season in June and July and harvest the main summer oilseed crop from October. Agriculture and Farmers' Welfare Minister Shivraj Singh Chouhan accepted a request from Madhya Pradesh to buy soybeans at the government-mandated support price, the statement said. Prices of soybeans have dropped well below the government-set support price of 4,892 rupees ($58.27) per 100 kg, angering farmers. Earlier, the government agreed to buy soybeans from growers of the western state of Maharashtra. Maharashtra and Madhya Pradesh together account for nearly 70% of India's total soybean output. The government would also buy soybeans in the southern state of Karnataka. Millions of farmers are seen as an influential voting bloc in India, the world's leading producer of an array of crops such as rice, wheat, cane and cotton. A spate of export curbs imposed by Prime Minister Narendra Modi's government has already fuelled anger among farmers. After Modi's Bharatiya Janata Party suffered losses in rural constituencies in this year's general election, the government is keen to placate farmers ahead of state assembly elections in states such as Haryana and Maharashtra, political commentators say. ($1 = 83.95 rupees)

0 notes

Text

Badani Corporation: Your Premier Peanut in Shell Supplier and Exporter in India

When it comes to sourcing high-quality peanuts in shell, Badani Corporation stands out as a leading supplier and exporter from India. With years of experience in the industry, Badani Corporation has earned a reputation for excellence, reliability, and commitment to delivering top-notch products to clients worldwide.

Why Choose Badani Corporation?

Badani Corporation is synonymous with quality and consistency. As a trusted peanut in shell supplier and exporter, the company ensures that each batch of peanuts meets the highest international standards. The company sources its peanuts from the finest farms in India, where they are grown under optimal conditions to achieve the best quality. The meticulous selection process guarantees that only the best peanuts make it to the final product.

Quality Assurance

Quality is at the core of Badani Corporation’s operations. The company employs rigorous quality control measures throughout the production process to ensure that the peanuts in shell are free from defects, contaminants, and impurities. From harvesting to processing and packaging, each step is carefully monitored to maintain the integrity of the product. The peanuts are subjected to thorough inspections and testing to ensure they meet the required specifications for size, color, and flavor.

Sustainable Practices

Badani Corporation is committed to sustainable and eco-friendly practices in its operations. The company recognizes the importance of environmental responsibility and strives to minimize its carbon footprint. By implementing sustainable agricultural practices and working closely with farmers, Badani Corporation ensures that its peanuts are grown in a manner that preserves soil health and promotes biodiversity. The company also emphasizes efficient water use and waste management to reduce its environmental impact.

Global Reach

With a robust logistics network, Badani Corporation is well-equipped to handle international orders efficiently. The company’s strategic location and partnerships with reliable shipping carriers enable it to deliver peanuts in shell to clients around the globe. Whether you are looking to import peanuts in bulk or require custom packaging solutions, Badani Corporation has the expertise and resources to meet your needs. The company’s dedication to timely delivery and exceptional customer service sets it apart in the competitive market.

Diverse Applications

Peanuts in shell are versatile and used in various applications, from snacking to culinary and industrial uses. Badani Corporation’s peanuts cater to a wide range of industries, including food processing, confectionery, and animal feed. The company’s commitment to providing high-quality peanuts ensures that customers receive a product that enhances their offerings and meets their specific requirements.

Customer-Centric Approach

At Badani Corporation, customer satisfaction is a top priority. The company’s team of professionals is dedicated to understanding and addressing the unique needs of each client. Whether you are a large-scale distributor or a small business, Badani Corporation offers personalized service and support to ensure a seamless experience. The company values long-term relationships with its clients and works diligently to exceed their expectations.

Conclusion

In the competitive world of peanut supply and export, Badani Corporation emerges as a leading player, offering premium peanuts in shell with a focus on quality, sustainability, and customer satisfaction. With its commitment to excellence and global reach, Badani Corporation is your ideal partner for sourcing high-quality peanuts in shell from India. Discover the difference that comes with working with a trusted supplier and exporter, and let Badani Corporation meet your peanut needs with unmatched expertise and dedication.

#Top peanut in shell supplier and exporter in India#High-quality peanuts in shell supplier India#Bulk peanuts in shell export from India#Best peanut in shell exporter in India#Reliable peanut in shell supplier India#Premium peanuts in shell supplier and exporter#Organic peanuts in shell exporter India#Sustainable peanut in shell supplier India#India’s leading peanut in shell supplier#Affordable peanuts in shell export India#Peanut in shell for international markets#Trusted peanut in shell supplier and exporter#Peanut in shell quality control India#Global peanut in shell export India#Peanuts in shell for food processing India#Custom packaging peanuts in shell exporter#Bulk purchase peanuts in shell India#Efficient peanut in shell logistics India#High-grade peanuts in shell for export#Top-rated peanut in shell supplier India

0 notes

Text

Top Food Grains Exporter, Trader and Wholesaler in India.

As one of the world's top food grains exporter, trader and wholesaler in India companies play a crucial role in supplying high-quality grains to global markets. These grains, which include rice, wheat, maize, and pulses, are essential staples in diets around the world.

Leading the Export Market

India’s position as a top food grains exporter is a result of its vast agricultural resources and the expertise of its farmers. The country’s favorable climate, fertile soils, and advanced farming techniques contribute to the production of a wide variety of grains that meet international quality standards. Indian exporters ensure that these grains reach international markets in their freshest and most nutritious state, catering to the demands of consumers worldwide.

Wide Range of Food Grains

Indian food grains wholesalers offer a wide range of grains to meet the diverse needs of their customers. Some of the most commonly exported grains include:

Rice: India is one of the largest exporters of rice, including Basmati and non-Basmati varieties, known for their aroma, flavor, and long grain.

Wheat: Indian wheat is prized for its high protein content and is used in baking and other food products.

Maize: Also known as corn, maize from India is used for food products, animal feed, and industrial applications.

Pulses: Lentils, chickpeas, and other pulses are exported in large quantities due to their high nutritional value.

Commitment to Quality

As a trusted food grains exporter Indian companies are committed to maintaining the highest quality standards. This commitment is reflected in the rigorous testing and quality control processes that grains undergo before they are exported. These processes ensure that the grains are free from contaminants, meet international safety standards, and retain their nutritional value.

Sustainable Practices

Indian food grains exporters are increasingly adopting sustainable agricultural practices to minimize environmental impact. This includes the use of organic farming methods, efficient water management, and crop rotation techniques. By promoting sustainability, Indian exporters not only protect the environment but also enhance the long-term viability of their agricultural industry.

Efficient Supply Chain

The efficiency of India’s supply chain is another factor that makes the country a leading food grains wholesaler. From harvesting to storage, transportation, and delivery, every step of the supply chain is carefully managed to ensure that grains reach their destination in perfect condition. Indian companies utilize state-of-the-art infrastructure, including modern warehouses and transportation networks, to handle large volumes of grain with ease.

Global Reach

Indian food grains exporters have established strong relationships with buyers across the globe. Countries in Asia, the Middle East, Africa, and Europe are among the top importers of Indian food grains. This global reach is supported by India’s strategic location, which provides easy access to major shipping routes and international markets.

Customer-Centric Approach

Indian food grains traders prioritize the needs of their customers by offering flexible solutions and personalized services. Whether it’s bulk orders for large buyers or smaller quantities for niche markets, Indian companies are equipped to meet varying demands with professionalism and efficiency. Their customer-centric approach ensures that clients receive the best possible service and products.

Conclusion

India’s position as a top food grains exporter, trader, and wholesaler is built on a foundation of quality, sustainability, and efficiency. Indian companies continue to play a vital role in feeding the world by supplying high-quality grains that meet the nutritional needs of millions. With their commitment to excellence and customer satisfaction, Indian food grains exporters are poised to maintain their leadership in the global market.

FAQs

Q1: What types of food grains does India export?

A1: India exports a wide variety of food grains, including rice, wheat, maize, and pulses like lentils and chickpeas.

Q2: How does India ensure the quality of its exported grains?

A2: Indian exporters follow rigorous quality control processes, including testing for contaminants and ensuring compliance with international safety standards.

Q3: Are Indian food grains exporters adopting sustainable practices?

A3: Yes, many Indian exporters are adopting sustainable agricultural practices, such as organic farming and efficient water management, to protect the environment.

Q4: Which countries are the main importers of Indian food grains?

A4: Indian food grains are exported to countries across Asia, the Middle East, Africa, and Europe.

Q5: How can I contact an Indian food grains exporter?

A5: You can reach out to Indian food grains exporters through their websites, trade portals, or industry contacts to inquire about their products and services.

0 notes

Text

Dairy Industry in India - UJA Market Report

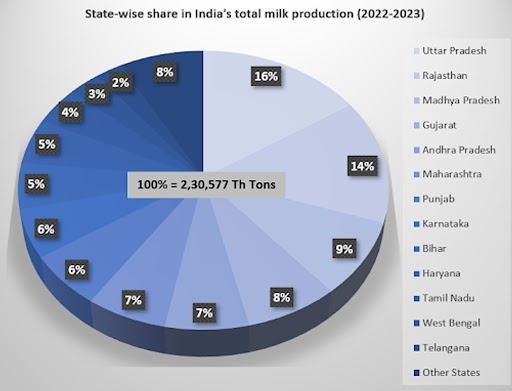

India is the world’s largest milk producer

24% contribution to global milk production

India’s milk processing capacity is 126 million liters per day

For a decade, the country’s milk industry has been growing at a CAGR of 5.8%

Milk production in India registered more than 50% increase during the last ten years

Globally, India exported 67,572 million tons of dairy products during the year 2022–2023

80 million people are employed in the dairy sector

The industry contributes 5% to the national economy

Per capita availability of milk is 459 grams per day

Overview: Dairy Sector in India

The top5 milk producing States are Uttar Pradesh, Rajasthan, Madhya Pradesh, Gujarat, and Andhra Pradesh. They together contribute around 53% of total milk production in the country.

The average yield per animal per day for exotic/crossbred is 8.55 Kg/day/Animal and for indigenous/non-descript is 3.44 Kg/day/Animal.

Milk production from exotic/crossbred cattle has increased by 3.75% and Indigenous/ non-descript cattle have increased by 2.63% as compared to the previous year.

The top13 states together contribute around 92% of total milk production in the country

India produced nearly 50% more milk than the US and more than three times as much as China.

The top5 milk producing States are Uttar Pradesh, Rajasthan, Madhya Pradesh, Gujarat, and Andhra Pradesh. They together contribute around 53% of total milk production in the country.

The average yield per animal per day for exotic/crossbred is 8.55 Kg/day/Animal and for indigenous/non-descript is 3.44 Kg/day/Animal.

Milk production from exotic/crossbred cattle has increased by 3.75% and Indigenous/ non-descript cattle have increased by 2.63% as compared to the previous year.

The top13 states together contribute around 92% of total milk production in the country

India produced close to 50% more milk than the US and more than three times as much as China.

India’s Dairy Industry Flow

The Indian dairy sector is divided into the organized and unorganized segments:

Unorganized segment consists of traditional milkmen, vendors, and self-consumption at home

Organized segment consists of cooperatives and private dairies

Indian dairy sector is dominated by an unorganized sector, selling 64% of the marketable surplus

Around 36% of the marketable milk is processed by the organized sector, with cooperatives & Government dairies, and private players contributing 50% each

Amul, the brand of Gujarat Coop Milk Marketing Federation (GCMMF) is the largest dairy co-operative and the largest organized player in India

It is the 9th largest dairy player in the world. It aims to be amongst the top 3 dairy players in the world. Amul plans to add 40–60 value-added products in the next 2 years.

Government & Milk Producers Initiatives

The governmentof India set up a 15,000 Cr fund for offering financial support to set up new units or expand existing units in areas of dairy processing & related value addition infrastructure, meat processing & related value addition infrastructure, and Animal Feed Plants. The benefits available are:

3% interest subvention on loans

2-year moratorium with 6-year repayment period

INR 750 Cr credit guarantee

The Rashtriya Gokul Mission has been extended till 2026 with an The INR 2,400 Cr commitment to boost productivity and milk output, making dairying more profitable for farmers.

50% Capital subsidy up to INR 2 Cr to eligible entrepreneurs, individuals, FPOs / FCOs, SHGs, JLGs, and Section 8 companies for the establishment of breed multiplication farms

Accelerated breed improvement program under the component subsidy of INR 5,000 for IVF pregnancy

National Program for Dairy Development (NPDD) scheme aims to enhance the quality of milk and milk products and increase the share of organized milk procurement, processing, value addition, and marketing. The scheme has two components:

Component ‘A’ focuses on creating/strengthening infrastructure for quality milk testing equipment as well as primary chilling facilities for State Cooperative Dairy Federations/ District Cooperative Milk Producers’ Union/SHG-run private dairy/Milk Producer Companies/Farmer Producer Organizations. The scheme will be implemented across the country for the period of five years from 2021–22 to 2025–26.

Component ‘B’ (Dairying Through Cooperatives) provides financial assistance from the Japan International Cooperation Agency (JICA) as per the project agreement already signed with them. It is an externally aided project, envisaged to be implemented during the period from 2021–22 to 2025–26 on a pilot basis in Uttar Pradesh and Bihar

In September 2023, AMUL had opened its 85th branch in Kutch, Gujarat. This new branch ensures the distribution of the entire range of Amul’s dairy products

In March 2024, Mother Dairy announced that it would invest INR 650 crore to set up two new plants for the processing of milk. The company will also invest INR 100 crore to expand the capacities

In December 2023, Karnataka Milk Federation (KMF) announced that the Company will start buffalo milk sales from December 21 in the country.

Want to know more info, click here https://uja.in/blog/market-reports/dairy-industry-in-india/

#Dairy Industry in India#Indian Dairy Sector#Dairy Sector#Milk Production#India’s Dairy Industry#Gujarat Coop Milk Marketing Federation#Rashtriya Gokul Mission#uja global advisory#uja global

0 notes

Text

Present Scenario of Poultry in India

The fowl industry in India has witnessed tremendous growth in last few decades. India is now the 3rd largest egg producer and 5th largest broiler meat producer in the world. The per capita consumption of eggs has risen from just 23 eggs in 1990 to 62 eggs in 2019. Similarly, broiler meat consumption has increased from 1 kg per person to 4 kg per person in last 20 years. The growth has been fuelled by multiple factors like rising disposable incomes, urbanization, health awareness and aggressive marketing by fowl players.

Role of contract farming and Integrators

Indian Poultry industry is primarily organized through a contract farming model where integrators provide inputs like chicks, feed and veterinary services to farmers while procuring the produce at a pre-determined rate. Major players like Venky's, Godrej Agrovet, CP Group etc. have established strong backward integration through hatcheries and feed mills while maintaining a large outgrower base. This model has led to standardization of operations and assured market access for small farmers. It has played a pivotal role in the overall development of the sector.

Government Support through policies and schemes

Successive governments have recognized the growth potential of fowl and implemented several schemes to boost production and investment in the sector. Introduction of National Fowl Development Board and National Poultry Mission are notable initiatives. State governments also provide subsidies on inputs and set up infrastructure development schemes. Focus on rural development and employment generation along with food security has kept fowl high on the policy agenda.

Opportunities in Processed Products and Export

With overall production rising, there is large untapped potential in processed value added products like frozen ready-to-cook items, cut parts and deboned meat. Major players are setting up dedicated processing plants to cater to urban consumers looking for convenient dining solutions. Export markets offer huge scope given India's competitive advantage of low cost production. China Plus One policy can boost shipments to non-Chinese markets in future. Strict implementation of quality and safety standards will open more global opportunities.

Challenges on the Environmental and Disease Front

Rapid intensification especially in broiler sector in some states poses risks to environmental sustainability due to issues like excessive ground water use, disposal of litter and manure etc. Recurrence of avian diseases like bird flu and Ranikhet also affects profitability and expansion plans periodically. Players will have to focus on biosecurity protocols and integrate sustainable practices to balance growth and environment protection responsibilities. Adoption of preventive vaccines and improved surveillance systems is the need of the hour.

To summarize, Indian Poultry industry has come a long way and is poised for further growth driven by domestic consumption as well as export potential. However, managing environmental fallouts and animal health challenges in evolving scenario will determine its sustainability and scope for the future. Continuous policy support coupled with private sector initiatives can help realize its full potential.

Get More Insights On, Poultry

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Poultry#Chicken#Geese#Poultry Farming#Organic Poultry#Poultry Nutrition#Poultry Processing#Poultry Equipment

0 notes

Text

Discover the Efficiency of FIBC Jumbo Sling Bags for All Your Storage Needs

In the evolving landscape of industrial storage solutions, the versatility and efficiency of FIBC (Flexible Intermediate Bulk Container) jumbo sling bags have garnered considerable attention. These bags, also known as bulk bags, are designed to handle a vast range of materials and applications, making them indispensable in various sectors. Whether you are in the manufacturing, agriculture, construction, or mining industry, FIBC jumbo bags offer a robust, efficient, and cost-effective solution for your storage and transportation needs.

The Benefits of FIBC Jumbo Sling Bags

FIBC jumbo sling bags are renowned for their ability to store and transport large quantities of materials securely and efficiently. One of the primary benefits of these bags is their impressive load-bearing capacity. Typically, FIBC jumbo bags can hold up to 2,000 kilograms of material, making them ideal for bulk handling. Their robust construction ensures that they can withstand the rigors of transport and handling, reducing the risk of material spillage or damage. Another significant advantage of FIBC jumbo bags is their versatility.

The ease of handling is another reason for the popularity of FIBC jumbo bags. Equipped with lift loops, these bags can be easily hoisted using forklifts or cranes, streamlining the loading and unloading process. This feature not only enhances operational efficiency but also reduces the risk of manual handling injuries. Moreover, FIBC jumbo bags are designed with durability in mind. Constructed from woven polypropylene (PP), they offer excellent resistance to abrasion, tearing, and UV radiation.

Applications of FIBC Jumbo Sling Bags

The versatility of FIBC jumbo bags extends to their wide range of applications. In the agriculture sector, these bags are commonly used for storing grains, fertilizers, and animal feed. Their ability to keep contents dry and protected from external elements makes them an ideal choice for agricultural storage. In the construction industry, FIBC jumbo bags are used to handle and transport materials such as sand, gravel, and cement. Their strength and capacity make them well-suited for bulk handling, reducing the need for multiple smaller containers and thus lowering transportation costs.

The mining industry also benefits from the use of FIBC jumbo bags. These bags are employed to store and transport minerals, ores, and other mined materials. Their robust construction ensures that they can handle the heavy and abrasive nature of mined substances without compromising their structural integrity. Additionally, FIBC jumbo bags find applications in the chemical industry for the safe handling and transport of chemicals and powders.

Choosing the Right FIBC Jumbo Bag

Selecting the appropriate FIBC jumbo bag is crucial to ensuring that your storage and transportation needs are met efficiently. When considering your options, it’s essential to evaluate the specifications of the bags in relation to the type of material being handled. For instance, if you are dealing with fine powders or hazardous materials, you might need bags with liners or additional coatings to prevent leakage and contamination. Collaborating with a reputable FIBC jumbo bag exporter in India can provide valuable insights and access to a range of bag types designed for different applications, helping you make an informed choice.

Another critical factor is the bag’s capacity and construction, which should align with the weight and granule size of the material. Different designs, such as U-panel, four-panel, or circular bags, offer varying strengths and functionalities. If you’re sourcing bags from a specialized FIBC jumbo bags exporter in Gujarat, you can benefit from their expertise in providing customized solutions that meet your specific requirements. Ensuring that the bags are compatible with your handling equipment and operational processes will enhance efficiency and safety.

Finally, consider working with a PP sling bag exporter in Ahmedabad to explore options that might be tailored to local industrial standards and requirements. These suppliers can offer insights into the latest innovations and best practices for using FIBC jumbo bags. By choosing the right exporter, you not only gain access to high-quality products but also receive support in selecting bags that best suit your operational needs, ultimately contributing to smoother and more effective material handling.

Conclusion

In conclusion, FIBC jumbo sling bags offer a practical and efficient solution for a wide range of storage and transportation needs. Their durability, versatility, and ease of handling make them an essential tool in many industries. By selecting the right type of bag and working with a reputable supplier, you can optimize your storage operations and ensure the safe and efficient handling of your materials.

Frequently Asked Questions

What are the key differences between various types of FIBC jumbo bags?

FIBC jumbo bags come in several designs, including U-panel, four-panel, and circular types. U-panel bags have a single seam running down the middle of the bag, while four-panel bags have seams on all four sides, providing more uniform strength. Circular bags have a continuous tube-like construction, offering maximum strength and durability. The choice depends on the material to be stored and the specific handling requirements.

Can FIBC jumbo bags be recycled or reused?

Yes, FIBC jumbo bags can be recycled or reused, depending on their condition and the material they have contained. Many manufacturers offer recycling programs for used bags, which helps in reducing waste and promoting environmental sustainability. Reused bags should be inspected for any signs of damage or contamination before being put back into service.

How can I ensure the safety of my materials when using FIBC jumbo bags?

To ensure the safety of materials, choose FIBC jumbo bags that are suitable for the type of material you are handling. Use bags with appropriate liners if necessary, and ensure they are properly closed and sealed. Regularly inspect bags for any signs of wear or damage, and follow best practices for handling and storage to minimize risks.

0 notes

Text

Exporter of Spray Dryer in Burundi

Drytech Engineering Systems is an Exporter of Spray Dryer in Burundi.

We Expertise in Spray Dryer, Flash Dryer, Spin Flash Dryer, Multi Effect Evaporator, Etc.

Drytech Engineering Systems is a Spray Dryer Manufacturer in Ahmedabad, Gujarat, India.

Our advanced atomizers efficiently transform liquid feeds into finely dispersed droplets, ensuring precise size and distribution.

Atomized droplets enter the drying chamber, where heated air swiftly evaporates moisture, yielding high-quality solid particles.

Post-drying, our machines effectively separate powder from air using cyclone separators or bag filters, ensuring purity and efficiency.

Spray Dryer Working Principle:

Step 1: Atomization

The liquid feed is transformed into fine droplets of adjustable size and distribution by our atomizer or nozzle.

Step 2: Droplet Drying

Atomized droplets enter the drying chamber, where heated air rapidly evaporates the liquid, forming solid particles.

Step 3: Powder Collection

Upon drying, the machine separates the powder from the drying air using a cyclone separator or bag filter.

Features of Our Spray Dryers:

An efficient aspirator reduces residual moisture.

Precise temperature control ensures optimal performance.

Low maintenance design extends functional lifespan.

Reliable operation ensures long-term usability.

Continuous drying techniques enhance production speed.

Consistent product quality is maintained throughout the drying process.

Applications:

We provide plants suitable for various applications, from heat-sensitive products like enzymes, blood, and flavors, to conventional products such as plant and animal extracts, milk, food, and pharmaceuticals.

Drytech Engineering Systems is an Exporter of Spray Dryer in Burundi and includes locations like

Bujumbura, Gitega, Ngozi, Muyinga, Ruyigi, Kayanza, Bururi, Rutana, Muramvya, Bubanza,

Cibitoke, Kirundo, Makamba, Karusi, Mwaro, Nyanza-Lac, Rumonge, Kabezi, Mpanda, Gihofi.

For detailed information and inquiries, please feel free to contact us.

View Product: Click Here

Read the full article

#Ahmedabad#Bubanza#Bujumbura#Bururi#Cibitoke#DrytechEngineeringSystems#Expertise#ExporterofSprayDryer#ExporterofSprayDryerinBurundi#FlashDryer#Gihofi#Gitega#Gujarat#India#Kabezi#Karusi#Kayanza#Kirundo#Makamba#Mpanda#MultiEffectEvaporator#Muramvya#Muyinga#Mwaro#Ngozi#Nyanza-Lac#Rumonge#Rutana#Ruyigi#SpinFlashDryer

0 notes

Text

Carotenoids Market to Record Steady Growth by 2029

The global carotenoids market is estimated at USD 2.5 billion in 2024 and is projected to reach USD 3.4 billion by 2029, at a CAGR of 6.3% from 2024 to 2029. Carotenoids offer numerous health benefits, primarily due to their antioxidant properties. These compounds play a crucial role in preventing chronic diseases and promoting overall health. Consequently, there's a growing demand for carotenoids in supplements and pharmaceuticals, where they are utilized for their therapeutic potential. Moreover, the shift towards natural ingredients in the food and beverage industry has boosted the use of carotenoids as natural colorants. This trend aligns with consumer preferences for healthier and more natural products, further driving market growth. Furthermore, carotenoids find applications beyond the food and beverage sector. They are utilized in cosmetics for their skin-enhancing properties, in animal feed to improve animal health and product quality, and in pharmaceuticals for various purposes. This diverse range of applications broadens the market presence of carotenoids and contributes to their continued growth and importance in various industries.

Carotenoids Market Opportunities: Increased opportunity for expansion into high-growth potential markets, including developing countries in the Asia Pacific and South America regions

Currently, Europe is poised to lead the carotenoids market, yet the Asia Pacific region anticipates sustained demand growth due to expanding markets for dietary supplements and food and beverages. Increasing awareness of carotenoids' benefits is expected to fuel demand in Asia Pacific and South America. Additionally, the burgeoning animal feed segment in Asia Pacific is projected to drive market expansion. According to the 2024 Alltech report, Latin America has demonstrated consistent growth over the past decade, driven by robust monogastric exports and expanding aqua and pet markets. With China, India, and Japan among the top feed-producing countries, the region's accelerating use of carotenoids in animal feed is forecasted to propel overall market growth.

Carotenoids Market Challenge: Challenges in achieving the necessary quality standards.

The prevalence of adulteration poses a significant challenge to maintaining carotenoid quality, endangering animals, humans, and the environment. Adulterated carotenoids, increasingly found in North America, can be hazardous, even fatal, when consumed excessively. Synthetic astaxanthin, prevalent in the US market, is typically derived from petrochemicals or genetically modified yeast, posing health risks. To counter this, manufacturers are shifting towards natural sources for carotenoid production, yet the limited adoption of natural alternatives may impede overall market growth. Moreover, heightened competition, particularly in burgeoning Asian Pacific and South American markets, has led to an influx of smaller regional players, potentially compromising carotenoid quality.

In the application segment, food & beverage segment is expected to grow at highest CAGR during the forecast period.

The food and beverage segment in the carotenoid market is witnessing the highest growth rate due to several key drivers. Firstly, increasing consumer demand for natural and healthy food additives drives the incorporation of carotenoids as natural colorants and functional ingredients. Secondly, growing awareness of the health benefits associated with carotenoids, such as antioxidant properties and potential disease prevention, fuels their utilization in a wide range of food and beverage products. Additionally, the rise in innovative product development and the introduction of clean-label products further stimulate market growth in this segment, catering to evolving consumer preferences for natural and nutritious food options.

Top Companies in the Carotenoids Market

Key players within this market consist of reputable and financially robust Carotenoids manufacturers. These entities boast extensive industry tenure, offering diversified product portfolios, cutting-edge technologies, and robust global sales and marketing networks. Prominent companies in this market are DSM (Netherlands), BASF SE (Germany), Cyanotech Corporation (US), Givaudan (Switzerland), ADM (US), NHU (China), Divi's Laboratories Limited (India), Allied Biotech Corporation (Taiwan), Lycored (US), Kemin Industries, Inc. (US), Fuji Chemical Industries Co., Ltd. (Japan), EW Nutrition (Germany), Döhler GmbH (Germany), ExcelVite (Malaysia) and Farbest Brands (US).

Carotenoids Market Recent Developments

In March, 2023, ADM (US) revealed the signing of a joint venture agreement with Marel (Netherlands), a leading provider of cutting-edge food processing solutions. This partnership aimed to establish an innovation center at the prestigious Wageningen Campus in the Netherlands, renowned as the epicenter of the nation's food valley. Tailored to foster collaboration among food manufacturers, food scientists, extrusion specialists, and culinary professionals, this strategic initiative is poised to bolster ADM's market expansion efforts and facilitate research and development in its carotenoid segments.

#Carotenoids Market#Carotenoids Market Size#Carotenoids Market Share#Carotenoids Market Growth#Carotenoids Market Trends#Carotenoids Market Forecast#Carotenoids Market Analysis#Carotenoids Market Report#Carotenoids Market Scope#Carotenoids Market Overview#Carotenoids Market Outlook#Carotenoids Market Drivers#Carotenoids Industry#Carotenoids Companies

0 notes

Text

Engineering Insights into HDPE Bag Strength

In the realm of packaging solutions, HDPE (High-Density Polyethylene) bags have emerged as a versatile and robust choice for various industries due to their exceptional strength and durability. Singhal Industries Pvt Ltd, one of India's foremost manufacturers and exporters of HDPE bags, plays a pivotal role in providing innovative packaging solutions tailored to meet diverse customer needs across the country.

Introduction to HDPE Bags

HDPE bags are crafted from high-density polyethylene, a thermoplastic polymer known for its strength, toughness, and resistance to moisture and chemicals. These bags are widely used in industries such as agriculture, pharmaceuticals, chemicals, food processing, and retail due to their reliability in protecting goods during storage and transportation.

Factors Influencing HDPE Bag Strength

Several key factors contribute to the impressive strength characteristics of HDPE bags:

Material Composition: HDPE bags are manufactured using high-density polyethylene resin, which undergoes extrusion to form strong, uniform sheets. The molecular structure of HDPE provides excellent tensile strength and impact resistance, crucial for withstanding various handling and environmental conditions. Know more about Plastic HDPE bags exporter.

Weaving and Lamination Techniques: Manufacturers employ advanced weaving and lamination techniques to enhance the structural integrity of HDPE bags. Multiple layers of HDPE fabric are often woven together, creating a dense network that improves tear resistance and load-bearing capacity.

Thickness and Density: The thickness and density of HDPE bags significantly influence their strength. Thicker bags with higher density can withstand heavier loads and provide greater puncture resistance, making them suitable for packaging bulk materials and sharp-edged goods.

Seam and Stitching Quality: The quality of seams and stitching is critical in determining the overall strength of HDPE bags. Singhal Industries ensures meticulous craftsmanship during the manufacturing process, employing high-strength stitching techniques and heat-sealing methods to reinforce bag seams.

Impact and Stress Testing: Prior to market release, HDPE bags undergo rigorous testing protocols to evaluate their strength under real-world conditions. Tests include impact resistance, tensile strength, tear resistance, and load-bearing capacity to ensure compliance with industry standards and customer requirements. Find every single details about the best HDPE woven bags suppliers.

Applications of HDPE Bags

HDPE bags manufactured by Singhal Industries find wide-ranging applications across various sectors:

Agricultural Sector: Used for packaging fertilizers, seeds, animal feed, and agricultural produce due to their moisture resistance and durability in outdoor environments.

Chemical Industry: Ideal for transporting hazardous chemicals and industrial materials safely, thanks to their chemical resistance and ability to prevent leakage.

Food Processing: Ensures hygienic packaging of food products such as grains, pulses, flour, and spices, maintaining freshness and quality.

Retail and Consumer Goods: HDPE bags are popular in retail for packaging textiles, apparels, groceries, and consumer goods due to their strength and cost-effectiveness. Know in details about HDPE bags price per kg.

In conclusion, HDPE bags manufactured by Singhal Industries Pvt Ltd exemplify robust engineering principles aimed at delivering superior strength and reliability. Through advanced manufacturing techniques, meticulous quality control, and a commitment to customer satisfaction, Singhal Industries continues to set benchmarks in the packaging industry. Whether for agricultural, industrial, or retail applications, HDPE bags play a vital role in safeguarding products while ensuring efficiency and sustainability. For businesses seeking durable and cost-effective packaging solutions, Singhal Industries remains a trusted partner in engineering excellence and innovation.

Frequently Asked Questions

Q: What are HDPE bags made of?

HDPE bags are made from high-density polyethylene resin, which is a type of thermoplastic polymer known for its strength and durability.

Q: What factors should be considered when choosing HDPE bags?

When choosing HDPE bags, factors such as thickness, density, intended use (e.g., for chemicals, food, or agriculture), and environmental conditions (e.g., moisture, temperature) should be considered.

Q: Where can I find HDPE bags manufacturers in major cities like Indore, Kolkata, Bangalore, Chennai, and Coimbatore?

Singhal Industries Pvt Ltd operates as a leading HDPE bags manufacturer with facilities and distribution networks in Indore, Kolkata, Bangalore, Chennai, Coimbatore, Vadodara, and Daman, catering to diverse regional requirements.

0 notes

Text

🌾 Elevate Your Nutrition with Green Millet (Bajra)! 🌾

At Greenx Industries, we specialize in supplying premium-grade Green Millet, also known as Pearl Millet, for various uses including human consumption, poultry feed, and animal feed. Our commitment to quality has earned us the trust of customers worldwide. 🌍

🌟 Why Green Millet?

High-energy food

Ideal for poultry, bird, and fish feed

Versatile and nutritious grain

As leading suppliers from India, we ensure a reliable and consistent supply to meet your needs.

📞 +91 78020 20364

✉️ [email protected]

🌐 www.greenxindustries.com

📱 Follow us:

Facebook

Instagram

LinkedIn (Company)

LinkedIn (Nishant Vachhani)

X

Threads

YouTube

WhatsApp

Line ID: greenxindustries

Skype: Greenx.industries

#millets supplier#food export#grain export#roasted gram#GreenMillet#PearlMillet#Bajra#Superfood#HealthyLiving#Agriculture#AnimalFeed#SustainableFarming#GreenxIndustries#roastedchickpeas#chickpeasnacks#healthysnacking#proteinpacked#plantbasedsnacks#crispychickpeas#snacktime#homemadesnacks#roastedgarbanzobeans#vegansnacks

1 note

·

View note

Text

Pharmaceutical Raw Materials Manufacturers and Suppliers in India: Caltron Clays & Chemicals Pvt Ltd

Introduction

Since our establishment in 2000, Caltron Clays & Chemicals Pvt Ltd has become synonymous with quality, innovation, and exceeding customer expectations. Guided by our visionary Managing Director, Mr. S.N. Jain, we set new standards in the minerals industry, delivering exceptional products and services worldwide.

Certifications and Accreditations

Caltron Clays upholds the highest quality standards, evidenced by our esteemed certifications, including ISO 9001 and a CRISIL rating. As a recognized Government of India export house, our commitment to superior quality control throughout our manufacturing and export processes ensures global trust and reliability.

Product Range and Expertise

Specializing in processing and exporting minerals, oxides, and chemicals, Caltron Clays serves the pharmaceutical and cosmetic industries with a diverse product portfolio:

Pharmaceutical Raw Materials

Cosmetic Raw Materials

Oil and Gas Drilling Chemicals

Minerals and Animal Feed Supplements

Each product undergoes meticulous crafting and adheres to stringent global safety and regulatory standards.

Infrastructure and Manufacturing Excellence

Operating from advanced facilities in Mumbai, India, equipped with cutting-edge machinery and thorough testing capabilities, Caltron Clays ensures efficient production and seamless global distribution. Our well-organized administration and robust warehousing system enable us to meet diverse client needs effectively.

Global Presence and Market Reach

With a presence in over 40 countries, Caltron Clays is the preferred partner for businesses seeking high-quality raw materials. Our strategic marketing offices, including one in Wyoming, USA, allow us to cater to local demands while maintaining a strong global presence. This extensive network enables us to cultivate enduring partnerships internationally, reinforcing our reputation as a reliable exporter.

Commitment to Sustainability and Growth

Eco-Friendly Practices

Caltron Clays is committed to sustainability and environmental responsibility by:

Sustainable Raw Materials: Prioritizing eco-friendly sourcing.

Waste Reduction: Implementing efficient waste management practices.

Energy-Efficient Processes: Adopting advanced, energy-saving manufacturing techniques.

Investment in Green Technologies

Our continual investment in cutting-edge green technologies helps us:

Reduce Energy Consumption: Utilizing technology that minimizes power usage.

Lower Emissions: Mitigating our carbon footprint.

Enhance Efficiency: Leading in technological advancements for eco-friendly and efficient operations.

Sustainable Growth

Caltron Clays focuses on responsible and sustainable growth through:

Long-Term Strategies: Developing environmentally beneficial plans.

Continuous Improvement: Regularly upgrading processes to meet global sustainability standards.

Supporting Global Goals: Aligning efforts with international sustainability initiatives for a healthier planet.

Conclusion

Caltron Clays & Chemicals Pvt Ltd stands at the forefront of the pharmaceutical and cosmetic raw materials industry, driven by our steadfast commitment to excellence, innovation, and customer satisfaction. Established in Mumbai, India, in 2000, we uphold rigorous quality standards and operate advanced manufacturing facilities.

Under the visionary leadership of Managing Director Mr. S.N. Jain, Caltron Clays continues to innovate, introducing cutting-edge solutions to meet global demands. Our extensive product line, including minerals, oxides, and specialized chemicals, exceeds stringent international regulations.

With a robust presence in over 40 countries, Caltron Clays is recognized for reliability, technical expertise, and responsive customer service. Continuously setting industry benchmarks, we remain dedicated to surpassing expectations and fostering enduring partnerships worldwide.

Contact Us:

Corporate Office: Office No. 210 & 211, Level 2, Orbit Premises, Mind Space, Chincholi, Malad (West), Mumbai – 400064, India

Phone: +(91)-(22)-3571 9844, +(91)-(22)-4010 6828

Email: [email protected], [email protected]

Websites: caltronclays.com

0 notes