#MultiEffectEvaporator

Explore tagged Tumblr posts

Text

Exporter of Spray Dryer in Burundi

Drytech Engineering Systems is an Exporter of Spray Dryer in Burundi. We Expertise in Spray Dryer, Flash Dryer, Spin Flash Dryer, Multi Effect Evaporator, Etc. Drytech Engineering Systems is a Spray Dryer Manufacturer in Ahmedabad, Gujarat, India. Our advanced atomizers efficiently transform liquid feeds into finely dispersed droplets, ensuring precise size and distribution. Atomized droplets enter the drying chamber, where heated air swiftly evaporates moisture, yielding high-quality solid particles. Post-drying, our machines effectively separate powder from air using cyclone separators or bag filters, ensuring purity and efficiency. Spray Dryer Working Principle: Step 1: Atomization The liquid feed is transformed into fine droplets of adjustable size and distribution by our atomizer or nozzle. Step 2: Droplet Drying Atomized droplets enter the drying chamber, where heated air rapidly evaporates the liquid, forming solid particles. Step 3: Powder Collection Upon drying, the machine separates the powder from the drying air using a cyclone separator or bag filter. Features of Our Spray Dryers: An efficient aspirator reduces residual moisture. Precise temperature control ensures optimal performance. Low maintenance design extends functional lifespan. Reliable operation ensures long-term usability. Continuous drying techniques enhance production speed. Consistent product quality is maintained throughout the drying process. Applications: We provide plants suitable for various applications, from heat-sensitive products like enzymes, blood, and flavors, to conventional products such as plant and animal extracts, milk, food, and pharmaceuticals. Drytech Engineering Systems is an Exporter of Spray Dryer in Burundi and includes locations like Bujumbura, Gitega, Ngozi, Muyinga, Ruyigi, Kayanza, Bururi, Rutana, Muramvya, Bubanza, Cibitoke, Kirundo, Makamba, Karusi, Mwaro, Nyanza-Lac, Rumonge, Kabezi, Mpanda, Gihofi. For detailed information and inquiries, please feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Bubanza#Bujumbura#Bururi#Cibitoke#DrytechEngineeringSystems#Expertise#ExporterofSprayDryer#ExporterofSprayDryerinBurundi#FlashDryer#Gihofi#Gitega#Gujarat#India#Kabezi#Karusi#Kayanza#Kirundo#Makamba#Mpanda#MultiEffectEvaporator#Muramvya#Muyinga#Mwaro#Ngozi#Nyanza-Lac#Rumonge#Rutana#Ruyigi#SpinFlashDryer

0 notes

Text

Taknik Inc proivde outsourcing Engineering Consultancy Services.

for more information contact us.

Email Id - [email protected]

Contact No- 9510430147

#taknikinc#incorporation#consultancy#consultancyservices#manufacturer#civilengineering#services#quality#engineering#WastewaterRecycling#Zeroliquiddischarge#multieffectevaporator#MVR#MEE#bharuch#Gujarat

0 notes

Text

MULTI EFFECT EVAPORATOR, MEE, MANUFACTURER IN CHINA

Evaporation technology can be used to reclaim precious items or separate dangerous materials through wastewater flows. Evaporation has been examined as an alternate technique in a rising group of wastewater treatments techniques. It can be used to concentrate or remove salts, other harmful elements, and heavy metals from a solution. It could also be used to extract beneficial by-products out of a solution or to condense municipal wastewater before they are treated further and disposed of. Most of the technology’s uses also create a high-quality, reusable distillate, which is a critical characteristic in areas where water preservation is a top priority.MULTI EFFECT EVAPORATOR , MEE, is very vital equipments in concentrating fluid, effluent, water economically with less consumption of steam. Please visit here https://watermanaustralia.com/evaporator-technique-for-effluent-treatment/ for more details. #Multieffectevaporator #Evaporatormeemanufacturerinchina

0 notes

Text

Taknik Inc is an Engineering Consultant which serve Zero liquid discharge system , Multi effect evaportor, Mechanical vapor recompression etc

For more information kindly visit

our Website : https://www.taknikinc.com/

Contact Us : 9510430147

Email Id - [email protected]

#taknikinc#engineering#engineer#consultant#consultancy#services#wastemanagement#watertreatment#wastewatertreatmentplant#MVR#ZLD#multieffectevaporator#mechanicalvaporrecompression#products#MEE#bharuchcity#gujarat

0 notes

Text

Supplier of Flash Dryer in Pune

Overview: Drytech Engineering Systems is a Manufacturer, Exporter, and Supplier of Flash Dryer in Pune, Maharashtra. Drytech Engineering Systems Specialized in Spray Dryer, Flash Dryer, Spin Flash Dryer, Multi Effect Evaporator etc. Our Flash Dryer offers rapid drying for a wide range of materials. Our flash dryer system is an inexpensive solution to drying powders and granular materials, and is designed for high moisture materials with a constant-rate drying zone and can use higher gas temperatures, versus other dryer types because the material retention time is very short. Working Principle: The drying chamber receives the heated thermal medium, creating a swirling airflow with mechanical agitation for efficient drying. A feeder introduces the wet material into the chamber, where it undergoes pulverization and drying through stirring and vortex flow. A particle-sized classifier at the top of the chamber separates fine powder meeting drying standards, which a separator collects. The classifier blocks larger particles, subjecting them to further pulverization and drying until they meet requirements. Clean exhaust gas is expelled by the induced draft fan, completing the drying process. Features: Low time of residence, minimal heat exposure, retains original product quality An ideal substitution for drying wet cakes on the tray It is possible to treat an extremely sticky/pasty wet cake Cyclone and baghouse with high quality for powder recovery The Automatic Plant The negligible dusting of goods Instrumentation & controls for reliable performance provision Application: Food industry Chemical industries Metallurgy ore industries Drytech Engineering System is a Supplier of Flash Dryer in Pune, Maharashtra., and various locations, including Mumbai, Pune, Amravati, Latur, Solapur, Sangli, Kolhapur, Chandrapur, Daulatabad, Dhule, Jalgaon, Kalyan, Karli, Sangli, Satara, Sevagram, Thane, Ulhasnagar, Vasai-Virar, Wardha, Yavatmal. For detailed information and inquiries, please feel free to contact us. Read the full article

#Amravati#blockedbytheclassifier#Chandrapur#constant-ratedryingzone#Daulatabad#Dhule#DrytechEngineeringSystems#Exporter#FlashDryer#FlashDryerinPune#flashdryersystem#heatedthermalmedium#highmoisturematerials#highqualityforpowderrecovery#Jalgaon#Kalyan#Karli#Kolhapur#Latur#Lowtimeofresidence#Maharashtra#Manufacturer#minimalheatexposure#MultiEffectEvaporator#Mumbai#Pune#retainsoriginalproductquality#Sangli#Satara#Sevagram

0 notes

Text

Taknik Inc is an enigneering consultant we are the Services Provider of engineering Design & consultancy Services, Industrial Waste water Treatment Plant, Zero Liquid Discharge Sytem, Process Equipment

for more information, Contact us : 9510430147 Email ID : [email protected]

#taknikinc#engineeringconsultants#ZeroLiquidDischarge#ZLD#systemengineer#solutions#nowater#savewater#environmentallyfriendly#government#treatment#manufacturer#multieffectevaporator#MVR#atfd#bharuch#gujarat

0 notes

Text

Multi Effect Evaporator (MEE) a multiple-effect evaporator is an apparatus for efficiently using the heat from steam to evaporate water.

It work as the higher numbers of effects higher steam economy, and lower steam consumption as per evaporation of water.

#Multieffectevaporator#Wastewatertreamentplant#industry#Zero liquid Discharge Plant#Engineering#Consultancy#MAnufacturer#India#Solution#Water#pharma manufacturing#artists on tumblr#youtube#writers on tumblr#immobile

0 notes

Text

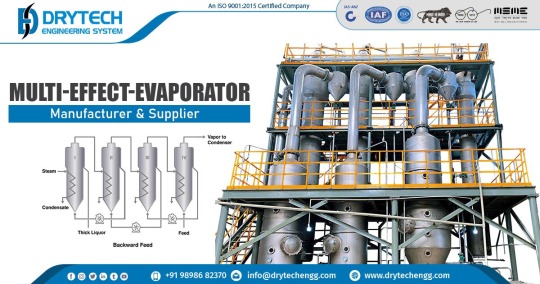

Supplier of Multi Effect Evaporator In Haydrabad

Drytech Engineering System is a 2017 ISO 9001:2015 certified company situated in Ahmedabad, Gujarat, India and Supplier of Multi Effect Evaporator In Haydrabad. We are a major manufacturer and supplier of a wide range of products such as Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, Dust Collector Systems, and many more. A multi-effect evaporator is a type of evaporator system that consists of a succession of evaporation stages. Each stage operates at a lower pressure than the previous one, allowing for more energy-efficient liquid evaporation. Steam provides the heat required for evaporation, making it a cost-effective alternative for concentrating liquids and recovering valuable goods. Features Oily emulsions, coolant fluids, mold release agents Purging of compressors, water from washing floors Water from washing tanks and reactors Working and washing baths in galvanic processes and surface treatments Penetrating liquids Water treatment plant rejection Multi-Effect-Evaporator Working Principle : Liquid Introduction Heat Transfer Vapor Recompression Concentrated Liquid Collection Types of Multi Effect Evaporator Fully Automatic Multi-Effect-Evaporator Semi Automatic Multi-Effect-Evaporator Application Food and Beverage Pharmaceuticals Chemicals Wastewater Treatment Desalination Drytech Engineering System is a Manufacturer and Supplier of Multi Effect Evaporator In Haydrabad, Telangana and various locations, including Hyderabad, Warangal, Nizamabad, Khammam, Karimnagar, Ramagundam, Mahbubnagar, Nalgonda, Siddipet, Miryalaguda, Suryapet, Jagtial, Bhongir, Kamareddy, Mancherial, Wanaparthy, Jangaon. Read the full article

#Ahmedabad#Bhongir#DrytechEngineeringSystem#FullyAutomaticMulti-Effect-Evaporator#Gujarat#Haydrabad#India#Jagtial#Jangaon#Kamareddy#Karimnagar#Khammam#Mahbubnagar#Mancherial#Miryalaguda#MultiEffectEvaporator#MultiEffectEvaporatorInHaydrabad#Nalgonda#Nizamabad#Ramagundam#SemiAutomaticMulti-Effect-Evaporator#Siddipet#Supplier#SupplierofMultiEffectEvaporator#SupplierofMultiEffectEvaporatorInHaydrabad#Suryapet#Wanaparthy#Warangal

0 notes

Text

Exporter of Spin Flash Dryer in Mauritius

Drytech Engineering Systems is a leading Manufacturer, Supplier, and Exporter of Spin Flash Dryer in Mauritius. We are Based in Ahmedabad, Gujarat, India. Drytech Engineering Systems offers spray dryers, flash dryers, spin flash dryers, and multi-effect evaporators. We provide two types of the spin flash dryer like Fully Automatic Spin Flash Dryer, Semi-Automatic Spin Flash Dryers. Features of Spin Flash Dryer: Disintegration System: Breaks down wet cakes for effective drying. Hot Air Injection: Pre-heated air is used to dry materials quickly. Cyclone Separator and Bag Filter: Collects dry powder efficiently. Energy-Efficient Operation: Operates at a voltage of 440V/50HZ. High Output Level: Rapid drying of paste and fluid-based substances. Chemical and Thermal Resistance: Durable design for various applications. No Sticking or Accumulation: Ensures smooth operation. Working Principle: Material Introduction: Materials are fed into the drying chamber in a fine, dispersed form. Hot Air Injection: We inject hot air at high velocity, promoting rapid moisture evaporation. Drying and Separation: A high-speed rotor creates agitation, mixing materials with hot air. Dried particles are carried to the cyclone separator for collection. What materials can be dried using a Spin Flash Dryer? Suitable for filter press wet cakes, fluids with high viscosity, and thick pastes. What are the energy requirements? Operates at 440V/50HZ, ensuring energy-efficient performance. How does the drying process work? The drying process involves material introduction, hot air injection, and drying/separation in a cyclone. What are the advantages of a fully automatic dryer? Enhanced efficiency, reduced manual intervention, and precise process control. Can I customize the drying parameters in a semi-automatic dryer? Yes, operators can adjust feeding rates, temperature, and drying times as needed. Drytech Engineering Systems is an Exporter of Spin Flash Dryer Mauritius covering locations such as Port Louis, Plaines Wilhems, Vacoas-Phoenix, Beau Bassin-Rose Hill, Curepipe, Quatre Bornes, Rivière Noire, Pamplemousses, Savanne, Grand Port and Flacq. Contact us today for more information, pricing, and availability. View Product: Click Here Read the full article

#Ahmedabad#BeauBassin-RoseHill#Curepipe#DrytechEngineeringSystems#Exporter#ExporterofSpinFlashDryerMauritius#Flacq#FlashDryers#GrandPort#Gujarat#India#Manufacturer#ManufacturerinAhmedabad#MultiEffectEvaporators#Pamplemousses#PlainesWilhems#PortLouis#QuatreBornes#RivièreNoire#Savanne#SpinFlashDryerMauritius#SpinFlashDryers#SprayDryers#Supplier#Vacoas-Phoenix

0 notes

Text

Exporter of Spin Flash Dryer in Zambia

Drytech Engineering Systems is an Exporter of Spin Flash Dryer in Zambia. Drytech Engineering Systems is a Manufacturer, Supplier, and Exporter of Spray Dryers, Flash Dryers, Spin Flash Dryers, and Multi Effect Evaporators. Our Manufacturing Unit is in Ahmedabad, Gujarat, India. An industrial drying equipment that utilizes hot air and mechanical agitation for quick drying of materials. Design: Consists of a cylindrical drying chamber. Equipped with a high-speed rotor. Operation: Material is introduced into the drying chamber through a feed mechanism. The material comes into contact with hot air for rapid drying. Raw Materials: Utilizes filter press wet cake. Suitable for fluids with high viscosity and thick pastes. Specifications: Voltage: 440V/50Hz. Material: Made of stainless steel. Advantages: Energy-efficient operation. High output levels. Drying Mechanism: Hot air generates a rotating wind area. High-speed rotation promotes fast drying of paste or fluid-based substances. We provide various types of Spin Flash Dryer like Fully Automatic Spin Flash Dryer and Semi Automatic Spin Flash Dryer. Features: It has a bag filter and cyclone separator for effective dry powder collection. Free from deposits, ensuring cleanliness. Efficiently dries cohesive and non-cohesive pastes, cakes, and highly viscous products. Chemical and thermal resistant for enhanced durability. Prevents sticking and accumulation during the drying process. Working Principle: The working principle of a spin flash dryer can be summarized in three main steps: Material Introduction: Introduce raw materials into the drying chamber through a controlled feed mechanism for processing. Hot Air Injection: Inject hot air into the chamber to facilitate efficient moisture removal from the material. Drying and Separation: Rapidly dry the material while separating dried particles from moisture for optimal product quality. Drytech Engineering Systems is an Exporter of Spin Flash Dryer in Zambia including locations Lusaka, Kitwe, Ndola, Chipata, Livingstone, Kasama, Kabwe, Chingola, Choma, Luanshya, Kafue, Mongu, Chinsali, Mazabuka, Mwinilunga, Solwezi, Mufulira, Kapiri Mposhi, Chililabombwe and Mansa. Feel free to contact us if you have any more information or questions. View Product: Click Here Read the full article

#Chililabombwe#Chingola#Chinsali#Chipata#Choma#DrytechEngineeringSystems#Exporter#ExporterofSpinFlashDryer#ExporterofSpinFlashDryerinZambia#FlashDryers#Gujarat#India#Kabwe#Kafue#KapiriMposhi#Kasama#Kitwe#Livingstone#Luanshya#Lusaka#Mansa#Manufacturer#ManufacturingUnitinAhmedabad#Mazabuka#Mongu#Mufulira#MultiEffectEvaporators#Mwinilunga#Ndola#Solwezi

0 notes