#Asphalt Drum mix Plant

Text

Asphalt Plant | Bitumen Sprayer Manufacturer in India - S.P. Enterprise

S.P. Enterprise is a manufacturer of road construction machinery like asphalt plant, hot mix plant, asphalt drum mix plant, bitumen sprayer in India. We are exporter and supplier of road construction equipments. Call us on +91-9712583240.

#asphalt plant#bitumen sprayer#mobile asphalt plant#asphalt drum mix plant#asphalt mixing plant#asphalt hot mix plant#bitumen pressure distributor

2 notes

·

View notes

Text

What is Asphalt Recycling Plant?

The use of reclaimed asphalt, or recycling, has become a necessity. Governments increasingly want the reclaimed asphalt from old roads re-used in an effort to be more environmentally friendly. Recycled asphalt also can provide you with cost savings on several fronts.

To use this valuable secondary resource, ZOOMLINE offers the Asphalt Recycling Plants to help your recycling and cost-saving efforts. Regardless of the system you choose, modern ZOOMLINE plant technology will provide a quality recycling process and product.

Asphalt Recycling Plant | Hot & Cold RAP Recycling, RAPpro 100% Recycled Asphalt Hot Mix Plant, Recycled asphalt hot mix plant, RAPpro 100% Recycled Hot Mix Asphalt Production Plant.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#recycling asphalt plant#asphalt recycling plant#recycled asphalt plant#RAP Recycling#recycled asphalt hot mix plant#recycled hot mix asphalt production plant#asphalt production plant

3 notes

·

View notes

Photo

Counter flow Asphalt Plant Manufacturer and Exporter – Atlas Technologies

Proven design of Atlas Counter flow drum mixers have helped customers achieve better quality of hot mix. The simple design of this equipment has helped customers achieve optimum fuel efficiency. It is also possible to use bag filter with the machine. We are looking to export counter flow asphalt plant to Europe and countries like Bangladesh and Sri Lanka.

#counter flow asphalt plant#Counter flow asphalt mixer#counterflow asphalt plant#asphalt drum mix plant#Drum Mix Plant#asphalt drum mix#construction equipment

4 notes

·

View notes

Text

Hot Drum Mix Plant Introduction

ot drum mix plant, also known as continuous drum asphalt mixing plant or drum mix asphalt plant, is a kind of asphalt plant that produces asphalt concrete using a continuous process. It realizes the continuous process of heating and drying of aggregate and mixing of mixture through a series of continuous working units. Hot drum mix asphalt plant occupies an important position in road construction projects with its high efficiency and continuous production.

The output of hot drum mix plant varies depending on the model and configuration. Generally speaking, the output of small hot drum mix plant may range from tens of tons/hour to hundreds of tons/hour, while the output of large hot drum mix plant can reach thousands of tons/hour. The specific output needs to be determined according to the model of the hot drum mix plant, production capacity and actual production demand.

Asphalt hot drum mix plant is mainly composed of the following parts:

- Batching system: responsible for feeding all kinds of aggregates into the mixing system according to the proportion.

- Drying System: Usually consists of drums which are used to heat and dry the aggregates.

- Combustion system: Provides heat, which is used to heat the aggregate in the drum.

- Mixing system: carried out in the drum to mix the heated aggregate with binder materials such as asphalt.

- Hot Aggregate Lifting and Storage System: Lifts the dried hot aggregate to the storage bin for subsequent metering and mixing.

- Weighing System: Accurately measures various raw materials to ensure the quality of the mix.

- Dedusting system: used to reduce the dust generated during the production process and protect the environment.

- Control system: automated control of the whole mixing plant to ensure the stability and efficiency of the production process.

Characteristics of hot drum mix asphalt plant:

- Continuous production: The drum hot mix asphalt plant adopts continuous process, which can realize continuous heating and drying of aggregate and continuous mixing of mixture, and improve the production efficiency.

- Simple process: Compared with intermittent mixing plant, the process of drum mix asphalt plant is simpler and the structure of the plant is relatively compact.

- High degree of automation: modern drum hot mix asphalt plant generally adopts PLC programmable centralized control, touch screen operation, automatic and manual switch freely, which greatly improves the degree of automation of production.

- Good environmental performance: Equipped with dust removal system, it can effectively reduce the dust emission in the production process and protect the environment.

Advantages of asphalt hot drum mix plant:

- Efficient production: the continuous production process makes the drum hot mix asphalt plant have high production efficiency, which can meet the demand of large-scale road construction projects.

- Stable quality: Through precise measurement and continuous mixing, the quality of the asphalt mixture is stable and reliable.

- Energy saving and environmental protection: modern drum hot mix asphalt plant emphasizes on energy saving and environmental protection design, and adopts high-efficiency combustion system and dust removal system to reduce energy consumption and emission.

- Strong adaptability: can be flexibly configured and adjusted according to the needs of different projects to meet the needs of different types and specifications of asphalt mixture production.

In summary, the hot drum mix plant plays an important role in road construction projects with its high efficiency, continuous and stable production characteristics. With the continuous development of science and technology, the technology and performance of the drum hot mix asphalt plant will be constantly upgraded and improved.

This resource is from http://www.asphalt-mixing-plants.net/industry-news/hot-drum-mix-plant.html

Should you be interested in, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

0 notes

Text

0 notes

Text

Operating and Maintaining Your Hot Mix Plant: Essential Tips

Operating a hot mix plant efficiently and effectively is crucial for the success of any road construction project. Whether you're new to managing a hot mix plant or looking to enhance your existing operations, here are some essential tips to ensure smooth functioning and optimal maintenance:

Preventive Maintenance Schedule

Regular maintenance is key to keeping your hot mix plant in top condition. Develop a detailed preventive maintenance schedule that includes daily, weekly, monthly, and annual checks specific to your Hot Mix Plant. This helps identify potential issues early on and prevents costly breakdowns.

Operator Training and Safety

Proper training of Hot Mix Plant operators is essential for safe and efficient operation. Ensure that your team is well-trained in Hot Mix Plant operations, safety protocols, and emergency procedures. Regular refresher courses can help maintain skills and awareness.

Monitoring and Control Systems

Invest in modern monitoring and control systems for your Hot Mix Plant. These systems allow operators to monitor temperature, moisture content, production rates, and other critical parameters in real-time. Automated controls can improve accuracy and consistency of the mix.

Quality Control Measures

Maintaining Consistent Hot Mix Plant quality is paramount. Implement rigorous quality control measures throughout the production process. Regular testing of raw materials, mixtures, and finished products ensures compliance with project specifications and regulatory standards.

Environmental Considerations

Hot Mix Plants can have environmental impacts due to emissions and noise. Adhere to local environmental regulations and implement measures to minimize pollution, such as using dust collection systems and noise barriers specific to your Hot Mix Plant.

Storage and Handling of Materials

Proper storage and handling of Hot Mix Plant raw materials, including aggregates and bitumen, are critical for maintaining mix quality. Ensure that storage facilities are clean, dry, and properly sealed to prevent contamination.

Emergency Preparedness

Have a comprehensive emergency plan in place for unexpected situations such as Hot Mix Plant equipment failure, fires, or spills. Train your team on emergency response procedures and maintain adequate firefighting equipment on-site.

Regular Inspections and Audits

Conduct regular inspections and audits of your Hot Mix Plant to assess equipment condition, adherence to safety standards, and compliance with operational protocols. Address any identified issues promptly to prevent disruptions in your Hot Mix Plant.

Efficient Energy Use

Optimize energy use at your Hot Mix Plant by implementing energy-efficient technologies and practices. Consider using recycled materials or warm mix asphalt technologies to reduce energy consumption and greenhouse gas emissions for your Hot Mix Plant.

Continuous Improvement

Encourage a culture of continuous improvement within your Hot Mix Plant team. Regularly solicit feedback from operators and stakeholders to identify opportunities for efficiency gains, cost savings, and enhanced performance in your Hot Mix Plant.

By implementing these essential tips for operating and maintaining your Hot Mix Plant, you can maximize productivity, ensure quality outputs, and contribute to the success of your road construction projects. Remember, proactive management and adherence to best practices are key to achieving long-term operational excellence in your Hot Mix Plant.

FAQ’S

What is a Hot Mix Plant?

A Hot Mix Plant is a facility used in road construction to produce asphalt, also known as hot mix asphalt (HMA). It blends aggregates (such as stone and sand) with liquid asphalt cement to create a material used for paving roads and highways.

2. How does a Hot Mix Plant work?

Hot Mix Plants heat aggregates to a high temperature before mixing them with asphalt cement. The heated aggregates are combined in precise proportions with the asphalt cement in a mixer to produce hot mix asphalt. This mixture is then transported and laid on roads using paving machines.

3. What are the types of Hot Mix Plants?

Hot Mix Plants can be classified based on their mobility and production capacity:

Stationary Hot Mix Plants: These are fixed plants that produce asphalt in a permanent location.

Mobile Hot Mix Plants: These plants are portable and can be easily transported to different construction sites.

Batch Mix Plants: These plants produce asphalt in batches, ensuring precise control over the mix quality.

Drum Mix Plants: These plants continuously produce asphalt as aggregates and asphalt cement are fed into a rotating drum.

4. What are the main components of a Hot Mix Plant?

A Hot Mix Plant typically includes:

Aggregates feeder bins

Conveyor belts

Drying drum (in drum mix plants)

Mixing unit (either batch or drum)

Bitumen heating and storage system

Control panel and computerized control system

Pollution control devices (dust collectors, etc.)

5. What are the environmental considerations when operating a Hot Mix Plant?

Environmental considerations include managing emissions, noise levels, and energy consumption. Hot Mix Plants should comply with local regulations regarding air quality and noise pollution. Implementing technologies like dust collectors and using warm mix asphalt can reduce environmental impact while maintaining operational efficiency. Regular maintenance and proper handling of materials also play a crucial role in minimizing environmental footprint.

0 notes

Text

We are leading manufacturer and supplier of Asphalt Drum Mix Plant in Ahmedabad, India. Specifically created for the manufacturing of hot-mix asphalt used in road construction and maintenance, an asphalt drum mix plant is a vital part of the construction sector. This complex piece of equipment effectively blends bitumen, aggregates, and other necessary components to produce a consistent and long-lasting asphalt mixture. Drum mix machines operate constantly, unlike batch plants that manufacture asphalt in discrete batches, making them extremely efficient and perfect for large-scale projects.

The revolving drum, where aggregates are heated and combined with hot bitumen to create the asphalt mixture, is the center of an asphalt drum mix plant. High levels of automation and exact temperature and proportion control throughout the process guarantee consistency and high-quality results. These facilities are essential for the building and upkeep of roads, bridges, and other infrastructure projects because of their reputation for dependability, speed, and capacity to generate a wide variety of asphalt mixtures. An asphalt drum mix plant is a crucial instrument in contemporary building projects because it improves the smoothness of road surfaces, lowers maintenance costs, and increases motorist safety.

0 notes

Text

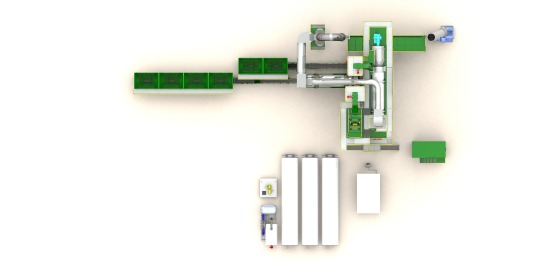

Asphalt Plant 60-90 tph - Morocco

Atlas 60-90 tph semi mobile plant installed in Morocco. The feeding unit, drying and mixing drum are fully mobile. The bitumen tank is stationary.

0 notes

Text

Stationary Asphalt Plant - Atlas Industries

Atlas for sale high quality of asphalt drum mix plant. We are manufacturer of stationary asphalt plants. Available 40 tph to 120 tph capacity of drum mixer.

0 notes

Text

5 Questions You Must Ask a Construction Equipment Manufacturer

Are you wondering what kind of questions to ask your construction equipment manufacturer? If yes, here is a complete guide to help you ask the right questions to your asphalt drum mix plant manufacturer. Read the article to learn more.

#asphalt drum mix plant#asphalt drum-mix plant manufacturer#construction machine manufacturer#asphalt mix plant#construction equipment manufacturers

0 notes

Text

Picson is a well-known brand among Gujarati manufacturers of asphalt drum mix plants, distinguished for its dedication to both quality and creativity. Designed to satisfy the various demands of road construction projects, Picson is a Gujarat-based company that specializes in the design, development, and manufacture of modern asphalt drum mix facilities. Visit our website https://www.picsinternational.com/asphalt-drum-mix-plant for additional information.

#Asphalt Drum Mix Plant Manufacturer in India#halt Drum Mix Plant Manufacturer in Gujarat#Construction Equipments Manufacturer in India#Construction Equipments Manufacturer in Gujarat

0 notes

Text

Reasons to buy Atlas asphalt drum mix plant - Atlas Industries

Many advantages and features have made Atlas asphalt drum mix plant the first choice of customers. Read about the many reasons to buy one.

0 notes

Text

What's the Functions of Asphalt Plant Dryer Drum?

The asphalt plant dryer drum is to preheat the cold aggregate, dry and heat it up to ensure that discharge temperature meets the requirements.

Drying drum is one of the core components of asphalt mixing plant. The performance of drying drum directly determine the production of a complete set of asphalt mixing plant.

The Advantages of Drying Drum:

Long service life

Energy saving

Low emission

Low fuel cost

ZOOMLINE provide stationary and mobile type drying drums for choice.

#dryer drum#drying drum#asphalt plant dryer#asphalt dryer drum#asphalt drum mix plant#asphalt mixing plant#road construction#asphalt plant#construction#asphaltplant#mobile asphalt drum mix plant#heavy equipment#concrete#bitumen#dryer#dryer drum mix

2 notes

·

View notes

Text

Asphalt batching plant manufacturers

Asphalt Drum mix plant manufacturers, Asphalt Batch Mix plantRMC plant manufacturers, Wet mix plant, Hot Mix Plants, Asphalt Mixing Plants, Asphalt plant, Concrete batching plant manufacturers, Wet mix macadam plant, Concrete mix plant, Bitumen sprayer, Hot mix plant service in Hyderabad, Batch mix services in Hyderabad, Bitumen pressure distributor, Batch mix plant, Asphalt batch mix plant suppliers, Batch mix plant suppliers, Drum mix plant suppliers

2 notes

·

View notes

Text

60-90 TPH Hot Mix Plant

60-90 tph hot mix plant is a kind of equipment used to produce asphalt mixture, which is widely used in road construction, maintenance and repair works. The main function of 60-90 tph hot mix asphalt plant equipment is to mix aggregate, asphalt and other additives in a certain proportion and produce asphalt mixture that meets the requirements of the project by heating and mixing. Haomei Machinery offer 60-90 ton per hour hot mix asphalt plant in the model of LB1000, whose production capacity is 80 ton per hour, and the mixer rated capacity is 1000L.

Here are some key features and considerations about 60-90 tph hot mix plant:

Production capacity:

60-90 tons per hour asphalt hot mix plant has a high production capacity and is suitable for small and medium-sized projects. Depending on the model and configuration, the actual capacity may vary.

Equipment Configuration:

Asphalt hot mix plant usually consists of aggregate conveying system, asphalt supply system, mixing system, control system and other parts. These systems need to work together to ensure the uniformity and stability of the asphalt mixture.

Environmental performance:

With the improvement of environmental awareness, hot mix asphalt plant pays more and more attention to environmental performance in the design and production process. For example, low emission burners, effective dust removal devices and noise control technologies are used to minimize the impact on the environment.

Degree of automation:

Modern asphalt hot mix plant usually has a high degree of automation, which can realize the functions of automatic batching, automatic control and automatic inspection to improve the production efficiency and product quality.

When choosing 60-90 tph hot mix plant, you need to consider the following factors:

Project demand:

According to the scale, duration and quality requirements of the project, choose the right model and configuration of asphalt hot mix plant.

Site conditions:

Asphalt hot mix plant needs to occupy a certain site space, so you need to consider factors such as the size, shape and infrastructure of the site.

Investment budget:

The price of asphalt hot mix plant varies according to the model, configuration and brand, so you need to make a reasonable choice according to the investment budget.

After-sales service:

Choose manufacturers or suppliers with good after-sales service and technical support to ensure the normal operation and timely maintenance of the equipment.

In short, 60-90 tph hot mix plant is an important road construction equipment, choosing the right equipment is important to ensure the quality and progress of the project.

This resource is from http://www.asphalt-mixing-plants.net/industry-news/60-90-tph-hot-mix-plant.html

Should you be interested in buying our product, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

0 notes