Coninfra Machinery Pvt. Ltd. is a leading manufacturer of road sweeping machines in India, specializing in high-quality equipment for road maintenance. Our state-of-the-art technology ensures efficient and effective cleaning solutions for roads, highways, and other infrastructure projects. As one of the premier road sweeping machine manufacturers in India, we are committed to delivering reliable and durable products that meet the stringent requirements of the industry. With a focus on innovation and customer satisfaction, Coninfra Machinery Pvt. Ltd. stands out as a trusted provider of road sweeping solutions nationwide.https://www.coninfra.in/

Don't wanna be here? Send us removal request.

Text

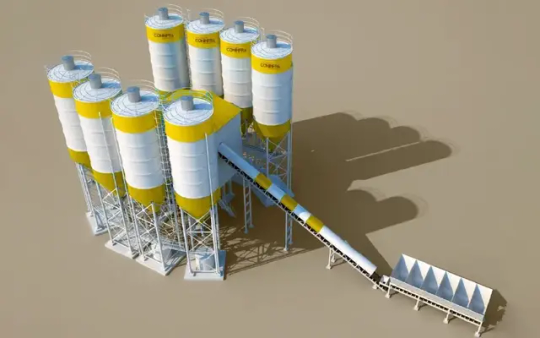

How to Safely Load and Unload Cement from Silos: A Guide for Site Operators

Cement silos are essential storage units used on construction sites to store bulk cement and fly ash efficiently. Ensuring safety during the loading and unloading process is vital for maintaining worksite productivity, preventing accidents, and preserving material quality. This guide provides site operators with practical knowledge on handling cement silos while following the latest safety standards used by industry leaders in road construction and material handling equipment.

What is a Cement Silo?

A cement silo is a specialized container used for storing dry bulk materials like cement and fly ash. These silos come in various types, including vertical silos, horizontal silos, and mobile silos. They are commonly used in infrastructure projects, ready-mix concrete plants, and road construction sites. Silo manufacturing companies in India design these units to handle large volumes efficiently and safely, often aligning with IS code standards and CPCB dust control norms. Operators should confirm whether the silo complies with IS 4925:2004 to ensure safe batching practices.

Why Proper Handling of Cement Silos is Crucial?

Proper handling of cement silos is essential to avoid material spillage, equipment damage, and safety risks. Incorrect procedures can lead to clogged discharge systems, dust pollution, and even structural damage to the silo. Following safe loading and unloading methods ensures that operations run smoothly and reduces downtime, especially when working with fly ash silo systems. Some advanced silos are designed with user-friendly safety features like digital level indicators and automatic venting systems that minimize human error.

Cement Loading Process: Step-by-Step Guide

The loading process involves transferring bulk cement into the silo from a tanker or bulk carrier. Here's how to do it safely:

Check all connections and pressure levels before starting.

Use appropriate conveyors or blowers as recommended by the equipment manufacturer.

Monitor the silo’s level indicator to avoid overfilling.

Ensure the dust collector is operational to prevent airborne particles. Skipping these steps can lead to material loss and air contamination.

Pro Tip: In one project involving high-output cement batching, an operator avoided a costly system shutdown by double-checking the pressure settings against the values in the manufacturer’s manual before initiating loading. Always confirm tanker pressure settings to prevent structural stress on the silo.

Cement Unloading Process: Best Practices

Unloading cement from silos should be done systematically:

Open discharge valves slowly to control material flow.

Use gravity or pneumatic systems as per equipment specifications.

Maintain silo pressure balance by using a functional air vent.

Clean the discharge line regularly to avoid clogging. Leading manufacturers often recommend scheduled maintenance and some provide digital alerts on silo health via SCADA systems, especially on high-volume projects.

Safety Measures to Follow During Loading and Unloading

Safety should always come first during cement handling. Key measures include:

Wearing personal protective equipment (PPE) such as helmets, goggles, and dust masks.

Implementing lockout/tagout systems to prevent accidental starts.

Installing emergency stop buttons near the control panel.

Using dust suppression equipment to reduce inhalation risks. Many construction equipment suppliers now integrate dust filters and pressure relief systems that comply with national safety standards.

Real-World Note: During a recent highway expansion project, one site team reduced handling-related delays by 30% by conducting pre-shift safety inspections and using silo systems with automatic dust control features.

Maintenance Tips for Cement Silos

Routine maintenance extends the life of a cement silo and enhances safety:

Inspect structural components for cracks or corrosion.

Clean filters and pressure relief valves.

Lubricate moving parts such as screw conveyors.

Keep a logbook of inspections and repairs. Several Indian silo manufacturers now provide maintenance kits and digital maintenance reminders for efficient site management.

How Modern Cement Silos Improve Safety and Efficiency

Advanced cement silos come equipped with automation and smart features:

Digital level indicators reduce manual checks.

PLC and SCADA systems allow real-time monitoring.

Better insulation and ventilation improve material preservation.

Adopting modern silo technology improves project timelines and supports remote monitoring features particularly useful in large-scale highway and infrastructure projects.

To Conclude

Handling cement silos properly is a key part of safe and efficient construction site operations. Following best practices for loading, unloading, and maintenance helps prevent accidents and material wastage. By choosing reliable equipment and adhering to safety protocols, site operators can ensure a smooth and secure workflow across construction and infrastructure projects.

FAQs

1. What is the purpose of a fly ash silo in construction?Ans: Fly ash silos store fly ash, a byproduct of coal combustion used in cement and concrete mixes to improve strength and durability. These silos help keep the material dry and uncontaminated. For projects in humid areas, look for silos with moisture control systems.

2. How often should cement silos be inspected?Ans: At a minimum, silos should be inspected once a month. For high-use sites, bi-weekly checks are recommended. Focus on structural integrity, discharge lines, and dust filtration systems. Sites that use SCADA-enabled systems can automate this process with real-time alerts.

3. Can one cement silo be used for different materials?Ans: Technically yes, but not advisable. Using the same silo for both cement and fly ash can lead to contamination and inconsistent mixing quality. Best practice is to use dedicated silos for each material.

4. What are the common causes of blockages in cement silos?Ans: Moisture infiltration, lack of routine discharge cleaning, and irregular maintenance schedules are major causes. Using anti-bridging devices, air dryer systems, and regular vent cleaning helps prevent buildup.

5. Are mobile silos a better option for remote projects?Ans: Yes. Mobile silos are particularly useful for projects in remote or temporary locations. They offer quick setup and disassembly, and reduce transportation costs by eliminating the need to haul cement daily from fixed storage units.

0 notes

Text

Why Invest in a Portable Batching Plant

On-Site Mixing for Consistency and Speed

In fast-moving projects whether it’s a rural road widening or an urban infill development, ready access to high-quality concrete is critical. A portable batching plant brings the precision of a permanent installation to your site. By situating the mixing unit directly where you pour, you eliminate long haul times, reduce rebound from drum mixers and ensure every cubic meter matches your design specifications. This on-site approach not only slashes RMC plant cost associated with third-party vendors but also tightens control over water‐cement ratios, aggregate grading and admixture dosing.

Key Features That Matter

Coninfra’s portable plants are engineered for quick deployment. Modular skids arrive pre-assembled, requiring minimal civil works—just a level pad and utility hook-ups. PLC‐based automation handles aggregate weighing, cement feed and water dosing to within ±1% accuracy, safeguarding mix consistency batch after batch. Integrated dust collectors and water-recycle systems minimize site pollution, while remote SCADA options let you monitor productivity and trigger preventive maintenance without leaving your office.

Applications in Road Construction

Portable batching plants excel in road paving projects where road alignment shifts frequently, such as long stretches of bituminous roads and highway extensions. Instead of trucking hot mix asphalt from a central facility, you can pivot your batch plant alongside the paver machine and road roller construction unit, ensuring materials are fresh and within pot life. This mobility also benefits emergency repairs mobile units can be on-site within days, supplying wet mix concrete for pothole patches or drainage channel backfills.

Balancing Cost and Capacity

While fixed tower batching plants deliver higher maximum throughput (up to 150 m³/hr), portable units from Coninfra still offer robust performance up to 80 m³/hr—with the added benefit of relocation. For contractors handling multiple sites or phased developments, this flexibility can offset the slight premium per cubic meter by reducing standby charges, haul costs and idle transit mixers.

Choosing the Right Portable Plant

When evaluating options, consider your daily volume, future project pipeline and site access. If you frequently switch between asphalt road construction and concrete pours, look for dual‐mode plants with optional heated bins or quick-connect silicone hosing for admixtures. Coninfra’s team can help tailor a package, complete with batch plant operator training, spare parts kits and ongoing technical support to ensure your mobile batching plant becomes the most reliable member of your construction fleet.

0 notes

Text

Reducing Dust and Ensuring Material Integrity with Coninfra’s Cement/Fly Ash Silo

In any large-scale concrete or asphalt operation, loss of material and site pollution from airborne cement dust can create serious environmental, health and economic problems. Coninfra Machinery Pvt. Ltd.’s Cement/Fly Ash Silo is designed to address these challenges head-on, providing sealed storage, precise dosing and integrated dust-collection in a single modular system.

1. Why Sealed Silos Matter

Open storage of fine powders like cement and fly ash leads to significant material loss through wind dispersal, especially in windy, ancillary industrial area settings, or during bulk transfers. Coninfra’s silo features dust-tight hoppers, pneumatic conveyance and emergency-vent filters that keep your on-site footprint clean and your stock levels accurate. By minimizing fugitive emissions, you comply with local CPCB regulations and reduce the need for costly site cleanup.

2. Precise Dosing for Consistent Batches

Whether you’re feeding a Concrete Batching Plant or mixing bituminous asphalt concrete in a Wet Mix Macadam Plant, accurate cement and fly ash proportions are critical. Coninfra’s silo-mounted load cells and screw-conveyor feeders deliver material at ±1% accuracy. This precision reduces over-use of binder, limits expensive rework and ensures every batch—be it hot mix asphalt or ready-mix concrete—meets the specified mix design.

3. Seamless Integration with Construction Equipment

As a leading road construction equipment supplier, Coninfra recognizes that on-site logistics often involve multiple engineering tools & equipment, from transit mixers to paver machines. Their silo modules are skid-mounted for quick hook-up to your batching plant’s pneumatic lines or belt conveyors. In retrofit scenarios, existing baghouses or vacuum systems can be tied into the silo’s dust collector, giving you a turnkey solution without rip-and-replace of your material handling.

4. Health, Safety and Environmental Benefits

Fine cement and fly ash particles pose inhalation risks to workers and can settle on machinery, accelerating wear. Enclosed silos with integrated cartridge filters trap over 99% of particulates, keeping your site ISO-certified clean and your crew safer. In combination with proper road cleaning brushes and sweepers, you maintain a dust-free environment around your mobile or stationary plant.

5. Scalability and Maintenance

Coninfra’s silos come in capacities ranging from 50 to 200 tonnes, so you can right-size your storage to match project demands—whether you’re running a compact ready mix plant in an urban infill site or a high-capacity asphalt plant on a highway corridor. Wear-resistant liners and easy-access inspection hatches simplify routine checks, while local service teams ensure that any filter or gasket replacements arrive within 24 hours.

By incorporating Coninfra’s Cement/Fly Ash Silo into your material flow, you’ll significantly cut dust-related losses, improve batch consistency for both concrete and asphalt and uphold environmental and safety standards across every job site.

0 notes

Text

How a Cement Batching Plant Transforms Project Workflows

A reliable cement batching plant is the heart of any large-scale construction site, whether you’re casting columns for high-rise buildings or precasting segments for infrastructure projects. Coninfra Machinery Pvt. Ltd.’s Cement Batching Plant seamlessly integrates material handling, precise dosing and automated control to deliver uniform cement mortar or grout mixes significantly speeding up work cycles and reducing waste.

1. Centralized Material Management

Traditional on-site mixing often relies on multiple silos, manual conveyors and bucket elevators, creating a maze of equipment that’s hard to monitor. Coninfra’s plant consolidates all aggregate, cement and admixture storage into a single system. Automated feeders and weigh scales ensure each batch follows your exact recipe, whether it’s for precast panels, brick grout or cement mortar. This centralization cuts down on manual labor for batching in concrete, freeing crews to focus on placement and finishing.

2. Consistency and Quality Control

One of the biggest challenges with field mixing is achieving consistent water-to-cement ratios, which directly affect strength and durability. With Coninfra’s PLC-driven controls, water dosing and cement feed are accurate to within ±0.5%. Operators select pre-programmed mix designs akin to choosing recipes on a ready mix concrete plant control panel—and the system reproducibly delivers each batch at the flip of a switch. Consistent batches lead to fewer on-site failures, reducing rework and material overuse.

3. Accelerated Pouring Cycles

Time is construction money. Coninfra’s cement batching plant can cycle through batches in under two minutes, thanks to high-speed mixers and low-maintenance gearboxes. For projects that require continuous grout injection—such as under-pinnings or post-tensioning ducts—this rapid turnaround keeps pumps fed without pause. Even for standard cement mortar, faster mixing means masons and finishers never run dry, maintaining a smooth workflow across the site.

4. Flexible Deployment and Footprint

Not all sites have room for sprawling RMC plant setups. Coninfra offers both skid-mounted and modular cement batching plants that fit into tight footprints, minimizing civil works. The RMC plant full form ready mix concrete, emphasizes how these systems can also handle grout or mortar mixes, making them true multi-taskers in material preparation. Quick installation and plug-and-play wiring allow sites to be up and running in days, not weeks.

5. Data-Driven Site Management

Modern construction demands traceability. Coninfra’s batching plant generates digital batch reports documenting mix times, quantities and mix IDs that feed into your project management software. This enables real-time tracking of material consumption and helps anticipate inventory needs, preventing delays due to stockouts of cement ready mix concrete or admixtures.

6. Reduced Waste and Environmental Impact

By accurately metering ingredients, the plant minimizes leftover slurry or over-mixed batches. Dust collection units and sealed conveyors contain fine cement particles, promoting a cleaner site and healthier work environment. For EPC contractors focused on sustainability, these features help meet environmental regulations without sacrificing productivity.

Investing in Coninfra Machinery Pvt. Ltd.’s Cement Batching Plant modernizes your material backbone, ensuring precise mixes, faster cycles and cleaner operations keys to finishing projects on time and within budget.

0 notes

Text

0 notes

Text

Road Construction Equipment Supplier

Coninfra Machinery Pvt Ltd is a leading road construction equipment supplier based in Ahmedabad, Gujarat. With a strong commitment to quality and innovation, we specialize in providing a comprehensive range of machinery designed to meet the diverse needs of the construction industry. Our products, including asphalt batch mix plants, bitumen sprayers, and hydraulic road sweepers, ensure efficiency and reliability on every project. Trust Coninfra for top-notch equipment that enhances productivity and safety in road construction endeavors.

0 notes

Text

Construction Equipment Manufacturing Companies

Coninfra Machinery Pvt. Ltd. is a leading name in the field of construction equipment manufacturing, based in Ahmedabad, Gujarat. Specializing in high-quality road construction machinery, Coninfra is committed to delivering innovative and reliable solutions for various construction needs. With a diverse range of products, including asphalt batch mix plants and hydraulic road sweepers, the company ensures efficiency and performance in every project. As one of the premier construction equipment manufacturing companies in India, Coninfra continues to set industry standards.

0 notes

Text

This article outlines the key benefits of utilizing hot mix plants in road construction projects. It details how these plants enhance the quality and durability of asphalt by producing a consistent mix of materials at high temperatures. The article highlights advantages such as improved workability, faster construction times, and superior performance of the final road surface. Additionally, it discusses the efficiency of hot mix plants in reducing waste and ensuring environmental compliance. By focusing on these benefits, the article provides a comprehensive understanding of why hot mix plants are a critical component in modern road construction.

0 notes

Text

Choosing the right road construction equipment supplier is crucial for successful project execution. This article outlines the top five qualities to consider, including product reliability, technical expertise, and customer support. It emphasizes the importance of assessing the supplier's reputation for delivering high-quality machinery, their ability to provide timely service and maintenance, and their commitment to innovation. By focusing on these factors, industry professionals can select a supplier who meets their needs for durable, efficient, and cutting-edge road construction equipment.

0 notes

Text

Exploring the Latest Technologies from Leading Road Construction Machine Manufacturers

In the rapidly evolving field of road construction, staying updated with the latest technologies is crucial for ensuring efficiency, durability, and safety in infrastructure projects. Leading road construction machine manufacturers are at the forefront of this innovation, delivering cutting-edge solutions that transform how roads are built and maintained. This blog delves into the latest advancements from top road construction equipment manufacturers, with a focus on how these innovations are reshaping the industry.

The Role of Technology in Modern Road Construction

Modern road construction is heavily reliant on advanced technologies to meet the demands of growing urbanization and infrastructure development. Road construction machinery has seen significant advancements, making it more efficient, precise, and eco-friendly. Road construction machine manufacturers are continuously pushing the envelope to introduce new features and capabilities that address various challenges faced during construction.

Innovations from Leading Road Construction Machine Manufacturers

Smart Road Construction Equipment One of the most notable advancements in road construction machinery is the integration of smart technology. Many road construction equipment manufacturers are now offering machines equipped with GPS tracking, automated controls, and real-time data monitoring. These features enhance precision, reduce manual errors, and ensure that construction activities are carried out efficiently.

Eco-Friendly Road Construction Machines As environmental concerns become more pressing, there is a growing emphasis on developing eco-friendly road construction machines. Road construction machine manufacturers are investing in technologies that reduce emissions, improve fuel efficiency, and utilize sustainable materials. This shift not only helps in meeting regulatory standards but also contributes to the overall sustainability of construction projects.

Advanced Asphalt Mixing Plants Asphalt mixing plants are integral to road construction, and recent innovations have made them more efficient and versatile. Leading road construction equipment manufacturers have introduced advanced asphalt mixing plants that offer better control over the mixing process, improved energy efficiency, and enhanced quality of the final product.

High-Tech Road Pavers Road pavers are crucial for laying down smooth and durable road surfaces. The latest road construction machinery features advanced control systems, automated screeds, and improved material handling capabilities. These innovations ensure that the paving process is more accurate, faster, and produces higher-quality results.

Improved Compaction Equipment Effective compaction is essential for the longevity of road surfaces. Modern compaction equipment from leading road construction machine manufacturers includes features such as intelligent compaction systems that provide real-time feedback on soil density and compaction quality. These advancements help in achieving optimal compaction and reducing the need for rework.

Coninfra Machinery Pvt. Ltd.: Leading the Charge in Innovation

At the forefront of these technological advancements is Coninfra Machinery Pvt. Ltd., a prominent name among road construction equipment manufacturers. Known for their commitment to quality and innovation, Coninfra Machinery Pvt. Ltd. offers a range of road construction equipment designed to meet the evolving needs of the industry.

Their latest offerings include state-of-the-art road construction machines that incorporate the latest technologies in automation, efficiency, and sustainability. By leveraging advanced features such as real-time monitoring, precise control systems, and eco-friendly technologies, Coninfra Machinery Pvt. Ltd. ensures that their equipment meets the highest standards of performance and reliability.

The Future of Road Construction Machinery

As the demand for better and more efficient infrastructure continues to grow, road construction machine manufacturers are likely to keep innovating. Future advancements may include even more sophisticated automation, enhanced connectivity, and further improvements in environmental sustainability. Keeping an eye on these trends is essential for staying ahead in the competitive landscape of road construction.

Conclusion

The latest technologies from leading road construction machine manufacturers are transforming the industry, offering more efficient, precise, and eco-friendly solutions for building and maintaining roads. Companies like Coninfra Machinery Pvt. Ltd. are at the forefront of this revolution, providing cutting-edge road construction machinery that sets new standards in performance and innovation. By embracing these advancements, construction professionals can ensure that their projects are not only successful but also aligned with the latest industry trends and sustainability goals.

0 notes

Text

A bitumen sprayer is essential in road construction for evenly applying bitumen on surfaces. It ensures optimal adhesion of the road surface, improves durability, and enhances performance. This equipment streamlines the application process, making roadwork more efficient and effective.

0 notes

Text

Discover why quality is crucial in road construction machinery. This blog explores insights from top manufacturers, highlighting how superior quality enhances performance, durability, and safety. Learn how investing in high-quality equipment can drive success and efficiency in road construction projects.

0 notes

Text

Why Quality Matters: Insights from Leading Road Construction Machinery Manufacturers

Discover why quality is crucial in road construction machinery. This blog explores insights from top manufacturers, highlighting how superior quality enhances performance, durability, and safety. Learn how investing in high-quality equipment can drive success and efficiency in road construction projects.

Sources:

0 notes

Text

The Comprehensive Guide to Wet Mix Macadam: Everything You Need to Know

When it comes to road construction, one of the most crucial aspects is selecting the right materials and techniques to ensure durability, strength, and cost-effectiveness. Among the various methods, Wet Mix Macadam (WMM) has emerged as a popular and efficient choice. This comprehensive guide will delve into everything you need to know about Wet Mix Macadam, its advantages, the process involved, and its comparison with other methods, particularly the hot macadam plant technique.

What is Wet Mix Macadam?

Wet Mix Macadam, commonly referred to as WMM, is a pavement base course made from crushed stone aggregates, granular materials, and water. This mixture is then laid and compacted to form a stable base for road construction. The WMM process ensures a uniform and strong base, which is essential for the longevity and durability of roads.

The Process of Wet Mix Macadam

Selection of Materials: The first step involves selecting high-quality crushed stone aggregates and granular materials. The materials should be free from dust, clay, and other impurities.

Mixing: The selected materials are mixed with water in a specified proportion. The mixing is typically done in a plant, ensuring a consistent and uniform mixture.

Transportation: The mixed material is then transported to the construction site using dumpers or trucks.

Laying: The wet mix is laid on the prepared surface using a paver or manually. The thickness of the layer is usually between 75 to 200 mm, depending on the road specifications.

Compaction: The laid mix is compacted using rollers to achieve the desired density and strength. Proper compaction ensures the removal of air voids and provides a stable base.

Curing: After compaction, the surface is allowed to cure for a specific period, usually 24 to 48 hours, before the next layer is applied.

Advantages of Wet Mix Macadam

Strength and Durability: WMM provides a strong and durable base, capable of withstanding heavy traffic loads.

Cost-Effective: The process is economical compared to other methods, reducing the overall construction cost.

Speed of Construction: The mixing and laying process is relatively faster, ensuring quick project completion.

Uniformity: The plant-mixed material ensures uniformity in quality and composition, leading to a consistent base layer.

Wet Mix Macadam vs. Hot Macadam Plant

While Wet Mix Macadam is a popular choice, the hot macadam plant technique, also known as Hot Mix Asphalt (HMA), is another widely used method in road construction. Here’s a comparison:

Materials Used:

Wet Mix Macadam: Uses crushed stone aggregates and granular materials mixed with water.

Hot Macadam Plant: Uses asphalt binder and aggregates, heated and mixed at high temperatures.

Process:

Wet Mix Macadam: Involves mixing materials with water, laying, and compacting.

Hot Macadam Plant: Involves heating aggregates, mixing with asphalt binder, and laying the hot mix.

Cost:

Wet Mix Macadam: Generally, more cost-effective due to the use of locally available materials and simpler processing.

Hot Macadam Plant: Higher cost due to the use of asphalt binder and heating process.

Application:

Wet Mix Macadam: Suitable for base and sub-base layers.

Hot Macadam Plant: Ideal for surface layers due to its smooth finish and durability.

Environmental Impact:

Wet Mix Macadam: Lower environmental impact as it does not involve heating and emissions.

Hot Macadam Plant: Higher environmental impact due to the heating process and emissions from asphalt binder.

Conclusion

Wet Mix Macadam is an efficient and cost-effective method for constructing durable and strong road bases. Its advantages, such as speed of construction, uniformity, and reduced cost, make it a preferred choice in many road projects. While the hot macadam plant technique also has its merits, particularly for surface layers, WMM stands out for its application in base and sub-base layers. Understanding the differences and benefits of each method can help in making informed decisions for road construction projects.

0 notes

Text

Operating and Maintaining Your Hot Mix Plant: Essential Tips

Operating a hot mix plant efficiently and effectively is crucial for the success of any road construction project. Whether you're new to managing a hot mix plant or looking to enhance your existing operations, here are some essential tips to ensure smooth functioning and optimal maintenance:

Preventive Maintenance Schedule

Regular maintenance is key to keeping your hot mix plant in top condition. Develop a detailed preventive maintenance schedule that includes daily, weekly, monthly, and annual checks specific to your Hot Mix Plant. This helps identify potential issues early on and prevents costly breakdowns.

Operator Training and Safety

Proper training of Hot Mix Plant operators is essential for safe and efficient operation. Ensure that your team is well-trained in Hot Mix Plant operations, safety protocols, and emergency procedures. Regular refresher courses can help maintain skills and awareness.

Monitoring and Control Systems

Invest in modern monitoring and control systems for your Hot Mix Plant. These systems allow operators to monitor temperature, moisture content, production rates, and other critical parameters in real-time. Automated controls can improve accuracy and consistency of the mix.

Quality Control Measures

Maintaining Consistent Hot Mix Plant quality is paramount. Implement rigorous quality control measures throughout the production process. Regular testing of raw materials, mixtures, and finished products ensures compliance with project specifications and regulatory standards.

Environmental Considerations

Hot Mix Plants can have environmental impacts due to emissions and noise. Adhere to local environmental regulations and implement measures to minimize pollution, such as using dust collection systems and noise barriers specific to your Hot Mix Plant.

Storage and Handling of Materials

Proper storage and handling of Hot Mix Plant raw materials, including aggregates and bitumen, are critical for maintaining mix quality. Ensure that storage facilities are clean, dry, and properly sealed to prevent contamination.

Emergency Preparedness

Have a comprehensive emergency plan in place for unexpected situations such as Hot Mix Plant equipment failure, fires, or spills. Train your team on emergency response procedures and maintain adequate firefighting equipment on-site.

Regular Inspections and Audits

Conduct regular inspections and audits of your Hot Mix Plant to assess equipment condition, adherence to safety standards, and compliance with operational protocols. Address any identified issues promptly to prevent disruptions in your Hot Mix Plant.

Efficient Energy Use

Optimize energy use at your Hot Mix Plant by implementing energy-efficient technologies and practices. Consider using recycled materials or warm mix asphalt technologies to reduce energy consumption and greenhouse gas emissions for your Hot Mix Plant.

Continuous Improvement

Encourage a culture of continuous improvement within your Hot Mix Plant team. Regularly solicit feedback from operators and stakeholders to identify opportunities for efficiency gains, cost savings, and enhanced performance in your Hot Mix Plant.

By implementing these essential tips for operating and maintaining your Hot Mix Plant, you can maximize productivity, ensure quality outputs, and contribute to the success of your road construction projects. Remember, proactive management and adherence to best practices are key to achieving long-term operational excellence in your Hot Mix Plant.

FAQ’S

What is a Hot Mix Plant?

A Hot Mix Plant is a facility used in road construction to produce asphalt, also known as hot mix asphalt (HMA). It blends aggregates (such as stone and sand) with liquid asphalt cement to create a material used for paving roads and highways.

2. How does a Hot Mix Plant work?

Hot Mix Plants heat aggregates to a high temperature before mixing them with asphalt cement. The heated aggregates are combined in precise proportions with the asphalt cement in a mixer to produce hot mix asphalt. This mixture is then transported and laid on roads using paving machines.

3. What are the types of Hot Mix Plants?

Hot Mix Plants can be classified based on their mobility and production capacity:

Stationary Hot Mix Plants: These are fixed plants that produce asphalt in a permanent location.

Mobile Hot Mix Plants: These plants are portable and can be easily transported to different construction sites.

Batch Mix Plants: These plants produce asphalt in batches, ensuring precise control over the mix quality.

Drum Mix Plants: These plants continuously produce asphalt as aggregates and asphalt cement are fed into a rotating drum.

4. What are the main components of a Hot Mix Plant?

A Hot Mix Plant typically includes:

Aggregates feeder bins

Conveyor belts

Drying drum (in drum mix plants)

Mixing unit (either batch or drum)

Bitumen heating and storage system

Control panel and computerized control system

Pollution control devices (dust collectors, etc.)

5. What are the environmental considerations when operating a Hot Mix Plant?

Environmental considerations include managing emissions, noise levels, and energy consumption. Hot Mix Plants should comply with local regulations regarding air quality and noise pollution. Implementing technologies like dust collectors and using warm mix asphalt can reduce environmental impact while maintaining operational efficiency. Regular maintenance and proper handling of materials also play a crucial role in minimizing environmental footprint.

0 notes

Text

The Ultimate Guide to Wet Mix Macadam Construction

Wet Mix Macadam (WMM) is a vital component in road construction, offering durability, stability, and cost-effectiveness. In this comprehensive guide, we delve deep into the intricacies of WMM construction, its benefits, and the step-by-step process involved.

Understanding Wet Mix Macadam

Wet Mix Macadam, often abbreviated as WMM, is a type of base course used in road construction projects. It comprises aggregates, filler materials, and water, blended together to form a strong foundation for roads. The mixture is laid and compacted while wet, hence the name "Wet Mix Macadam."

Benefits of Wet Mix Macadam

Durability: Wet mix macadam offers excellent durability, withstanding heavy traffic loads and adverse weather conditions.

Stability: The compacted WMM layer provides a stable base for asphalt or concrete overlays, ensuring longevity and structural integrity.

Cost-effectiveness: Compared to traditional methods, Wet mix macadam construction is cost-effective due to its use of locally available materials and simplified construction process.

Construction Process

1. Aggregate Preparation

The first step in Wet mix macadam construction is the preparation of aggregates. High-quality aggregates, including crushed stone, gravel, and sand, are selected based on specifications provided by engineering standards.

2. Mixing

Once the aggregates are prepared, they are mixed with filler materials, such as cement or lime, to enhance stability and cohesion. Water is added to the mixture to achieve the desired moisture content.

3. Spreading and Compaction

The mixed WMM is then spread uniformly on the prepared sub-grade using motor graders or pavers. Specialized compaction equipment, such as vibratory rollers, is used to compact the WMM layer thoroughly.

4. Quality Control

Throughout the construction process, rigorous quality control measures are implemented to ensure compliance with project specifications and standards. This includes regular testing of materials, moisture content, and compaction levels.

Advantages Over Conventional Methods

Wet Mix Macadam offers several advantages over conventional methods of road construction, making it a preferred choice for many infrastructure projects:

Improved Strength: The controlled mixing and compaction process result in a higher strength base course, capable of withstanding heavy traffic loads.

Reduced Construction Time: WMM construction requires fewer layers compared to traditional methods, leading to reduced construction time and costs.

Environmental Sustainability: By utilizing locally available materials and minimizing the use of natural resources, WMM construction promotes environmental sustainability.

Applications of Wet Mix Macadam

Wet Mix Macadam finds wide-ranging applications in various road construction projects, including:

Highways and Expressways

Rural Roads

Industrial and Commercial Areas

Airport Runways

Conclusion

Wet Mix Macadam is a versatile and cost-effective solution for road construction, offering durability, stability, and environmental sustainability. By understanding the construction process and its benefits, engineers and contractors can make informed decisions to optimize infrastructure projects.

FAQ’S

What is Wet Mix Macadam (WMM)?

Wet Mix Macadam (WMM) is a type of road construction material used for laying a base or sub-base layer. It comprises aggregates, water, and binder mixed thoroughly to form a homogeneous mixture.

What are the key components of Wet Mix Macadam?

The main components of Wet Mix Macadam include aggregates of various sizes (stone chips), water, and a binding agent such as bitumen or cement. These components are mixed in specific proportions to achieve the desired consistency and strength.

What are the advantages of using Wet Mix Macadam?

Wet Mix Macadam offers several advantages in road construction, including better strength and durability compared to conventional granular bases. It provides good resistance against water damage, improves load-bearing capacity, and facilitates faster construction due to its ability to be compacted easily.

What is the construction process for Wet Mix Macadam?

The construction process for Wet Mix Macadam involves several steps: preparation of the sub-grade, mixing of aggregates, water, and binder in a mixing plant, transportation and spreading of the mixture on the prepared sub-grade, compaction using rollers, and curing to achieve the desired strength.

What are the applications of Wet Mix Macadam?

Wet Mix Macadam is commonly used in the construction of highways, rural roads, airport runways, and industrial areas where a strong and durable base layer is required. It is particularly suitable for areas with heavy traffic loads and high moisture content in the soil.

Name: Coninfra Machinery Pvt.Ltd

Website: https://www.coninfra.in/

Address: 504, Sahitya Business Park, Nr. Keshav Hero Showroom , S.P Ring Road Nikol, Ahmedabad - 382350, INDIA

Phone No: +91 90999 41311

0 notes