#Auto Nesting CNC Machine

Explore tagged Tumblr posts

Text

How to Choose the Best Sheet Metal Laser Cutting Machine in India

Choosing the right sheet metal laser cutting machine is one of the most important decisions for any fabrication or manufacturing business. With the growing demand for precision and speed in metal processing, selecting the right equipment can greatly impact your productivity, cut quality, and operational efficiency. At Pusaan Automation, we bring you this practical guide to help you make the best choice for your business in the Indian market.

Understand Your Material and Production Requirements

The first step in choosing a laser cutting machine is to understand your application. Consider the type of sheet metal you work with—such as mild steel, stainless steel, aluminum, brass, or copper—and the range of thicknesses you regularly cut. If you typically work with thin materials, a lower power machine (1kW to 3kW) may be sufficient. For medium to thick materials, machines with 4kW to 6kW or higher are recommended. Knowing your material and volume requirements helps you choose the right machine without overspending on unnecessary power.

Choose the Right Laser Technology

In India, fiber laser cutting machines are now the industry standard due to their energy efficiency, lower maintenance, and ability to cut reflective materials. Compared to older CO₂ laser systems, fiber lasers offer faster cutting speeds, reduced operating costs, and longer lifespan. we focus exclusively on advanced fiber laser technology that delivers high-quality, high-speed cutting tailored to Indian industrial needs.

Focus on Machine Build Quality and Precision

The build quality of the laser cutting machine plays a critical role in achieving consistent and accurate results. A machine with a strong, welded steel frame offers better stability, especially during high-speed operations. Look for machines equipped with precision linear guides, ball screws, and servo motors. These components ensure long-lasting performance with minimal deviation, even under continuous load. Pusaan Automation machines are designed with robust construction for reliable performance in demanding production environments.

Consider Automation and Software Features

Automation enhances efficiency, reduces human error, and increases throughput. Look for machines with user-friendly CNC control systems, auto-focus laser heads, and nesting software that optimizes material usage. Additional features such as automatic loading and unloading systems can significantly reduce cycle time in high-volume operations. We integrates smart features and automation options to help you streamline your production line and boost output.

Evaluate After-Sales Service and Local Support

Even the best machines require support, spare parts, and maintenance. Reliable after-sales service is essential to minimize downtime and keep your operation running smoothly. When choosing a laser cutting machine, ensure the manufacturer offers local service engineers, technical support, and quick access to spare parts. Pusaan Automation is known for its strong after-sales support network across India, offering training, preventive maintenance, and responsive service.

Look Beyond Initial Cost—Think Long-Term Value

While pricing is an important factor, consider the total cost of ownership. A lower-priced machine may lead to higher operating and maintenance costs over time. Instead, focus on value—choose a machine that offers energy efficiency, low maintenance, long service life, and high resale value. we help you make smart investments that provide long-term returns.

Request a Live Demo or Trial Cut

Before finalizing your purchase, it’s highly recommended to see the machine in action. A live demonstration or trial cut on your own material will show you the machine’s capabilities in real-time. It also gives you an opportunity to assess the cut quality, speed, and ease of use. Pusaan Automation welcomes you to visit our demo center for a hands-on experience and personalized consultation.

Why Pusaan Automation?

At Pusaan Automation, we specialize in designing and delivering high-performance fiber laser cutting machines tailored for Indian manufacturers. Our machines combine cutting-edge technology, precision engineering, and practical features to meet the needs of businesses of all sizes. Backed by strong local support, customization options, and a customer-first approach, we are proud to be a trusted partner for metal fabrication across the country.

Ready to Choose the Right Machine?

If you're planning to invest in a sheet metal laser cutting machine, let Pusaan Automation help you make the right choice. Our team will guide you through the process—from requirement analysis to machine installation and ongoing support. Contact us today for a free consultation and machine demo.

0 notes

Text

Kitchen Cabinet Door Making CNC Router Machine for Sale

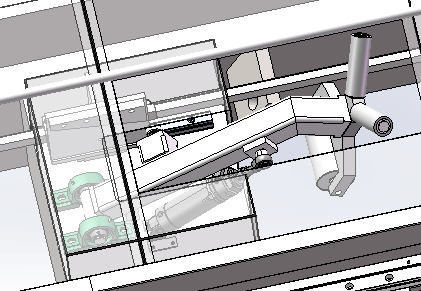

The pneumatic 4 process nesting CNC machine is a multi-function��automatic CNC nesting machine, which integrates cutting, chamfering, relief, hollowing, punching, slotting and other processes, while meeting the processing requirements of cabinet doors and cabinets, can realize automatic loading and unloading, save labor, and greatly improve the processing speed and efficiency.It has the advantages of low procurement cost, simple operation and complete functions. Four different bits can be installed to complete various processing functions, such as cutting, engraving and drilling at one time. It is equipped with auto loading and unloading tables. So it can load and unload the materials automatically. It is an ideal machine for large production enterprises, specially for making cabinet.

It can be used with edge banding machine, laminating machine, side hole machine and other machines to customize the whole house.

The CNC router for cabinet making relates to a four process double station double pusher material opening machine. The feeding machine consists of a working bench, which is equipped with a two working table along the length direction of the platform support at the top of the workbench support, and there is a Y moving mechanism above the bench bracket. The two transverse symmetrical Y to the rack in the Y moving mechanism is fixed on both sides of the platform bracket, and the transverse beam in the moving mechanism at the Y. The top is fixed with a X direction rack with a transverse setting of X to the moving mechanism, and a Z direction moving mechanism on the left side of the moving mechanism along the direction of the feeding, and the Z to the driving motor in the Z moving mechanism is fixed vertically on the X slide plate in the X to the moving mechanism, and the Z direction slide plate in the Z moving mechanism is equipped with a processing device. The opening machine can make maximum use of the working time of the opening machine, high processing efficiency, convenient feeding and unloading, and can avoid the droop of the drag chain. The cabinet making CNC router is suitable for kitchen cabinet making, cabinet door making, corner cabinet making, decorative cabinet making, home cabinet making, wall cabinet making, wood cabinet making, base cabinet making and other custom cabinet making in bathroom, garage, living room, and office.

Cabinets Making CNC Router Applications

Cabinet making:CNC router is ideally suitable for furniture decorations, musical instruments, wooden crafts, solid wood furniture, MDF door, wood composite door, cabinet making, kitchen cabinet doors, windows, tables, etc.

Decoration Industry:Art model, wall art, screen relief engraving and cutting, decoration processing, gifts wrapping, waved plate, electrical cabinets panels, sports equipment, and other industrial wood works.

Kitchen Cabinet Door Making CNC Router Machine Advanced Performance

4 kinds of process switching processing, to achieve 0 seconds tool change, greatly improve the work efficiency.

Using HQD6.0kw air cooled automatic tool change spindle, long life, low noise, reliable quality.

IGOLDENindependent electric control cabinet, humanized design, Taiwan Baoyuan system, easy to operate.

Using Taiwan silver guide rail and crescent rack, high positioning accuracy, smooth sliding, reliable quality, long life.

Professional CNC Taiwan Baoyuan control system, easy to learn and easy to operate.

Can increase the automatic loading and unloading platform, save labor costs, fast cost recovery, meet the needs of the production line, automatic intelligent operation, efficiency is greatly improved.

The 4 spindle CNC router is very easy to use.You only need to save the position of the cutters in the tool path, then the system could realize the cutter auto changing according to the cutter code.So this four-axis CNC machine kitchen cabinet machine runs very efficiently and stably.

Powerful 4 Spindle Auto-Change Of Drilling Milling Machine

The Heavy structure adopts thicken steel square which improves the stability of wood CNC 4×8. This Stronger structure is necessary for cutting solid materials such as hardwood. During the 4×8 wood CNC machine cutting and carving process, the XYZ axis remains stationary against external cutting forces.

High Efficiency Cutter Changing Of Multi Spindle CNC Router For Sale

The advantage of This 4 spindle CNC machine kitchen cabinets is that the spindle change speed is fast or we call it tool change. It only takes 2 seconds to turn on the spindle in advance for preheating. And you can use different spindles from 800w to 6.5kw, instead of using 8.5kw ATC spindle for drilling.This 4 spindle CNC router is easy to maintain and easy to replace the spindle; there is no tool change problem, and it will not stop work due to the tool change problem. It is beneficial to the mass production line.

Stable Working Sturcture Of CNC Machine Kitchen Cabinets

As a drilling milling machine,a strong and stable structure is very important,because this machine has 4 spindle,it need to process many material in a very stable environment.So the gantry and base frame of our 4 spindle CNC router is made of tubular steel.and the entire length of the column is welded with reinforcing ribs to achieve a stable beam Components.The Gantry uprights of this machine are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, belts, and wiring harnesses.Moreover the base frame has a long service life after precision welding.

0 notes

Text

Remcor Apollo BK series three chuck tube fiber laser cutting machine can cut all types of metal tubes, from mild steel to stainless and also non-ferrous metals. It is also valid for cutting some reflective metals like aluminum, brass and copper, etc. The thickness of the metal can be anywhere up to 30 mm. The diameters can be up to Ø 350mm tubes. Can cut different shapes on the surface of square tubes, oval tubes, U tubes or rectangular tubes or other special shape tube products. The most outstanding feature of our BK system is that can realize the real Zero-tailing cutting. And our automatic loading system freedom operator from the hard and heavy pipe loading problem.

Apollo BK Three-chuck Tube Laser Cutting Machine 1000w-6000w Features

Different shapes & Different sizes

1. All kinds of pipe processing, no need to change clamping scheme.

2. Match the three-dimension head to solve all kinds of the pipe inflection points.

3. CNC and CAM can calculate complex profile sections. Φ8-Φ440 mm range.

Max weight

600kgs load and unload maximum length up to 12M.

Raw material waste

Unique 3 chucks technology, zero tailing, high pipe utilization Average material can reduce up to 30%.

Labor cost

Real time, high precision, fast troubleshooting servo motor control automatic and semi load can be chosen.

Environment pollution

Dust collection box included full sealing chuck to prevent dust into chuck to have a longer lifetime.

Low efficiency

1. Simple to operate, new upgraded system with servo motor to realize the high automation and simplication.

2. High-precision chuck to make sure high speed, stability, high quality cutting.

3. Automatic loading and unloading to improve efficiency.

Apollo BK Three-chuck Tube Laser Cutting Machine 1000w-6000w Parameter Details

Item

6020-BK

7025-BK

9025-BK

9034-BK

Power range

1500-6000W

Chuck structure

3 chucks

Tube size

Round Type: Φ15-200mm

Round Type: Φ15-245mm

Round Type: Φ15-245mm

Round Type: Φ15-330mm

Square Type:15-140mm

Square Type:15-175mm

Square Type:15-175mm

Square Type:15-230mm

Positioning accuracy of x& y

±0.05mm/m

Max positioning speed x&y

100m/min

80m/min

Max cutting length

6000mm

7000mm

9000mm

9000mm

Tail length

≥ 0mm

Max weight single tube

135KG

260KG

260KG

500KG

Max loading length

6000mm

7000mm

9000mm

9000mm

Fully Annealed Table

The bed body adapts the segmented rectangular tube welding bed with fully annealed treatment at over 600⁰. After tempering, the strength, rigidity and stability are guaranteed, the precision would be tested and debugged which can make sure the precision can be maintained for a long time. The table is equipped with automatic lubrication device, which ensure the moving parts operate in good condition and improve the service life of guide rails, gears and rack.

Follower Support

The follower support device will be optional. The follower support is mainly to assist in controlling the excessive deformation of cutting longer pipes (pipes with smaller diameter), and the servo motor drives the up and down movement of the pallet assembly. When the chuck moves to the corresponding position, the auxiliary support automatically drops for avoidance.

Smart Auto Focus Laser Head

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

Intelligent CNC Operating System

tube laser cutting machine intelligent cnc operating system

It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks on big IPAD Screen. Realize the intelligent diagnosis, multi-threading operation, three-level perforation, laser energy control, adaptive edge-finding, automatic corner acceleration and deceleration, flight cutting, switching worktables, mechanical accuracy compensation etc.

Pneumatic Clamp Chucks

Pneumatic clamp design on both sides. The dual-chucks help reduce tube vibration to a minimum, guaranteeing high accuracy in even complex tube configurations at high cutting speed. Suitable for cutting a range of tube diameters from Ø20 mm to Ø220 mm and various wall thicknesses.

Front chuck

tube laser cutting machine front chuck

Back chuck

tube laser cutting machine back chuck

Fractional Automatic Support Technology

Applies the intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Equipped with two sets of variable-diameter support structures, which are automatically lifted by the cylinder to avoid the rear chuck in processing. When processing profiles with different diameters, manually turn the variable-diameter wheels to achieve fit and support for different-sized profiles. The variable-diameter wheels It can be supported every two degrees of rotation to reduce the diameter of the circumscribed circular tube by 2mm

0 notes

Text

Cabinet Making CNC Machine/ CNC Kitchen Cabinet Wooden Door

The cabinet making cnc machine is our newly-developed CNC Router with combined function of material loading and unloading for cabinet-making, widely used in home decoration, shop and office furniture. It is equipped with Italy HSD Spindle, Italy Boring unit and advanced Syntec control system, Japanese Yaskawa servo and Taiwan reducers.

Custom and general Cabinet Making Machineis one of the most popular applications for CNC routers. IGOLDENCNC CNC routers have brought industry standards to a new level with our quality and components, delivering what you would find in much higher-priced CNC routers at a cost competitive with the less industrial designs.

📷

Features of Cabinet Making Machine:

* Square tube lathe bed with more solid structure and strong stability because of low center of gravity.

• Vacuum table in 4zones can fix materials of different sizes effectively.

• Taiwan TBI balls screws, HIWIN square guide rails, high precision, large load bearing and stable running.

• Gantry-travelling, sturdy, reliable and stable, non-deforming, high locating accuracy.

• Mach3 control system, with computer controlled, very stable.

• Unique ability to save several point of origin on several workpieces.

• No engraving saw-tooth, smooth undersurface, legible contour, by high-power spindle.

• Auto seeking original point system, a good way to improve the working effeciency.

• Large compatibility of drawing software, such as Type3, artcam and some other CAD or CAM.

Cabinet Making Machine application:

* Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

* The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

* Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti-Bate board, epoxy resin, ABS, PP, PE, PEHD and other carbon mixed compounds.

* Decorate industry: Acrylic, PVC,MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

Model

1325 CNC Nesting Machine

Working area

1300*2500mm

Spindle

ATC 9KW HQD air cooling spindle

Inverter

Fuling

Motor

Dorna servo motors

Driver

Dorna servo driver

Control System

Taiwan LNC control system

Table

Double layer Vacuum table + position cylinder + secondary dust collection + Pusher system

Oil lubrication

Automatic lubrication

Limit

Omron limit

Transmission

XY axis Taiwan helical rack Z axis Taiwan ball screw

Rail

X,Y,Z axis Germany Square guide rail

Screw

Z axis TBI ball screw

Bed

Thick steel welded big square tube

Gangry

Strong frame

Pillars

Steel pillar(Suitable for high-end customers)

Cabinet

Independent cabinet

Voltage

3 phase/380V

Color

As requirement

Tools

1 box(10 pieces)

Company Information

Jinan iGolden CNC Equipment Co.,Ltd. is a R&D,manufacturing,sales integration company that specializing in router cnc, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany, etc.We adopt international advanced producing technologies to improve our products.Our products are widely used in advertising,woodworking, artworks, model, electric, CAD/CAM Industry Model, Clothing, Package Printing, Marking, Laser Sealing and so on.And welcome to visit us for more choices.

2 notes

·

View notes

Photo

DNE Laser Two Chucks Laser Tube Cutting Machine with Automatic Loading and Unloading System D-Fast fiber laser cutting machine is a product developed for the profile and tube cutting market, using the latest independent research and development EtherCAT type CNC laser cutting system, realizing control of tubes support device and chuck, etc... Function: ◆Wide Cutting Applications ◆Special Profiles of Tubes ◆Auto Pneumatic Chucks ◆Full-auto loading system ◆Auto unloading function ◆Powerful and User-friendly Nesting software ◆Overloading weight and unloading tube length ... More: https://en.dne-china.com/list-13.html #dnelaser #bystronic #manufacturing #power #machinetools #machineshop #cnc #machine #metalworking #engineering #equipment #industrial #tools #machinery #industrialmachinery #production #industrialequipment #metalwork #powertools #metalshaping #toolshop #powertool #lasercutting #metalcutting #metalworks #lasercuttingmachine

1 note

·

View note

Text

Technology Used in Steel Detailing

Today’s technology has taken over to simplify and diversify the work of Steel Detailing Companies in us. Today, manual drafting is no longer used in this industry, which was once run with pencils, pens, protractors, and subsequently calculators. The majority of detailers now use CAD, or computer-aided drafting. Steel detailers can express their creativity on a digital pad, which can then be reproduced as a 3D model or out on paper for 2D projects.

BIM in 3D technology

3D BIM is one of the newest technologies (Building Information Modelling). The 3D BIM software TEKLA is well-known in the field and has placed fourth in the last two years as a crucial and effective tool for the pre-engineered building sector. It can address any issue regions and is quicker than 2D detailing. After design is complete, modelling is done using BIM software. A list of raw materials, a dispatch list, shop floor plans for fabrication, etc. are sent once the model is finished.

For large projects, BIM is helpful in integrating important and essential services. Compared to 2D drafting, 3D models have several advantages.

It is simpler to implement changes and manage complex shapes.

Since all organisations involved in detailing, manufacturing, and erection follow the same model, there is little risk of misalignments occurring on project sites.

Software for nesting and site fabrication

The PEB business frequently and extensively uses site fabrication, yet there are better options available. High speed CNC plate cutting machines that use plasma or oxygen as fuel and nesting software to reduce scrap creation are available in PEB facilities. CNC punching and drilling are crucial for accurate site alignments and for creating holes for connections. Clips and other items can be welded using MIG equipment. Surfaces are prepared for painting using methods like shot and sand blasting.

CNC devices

C/Z purlins, roof and wall cladding are made using CNC cold roll forming equipment with auto pinching and shearing. Trims and accessories are produced by CNC folding machines. Other specialised equipment are employed in the production of various components, including anchor bolts, clips, and downtake pipes.

Designing Softwares

The majority of structural engineers conduct structural analysis using STAAD (from Bentley). The widely used and well-liked software MBS (Metal Building Software) provides the most accurate estimate, designing, and detailing of PEB buildings, together with shipping lists and 3D drawings. The PEB sector is now demonstrating its prowess in the construction of infrastructure, including high-rise and multi-story buildings, electricity transmission lines, metro tracks, and complicated constructions like airports.

There are some more internal softwares utilised for detailing in addition to MBS.

Benefits of Structural Steel Detailing Software

Employees in the structural steel sector possess a mastery of logic and reason as well as specialised training in all branches of mathematics.

The main advantage of using a Structural Steel Detailing Servicesis that the user gains further computer and programme knowledge. Once they have it down, trigonometry and geometry may be easily accessed without having to be memorised or manually calculated.

Why Having a 2D print version allows the steel detailer to provide a mock-up to the client before spending the time and money necessary to create a 3D representation. Any alterations or revisions made to the original blueprints are likewise recorded by the steel detailing programme. When input can be applied, the workflow is streamlined and the customer and creative can choose what works best for them both.

Using Structural Steel Detailing software decreases human mistake, promotes coherent brain-storming, and makes the process easier. Quick adjustments can be made instead of sketching numerous rounds, and maintained in notation in case there is a need to reverse back later.

The PEB industry is prepared and ready to take on a far larger role. The most cutting-edge technology are employed. The new airports serve as a superb illustration of PEB business. RCC structures have long dominated the housing market, but new PEB technologies are intended to displace RCC. The use of steel buildings with composite constructions can be significant in the provision of affordable housing for large numbers of people. Structural Steel Detailing Companieshas been employed in high rise structures, but the fact that it also presents fantastic opportunities in low and medium rise structures is a game-changer.

#structural steel detailing services#steel detailing companies in us#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us

0 notes

Text

Cut2d pro torrent

#Cut2d pro torrent for mac

#Cut2d pro torrent full

#Cut2d pro torrent pro

Parallels Toolbox Business Edition 5.5.1 posted on Aug| under Application.

Adobe Illustrator 2022 v26.3.1 posted on | under Adobe, Application, Graphics & Design.

Blackmagic Design DaVinci Resolve Studio 18.0.1 posted on J| under Application, Graphics & Design, Video.

#Cut2d pro torrent pro

Logic Pro X 10.7.4 posted on | under Apple, Application, Music.

Luminar Neo 1.2.0 (12210) posted on J| under Application.

Adobe Lightroom Classic v11.4.1 posted on J| under Adobe, Application, Graphics & Design, Photography.

Adobe Premiere Pro 2022 v22.5 posted on J| under Adobe, Application, Video.

Adobe Acrobat DC Pro 2022.001.20112 posted on Ap| under Adobe, Application.

Final Cut Pro 10.6.3 posted on | under Apple, Application, Video.

CleanMyMac X 4.10.6 posted on | under Application, Utilities.

#Cut2d pro torrent for mac

Microsoft Office 2021 for Mac LTSC v16.63.1 VL posted on J| under Application, Business, office.Adobe Illustrator 2022 v26.4.1 posted on Aug| under Adobe, Application, Graphics & Design.Adobe Photoshop 2022 v23.4.2 posted on J| under Adobe, Application, Photography.Parallels Desktop Business Edition 17.1.4 posted on Aug| under Application, Utilities.The videos are accompanied by associated files that allow users to view and work through the training materials at their own pace.Ĭut2D Pro is ideal for production-oriented work and allows you to maximize material yield or to make multiple copies of the same part. Over 15 hours of tutorials are available for Cut2D Pro, which are based on real examples and cover all aspects of using the program. The main focus of ease of use relates not only to the user interface and the workflow of the software, but was also transferred to the training documents. This enables immediate feedback so that the toolpaths can be further optimized.Ĭut2D Pro provides the functionality required for complex work while being incredibly easy to use and inexpensive.Ĭut2D Pro is used by carpenters, woodworkers, prop makers, plastic processors, hobbyists and in many other applications. In addition, all toolpaths can be previewed to see what the part will look like when actually milled. The toolpath options cover all typical 2D milling operations such as profiling, pocket milling, auto inlays and drilling.Įach toolpath contains appropriate options to customize the settings and provide a high level of control for different modes of operation.

#Cut2d pro torrent full

The software can import 2D designs from other programs, but it also offers a full set of drawing and editing tools. No restrictions on the size of parts or materials you can work with Including: Profiling, Pocket Milling, Drilling, Insertion and Quick EngravingĬombine toolpaths with the same tool for efficient machining Cut2D Pro has easy-to-use vector drawing and editing tools with powerful 2D machining strategies for CNC milling or engraving, and offers a powerful yet intuitive software solution for milling parts on a CNC router.Ĭomplete set of 2D design and layout toolsĮasily create or import vectors from scratch and edit bitmap images With unlimited job and toolpath size, real-form nesting, and job setup sheets. Vectric Cut2D Pro 10.514 (圆4) MultilingualĬut2D Pro gives you the ability to create complex 2D patterns with profile, pocket, drilling and insertion toolpaths.

0 notes

Text

How to Choose the Best CNC Metal Laser Cutting Machine in India

In today’s rapidly evolving manufacturing industry, CNC metal laser cutting machines have become essential for precision cutting, efficiency, and cost-effectiveness. If you are looking for the best CNC metal laser cutting machine in India, this guide will help you make an informed decision.

1. Understand Your Cutting Needs

Before investing in a CNC laser cutting machine, identify the materials you will be cutting, their thickness, and the required precision. Machines vary in their cutting capabilities, so choosing one that meets your production needs is crucial.

2. Types of Laser Sources

The performance of a CNC laser cutting machine depends on the type of laser source used. The main types are:

Fiber Laser: Ideal for cutting metals like stainless steel, carbon steel, aluminum, and brass. Fiber lasers offer high efficiency and lower maintenance.

CO₂ Laser: More suitable for non-metallic materials but also used for some metals. However, it has higher operational costs compared to fiber lasers.

3. Power and Cutting Speed

The power of the laser (measured in watts or kilowatts) determines the machine’s cutting ability. Higher power machines cut thicker materials faster and with greater precision. For example:

1kW - 3kW: Suitable for thin sheets (up to 8mm steel, 6mm stainless steel, 3mm aluminum).

4kW - 6kW: Suitable for medium-thickness sheets.

10kW and above: Ideal for thick materials (over 25mm steel, 15mm stainless steel).

4. Machine Build Quality and Precision

A CNC machine’s frame and build quality impact its durability and accuracy. Look for machines with a robust structure, high-precision linear guides, and a stable motion control system to ensure consistent cutting quality.

5. Automation and Software

Modern CNC laser cutting machines come with advanced software for easy operation, design import, and production optimization. Features like auto-focus, nesting software, and real-time monitoring can enhance efficiency and reduce waste.

6. After-Sales Support and Spare Parts Availability

Choosing a reliable manufacturer or supplier with strong after-sales support, warranty, and easy access to spare parts is essential. Pusaan Automation provides high-quality CNC laser cutting machines along with expert service support across India.

7. Cost vs. ROI Analysis

While price is an important factor, consider the long-term return on investment (ROI). A high-quality CNC laser cutting machine may have a higher upfront cost but will offer better efficiency, lower maintenance, and improved productivity in the long run.

Why Choose Pusaan Automation?

At Pusaan Automation, we offer state-of-the-art CNC metal laser cutting machines designed to meet various industrial requirements. Our machines are Sheet Metal Laser Cutting Machine, CNC Laser Cutting Machine, Fiber Laser Cutting Machine and Laser cutting machine for metal etc. known for their precision, durability and cost-effectiveness. We provide expert guidance, installation, training and after-sales support to ensure you get the best value for your investment.

Conclusion

Selecting the best CNC metal laser cutting machine in India requires careful consideration of your material requirements, machine specifications, and long-term benefits. With Pusaan Automation, you can be assured of high-performance machines backed by professional support.

For more details, contact us today!

0 notes

Text

4 Axis CNC Wood Furniture Cabinet Door Making and Drilling Machine

This CNC wood furniture machine is a multifunctional CNC wood router machine that can process a variety of products. it is a multifunctional machine,this machine contains ATC Function.So it can be used in making cabinet furniture.It not only supports automatic tool change, but also installs two machining axes, namely horizontal spindle and rotary axis. So this machine It has high work efficiency and is widely used in the cabinet furniture industry. And the horizontal spindle can be used to drill and milling the keyhole and hinge for door making. The rotary axis can be used to make furniture legs, such as chair legs, table legs, sofa legs and many other three-dimensional sculpture projects.

5×10 Nesting CNC Router Machine

1530 CNC router 5×10 ATC spindle machine with a rotary device is used mainly for the automatic carving of hardwood, MDF, 3D objects, cabinets, doors, staircase handrails, wooden pillars, stool legs, table legs, etc. The table size and rotary diameter can be ordered on your request. Affordable 5×10 CNC router ATC machine is now for sale at the best price.

ATC Nesting CNC Router with Rotary Device Features

The rotary device on CNC router table 5×10 is portable. And it also can be detached in the process of transporting.

ATC machine always has a more firm and reasonable structure. It is easy to operate and durable for long time heavy-duty work.

Italy HSD air cooling ATC spindle has a top speed up to 24000RPM, which greatly improves working efficiency.

Table 5×10 always means 1500x3000mm, we can also customize it on your request.

5×10 Nesting CNC Machine is a Wooden Furniture production line, it includes loading equipment, auto-feeding equipment, Nesting CNC Router with auto tool changer, unloading equipment, it automatic the whole process of MDF prepare, feeding, fixing, cutting, carving and unloading; best choice for Wooden Furniture making.

A 5×10 Nesting CNC Machine is an invaluable tool for industries that work with large sheet materials, offering the ability to efficiently process, nest, and cut components with precision. Its automatic nesting and CNC control capabilities help optimize material utilization, improve productivity, and reduce production costs.

What is the difference between the 3 axis and 4 axis CNC machine?

3 axis: the spindle is vertical and used for making flat working and engraving.

4 Axis CNC Wood Machine Applications:

Furniture Manufacturing: Craft intricate and detailed designs on wooden furniture pieces, including tables, chairs, cabinets, and decorative panels.

Cabinet Making: Create precise cuts and joinery for kitchen cabinets, bathroom vanities, and storage solutions.

Signage: Produce custom signs, plaques, and decorative wooden signs with high-quality lettering and graphics.

3D Carvings: Carve intricate 3D designs, reliefs, and sculptures on wood for artistic and architectural applications.

Prototyping: Rapidly prototype and test new product designs or components with precision.

Art and Crafts: Explore creative woodworking projects such as intricate wood carvings, inlays, and wooden artwork.

Panel Processing: Accurately size and shape wooden panels and sheets for various applications.

Types of Nesting CNC Machine

ATC CNC Nesting Furniture Making Machine

Here are two type of ATC nesting CNC router for cabinet and furniture. One type is the linear ATC CNC nesting machines, and another is the ATC wood nesting machine with carousel tool magazine. And the automatic tool change spindle of this panel furniture CNC making machine is a top-brand high-power spindle with fast processing speed. The nesting machine bed is specially customized and has very high stability. This ATC wood nesting CNC machine is equipped with an independent tool changer magazine. Any tool can be placed in the magazine. The tool can be changed automatically according to different processing techniques during processing, which saves the time of manual tool changing. With the highest configuration, this type of nesting CNC router for sale is widely used for customers of various types of processing.

Multi-functional Nesting CNC Furniture Manufacturing Machines

Actually, IGOLDEN CNC Machinery Company provides many different types of nesting CNC machines for sale with many different functions, such as CNC wooden door lock making machine for sale, nesting CNC cabinet door making equipment with saw, auto nesting CNC feeding furniture making machine, automatic furniture making machine with drill, CNC nesting router machine with two worktables, labeling CNC nesting machine for sale, intelligent labeling and nesting cell, etc. They are all entry level nesting machines that added with different processing tools like CNC drill bits, saws, ATC spindles, worktables, labeling system, loading and unloading system, etc, to achieve more processes.

Single-head Nesting CNC Machine

This nesting machine is mainly used for cutting, grooving, engraving, and drilling vertical holes on plates. Generally, friends who have just entered the furniture industry will choose this entry level CNC nesting router machine. Because it is the most basic nesting machine for sale and this kind of nesting CNC machine price is relatively cheap. Therefore, it is also named as the best nesting CNC machine for beginners or CNC nesting router for small business. The disadvantage of such a type of wood nesting CNC router machine is that there is only one machining spindle and can not realize complex nesting CNC projects. If you want to perform multiple processes, you need to manually change several different tools. Of course, very few processing plants now use this machine because of low production efficiency.

Multi-process CNC Nesting Machine

The multi-process nesting machine mainly refers to double process nesting CNC machine, three process nesting CNC machine, or four process nesting CNC router. What does the multi process mean? It means that the multi-functional nesting CNC machine is equipped with multiple machining spindles, which can continuously and uninterruptedly complete the work of cutting, slotting, punching, cutting, etc. No manual tool changing is required, and the processing speed is more than three times faster than ordinary single-head nesting machines. Manufacturers of a little scale and some newcomers with sufficient funds will choose this CNC machine.

The biggest highlight of the double-process nesting CNC machine is that a drilling package is added to the nesting machine. Therefore, this type of nesting CNC machine for sale includes a single spindle router with row drilling, a dual spindle CNC nesting machine with row drilling, automatic tool change spindle nesting CNC with row drilling. This type of nesting CNC can realize rapid vertical drilling and can automatically change the CNC drilling tool according to different hole positions. Therefore, the production efficiency of this type of CNC nesting cutting machine is very high.

0 notes

Text

Automatic loading and unloading machine

https://www.igolden-cnc.com/product/nesting-cnc-machine-with-auto-loading-table-for-furniture-making/

0 notes

Text

The evolution of plasma cutting

Plasma cutting has come a long way since it was first developed in the late 1950s by engineers at Union Carbide Corp. Today it is one of the most widely used metal plate cutting processes for a large variety of industries.

Early plasma cutting systems were used primarily for cutting stainless steel and aluminum plate from 0.5 to more than 6 in. thick. These systems, primitive by today’s design standards, were the most practical method for cutting heavy nonferrous plate. Most were mounted on XY cutting pantograph-style machines that used either photo-cell tracers to duplicate large black line engineering drawings of the parts to be cut, or a magnetic tracer to follow the path of a steel template.

Engineers continuously worked on the process throughout the 1960s with the goal of improving cut quality and the life of the consumable nozzles and electrodes in the cutting torch. Plasma began gaining momentum during this period as the process improved and as users became aware of its ability to cut complex shapes in nonferrous materials at very high speeds.

In 1968 radial water injection was introduced. This patented nozzle technology used pure water injected radially around the plasma jet to constrict the arc, increasing its energy density while improving nozzle cooling and thus allowing faster cut speeds, higher-quality cuts, and the ability to cut carbon steels at speeds four to six times faster than an oxyfuel cutting process.

At about that same time, XY coordinate drive cutting machine technology was being improved. Microprocessor control technology started to become the brains of the XY motion control machines, allowing for better accuracy, higher cutting speeds (necessary for the new-technology plasma systems), and higher levels of automation and productivity on the shop floor.

Through the 1970s plasma cutting technology replaced many oxyfuel-based steel cutting applications from 0.25 to 1 in. thick, while still maintaining its stronghold on the stainless and aluminum markets. While plasma could cut steel thicker than 1 in., the oxyfuel process still was a lower-cost alternative for heavier steel plate.

Timeline of Major Engineering Breakthroughs

With the baseline of plasma’s early history established, let’s take a look at some of the major engineering breakthroughs with this technology:

1957 The plasma cutting process was developed and patented by Union Carbide as an extension of the gas tungsten arc welding (GTAW) process.

1962-1967 Several new developments were completed in consumable design, and the dual flow torch was designed to help improve consumable life and cut quality on nonferrous materials.

1968 The water injection process was commercialized. This process allowed for cutting with clean, square-cut edges and faster speeds, as well as cutting of carbon steels with acceptable cut quality.

1970-1979 The water table and water muffler, designed to provide fume and smoke control, debuted. Automated arc voltage-based height controls for more consistent cut quality and longer consumable parts life emerged.

1980-1984 Oxygen-based plasma cutting systems that helped improve edge squareness and edge metallurgy (softer, weldable edge) and allowed for cutting carbon steels at lower power levels and higher cut speeds (see Figure 2) were introduced.

1984-1990 Many developments in the air plasma cutting process allowed for better portability and lower power levels for hand cutting and mechanized thin-sheet cutting.

1990 Better power supply designs using pulse width-modulated, current-controlled outputs were developed. Some systems started to use lighter-weight, smaller inverter technology power supplies suitable for portable, hand-held plasma systems.

1992 Long-life oxygen process technology was introduced. This was essentially a microprocessor-controlled method of controlling plasma gas ramping pressures as well as power supply output amperage. It helped increase typical oxygen plasma consumable parts life by four to six times; improved parts consistency; and helped lower the cost of plasma cutting.

1993 High-definition plasma, a technique that required the previous long-life oxygen technology to implement, was developed. This process allowed for a new nozzle design that increased the energy density of an oxygen plasma arc by as much as four times, allowing for squarer, cleaner cuts in all material thicknesses.

1996 Automated gas flow control systems emerged. They interfaced digitally with the machines’ CNCs. These gas flow controls eliminated some of the potential for machine operator-related errors in setting parameters for the cutting process.

1996-2006 Many developments occurred relating to improving cut quality and productivity and automating the many process cut parameters. These included integrated plasma, a system that closely coupled the CNC, the plasma power supply, the gas flow control, the CAM software, and the height control system to automate the process. With this expertise built into the system, the machine operator’s job became much simpler, and the process relied less on operator expertise.

Recent Technology Developments

In the last seven years, developments in plasma cutting technology have come at a fast pace. The latest revision on high-definition machines is their full integration with the CNC machines they are coupled with. New CNCs have touchscreen accessibility, minimizing the number of buttons involved in operating a plasma cutting machine and making operation as simple as almost any Windows?-based software. Operator training has been simplified on even the largest, most complex CNC plasma cutting machines.

The operator’s job also has been made easier with improvements in auto-calibrating height control functionality. The operator does not need to make adjustments as the consumable parts in the torch wear out.

Hole cutting has been improved with a large database of information in the CAM software that automatically recognizes CAD features and implements the best possible cut path and plasma cutting parameters, including on-the-fly shield gas changes that nearly eliminate the normal taper found in plasma-cut holes on steel (see Figure 3). This process is transparent to the machine operator and system programmer, eliminating the need for them to be experts.

Improvements in cut-to-cut cycle times have been incorporated into CAM software. The software automatically recognizes areas of a full cutting nest (multiple parts) and modifies the traverse time, torch retract time, and gas preflow time to decrease production times and improve product throughput.

Nesting software now applies the lead-in points in the most effective way to avoid traversing over areas prone to collisions with previously cut parts.

Improved plate beveling software has simplified the integration and operation of a bevel head with XY CNC cutting machines. This advancement, again associated with the system’s CAM software, saves much of the programmer/operator trial-and-error testing that has always been necessary to hold the best tolerances on plate edge beveling applications, such as weld prep.

Very new vented nozzle and gas mixing technology has helped improve stainless steel edge quality. Edges are squarer, shiny, and weldable.

Air plasma cutting systems from the major manufacturers also improved dramatically in terms of cut quality, consumable life, and duty cycles. These systems, primarily designed for portable and in-shop hand-held cutting applications, now are available with quick-change mechanized torches and interface easily to a variety of lower-cost CNC machines. Systems are available from a 30-amp, toaster-sized unit that operates on 120-V household current to sever materials up to 0.5 in. thick, to a 125-amp, 100 percent duty cycle industrial unit that can sever 2.25-in. materials. Both portable systems can be used with a hand torch or can be mechanized for a variety of automated cutting applications.

Industrial mechanized systems typically are 100 percent duty cycle, available with machine torches, and designed to use a variety of compressed gases to fine-tune the cut quality for different materials. These systems are available in various sizes and capacities from 130 to 800 amps.

Many other advances have been made to improve reliability, performance, consumable life, cut quality, and ease of use since the first plasma system was created. The process shares the cutting market with laser cutting, abrasive waterjet, and oxyfuel cutting, all of which deliver accuracy, productivity, and long-term cost-effectiveness when used for the appropriate applications.

What can be considered light duty?

A light duty plasma cutting machine can become a need for any workshop, artist, contractor, etc. that so far have been using oxy-fuel and is ready to make the leap to a better solution.

Actually, after experiencing a handheld plasma machine, almost nobody wants to return to oxy-fuel.

That is because even a light-duty plasma cutting system can make a big difference in efficiency and productivity.

So, in this post, we are going to consider what a light-duty plasma cutting system is and which one you should get.

But before getting into this amazing topic, let’s consider what plasma cutting is.

Most people classify plasma cutting systems in light, medium and heavy-duty. A handheld plasma cutting machine used in a small cutting table can be considered light-duty.

In general terms, a medium-size cutting table powered by some plasma cutting machine would be a medium-duty system.

A mechanized cutting system, which could occupy the heavy-duty slot, can be built in a stronger structure and composed by more than one cutting machine.

But that classification is not a general rule for plasma cutting manufacturers.

For the sake of this post, as quoted before, we are considering a handheld or portable plasma cutting machine as a light-duty one.

Now, before buying a light-duty plasma system, you may need to know when to use a portable and when to use an automated system. So, let’s consider some of it.

What Are The Advantages Of Fiber Laser Cutting Machine

Fiber laser is well received in the market now, because of its outstanding advantages of good beam quality and high conversion efficiency, it is widely loved in some finishing fields. At present, the proportion of fiber laser in the industrial field is close to 50%, which is also a kind of active choice for products in many industrial applications. Compared with traditional gas and solid-state lasers, fiber lasers have great advantages as frequency conversion light sources. In this article, we are going to talk about what is fiber laser cutting machine, what are the features, advantages & benefits of fiber laser cutting machine and applications & uses of fiber laser cutting machine.

What Is A Fiber Laser Cutting Machine?

Fiber laser cutting machine is a new type of machine in the world, which is used to output high energy density laser beam. The laser beam is concentrated on the surface of the workpiece, so that the area of ultra-fine focus on the workpiece is instantly melted and evaporated, and the spot is moved through the CNC mechanical system. Automatic cutting by illuminating the position. Compared with large volume gas laser and solid-state laser, it has obvious advantages and has gradually become an important choice in high-precision laser processing, lidar system, space technology, laser medicine and other fields.

The optical plate fiber laser cutting machine can be used for both plane cutting and oblique cutting, with neat and smooth edges. It is suitable for high precision cutting of metal plate. At the same time, the manipulator can replace the original five axis laser for 3D cutting. Compared with ordinary CO2 laser cutting machine, it saves more space and gas consumption, and has high photoelectric conversion rate. It is a new energy-saving and environmental protection product, and also one of the world’s leading technology products.

0 notes

Text

TECHNOLOGY IN STEEL DETAILING: SOFTWARES USED & EMERGING AREAS

Today innovation has taken over to make a primary steel detailer’s work simpler and various.

The field where manual drafting was the backbone for quite a long time and was before made do with pencils, pens, protractors, and afterward adding machines has today gone computerized. Most detailers have continued on to PC supported drafting, otherwise called CAD. Steel detailers can draw out their minds on an advanced cushion which would then be able to be printed out on paper for 2D tasks or printed as a 3D portrayal.

3D BIM Technology

One of the arising advancements is 3D BIM (Building Information Modeling). TEKLA, the 3D BIM programming, is extremely mainstream in the business and over the most recent two years has positioned fourth as a significant and intense instrument for the PEB (pre-designed structure) industry. Being quicker than 2D itemizing, it is exceptional to deal with any pain points. BIM programming projects are utilized for demonstrating once the planning is finished. When the model is finished, it gives a rundown of crude materials, dispatch list, shop floor drawings for creation, and so on

BIM is helpful to coordinate fundamental and significant administrations for huge activities. 3D model have numerous advantages over 2D drafting.

It is simpler to get changes

It is simpler to deal with complex shapes

There is no risk of misalignments at projects locales as all offices from enumerating, manufacture and erection work on a similar model.

Site Fabrication and Nesting Softwares

Site manufacture is normal and generally utilized in the PEB business, yet there are better other options. PEB plants are outfitted with fast CNC plate cutting machines offering burr free cutting utilizing Plasma or Oxy as fuel and settling programming projects limit scrap age.

CNC punching and penetrating assists with making openings for associations and are vital for appropriate arrangements at site. MIG machines are helpful for welding cuts, and so on Strategies like Shot impacting and Sand impacting are utilized to plan surfaces for painting.

CNC Machines

CNC cold roll framing machines with auto squeezing and shearing are utilized to deliver C/Z purlins, rooftop and divider cladding. CNC collapsing machines fabricate trims and extras. There are other specific machines which are utilized for assembling of various embellishments like down take pipes, anchor bolts, cuts and so forth

Planning Softwares

Most underlying architects use STAAD (from Bentley) to do primary investigation. MBS (Metal Building Software) which gives the most exact assessment, planning and enumerating of PEB structures, alongside transportation records and 3D drawings is a broadly utilized and mainstream programming. Presently the PEB business is showing its solidarity in framework — building spans, power transmission, metro rails, complex constructions like air terminals, skyscraper and multi-storeyed structures, and modern undertakings.

Alongside MBS, there are some other in-house virtual products utilized for itemizing.

Advantages of

Structural Steel Detailing

Software

The primary steel industry laborers are talented in stunning rationale and reason and have particular preparing in every single numerical region.

The essential advantage of utilizing an underlying steel itemizing programming is that the client has the additional abilities of PC utilization and the particular programming. When they ace it, geometry and math are readily available without being remembered or determined physically.

The advantage of having a 2D print form allows the steel detailer the opportunity to show a model to the customer first prior to delivering a 3D delivering which requires time and capital. The steel enumerating programming likewise monitors any progressions or alters made to the first plans. It is extremely advantageous when input can be followed as it serves to makes work process smoother with the maker and customer settling on what best suits them both. Rather than drawing a few rounds, speedy changes can be made and kept in documentation on the off chance that there is a need to return later.

Utilizing primary steel enumerating programming reduces human blunder, advances strong conceptualizing, and makes the work simpler.

The PEB business is exceptional and all set to assume a lot greater part. It utilizes the most current advances on the planet. The new air terminals are a fine model exhibiting PEB industry. The lodging area has been overwhelmed by RCC structures yet the new PEB advances accessible are outfitted to supplant RCC. Steel structures utilizing composite constructions can assume a pivotal part in giving mass lodging to the lower pay level. Steel has been utilized in the elevated structures however the distinct advantage is that it offers extraordinary freedom in low/medium ascent structures as well.

0 notes

Text

Auto loading and unloading Center RCA1325

Auto loading and unloading Center RCA1325

Features: 1.With intelligentialize, humanization, and high automatic operation, this machine can make the operator much more easier for handling all, any people can learn in couples of hours for operation, can save cost of labors. 2. Automatically uploading and downloading, Automatically Nesting, optimizing cutting orders, drilling, to maximum the productive. 3.Leading brand components such as Italian HSD spindle (automatic tool change), Japanese Yaskawa servo motors,Taiwan Syntec controller, Apex reducer and transmissions ensure high efficiently. 4. Double layer vacuum table can hold small pieces for excellent cutting, realize all kinds of customaries cabinet.

https://www.roc-tech.com/feeding-CNC-Router/Auto-loading-and-unloading-Center-RCA132.html

0 notes

Text

Elevate Woodworking Projects With High-Performance CNC Machines

Are you passionate about woodworking and looking to take your projects to the next level? Madbytes brings you cutting-edge CNC machines designed to revolutionise your woodworking experience. In this article, we'll explore the benefits of investing in high-performance CNC machines, specifically focusing on the flatbed nesting CNC and auto nesting CNC machines. Discover how Madbytes can enhance precision, efficiency, and creativity in your woodworking projects.

The Power of CNC Woodworking Machines:

CNC (Computer Numerical Control) machines have become indispensable tools in modern woodworking shops. These machines offer unparalleled precision and automation, enabling woodworkers to create intricate designs with ease. Madbytes, a renowned name in the industry, takes this to the next level with their flatbed nesting CNC machines.

Buy Flatbed Nesting CNC Unleash Precision and Productivity:

The Flatbed Nesting CNC machine from Madbytes is a game-changer for woodworkers seeking precision and productivity. This machine allows you to nest different pieces of wood on a flatbed, optimising material usage and minimising waste. Imagine the cost savings and environmental impact reductions that come with efficient material utilisation.

Key Features of the Madbytes Flatbed Nesting CNC:

High-precision cutting for intricate designs.

Customisable nesting options for optimal material usage.

User-friendly interface for easy operation.

Robust construction for durability.

CNC woodworking machines The Madbytes Advantage:

Madbytes is synonymous with quality and innovation in the CNC woodworking machine industry. Their machines go beyond traditional cutting methods, offering advanced features that cater to the evolving needs of woodworkers.

Auto-Nesting CNC Machine Streamlining Your Workflow:

For those who prioritise efficiency, Madbytes' auto-nesting CNC machine is a must-have. This automated solution intelligently arranges and nests pieces on the material, saving time and reducing manual effort. Say goodbye to tedious layout planning and hello to a streamlined workflow.

Benefits of Madbytes Auto-Nesting CNC:

Automated nesting for increased efficiency.

Reduction in human error during layout planning.

Faster production cycles for quicker project completion.

Compatibility with various design software for seamless integration.

Elevate Your Woodworking Game with Madbytes:

In conclusion, Madbytes' high-performance CNC machines redefine the woodworking experience. Whether you're a seasoned professional or a hobbyist, investing in flatbed nesting CNC or auto nesting CNC from Madbytes ensures precision, efficiency, and a competitive edge in the industry.

Take a leap into the future of woodworking technology with Madbytes. Elevate your projects, unleash your creativity, and experience the difference that advanced CNC machines can make in your workshop.

Remember, the right tools make all the difference, and Madbytes is here to empower your woodworking journey. Invest wisely, create passionately, and watch your projects reach new heights with Madbytes CNC machines. For more information, visit their website: https://madbytes.com.au/

0 notes

Video

youtube

QUOC DUY | CNC ROUTER MACHINE WITH AUTO LOADING AND UNLOADING AND AUTOMA...

#CNC ROUTER MACHINE WITH AUTO LOADING AND UNLOADING#CNC ROUTER MACHINE#AUTOMATIC LABELLE#cnc router nesting machine

0 notes

Text

Cnc Lathe Machine Parts And Components

According to your US Census there are gone 25,000 machine shops with less than 4 employees, not counting thousands of 1-man operations scattered throughout the country. Making a profit while owning a minor machine shop can be tough of these economically depressed times. Any kind of on creating a profit. CNC Routers are machines that are employed different directions. They can work in these directions simultaneously to develop patterns and shapes how the operator would take a long time to do by part. The cnc parts Router moves along an axis to cut front to back, left to right or up and down. Pick the motors - You must know the right information's about the CNC motors as well as their types. You'll want to carefully choose the right motor type and motor size for your design. Is it easier to benefit from? For a plasma cutter to provide long-term value, it must be easy to get going and use. Look for one that easy to learn and operate and cnc maching which comes loaded with time-saving features such as being a large shapes library, import of AutoCad files with nesting possibilities, kerf-on-the-fly adjustment, and auto-gas console integration. A machine that is simple to operate and which incorporates cost-saving features increase your productivity and your bottom set. Some synthetic to bypass some on the making belonging to the custom cnc parts Router and cash by obtaining kit. Kits are a good idea to get a start precisely what you wish to accomplish because they demonstrate you, step by step, how your machine will work. If you are a visual person who needs something to look at while you build, this will be a perfect way to be able to start your do-it-yourself product. So a person you commenced? A great in order to begin is to try using the ABC's of CNC video. This two hour long DVD takes you through the entire CNC work-flows. starting with the basics of machine designs, G Code, CAD and CAM software, last but not least through the actual cutting act. You'll see sample parts start being a design, sketched on a napkin, taken through CAD software, you receive is to pc Assisted Machining (CAM) software where the particular cutting paths to boost the risk for part were created. The output from the CAM program then takes it to the actual machine controller, which converts the digital information into actual procedure. to cut the part. Give proper consideration to coolant. Good coolant may reduce tooling costs, with respect to the operation. Coolant accomplishes three objectives. Lubrication, Cooling, and moving chips away for this cutting strategy. There are lots of folks that have pieced them together. Generally these become the electronic associated with people together with CNC. Enjoy this extra challenge. Once you see home brew pendants actually come out very amazing. Many of these folks be proud of them and share their plans and component lists readily. The secret is finding them.

0 notes