Don't wanna be here? Send us removal request.

Text

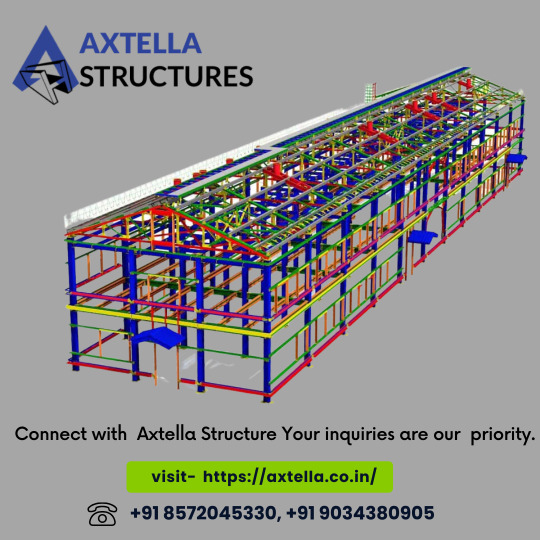

The Importance of Structural Steel Detailing in Steel Construction

Structural steel detailing is an integral component of steel construction, ensuring the precise documentation of every structural steel member required for a project. This process involves the creation of comprehensive fabrication drawings for both the primary structural steel and miscellaneous steel components within a structure.

The Significance of Structural Steel Detailing Structural steel detailing is invaluable for achieving accurate and high-quality results in steel construction. It serves as the blueprint that guides the entire construction process. Here’s why it is of utmost importance:

Precision is Paramount: To successfully execute any steel construction project, every structural steel member must be detailed with absolute precision. Structural Steel Detailing is the process that guarantees accurate representation, reducing errors and rework during construction.

Widespread Utilization: The realm of steel detailing extends its influence to a broad spectrum of professionals, including engineers, architects, contractors, fabricators, and various individuals within the civil and construction engineering industries. Moreover, it plays an essential role in the domain of structural Building Information Modeling (BIM) services, reflecting the latest industry advancements.

Inherent to Steel Structures: Steel detailing is most commonly employed in the construction of steel structures. These structures consist of diverse structural elements, such as columns, plates, beams, floor components, sidewall covering members, roof members, and more. These components vary in size and shape, interconnected through welding or bolting. To ensure structural integrity and safety, contractors necessitate detailed plans and drawings for each structural element. These drawings specify crucial details like shape, size, cutting length, diameter, and the precise location of connecting bolt holes. Additionally, contractors rely on erection drawings for the installation of fabricated items.

Two Distinct Types of Drawings: Structural steel detailing typically involves two primary types of drawings:

Shop Drawings: Shop drawings offer a comprehensive representation of every component. They include information on member sizes, steel material specifications, exact dimensions, welding specifics, bolt-hole locations, surface preparation requirements, and painting instructions. Shop drawings leave no room for ambiguity and provide a clear roadmap for fabrication.

In conclusion, structural steel detailing is the cornerstone of steel construction. We at Axtella Structures guarantee the accuracy, safety, cost-efficiency, and timely completion of projects. Beyond this, it fosters effective communication among project stakeholders, ensures compliance with building codes and industry standards, and contributes to the overall quality of the final structure.

CONTACT US FOR DETAILING SERVICES ON +91–9034380905, +91–8572045330

#"structural steel detailing services#steel detailing companies in us#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us#stair steel detailing services#Steel Detailing company in us#steel stairs detailing services near me#structural steel detailers near me#steel detailing services in usa

0 notes

Text

Axtella Structures is a reputable company that specializes in creating high-quality steel detail drawings for a wide range of construction projects. These drawings include detailed plans, sections, and elevations that accurately represent the structural components and connections of a building or structure. The drawings are created using advanced computer-aided design (CAD) software and are customized to meet the unique needs and specifications of each project. Axtella Structures is committed to delivering accurate and reliable steel detail drawings that are easy to read and understand, ensuring that every project is completed on time and within budget.

#top steel detailing companies in usa#steel detailing companies in us#structural steel detailing companies in usa#structural steel detailing services in us#stair steel detailing services#Steel Detailing company in us#structural steel detailers near me#steel detailing services in usa#structural steelwork detailing

0 notes

Text

If you are looking for structural steel detailing services choose Axtella Structures. We are offering advanced steel fabrication services using safe and effective methods.

#structural steel detailing services#steel detailing companies in us#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us#stair steel detailing services#Steel Detailing company in us#steel stairs detailing services near me#structural steel detailers near me#steel detailing services in usa#axtella structures#axtella#axtella structure.

0 notes

Text

If you are looking for structural steel detailing services choose Axtella Structures. We are offering advanced steel fabrication services using safe and effective methods.

#structural steel detailing services#steel detailing companies in us#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us#stair steel detailing services#Steel Detailing company in us#steel stairs detailing services near me#structural steel detailers near me#steel detailing services in usa#axtella structures#axtella#axtella structure.

0 notes

Text

Because of changes some problems we face in the construction of steel structural detailing, .These changes can occur from sometimes some errors, mistakes, and sometimes if the client’s desires change. this can affect. The structural design and geometry.

#structural steel detailing services#steel detailing companies in us#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us#stair steel detailing services#Steel Detailing company in us#steel stairs detailing services near me#structural steel detailers near me#steel detailing services in usa#axtella structures#axtella#axtella structure

0 notes

Text

THE IMPACT OF ERRORS, AND CHANGES ON THE PROCESS OF STRUCTURAL STEEL DETAILING

Because of changes some problems we face in the construction of steel structural detailing, .These changes can occur from sometimes some errors, mistakes, and sometimes if the client's desires change. this can affect. The structural design and geometry. There are four primary events- engineering, detailing, fabrication, and erection.

Engineering- The best time to discover an error basically the change is usually during the construction of steel design. from these chnages including the placement of new steel not anticipated, this change might be already in the model, and any one of these changes may impact engineering. luckily, the impact is usually a little bit in the terms of time and cost because the changes are known and we implemented for the long term before fabrication.

Detailing: some times minor changes during the phase of detailing may have a large impact on the project, all depending upon the nature of the change. Sometimes the changes might be important but has little impact. This all depends on the type and timing of changes. to understand by dividing the detailing activities into four parts, details drawing, submittals erection drawing, and bill of materials.

If the changes initially occur.it is called an advanced bill. the new or replaced steel caused

sometimes the newly replaced part is not available in the purchased order. therefore the changed steel needs to be purchased separately, material handling and storage is a huge labor expense for fabricators.

Fabrication: Now the detailer sends the drawing to the fabricator's office to process. in this process includes we check the drawing to ensure all pieces are detailed, make a template, and then decide which piece will be fabricated first.

if a change comes in between fabrication it will inherently impact both detailing and fabrication.

then the impact is very high very half of the prioject is completed

Erection : changes that are occurred during erection are the most costly and expensive.

After changes were made the erection of the assembly is complete now requires the big cranes for the move or may require some additional rental equipment.

so at last Axtella structure's main focus is that we provide accurate drawings at once. No rectification is needed again and again.

#structural steel detailing services#steel detailing companies in us#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us#stair steel detailing services#Steel Detailing company in us#steel stairs detailing services near me#structural steel detailers near me#steel detailing services in usa#axtella structures#axtella#axtella structure

0 notes

Text

If you are looking for structural steel detailing services choose Axtella Structures. We are offering advanced steel fabrication services using safe and effective methods.

#structural steel detailing services#steel detailing companies in us#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us#stair steel detailing services#Steel Detailing company in us#steel stairs detailing services near me#structural steel detailers near me#steel detailing services in usa#axtella structures#axtella#axtella structure

0 notes

Text

In structural steelwork joining one component to another we use bolt is a common method. Sometimes bolting may be removed on sites or onto the shop and Axtella structures have the advantage that all instruments can be separated very easily because of some reason.

#structural steel detailing services#steel detailing companies in us#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us#stair steel detailing services#Steel Detailing company in us#steel stairs detailing services near me#structural steel detailers near me#steel detailing services in usa#axtella structures#axtella#axtella structure

0 notes

Text

component of structural steelwork

In structural steelwork joining one component to another we use bolt is a common method. Sometimes bolting may be removed on sites or onto the shop and Axtella structures have the advantage that all instruments can be separated very easily because of some reason. and much more businessman uses weldings for shop connection but shop bolting is generally found a cheaper way. the bolting is a universal medium for connection. the main function of a bolt is to join 2 components to one another. for steelworkers detailers need to understand how the bolts have to work

various types of bolts

Bolts have 6 heads and nuts, parallel shanks, and threads cut or rolled into the shanks. They come in standard shank diameters of 12 mm, 16 mm, 20 mm and 24 mm in a large range of lengths and in various grades of strength

• Type 1 — bolts of medium-carbon steel, in sizes 1 2 to 11 2 in. diameter, inclusive

• Type 2 — bolts of low-carbon martensite steel, in sizes 1 2 to 1 in. diameter, inclusive (not to be hot galvanized)

• Type 3 — bolts having atmospheric corrosion resistance and weathering

characteristics comparable with those of A588 and A242 steels in sizes 1

2 to 1 2 in. diameter, inclusive.

Bolt holes

The holes for the bolts will usually be punched or drilled and will have a diameter 2 mm larger than the bolt shank diameter for bolt sizes up to 24 mm diameter and 3 mm larger for bolts of greater diameter. Such holes are called clearance holes; they facilitate the assembly of components by making allowance for slight inaccuracies in the fabrication of the steelwork. Reference should bemade to specific codes where variations exist.

The three most commonly used types of bolt are the following:

(a) grade 4·8 ordinary bolts

(b) grade 8·8 precision bolts

(c) high-strength friction-grip bolts.

These bolts are used for force

transfer by friction between the connected parts

the rectangular pattern is usually followed for the arrangement of the bolt holes. The holes are in rows and the holes in one row are opposite those in other rows, because if it it gives us a neat and clear appearance. pitch is called spacing between bolts in the longitudinal direction of the member and cross-center distance is called spacing at right angles. Holes in the flanges of I- and H-sections and channels and the legs of angles are usually placed on lines at a set distance from the web centers of the I- and H-sections (gauge lines or cross-center lines) or from the backs of channels or angles. We will work with your project team to incorporate your specific shop standards and drawing styles to provide a smooth transition from shop to field erection.

At Axtella structures we use a 3D software program from Autodesk called Advance Steel. This program is ranked as one of the top software programs on the market. Modelling all projects in 3D, allows us to get a realistic view of what the finished project will look like and has several beneficial features to help the project go smoothly.

#structural steel detailing services#steel detailing companies in us#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us#stair steel detailing services#Steel Detailing company in us#steel stairs detailing services near me#structural steel detailers near me#steel detailing services in usa#axtella structures#axtella#axtella structure

0 notes

Text

If you are looking for structural steel detailing services choose Axtella Structures. We are offering advanced steel fabrication services using safe and effective methods.

#structural steel detailing services#steel detailing companies in us#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us#stair steel detailing services#Steel Detailing company in us#steel stairs detailing services near me#structural steel detailers near me#steel detailing services in usa#axtella structures#axtella#axtella structure

0 notes

Text

Erection is the process of erecting or connecting together the shipping pieces in the field at the project site. Generally columns get erected first, then trusses and major girders, then beams, bracing, stairs and other miscellaneous steel. for more details visit us on https://axtella.co.in/

#structural steel detailing services#steel detailing companies in us#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us#stair steel detailing services#Steel Detailing company in us#steel stairs detailing services near me#structural steel detailers near me#steel detailing services in usa#axtella structures#axtella#axtella structure

0 notes

Text

Erection is the process of erecting or connecting together the shipping pieces in the field at the project site. Generally columns get erected first, then trusses and major girders, then beams, bracing, stairs and other miscellaneous steel. for more details visit us on https://axtella.co.in/

#structural steel detailing services#steel detailing companies in us#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us#stair steel detailing services#Steel Detailing company in us#steel stairs detailing services near me#structural steel detailers near me#steel detailing services in usa#axtella structures#axtella#axtella structure

0 notes

Text

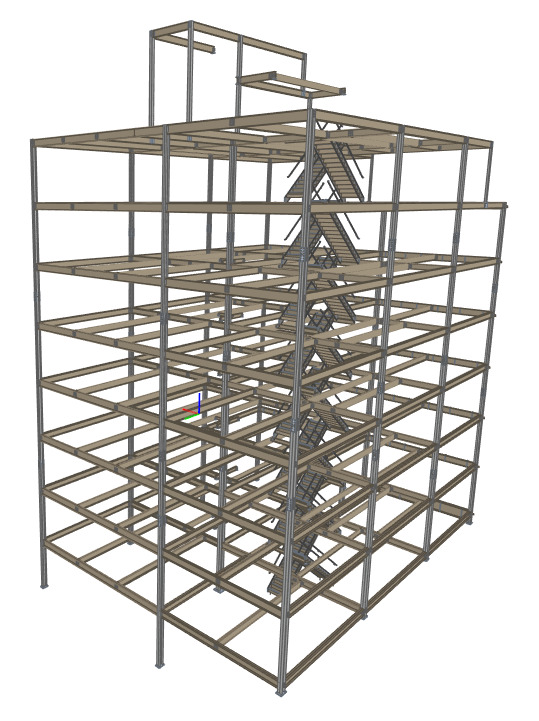

ALL ABOUT ERECTION

Erection is the process of erecting or connecting together the shipping pieces in the field at the project site. Generally columns get erected first, then trusses and major girders, then beams, bracing, stairs and other miscellaneous steel.

The success of erection is dependent on a few important factors.

In structural steel detailing services most critical element is erection of the columns. Column base plates are connected to the foundation using anchor bolts placed in the concrete by the foundation contractor. The location of the anchor bolts (usually four or more) for a single column in the foundation must match exactly the pattern of bolt holes in the base plate of a single column.

Moreover, because it is more economical to erect frames comprised of multiple columns held together with beams and braces, rather than individual columns, the spacing between anchor bolt groupings must line-up exactly with the location of the columns. In the real world bolt whole patterns in base plates often do not match the anchor bolt locations. Also, the centrelines of columns often do not line up with the centreline of the anchor bolt grouping. To prevent these errors, fabricators usually insist on a survey of the anchor bolt locations prior to fabricating base plates and frames. Another method of mitigating the tight tolerances is for the foundation contractor and the fabricator to use templates to insure an exact match. Another critical element of erection is crane access and movement. Steel is erected using one or more cranes, usually more than one.

Typically a few different types of cranes are used for steel erection

tower cranes, crawler cranes and hydraulic cranes. Tower cranes are those large T-shaped, counterbalanced configurations used to erect multi-story structures and capable of heavy lifts.

These cranes rotate about a single point and are capable of lifting steel anywhere within the radius of the tower arm. Crawler cranes are mobile and move around the site to make the necessary steel “picks.” Hydraulic cranes tend to be smaller, more mobile, and are used for lighter loads. Crane movement is an important consideration in the constructibility review of a project. Erectors usually divide the job into phases based on the anticipated movements of the cranes. For the sake of efficiency the fabricator usually fabricates the job in these same phases so that the erector has the necessary steel for a single phase (or area)1. One or more of these cranes may be designated for unloading steel when it shows up at the jobsite. On most projects, the erection process starts with unloading the shipping pieces using one of several cranes usually on the site. Sometimes shipping pieces are erected into the framework directly from the truck; othertimes pieces must be placed first in a staging area for later erection.

Other structural steel detailing erection activities include plumb and bolt, safety, welding, decking, and buttoning-up. Plumb and bolt is the process of placing the steel assemblies in their proper location, aligning them and temporarily bolting them in place (bolts are not typically torqued to their final state until a majority of the area or frame has been erected). Safety is an activity performed by a separate crew that installs cable handrails and other safety devices in an area before the ironworkers begin to work.

This allows the ironworkers to move freely from one area to another without interruption. A welding crew or multiple welding crews are then responsible for final welding of all the assemblies in accordance with the erection drawings. A bolting crew may also be utilized. Decking is the process of placing corrugated bent plate on the structural frame to later accept cast-in-place concrete to form a slab. Decking is a structural element formed by bending plate into a corrugated shape. The height or deepness of the corrugations and the length and frequency of the corrugations determine the decking’s strength.

Oftentimes the erector will contract with a second tier contractor to design, detail, fabricate and erect the deck. Included in the decking erection activity is the installation of studs that weld to the deck for the purpose of mechanically fastening the poured-in-place concrete to the deck forming a monolithic (composite) structural element.Section of two-level slab illustrating main steel beams, decking and studs.

The corrugations of the decking run perpendicular to the beams. Notice how this structural section of Axtella structures is referencing architectural drawings for dimensional information. Details regarding beam sizes, connections, stud locations, rebar placement, etc. are contained on other drawings. The final torquing of bolts, welding of deck, installation of stairs, and installation of studs is an activity commonly referred to as buttoning-up.

#top steel detailing companies in usa#steel detailing companies in us#structural steel detailing companies in usa#structural steel detailing services in us#structural steel detailing services#stair steel detailing services#structural steel detailers near me#steel detailing services in usa

0 notes

Text

Technology Used in Steel Detailing

Today’s technology has taken over to simplify and diversify the work of Steel Detailing Companies in us. Today, manual drafting is no longer used in this industry, which was once run with pencils, pens, protractors, and subsequently calculators. The majority of detailers now use CAD, or computer-aided drafting. Steel detailers can express their creativity on a digital pad, which can then be reproduced as a 3D model or out on paper for 2D projects.

BIM in 3D technology

3D BIM is one of the newest technologies (Building Information Modelling). The 3D BIM software TEKLA is well-known in the field and has placed fourth in the last two years as a crucial and effective tool for the pre-engineered building sector. It can address any issue regions and is quicker than 2D detailing. After design is complete, modelling is done using BIM software. A list of raw materials, a dispatch list, shop floor plans for fabrication, etc. are sent once the model is finished.

For large projects, BIM is helpful in integrating important and essential services. Compared to 2D drafting, 3D models have several advantages.

It is simpler to implement changes and manage complex shapes.

Since all organisations involved in detailing, manufacturing, and erection follow the same model, there is little risk of misalignments occurring on project sites.

Software for nesting and site fabrication

The PEB business frequently and extensively uses site fabrication, yet there are better options available. High speed CNC plate cutting machines that use plasma or oxygen as fuel and nesting software to reduce scrap creation are available in PEB facilities. CNC punching and drilling are crucial for accurate site alignments and for creating holes for connections. Clips and other items can be welded using MIG equipment. Surfaces are prepared for painting using methods like shot and sand blasting.

CNC devices

C/Z purlins, roof and wall cladding are made using CNC cold roll forming equipment with auto pinching and shearing. Trims and accessories are produced by CNC folding machines. Other specialised equipment are employed in the production of various components, including anchor bolts, clips, and downtake pipes.

Designing Softwares

The majority of structural engineers conduct structural analysis using STAAD (from Bentley). The widely used and well-liked software MBS (Metal Building Software) provides the most accurate estimate, designing, and detailing of PEB buildings, together with shipping lists and 3D drawings. The PEB sector is now demonstrating its prowess in the construction of infrastructure, including high-rise and multi-story buildings, electricity transmission lines, metro tracks, and complicated constructions like airports.

There are some more internal softwares utilised for detailing in addition to MBS.

Benefits of Structural Steel Detailing Software

Employees in the structural steel sector possess a mastery of logic and reason as well as specialised training in all branches of mathematics.

The main advantage of using a Structural Steel Detailing Servicesis that the user gains further computer and programme knowledge. Once they have it down, trigonometry and geometry may be easily accessed without having to be memorised or manually calculated.

Why Having a 2D print version allows the steel detailer to provide a mock-up to the client before spending the time and money necessary to create a 3D representation. Any alterations or revisions made to the original blueprints are likewise recorded by the steel detailing programme. When input can be applied, the workflow is streamlined and the customer and creative can choose what works best for them both.

Using Structural Steel Detailing software decreases human mistake, promotes coherent brain-storming, and makes the process easier. Quick adjustments can be made instead of sketching numerous rounds, and maintained in notation in case there is a need to reverse back later.

The PEB industry is prepared and ready to take on a far larger role. The most cutting-edge technology are employed. The new airports serve as a superb illustration of PEB business. RCC structures have long dominated the housing market, but new PEB technologies are intended to displace RCC. The use of steel buildings with composite constructions can be significant in the provision of affordable housing for large numbers of people. Structural Steel Detailing Companieshas been employed in high rise structures, but the fact that it also presents fantastic opportunities in low and medium rise structures is a game-changer.

#structural steel detailing services#steel detailing companies in us#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us

0 notes

Text

Steel Detailing Structure Services

Axtella Structure is the first choice of steel detailing services in the USA. We have worked with big brands, and our team has expertise in their work. Whether you need help with the design of a new building or the retrofitting of an existing one,Wecan provide the complete structural steel solutions you need and also offer a full range of value-added services, from project management to on-site support.

Importance of steel detailing services

There are many reasons why steel detailing services play a vital role in making a building. Perhaps the most important reason is that steel detailing ensures the accuracy of the drawings used in the construction process. Without accurate pictures, construction could be delayed or even halted altogether.

In addition to accuracy, Axtella structure also provides a level of precision that is often critical in the construction process. For example, when constructing a building, the dimensions of the steel beams must be precise in order to ensure the stability of the structure. If even one beam is not cut to the correct size, it could jeopardize the entire building.

Another essential reason to use steel detailing services is for safety purposes. When constructing a building, workers are putting their lives at risk. If there are any errors in the drawings or specifications, it could lead to a dangerous situation on the job site. Steel detailers work diligently to avoid any mistakes that could put workers in danger.

Overall, steel detailing services play a vital role in ensuring accuracy and safety in the construction process. Without these services, construction projects would be far more likely to experience delays or even complete failures

Importance of steel detailing services for client :

Steel detailing services is the process of creating a set of drawings that specify the dimensions, properties, and tolerances of the steel members that will be used in your project. These drawings are then used by the fabricator to produce the steel parts.

There are many benefits to using steel detailing services. First, it ensures that all of the parts will fit together correctly. Second, it can save time and money by avoiding errors and rework. Third, it can improve communication between you and the fabricator. Finally, it can help you make informed decisions about your project.

Importance for fabricators

Axtella structure is atop steel detailing company in usa. First and foremost, it provides an extremely user-friendly environment for creating accurate 3D models of steel structures. This is essential for creating bids and proposals that accurately reflect the true cost and scope of a project. Additionally, the ability to share models with other team members via the cloud-based collaboration platform ensures that everyone is working from the same set of data, which reduces mistakes and miscommunications.

Another key benefit of using Axtella structures is that it offers a wide range of pre-fabricated components that can be easily inserted into models. This saves fabricators a considerable amount of time and effort when compared to traditional methods of manually creating everything from scratch. In addition, the software’s powerful BIM tools allow fabricators to generate highly detailed shop drawings that show every aspect of a component, including welding symbols, cut lists, and material callouts. This ensures that all members of the fabrication team are on the same page from start to finish.

Ultimately, fabricators turn to Axtella structure because it streamlines the entire process from start to finish. The software’s intuitive interface and wealth of features make it an indispensable tool for anyone in the steel industry.

#structural steel detailing services#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us#steel stairs detailing services near me

0 notes