#Automated Garment Conveyor

Explore tagged Tumblr posts

Text

Reasons to Get Automated Garment Conveyor

Garment conveyor is a high-performance automated storage system, garments sorting and handling process that easily reduces human resources in a customer service industry. Garment sorting conveyor is an exceptional automated storage system, garments arranging and taking care of procedures that lessen human resource in a client care chain. For more info visit now: https://livepositively.com/reasons-to-get-automated-garment-conveyor/

0 notes

Text

Conveyor Systems in Garment Industry Enjoying Big Demand as Manufacturers Making Big Investments

View On WordPress

0 notes

Text

Top Conveyor Systems Manufacturers in the UK: Streamlining Modern Industry

In today's fast-paced industrial environment, efficiency and automation are more crucial than ever. At the heart of many efficient production lines lies a vital component—conveyor systems. From automotive factories and food processing plants to logistics hubs and warehouses, conveyor systems are transforming how materials are handled and moved. The UK boasts a number of leading conveyor systems manufacturers who are driving this innovation forward.

Why Conveyor Systems Matter

Conveyor systems are mechanical handling devices that transport materials from one location to another with minimal effort. They are used to move heavy or bulky items, automate processes, reduce manual labour, and improve safety and productivity.

Benefits of using conveyor systems include:

Faster processing and handling

Reduced operational costs

Consistent movement and flow of goods

Customisation for different industries and products

Enhanced workplace safety

Leading Conveyor Systems Manufacturers in the UK

Here are some of the top conveyor system manufacturers known for their engineering excellence, custom solutions, and industry-specific innovations:

1. L.A.C. Conveyors & Automation

Based in Nottingham, L.A.C. is a trusted name for designing, manufacturing, and installing conveyor systems and automation solutions. They serve sectors such as warehousing, logistics, and food production with bespoke conveyor designs.

2. CKW Pro-Can (Engineering) Ltd

Specialising in conveyors for the food and beverage industry, CKW Pro-Can offers stainless steel conveyors that meet strict hygiene standards. They are known for quality craftsmanship and durable solutions.

3. Coveya Ltd

Coveya is a market leader in supplying conveyor systems for hire and sale. Their robust equipment supports industries like construction, recycling, and manufacturing with flexible and portable conveyor options.

4. Facet Engineering

Facet Engineering delivers comprehensive conveyor systems, from belt and roller conveyors to more complex automated material handling solutions. Their systems are widely used in packaging, agriculture, and chemical industries.

5. Amber Industries Ltd

With decades of experience, Amber Industries provides overhead and floor conveyor systems suitable for automotive, garment, and warehouse automation applications.

Choosing the Right Conveyor Manufacturer

When selecting a conveyor system manufacturer, consider the following:

Industry Expertise: Do they specialise in your sector?

Customisation Options: Can they tailor the system to your needs?

Support and Maintenance: Do they offer long-term service support?

Compliance: Are their systems in line with UK and EU standards?

Innovation: Do they offer smart or automated solutions?

Trends in Conveyor Technology

UK manufacturers are now embracing smart automation, IoT integration, and energy-efficient designs. Conveyor systems are becoming more intelligent—with sensors, AI-based monitoring, and data analytics to ensure performance and predictive maintenance.

Final Thoughts

The UK continues to be a hub of conveyor system innovation, serving a wide range of industries with reliable and efficient solutions. Whether you're upgrading your production line or automating your warehouse, working with an experienced UK-based conveyor manufacturer ensures quality, compliance, and tailored performance.

If you’re looking for durable, scalable, and high-performance conveyor systems—look no further than the engineering powerhouses in the UK.

0 notes

Text

What is a conveyor gearbox? everything about it

In the world of industrial automation and heavy machinery, a conveyor gearbox is an essential component that ensures smooth and efficient operation of conveyor systems.

These gearboxes are specifically designed to transmit mechanical power from a motor to the conveyor, allowing materials to move seamlessly through various stages of production. As a vital link between the motor and conveyor belt, the gearbox reduces the motor speed and increases torque to suit the specific requirements of the conveyor system.

Understanding the Role of Conveyor Gearboxes

Conveyor gearboxes play a critical role in controlling the speed, direction, and torque of a conveyor belt. They ensure that materials are moved at the right pace, whether it's on a production line, in a packaging facility, or in a mining operation.

A well-chosen gearbox not only improves efficiency but also extends the life of the conveyor system by minimizing mechanical stress and wear.

Types of Conveyor Gearboxes

There are several types of conveyor gearboxes used in industrial settings:

Helical Gearbox: Known for high efficiency and low noise, ideal for heavy-duty applications.

Worm Gearbox: Compact and cost-effective, suitable for low to moderate power applications.

Bevel Helical Gearbox: Used for high torque and right-angle orientation.

Planetary Gearbox: Offers high torque density in compact size, ideal for space-constrained systems.

Each type offers unique advantages depending on the operational needs and space constraints of the conveyor system.

Key Factor in Choosing the Right Conveyor Gearbox

When selecting a gearbox for your conveyor, several factors should be considered:

Load Requirements: The gearbox must be capable of handling the maximum load without overloading.

Speed and Torque: A proper balance of speed reduction and torque output is essential.

Environmental Conditions: Gearboxes should be chosen based on exposure to dust, moisture, and temperature extremes.

Mounting Configuration: The layout and design of your conveyor system will determine the suitable gearbox orientation.

Efficiency and Maintenance: Opt for gearboxes that require minimal maintenance and offer high operational efficiency.

Choosing the right gearbox ensures operational stability, reduces downtime, and cuts maintenance costs.

Why Work with a Trusted Conveyor Gearbox Manufacturer in India

India has become a hub for reliable and cost-effective industrial gearbox manufacturing. A trusted Conveyor Gearbox Manufacturer in India provides:

Quality assurance through rigorous testing

Customization to meet specific industry requirements

Timely delivery and support services

Competitive pricing without compromising on performance

Working with a reputable manufacturer ensures that you receive not only a high-performing gearbox but also ongoing technical support.

Applications of Conveyor Gearboxes in Industry

Conveyor gearboxes are used in various industries, including:

Mining: Transporting ores and minerals

Cement: Moving raw materials and finished products

Food and Beverage: Handling packaged goods on production lines

Textile: Managing fabric and garments during manufacturing

Automotive: Conveyor-driven assembly lines

These applications demonstrate the versatility and critical role of conveyor gearboxes across sectors.

Conclusion

Conveyor gearboxes are indispensable to the smooth and efficient functioning of conveyor systems across industries. Selecting the right gearbox is a strategic decision that depends on load, speed, environmental conditions, and overall system design.

Partnering with a reliable Conveyor Gearbox Manufacturer in India ensures that your operation benefits from durable, high-performance solutions tailored to your needs. By understanding the key factor in choosing the right conveyor gearbox, businesses can enhance productivity, reduce maintenance, and achieve long-term operational success.

0 notes

Text

10 Luxury Walk-In Closet Design Ideas for 2025

2025 is all about smart closets. Think motion-sensor LED lights that illuminate your wardrobe when you enter, automated garment conveyors that organize and retrieve clothes with the push of a button, or even climate-controlled sections designed to protect delicate fabrics like wool or silk. Some advanced models even offer voice-activated systems, allowing you to request a specific outfit or adjust the room temperature. Integrating these smart features transforms a simple closet into a cutting-edge wardrobe experience, where organization meets innovation, creating an efficient, personalized space that simplifies your daily routine.

#Walk-In Closet Design Ideas#large luxury kitchen design#kitchen design#luxury kitchen#luxury closets#luxury kitchen design

0 notes

Text

Belt Conveyor Manufacturers in Faridabad: A Complete Guide

In the realm of material handling systems, belt conveyors are essential for optimizing efficiency, productivity, and automation across industries. From moving lightweight cartons to transporting heavy bulk materials, belt conveyors offer a reliable solution for streamlined operations. Among the various manufacturing hubs in India, Faridabad, Haryana stands out as a significant center for producing high-quality belt conveyor systems.

This guide explores the belt conveyor manufacturing landscape in Faridabad, highlighting the types of conveyors available, the industries served, and the top manufacturers you can trust.

The Factors Contributing to Faridabad's Concentration in Belt Conveyor Manufacturing

One of the biggest industrial cities in India is Faridabad, which is situated in the National Capital Region (NCR). Faridabad is the ideal location for the production of material handling equipment because of its well-established engineering infrastructure, highly skilled workforce, and convenient access to raw materials and transportation.

Over the past two decades, Faridabad has become home to dozens of companies specializing in the design, fabrication, and export of belt conveyors, ranging from small custom systems to large-scale industrial solutions.

Types of Belt Conveyors Manufactured in Faridabad

Manufacturers in Faridabad cater to a wide variety of applications by offering multiple types of belt conveyor systems:

1. Flat Belt Conveyors

Ideal for transporting light to medium-weight materials.

frequently seen in packing processes, inspection stations, and manufacturing lines.

2. Inclined/Declined Belt Conveyors

Useful for moving materials between different elevations.

Equipped with rough top belts or cleats for added grip.

3. Cleated Belt Conveyors

Designed for vertical or steep incline transport.

Cleats help keep materials in place, preventing rollback.

4. Trough Belt Conveyors

Best suited for transporting bulk materials such as grains, coal, and minerals.

In addition to increasing load capacity, the trough design prevents material leakage.

5. Modular Belt Conveyors

Constructed using plastic modules that interlock, allowing easy cleaning and maintenance.

Common in food processing and pharmaceuticals.

6. Portable Belt Conveyors

Lightweight and mobile.

Ideal for temporary setups or loading/unloading operations.

Key Features Offered by Faridabad-Based Conveyor Manufacturers

Faridabad manufacturers are known for their customization capabilities, engineering precision, and adherence to international quality standards. Here are some features commonly integrated into their belt conveyor systems:

Custom lengths, widths, and load capacities

Mild steel, stainless steel, or aluminum frames

Variable speed drives (VFDs) for speed control

Motorized or gravity-driven systems

Integration with automation and PLC control

Corrosion-resistant and food-grade belts

Side guards, sensors, and safety switches

Energy-efficient and low-maintenance designs

These characteristics enable industries to customize conveyor systems to meet their unique operational needs.

Industries Served by Belt Conveyor Manufacturers in Faridabad

The versatility of belt conveyors makes them a critical part of many industries. Manufacturers in Faridabad supply to sectors such as:

Automotive and Auto Components

FMCG and Packaging

Pharmaceutical and Healthcare

Food and Beverage

Textile and Garments

Electronics and Appliances

Mining and Cement

E-commerce, Warehousing, and Logistics

These industries rely on the consistent performance, efficiency, and durability of conveyors supplied by Faridabad-based firms.

Top Belt Conveyor Manufacturers in Faridabad

Here are some of the most reputable belt conveyor companies based in Faridabad:

1. Neo Conveyors

A leading player in the field of material handling equipment, Neo Conveyors offers customized belt conveyors for various industrial needs. They are known for precision design and robust construction.

2. Aline Conveyors Pvt. Ltd.

Specializing in modular and automated solutions, Aline Conveyors supplies high-tech belt conveyor systems to industries like packaging, pharma, and automotive.

3. Saifi Con-Fab Systems Pvt. Ltd.

With over three decades of experience, Saifi Con-Fab is a trusted name for conveyor automation. Their belt conveyors are widely used across India and exported abroad.

4. Jay Engineering

Jay Engineering is known for affordable, custom-engineered belt conveyors with a strong client base in the manufacturing and logistics sectors.

5. Aravali Engineers

Aravali Engineers is a recognized manufacturer offering modular, cleated, and inclined belt conveyors with advanced automation options.

These companies often provide end-to-end services, including design, manufacturing, installation, and after-sales support.

Advantages of Sourcing Belt Conveyors from Faridabad

Choosing a manufacturer from Faridabad offers several benefits:

✅ Custom Designs: Tailored solutions for specific industries and operations

✅ Faster Turnaround Times: Short lead times due to proximity to Delhi-NCR

✅ Competitive Pricing: Cost-effective solutions without compromising quality

✅ Export Capabilities: Many manufacturers are export-ready and certified

✅Technical Assistance: AMC services, instruction, and installation on-site

How to Choose the Right Manufacturer

Take into account the following while choosing a belt conveyor manufacturer in Faridabad:

📐 Experience in your industry

📋 Quality certifications (ISO, CE, etc.)

⚙️ Capability to offer tailored solutions

📞 Availability of after-sales service

🌍 Track record of domestic and international supply

🛠 Warranty and maintenance support

Asking for a site visit, reviewing past project portfolios, and evaluating technical drawings and proposals can help in making a well-informed decision.

Conclusion

Faridabad keeps enhancing its standing as India's reliable center for belt conveyor manufacture. Businesses from a variety of industries can discover the ideal partner for their material handling needs thanks to the wide range of manufacturers providing creative, personalized, and high-performance solutions.

If you're looking for efficient, reliable, and cost-effective belt conveyor systems, exploring Faridabad-based manufacturers is a strategic move that delivers long-term value.

Address: Plot No. 7, Gali no 2 Sahupura Industrial Area, Near Bypass, Faridabd-121004 Haryana (India)

Phone No. : 9958352003

https://beltconveyorindia.com/belt-conveyor-manufacturer-in-faridabad/

#BeltConveyor#BeltConveyorManufacturer#ConveyorManufacturerFaridabad#MaterialHandlingEquipment#IndustrialConveyors#FaridabadIndustry#ConveyorSystemsIndia#ManufacturingSolutions#FactoryAutomation#BeltConveyorIndia#CustomConveyor#IndustrialMachinery#MadeInIndia#EngineeringSolutions#VashnaviConveyor#FaridabadManufacturers#AutomationEquipment#HeavyDutyConveyors#SmartMaterialHandling#ConveyorBeltSystem

0 notes

Text

Understanding Industrial Packaging Solutions: Key to Efficiency, Safety, and Sustainability

In the world of logistics, manufacturing, and supply chain management, industrial packaging solutions are more than just containers—they are essential components of product safety, operational efficiency, and even environmental stewardship. As industries evolve and global commerce becomes more complex, the demand for specialized, efficient, and sustainable packaging systems has surged. This article explores what industrial packaging solutions are, why they matter, and the trends shaping their future.

What Are Industrial Packaging Solutions?

Industrial packaging refers to the materials and methods used to protect, transport, and store goods in an industrial setting. Unlike consumer packaging—which prioritizes aesthetics and retail display—industrial packaging solutions are designed primarily for durability, functionality, and efficiency. These solutions include a broad array of items such as:

Palletized containers

Crates and drums

Stretch wrap and shrink films

Protective sheets and partitions

Returnable transit packaging

Dunnage and separators

Foldable bulk containers

Each type serves a specific role in maintaining product integrity during storage, handling, and transit, particularly in challenging environments or long-distance shipping.

Why Industrial Packaging Matters

1. Protection of Goods

The most obvious role of industrial packaging is to safeguard products from physical damage, moisture, dust, or contamination. Fragile components, such as electronics or automotive parts, may need cushioned interiors or anti-static packaging. On the other hand, items like steel coils or large equipment might require rigid containers with impact resistance.

Packaging plays a critical role in reducing waste and returns caused by product damage—directly affecting the bottom line.

2. Operational Efficiency

Industrial packaging can streamline processes across the supply chain. For instance, returnable packaging systems allow companies to use the same containers multiple times, reducing the need for repacking. Modular or stackable containers can save valuable space in transport and storage, making warehouse management and inventory control more efficient.

Customized industrial packaging solutions can also align with automated systems, such as robotic handling or conveyor belts, boosting overall productivity.

3. Sustainability

Sustainability is no longer optional; it’s a business imperative. Industrial packaging, traditionally associated with heavy-duty plastic or metal components, is now being reevaluated through the lens of eco-friendliness. Companies are increasingly seeking recyclable, reusable, and biodegradable alternatives to minimize their environmental footprint.

Solutions like returnable dunnage, reusable pallets, or foldable containers are designed to reduce single-use packaging and encourage circular usage within the supply chain.

Common Industries Using Industrial Packaging Solutions

Automotive Industry Uses robust dunnage systems and returnable containers for parts like engines, radiators, and electronic modules.

Textiles & Garments Employs separator sheets, protective wraps, and stacking solutions to preserve fabric quality.

Food & Beverage Requires hygienic, temperature-controlled packaging to ensure product safety and compliance.

Pharmaceuticals Demands highly secure and traceable packaging to protect against tampering or contamination.

Electronics & Technology Needs anti-static materials and compartmentalized packaging for delicate components.

Heavy Machinery & Metals Utilizes palletized, weatherproof, and high-load capacity containers for large or irregular-shaped equipment.

Emerging Trends in Industrial Packaging

Smart Packaging

With the rise of IoT and data-driven logistics, smart packaging has found its way into industrial use. This includes sensors embedded in packaging to monitor temperature, humidity, and shock levels. Real-time tracking through QR codes or RFID tags also helps with inventory visibility and loss prevention.

Customization

A one-size-fits-all approach doesn’t work for industrial clients. Customized packaging solutions—tailored to the specific dimensions, fragility, and weight of a product—are becoming more common. Companies are looking for partners who can deliver bespoke packaging designs aligned with their handling and shipping requirements.

Lightweight Yet Durable Materials

Innovations in material science have led to lightweight packaging that does not compromise on strength. This helps in reducing shipping costs and carbon emissions. Corrugated plastic sheets, high-density polyethylene (HDPE), and molded fiber are gaining popularity for their durability and recyclability.

Regulatory Compliance

With stricter international trade and safety regulations, industrial packaging must often meet standards like ISPM 15 for wood packaging, FDA compliance for food contact, or UN-certified containers for hazardous materials. This has increased the need for knowledgeable packaging providers who understand the legal landscape.

Challenges in Choosing the Right Packaging Solution

Despite the array of options, businesses often struggle to identify the best solution for their needs. Common challenges include:

Balancing cost and quality

Managing packaging inventory and return logistics

Adapting to multi-modal transportation (e.g., sea, air, road)

Navigating environmental regulations

Ensuring consistency across global operations

To address these, companies increasingly rely on expert consultations and data analytics to optimize packaging choices.

Conclusion

Industrial packaging solutions are a vital, though often overlooked, part of modern manufacturing and logistics. They go beyond containment, offering protection, operational streamlining, and sustainability. As supply chains become more global and complex, the importance of strategic packaging will only grow.

Businesses looking to enhance their packaging systems should consider not only the physical protection of their products but also how packaging impacts costs, workflows, environmental goals, and customer satisfaction. In this dynamic landscape, innovative, well-designed industrial packaging isn’t just a necessity—it’s a competitive advantage.

0 notes

Text

Overhead Conveyor System for Industries

Revolutionizing Material Handling with Overhead Conveyors by ArSai Conve Systems

Material handling is a critical component of modern industries, and overhead conveyors are a game-changing solution in this space. ArSai Conve Systems is a leading provider of innovative overhead conveyor systems, empowering businesses to optimize operations, enhance productivity, and ensure workplace safety. With a commitment to quality and innovation, ArSai Conve Systems is setting new standards in the material handling industry.

The Role of Overhead Conveyors

Overhead conveyors are designed to transport materials efficiently by utilizing the space above ground. They provide a seamless way to move products through various stages of production or distribution, ensuring a smooth workflow and minimizing floor congestion.

Why Choose ArSai Conve Systems for Overhead Conveyors?

ArSai Conve Systems is a trusted name in the field of conveyor solutions. Here’s what sets their overhead conveyors apart:

1. Innovative Design

ArSai’s overhead conveyors are engineered with precision, ensuring robust performance and adaptability to diverse industrial needs. Their designs are not only functional but also energy-efficient and user-friendly.

2. Customizable Solutions

Understanding that every business has unique requirements, ArSai offers tailored conveyor systems. From layout design to operational features, their solutions can be customized to fit specific applications.

3. Durability and Reliability

Built with high-grade materials, ArSai’s overhead conveyors are designed to withstand heavy loads and challenging conditions, ensuring long-term reliability and minimal maintenance costs.

4. Safety Features

Safety is a top priority at ArSai Conve Systems. Their overhead conveyors are equipped with advanced safety features to protect both the workforce and the transported materials.

5. Cost Efficiency

By maximizing space utilization and minimizing manual labor, ArSai’s solutions offer significant cost savings for businesses.

Applications of Overhead Conveyors

ArSai Conve Systems’ overhead conveyors are versatile and find applications across a range of industries:

Automotive Industry: Streamlining the assembly line by moving parts efficiently.

Food and Beverage: Ensuring hygienic and efficient transportation of goods.

Textile and Garment: Facilitating smooth handling of materials in production and packaging.

Warehousing and Logistics: Optimizing space and enhancing order fulfillment processes.

E-Waste Management: Providing efficient solutions for sorting and transporting recyclable materials.

The ArSai Advantage

Partnering with ArSai Conve Systems for overhead conveyors comes with several benefits:

Enhanced Productivity: Streamline processes and improve throughput.

Space Optimization: Maximize floor space by utilizing overhead areas.

Rduced Manual Labor: Automate material handling tasks, reducing labor costs.

Improved Workflow: Ensure smooth movement of materials across different operational stages.

Looking Ahead

As industries continue to evolve, the demand for efficient and sustainable material handling solutions will grow. ArSai Conve Systems is dedicated to staying ahead of the curve, delivering innovative overhead conveyors that meet the dynamic needs of modern businesses.

Contact ArSai Conve Systems Today

If you’re looking to revolutionize your material handling operations, ArSai Conve Systems has the expertise and solutions to make it happen. Invest in their state-of-the-art overhead conveyors and experience the benefits of innovation, efficiency, and reliability.

Website: https://www.arsaiconveyor.com/overhead-conveyors/

Corporate Office

B-11, Duplex, Sanjay Nagar, Sector -23, Rajnagar, Ghaziabad — 201003 (UP), India

Manufacturing Unit

Khasra №74, Morta Industrial Area, Delhi-Meerut Road, Ghaziabad 201003, (U.P.), India

Call Us

+91–9811772712 +91–9810773412

Mail Us

0 notes

Text

The Role of Fabric Sponging Machines in Modern Textile Manufacturing

The Role of Fabric Sponging Machines in Modern Textile Manufacturing In the textile industry, the quality and stability of fabric are paramount. One of the key processes that ensure these attributes is fabric sponging. Fabric sponging machines play a crucial role in preparing fabrics for further processing and garment production. This article delves into the workings, benefits, and significance of fabric sponging machines in modern textile manufacturing.Get more news about fabric sponging machine seller,you can vist our website!

What is a Fabric Sponging Machine? A fabric sponging machine is a specialized piece of equipment designed to stabilize fabric before it undergoes various stages of garment production. The machine operates under controlled conditions of temperature, humidity, and pressure to relax the fabric, eliminate potential shrinkage, and ensure dimensional stability. This process is essential for maintaining the quality and appearance of the final garment.

How Does a Fabric Sponging Machine Work? The fabric sponging process involves several stages, each contributing to the overall stability and quality of the fabric:

Steaming: The fabric is conveyed into a steaming zone where high humidity steam is applied. This relaxes the fibers and reduces tension within the fabric. The steaming process is crucial for eliminating potential shrinkage and ensuring the fabric remains stable during subsequent processing stages. Heating: After steaming, the fabric passes through a heating section. High-efficiency steam heaters are used to further relax the fabric and ensure even heat distribution. This step helps in setting the fabric’s dimensions and preventing any further shrinkage. Cooling: The heated fabric is then cooled using a conveyor mesh belt. The cooling process is essential for stabilizing the fabric and ensuring it retains its relaxed state. Vacuum adjustments can be made to control the cooling process and achieve the desired fabric properties. Folding: Finally, the fabric is folded to a specific width, typically around 600mm. This step ensures the fabric is neatly organized and ready for further processing or storage. Benefits of Using Fabric Sponging Machines The use of fabric sponging machines offers several advantages to textile manufacturers:

Improved Fabric Quality: By eliminating potential shrinkage and ensuring dimensional stability, fabric sponging machines enhance the overall quality of the fabric. This results in garments that maintain their shape and appearance even after multiple washes. Increased Production Efficiency: Fabric sponging machines automate the sponging process, reducing the need for manual intervention. This leads to increased production efficiency and allows manufacturers to meet high demand without compromising on quality. Energy Efficiency and Environmental Friendliness: Modern fabric sponging machines are designed with energy-saving features and environmentally friendly structures. These machines consume less energy and produce fewer emissions, contributing to a more sustainable manufacturing process. Customization and Flexibility: Many fabric sponging machines offer customization options to meet specific production needs. Manufacturers can adjust the machine settings to achieve the desired fabric properties, making the process highly flexible and adaptable. Conclusion Fabric sponging machines are indispensable tools in the textile industry, ensuring the stability and quality of fabrics before they are transformed into garments. By automating the sponging process and offering numerous benefits such as improved fabric quality, increased production efficiency, and energy efficiency, these machines play a vital role in modern textile manufacturing. As the industry continues to evolve, fabric sponging machines will remain essential for producing high-quality, durable garments that meet the demands of consumers worldwide.

0 notes

Text

How do overhead conveyors improve workflow efficiency?

The dynamic world of material handling, efficiency, space optimization, and safety are paramount. One of the most effective solutions to meet these demands is the use of overhead conveyors. As industries continue to evolve, the need for advanced conveyor systems has become more critical than ever. ArSai Conveyor Systems Pvt. Ltd., a leading Overhead Conveyor Manufacturer, is at the forefront of delivering state-of-the-art solutions that cater to various industrial needs.

Understanding Overhead Conveyors

Overhead conveyors are a type of material handling system that utilizes the space above the production floor. These conveyors are designed to transport materials, products, or components along a fixed path, often suspended from the ceiling. This design not only saves valuable floor space but also improves workflow efficiency by reducing the need for manual handling.

The Importance of Overhead Conveyors in Modern Industries

As industries grow and production demands increase, the need for efficient and space-saving solutions becomes essential. Overhead conveyors are particularly useful in environments where floor space is limited or where the movement of materials needs to be streamlined.

Space Optimization: By utilizing overhead space, these conveyors free up valuable floor area, allowing for more efficient use of the production facility.

Improved Workflow: Overhead conveyors can be designed to transport materials seamlessly across different stages of production, reducing the need for manual transport and minimizing delays.

Enhanced Safety: By automating the movement of materials, overhead conveyors reduce the risk of accidents associated with manual handling.

Key Features of ArSai Conveyor Systems’ Overhead Conveyors

ArSai Conveyor Systems Pvt. Ltd. specializes in the design and manufacture of high-quality overhead conveyors tailored to meet the specific needs of various industries. Here are some of the standout features of their overhead conveyors:

Robust Construction: Built with high-quality materials, these conveyors are designed to withstand the rigors of continuous operation in industrial environments.

Customizable Design: Whether you need a simple overhead conveyor or a complex system with multiple tracks and turns, ArSai Conveyor Systems offers fully customizable solutions.

Efficient Operation: Engineered for smooth and efficient operation, these conveyors help streamline production processes and improve overall productivity.

Low Maintenance: Designed with durability in mind, ArSai’s overhead conveyors require minimal maintenance, reducing downtime and maintenance costs.

ArSai Conveyor Systems Pvt. Ltd.: Leading the Way in Overhead Conveyor Solutions

Company Overview

ArSai Conveyor Systems Pvt. Ltd. has established itself as a leader in the field of material handling solutions. With years of experience and a commitment to innovation, the company has become a trusted partner for businesses across various industries. Their expertise in designing and manufacturing overhead conveyors has earned them a reputation for quality and reliability.

Applications of Overhead Conveyors by ArSai Conveyor Systems

Overhead conveyors manufactured by ArSai Conveyor Systems Pvt. Ltd. find applications in a wide range of industries, including:

Automotive Industry: Used for transporting car parts and assemblies, overhead conveyors help streamline the production process in automotive manufacturing plants.

Food and Beverage Industry: These conveyors are ideal for moving products through different stages of production, packaging, and storage, ensuring a smooth and efficient operation.

Textile Industry: In textile manufacturing, overhead conveyors are used to transport fabrics and garments between different stages of production, reducing handling time and improving efficiency.

Warehousing and Distribution: Overhead conveyors are widely used in warehouses and distribution centers to move goods efficiently across large facilities, optimizing space and reducing manual handling.

Why Choose ArSai Conveyor Systems Pvt. Ltd.?

Commitment to Quality: ArSai Conveyor Systems Pvt. Ltd. is dedicated to providing the highest quality products. Their overhead conveyors are manufactured to meet or exceed industry standards, ensuring durability and reliability.

Expert Support and Service: From initial consultation to installation and ongoing support, ArSai Conveyor Systems provides comprehensive services to ensure that your conveyor system meets your specific needs.

Innovation and Customization: The company’s focus on innovation allows them to offer customized solutions that are tailored to the unique requirements of each client.

How to Get Started with ArSai Conveyor Systems Pvt. Ltd.

Consultation and Design

The process begins with a consultation where ArSai Conveyor Systems’ experts work closely with you to understand your specific material handling needs. This collaboration ensures that the overhead conveyor system is designed to optimize your production processes.

Manufacturing and Installation

Once the design is finalized, ArSai Conveyor Systems Pvt. Ltd. begins the manufacturing process using the latest technology and high-quality materials. Their experienced team then handles the installation, ensuring that the system is fully operational and integrated into your existing processes.

Ongoing Support and Maintenance

To ensure the long-term success of your conveyor system, ArSai Conveyor Systems offers ongoing support and maintenance services. Their team is always available to provide assistance, whether it’s for routine maintenance or addressing any issues that may arise.

Conclusion

For businesses looking to enhance their material handling capabilities, investing in a high-quality overhead conveyor system is essential. ArSai Conveyor Systems Pvt. Ltd. offers innovative solutions that are designed to meet the diverse needs of various industries. With a commitment to quality, customization, and customer satisfaction, ArSai Conveyor Systems is the go-to choice for businesses looking to improve efficiency and optimize space in their production facilities.

Contact ArSai Conveyor Systems Pvt. Ltd.:

Mobile Number: +91–98117 72712

Email: [email protected]

Get in touch with ArSai Conveyor Systems Pvt. Ltd. today to learn more about their overhead conveyor solutions and how they can help you optimize your production processes.

#overhead conveyor#overhead Conveyor Manufacturer in India#overhead conveyors#Overhead Conveyor Systems#Overhead Conveyor Manufacturer in Ghaziabad

0 notes

Text

Reasons to Get Automated Garment Conveyor

Garment conveyor is a high-performance automated storage system, garments sorting and handling process that easily reduces human resources in a customer service industry. Garment sorting conveyor is an exceptional automated storage system, garments arranging and taking care of procedures that lessen human resource in a client care chain.

Automated garment conveyor come with mesmerizing features including face recognition access systems, automated systems by RFID card access or just by cell numbers. These systems are truly wonderful for use if you want to exclude contacts between people and use contactless access technology.

Reasons Why Should You Get Garment Conveyor with Innovative Technology

Ensure to get garment conveyor systems with latest technology like Face Recognition Access or RFID Access by Cards. You should get automated garment conveyor system into your business. High-tech garment conveyors come with face recognition or RFID access by cards. These conveyor systems are broadly utilized in cleaning and mechanical clothing units and as well as in any event.

Overhead conveyors enable administrators to utilize the space over their heads for garment storage and recovery. Starting out with a large number of garments that are ready at the dry cleaners, these assembly conveyor cleaners make the most of garment and order tracking features to simplify assembly and sorting. The best thing about such systems is that they offer multiple levels of automation.

Automated Garment Conveyor systems are ideal for hospitals, hotels, industrial laundries, dry cleaners, wellness centers, factories, fashion houses, e-commerce, large-scale retailing, public entertainment and many more.

Garment Sorting System for Dry Cleaner plays key role in dry cleaning industry. Their unending number of designs helps the system work in even the littlest spaces. They are simple to install and work in a way to set up your client’s garments smoothly. On the other hand, encased track conveyors imply that clients don’t need to stress over interacting with overhead conveyor chains. Dust shields features keep the garments clean. Now a day, there are numerous conveyor systems available for laundry business. An overhead system like garment conveyor with face recognition access can be easily added to a reconfigured to meet the changing needs of your business.

Automated U-sort systems were smartly designed to improve productivity by providing a more efficient means of sorting garments on hangers. You will be wonder to know that the common applications such conveyors include. Those are high volume industrial laundries, institutional laundries, dry cleaners and retail organizations requiring automated sorting.

Incredible benefits of using automated conveyor systems include maximize labor efficiency, very much compatible with existing facilities and management systems, rapid installation, low maintenance, and best customer service.

From the finishing tunnel, each garment is served into the first sort loading station where it is automatically scanned and loaded onto route sorting. The inbuilt system scanner is best programmed to read bar codes, or radio frequency identifiers. Ultimately, the system can best handle the output of multiple finishing tunnels, and is capable or sorting thousands of pieces every hour.

#Automated Garment Conveyor#garment warehousing rail systems#overhead conveyor case studies#garment storage and retrieval system#auto uniform conveyor for hotel

0 notes

Text

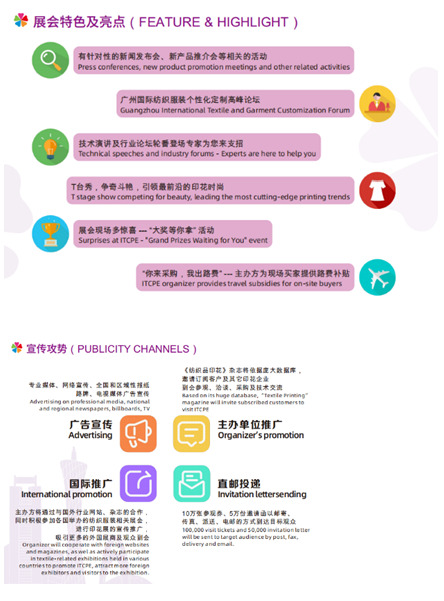

The Registration Channel for the 2024 (19th) Guangzhou International Textile, Clothing and Printing Industry Expo(ITCPE) is officially open!

For nearly two decades, the HK Allallinfo Group has proudly hosted the Guangzhou International Textile, Clothing and Printing Industry Expo(ITCPE). Throughout this journey, we have shouldered the responsibilities of numerous exhibitors and spectators, exceeding expectations with each successful exhibition. Leveraging our extensive event organization experience and the professionalism of our team, we have consistently exceeded goals, facilitating access to industry leaders, cutting-edge technologies, and valuable business opportunities. Join us at the 19th edition of this highly anticipated event, and witness the power of professional expertise driving the future of textiles, clothing, and printing!

To meet the evolving needs of textiles, dressmaking, printing, and dyeing, and to respond to the needs of exhibitors and spectators, the organizing committee of ITCPE has opened the registration and investment channels for the 2024 Guangzhou (19th) International Textile Clothing and Printing Industry Expo in advance.

Larger Scale

Among participating exhibitors, there are more than 1,000 quality enterprises with the reputations of High and New-tech Enterprises and specialized, high-end and innovation-driven SMEs.

More Spectators

Invitations have expanded to include over 60,000 professional visitors online and offline. One-on-one invitations boost purchasing power and conversion rates.

Overview

Four Sub-exhibitions

Textile Printing Industry Technology Exhibition.

Intelligent Sewing and Embroidery Industry Technology Exhibition.

International Printing, Dyeing, and Finishing Technology Exhibition.

Clothing Fabrics and Accessories Exhibition

2. Exhibition Scope

Textile Printing Machines - Inkjet digital printing system, Fully automatic/semi-automatic/manual printing machines, heat transfer equipment, steaming machines, stretching machines and other finishing equipment, Flatbed and rotary printing machines, laser engraving and cutting equipment, printing plates conveyor system, etc

Textile Dyeing Machines and Accessories - Pre- and post-treatment equipment for printing and dyeing, Dewatering and drying equipment, Sizing systems, Printing and dyeing waste gas and water treatment systems, etc.

Embroidery Machines - Single-needle embroidery machines, multi-needle/super multi-needle embroidery machines, garment computer embroidery machines, Embroidery-making system and embroidery software, CNC system and components, etc.

Intelligent Sewing Machines - Sewing machines, CNC and drive systems, fabric cutting/stretching/ironing/finishing equipment, hanger systems, packaging equipment, laser equipment, automated garment production line solutions, etc.

Apparel Fabrics and Accessories - Various types of clothing fabrics, functional/sportswear fabrics, pattern designs, transfer films, rhinestones/appliques/sequins, glitter, etc.

Materials for Textile Printing - Printing dyes, coatings, adhesives, water-based inks, heat-set inks, inks, pastes, thickeners, and other printing auxiliaries

Related Software - CAD systems, 3D body measurement software, 3D virtual fitting software, 3D smart design systems, etc.

Chemical and Auxiliaries Used for Dyeing - Various dyes, pre- and post-printing and dyeing treatment agents, etc.

Customization - Fabrics and accessories, blank T-shirts, patterns and designs, e-commerce platforms, equipment suppliers, etc.

Others - Plate-making equipment, silk screen, photosensitive adhesives, equipment and material concerning heat/transfer, various patents, technologies and software related to textile printing, professional newspapers, magazines and media, etc.

3. Date and Address

Date: May 20, 2024-May 22, 2024

Address: China, Guangzhou, Poly World Trade Center

4. Multi-channel Publicity

5. Our Cooperative Partners

https://textilesouthasia.com/wp-content/uploads/2023/12/9.png

A Retrospect of ITCPE 2023

Now, the recruitment channel for the 2024 ITCPE has been opened, and you are just one registration away from a great business opportunity! Click for more details: https://www.allallinfo.com/itcpe/ad.html or mail us at: [email protected].

1 note

·

View note

Text

Needle Detector Machine for Garment

1. When sensor detect a broken needle chip which diameter is over the ability, the machine buzzers conveyor b stops and returns the product detected

2. Monitor of detecting sensitivity helps to adjust sensitivity

3. 10 pcs. Of indicator lamps identify exact location of object that you can find it easily

4. Detecting sensitivity can be adjusted

Welco Garment Machinery Pvt. Ltd., since 1994, has been focused on bringing innovative concepts and better technology to foster the growth of GARMENT FINISHING, HOME FURNISHING, LEATHER FINISHING AND INDUSTRIAL & COMMERCIAL LAUNDRY WASHING - DRY CLEANING MACHINES. WGM has been awarded the ISO 9001:2015 certification by Dubai Accreditation centre (DAC), Emirates International Accreditation Centre (EIAC). Awarded with International Quality Certification Services by UKAC UK Ackreditering Certification Limited. ISO 14001: 2015, ISO 45001: 2018 and GMP (Good Manufacturing Practices) by UK Certification & Inspection Authority UK. Welco Garment Machinery Private Limited endeavor is to provide automation with world’s most advanced technology, and saving energy and resources to make a better tomorrow; yet specific to Indian needs at affordable prices.

For more details visit our website - https://www.welcogm.com/Needle_Detectors.php

1 note

·

View note

Text

Project 4: Research

We all delegated jobs for everyone to look into some research on fashion so that we could have some foundation information and statistics to work off of.

Waste Statistics on Fashion Consumption - Claudia

- Second to oil, the clothing and textile industry is the largest polluter in the world. - The fashion industry contributes 10% of global greenhouse gas emissions due to its long supply chains and energy intensive production. - Nearly 20% of global waste water is produced by the fashion industry - 15.1 million tons of textile waste was generated in 2013, of which 12.8 million tons were discarded. - A few communities have textile recycling programs, about 85% of this waste goes to landfills where it occupies about 5% of landfill space and the amount is growing. - Up to 95% of the textiles that are land filled each year could be recycled. - Using recycled cotton saves 20,000 liters of water per kilogram of cotton, a water-intensive crop. - Only about 0.1% of recycled fiber collected by charities and take-back programs is recycled into new textile fibers - Consumers are regarded as the main culprit for throwing away their used clothing, as only 15 percent of consumer-used clothing is recycled, whereas more than 75 percent of pre-use clothing is recycled by the manufacturers. - The average person buys 60 percent more items of clothing every year and keeps them for about half as long as 15 years ago, generating a huge amount of waste.The average lifetime of a piece of clothing is approximately 3 years.

https://ecowarriorprincess.net/2018/10/facts-statistics-about-fast-fashion-inspire-ethical-fashion-advocate/

https://edgexpo.com/fashion-industry-waste-statistics/

https://www.thebalancesmb.com/textile-recycling-facts-and-figures-2878122

Fast Fashion - Huy

Negative - Cheap, trendy clothing - One of the most polluting industries - Creates a huge climate change footprint through its unsustainable practices - Popular brands include ASOS, Boohoo, H&M, Zara, Missguided, Shein - Average person discards about 80 pounds (36kgs) of textiles each year, being almost double of what was discarded 20 years ago - Cheap labor, harsh working conditions - H&M produces so much surplus inventory, they began burning the clothing for fuel

Positive - Better to prioritise quality > quantity of clothing - “Slow fashion” promotes conscious consumption and supports companies that protect the environment and respects their workers. - rent /sell clothing, there is a growing market for second-hand clothes - Many aren’t actually aware of the damage because information on the impacts of our clothes are not readily available to us, so once they are educated, their behaviour is likely to change - Good to inform people in a way that is easily digestible and visually appealing

https://experiencelife.com/article/6-ways-to-quit-fast-fashion/

https://goodonyou.eco/five-fast-fashion-brands-we-avoid/

https://www.chathamhouse.org/expert/comment/understanding-sustainable-fashion?gclid=CjwKCAjw8e7mBRBsEiwAPVxxiCd-idEeP1-zAubixbxUQd0QIAf-LP5FT5ueX2bM91LWgqAJQnmgghoC_7gQAvD_BwE

Fabric/Material Analysis - Oliver

Common clothing fabric

1. Cotton cloth

Cotton cloth is a general term for all kinds of cotton textiles. Most of them are used for making casual wear, underwear, shirts, etc. The advantages are good warmth, softness, moisture absorption and good breathability. The disadvantage is that it is easy to shrink and wrinkle.

2. Burlap

Burlap is a kind of cloth made of linen, jute, sisal, and hemp. Generally used to make casual wear, work wear, summer wear, the advantages are extremely high strength, moisture absorption, heat conduction, and good ventilation. The disadvantage is that it is uncomfortable to wear, rough and blunt.

3. Silk

Silk is a general term for various silk fabrics made from silk. It is used to make a variety of clothing, especially suitable for making women's clothing, such as some scarves and dresses. The advantages are light, fit, soft, smooth, breathable, multi-colored, shiny and comfortable to wear. The disadvantage is that it is prone to wrinkles, easy to stick, not strong, and easy to fade.

4. Wool

Wool is a general term for fabrics of various types of wool and cashmere. Usually used to make dresses, suits, coats, and other high-end clothing. The utility model has the advantages of anti-wrinkle and abrasion resistance, soft hand feeling, elasticity, strong heat retention and secondary use. The disadvantage is that the washing is difficult, and the material is heavy.

5. Leather

Leather is an animal fur fabric that has been tanning. Divided into two categories, one is leather, depilated leather. The other is suede, a treated leather with skin and hair that has the advantage of being light and warm. The disadvantages are that they are expensive, storage, and care.

6. Chemical fiber

Chemical fiber is a kind of fiber textile made from high molecular compound, which is usually divided into artificial fiber and synthetic fiber. Their common advantages are bright colors, soft texture and comfort. The disadvantages are wearing resistance, heat resistance, moisture absorption, poor gas permeability, preheating and deformation, and easy generation of static electricity. Can make all kinds of clothes, but most of them are not comfortable.

7. Blended

Blended, it is a fabric made of natural fiber and chemical fiber mixed in a certain proportion, which can be used to make all kinds of clothing. The advantages are that there are advantages of cotton, hemp, silk, woolen cloth and chemical fiber, and they avoid their respective shortcomings, and the value is relatively low and relatively popular.

Fiber classification: natural fabrics and non-natural fabrics

Natural

A. Plant fiber: cotton, hemp, fruit fiber

B. Animal fiber: wool, rabbit hair, silk

C. Mineral fiber: asbestos

Unnatural

D. Recycled fiber: viscose, acetate, modal, bamboo fiber

E. Synthetic fiber: synthetic cotton, polyester, acrylic, spandex... (Synthetic fiber: Polyester fiber: Polyester, melting point 255~260°C, bonding starts at 205°C, safe ironing temperature is 135°C.

Polyamide: Nylon, melting point 230~270 °C, available on the Internet.)

F. Inorganic fiber: glass fiber, metal fiber.

Old clothes collection process:

1. Clothing eligible for donation - disinfection - donation, charity;

2. white cotton fabric - fiber treatment - cotton yarn;

3. colored fines - fiber treatment - non-woven fabrics;

4. polyester fabric - chemical treatment decomposition - polyester raw materials;

How Clothing Recycling Works (https://www.thebalancesmb.com/textile-recycling-facts-and-figures-2878122)

Clothing recycling is part of textile recycling. It involves recovering old clothing and shoes for sorting and processing. End products include clothing suitable for reuse, cloth scraps or rags as well as fibrous material. Interest in garment recycling is rapidly on the rise due to environmental awareness and landfill pressure. For entrepreneurs, it provides a business opportunity. In addition, various charities also generate revenue through their collection programs for old clothing.

Garment recycling involve a series of sequential activities as outlined below:

Creating Awareness of Clothing Recycling

Website information. A basic step for garment recyclers is to raise public awareness with information about the importance and benefits of donating used items like clothing and shoes. As such, recycling companies often provide educational materials at their websites regarding garment recycling and its importance. They may also explain what items they accept for recycling.

Informative bins and truck signage. Other approaches to raising awareness truck and bin markings. Colorful bins help describe what articles of clothing are accepted and what charity benefits from the contribution. Truck signage can be useful in raising awareness, for example, of home pickup programs for old clothing.

Collection

Clothing recyclers use a variety of strategies for picking up clothing. Post-consumer clothing is picked up generally from bins placed in public places, as well as from clothing drives and door-to-door collection. Bins are typically placed strategically in public places like parking lots in business centers and shopping malls. Colorful bins are positioned in high traffic, high visibility locations to help maximize donations.

One recent development has been the partnering of leading retailers with garment recycling companies such as I:Co. In collaboration with its partners, I:CO collected around 17,000 tons of clothing and shoes in 2015 (or 37 million pounds) while recycling 40 percent of the clothing or almost 15 million pounds.

Clothing sorting

Once collected, clothing is classified into three groups: reuse, rags, and fiber. Typically this is a manual sorting process that requires expertise in identifying various types of material. The process can be aided by such mechanical systems as conveyor belts and bins to segregate various grades of material. There is, however, at least one initiative to automate the sorting process, known as Textiles4Textiles.

Recyclers report that about one-half of donated garments can be reused. Some recyclers bale this clothing for export to developing countries, while some garments are used domestically for sale in thrift shops. Industrial cloth rags and wipes are another important residuals of the recycling process. Additionally, clothing may be reduced to fibrous material.

Processing

Textile fabric and clothing commonly consist of composites of synthetic plastics and cotton (biodegradable material). The composition will influence its method of recycling and durability.

Collected clothing is sorted and graded by highly experienced and skilled workers. These sorted items are sent to different destinations as outlined.

For natural textiles, incoming items are sorted in terms of color and material. By segregating colors, the need for re-dying can be eliminated, reducing the need for pollutants and energy. Then the clothing is torn into sloppy fibers and combined with other chosen fibers, conditional on the planned end use of the recycled fiber. Once cleaned and spun, fibers can be compressed for use in mattress production. Textiles which are sent to the flocking industry are used to produce filling material for furniture padding, panel linings, loudspeaker cones, and car insulation.

The recycling process works somewhat differently for polyester-based materials. In this case, the first thing is to remove zippers and buttons and then to cut the clothing into smaller pieces. Those shredded small fabrics are then granulated and shaped into pellets.

As the textile industry continues to grow, it will be challenged to devise ways to boost recycling rates as well as to develop technologies that will help maximize the value of recovered material.

Conversation with Galleries - Mac

Guidance for appropriate places to display our creative creator as an interactive installation. - Asking what they are looking for and requirements to get published/displayed. - What is required to get it displayed on a national level. Contacted the acting director at Auckland city art gallery Toi o Tamaki about what it would take to have an installation at that level. The results being that they only publish widely known artists as installations. They gave recommendations for local community hubs and suggested starting at that level.

1 note

·

View note

Text

Choosing the Right Car Wash

Self-service facilities

Self service automobile wash facilities allow the car owner to wash his or perhaps her very own automobile using hoses, drying machines and cleaning agents provided by the carwash. These are usually coin-operated and work on a time limit.

Pros: Usually very cheap. You could be as thorough (or as careless) with your paint as you'd like.

Cons: Manual work is involved. Do you really need to get wet as well as potentially dirty for the benefit of a thoroughly clean vehicle?

Hand vehicle wash facilities

Hand car washes employ staff members to wash your car, usually using sponges and buckets - the traditional way. Some hand automobile wash facilities cater to specific market segments by providing somewhat different services, which includes supplying the customer with scantily-clad attractive women to clean his (or her) car.

Pros: No manual labour on the customer's behalf.

Cons: Price begins to get somewhat higher at this stage.

Tunnel washes

A tunnel wash uses a large conveyor belt to move the automobile through the garments machine. There are automated cranes and booms that conduct a variety of actions on the car, for example spraying soap, rubbing grime off as well as rinsing with h2o.

Pros: Fully automated - the purchaser is able to sit back and enjoy the ride. Usually provides a very thorough clean.

Cons: Starting to get pricey. In the past, some were worried that the automatic process may cause problems for the exterior of the car. This's usually no longer the case. Some tunnel washes call for that someone remain in the vehicle to go it between stages.

In-bay automatics

When using an in bay automatic carwash, the vehicle stays fixed and the clothes mechanism operates around it. These occupy a smaller foot print compared to a Tunnel Washer, so usually are employed when room is a concern.

Pros: Again, entirely automated. No-one is necessary to run the wash / automobile - press the key and walk away!

Cons: Usually quite expensive (by comparison).

Thus, based on this info you ought to now be in a position to get the best car wash equipment option for your car.

https://sparklescarwash.com.au/

2 notes

·

View notes

Photo

Flying, I always imagine the conveyor belt to be a automated ramp. Rest is just a logo for the sexiest garment or non-garment in the world :-)

0 notes