#Automatic Linear Vial Washing Machine

Explore tagged Tumblr posts

Text

Automatic Washing and Air Jet Cleaning Machine - Lodha Machine

Lodha Machine is manufacturer and exporter of Automatic Washing and Air Jet Cleaning Machines in India. We offer a wide range of high-quality pharmaceutical machines designed to meet the stringent requirements of the pharmaceutical industry. Our automatic washing and air jet cleaning machines are engineered for precision and efficiency, ensuring thorough cleaning and sanitization. Known for our commitment to quality, innovation, and excellent customer service, Lodha Machine stands out as a trusted name in the industry. Our machines are ideal for various applications, providing reliable and effective cleaning solutions that enhance operational efficiency. Choose Lodha Machine for your automatic washing and air jet cleaning needs and experience superior performance. Visit our site - https://www.lodhamachines.com/washing-and-airjet-cleaning-machine

#washing & air jet cleaning machine#air jet and vacuum cleaning machine#automatic air jet and vacuum cleaning machine#automatic linear vial washing machine#airjet cleaning machine price in india#washing and air jet cleaning machine exporter in india#automatic airjet cleaning machine manufacturer in gujarat#airjet cleaning machine manufacturer in india

0 notes

Text

Inverter type Linear Vial Washing Machine

youtube

Injectable glass vials can be cleaned with an Inverter type Linear Vial Washing Machine. The machine has seven interchangeable washing stations that can be used to suit the needs of different customers. This linear vial washer offers three air and four water washes and a positive pressurization wash for vials. AISI SS 316L was used for all contact parts, whereas AISI SS 304 was used for non-contact parts. To comply with GMP regulations, vials invert into a neck-down position and nozzles enter the vial during the washing cycle. The most cost-effective and appropriate option for an online sterile vial filling line is an automatic linear vial washer.

#Linear Vial Washing Machine#Vial Washing Machine#automatic linear vial washer#linear vial washer#Youtube

0 notes

Text

Leading Manufacturer of Pharmaceutical Machinery in China: Comprehensive Solutions for Vial and Ampoules Packaging Line

As a trusted manufacturer of pharmaceutical machinery and equipment, we specialize in delivering complete solutions designed for the production of tablets, liquids, capsules, powders, granules, and especially Vial and Ampoules Packaging Line. Our robust manufacturing capabilities, advanced R&D, and unwavering commitment to quality position us at the forefront of the pharmaceutical equipment industry in China and globally.

Why Choose Our Pharmaceutical Machinery Solutions

Unmatched Expertise in Pharmaceutical Engineering

We bring decades of experience in pharmaceutical engineering, offering high-precision machinery tailored for all production stages. Our pharmaceutical equipment is designed to comply with international standards such as GMP, CE, and ISO, ensuring safe, efficient, and compliant pharmaceutical production.

End-to-End Production Capabilities

From tablet compression machines to granule processing units, our product lineup covers every essential stage of pharmaceutical manufacturing:

Tablet Press Machines

Capsule Filling Machines

Liquid Filling and Sealing Machines

Powder Mixing & Blending Systems

Granulation Lines

Vial and Ampoules Packaging Line

Our integrated solutions streamline production processes, reduce downtime, and increase yield, which directly translates into higher profitability for pharmaceutical manufacturers.

Vial and Ampoules Packaging Line – Precision and Performance

Fully-Automated Packaging Line for Sterile Injectables

Our Vial and Ampoules Packaging Line offers high-speed, fully automated systems suitable for sterile environments. These lines are designed to handle delicate ampoules and glass vials with pinpoint precision, ensuring integrity, sterility, and consistent quality across batches.

Key features of our vial and ampoule packaging lines include:

Washing, Sterilizing & Drying Units

Liquid Filling Systems (Peristaltic or Piston Pump Based)

Rubber Stoppering and Capping Machines

Ampoule Sealing & Vial Crimping

Visual Inspection Systems

Labeling & Serialization Modules

Integrated PLC and SCADA Control Systems

Each component is designed to maintain aseptic conditions, protect product integrity, and deliver consistent performance.

Core Components of Vial and Ampoules Packaging Line

1. Automatic Vial and Ampoule Washing Machines

These machines are engineered to remove particulates and contaminants from containers using multi-stage ultrasonic and pressure-based washing with WFI (Water for Injection) and clean compressed air. Features include:

In-feed and out-feed automation

Multiple needle spray systems

Customizable formats for different vial sizes

2. High-Temperature Sterilization Tunnels

Utilizing dry heat sterilization, our tunnels eliminate microbial contamination and maintain the sterility of containers post-wash. They feature:

HEPA filtration

Conveyor system with variable speed

Temperature monitoring and validation systems

3. Liquid Filling and Stoppering Machines

These are precision filling machines with servo-driven pistons or peristaltic pumps, ensuring accurate filling volumes for even the smallest doses.

Filling range flexibility (0.1 ml to 100 ml)

In-line or rotary stoppering mechanisms

Laminar airflow units integrated for Class 100 environments

4. Sealing and Capping Units

For ampoules, flame-sealing systems provide hermetic closures, while for vials, aluminum caps are crimped tightly for maximum security.

Flame annealing systems for ampoules

Rotary or linear vial crimping systems

Cap feeding and sorting automation

5. Visual Inspection Systems

High-speed cameras and AI-powered software ensure every ampoule or vial is visually inspected for foreign particles, fill volume, seal integrity, and cosmetic defects.

360-degree inspection

Rejection systems for non-conforming units

Batch reporting and traceability

6. Labeling, Serialization, and Track & Trace

Incorporating advanced serialization technology, our labeling systems help comply with global traceability regulations including 21 CFR Part 11, EU FMD, and DSCSA.

Inkjet and thermal transfer printing

Tamper-evident labels

QR code and barcode support

Made in China, Trusted Worldwide

Our pharmaceutical machinery, proudly made in China, is exported to over 70 countries, including markets in Europe, the Americas, Middle East, Southeast Asia, and Africa. We offer turnkey projects and full support, from design consultation to post-installation training and after-sales service.

Custom-engineered solutions are our specialty. Whether you need a small-scale line for clinical trials or a full commercial production system, we provide flexible configurations tailored to your needs.

Innovation and Compliance – Our Manufacturing Promise

Research-Driven Development

Our dedicated R&D center is continuously innovating to enhance performance, reduce footprint, and integrate AI, IoT, and smart automation into our systems.

Digital twin modeling

Predictive maintenance systems

Cloud-connected data analytics

Regulatory Compliance

Our equipment complies with international regulatory frameworks, including:

GMP (Good Manufacturing Practices)

FDA 21 CFR Part 11

EU Annex 1 Guidelines

WHO and PIC/S Recommendations

Each machine undergoes rigorous FAT (Factory Acceptance Testing) and SAT (Site Acceptance Testing) to ensure seamless compliance during audits.

Unparalleled Customer Support and Global Services

Our team of multilingual engineers and service professionals provides 24/7 remote and on-site support to ensure uptime, training, and continuous improvement. Our global network of distributors and service hubs ensures fast delivery of spare parts and preventive maintenance services.

Industries We Serve

Our solutions are ideal for:

Pharmaceutical manufacturers

Biotech companies

Veterinary drug producers

Clinical research facilities

Contract manufacturing organizations (CMOs)

Partner with Us for Advanced Pharmaceutical Machinery Solutions

As a manufacturer of pharmaceutical machinery, we are proud to set benchmarks in precision engineering, sterile manufacturing, and packaging automation. Our specialized Vial and Ampoules Packaging Line is one of the most trusted solutions for injectable drug manufacturers worldwide.

Contact us today to discuss your production needs and discover how our China-based manufacturing facility can support your end-to-end pharmaceutical production goals.

Contact us:

GRAND INTELLIGENT EQUIPMENT (GUANGZHOU) CO.,Ltd

301A, Building 5, No.333, Juhuashi Ave, Huadu District, Guangzhou City, Guangdong, China.

+86-15361285728 ; +86-020-86886090

Email [email protected]

Wenzhou Grand Machinery Technology Co.,Ltd

Floor 4, Building 2, No.116, Xinglong Road, Wanquan Town, Pingyang County, Wenzhou City, Zhejiang Province, China

+86-15323319612 ; +86-577-65565288

Also available on

On Whatsapp

On Facebook

On Twitter

On Pinterest

On Youtube

On Tumblr

0 notes

Text

Automatic Linear Type Bottle Washing Machine in Comoros

Laxmi Pharma Equipment is a Manufacturer, Supplier, and Exporter of Automatic Linear Type Bottle Washing Machine in Comoros. Our Headquartered in Ahmedabad, Gujarat, India. An Automatic Linear Type Bottle Washing Machine cleans bottles efficiently in high-speed and large-scale production environments. The "linear" design ensures that bottles are fed through a continuous process, with each stage in the washing cycle executed with high precision. This machine is ideal for industries where cleanliness is crucial, such as in the pharmaceutical, food and beverage, and cosmetic sectors. The automated machine eliminates the need for operators to manually load and unload bottles, making bottle cleaning highly efficient. The washing process includes thorough washing with water, detergent, or other cleaning agents, followed by drying and sterilization in some cases. Types of Automatic Linear Type Bottle Washing Machines: Single-Stage Bottle Washing Machines Multi-Stage Bottle Washing Machines Rotary Bottle Washing Machines Inline Bottle Washing Machines Process of Automatic Linear Type Bottle Washing Machine: Feeding: Bottles are automatically fed into the washing machine through a conveyor belt system. Rinsing: Bottles are rinsed with water or a cleaning solution to remove any residual material. Washing: High-pressure jets of water or detergent clean the bottles from the inside and outside. Sterilizing: Depending on the configuration, the bottles may go through a sterilization process using hot water, steam, or chemicals. Drying: After cleaning, bottles are dried using high-efficiency blowers or drying agents to remove any moisture. Exit: Clean, sterilized, and dried bottles exit the machine, ready for the next step in the production process. FAQs: How long does the cleaning process take? The cleaning process typically takes only a few minutes per bottle, depending on the machine configuration and washing stages. The high-speed operation ensures fast throughput. Is the bottle washing machine customizable for different bottle sizes? Yes, manufacturers can customize the machine to handle different bottle sizes, from small vials to large bottles. Adjustable settings allow for flexibility in bottle handling. Laxmi Pharma Equipment is an Automatic Linear Type Bottle Washing Machine in Comoros Including Moroni, Moutsamoudou, Fomboni, Domoni, Tsimbeo, Adda-Doueni, Sima, Ouani, Mirontsi, Mkiriwadjumoi, Koni-Djodjo, Moya, Mbeni, Mitsamiouli, Barakani, Chandra, Ouellah, Mramani. Feel free to contact us if you have any more information or questions. View Product: Click Here Read the full article

#Adda-Doueni#AutomaticAmpouleStickerLabellingMachine#AutomaticLinearTypeBottleWashingMachineinComoros#AutomaticLinearTypeBottleWashingMachineinGujarat#Barakani#CappingMachines#Chandra#Comoros#Domoni#ExporterofAutomaticLinearTypeBottleWashingMachine#ExporterofAutomaticLinearTypeBottleWashingMachineinComoros#Fomboni#Koni-Djodjo#Mbeni#Mirontsi#Mitsamiouli#Mkiriwadjumoi#Moroni#Moutsamoudou#Moya#Mramani#Ouani#Ouellah#PackagingMachines#Sima#StopperingMachines#SupplierofAutomaticLinearTypeBottleWashingMachine#Tsimbeo

0 notes

Text

0 notes

Text

External Air Jet Bottle Cleaning and Washing Machine Manufacturer

Brothers is a leading manufacturer of Air Jet Cleaning and Washing Machines in India. We deliver all types of Ampoule Washing machine, linear vial washing, with all industrial safety and quality features. External Vial Washing Machine & Rotary Bottle Washing Multi Head Air Jet Cleaning Machine External Vial Washing Machine Automatic air jet cleaning machine Air Jet Cleaning Machine manufacturer Air Jet bottle washing machine air jet washing machine Bottle Washing and Air Jet Cleaning Machine Air jet bottle cleaning machine Air jet cleaning machine High Speed Automatic Rotary Ampoule linear tunnel bottle washing machine Air jet vacuum cleaning machine Rotary vial washing machine Rotary Bottle Washing Machine Multi head air jet cleaning machine Washing and air jet cleaning machine

For More Details Click here : https://www.brothers.in

0 notes

Link

We have wide range of Products Including Multijet Ampoule Vial Washing Machine, High Speed Rotary Ampoule Washing Machine, Automatic Linear Vial Washing Machine, Automatic Linear Bottle Washing Machine, Automatic Airjet Vacuum Cleaning Machine, Automatic External Vial Washing Machine, Automatic Rotary Vial Washing Machine, Rotary Bottle Washing Machine Model.

#Multijet Ampoule Vial Washing Machine#High Speed Rotary Ampoule Washing Machine#Automatic Linear Vial Washing Machine#Automatic Linear Bottle Washing Machine#Automatic Airjet Vacuum Cleaning Machine

0 notes

Photo

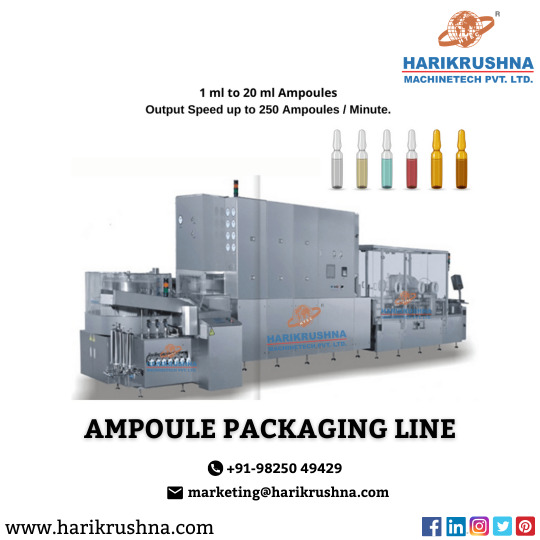

The Ampoule Packing line consists of Rotary Ampoule Washing Machine, Sterilizing Tunnel, Ampoule Filling & Sealing Machine and Ampoule Sticker Labelling Machine, etc. with the speed up to 300 Ampoules/Minute. Contact us:- [email protected] For more info visit our site:- http://harikrushna.com/ #Packagingmachinery #Machinery #PharmaMachinery #harikrushnamachinetech #FillingLine #BottleCappingMachine #packagingmachinery #ampoulefillingmachine #ampoulesealingmachine Vial Washing Machine, Linear Vial Washing Machine, Rotary Vial Washing Machine, Vial Capping Machine, Vials Sealing Machine, Dry Powder Injection Filling Machine, Injectable Liquid Filling Machine, Injection Vial Filling Machine, Pharmaceutical Vial Filling Machine, Vial Cap Sealing Machine, Vials Filling and Capping Machine, Filling and Sealing Machine For Vial, Automatic Vial Filling Equipment, Vial Filling Line For Pharma, Vial Filling Machine, Filling Machine For Vials

#Packagingmachinery#Machinery#PharmaMachinery#harikrushnamachinetech#FillingLine#BottleCappingMachine#ampoulefillingmachine#ampoulesealingmachine#Vial Washing Machine

1 note

·

View note

Photo

Devikrupa industries would like to inform following few lines for your ready information in respect of our range Pharmaceuticals & Packaging Machinery and more particularly our Wet Glue and specialty Sticker Labeling Machines.

We are the foremost Manufacturer and Exporter of Packaging Machinery, which are being used by Pharmaceutical, Agro-Chemical, Cosmetic, Food, Beverage and Pesticide Industries throughout India and export to Turkey, Morocco, Germany, Thailand, Haiti, Iraq, Saudi Arabia, Ukraine, Malawi, Nigeria, Bulgaria, Srilanka, Canada, Dubai, Ghana, Camroon, Moscow. etc.

Devi Krupa Industries - Leading manufacturer and exporter of Automatic Sticker Labeling Machine, Coding Machine, Code Printer Machine, Batch Printing Machine, Rotary Bottle Washing Machine, Tube, Liquid & Sealing Machine suppliers based in India.

Rotary Bottle Washing Machine, Label Stamping Machine, Liquid Bottle Packing Line, Linear Bottle Washing Machine, Tube Filling Sealing Machine, Semi Automatic Liquid Filling Machine, Visual Bottle Inspection Table, Automatic Sticker Labeling Machine, Ampoule Labeling Machine, Vial Sticker Labeling Machine, Automatic Ampoule Sticker Labeling Machine, Packing Belt Conveyor

1 note

·

View note

Text

Uflow Solenoid Valve Features and Use

Uflow Automation is an Indian manufacturer and supplier of solenoid valves and pneumatic valves. Founded in 2007, Uflow Automation is manufactured under ISO 9001. It manufactures and supplies starting from standard valves to specialty valves to custom manufacturing expertise. Uflow Automation produces valves for most applications. UFLOW solenoid valves are for demanding applications in industries such as-

· Chemical industries

· Textile processing equipment

· Oil & Gas (petrol, diesel, kerosene) flow on/off applications

· Water treatment plant (membrane flushing applications)

· Combustion equipment (LPG vaporiser on/off applications)

· Air dryer (air on/off applications)

· Cleaning/laundry/kitchen equipment

· Pharma-machinery (bottle/vial washing machine)

· Irrigation

Perfect Enterprises is one of the best authorized uflow solenoid valve dealers in Chennai offering wide-ranging types of Pneumatic tools of high-performing and high quality.

Solenoid Valves

Solenoid valves are used when the flow of liquids needs to be automatically controlled. They are being used extensively these days in diverse types of systems and devices. Various designs available allow application-specific valve selection. A solenoid valve is a control unit that shuts off or permits fluid flow when electrically energized or de-energized. The actuator is in the form of an electromagnet. When energized, there is a magnetic field created that pulls the plunger or pivot armature against the action of the spring. In the de-energized state, the plunger or pivot armature returns to its initial position under the action of a spring.

Features of Solenoid Valve

The solenoid valve is an electric control valve and has an electromagnet. This is an electric coil with a ferromagnetic core (piston) moving in the middle. In the rest position, the plunger closes or blocks the small opening. A magnetic field is generated when a current flows through the coil.

· The base magnet is not polarity sensitive. Solenoids work the same regardless of current flow.

· Solenoids have a duty cycle.

· Magnetic force has a curve.

· Solenoids can be made to perform many kinds of linear operations.

0 notes

Text

Washing & Air Jet Cleaning Machine - Lodha Machine

Lodha Machine is the leading manufacturer and exporter of Washing & Air Jet Cleaning Machines in India, offering a comprehensive range of high-quality pharmaceutical machines. Our machines are specifically designed to meet the diverse needs of the pharmaceutical industry, ensuring efficient and thorough cleaning processes. With a strong reputation for quality, innovation, and customer support, Lodha Machine is the preferred choice for businesses seeking reliable cleaning solutions. Whether you require machines for tablet making, capsule filling, or powder filling, we provide top-notch equipment that provide best performance and durability. Our commitment to excellence ensures that you receive the best products and services, making Lodha Machine your go-to partner for all your pharmaceutical machinery needs. Visit our site - https://www.lodhamachines.com/washing-and-airjet-cleaning-machine

#washing & air jet cleaning machine#air jet and vacuum cleaning machine#automatic air jet and vacuum cleaning machine#automatic linear vial washing machine#airjet cleaning machine price in india#washing and air jet cleaning machine exporter in india#automatic airjet cleaning machine manufacturer in gujarat#airjet cleaning machine manufacturer in india

0 notes

Text

Linear Bottle Washing Machine

Pharmaceutical businesses use linear bottle washing machine, also known as linear bottle washers, extensively. These machines are best suited for round vials. Vials can be manually pushed off the feed table or loaded onto an SS wire mesh conveyor using the feed conveyor’s automatic loading setup. Because vials are automatically fed into pockets, this saves labor. The automated unloading process involves emptying the vial and moving on to the turn table (Optional).

Glass bottles can be cleaned with an automatic linear bottle washer. Six washing stations on the machine are interchangeable to meet the needs of individual customers. For positive and pressurizing bottle washes, this linear bottle washer has three water and three air wash settings. All of the contact parts are composed of stainless steel 316, while the non-contact parts are composed of stainless steel 304. To comply with GMP regulations, the bottle is turned neck down and has nozzles inserted into it during the washing cycle. For an online bottle filling line, an automatic linear bottle washer is a cost-effective and perfect option. Machines are used in the food, chemical, pharmaceutical, and related industries. We offer extended assistance for validation of bottle washing machines and replacement parts. We also have Rotary Vial Washing Machine and Rotary Ampoule Washing Machine in our product line.

0 notes

Text

Pharma Machinery: Importance and Benefits

Being an owner of a pharma company, you require a set of quality-driven machines and equipment that enable a smooth end-to-end packaging process.

In this blog, we are going to highlight various pharma machinery produced by leading pharma machinery manufacturers in Ahmedabad, India, and their significance and benefits for the pharma industry.

Understanding the pharma machinery

What do you mean by pharma machinery? In simple language pharma machinery broadly means a wide range of machines, equipment, and tools that aid in the end-to-end manufacturing and packaging process of pharma products.

Types of machines used in the pharma industry

Machinery manufacturers in India are engineering a wide range of machinery that has found usage in the pharma industry. These include:

Oral Liquid/ Syrup/ Suspension Manufacturing Plant

Ointment/ Cream/ Lotion/ Shampoo/ Toothpaste Manufacturing Plant

Semi-Automatic Air Jet Vacuum Cleaning Machine

Automatic High-Speed Rotary Ampoule & Vial Washing Machine

Automatic Linear Vial Washing Machine

Automatic Linear Tunnel Type Bottle Washing Machine

Automatic Rotary Bottle Washing Machine – Glass and PP Bottles

Automatic Combi Air Jet Vacuum Cleaning & Water Washing Machine

Automatic Air Jet Vacuum Cleaning and Washing Machine

S.S. Air Jet Cleaning Machine

Automatic Bottle Air Jet Cleaning Machine

Automatic Linear Rotary Bottle Washing Machine

Semi Automatic Rotary Bottle Washing Machine

Semi Automatic Filling Machine

Semi Automatic Digital Filling Machine

Semi Automatic Piston Filling Machine – Table Top

Semi Automatic Volumetric Liquid Filling Machine – Table Top

Furthermore, there are tons of other pharma machinery that are aiding in various processes in pharma setup. Depending on your manufacturing unit’s requirement, you can choose the machine. Every product has its own application. What suits X, may not suit Y. As a result, it makes sense to use the product that suits your manufacturing requirement. In this regard, you can connect with a few pharma machinery manufacturers in Ahmedabad, India.

Applications of pharma machinery

The quality-driven range of pharma machinery has found usage for a wide range of applications. These include:

Manufacturing

Filling

Washing

Sealing

Labeling

Mixer

Dryer

Pharma machinery manufacturers in India are drawing benefits from the latest technology. Changing market dynamics throws new challenges every day for machinery manufacturers in India. Backed by modern technology, they are manufacturing industry-ready machines.

Salient features of pharma machinery

Let’s now shift our focus to salient features of the machinery. Quality-focused machines are recognized with numerous salient features; these include:

Less noise

Easy to clean

Low maintenance cost

Seamless functioning

Durable

Additionally, the quality-driven range of machines for pharmaceuticals is easy to operate. Your workforce doesn’t require any kind of specific training to operate and manage the pharma machinery.

Custom-designed pharma machinery

Quality matters a lot in a production setup. Never compromise with the quality and specifications of the machinery you require for your production process. A few prominent pharma machinery manufacturers in India hold the expertise to deliver custom-designed solutions.

In case, you are looking for machines with specific dimensions, get in touch with a professionally competent manufacturer. Enter into a dialogue with their engineers, technician, and designers. Based on the dialogue, the team will design a layout of the machine. Once it is approved, the design is sent for the production process.

1 note

·

View note

Text

Automatic Linear Type Bottle Washing Machine in Ahmedabad

Laxmi Pharma Equipment is Leading Manufacturer And Exporter of Pharmaceutical Machinery and Automatic Linear Type Bottle Washing Machine in Ahmedabad. We stand as a premier manufacturer and exporter in the pharmaceutical machinery sector. Our extensive range includes vial filling machines, bottle filling machines, liquid filling machines, powder filling machines, vial sealing machines, ampoule filling machines, ROPP capping machines, screw capping machines, aluminum cap sealing machines, sticker labeling machines, and more. Our products cater to the diverse needs of the pharmaceutical, cosmetic, chemical, food, ayurvedic, herbal, and pesticide industries. An automatic linear type bottle washing machine stands at the forefront of hygiene and efficiency in the beverage industry. This specialized equipment automates the crucial process of cleaning bottles before they are filled with beverages. With a linear design, it optimizes space and ensures a seamless workflow, contributing to the overall productivity of beverage manufacturing plants. Features: Specially engineered pockets on the platform cater to bottles ranging from 30 ml to 1000 ml, accommodating various sizes effortlessly. Simplified loading and unloading process for enhanced convenience. GMP model ensuring compliance with Good Manufacturing Practices. Robust machine construction using SS-304 for durability and longevity. Contact parts made from SS-316, ensuring high-quality and hygienic operation. Applications: Suitable for a wide range of industries including Pharmaceuticals, Food, Cosmetics, Pesticides, and more. We Provide Automatic Linear Type Bottle Washing Machine in Ahmedabad with other area such as Sanand, Vani, Kathawada I & II, Odhav, Vatva, Rakhial, Singarva, Bakrol, Kadi, Kalol, Kanbha, Kujad, Changodar, Naroda, Dhandhuka, Dholka, Viramgam, Kerala, Vatva- Zone 'D'. For more information, please engage in a professional conversation with our team. Read the full article

0 notes

Text

Explore the complete range of sterile washing machines like multijet ampoule & vial washing machines, rotary bottle washing machines, automatic linear vial washing machine, automatic external vial washing machine and many more are suitable for large & small industrial applications.

Visit our website https://www.lodhapharma.com/sterile-washing-machines.php for more information.

#SterileWashingMachines#VialWashingMachines#RotaryBottleWashingMachines#AutomaticLinearVialWashingMachine

0 notes

Photo

Some of the most salient features like contact parts made from SS316L, low water consumption during process, automatic in feed of vials through Unscrambler while being suitable for Siliconization makes Linear Vial Washing Machine an excellent machine for pharmaceutical industries.

Visit https://www.harsiddhengineering.com/linear-vial-washing-machine/ to know more.

0 notes