#Benchtop water hardness meter

Text

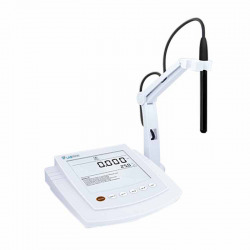

Benchtop Water Hardness Meter

The tabletop water hardness metre features a large backlit LCD, two to five calibration points, and a concentration range of low to high. The calibration reminder reminds the user to calibrate the metre on a regular basis. You may customise seven features in the System menu, such as stability condition, auto-power down, and so on. It calculates hardness in water by measuring calcium and other element salts at mg/L and mol/scale.

#Water hardness meter#Benchtop water hardness meter#water testing equipment#scientific equipment#laboratory equipment#analytical equipment

0 notes

Text

Benchtop Water Hardness Meter features a UK electrode and offers convenient functionality. Its stability indicator provides real-time status updates, ensuring reliable measurements of calcium salts and other hardness-causing elements in water, displayed in milligrams per Liter (mg/L) or millimoles per Liter (mmol/L) scales. The device boasts an automatic electrode diagnosis system that assesses sensor performance. With a spacious backlit LCD display, the meter supports calibration with 2 to 5 reference points across a broad concentration range. Data storage is a breeze, and you can effortlessly transfer stored information to your computer through the built-in USB communication interface. This meter streamlines water hardness assessment, making it a valuable tool for various applications.

It is widely used in testing the hardness level of tap water, drinking water, filtered water, water used for different experiments and testing across food, textile, painting, and other industries. Hard water can negatively affect industrial equipment and product quality.

0 notes

Text

Top Scrub Abrasion And Washability Testers - Things You Need to Know

There are many different types of surface testers for abrasion tests, analyzing scratching and wetness qualities. The latest trend in testing has been to include hybrid machines that test both dry and wet conditions. For those who are curious, here's a list of what we believe to be the best testers for various abrasion/scratch analyses.

1. Linear Abrasion Tester BEVS 2803-Touch Screen:

2. Automatic Scratch & Washability Tester BEVS2801 – Touch screen:

3. Wet Abrasion Scrub Tester TC 2805/2 ASTM D2486:

4. Wet Abrasion Scrub Tester TC 2805/1 - DIN53778:

5. Wet Abrasion Scrub Tester TC 2805/3 – ASTM D 3450:

Besides, you want your tests to be reliable, so it's important to make sure that you buy washability testers from a reputable source. Your best bet is to read individual product reviews online. One of the most popular brands for industrial equipment such as scrub abrasion and washability is TestCoat. Each of the products has its own unique features and benefits, and the same can be said for their service. For example, TestCoat offers a wide variety of scrub abrasion and washability testers in different capacities. This means that they can test for different types of abrasive materials. TestCoat also takes account for varying washability levels with their washability testers, so your results are always accurate.

The methods of testing vary depending on the properties that you want to test: crack, abrasion and also wet ability of a material in liquid, emulsion or suspension state which affect in particular the lifetimes of adhesives and other materials used in the industry.

Abrasion tests can be performed dry or wet. In the dry test, the material is rubbed by a standard load (50 N) on a 10 and 1/2 cm steel ball for 120 seconds. The wear depth (mm) is calculated from the average of 3 measurements carried out in 5 points on the sample surface. The washability test determines the resistance of materials to washing with water, using a spray gun with water at 15 bar pressure and room temperature for 10 minutes, and then drying. A reduction in mass is regarded as evidence of washing ability.

During normal use, some materials such as paints are exposed to damage through rubbing between two surfaces in contact. This phenomenon can be measured in a laboratory using the test for abrasion resistance (Cobb Test), or the wet abrasion test, which simulates the effect of two rubbing surfaces in contact, immersed in water. The test comprises rubbing each surface against the other by means of a rotating steel ball for 10 minutes. The steel ball has a diameter of 10.2 cm and weighs 50 g.

Wear is defined as depth (mm) lost due to friction between 2 surfaces in contact immersed in water at room temperature for 10 minutes, with at least 3 measurements per point on the surface to be tested. The reduction in surface area is measured in mm squared. The results are expressed as % weight loss on mass of a sample.

The test results are determined by the energy of friction, and therefore based on the law of conservation of energy, which states that during the rubbing process energy is lost by friction and dissipated into heat (according to the second law of thermodynamics). In practice, it is not possible to measure all this dissipated energy.

It's easier than ever to find the best and most affordable scrub abrasion and washability testers. The price differences can be dramatic, so it pays to shop around a bit, and make sure that you know exactly what you need.

About TestCoat:

For many years, TestCoat has been a trustworthy partner and leader in the supply and distribution of inspection equipment, laboratory & physical test equipment for the coatings and paint industries. We supply non-destructive quality control and testing instruments such as Paint thickness Mil Gauges, Gloss meters, portable and benchtop metal hardness testers, laboratory mixersviscometers, film applicatorsdrying time recorder, cupping testers, Wet scrub abrasion testers, Coating inspection kits with advanced technology, and of the highest standards.

For more information, visit https://www.testcoat-usa.com/

Original Source: https://bit.ly/3fvFfKn

0 notes

Text

Benchtop Conductivity Meter

Labtron benchtop meters are easy to use. The LCD display, manual or automatic mode of calibration, universal connector, and other features are included in this range to produce accurate, reliable results. It consists of a benchtop meter for measuring pH, conductivity, dissolved oxygen content, Ion concentration, and water hardness level. These meters are suitable for simple to complex applications in water quality testing, research and analysis, etc.

#lab equipment#scientific equipment#laboratory equipment#analytical equipment#water testing equipment#testing equipment#equipment

0 notes

Text

What are the best instruments for measuring coating thickness?

If you want to measure coating thickness accurately and efficiently, you need a tool that will suit your needs. Whether you are measuring one layer or many overlapping layers of paint, there is an instrument for your job.

Depending on how you want to use it, a coating thickness gauge may measure the thickness of a liquid or solid material. It is often used in the production and recycling of coatings to ensure uniformity in product quality. Other applications include measuring coating thickness on metal or plate materials with an industrial lot measurement system. The gauges are also used in research labs for fluid surface tension measurements as well as process monitoring at sensitive surfaces like patterned wafers, geotextiles, and textiles.

What is a coating thickness gauge?

A coating thickness gauge is a device used to measure and monitor the surface of coatings and films as they are applied. The gauge is usually designed as an indicator that has a fixed calibration bar that moves across the surface of your product. Some gauges have both a fixed and variable measurement scale.

Other instruments are digital with numerical readouts and graphs on their screens that show changes in volume, weight, or thickness depending on product usage. Choose from aluminum, stainless steel, or plastic gauges with a variety of coating capabilities to meet your screening equipment needs.

Coating thickness gauges are designed to measure coating thickness on your products. They are commonly used to monitor orifices for pipe coatings and measuring the coating thickness on a variety of surfaces such as pipes, printed circuit boards, and other metal surfaces. These gauges are also used for measuring liquid ingress in cable screens.

They can be adapted with specific applications depending on the type of product you want to measure. Paint thickness gauge works with paint of any viscosity type and color. Coating thickness gauges are easy to operate and help ensure that you receive the most desirable surface finish possible with your product or service.

BYK Gloss Meter

A BYK gloss meter is the best instrument for measuring coating thickness. This device can measure a wide variety of materials and can precisely pinpoint coating thickness. They are widely used as they are easy to use, cost-effective, and quick to generate results. These measurements help customers ensure their requirements for a product have been met before it is shipped out the door.

Some of the more unique functionalities that these instruments offer are:

The ability to adjust measurement range based on user needs

Quick response from the instrument

Specialized coatings key so that only certain types of material need to be tested

Paint meter: A paint meter is a device designed to measure the thickness of one or two layers of paint for touch-up purposes. After you calibrate your meter, it will indicate how many mils, as in thousandths of an inch, are on the surface you're measuring. The color and type of paint can affect the readings on a paint meter too, so make sure you use the appropriate settings.

Choosing the right paint meter:

Key questions to ask when selecting a paint meter include:

What type of paint am I measuring? Is it latex? Oil-based? Urethane? Water-based?

Do I need to measure lead in the paint or latex for child safety reasons?

How accurate does my meter need to be and how often do I plan on checking the thickness of the coats I'm applying?

What is my budget for the meter and can it detect a thin coating?

Conclusion: It’s important to understand your needs before deciding on a coating thickness measuring instrument. However, the best you can do is recognize your needs and choose the right place to buy coating instruments. For a quick suggestion, TestCoat is one of the most trusted brands to buy industrial equipment online.

About TestCoat:

For many years, TestCoat has been a trustworthy partner and leader in the supply and distribution of inspection equipment, laboratory & physical test equipment for the coatings and paint industries. We supply non-destructive quality control and testing instruments such as Paint thickness Mil Gauges, Gloss meters, portable and benchtop metal hardness testers, laboratory mixersviscometers, film applicatorsdrying time recorder, cupping testers, Wet scrub abrasion testers, Coating inspection kits with advanced technology, and of the highest standards.

For more information, visit https://www.testcoat-usa.com/

Original Source - https://bit.ly/340TeSb

0 notes

Text

Common Inspection Equipment for Coating & Paint Industry

The inspection of paint and coatings is one of the most important stages in production. Without proper inspection, it is impossible to ensure quality or determine if a coating has achieved the desired properties.

Paint and coatings industry-specific inspection equipment are designed for different applications, e.g.: durability testing, washability testing, hardness testing, glossmeter and even color measurement. Which testing equipment to choose depends on the production process, production quality requirements and the specific properties of the product being manufactured.

Washability tester: This is one of the most common paint inspection tools used in the coating industry. Washability tester measures both flash rust and salt spray resistance of a product by using a washability test bench. Flash rust is the rusting that occurs when exposed to air for 24 hours after washing with water.

Paint Microhardness Testing System: Micro hardness testing is an important tool for coating and paint testing. It utilizes a roller with the thickness of a 0.5mm steel plate in order to receive a sample from the base coat layer of the product being tested and then apply a stamping force of over 25N to measure the hardness of the material. Hardness value is normally expressed in Rockwell (HV) scale, which is determined by measuring the number of indentations made by a ruby ball under constant pressure against compound steel that has grains. The higher the hardness value, the lower the indentation.

Paint Vickers Hardness Testing System: Vickers hardness testing measures a coating or paint's ability to achieve high-gloss or passes a polish test without showing signs of flaking, cracking or disintegration. A hammer is used to repeatedly strike an aluminum plate with a specific force until it cracks. The set force required to produce a single crack is called Vickers hardness. It can be used in coating and paint inspection as well as in product quality control before packaging and shipping.

Color measurement device: Color measurement is important to determine the color of the paint or coating before applying. This will help prevent color errors, which result in poor paint quality (color reversal), reduced life, and increased cost of production.

Digital micro Vickers hardness testing system: This Digital micro Vickers hardness testing system provides a fast and efficient way to evaluate the hardness of coating layers by measuring the depth of indentation made by a ruby ball under constant pressure as it rolls against steel bars with grains. The hardness value is usually expressed in Rockwell (HV) scale, but can be converted to another standard such as Vickers (HV) scale if desired.

Rockwell hardness testing system: The Digital Rockwell hardness testing system is widely used in the industrial field to measure the surface hardness of a variety of materials such as paints, coatings, plastics, rubber and metal alloys.

Paint meter: Paint meter is a small precision device or instrument that will measure the amount or density of a particular paint or coating applied onto an object/surface. Paint meters are especially helpful when applying coatings like wall-paint, window-paint and cabinet-paint in residential homes.

About TestCoat:

For many years, TestCoat has been a trustworthy partner and leader in the supply and distribution of inspection equipment, laboratory & physical test equipment for the coatings and paint industries. We supply non-destructive quality control and testing instruments such as Paint thickness Mil Gauges, Gloss meters, portable and benchtop metal hardness testers, laboratory mixersviscometers, film applicatorsdrying time recorder, cupping testers, Wet scrub abrasion testers, Coating inspection kits with advanced technology, and of the highest standards.

For more information, visit https://www.testcoat-usa.com/

Original Source - https://bit.ly/3vsmahI

#Washability tester#Digital micro Vickers hardness testing system#Digital Rockwell hardness testing system

0 notes

Text

TestCoat: QNix® 9500 series of Paint Mil Thickness Gauges

The QNix® 9500 inspection series of dry film gauges are built for corrosion inspection in shipbuilding, infrastructure, offshore wind farms, Fireproofers, chemical plants, etc. This series of Coating thickness gauges sets a new standard in the coating inspection industry, in terms of durability – for long and reliable use, even undder very harsh work conditions – splash-proof housing. The operating temperature ranges from -20 °C to +70 °C with the scratch-proof, the high-contrast display rotates according to user angle. The QNix® 9500 Paint Gauge series is fiberglass reinforced and has a- 5 pieces IP65 dust and water-resistant housing. It is the most rigorously tested paint thickness measuring device from Automation Dr. Nix, Germany. The QNix® 9500 series comes with a body gauge that is either accompanied by an integrated probe- Fe, NFe, Dual or a gauge body able to accommodate the different types of probes interchangeably. With the QNix® 9500 Paint thickness meter, the user immediately recognizes conceptual and perceived integrity. QNix® 9500 paint meter automatically recognizes the base metal, when deployed with a dual probe. This is an important aspect and a perfect solution for thickness measurement on double-coated surfaces – duplex measurement on both rough and smooth surfaces in shipyard repairs- blasting, Offshore wind turbines, petrochemical plants, bridge construction, and repairs. QNix® 9500 also has very high reliability when measuring very thin coating thicknesses. Measuring according to international standards- SSPC-PA2 with levels 1-5, IMO PSPC, ISO 19840, Australian AS 3894.3B, Swedish IS 184160 are preconfigured in the premium plus models.

About TestCoat:

For many years, TestCoat has been a trustworthy partner and leader in the supply and distribution of inspection equipment, laboratory & physical test equipment for the coatings and paint industries. We supply non-destructive quality control and testing instruments such as Paint thickness Mil Gauges, Gloss meters, portable and benchtop metal hardness testers, laboratory mixersviscometers, film applicatorsdrying time recorder, cupping testers, Wet scrub abrasion testers, Coating inspection kits with advanced technology, and of the highest standards.

For more information, visit https://www.testcoat-usa.com/

Original Source - http://bit.ly/36egSMA

0 notes