#BoxCompressionTesting

Explore tagged Tumblr posts

Text

Pacorr Box Compression Tester – Accurate Solution for Packaging Strength Evaluation

Pacorr’s Box Compression Tester is a high-precision instrument developed for determining the compressive strength of corrugated boxes and packaging containers. Designed to help packaging professionals ensure quality and structural integrity, this machine plays a critical role in avoiding box deformation and collapse during stacking, storage, and transportation.

Whether in FMCG, pharmaceutical, logistics, or e-commerce, companies rely on strong packaging to protect products throughout the supply chain. The Box Compression Tester by Pacorr gives manufacturers and QA teams confidence in the durability of their packaging materials.

What is a Box Compression Tester?

A Box Compression Tester is used to measure the maximum load-bearing capacity of boxes made from corrugated board. It replicates real-world pressure and stacking conditions to ensure that the boxes can endure the vertical load applied during transit or warehousing.

The machine presses down on the box with a uniform load until it deforms or fails. The highest load the box can withstand before failure is recorded as its compressive strength.

Why Use Pacorr’s Box Compression Tester?

Pacorr delivers advanced testing solutions that combine accuracy, durability, and user-friendly functionality. Key benefits of choosing Pacorr’s model include:

Precision Load Cells: Accurate measurement of compression force

Heavy-Duty Frame: Stable structure for repeatable testing

Digital Controls: Easy test parameter setup and data monitoring

Standard Compliance: Adheres to ASTM D642, ISO 12048, and TAPPI T804

Software Connectivity: Real-time test reports, graphs, and statistical analysis

With these capabilities, manufacturers can confidently validate packaging quality, reduce product damage, and maintain regulatory compliance.

Industries Using Box Compression Testers

The Box Compression Tester is essential in industries where packaging strength is directly linked to product safety:

Corrugated box manufacturers

Food and beverage industries

Pharmaceutical packaging

Consumer electronics

Third-party logistics (3PL) services

Industrial and automotive components packaging

Features of Pacorr’s Box Compression Tester

Load Capacity: Available from 1000 kg to 5000 kg

Digital Display: Real-time load and deformation values

Customizable Platform Sizes: Suitable for different box dimensions

Overload Protection: Prevents damage to the machine

Data Output Options: USB, printer, or computer software

Fully Automatic Operation: Automatic return and preload functions

These features ensure smooth operation, even for high-throughput quality control environments.

How the Compression Test Works

During the test:

The sample corrugated box is placed between two flat compression plates.

The upper plate descends at a set speed, applying pressure.

The box continues to receive pressure until it buckles or collapses.

The maximum load is recorded and used to evaluate box performance.

This test helps determine the stacking load a box can endure without structural failure.

Advantages of Using a Box Compression Tester

Product Protection: Minimize in-transit damage with verified box strength

Optimized Packaging Design: Avoid under or overdesigning boxes

Cost Efficiency: Use right-grade materials for safe but economical packaging

Standards Compliance: Meet quality control guidelines and international standards

Customer Satisfaction: Deliver intact products, enhancing brand trust

Technical Details

Parameter Specification Load Range 1000 kg to 5000 kg Accuracy ±1% of full scale Drive System Motorized with digital control Display Type LED/Digital/Touchscreen (customizable) Platform Area Based on user requirements Power Source 220V AC, 50Hz Safety Mechanism Overload and emergency stop

Test Standards Followed

Pacorr’s Box Compression Tester is compatible with these global standards:

ASTM D642 – Compression testing of shipping containers

ISO 12048 – Compression and stacking tests

TAPPI T804 – Compressive strength of corrugated shipping boxes

These standards help ensure that your packaging complies with national and international quality benchmarks.

Why Box Compression Testing Matters

Corrugated boxes must survive stacking pressure during warehousing, shipping, and handling. A box that fails to perform can cause:

Product breakage

Delays in delivery

Increased return rates

Brand reputation loss

By using Pacorr’s Box Compression Tester, manufacturers can prevent such risks through reliable data and proactive quality checks.

Pacorr – Trusted Name in Packaging Testing

Pacorr Testing Instruments is known for providing innovative testing equipment designed to meet the growing demands of the packaging industry. The Box Compression Tester is engineered with attention to detail, giving users the confidence to conduct critical tests with precision and repeatability.

Pacorr also offers custom configurations, on-site installation, and technical support to ensure clients get the most value from their testing systems.

Final Thoughts: Improve Packaging Reliability with Pacorr

If you want to eliminate packaging failure, improve product protection, and reduce material waste, the Box Compression Tester Price from Pacorr is the tool you need. With advanced features, intuitive controls, and accurate testing, it sets a new benchmark for packaging evaluation.

Get in touch with Pacorr today for a demo, pricing, or technical consultation.

0 notes

Text

Maximizing Packaging Efficiency with Box Compression Tester

When it comes to packaging, ensuring your boxes can withstand the challenges of transport, stacking, and storage is crucial. At Labzenix.com, we offer advanced Box Compression Tester that allow you to thoroughly evaluate your packaging’s strength and performance. By simulating real-world conditions, these testers provide the insight you need to protect your products and optimize your packaging design.

What is a Box Compression Tester?

A Box Compression Tester is a device designed to measure the strength and durability of corrugated boxes under compressive forces. The tester applies pressure to the box to determine how much weight it can bear before buckling or collapsing. This test is vital for assessing the box's ability to survive stacking, storage, and shipment, where external pressures could damage the product inside.

Why Is Box Compression Testing Important?

In the packaging industry, strength matters. Whether you’re shipping delicate electronics or heavy goods, your packaging needs to be up to the task. Here’s why box compression testing is essential:

Ensures Packaging Durability: Packaging must be strong enough to endure stacking during transportation and storage. Box Compression Testing simulates these stresses, ensuring your boxes remain intact and reliable.

Reduces Costs: Testing helps optimize material use, ensuring you aren’t overusing packaging material while still maintaining strength and durability. This translates into cost savings without compromising product protection.

Minimizes Damage: A poorly designed box can lead to product damage during transport. Box Compression Testing ensures that your boxes provide adequate protection, reducing the likelihood of returns and customer dissatisfaction.

Meets Industry Standards: Various industries have packaging requirements. Box Compression Testing helps ensure that your packaging complies with these standards, providing peace of mind for both manufacturers and customers.

How Does a Box Compression Tester Work?

A Box Compression Tester works by applying controlled pressure to a box. The machine gradually increases force until the box reaches its limit. It measures various parameters such as:

Compression Strength: How much pressure the box can handle before collapsing.

Edge Crush Test (ECT): The box’s edge strength, important for stacking.

Stacking Strength: How well the box holds up when stacked under weight.

This testing provides valuable data, allowing manufacturers to understand the performance and reliability of their packaging materials.

Types of Box Compression Testers

At Labzenix.com, we offer various Box Compression Testers to meet your specific needs:

Manual Testers: A budget-friendly option for basic testing needs, these testers are operated manually, making them perfect for small operations.

Digital Testers: For more precise measurements, digital testers provide automated readings and are ideal for larger operations requiring high throughput.

Automatic Testers: These fully automated testers are designed for high-volume testing, offering faster and more efficient results with customizable settings.

Benefits of Box Compression Testing

Improved Packaging Design: By identifying the strengths and weaknesses of different box designs, you can create packaging that is both cost-effective and durable.

Reduced Product Returns: Test your packaging to minimize the risk of damaged goods, leading to fewer returns and higher customer satisfaction.

Enhanced Quality Assurance: Regular testing ensures that your packaging consistently meets the required standards and performs under real-world conditions.

Cost Efficiency: Properly tested packaging reduces material waste and minimizes the risk of costly shipping delays or product damages.

Conclusion

A Box Compression Tester Price is an invaluable tool for anyone involved in the packaging industry. Whether you’re designing new packaging or testing existing solutions, using a Box Compression Tester ensures that your boxes are strong, reliable, and cost-effective. At Labzenix.com, we offer a range of testers to meet your needs, providing you with the insights you need to deliver better packaging solutions.

Invest in the future of your packaging and test for durability today with Labzenix.com.

0 notes

Text

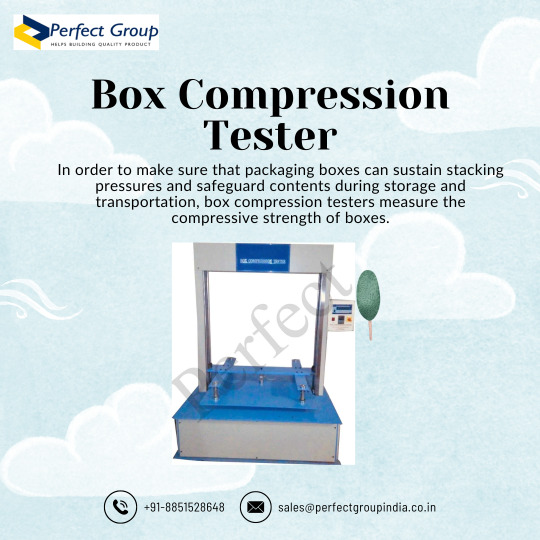

Box Compression Tester | Perfect Group

The Perfect Group's box compression tester is an essential tool for evaluating the durability and robustness of packaging materials. Designed with precision and dependability in mind, this tester ensures accurate readings of the compression strength of boxes, helping businesses maintain quality control and adhere to industry requirements. The robust construction and intuitive interface of The Perfect Group's tester ensure that products get to clients safely and unharmed. Packaging processes might gain from its effectiveness and assurance.

0 notes

Text

Box Compression Test (Máy đo độ nén thùng Carton) .

DRK123 Box Compression Tester 800 is professionally used to test the compression resistance property of carton box, corrugated box, honeycomb cardboard box and other packaging. .

https://lnkd.in/gyppQYt

#BoxCompressionTest #Drick #DRK123 #BoxCompressionTestDRK123

0 notes

Text

Box Compression Tester The Key to Durable and Reliable Packaging

In the world of logistics, the strength of packaging is essential to protect products from damage during shipping and storage. A Box Compression Tester is the perfect tool for evaluating the compressive strength of packaging materials like corrugated boxes. At Pacorr Testing Instruments, we provide top-quality Box Compression Testers that help businesses ensure their packaging can withstand real-world pressures and safely protect their products.

What is a Box Compression Tester?

A Box Compression Tester is a device that measures the compressive strength of packaging materials by applying controlled pressure until the box deforms or collapses. This tool simulates the forces a package will experience during shipping and storage, helping manufacturers evaluate whether their packaging is strong enough to handle these stresses. By testing the box’s ability to endure compression, manufacturers can ensure it will safely protect their products throughout their journey.

Why Box Compression Testing is Crucial?

Box compression testing is crucial for several reasons, and here’s why it matters:

Protecting Your Products: The main job of packaging is to keep the product inside safe. Box compression testing helps ensure your packaging is strong enough to withstand external pressures like stacking, shipping, and handling, preventing damage to your products.

Cost-Effective Packaging: Testing the compressive strength of packaging materials helps businesses find the optimal design that balances cost and strength. This means manufacturers can use less material without sacrificing the packaging's protective qualities.

Regulatory Compliance: Many industries have strict packaging standards. Box compression testing ensures that your packaging complies with international standards such as ASTM and ISO, helping your business meet regulatory requirements and avoid potential issues.

Enhanced Customer Satisfaction: Packaging that holds up under pressure ensures products are delivered intact, leading to fewer returns and better customer satisfaction.

How Does a Box Compression Tester Work?

The Box Compression Testing applies controlled pressure to a box to simulate the forces it will face during transport and storage. The test involves placing the box on a flat platform, then gradually applying force from above. The machine continues increasing the pressure until the box collapses or deforms. The force at which the box fails is recorded, providing a measurement of its compressive strength.

This process simulates real-life conditions such as stacking, where boxes at the bottom bear the weight of those above them. By mimicking these stresses, the Box Compression Tester provides accurate data on how well packaging will hold up in actual shipping conditions.

Features of Pacorr's Box Compression Tester

At Pacorr, we design Box Compression Testers that deliver precise and reliable results, with features that include:

High-Precision Load Cells: For accurate and consistent measurements of compressive strength.

User-Friendly Digital Display: Clear and easy-to-read results, making it simple to interpret data.

Adjustable Testing Speed: Customize the test speed based on different packaging materials for versatile testing.

Global Compliance: Our testers meet international standards such as ASTM and ISO, ensuring your test results are valid worldwide.

Applications of Box Compression Testing

The Box Compression Tester is indispensable for several industries where packaging is essential to product protection. Here are some key applications:

Packaging Industry: To test the strength of corrugated boxes and other packaging materials used in shipping.

Food and Beverage: To ensure food packaging can withstand the stresses of transport, preserving freshness and product safety.

Electronics: To verify that electronic products are safely packaged and protected during transit.

Pharmaceuticals: To ensure that medical products and pharmaceuticals are securely packaged, preventing damage or contamination.

How to Choose the Right Box Compression Tester

When selecting a Box Compression Tester Price, consider the following factors to ensure the right fit for your business needs:

Testing Capacity: Ensure the tester can accommodate the size and weight of the packaging materials you need to test.

Precision and Accuracy: Look for a tester that provides precise, repeatable results to ensure reliable performance.

Ease of Operation: Choose a machine with a user-friendly interface to simplify operation and reduce training time.

Compliance with Industry Standards: Ensure that the tester meets relevant industry standards such as ASTM and ISO to guarantee reliable test results.

Conclusion

The Box Compression Tester is an essential tool for manufacturers looking to ensure the strength, durability, and safety of their packaging. With accurate test results, businesses can optimize packaging designs, minimize costs, meet regulatory standards, and protect their products during transit. Pacorr offers Box Compression Testers that deliver precise and dependable results, helping you enhance packaging quality and improve your overall supply chain.

Visit www.pacorr.com to learn more about our Box Compression Testers and discover how our testing instruments can help you ensure the best packaging for your products.

#BoxCompressionTester#BoxCompressionTesting#BoxCompressionTesterComputerized#BoxCompressionTesterPrice

0 notes

Text

Box Compression Tester Your Solution for Packaging Durability Testing

At Pacorr, we understand that packaging is a critical component in ensuring the safe transport and storage of products. The ability of packaging materials to withstand compression forces is essential to guarantee that products arrive in perfect condition. Our Box Compression Tester is designed to help manufacturers measure the compressive strength of packaging materials, ensuring that every product remains secure throughout its journey from warehouse to customer.

What is a Box Compression Tester?

A Box Compression Tester is a specialized piece of equipment used to evaluate the compressive strength of packaging materials such as cardboard, corrugated boxes, and other similar packaging materials. The tester applies a controlled compressive force to the packaging and measures the maximum load it can endure before failing. This test is vital for ensuring that your packaging can withstand the pressures it will face during transport, handling, and storage.

Why is Box Compression Testing Important?

In today’s competitive market, packaging plays a crucial role in product protection. A weak package can lead to product damage, customer dissatisfaction, and increased returns. By using the Box Compression Testing, manufacturers can assess the durability and strength of their packaging materials. This ensures that they meet the required standards and are capable of protecting products during the shipping process. The result is reduced costs, fewer returns, and a better customer experience.

How the Box Compression Tester Works

The Box Compression Tester applies a uniform compressive force to the packaging until the box fails. It simulates the pressure and forces that the packaging will endure during handling, transportation, and stacking. Key measurements provided by this test include:

Maximum Compression Force: The maximum load a box can withstand before deformation or collapse.

Edge Crush Resistance: The force needed to crush the edges of the packaging, which simulates rough handling during shipping.

Box Compression Strength (BCT): Measures how much weight or pressure a box can support without failing, ensuring the packaging is strong enough to protect the product inside.

Applications of Box Compression Testing

Packaging Manufacturers: Ensuring the durability of cardboard boxes, cartons, and other packaging materials is a priority for packaging manufacturers.

Logistics & Supply Chain: Logistics companies use Box Compression Testers to ensure the packaging used for shipments is capable of surviving the challenges of transit, storage, and handling.

Retail and E-commerce: Retailers and e-commerce companies can use this test to make sure their packaging maintains its integrity during shipping, reducing the chances of returns or complaints.

Product Safety Testing: Manufacturers of sensitive or fragile products rely on compression testing to ensure their packaging meets the required strength standards.

Key Features of Pacorr’s Box Compression Tester

Accurate Load Application: The Box Compression Tester applies pressure gradually, ensuring that the test is precise and replicable.

Digital Interface: The tester comes with an intuitive digital display that makes it easy to control test parameters, start tests, and record results.

Wide Compatibility: It can handle various box sizes and materials, making it a versatile tool for packaging manufacturers across industries.

Built for Durability: Constructed with high-quality materials, the tester is built to last and withstand regular use in production environments.

Why Choose Pacorr’s Box Compression Tester?

Improved Packaging Quality: By ensuring your packaging meets durability standards, you can prevent product damage and increase the reliability of your shipping process.

Minimized Risk of Product Damage: With Pacorr’s Box Compression Tester Price, you can be confident that your packaging will hold up under pressure, reducing the likelihood of product breakage.

Cost Savings: Testing your packaging to determine the correct strength can help you reduce over-engineering costs while ensuring your packaging is strong enough to protect the product.

Compliance with Industry Standards: Our Box Compression Tester helps you meet industry standards and ensures that your packaging will pass any regulatory testing.

Conclusion

At Pacorr, we offer a top-of-the-line Box Compression Tester designed to help you test the strength and durability of your packaging. Our equipment is engineered for precision and ease of use, helping you ensure that your packaging meets the highest standards of quality and durability. With our Box Compression Tester, you can be confident that your products will reach their destination safely and without damage.

For more information or to schedule a demonstration, visit pacorr.com.

FAQ Section

What is the price of the Box Compression Tester? The price of Pacorr’s Box Compression Tester ranges between INR 70,000 to INR 1,50,000 depending on the model and specifications. Contact us for a personalized quote.

How accurate is the Box Compression Tester? Our Box Compression Tester provides highly precise and repeatable results, allowing you to measure the strength of your packaging materials with confidence.

What types of materials can be tested with the Box Compression Tester? The tester can be used to test a variety of materials, including cardboard, corrugated boxes, paperboard, and other types of packaging materials.

Is the Box Compression Tester easy to operate? Yes, Pacorr’s Box Compression Tester is designed with a user-friendly interface, making it simple to operate and set up for different test scenarios.

How can I purchase a Box Compression Tester from Pacorr? To purchase a Box Compression Tester or request more information, please visit pacorr.com or contact our sales team.

#BoxCompressionTester#BoxCompressionTesting#BoxCompressionTesterComputerized#BoxCompressionTesterPrice

0 notes

Text

Box Compression Tester Essential for Packaging Strength and Durability - Pacorr Testing Instruments

The Box Compression Tester is an indispensable tool for industries involved in packaging and logistics. It plays a critical role in evaluating the strength and durability of corrugated boxes, ensuring they can withstand the pressures of transportation and storage. In this article, we’ll explore the significance of the Box Compression Tester and how it contributes to enhancing the quality and reliability of packaging for businesses worldwide.

Introduction to Box Compression Testing

The Box Compression Tester measures the force required to crush or compress a box. This test is essential in determining the structural integrity of packaging materials, especially those used in shipping and handling processes. By simulating real-world conditions, it helps manufacturers identify potential weaknesses in their packaging design and materials, enabling them to make necessary adjustments before reaching the market.

Strength Begins with Quality – Try the Box Compression Tester Today!

For packaging to be effective, it must endure various external pressures such as stacking, transportation, and handling. The Box Compression Tester ensures that packaging maintains its strength and protects its contents throughout these processes.

How the Box Compression Tester Works

The Box Compression Tester operates by applying a controlled amount of force to a box placed on a testing platform. The machine gradually compresses the box until it fails or collapses, and the tester records the amount of force required to reach this point. This force is then used to assess the box's ability to handle pressure without losing its shape or structure.

Key Features of the Box Compression Tester

Accurate Force Measurement: The tester provides precise readings of the compressive force, helping businesses assess the packaging’s ability to withstand external pressure.

Versatility: Suitable for testing various box types, including those made from corrugated cardboard, paperboard, and other materials.

User-friendly Interface: Equipped with a digital control system, the Box Compression Tester ensures ease of use while allowing for the customization of test parameters such as test speed and compression rates.

Real-time Data and Reports: Modern testers provide immediate feedback, enabling companies to make adjustments to their packaging designs quickly.

Durability: Built with high-quality materials, the Box Compression Testing is designed for long-term use in a variety of industrial environments.

Importance of Box Compression Testing

Ensures Packaging Durability: Packaging that cannot withstand the rigors of shipping and storage can lead to damage, returns, and customer dissatisfaction. The Box Compression Tester helps identify these vulnerabilities early, preventing costly mistakes.

Improves Product Safety: Stronger packaging ensures that products are safely protected during transit, reducing the likelihood of damage to fragile or sensitive items.

Reduces Packaging Costs: By testing packaging designs and materials, businesses can optimize packaging costs without sacrificing protection, leading to a more cost-effective solution in the long run.

Compliance with Industry Standards: Many industries have specific packaging standards and regulations that need to be met. The Box Compression Tester ensures that packaging designs comply with these requirements, mitigating the risk of fines or penalties.

Visit the Official Website for the Full Report

Applications of Box Compression Testing

E-commerce and Retail: With the rise of online shopping, product packaging must be robust enough to survive long shipping routes and handling. The Box Compression Tester ensures that e-commerce and retail businesses can deliver their products safely.

Food and Beverage Industry: Packaging is crucial in maintaining the quality and safety of food and beverages. The Box Compression Tester ensures that packaging can handle the stresses of distribution and shelf storage without compromising the contents.

Pharmaceuticals and Medical Devices: Sensitive medical products and pharmaceutical goods require extra care during transportation. The Box Compression Tester helps test packaging for compliance with health and safety standards, ensuring safe delivery to healthcare providers and consumers.

Consumer Electronics: Electronics often come in protective packaging to prevent damage. The Box Compression Tester ensures that these products are safe from the rigors of handling and transportation, reducing the risk of costly returns.

Advantages of Using the Box Compression Tester

Enhances Packaging Quality: With accurate test results, companies can design stronger, more durable packaging that will better withstand the challenges of shipping and handling.

Boosts Consumer Confidence: High-quality packaging not only protects products but also reflects a brand's commitment to delivering value and care to its customers.

Improves Efficiency: By identifying weaknesses in packaging designs early, businesses can avoid rework and redesigns, streamlining their production and reducing delays in shipping.

Conclusion

The Box Compression Tester is a crucial tool in the modern packaging industry. By providing precise measurements and data, it enables companies to ensure their packaging can withstand the forces encountered during transportation and storage. Investing in a reliable Box Compression Tester from a trusted brand like Pacorr ensures that packaging designs meet the highest standards of quality and durability.

For the full report, visit our official website now!

By incorporating this tool into their testing processes, businesses can improve their packaging’s performance, reduce costs, and ultimately enhance their customers' satisfaction. Whether you're in e-commerce, retail, food, pharmaceuticals, or electronics, the Box Compression Tester is a vital part of your quality control process.

For more information, visit Pacorr Testing Instruments.

#BoxCompressionTester#BoxCompressionTesting#BoxCompressionTesterComputerized#BoxCompressionTesterPrice

0 notes

Text

Box Compression Tester Reliable Packaging Strength Testing | Pacorr

In the world of packaging, it is crucial to ensure that products stay intact during transit. For manufacturers, packaging designers, and logistics providers, understanding the compressive strength of boxes is essential. Pacorr’s Box Compression Tester is a state-of-the-art device designed to simulate real-world conditions that packaging undergoes during shipping, storage, and handling. It provides precise and reliable data on the durability and strength of boxes.

What is a Box Compression Tester?

A Box Compression Tester is an essential tool used to assess the strength and durability of packaging materials, specifically corrugated boxes. It measures the amount of pressure a box can handle before it fails or collapses. By simulating the stress packaging faces during shipping, this device ensures that manufacturers can create boxes that will safeguard their products and prevent damage.

Pacorr’s Box Compression Tester meets international testing standards, ensuring that the results are both accurate and consistent. The tester is designed to evaluate packaging materials of all sizes, from small cartons to large boxes, providing businesses with the information needed to improve the quality of their packaging.

Applications of the Box Compression Tester

The Box Compression Testing is beneficial for various industries:

Packaging Manufacturers: Packaging manufacturers use the tester to evaluate the strength of corrugated boxes, ensuring that they meet industry standards for durability.

Retail & E-commerce: Retailers and e-commerce companies rely on the tester to verify that their packaging can withstand the rigors of shipping, preventing damage to products and enhancing customer satisfaction.

Food & Beverage Industry: The packaging used for food products must be strong enough to prevent contamination or spoilage. The tester ensures that food packaging meets the required standards for transport and handling.

Electronics & Consumer Goods: For fragile products such as electronics, robust packaging is essential to prevent damage. The Box Compression Tester helps ensure that boxes are sufficiently durable to protect these sensitive items during transportation.

Quality Control & Research: Testing packaging materials is critical in research labs and quality control environments. The Box Compression Tester allows for precise evaluation and testing of packaging materials to ensure reliability and quality compliance.

Benefits of the Box Compression Tester

Precise Testing: The tester delivers highly accurate measurements of the compressive strength of packaging materials. It ensures that businesses can rely on consistent, repeatable results.

Versatility: Whether you need to test small cartons, large boxes, or other types of packaging, the Box Compression Tester is equipped to handle a variety of sizes and materials, offering businesses comprehensive testing solutions.

Enhanced Packaging Quality: By providing reliable testing data, the Box Compression Tester helps manufacturers optimize their packaging design. This results in fewer product damages during shipping and reduced costs associated with returns and replacements.

Ease of Operation: The user-friendly interface makes it easy for operators to perform tests, monitor results, and analyze packaging strength without requiring specialized training or complex setup.

Compliance with Industry Standards: The Box Compression Tester complies with a variety of international standards, including ASTM and ISO, ensuring that your packaging meets global quality and safety requirements.

How Does the Box Compression Tester Work?

The Box Compression Tester Price operates by applying a controlled compressive force to the packaging material. A box is placed between two plates, and the tester slowly applies pressure until the box collapses. The tester measures the force applied at the point of failure, allowing manufacturers to evaluate the box’s compressive strength.

The Box Compression Tester provides digital readouts of the maximum compressive force the packaging material can withstand before it fails. This data is essential for businesses to determine if their packaging can endure the stresses of transit and storage.

Conclusion

The Box Compression Tester is an invaluable tool for industries that depend on the durability of packaging materials. Pacorr’s advanced technology ensures that your boxes can withstand the pressures of shipping and handling, ultimately leading to reduced product damage, lower shipping costs, and improved customer satisfaction. Trust Pacorr to help you achieve packaging excellence.

FAQs

Q1: What types of boxes can the Box Compression Tester assess? A1: The Box Compression Tester is capable of testing a variety of packaging materials, including corrugated boxes, paperboard, and other flexible packaging types, to measure their compressive strength.

Q2: How can the Box Compression Tester improve packaging? A2: By providing precise data on the compressive strength of packaging materials, the tester helps manufacturers optimize their packaging design, ensuring that boxes are strong enough to protect products during transport and storage.

Q3: Which industry standards are followed by the Box Compression Tester? A3: The Box Compression Tester complies with international standards such as ASTM D4169, ISO 2233, and others, ensuring reliable and consistent testing results that meet global quality requirements.

Q4: Can the Box Compression Tester test large boxes? A4: Yes, the Box Compression Tester is versatile and can be used to test both small and large packaging, making it ideal for a variety of product sizes and packaging needs.

Q5: What are the benefits of using the Box Compression Tester for e-commerce businesses? A5: For e-commerce businesses, the Box Compression Tester ensures that packaging can withstand the rigors of shipping, reducing the risk of product damage and returns. It also helps optimize packaging to reduce shipping costs by ensuring the right balance of strength and material usage.

#BoxCompressionTester#BoxCompressionTesting#BoxCompressionTesterComputerized#BoxCompressionTesterPrice

0 notes

Text

Pacorr’s Box Compression Tester Ensuring Packaging Strength and Reliability

At Pacorr Testing Instruments Pvt. Ltd., we understand that packaging quality directly impacts product safety during transport and storage. Our Box Compression Tester is designed to provide accurate testing of the strength and durability of packaging materials, ensuring they can withstand the stresses of shipping and handling. This crucial testing equipment helps manufacturers safeguard their products, reduce damages, and ensure compliance with global packaging standards.

What is a Box Compression Tester?

A Box Compression Tester is an essential tool used to evaluate the compressive strength of packaging materials, particularly boxes and cartons. This device simulates the compressive forces that packaging materials endure during transport, stacking, and storage. By identifying weak spots in the packaging design, manufacturers can improve their packaging to prevent product damage, ensuring better protection during transit and distribution.

With the Box Compression Tester from Pacorr, manufacturers can conduct thorough tests on a variety of packaging materials, including corrugated boxes, fiberboard, and cartons, providing vital data to improve packaging strength and reliability.

Key Features of the Box Compression Tester

Accurate Load Testing: The tester provides highly accurate readings of the maximum load that packaging can handle before failure, helping you determine the strength of the box.

Versatile Testing Capability: It is designed to accommodate different box sizes and materials, making it ideal for a wide range of packaging applications.

User-Friendly Interface: The Box Compression Testing is easy to operate, with a simple interface that makes testing efficient and straightforward.

Compliant with Global Standards: It adheres to internationally recognized standards such as ASTM D642 and ISO 12048, ensuring that your packaging is tested according to the highest quality benchmarks.

How Does the Box Compression Tester Work?

The Box Compression Tester functions by applying gradual pressure to a box placed between two compression plates. One plate remains stationary, while the other applies downward pressure. As the pressure increases, the tester measures how much force the box can handle before it deforms or collapses. This simulation of real-world stress allows manufacturers to assess the durability of packaging materials and make necessary adjustments to improve strength.

Why Is a Box Compression Tester Important?

Prevents Product Damage: By ensuring that packaging can withstand the pressures of transport, the Box Compression Tester helps reduce the risk of damage to products.

Ensures Compliance: The device helps manufacturers meet international packaging standards like ASTM D642 and ISO 12048, demonstrating commitment to quality.

Reduces Operational Costs: Early detection of weak packaging can prevent costly returns and product damage, ultimately saving on operational expenses.

Enhances Brand Reputation: Packaging that can withstand the rigors of transport boosts customer satisfaction and increases trust in the brand.

Applications of the Box Compression Tester

Packaging Manufacturers: Essential for testing the strength of cardboard boxes, fiberboard, and other packaging materials.

Logistics Companies: Used to assess whether packaging will endure the forces of stacking, transit, and handling.

Quality Control Labs: Perfect for testing and improving packaging materials before they are used in production, ensuring they meet the necessary durability requirements.

E-Commerce Companies: Essential for ensuring that products remain safe during long-distance shipping and delivery.

Benefits of Using a Box Compression Tester

Improved Packaging Quality: By identifying weaknesses in the packaging design, manufacturers can ensure better protection for their products.

Cost Savings: Testing your packaging in advance can prevent costly shipping damage and reduce returns.

Compliance Assurance: The Box Compression Tester Price helps businesses ensure their packaging complies with global standards like ASTM and ISO.

Enhanced Efficiency: With fast and reliable testing, the Box Compression Tester improves the efficiency of your packaging quality assurance processes.

Conclusion

The Box Compression Tester from Pacorr Testing Instruments Pvt. Ltd. is a crucial tool for businesses involved in packaging and shipping. It helps manufacturers improve packaging design, prevent product damage, and comply with global packaging standards. Investing in a Box Compression Tester ensures that your products are protected during transit, leading to increased customer satisfaction and a reduction in shipping-related issues.

FAQ:

Q1: What does a Box Compression Tester do? A Box Compression Tester evaluates the strength of packaging materials by simulating the pressures they endure during transport, helping manufacturers ensure the packaging will protect the product effectively.

Q2: What standards does the Box Compression Tester meet? The Box Compression Tester meets global standards, including ASTM D642 and ISO 12048, ensuring accurate and internationally recognized testing results.

Q3: Can the Box Compression Tester be used for various types of packaging? Yes, it is versatile and can be used to test different types of packaging, including corrugated boxes, cartons, and fiberboard.

#BoxCompressionTester#BoxCompressionTesting#BoxCompressionTesterComputerized#BoxCompressionTesterPrice

0 notes

Text

Pacorr's Box Compression Tester Ensuring Packaging Strength and Durability

In today’s fast-paced logistics and retail world, packaging plays a critical role in protecting products during transportation and storage. One of the most effective ways to assess packaging durability is through the use of a Box Compression Tester. This testing instrument helps businesses measure the strength of their boxes, ensuring that they can withstand various pressures in the supply chain, from stacking to shipping.

What is a Box Compression Tester?

A Box Compression Tester is a specialized device used to evaluate the compressive strength of packaging materials, especially corrugated boxes. By applying a controlled force, this machine simulates the conditions boxes will face during shipping and storage, helping manufacturers and retailers ensure their packaging is strong enough to protect the products inside.

Why is Box Compression Testing Essential?

In the world of packaging, durability is paramount. Without proper testing, boxes can fail under the pressure of transportation, leading to damaged goods, dissatisfied customers, and higher costs. The Box Compression Testing allows manufacturers to evaluate how well their boxes will hold up under real-world conditions, preventing potential failures that could damage products and harm the business’s reputation.

Testing a box’s ability to resist compression forces helps in selecting the right materials and design, ensuring the box will hold its shape and strength throughout the journey. It provides a clear understanding of how much pressure the box can take before it begins to deform or fail.

How Does a Box Compression Tester Work?

The Box Compression Tester works by applying a steady compressive force on the packaging material, simulating the weight and pressure a box would face during storage or shipping. The machine uses hydraulic or pneumatic systems to compress the box between two platens, and the force is gradually increased until the box fails or reaches a set limit. Throughout the test, critical data such as force, deformation, and failure point are recorded for analysis.

Key features of the Box Compression Tester include:

Precise Load Measurement: Equipped with digital load cells for accurate and reliable force measurement.

Adjustable Speed: Offers variable speeds for testing under different conditions.

Data Logging: Automatically records and stores test data for easy review and analysis.

User-Friendly Interface: Modern machines feature touchscreen controls for easy operation and result tracking.

Applications of Box Compression Testing

The Box Compression Tester is widely used across various industries to ensure packaging strength, including:

Packaging: Ensures corrugated boxes can endure the rigors of transportation and handling.

Food and Beverage: Verifies packaging integrity to protect perishable products during shipping.

Pharmaceuticals: Helps ensure packaging safeguards medicinal products during distribution.

E-commerce: With online shopping growing, strong packaging is crucial for preventing damage during transit.

Consumer Goods: Protects items like electronics, clothing, and other goods from external pressures during shipment.

The Advantages of Using Pacorr’s Box Compression Tester

Choosing Pacorr’s Box Compression Tester Price guarantees top-notch testing accuracy and reliability. Designed with advanced technology and user-centric features, it’s perfect for manufacturers looking to maintain consistent packaging quality. Some advantages of Pacorr’s Box Compression Tester include:

Accurate Testing: With advanced digital systems, the tester provides precise and repeatable results.

Intuitive Design: Easy-to-use interface ensures seamless operation, even for users with limited technical knowledge.

Long-Term Durability: Built with high-quality materials, Pacorr’s tester is made to last and provide reliable results over time.

International Compliance: Meets global standards like ASTM D642 and ISO 12048, ensuring regulatory compliance for packaging materials.

Understanding Industry Standards in Box Compression Testing

To maintain consistency and reliability in packaging testing, Box Compression Testing is governed by international standards. These standards define testing procedures, including the specific forces and conditions to be used for testing various types of boxes and packaging materials.

Common industry standards include:

ASTM D642: A widely recognized standard for testing the compression strength of corrugated fiberboard containers.

ISO 12048: International standard that defines guidelines for testing the compression resistance of boxes, ensuring that packaging materials can withstand shipping conditions.

ISO 2234: Specifies tests for packaging materials to withstand dynamic conditions during transport, ensuring box strength during movement and stacking.

By following these standards, businesses can ensure that their packaging will meet global requirements and will perform under real-world conditions.

How to Analyze Box Compression Test Results

After conducting a Box Compression Test, it’s important to evaluate the results carefully to assess the box’s suitability for transportation. Key aspects to consider include:

Compression Strength: The maximum force the box can endure before failing. This metric is essential in determining whether the box is strong enough to protect the product during shipping.

Failure Point: The force at which the box starts to show structural failure, which can guide manufacturers in designing stronger packaging.

Deflection: The amount of deformation the box undergoes under load. A minimal deflection indicates a well-designed, durable box.

Conclusion: Strengthening Packaging with Pacorr’s Box Compression Tester

The Paper and Packaging Testing Instruments is an essential tool for ensuring packaging quality, preventing product damage, and enhancing customer satisfaction. Whether for food, pharmaceuticals, electronics, or e-commerce, testing your boxes’ compressive strength is critical to maintaining packaging integrity throughout shipping and handling.

With Pacorr’s Box Compression Tester, manufacturers can ensure their packaging meets industry standards and provides reliable protection for their products. By investing in high-quality testing equipment, businesses can save on costly returns, improve packaging designs, and offer products that reach customers in perfect condition. Pacorr’s tester helps guarantee that your packaging is up to the task, ensuring long-term reliability and brand trust.

#BoxCompressionTester#BoxCompressionTesting#BoxCompressionTesterComputerized#BoxCompressionTesterPrice

0 notes

Text

Box Compression Tester Ensuring the Strength and Durability of Packaging

At Pacorr Testing Instruments, we recognize the importance of reliable packaging in protecting products during transportation and storage. One essential tool for ensuring packaging strength is the Box Compression Tester. This device helps manufacturers assess whether their packaging can endure the forces it will face during real-world handling and shipping.

In this article, we will explain what a Box Compression Tester is, how it works, its applications, and the key standards it complies with. Whether you're in manufacturing, logistics, or retail, understanding the Box Compression Tester can help you ensure your packaging is fit for purpose, reducing the risk of product damage and improving overall quality.

What is a Box Compression Tester?

A Box Compression Tester is a testing device designed to measure the compressive strength of packaging, specifically corrugated boxes, containers, and other packaging materials. The tester simulates the stacking process by applying pressure to the packaging until it either deforms or collapses. This test provides valuable insights into how well the box can withstand the pressure it will encounter during storage, transport, and handling.

By applying uniform pressure across the surface of the box, the Box Compression Tester helps manufacturers and packaging designers ensure that their products are safe for transit and delivery, reducing the risk of product damage and improving packaging reliability.

How Does a Box Compression Tester Work?

The Box Compression Tester works by replicating the pressures that packaging will experience during transit, stacking, and storage. Here’s how the test is conducted:

Sample Preparation: The box is placed between two parallel compression plates. These plates are aligned to apply uniform pressure across the box.

Compression Testing: The tester gradually applies pressure to the box, increasing the load step by step. This simulates the stacking process and conditions encountered during transport.

Measurement and Results: As the force increases, the box begins to deform or collapse. The machine records the amount of pressure applied at the point of failure, providing valuable data on the box’s strength and durability.

This test data helps manufacturers determine if the packaging is robust enough for shipping and handling, ensuring that the contents remain safe during transit.

Applications of the Box Compression Tester

The Box Compression Tester is vital across various industries where packaging plays a crucial role in product protection. Here are some key industries where this testing equipment is widely used:

1. Packaging Industry

Manufacturers of corrugated boxes, cartons, and other packaging materials rely on the Box Compression Tester to evaluate the strength and durability of their products. The tester helps them ensure that their packaging can endure the weight and pressures it will face during shipping and handling.

2. Retail and E-commerce

Retailers and e-commerce companies need packaging that can withstand the rigors of shipping. By using the Box Compression Testing, these businesses ensure that their packaging remains intact and secure, preventing costly product returns due to damage during transit.

3. Logistics and Supply Chain

In logistics, packaging strength is critical for the safe and efficient transport of goods. The Box Compression Tester ensures that packaging can handle the stacking forces it will encounter while stored or in transit, reducing the likelihood of damaged products and increasing customer satisfaction.

4. Pharmaceutical and Food Packaging

In industries where the integrity of the product is essential—such as pharmaceuticals and food packaging—Box Compression Testing ensures that packaging protects sensitive products from contamination or physical damage during transportation.

Benefits of Using a Box Compression Tester

Ensures Packaging Durability: By simulating real-world stresses, the Box Compression Tester ensures that packaging can withstand the pressures it will face, preventing product damage during transit.

Cost Savings: Testing packaging designs before production helps companies identify weaknesses early, reducing the likelihood of damaged products and the need for costly redesigns.

Quality Control: Consistent testing ensures that packaging materials meet required strength standards and maintain a high level of quality.

Compliance with Industry Standards: Adhering to packaging durability standards helps businesses stay compliant with regulations, ensuring their packaging meets industry-specific requirements.

Key Standards for Box Compression Testing

The Box Compression Tester is designed to comply with various industry standards that ensure the packaging performs optimally under transportation and handling conditions. Some of the key standards for Box Compression Testing include:

ASTM D642: This standard outlines the test method for determining the compressive strength of containers, particularly for packaging made of corrugated materials.

ISO 12048: An international standard that provides guidelines for conducting compressive strength tests on packaging to simulate transport and stacking conditions.

ISTA 3A: This standard is used to test the durability of packaging under conditions similar to those encountered during high-speed transportation, ensuring that packaging can withstand rough handling.

By adhering to these standards, manufacturers can ensure that their packaging is fit for purpose and complies with industry regulations.

Conclusion

The Box Compression Tester is an indispensable tool for ensuring that packaging is strong and durable enough to protect products during transportation and storage. By providing insights into the compressive strength of packaging, the tester helps manufacturers and businesses create reliable, cost-effective solutions for product protection.

At Pacorr Testing Instruments, we offer high-quality Box Compression Testers designed to deliver accurate results and help you optimize your packaging. Whether you're in the manufacturing, logistics, or retail industry, our Box Compression Tester Price is the ideal solution for ensuring that your packaging is capable of withstanding the rigors of transit and handling.

For more information about our Box Compression Testers and other testing equipment, visit pacorr.com.

FAQs

1. What is the purpose of a Box Compression Tester? A Box Compression Tester measures the strength and durability of packaging materials, ensuring they can withstand the pressure and stacking forces they will face during transportation and storage.

2. Which industries benefit from using Box Compression Testers? Industries such as packaging, retail, logistics, e-commerce, pharmaceuticals, and food packaging benefit from using Box Compression Testers to ensure the durability of their packaging materials.

3. What standards do Box Compression Testers comply with? Box Compression Testers adhere to standards like ASTM D642, ISO 12048, and ISTA 3A, which ensure packaging can withstand stacking pressures and other stresses encountered during transportation.

#BoxCompressionTester#BoxCompressionTesting#DropTester#VacuumLeakTester#SaltSprayChamber#MeltFlowIndexTester

0 notes

Text

The Essential Role of Box Compression Tester in Packaging Quality

Packaging is more than just a protective barrier for products—it's a crucial element in ensuring the safety and integrity of goods throughout transportation and storage. Whether shipping delicate electronics or heavy-duty industrial products, the strength and durability of packaging are critical. The Box Compression Tester is an indispensable tool that helps manufacturers ensure their packaging can withstand the pressures of shipping and handling, protecting the products inside.

What Is a Box Compression Tester?

A Box Compression Tester is a testing device used to measure the compressive strength of packaging boxes. By applying a controlled amount of pressure, it simulates the stresses that packaging will face during shipping, stacking, and storage. The tester measures how much force the box can handle before it begins to buckle, collapse, or fail.

The results from these tests provide manufacturers with crucial data that can be used to optimize packaging materials and designs, ensuring the packaging can endure real-world conditions and effectively protect the products inside.

Why Box Compression Testing Is Crucial

1. Ensuring Product Safety

Packaging’s primary function is to protect the product during transit. Boxes that fail to withstand the pressures of shipping can result in product damage, returns, and customer dissatisfaction. Box Compression Testing ensures that the packaging will hold up under stacking and transportation conditions, reducing the likelihood of product damage and ensuring that products arrive safely to customers.

2. Complying with Industry Standards

Certain industries, such as food, pharmaceuticals, and electronics, have strict packaging regulations. Box Compression Testing helps manufacturers meet these regulatory standards by confirming that their packaging can handle specific strength requirements. Compliance with industry standards not only ensures the safety of the products but also helps avoid penalties, recalls, or legal issues arising from non-compliant packaging.

3. Optimizing Material Usage

By determining the minimum strength required for packaging, manufacturers can avoid over-packaging—using more material than necessary—which leads to wasted resources and higher production costs. Box Compression Testing help identify the most efficient packaging design that meets strength requirements while using the least amount of material. This optimizes both cost efficiency and environmental sustainability.

4. Enhancing Packaging Design

Box Compression Testers offer valuable insights into how packaging materials perform under pressure. By testing different box designs, materials, and thicknesses, manufacturers can pinpoint areas for improvement and make necessary adjustments to enhance packaging strength. This helps in the creation of more durable, cost-effective packaging that offers better protection for products.

Key Features of a Box Compression Tester

Accurate Compression Measurement: The tester precisely measures the force required to compress or collapse a box, providing manufacturers with accurate and reliable data to assess packaging strength.

Customizable Test Parameters: The Box Compression Tester can be adjusted to simulate various real-world conditions, such as compression speed and pressure levels, allowing manufacturers to replicate shipping conditions accurately.

User-Friendly Interface: Modern Box Compression Testers come equipped with intuitive interfaces, making them easy to operate and set up, even for those with minimal technical expertise.

Data Logging and Reporting: Many Box Compression Testers offer data logging features, enabling manufacturers to store and analyze test results over time. This data is essential for ongoing packaging improvements and quality control.

Durability and Reliability: Box Compression Testers are designed for high-frequency use and built to last, offering reliable results with minimal maintenance.

Applications of Box Compression Testers

Packaging Manufacturers: Packaging companies use Box Compression Testers to verify that their products meet strength standards before being shipped to customers.

Shipping and Logistics: Companies involved in shipping rely on Box Compression Testers to ensure that packaging can endure the stresses of transport, handling, and stacking without failing.

Retail and E-Commerce: Retailers, especially those in e-commerce, use Box Compression Testers to ensure that products arrive at their destinations intact and undamaged, reducing the risk of returns and complaints.

Food and Pharmaceutical Industries: These industries require packaging that meets strict regulations and strength standards. Box Compression Testers ensure that packaging can protect sensitive products while adhering to industry standards.

Electronics Manufacturers: Electronics manufacturers rely on Box Compression Testers to ensure that their packaging can protect fragile devices from the physical stresses they encounter during shipping.

Benefits of Using a Box Compression Tester

Better Product Protection: Box Compression Testers help verify that packaging can withstand the rigors of transport, providing reliable protection for products and reducing the risk of damage.

Cost Savings: By identifying the right amount of material needed to maintain packaging strength, Box Compression Testers help manufacturers reduce material costs and minimize waste.

Enhanced Packaging Design: The data provided by Box Compression Testing helps manufacturers improve their packaging designs, ensuring that boxes are strong, cost-effective, and efficient.

Compliance with Industry Standards: Box Compression Testers ensure that packaging meets regulatory requirements, helping manufacturers avoid potential fines, recalls, and legal complications.

Conclusion

The Box Compression Tester Price is a vital tool for any manufacturer looking to ensure the durability and strength of their packaging. By simulating real-world conditions and providing reliable testing data, this tool enables manufacturers to optimize packaging materials and designs, reduce costs, and ensure product safety during transport.

At Pacorr Testing Instruments, we offer high-quality Box Compression Testers that deliver reliable, accurate results to help manufacturers improve packaging quality. For more information on how our Box Compression Testers can enhance your packaging process, visit pacorr.com.

0 notes

Text

Boost Packaging Reliability with Pacorr’s Advanced Box Compression Tester

In today’s fast-paced industrial and e-commerce environment, packaging plays a crucial role in ensuring the safe delivery of products. Whether it's fragile electronics or heavy industrial goods, packaging must be strong enough to withstand stacking, shipping, and handling. One of the most critical tools to evaluate the strength of packaging is the Box Compression Tester—a machine designed to measure how much pressure a box can handle before collapsing. At Pacorr.com, we provide precision-engineered Box Compression Testers that set the benchmark for packaging strength testing.

Understanding the Box Compression Tester

The Box Compression Tester (BCT) is a specialized piece of lab equipment used to assess the compressive strength of corrugated boxes and cartons. It determines how much vertical load a box can endure without collapsing. This is vital information for businesses that need their products to remain intact during transport and storage.

When a product is shipped or stored, it often experiences stacking pressure. A weak box can buckle under the weight, leading to damaged goods and customer dissatisfaction. With a reliable BCT from Pacorr, businesses can test the performance of their packaging under simulated real-world conditions.

Why Compression Testing is Important

Compression testing is essential for manufacturers and packaging professionals aiming for quality control. Here's why:

Protection Against Product Damage: Helps prevent product loss due to packaging failure.

Efficient Packaging Design: Avoid overuse of packaging material while maintaining structural integrity.

Regulatory Compliance: Ensures packaging meets industry standards and certifications.

Customer Satisfaction: Delivers products safely, enhancing the customer experience and brand credibility.

Cost Reduction: Minimizes returns and replacements by reducing packaging failures.

Key Features of Pacorr’s Box Compression Tester

Pacorr’s Box Compression Testing are designed with both precision and ease of use in mind. Here are the standout features:

Digital Display: Real-time readings with high accuracy.

Custom Load Capacities: Available in various models depending on the weight capacity required.

Strong Build Quality: Built from durable materials to ensure longevity.

User-Friendly Controls: Simple operation interface for seamless testing.

Standard Compliance: Follows global testing standards including ASTM D642 and ISO 12048.

These features make Pacorr’s equipment ideal for use in quality control labs, manufacturing units, and packaging design centers.

How the Testing Works

To conduct a compression test, the box sample is placed between two compression plates. The top plate moves downward, applying pressure until the box begins to deform or fails entirely. The maximum force withstood by the box is recorded as its compressive strength.

This data is crucial for engineers and quality teams to make informed decisions about packaging design, material selection, and load-bearing limits.

Industries That Rely on BCT

A wide variety of industries benefit from compression testing of packaging:

Logistics and Warehousing: For evaluating storage conditions.

E-commerce and Retail: Ensuring goods arrive intact to end-users.

Food and Beverage: Maintaining structural integrity during bulk shipping.

Pharmaceuticals: Keeping medicines and medical devices safe.

Consumer Electronics: Preventing damage to fragile tech products.

Regardless of the sector, a dependable Box Compression Tester ensures that packaging can withstand stress during real-world usage.

Best Practices for Accurate Compression Testing

To get the most accurate and reliable results from your testing process, consider these tips:

Ensure Proper Calibration: Regular calibration ensures measurement accuracy.

Condition Boxes Before Testing: Let boxes sit in a standardized environment for 24 hours.

Use Multiple Samples: Testing a group of boxes provides more consistent and reliable data.

Document Results: Maintain detailed records for quality audits and process improvements.

Train Your Team: Make sure operators are trained to handle equipment safely and efficiently.

Why Choose Pacorr?

Pacorr is a trusted name in the field of quality testing instruments. Our Box Compression Tester Price are manufactured with precision and care, delivering high performance across industries. When you choose Pacorr, you benefit from:

Innovative Technology

Durable Engineering

Exceptional Accuracy

Dedicated Customer Support

Fast Delivery and After-Sales Service

Our goal is to empower businesses to achieve the highest standards of packaging integrity, which directly translates to better customer satisfaction and reduced losses.

Conclusion

A Box Compression Tester is not just a quality control tool—it’s an investment in brand reputation, customer trust, and operational efficiency. For businesses that want their packaging to perform under pressure—literally—Pacorr’s BCT offers the perfect solution.

Whether you’re in e-commerce, manufacturing, or logistics, testing your packaging strength is vital to delivering products safely and minimizing losses. Choose Pacorr.com for reliable, accurate, and industry-compliant testing solutions.

Explore our complete range of testing instruments at Pacorr.com and take your packaging strength to the next level.

#BoxCompressionTester#BoxCompressionTesting#DropTester#VacuumLeakTester#SaltSprayChamber#MeltFlowIndexTester

0 notes

Text

Understanding the Box Compression Tester Essential for Packaging Strength

In the realm of packaging, ensuring the safety and durability of products during transportation and storage is essential. The Box Compression Tester is an invaluable tool that helps manufacturers assess the strength of corrugated boxes and ensures that packaging materials are up to the task. This article delves into the importance of Box Compression Testing, how the tester works, and why it is a must-have for businesses focused on packaging quality.

What is a Box Compression Tester?

A Box Compression Tester is a specialized piece of equipment designed to measure the compressive strength of packaging boxes, typically corrugated cartons. By subjecting a box to increasing pressure, the tester simulates the weight and force boxes endure during stacking, shipment, and storage. This test is vital for determining the ability of a box to protect the contents inside during transit.

At Pacorr, we offer a Box Compression Tester that is engineered to meet the highest standards, offering businesses reliable, repeatable results for all types of corrugated boxes, from single-wall to multi-wall constructions. Whether you’re testing for structural integrity or load-bearing capacity, our tester provides the precision you need.

How Does the Box Compression Tester Operate?

The operation of a Box Compression Tester is straightforward. The test begins by placing a box on a testing platform. From here, controlled pressure is applied to the top of the box until it reaches its breaking point, which could be the point of deformation or collapse. The maximum force at which the box breaks is recorded, which indicates its compression resistance.

With the Box Compression Testing from Pacorr, the test can be adjusted to mimic real-life conditions, such as different weights and stacking heights. The tester's versatility allows businesses to simulate various scenarios, ensuring that their packaging can handle the specific pressures of transportation and storage.

Why Is a Box Compression Test Crucial?

The performance of packaging during shipping can make or break the product’s success. A box that collapses under pressure can result in damaged goods, leading to customer dissatisfaction, product returns, and additional costs. A Box Compression Tester helps businesses prevent such issues by providing precise data on packaging strength.

Here’s why using a Box Compression Tester is essential for any company involved in packaging:

Enhanced Product Protection: A properly tested box offers better protection to the product inside, minimizing the chance of damage during transit.

Cost Savings: By ensuring boxes are durable and meet performance standards, companies can avoid costly returns and re-shipping.

Industry Compliance: Many industries require specific packaging strength standards. A Box Compression Tester ensures your products are compliant with relevant regulations.

Customer Satisfaction: Durable packaging that prevents damage leads to higher customer satisfaction and reduced complaints.

Why Choose Pacorr’s Box Compression Tester?

Pacorr’s Box Compression Tester provides multiple benefits for businesses looking to enhance their packaging process:

Precise and Consistent Results: Our tester delivers highly accurate results, helping businesses maintain a high level of quality control.

Long-lasting and Reliable: Built with durable materials, Pacorr's tester is designed for long-term use and consistent performance.

Ease of Use: The tester features an intuitive interface, making it easy to operate, even for new users.

Flexible Testing Parameters: With customizable settings, businesses can test boxes under various conditions, ensuring that the packaging is ready for real-world challenges.

Meets Global Standards: Pacorr’s Box Compression Tester complies with a variety of international testing standards, providing peace of mind regarding regulatory compliance.

Conclusion

The importance of ensuring the strength and durability of packaging cannot be overstated. By investing in a Box Compression Tester Price, businesses can ensure that their packaging performs under the pressures of transit and storage, ultimately protecting products and boosting customer satisfaction.

At Pacorr, we are committed to providing high-quality testing instruments that help businesses improve their product packaging. Our Box Compression Tester offers precise, reliable results, helping you meet industry standards while improving your packaging’s overall strength.

To learn more about how Pacorr’s Box Compression Tester can help you optimize your packaging, visit pacorr.com today.

0 notes

Text

Understanding Box Compression Tester A Key to Packaging Durability

Introduction

In the fast-paced world of shipping and logistics, ensuring that your packaging can withstand the pressure it will face during transportation and storage is essential. Whether shipping delicate products across the globe or ensuring that boxes stay intact on store shelves, reliable packaging is critical. One of the best tools to guarantee packaging strength is a Box Compression Tester (BCT).

A Box Compression Tester is an essential piece of equipment that measures the strength of packaging materials such as corrugated cardboard boxes by simulating the forces they will endure during shipping and storage. By understanding how much weight a box can handle before it collapses, businesses can ensure their packaging will protect their products from start to finish.

What is a Box Compression Tester?

A Box Compression Tester measures the compressive strength of packaging boxes. Typically, it simulates the stress experienced by boxes in real-world environments, applying pressure to the box until it reaches failure. This test is often performed by placing a box on a machine that applies constant pressure to the sides and top to measure at which point the box buckles, collapses, or shows significant damage.

Such testing ensures the box can withstand stacking pressure and transit conditions that it would normally face. While corrugated cardboard is the most common material tested, Box Compression Testers can evaluate a wide variety of box types and materials used in packaging.

Why is a Box Compression Tester Crucial?

Ensures Packaging Strength: The Box Compression Test ensures that packaging holds up under pressure, protecting both products and consumer trust. Weak packaging can cause breakages and lead to customer dissatisfaction, higher costs, and damage to a brand���s reputation.

Cost-effective Packaging Solutions: With accurate compression testing, companies can experiment with various box materials and structures to determine the most durable yet cost-efficient packaging solutions. This optimization helps reduce waste and improves profit margins.

Enhanced Product Safety: By evaluating packaging strength early, businesses can avoid product damages during transit, leading to fewer returns, claims, and complaints.

Meets Industry Standards: Many shipping carriers, retailers, and regulatory agencies require packaging testing to comply with standards. Performing compression tests on packaging ensures that your products meet the necessary shipping regulations, reducing the likelihood of delays or rejected shipments.

How Does Box Compression Testing Work?

Preparing the Box for Testing: The box is placed on the compression tester’s platform, where the machine is set up according to specific parameters—such as rate of compression or desired test duration. These parameters guide how the machine applies pressure.

Testing: The tester applies a uniform pressure to the box from above. This simulates the conditions packaging would encounter during stacking in warehouses and containers. The tester’s load cells record the applied force and the response of the box, noting any signs of failure or deformity.

Recording Data: The system tracks critical data, including the compressive force the box can endure, its deflection, and the moment it begins to collapse. This data gives valuable insights into the strength of the packaging material and its ability to withstand pressure.

Why Should You Use a Box Compression Tester?

Accuracy and Consistency: Provides precise and repeatable testing results every time.

Material & Design Testing: Supports testing of different materials and custom box designs, giving businesses flexibility in their packaging approach.

In-depth Analysis: Helps analyze packaging durability, optimizing strength while minimizing material waste.

Regulatory Compliance: Ensures packaging complies with safety and shipping regulations, particularly for international shipping.

Conclusion

For businesses looking to improve their packaging processes and ensure their products make it safely to customers, investing in a Box Compression Tester is a smart decision. Strong, durable packaging goes hand-in-hand with reducing operational costs and enhancing customer satisfaction. A reliable Box Compression Tester price helps you achieve this by giving you the tools to rigorously evaluate packaging durability before it leaves your warehouse.

If you're looking for cutting-edge Box Compression Testers to improve your packaging performance, head over to labzenix.com for more information. We offer advanced testing solutions that ensure your packaging is tough enough to stand up to any challenge.

0 notes