#CNC Machining Melbourne

Text

Parish Engineering: Your Trusted Partner For Precision CNC Machining In Melbourne

At Parish Engineering, we pride ourselves on delivering top-quality, precision-manufactured turned components to a wide variety of industries. As a leading provider of CNC machining services in Melbourne, we utilize the latest technologically advanced Swiss-style sliding headstock and multi-axis CNC machines to produce components that meet or exceed the highest standards of accuracy and functionality.

With our team of highly skilled engineers and state-of-the-art equipment, we are able to offer competitive pricing without compromising on quality. We specialize in machining intricate, small and slender components for a range of materials including Mild Steels, Stainless Steels, Brass, Copper, Titanium, and other exotic materials.

Whether you require simple or complex turned components, Parish Engineering has the expertise and resources to get the job done efficiently and cost-effectively. Contact us today to discuss your CNC machining needs in Melbourne.

0 notes

Text

Custom CNC Router Solutions: Meeting Unique Manufacturing Needs

In the fast-evolving landscape of modern manufacturing, custom CNC router solutions have become indispensable for businesses seeking precision, efficiency, and flexibility. As industries demand increasingly specialised components and products, companies like MadBytes are stepping up to offer tailored CNC machine solutions that cater to these unique needs. Whether you're looking for a CNC machine for sale in Melbourne or require a custom CNC router, MadBytes is a trusted name in the field.

Why Custom CNC Router Solutions?

The manufacturing sector today requires equipment that can adapt to diverse and complex tasks. A custom CNC router provides the versatility to meet these demands, allowing manufacturers to produce intricate designs and components with unmatched accuracy. By investing in a tailored CNC solution, businesses can enhance their production capabilities, reduce waste, and improve overall efficiency.

The Role of MadBytes in CNC Solutions

MadBytes, a leading CNC machine supplier, understands the importance of customisation in modern manufacturing. With years of experience and a commitment to innovation, MadBytes offers a range of CNC solutions that are designed to meet specific industrial requirements. From flatbed nesting CNC machines to advanced multi-axis routers, their products are built to deliver high performance and reliability.

Flatbed Nesting CNC Machines

One of the standout offerings from MadBytes is the flatbed nesting CNC machine. This type of CNC router is ideal for optimising material usage and streamlining the production process. By nesting multiple parts within a single sheet, manufacturers can significantly reduce material waste and increase productivity. Whether you're producing cabinetry, signage, or complex components, a flatbed nesting CNC machine from MadBytes can make a substantial difference in your operations.

Custom CNC Router Solutions

MadBytes excels at providing custom CNC router solutions tailored to specific industry needs. By working closely with clients, they ensure that every machine is configured to meet precise operational requirements. This bespoke approach not only enhances the functionality of the equipment but also maximises its efficiency. Customisation options include varying bed sizes, spindle configurations, and software integrations, ensuring that every aspect of the machine aligns with the client's needs.

Finding the Right CNC Machine for Sale in Melbourne

For businesses based in Melbourne, finding the right CNC machine can be a game-changer. MadBytes offers a wide selection of CNC machines for sale in Melbourne, catering to various industries and applications. Whether you're a small workshop or a large manufacturing plant, their team can help you identify the perfect machine to boost your production capabilities. With a focus on quality and customer satisfaction, MadBytes stands out as a premier CNC machine supplier in the region.

Conclusion

In today's competitive manufacturing environment, having the right tools is crucial. Custom CNC router solutions from MadBytes provide businesses with the flexibility and precision they need to stay ahead. Whether you're in need of a flatbed nesting CNC or a specific custom CNC router, MadBytes has the expertise and products to meet your requirements. For those in Melbourne, the search for a reliable CNC machine supplier ends with MadBytes, offering an extensive range of CNC machines for sale that can transform your manufacturing process.

#CNC Machine Supplier#Custom CNC Router#CNC Machine For Sale Melbourne#Flatbed Nesting CNC#CNC Router Machine Melbourne#CNC Machine Suppliers#CNC Router For Sale Melbourne#Edge Bander For Sale

0 notes

Text

Plywood Cut to Sizes Melbourne | Viking Woodworks

Viking Woodworks is an Australian based family enterprise and was established in 2010. Since then Viking Woodworks has expanded the services it offers. We have achieved this by listening to our customers every step of the way, our customers and our staff are our most important assets.

0 notes

Text

Everything You Need to Know About Plastic Fabrication in Melbourne: Techniques, Applications, and Key Players

Plastic fabrication is an essential part of modern manufacturing, with applications spanning a wide range of industries. Whether it’s custom components for automotive purposes, signage for businesses, or medical equipment parts, plastic fabrication plays a crucial role. In Melbourne, plastic fabrication has grown into a specialized industry, catering to both large-scale manufacturing and bespoke projects for small businesses and individuals.

In this comprehensive blog, we’ll explore the different aspects of plastic fabrication in Melbourne, including the various techniques used, industries that rely on it, and notable companies in the field. We will also look at the reasons why Melbourne is an important hub for plastic fabrication and what sets it apart in terms of innovation, sustainability, and expertise.

What is Plastic Fabrication?

Plastic fabrication refers to the process of designing, forming, and assembling plastic materials into finished products or parts. This can involve a variety of methods, including cutting, welding, thermoforming, and molding, depending on the type of plastic and the intended use of the product.

Plastic is a versatile material that can be molded into a vast array of shapes and sizes, offering durability, flexibility, and cost-effectiveness. Because of these qualities, plastic fabrication has become increasingly popular across industries such as automotive, medical, retail, and construction.

Why Melbourne is a Hub for Plastic Fabrication

Melbourne is known for being one of Australia’s key manufacturing centers, with a strong emphasis on innovation and precision in industrial processes. Plastic fabrication in Melbourne has thrived due to several factors:

Diverse Market Demand: Melbourne's economy is a mix of industries, from manufacturing to healthcare and technology, all of which require plastic components. This diverse demand ensures a steady growth in plastic fabrication.

Skilled Workforce: The city is home to a highly skilled workforce with expertise in advanced manufacturing techniques, engineering, and design. This ensures that plastic fabrication projects are completed with precision and quality.

Innovative Industry Practices: Melbourne-based fabricators often adopt the latest technologies and sustainable practices. The city’s emphasis on environmentally friendly manufacturing has pushed companies to explore recycled materials and eco-friendly processes.

Access to Suppliers: Proximity to both local and international suppliers allows fabricators to source the best materials and components for their projects.

Plastic Fabrication Techniques

Various plastic fabrication methods are used depending on the type of plastic, the complexity of the design, and the desired end result. Here are some of the most common techniques used by fabricators in Melbourne:

1. CNC Machining

CNC (Computer Numerical Control) machining is a method of precisely cutting plastic materials to a desired shape using automated tools. The process is highly accurate, allowing for the creation of intricate designs and complex parts. CNC machining is especially popular in the automotive and electronics industries, where precision is crucial.

In Melbourne, CNC machining is frequently used for custom parts and prototypes. By leveraging this technology, fabricators can create components with tight tolerances and minimal material waste.

2. Laser Cutting

Laser cutting involves using a high-powered laser to cut or engrave plastic sheets. This method is highly precise and can be used to create detailed patterns, sharp edges, and smooth finishes. Laser cutting is often employed in creating signage, display items, and other decorative or functional products.

In Melbourne’s retail and signage industries, laser cutting is a popular choice for producing custom branding materials, point-of-sale displays, and intricate architectural elements.

3. Vacuum Forming

Vacuum forming is a thermoforming process that involves heating a plastic sheet until it becomes pliable, then forming it over a mold using a vacuum. This method is typically used to create large, lightweight, and durable parts, such as packaging materials, trays, and enclosures.

Melbourne’s food and packaging industries rely on vacuum forming to produce custom packaging solutions for a variety of products, from electronics to consumables.

4. Injection Molding

Injection molding is one of the most common plastic fabrication methods, especially for mass production. In this process, melted plastic is injected into a mold where it cools and hardens into the desired shape. Injection molding is efficient, cost-effective, and ideal for producing large quantities of identical parts.

In Melbourne, injection molding is used across various industries, including automotive, medical, and consumer goods. Many of the city's plastic fabricators specialize in creating small components that require intricate molds.

5. Plastic Welding

Plastic welding is used to join two or more plastic components together. This can be done using heat or ultrasonic waves, depending on the type of plastic. Welding is essential in creating airtight or watertight seals and is commonly used in fabricating tanks, pipes, and containers.

Melbourne-based fabricators often use plastic welding in the construction and industrial sectors, particularly for custom projects that involve durable and resilient components.

6. 3D Printing

3D printing, also known as additive manufacturing, is becoming increasingly popular in plastic fabrication. This technique involves creating three-dimensional objects by layering materials based on a digital design. 3D printing offers flexibility, allowing for rapid prototyping and on-demand production of complex geometries that would be difficult to achieve through traditional methods.

In Melbourne’s tech and startup scenes, 3D printing is particularly valued for its ability to produce prototypes quickly, test new designs, and push the boundaries of innovation.

Applications of Plastic Fabrication

The versatility of plastic allows it to be used in a wide range of industries. In Melbourne, the most prominent sectors that rely on plastic fabrication include:

1. Automotive

Plastic components are essential in modern vehicle design due to their light weight and durability. Parts like dashboards, trims, and even external body panels are commonly made from plastic. Melbourne’s automotive industry depends heavily on local fabricators to produce high-quality plastic components for both production and aftermarket uses.

2. Construction

From piping systems to insulation materials, plastic plays a significant role in the construction industry. Fabricators in Melbourne produce custom plastic parts for building projects, often using methods like plastic welding and CNC machining to create durable and weather-resistant components.

3. Healthcare and Medical Devices

Plastic is widely used in the medical field for everything from disposable syringes to high-tech medical equipment. The ability to create sterile, durable, and lightweight components makes plastic an ideal material for medical applications. Melbourne’s thriving healthcare sector works closely with plastic fabricators to develop custom parts for devices and tools.

4. Retail and Signage

In the retail world, eye-catching signage and displays are critical for business branding and customer engagement. Melbourne’s plastic fabrication industry supports this demand by offering services like laser cutting and vacuum forming to create custom displays, point-of-sale materials, and decorative elements.

5. Packaging

Plastic packaging remains a dominant force in industries such as food, electronics, and consumer goods. Melbourne’s plastic fabricators often produce custom packaging solutions that are not only functional but also aesthetically appealing and eco-friendly, thanks to advances in material science and sustainability practices.

Sustainability and Eco-Friendly Practices in Plastic Fabrication

One of the key challenges for the plastic fabrication industry globally is the environmental impact of plastic waste. However, Melbourne fabricators are increasingly adopting eco-friendly practices, including the use of recycled plastics, biodegradable materials, and sustainable production processes.

In Melbourne, many plastic fabricators are focused on reducing waste through precise manufacturing techniques like CNC machining and laser cutting. These methods minimize material usage and scrap, contributing to more sustainable production.

Additionally, some fabricators offer services in recycling plastic products, helping businesses reduce their environmental footprint by turning discarded plastic into new products.

Leading Plastic Fabricators in Melbourne

If you're looking for plastic fabrication services in Melbourne, here are a few of the top companies that have earned a reputation for quality, innovation, and sustainability:

Melbourne Plastics Engineering: Specializing in custom fabrication and CNC machining, this company serves industries such as automotive, construction, and healthcare.

Plastics For Industry (PFI): Offering services ranging from injection molding to thermoforming, PFI provides tailored solutions for various sectors, including packaging and consumer goods.

C&M Plastics: Known for its focus on sustainable practices, C&M Plastics offers laser cutting, vacuum forming, and 3D printing services.

Profile Plastics: With an emphasis on high-precision fabrication, Profile Plastics caters to the medical, industrial, and retail industries, offering custom solutions for complex projects.

Conclusion

Plastic fabrication in Melbourne is an integral part of the city’s manufacturing ecosystem, providing vital components and products across a range of industries. The combination of skilled labor, cutting-edge technology, and a focus on sustainability has positioned Melbourne as a leader in plastic fabrication, both within Australia and globally. Whether you need custom parts, mass production, or innovative prototypes, Melbourne’s plastic fabrication industry offers a comprehensive range of services to meet your needs.

4o

0 notes

Text

Maximizing Your Investment — Why a Certificate III in Cabinet Making is Worth It in Melbourne

1. High Demand for Skilled Cabinet Makers

Trend: Melbourne is experiencing a boom in both residential and commercial construction, leading to a high demand for skilled tradespeople, including cabinet makers.

Benefit: By earning a Certificate III in Cabinet Making, you position yourself in a field with strong job prospects and consistent demand for skilled labour.

2. Comprehensive Skill Development

Content: The Certificate III in Cabinet Making program covers a wide range of skills, including design, construction, installation, and finishing of cabinetry. It also includes training in the use of advanced tools and machinery.

Benefit: This comprehensive training ensures you are well-prepared for various tasks and challenges in the industry, making you a versatile and valuable employee.

3. Hands-On Experience

Content: The program emphasizes practical, hands-on experience through workshops and real-world projects. This practical approach is essential for mastering the craft of cabinet making.

Benefit: Gaining hands-on experience during your training ensures that you are job-ready and can confidently handle tasks from day one in a professional setting.

4. Access to Modern Technology

Content: Students at Orange College have access to state-of-the-art facilities and equipment, including Computer-Aided Design (CAD) software and CNC machines.

Benefit: Familiarity with modern technology not only enhances your skill set but also makes you more competitive in the job market, where such expertise is increasingly sought after.

5. Pathway to Specializations

Content: The Certificate III in Cabinet Making provides a solid foundation for further specialization in areas such as custom furniture design, kitchen and bathroom cabinetry, and commercial fit-outs.

Benefit: Specializing can open up higher-paying and more specialized job opportunities, allowing you to tailor your career to your interests and strengths.

6. Strong Industry Connections

Content: Orange College has established connections with industry professionals and companies, providing students with opportunities for networking, internships, and job placements.

Benefit: These connections can be invaluable for securing employment after graduation and for ongoing professional development.

7. Entrepreneurial Opportunities

Content: The skills learned in Certificate III in Cabinet Making can also be applied to starting your own business, whether it’s a custom cabinetry shop or a restoration service.

Benefit: For those with an entrepreneurial spirit, this certification provides the knowledge and skills needed to successfully run your own business, offering greater control over your career and income.

8. Competitive Earning Potential

Trend: Skilled cabinet makers in Melbourne can command competitive salaries, with opportunities for increased earnings through specialization and experience.

Benefit: Investing in your education with a Certificate III Can lead to a financially rewarding career, providing a strong return on investment over time.

9. Job Satisfaction and Creativity

Content: Cabinet-making is a profession that combines creativity with practical skills, allowing you to see tangible results from your work.

Benefit: Many cabinet makers find great satisfaction in their craft, as it allows for creative expression and the creation of beautiful, functional pieces that clients appreciate.

10. Supportive Learning Environment

Content: Orange College offers a supportive and inclusive learning environment, with experienced instructors who are dedicated to student success.

Benefit: The college’s commitment to providing quality education and support ensures that you have the resources and guidance needed to excel in your studies and future career.

Investing in a Certificate III in Cabinet Making at Orange College is a smart choice for those looking to enter a stable and rewarding profession. The skills, experience, and industry connections you gain will maximize your career potential and provide a strong foundation for future success in Melbourne’s dynamic trades industry.

#carpentry courses in melbourne for domestic students#carpentry courses in melbourne for international students#carpentry courses melbourne for international students#Beginner to Advanced Level English Courses in Melbourne#certificate iii in cabinet making melbourne#certificate 3 in cabinet making melbourne#Beginner English Courses in Melbourne#Advanced Level English Courses in Melbourne#painting and decorating course melbourne#Advanced English Courses in Melbourne#diploma of leadership and management melbourne for international students#carpentry course melbourne#cabinet maker course melbourne#carpentry course for international students#General English Courses Melbourne#General English Program Melbourne#certificate iii in carpentry course#diploma in leadership and management melbourne#certificate iii in painting and decorating#diploma of leadership and management melbourne#certificate 3 painting and decorating#Certificate III in Cabinet Making and Timber Technology#leadership and management courses melbourne#building and construction courses melbourne#diploma of leadership and management for international students#MSF30322#MSF30322 Cabinet Making#MSF30322 Certificate III in Cabinet Making#carpentry certificate iii course#certificate iv in building and construction

0 notes

Text

CNC Cutting Services in Melbourne - Ballarat Engineering Plastics

At Ballarat Engineering Plastics, we offer a range of CNC cutting services to precision-engineered parts in Melbourne. Our state-of-the-art CNC machines enable us to accurately cut plastics, acrylics, and other materials with precision and speed. From prototyping to production, our skilled team provides expert cutting solutions for industries such as aerospace, automotive, and medical devices.

Visit: https://www.ballaratengineeringplastics.com.au/cnc-routing-service-melbourne

0 notes

Text

Timber Machining Services Melbourne

When it comes to woodworking, precision and quality are paramount. In Melbourne, timber machining services have become a cornerstone for builders, carpenters, and DIY enthusiasts alike. These services offer a range of solutions to meet the diverse needs of the woodworking community. Here, we explore what makes Timber Machining Services in Melbourne a cut above the rest.

1. Precision Cutting

Timber machining services ensure precision cutting, providing perfectly measured and shaped pieces. Whether it's for creating intricate designs or ensuring the exact fit of structural components, precision cutting minimizes waste and maximizes efficiency. The advanced machinery used can handle a variety of timber types, from softwoods to hardwoods, ensuring versatility in applications.

2. Customization Options

One of the key benefits of utilizing timber machining services is the high level of customization available. From bespoke furniture pieces to unique architectural elements, these services can tailor timber products to specific requirements. This customization extends to various finishes, edges, and profiles, allowing for truly unique creations that stand out.

3. Sustainability Practices

In an era where sustainability is crucial, many timber machining services in Melbourne are committed to eco-friendly practices. This includes sourcing timber from sustainably managed forests and employing processes that reduce waste and energy consumption. By choosing these services, clients can contribute to environmental conservation while receiving high-quality timber products.

4. Advanced Technology

Modern timber machining leverages advanced technology to enhance precision and efficiency. CNC (Computer Numerical Control) machines and CAD (Computer-Aided Design) software are commonly used to create detailed and complex designs with remarkable accuracy. This technological integration ensures that even the most intricate designs are executed flawlessly.

5. Expert Craftsmanship

Behind every machine is a skilled craftsman who ensures that each piece of timber is machined to perfection. The expertise and experience of these professionals play a vital role in delivering high-quality results. Their knowledge of timber properties and machining techniques is indispensable in achieving the desired outcome.

6. Cost-Effective Solutions

While high-quality craftsmanship might seem expensive, timber machining services in Melbourne often provide cost-effective solutions. The precision of the machines reduces material waste, and the efficiency of the processes lowers labor costs. This combination results in a final product that offers excellent value for money.

In conclusion, timber machining services in Melbourne offer a blend of precision, customization, sustainability, advanced technology, and expert craftsmanship. Whether you're a professional builder or a hobbyist, these services provide the tools and expertise needed to bring your woodworking projects to life with unparalleled quality and efficiency.

For More

Website https://jakstimber.com.au/

Facebook https://www.facebook.com/jakstimber/

Instagram urlhttp://instagram.com/jaks_timber

Ph: 0488 029 108

Mail Id: [email protected]

Working Time: Monday to Friday 8am — 4pm

#timber flooring for sale#Timber Machining Services#Timber Machining#Timber Machining Services Melbourne

0 notes

Text

Crafting Excellence: Plastic Fabrication in Melbourne.

Plastic fabrication in Melbourne is a cornerstone of the city's manufacturing landscape, offering bespoke solutions for a diverse range of industries. In this blog post, we'll explore the intricacies of plastic fabrication in Melbourne, highlighting its versatility, craftsmanship, and the vital role it plays in driving innovation across sectors.

Versatility in Applications: Tailored Solutions for Every Need

Melbourne's plastic fabrication industry caters to a wide array of applications, from signage and displays to industrial components and consumer products. With its versatility in shape, size, and material, plastic fabrication offers tailored solutions that meet the unique requirements of each project, whether it's creating intricate prototypes or large-scale production runs.

Precision Engineering: Crafting with Expertise

At the heart of plastic fabrication in Melbourne lies precision engineering and craftsmanship. Skilled fabricators leverage advanced techniques such as CNC machining, laser cutting, and thermoforming to transform raw materials into intricate and precisely engineered components. With attention to detail and a commitment to quality, Melbourne's fabricators ensure that each product meets the highest standards of excellence.

Innovative Solutions: Driving Progress and Innovation

Melbourne's plastic fabrication industry is a hotbed of innovation, constantly pushing the boundaries of what's possible with plastic materials. From developing lightweight and durable components for the automotive industry to creating cutting-edge medical devices and consumer electronics, plastic fabrication in Melbourne drives progress and innovation across sectors, shaping the future of manufacturing.

Customization and Collaboration: Partnering for Success

Collaboration is key in Melbourne's plastic fabrication industry, with fabricators working closely with clients to bring their ideas to life. Whether it's collaborating on design concepts, material selection, or production timelines, Melbourne's fabricators prioritize open communication and partnership to ensure the success of each project. By working together, clients and fabricators achieve innovative solutions that meet and exceed expectations.

Sustainable Practices: Building a Greener Future

In an era of heightened environmental awareness, sustainability is a top priority for Melbourne's plastic fabrication industry. Fabricators are adopting eco-friendly materials, reducing waste, and implementing energy-efficient processes to minimize their environmental footprint. By embracing sustainable practices, Melbourne's plastic fabricators are not only driving progress but also building a greener future for the industry and the planet.

Conclusion: Excellence in Plastic Fabrication

In conclusion, plastic fabrication in Melbourne is a testament to the city's commitment to excellence, innovation, and sustainability. With its versatility, precision engineering, and collaborative spirit, Melbourne's plastic fabrication industry continues to drive progress and shape the future of manufacturing across diverse sectors. Whether it's creating custom solutions for local businesses or contributing to global innovations, Melbourne's fabricators are at the forefront of excellence in plastic fabrication.

For More Information Visit - https://www.sjrpatterns.com.au/

Contact US - Phone - 0393303597 Email ID - [email protected] Timings - 7AM-4PM (Monday-Friday).

0 notes

Text

Boosting Industrial Efficiency: The Importance of Metal Fabrication in Melbourne

Metal fabrication in Melbourne is crucial for productivity and profitability whether one is in charge of a manufacturing plant, a construction site, or a fleet of heavy machinery. This is something that machining companies are aware of and can handle. If machines' parts are not maintained, they have a reputation for wearing out rapidly, which can lead to costly running expenses from frequent breakdowns. As soon as there are minor flaws, it's crucial to schedule skilled professionals for repairs in order to avoid any failures and to protect the individuals using the device.

An Overview of a Few Important Machining Services

CNC Machining Services: It is a precision machining in Melbourne service and CNC machines are now required for a variety of activities, including laser cutting, turret punching, and tube bending. This type of work should only be assigned to knowledgeable CNC specialists. Leading specialists offer cutting services, CNC turret punching, CNC laser cutting, and other services.

Workshop Services and Capabilities: Top machining service providers provide a wide range of workshop services and capabilities, such as CNC lathes, presses, line boring, heavy equipment, and CNC milling.

Welding Services: To weld different metal pieces, welding is necessary in all industrial buildings, including mills, factories, refineries, and other structures. The top businesses provide a variety of welding services, including TIG, ARC, and aluminium welding.

Plant Design Engineering Services: It is crucial to give careful thought to the industrial facility's design and worker safety. Working with expert businesses can help complete plumbing, structural design, electrical work, procurement, and other associated essential tasks as swiftly and simply as possible.

Install & Commission: Leading engineering service suppliers are also competent in the installation and commissioning of systems in many industries. Among the industries are sand mining, quarrying systems, and paper machine modifications.

Experts are necessary when providing the best solution for industrial issues, such as repairing crusher swing jaws or grinding large-diameter bores. Get the best pricing on solutions to a variety of industrial problems by speaking with reliable machining service suppliers.

Source

0 notes

Text

what is structural steel manufacturers

Structural steel manufacturers are companies that specialize in the fabrication of structural steel components used in construction projects. These components include beams, columns, girders, and other elements that form the framework or skeleton of buildings, bridges, industrial facilities, and other structures.

Structural steel manufacturers typically work closely with architects, engineers, and construction firms to produce steel components that meet the specific requirements and specifications of each project. They may provide services such as design assistance, fabrication, welding, surface treatment, and delivery of the steel components to the construction site.

These manufacturers often have advanced facilities equipped with cutting-edge technology for steel fabrication, including computer-aided design (CAD) software, CNC machining equipment, welding machines, and quality control systems to ensure the precision and reliability of their products.

Some structural steel manufacturers may also offer installation services or work in partnership with construction contractors to erect the Steel Suppliers Melbourne.

Steel fabricators serve various industries, including construction, infrastructure, oil and gas, manufacturing, transportation, and more. They are often equipped with advanced machinery, computer-aided design (CAD) software, and skilled technicians to efficiently and accurately fabricate steel components.

Choosing a reliable steel fabricator is essential for ensuring the successful completion of construction projects and obtaining high-quality steel products. Reputable fabricators have a track record of delivering precision-crafted steel products that meet industry standards and client expectations.

Address : 2/28 Commercial Drive Dandenong South 3175 Victoria Australia

Email : [email protected]

Phone no : 03 9768 2477

Website : https://barrasteel.com.au/

0 notes

Photo

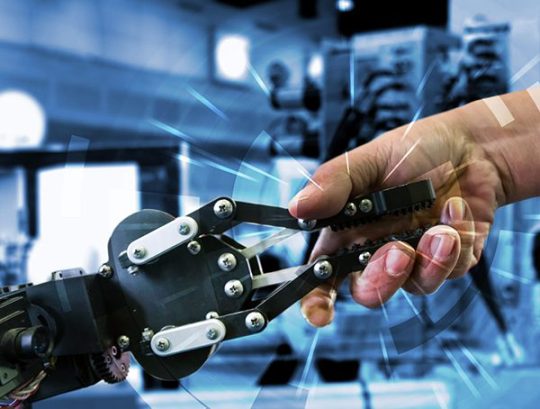

When it comes to manufacturing both simple and complex turned components for a wide range of industries, Parish Engineering is your ultimate destination. We are capable of producing high precision components. We work on all details and ensure the best quality outcomes. For more details on our CNC machining in Melbourne, please visit our website: https://www.parishengineering.com.au/cnc-turning/ or call on +61 3 9555 3377.

0 notes

Text

MadBytes Delivers Quality CNC Machine Manufacturing in Australia

MadBytes, a leading name among CNC machine manufacturers, is revolutionising the industry with their innovative and high-quality CNC machines. Known for their cutting-edge technology and exceptional customer service, MadBytes stands out as a premier CNC machine supplier.

MadBytes specialises in a wide range of CNC machines, including the highly sought-after CNC Router Machine. With an eye for precision and durability, their CNC routers are perfect for a variety of applications, from woodworking to metal fabrication. For businesses and hobbyists looking for a reliable CNC router for sale, MadBytes offers products that meet the highest standards of performance and reliability.

Our mission at MadBytes is to provide our customers with the best CNC solutions available. As one of the top CNC machine manufacturers; we are committed to innovation and excellence in every product we deliver.

What sets MadBytes apart in the competitive market of CNC machine manufacturers is their unwavering focus on quality and customer satisfaction. Every CNC router machine is designed and tested to ensure it meets stringent quality standards. This attention to detail has earned MadBytes a loyal customer base that trusts them as their go-to CNC machine supplier.

In addition to their superior products, MadBytes offers unparalleled customer support. Their team dedicates itself to ensuring a seamless experience, from helping customers choose the right CNC router for sale to providing after-sales service. This commitment to customer care is a key factor in their reputation as a leading CNC machine supplier.

MadBytes’ innovative approach to CNC technology doesn't stop at manufacturing. They are continuously researching and developing new ways to enhance their machines' capabilities, ensuring they stay ahead of the curve in the ever-evolving landscape of CNC machine manufacturers.

MadBytes is a top-tier CNC machine supplier dedicated to delivering high-quality CNC machines. With a focus on innovation and customer satisfaction, MadBytes has become a trusted name among CNC machine manufacturers. Their range of products, including the advanced CNC router machine, is designed to meet the diverse needs of their customers. For more information on MadBytes and their range of CNC machines, including the best CNC router for sale options, visit their website at madbytes.com.au. Or call us at (03) 9005 6504.

#cnc router for sale#cnc router machine#CNC machine supplier#cnc machine manufacturer#cnc machine sales#cnc mill for sale#cnc milling machine#cnc for sale#cnc router melbourne

0 notes

Text

Precision CNC machine parts and services Melbourne

Arrow MPS is a precision milling, turning and welding jobbing shop, specialising in mechanical components from simple one-off parts to complex assemblies. If it fits on a pallet, we can do it. If it doesn’t fit on a pallet, we can help engineer, organise and get it done. Our customer list is long and distinguished, having completed work for many multi-national, national, statewide and small companies alike. Our customers are often leaders in their own field, from industries including pharmaceutical, food, manufacturing, heavy industrial, mining, defence and general engineering. If you want CNC machining services Melbourne or parts done right, you need a supplier you can trust. Arrow MPS should be your first call.

0 notes

Text

Engrave Write - Professional Signage Designing & Printing Service

Engrave Write is a printing and signage business founded in 2001 located at the heart of Dandenong, Melbourne. Initially, the business started out with a laser and engraving machine and later equipped with a small CNC machine. As the years passed, we saw an increase in demand from our clients and decided to invest in a Large Format Printer to help deliver jobs faster and with the highest quality. Thanks to the increase in workload and clients we were able to invest in a new CNC machine that helped us work on a larger scale of diverse jobs and complete them in a timely manner.

0 notes

Text

Industry Insights: The Future Outlook for Cabinet Makers in Melbourne

Cabinet-making is a dynamic and evolving field that offers numerous opportunities for skilled professionals. As Melbourne grows and develops, the demand for high-quality cabinetry remains strong. At Orange College, we prepare our students to meet the challenges and seize the opportunities of this thriving industry. In this blog, we’ll explore the future outlook for cabinet makers in Melbourne, highlighting key trends and opportunities that can shape your career.

1. Growing Demand for Custom Cabinetry

Trend: Homeowners and businesses increasingly seek custom cabinetry to fit specific needs and aesthetic preferences. This trend is driven by the desire for unique and personalized spaces.

Opportunity: As a cabinet maker, specializing in custom designs can set you apart in the market. Mastering skills in bespoke cabinetry and offering tailored solutions can attract a loyal client base.

2. Sustainability and Eco-Friendly Practices

Trend: There is a rising awareness and demand for sustainable and eco-friendly building practices. Clients are looking for cabinetry made from responsibly sourced materials and using environmentally friendly processes.

Opportunity: By incorporating sustainable practices into your work, such as using recycled materials and low-VOC finishes, you can appeal to eco-conscious consumers and differentiate yourself from competitors.

3. Technological Advancements

Trend: The integration of technology in cabinet-making is transforming the industry. Tools such as Computer-Aided Design (CAD) software and CNC machines are becoming standard.

Opportunity: Staying updated with the latest technological advancements and becoming proficient in digital tools can enhance your efficiency, precision, and creativity. This knowledge can also open doors to high-tech cabinetry firms.

4. Increased Demand for Renovations and Home Improvements

Trend: The real estate market in Melbourne is seeing a significant trend towards home renovations and improvements. Homeowners are investing in upgrading their living spaces, including kitchens and bathrooms.

Opportunity: Specializing in kitchen and bathroom cabinetry can be highly lucrative. Providing high-quality renovation services can cater to this growing market and lead to consistent work.

5. Commercial and Retail Fit-Outs

Trend: As Melbourne’s economy grows, there is an increased need for commercial and retail fit-outs. Businesses require functional and aesthetically pleasing cabinetry to enhance their spaces.

Opportunity: By offering specialized services in commercial cabinetry, you can tap into projects for offices, retail stores, and hospitality venues. Understanding commercial design requirements and regulations is crucial for success in this sector.

6. Heritage and Restoration Projects

Trend: Melbourne is home to many heritage buildings and historic properties that require restoration and conservation. There is a niche market for skilled cabinet makers who can restore antique furniture and cabinetry.

Opportunity: Developing expertise in restoration techniques and historical woodworking methods can open up unique projects in the heritage sector. This specialization can be both rewarding and prestigious.

7. Increased Collaboration with Designers and Architects

Trend: There is a growing trend of collaboration between cabinet makers, interior designers, and architects. This partnership ensures cohesive and well-integrated designs.

Opportunity: Building strong relationships with designers and architects can lead to consistent and high-profile projects. Networking within these professional circles can enhance your reputation and expand your business opportunities.

8. Upskilling and Continuous Learning

Trend: The need for continuous learning and upskilling is more important than ever. Staying current with industry trends, new techniques, and materials is essential.

Opportunity: At Orange College, we emphasize the importance of lifelong learning. By participating in workshops, attending industry events, and enrolling in advanced courses, you can stay ahead of the curve and remain competitive.

The future outlook for cabinet makers in Melbourne is bright and full of opportunities. You can carve out a successful and fulfilling career by staying informed about industry trends and continuously honing your skills. At Orange College, we provide the education and support you need to thrive in this dynamic field.

Are you ready to embrace the future of cabinet-making? Enroll in the Certificate III in Cabinet Making program at Orange College today and equip yourself with the skills and knowledge to succeed in this exciting industry. Visit our website or contact our admissions team for more information.

best cabinet makers in Perth cabinet making course cabinet maker cabinet makers in Melbourne Cabinet-making carpentry course Melbourne Certificate III in Cabinet Making

#Certificate III in Cabinet Making program#cabinet makers in Melbourne#carpentry courses in melbourne for domestic students#carpentry courses in melbourne for international students#carpentry courses melbourne for international students#Beginner to Advanced Level English Courses in Melbourne#certificate iii in cabinet making melbourne#certificate 3 in cabinet making melbourne#Beginner English Courses in Melbourne#Advanced Level English Courses in Melbourne#painting and decorating course melbourne#Advanced English Courses in Melbourne#diploma of leadership and management melbourne for international students#carpentry course melbourne#cabinet maker course melbourne#carpentry course for international students#General English Courses Melbourne#General English Program Melbourne#certificate iii in carpentry course#diploma in leadership and management melbourne#certificate iii in painting and decorating#diploma of leadership and management melbourne#certificate 3 painting and decorating#Certificate III in Cabinet Making and Timber Technology#leadership and management courses melbourne#building and construction courses melbourne#diploma of leadership and management for international students#MSF30322#MSF30322 Cabinet Making#MSF30322 Certificate III in Cabinet Making

0 notes

Text

CNC Cutting Services in Melbourne - Viking Woodworks

We offer a variety of CNC cutting services with utmost precision. With years of experience in Woodworking CNC machine services across a diverse range of sectors including Residential, Commercial, Government, Non-Profit and Healthcare industries. If you are looking for cnc cutting services in Melbourne then contact with Viking Woodworks.

0 notes