#CNC Pneumatic Chuck Systems

Text

#system 3r edm#erowa compatible#erowa tooling#system 3r#3r erowa system#edm tooling#system 3r mini#3r system#erowa system#CNC Pneumatic Chuck Systems

1 note

·

View note

Text

1 note

·

View note

Text

CNC Lathe Machine Manufacturer

This is a compact industrial slant bed lathe with 8 station programmable turret.

This can be integrated with automation components to create various configuration of Smart Factory Automation System.

This is offered with optional accessories such as CNCTrain software, eCNC e-learning, loading and unloading device, pneumatic chuck, auto door.

Its design replicates industrial machine features such as cast iron bed, precision grade grounded ball screws, LM guide ways, servo motors, coolant system, AC panel cooler for control box, full machine guard, etc.

Contact ELE for your School, College Civil and Mechanical Engineering Lab Instruments. We are the best and renowned engineering lab equipment exporter, chemical engineering lab equipments suppliers, chemical engineering lab instruments manufacturer, chemical engineering lab equipment manufacturer, chemical engineering lab equipments supplier, chemical engineering lab equipments manufacturers in Ambala, India.

This is a compact industrial slant bed lathe with 8 station programmable turret.

This can be integrated with automation components to create various configuration of Smart Factory Automation System.

This is offered with optional accessories such as CNCTrain software, eCNC e-learning, loading and unloading device, pneumatic chuck, auto door.

Its design replicates industrial machine features such as cast iron bed, precision grade grounded ball screws, LM guide ways, servo motors, coolant system, AC panel cooler for control box, full machine guard, etc.

0 notes

Text

Remcor technology is a global supplier for the turnkey fiber laser cutting lines, which have around 18 years experiences, 5000 sets installations globally. No matter what type what size and how thickness your sheet material is, we can provide you the suitable equipment. Pipe Fiber laser cutting machine mainly been applied in metal pipes and tubes fabrications, with the character of fast speed, high precision or accuracy, environmental friendly, low power consumption, low table cost, and low maintenance cost. which is widely applied in fast cutting metal pipes of steel, stainless steel, carbon steel, aluminum, copper, galvanized steel, titanium alloy, gold, silver and other material. OEM ODM services are available.

Heavy Duty bed, apply the fully plate welding bed, with higher rigidity and durable use.

Compared with two chuck clamping or traditional metal pipes cutter. Three chucks equipment can realize the real zero tailing .processing details as the following descriptio.

More flexible for pipe cutting processing especially for extra heavy duty pipes or tubes, less swing or shake.Perfect accuracy and precision.

Heavy duty type load longer tailing material avaliable.

Apollo AK Two-chuck Tube Laser Cutting Machine 1000w-6000w Parameter Details

APOLLO BK SERIES-3 Chucks

Type

6020-BK

7025-BK

9025-BK

9034-BK

Power Range

1500-6000W

Chuck Structure

3 chucks

Tube Size

Round Type: 15-200mm Square

Round Type:15- 245mm

Round Type:15- 245mm Square

Round Type:15- 330mm Square

Type:15- 140mm

Square Type:15- 175mm

Type:15- 175mm

Type:15- 230mm

Positioning accuracy of X& Y

土0.05mm/m

Max Positioning speed X&Y

100m/min

80m/min

Max cutting length

6000mm

7000mm

9000mm

9000mm

Tail length

2 0mm

Max weight single tube

135KG

260KG

260KG

500KG

Max loading length

6000mm

7000mm

9000mm

9000mm

Fully Annealed Table

The bed body adapts the segmented rectangular tube welding bed with fully annealed treatment at over 600⁰. After tempering, the strength, rigidity and stability are guaranteed, the precision would be tested and debugged which can make sure the precision can be maintained for a long time. The table is equipped with automatic lubrication device, which ensure the moving parts operate in good condition and improve the service life of guide rails, gears and rack.

Follower Support

The follower support device will be optional. The follower support is mainly to assist in controlling the excessive deformation of cutting longer pipes (pipes with smaller diameter), and the servo motor drives the up and down movement of the pallet assembly. When the chuck moves to the corresponding position, the auxiliary support automatically drops for avoidance.

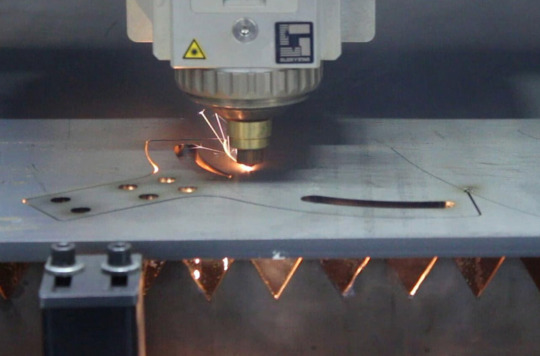

Smart Auto Focus Laser Head

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

Intelligent CNC Operating System

It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks on big IPAD Screen. Realize the intelligent diagnosis, multi-threading operation, three-level perforation, laser energy control, adaptive edge-finding, automatic corner acceleration and deceleration, flight cutting, switching worktables, mechanical accuracy compensation etc.

Pneumatic Clamp Chucks

Pneumatic clamp design on both sides. The dual-chucks help reduce tube vibration to a minimum, guaranteeing high accuracy in even complex tube configurations at high cutting speed. Suitable for cutting a range of tube diameters from Ø20 mm to Ø220 mm and various wall thicknesses.

Front chuck

tube laser cutting machine front chuck

Back chuck

tube laser cutting machine back chuck

Fractional Automatic Support Technology

Applies the intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Equipped with two sets of variable-diameter support structures, which are automatically lifted by the cylinder to avoid the rear chuck in processing. When processing profiles with different diameters, manually turn the variable-diameter wheels to achieve fit and support for different-sized profiles. The variable-diameter wheels It can be supported every two degrees of rotation to reduce the diameter of the circumscribed circular tube by 2mm

0 notes

Text

What Are The Functions Of Erowa EDM Tooling System?

Efficiency and accuracy are critical in the realm of precision machining and production. The Electrical Discharge Machining (EDM) procedure has transformed the profession. Using electrical discharges, EDM enables the exact shape and machining of complicated objects. The Erowa EDM Tooling System was created to improve the EDM process even more. This unique technology provides a variety of functionalities that expedite and improve the EDM workflow, resulting in significant industrial benefits.

Let’s Take a Closer Look To The Functions Of Erowa Edm Tooling:

Electrode Holding and Positioning:

Electrode holding and positioning is a critical components of the Erowa EDM Tooling System. Electrodes are used in EDM to generate the required form in the workpiece. Erowa's tooling technology ensures consistent and accurate machining results by firmly retaining and placing these electrodes. The modular nature of the system enables rapid and easy setup, decreasing downtime and enhancing productivity.

Workpiece Clamping:

Accurate workpiece clamping is critical for effective EDM operations. The Erowa system provides a variety of clamping methods with exceptional stability and repeatability. The system's varied clamping options provide perfect placement and fixation during machining, whether it's a single workpiece or several pieces. It reduces the possibility of workpiece movement or vibration, resulting in greater machining precision and surface finish quality.

Palletization and Automation:

The Erowa EDM Tooling System has palletization and automation features to increase productivity and efficiency. The technology enables rapid and easy workpiece interchange, minimizing setup times and enhancing machine usage. Palletization allows numerous workpieces to be machined at the same time, reducing idle time and increasing output. Furthermore, the system connects smoothly with automated systems, providing unmanned operations and 24/7 manufacturing capabilities.

Tool and Electrode Management:

Efficient tool and electrode management are critical for any machining operation. The Erowa EDM tooling system has complete tool and electrode management functionalities that allow for simple access, organization, and tracking of these crucial components. The tooling cabinets and holders in the system allow for systematic storage, reducing tool damage or loss. Furthermore, integrated RFID technology allows for precise inventory control, tool life monitoring, and automated tool presetting, all of which help to optimize machining operations.

Conclusion:

The possibilities for precise machining are endless with the Erowa EDM Tooling System. Are you looking to buy the same? If so, then explore the Maxx Tools collection at Maxx Tooling - Michigan's most reputable tool store. It concentrates on delivering cutting machines and instruments that are among the best in the industry. System 3R, Erowa tools, and CNC Pneumatic Chuck Systems are available from Maxx Tooling. Check out their website to get started on purchasing industrial cutting tools right away!

#Erowa Edm Tooling#3r Edm Tooling#Maxx Tools#System 3r Tooling#System 3r Edm#System 3r#Erowa Tooling#Tools#design

0 notes

Text

Laser cutting machine - a good helper for cutting pipes

youtube

1. Automatic laser cutting and blanking of metal tubes in full stroke.

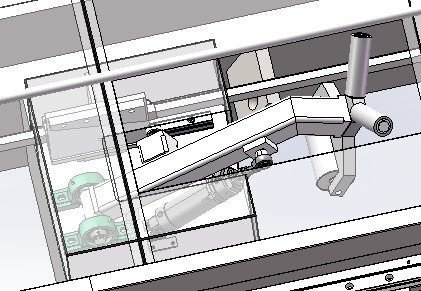

According to the technical requirements of full-stroke automatic laser cutting materials for large-length metal pipes, the mechanical structure adopts a unique dual-drive pneumatic chuck rotation mechanism (driving shaft W, driven shaft W1), and the left driving shaft W-axis pneumatic chuck rotation mechanism A unique double-drive pneumatic chuck rotation mechanism is used to realize the axial movement of large-sized metal pipes.

2. CNC cutting process.

CNC cutting is a high-volume, high-efficiency, high-quality cutting production method, and its core is the CNC cutting system. The quality problems existing in the current laser pipe cutting process include: excessive cutting point of parts, high corner, deflection of cutting surface, circular deformation or inability to close, etc., which directly cause serious waste of pipe fittings and low cutting production efficiency.

CNC cutting technology refers to the advanced cutting technology and rich cutting experience provided by the cutting control software of the CNC system, so that the cutter can obtain high-quality and high-efficiency CNC cutting by skillfully using the control system.

3. A complete set of professional material technology.

Laser CNC cutting has high efficiency and complex programming materials. Improper use will waste piping and reduce cutting efficiency. On the computer, the NC cutting program is generated through professional pipe cutting software drawing, package and segment programming to realize full-stroke automatic laser cutting of large-length metal pipes. The special pipe sleeve software is the basis and premise to realize mass production, high efficiency and high quality blanking.

4. Pipe cutting process.

Because of pipe cutting (especially for small square pipes), slag adheres to the pipe wall, and most of the heat generated by cutting is absorbed by the workpiece. When the cutting density is high, the angle of the pipe is often overheated and the four angles of the square pipe are overheated, which seriously affects the cutting quality, and even cannot be cut.

To address these issues:

(1) The laser cutting head has a height sensing follow-up system, which can ensure that the height of the cutting nozzle is consistent with the surface of the workpiece during the cutting process (the focus remains unchanged), so that the cutting effect is not affected by the change of the surface of the workpiece;

(2) The method of increasing the oxygen pressure (6-8Mpa);

(3) Use software to increase the speed of sharp corner synthesis.

0 notes

Text

Maxx Tooling is the right place to buy CNC Pneumatic Chuck System. We provide you with a wide range of options in chucks. Our chucks are susceptible to wear and tear which makes them the best option to buy for your electric systems. Order the best chucks at earliest by visiting our website.

0 notes

Link

Have a look at our premium System 3R Macro Holders? These high-quality macro holders are 100% compatible with existing 3R system. Visit our website to see our wide variety of best EDM and 3R tooling products.

1 note

·

View note

Link

CNC Pneumatic Chuck Systems

#System 3R Macro Holders#Erowa Tooling#Erowa System#Erowa Compatible#CNC Pneumatic Chuck Systems#Macro Magnum

0 notes

Photo

MaxxTooling is a reliable, affordable, and professional online store to buy Macro Magnum. With a large selection of best macro magnum products, you can choose as per your needs and budget. Shop now.

0 notes

Link

Check out the best tooling for your machines that is the 3R Erowa Tooling available at Maxx Tooling. We know what our customers are looking for and strive to provide them with the tools that combat their industry needs. All our tools are highly tested and verified at several levels. Visit our website to learn more!

0 notes

Text

CNC Laser Pipe Cutting Machine

Large size CNC laser pipe cutting machine

Especially for large diameter metal tubes and heavy pipe cutting... The tube outer diameter can be 20-300mm, suit for various shape tube and pipe CNC laser cut. pipe length reaches to 8 meters. With an 8-meter Automatic bundle loading system for continuous batch production.

DOUBLE PNEUMATIC CHUCK

The diagonal adjustable range is 20-240mm, the servo motor and reducer are driven synchronously, and the smart tube bracket design is adopted, which can solve the deformation problem in the tube cutting process.

To ensure the machining accuracy, precise cutting of round pipes, square pipes, rectangular pipes, angle steels, channel steels, irregular pipes and oval pipes can be realized Flexible and adjustable to improve efficiency.

Suitable for cutting tubes of various shapes.

Safer, easy to install, save manpower, consume less and cost less.

The minimum tail length is 20mm, which truly realizes zero tail cutting, reduces the cost of raw materials, and brings huge production benefits.

PIPE CUTTING SOFTWARE

CypTube professional tube cutting software.

Automatic tracking of the center and eccentric compensation to ensure cutting accuracy.

Corner cutting technology, no excessive burning, high section quality.

Common cutting processing, reducing discounts and saving production costs.

Metal Tube Cutting

Laser pipe cutting machine Material & Industry Application

Applicable MaterialsStainless steel, carbon steel, aluminum, brass, copper, galvanized steel, alloy steel and so on.Applicable Types of TubesLarge diameter Round tube, Squre tube, Rectangle tube, I beam, Channel beam, Angle iron and so onApplication IndustryMainly used in tubes processing industry etc, building structure, bridge fitness equipment, office furniture, shelves, steel structure, medical industry, rail rack and other industries tube and shaped pipe and other profile processing.

1 note

·

View note

Photo

DNE Laser Two Chucks Laser Tube Cutting Machine with Automatic Loading and Unloading System

D-Fast fiber laser cutting machine is a product developed for the profile and tube cutting market, using the latest independent

research and development EtherCAT type CNC laser cutting system, realizing control of tubes support device and chuck, etc...

Function:

◆Wide Cutting Applications

◆Special Profiles of Tubes

◆Auto Pneumatic Chucks

◆Full-auto loading system

◆Auto unloading function

◆Powerful and User-friendly Nesting software

◆Overloading weight and unloading tube length

...

More: https://en.dne-china.com/list-13.html

#dnelaser #bystronic #manufacturing #power #machinetools #machineshop #cnc #machine #metalworking #engineering #equipment #industrial #tools #machinery #industrialmachinery #production #industrialequipment #metalwork #powertools #metalshaping #toolshop #powertool #lasercutting #metalcutting #metalworks #lasercuttingmachine

1 note

·

View note

Text

CNC Pneumatic Chuck Systems

CNC Pneumatic Chuck Systems in USA.We provide best CNC Pneumatic Chuck Systems in cheap price. Maxxtooling offers system 3R mini tools reduces setting-up times and gives rapid and precise mounting. The products offered by us are suitable for automatic changing with System 3R's automation program

To know more information follow these links:

1. https://disqus.com/by/erowacompatible/

2. https://disqus.com/by/disqus_IzX2HIkGEi/

3. https://pix.sfly.com/iPUER4

4. https://www.chestermachinetools.com/blogs/news/an-engineers-guide-to-cnc-lathes?comment=19006324798#comments

5. https://piggo.wikitechguru.com/2018/09/12/3r-compatible-store/

6. https://thomesporter.wordpress.com/2018/08/30/important-backlinks-about-edm-tooling-that-will-make-you-think-twice/comment-page-1/#comment-1

7. http://www.mediafire.com/view/aj24sfty24di3ro/csm_its_002_076580fd28.jpg

8. http://postbits.net/p/erowa-tooling/

9. https://www.bloglovin.com/@cncpneumaticchucksystems4/cnc-pneumatic-chuck-systems

10. http://tuffsocial.com/system-3r/

11. https://www.ted.com/profiles/10811614

0 notes