#CNC drilling services

Text

Beyond Limits: Innovations in CNC Drilling Services

In today's fast-paced industrial landscape, precision and efficiency are paramount. This is where CNC (Computer Numerical Control) drilling services shine, offering unparalleled accuracy and speed in various drilling applications. From aerospace to automotive industries, CNC drilling has revolutionized manufacturing processes, pushing the boundaries of what's possible.

CNC drilling services utilize advanced machinery controlled by computer programs to execute precise drilling operations. This technology enables complex patterns, depths, and angles to be achieved with incredible consistency and reliability. By automating the drilling process, CNC systems minimize human error and maximize productivity, making them indispensable in modern manufacturing facilities.

One of the key innovations in CNC drilling services is the integration of advanced software and hardware solutions. Modern CNC machines are equipped with sophisticated software that translates design specifications into precise drilling instructions. This software allows for seamless communication between design engineers and machine operators, ensuring that the final product meets exact specifications.

Another notable innovation is the development of multi-axis CNC drilling machines. Unlike traditional drilling machines limited to linear movements, multi-axis CNC machines can move along multiple axes simultaneously, enabling complex drilling operations in three-dimensional space. This capability opens up new possibilities for intricate and challenging drilling tasks across various industries.

Furthermore, advancements in tooling technology have significantly enhanced the performance and efficiency of CNC drilling services. High-speed steel (HSS) and carbide drill bits are commonly used in CNC drilling applications due to their durability and precision. Additionally, specialized coatings and geometries optimize tool life and chip evacuation, further improving drilling accuracy and efficiency.

The benefits of CNC drilling services extend beyond precision and efficiency. These services also offer versatility, allowing for the drilling of a wide range of materials, including metals, plastics, and composites. Whether it's creating intricate patterns on aerospace components or drilling precise holes in automotive parts, CNC drilling services can handle diverse manufacturing requirements with ease.

Moreover, CNC drilling services contribute to cost savings and waste reduction in manufacturing processes. By minimizing errors and optimizing material usage, manufacturers can achieve higher yields and lower production costs. Additionally, the ability to produce complex components in a single operation reduces the need for secondary machining operations, further streamlining the manufacturing workflow.

In conclusion, CNC drilling services represent a cutting-edge solution for precision drilling applications across various industries. With continuous innovations in technology and tooling, these services continue to push the boundaries of what's achievable, enabling manufacturers to create high-quality products with unmatched accuracy and efficiency.

1 note

·

View note

Text

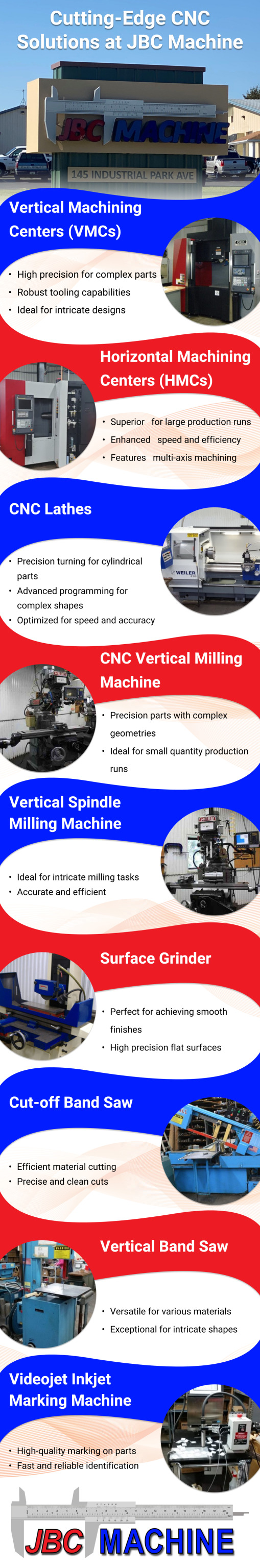

Precision CNC Machining & Custom Engineering Solutions at JBC Machine

https://jbcmachine.com/ - JBC Machine, Inc. offers advanced machining solutions with Vertical and Horizontal Machining Centers for precision and complex designs, ideal for intricate parts and large runs. Our CNC Lathes and Milling Machines excel in turning and milling precision parts, optimized for speed and accuracy. The facility also includes a Surface Grinder, Cut-off, and Vertical Band Saws for precise finishes and shapes, alongside a Videojet Inkjet Marking Machine for fast, reliable part identification. Call JBC Machine Inc. at 920-779-4075 for custom machining services.

JBC Machine, Inc.

145 Industrial Park Avenue, Hortonville, WI 54944

Phone: (920) 779-4075

E-mail: [email protected]

https://jbcmachine.com/

#CNC Plastic Machining#Plastic Machining#Aluminum Machining Custom Machine Shop#CNC Shaft Machining#Custom Machine Shop#CNC Drilling#CNC Drilling Services

0 notes

Text

Understanding Laser Cutting Machines: Revolutionizing Precision and Creativity

In the world of manufacturing and design, the advent of laser cutting technology has been nothing short of transformative. With its unparalleled precision and versatility, the laser cutting machine has become an indispensable tool in various industries, from aerospace and automotive to fashion and architecture. But what makes this technology so special? Let's delve into the details.

What is a Laser Cutting Machine?

A laser cutting machine utilizes a focused beam of light to slice through materials with extreme accuracy. This technology relies on the principle of concentrating light into a thin beam to cut or engrave materials. The laser's high energy melts, burns, or vaporizes the material, leaving behind a clean and precise cut.

Key Features of Laser Cutting Machines

Precision and Accuracy: Laser cutting machines offer exceptional precision, with the ability to cut intricate patterns and detailed designs. This is achieved through the controlled focus of the laser beam, which can be adjusted to achieve different levels of detail.

Versatility: These machines are capable of cutting a wide range of materials including metals, plastics, wood, glass, and fabric. This versatility makes them suitable for various applications, from industrial parts to artistic creations.

Minimal Waste: The precision of laser cutting results in minimal material waste compared to traditional cutting methods. The narrow laser beam ensures that only the material being cut is affected, leading to cleaner cuts and more efficient use of resources.

Automation and Efficiency: Modern laser cutting machines are often equipped with computer numerical control (CNC) systems. This automation allows for high-speed production and repeatability, reducing manual intervention and increasing overall efficiency.

Applications of Laser Cutting Machines

Manufacturing: In manufacturing, laser cutting is used to create precise components for machinery and vehicles. Its ability to handle complex shapes makes it ideal for producing intricate parts and assemblies.

Architecture and Design: Architects and designers use laser cutting to create detailed architectural models and decorative elements. The technology allows for the creation of complex patterns and textures that would be difficult to achieve with other methods.

Fashion and Textiles: In the fashion industry, laser cutting is employed to produce intricate designs on fabrics and leather. It allows designers to experiment with complex patterns and textures, adding a unique touch to their creations.

Signage and Displays: Laser cutting is widely used in the creation of custom signage and promotional displays. The precision and variety of materials that can be used make it a popular choice for creating eye-catching and durable signs.

Benefits of Using Laser Cutting Machines

Enhanced Creativity: The precision and versatility of laser cutting open up new possibilities for designers and artists. The ability to create intricate designs with minimal limitations encourages creativity and innovation.

Cost-Effective Production: Despite the initial investment, laser cutting machines can be cost-effective in the long run due to their efficiency and minimal material waste. This makes them an attractive option for both large-scale production and small-scale projects.

Reduced Labor Costs: Automation reduces the need for manual labor, lowering overall production costs. The machine's ability to repeat designs with consistent quality also means less time is spent on rework and adjustments.

Improved Safety: Laser cutting machines are generally safer compared to traditional cutting methods. The cutting process is controlled by the machine, reducing the risk of accidents and injuries associated with manual cutting techniques.

Challenges and Considerations

Initial Investment: The cost of purchasing and maintaining a laser cutting machine can be significant. For small businesses or hobbyists, this initial investment might be a barrier.

Material Limitations: While laser cutting is versatile, it is not suitable for all materials. Certain reflective or highly absorbent materials may present challenges or require special considerations.

Skill Requirements: Operating a laser cutting machine requires a certain level of technical skill and knowledge. Proper training and understanding of the machine's capabilities are essential to achieving optimal results.

Conclusion

Laser cutting machines represent a remarkable fusion of technology and artistry, offering unparalleled precision and versatility across various fields. Their ability to transform ideas into tangible creations with minimal waste and high efficiency has revolutionized industries and opened new avenues for creative expression.

While there are challenges, such as the initial investment and the need for specialized skills, the benefits far outweigh these considerations for many businesses and creators. As technology continues to evolve, the capabilities of laser cutting machines will likely expand, further enhancing their impact on manufacturing, design, and beyond.

In essence, laser cutting machines are more than just tools—they are gateways to innovation, enabling us to push the boundaries of what is possible and bring our most intricate and ambitious designs to life.

0 notes

Text

Integrating CNC Grinding, Gundrilling, and Steering Machines for Maximum Efficiency

When you run a workshop, your goal is to be as efficient as possible. This means making sure all your machines, like CNC grinding machines, gundrilling machines, and steering machines, work well together. This blog will guide you on how to integrate these machines to maximize workshop efficiency.

Understanding Your Machines

CNC Grinding Machine:

A CNC grinding machine uses a rotating wheel to smooth surfaces. This machine is perfect for creating precise shapes and smooth finishes on metal pieces. It’s controlled by a computer, which means it can produce parts that are consistent and of high quality.

Gundrilling Machine:

Gundrilling machines are designed to drill deep holes with a high degree of accuracy. These machines are key in industries where precision is crucial, such as in the making of molds, dies, and various engineering components.

Steering Machine:

Steering machines shape and finish steering components, ensuring they meet specific design requirements. This is critical in automotive manufacturing, where the precision of steering components can affect vehicle performance and safety.

Steps to Integrate Your Machines

Layout Planning:

Start by planning the layout of your workshop. Place machines that are part of a similar processing line close to each other. For example, materials that are first processed in a CNC grinding machine should have easy access to the gundrilling machine if the next step involves drilling.

Scheduling Software:

Use scheduling software to manage each machine's operation times. This software can help prevent bottlenecks where one machine is waiting for another to finish. It ensures that each machine starts its task at the right time, keeping the workflow smooth and continuous.

Regular Maintenance:

Keep all machines in top condition. Regular maintenance checks can prevent unexpected breakdowns that could slow down the whole production line. Each machine, from the CNC grinder to the steering machine, should have a clear maintenance schedule.

Feedback Loop:

Create a feedback loop where data from the machines' operation is regularly analyzed to find areas for improvement. For example, if the data shows that parts from the CNC grinding machine often need adjustments before gundrilling, it might be time to recalibrate the machine.

Leveraging WIDMA's Expertise

As a final point, consider partnering with technology providers like WIDMA, a renowned leader in manufacturing precision tooling solutions. WIDMA offers a range of CNC grinding machines, gundrilling machines, and other specialized equipment tailored to enhance manufacturing efficiency.

WIDMA’s machines are built with the latest technology to ensure they deliver high performance and reliability. Moreover, WIDMA provides comprehensive support and training, which can be invaluable for workshops looking to integrate new machinery or optimize existing setups.

Using WIDMA’s advanced equipment and expert services, you can achieve a streamlined workflow that maximizes productivity and reduces downtime. Their commitment to innovation and quality makes them a smart choice for any workshop serious about staying competitive in today’s fast-paced market.

Conclusion

Integrating your CNC grinding machine, gundrilling machine, and steering machine efficiently requires thoughtful planning and the use of advanced technologies. By optimizing the workflow, maintaining machines properly, and leveraging expert solutions like those from WIDMA, your workshop can achieve the high efficiency and productivity needed to succeed in the manufacturing industry.

2 notes

·

View notes

Text

Coach wants you on the team (CNC Gay fantasy)

One day as you are leaving class your gym teacher stops you. He tells you he wants you to join the football team. You could have understood the soccer team or any other team. But you are not a big guy. But after a few awkward minutes you relent and join the team.

Three days a week coach has practice after school. First you have to run laps, Then push ups, Then drills. And every practice coach singled you out to run extra laps at the end. Exhausted you make your way back to the locker room. You had to admit it was nice showering when no one else was there.

After a few weeks of this routine you hadnt figured out why coach put you on the team. Or why you always had to stay after practice to run more laps. But the first game of the season was approaching and you wondered if you were going to be able to handle yourself against this other team.

You finish running your laps and walk back to the locker room. You take off your clothes and walk to the showers. Once the waters running you couldnt hear the door open again. After a few minutes you can hear some footsteps. When you turn to look you see that's it's your coach.

"You finished all your laps?" He said walking directly towards you and turning on the shower directly next to yours.

"Yes coach." You reply. You're little stunned, no one has been here this late before. And now your coach is here. Without saying a word your coach removes with towel and hangs it up. Naked he now begins to wash himself. Uncomfortable you just look down to the floor, trying to finish showering so you can leave. But out of the corner of your eye you see your coach's semi hard cock. You just find yourself looking at it for a moment and as you do you see it grow harder. Quickly you look up at your coach and you can see him looking at you. You make eye contact some a moment and he begins to slowly stroke the length of his cock.

"Its ok, relax" he says "its just us guys here." You feel his hand on your shoulder. He is firmly pressing on your shoulder. Slowly you begin to crouch down. "That's right. All the way down. "

You are now kneeling on the hard tile floor. The warm water of the showers running over you. "What going on coach? " you say trying to look up at him with the water spraying against your face. He looks massive standing over you and his huge cock is now fully erect. He looks down at you still stroking his dripping wet dick.

"You're going to do what I tell you, because i am your coach. Right?" He says putting his free and on the top of your head.

"Ye..yes coach" you stammer. You try to look down at the floor but you feel him raise your chin back up.

"Stick out your tongue for me." He says "Now!" He demands. Immediately you look at him and stick your tongue out. He starts pulling your head in and running the tip of his big cock across your tongue. "Lick it"

You're shacking and the water is dripping into your eyes so you close them and begin to lick his large vainy cock. Running your tongue up and down the length of his hard shaft. You reach the tip and slide your lips down over the end. You start licking thhead of his cock as you suck on it. "Fuck! I knew you'd be a good whore." Coach moans as you service him.

You keep your eyes shut as the water runs over your face and down your body. You know that you are fully erect and there is no way that he wont see it. Both of his hands are firmly holding your head. He feels so strong as he firmly holds you, guiding you slowly up and down his huge cock as you suck and lick it. With every moan you hear you begin to think less and less. Now he is beginning to push his cock to the back of your throat. With each thrust you gag a little. The first few times he would release you but this time he jams his cock into your throat and hold your head down. "Just relax" he moans "Going to train this throat."

You try your hardest to relax your throat as he slides his huge cock down it. Tears are running down your face but the water from the shower masks them. You are now sucking and deepthroating his massive manly cock your own. Licking and sucking his cock you reach up and begin to massage his balls.

"That my good little whore!" He moans stroking your head. Something about hearing those words made you hornier than every. Now you needed to be his good whore.

His moans are becoming more rapid and you know hes going to cum. You start jamming his rock hard dick down your own throat. Trying not to gag as again and again you push it as deep as you possibly can.

You feel a pulse in his cock and the salty sticky cum begins to fill your mouth as your push his cock into your throat again and swallow. You massage his balls as he gives you the last of his cum.

"You suck cock just like a girl. You're a good little whore" coach says as he turns off the shower. You open your eyes finally and see satisfaction on his face as he leaves the showers. You couldnt believe how good it felt to hear him say that. You couldn't wait for tomorrow's practice.

#fr33use#cnc fr33use#18+ minors dni#soft cnc#nsft#fantasy#0ral fixation#bi curious#bi oral#bi fantasy#bi nsft#bi ns/fw#Bi curious#dm me#literotica

2 notes

·

View notes

Text

CNC Machining - Everything You Need to Know

CNC machining is a very broad category of possible operations and processes. Among CNC machining operations, drilling, milling, and turning are the most common.

DRILLING

Drilling processes use bits with a diameter the same size as the diameter of the desired hole. The machining equipment inserts the spinning drill bit perpendicularly into the workpiece until it drills a hole of a predetermined length. More complex equipment can produce angular holes, and drilling tools can provide capabilities such as:

MILLING

The milling process removes cuts of material from the workpiece by moving the material against a spinning cutting edge. The tools have multiple cutting points, and each tool spins to provide a sharp cutting surface with a different length and shape. When the workpiece is pressed against milling tools, thin strips or cuts of material are removed from the existing edge. This can create shallow cuts, wide cuts, or flat-bottom cavities to shape the part. Peripheral milling processes may cut deeper to create slots or threads into the piece’s general shape.

TURNING

Turning processes turn the workpiece instead of the cutting tool. They include cutting processes such as boring, grooving, and facing. They cut excess material off of a workpiece by using single-point cutting tools precisely applied to the rotating workpiece. Turning creates cylindrical parts that have a specified diameter. Turning can create linear features both inside and on the exterior edge of the parts. These features include:

ADVANTAGES OF CNC MACHINING

Many manufacturers prefer machining processes because they create parts or components from a single workpiece. CNC machining has several additional advantages. These include:

Increased productivity. Facilities with CNC machining can produce parts 24/7. The machines may run continuously with little-to-no human intervention. The machines also require less space than workstations or manual machining setups, so a facility with a set square footage can have more machines running simultaneously.

A high degree of accuracy. CNC machining uses highly detailed programming operations. The machines follow these instructions without allowing any unwanted variation or human error. The parts will be high-quality, precise, and identical. CNC machining can also produce parts with intricate, complex designs.

Faster project completion. Every CNC machining process starts with a CAD design, so the prototyping process will be much faster. The software catches or prevents many possible design flaws or potential risks with different materials. When the prototyping and testing processes are shortened, products can go from design into production faster. CNC machining instructions can also be modified or replaced quickly, so there is little delay between changes in production runs.

Cost-effectiveness. CAD file designs and reduced risks of manufacturing errors reduce the per-unit cost of production. CNC machining also requires less human labor, which further reduces the price of manufacturing the products.

For customers seeking a complete manufacturing solution, Pro-Type Industries, Incorporated offers a level of value and process flexibility that is unmatched in the industry. We operate a state-of-the-art facility that is equipped with some of the most advanced CNC machining systems available.

With our experienced skillful engineers team, we providing high quality custom CNC metal and plastic parts to world wide clients in many industries field. We are always appreciated by high tolerance quality and one-stop service of multiple processes. We are now working for clients partners from USA, Euro, Mid-East, Asian, supporting clients’ projects by excellent quality, bottom cost and quick lead-time.

3 notes

·

View notes

Text

Custom CNC Machining Services

Various industries require precision-engineered components and Custom CNC machining services are a basic requirement for the same. CNC stands for Computer Numerical Control, this technology allows manufacturers to produce highly detailed and accurate parts with high precision and repeatability making it a choice in sectors like aerospace, automotive, medical as well electronics.

Clients initiate the process by submitting intricate sketches or design inputs. With the help of CAD (Computer-Aided Design) software, engineers can draft exact models that tell CNC machines how to create parts. Milling, turning, drilling and grinding are among the many operations that one of these machines can perform; its flexibility enables both complex geometries to be created as well as very tight tolerances.

Versatility is one of the biggest benefits when it comes to custom cnc machining. Materials — can work with a number of materials including metals (aluminum, stainless steel, brass and even titanium), plastics & composites. They can also be used for anything from prototypes to high volume production runs.

The first requirement for a good custom machining services is quality control. All parts are inspected under thorough scrutiny of advanced measuring tools to ensure they meet the expected set of standards. By providing great care into their products, the narrative shifts from product quality to long-term relationships with clients.

Other benefits of custom CNC machining services often have to do with rapid prototyping, where clients can try out designs faster than full production. This in turn accelerates the design process as well and reduces costs related to design re-works.

In conclusion, custom parts production CNC machining services allow to get high-quality and precision items designed for a specific order. These can be some of the reasons why in today's race to make it big by manufacturing as efficiently and cost-effectively, CNC machining is considered a valuable aid.

0 notes

Text

Ensuring Precise Dimensions: The Art of Custom Plastic Profile Extrusion

Whether it’s creating components for machinery or crafting intricate parts for consumer products, the ability to achieve precise dimensions is crucial. One technology that excels in this arena is custom plastic profile extrusion. In this article, we’ll explore the art of custom plastic profile extrusion and how it revolutionizes manufacturing processes by ensuring precise dimensions.

Channels Ready for Immediate Use

Flexibility in Application

Custom plastic profiles are designed to be ready for immediate use, offering unparalleled flexibility in application. These profiles can be seamlessly integrated into existing systems without the need for extensive modifications, saving time and resources.

Rapid Adaptation to Specifications

One of the key advantages of custom plastic profile extrusion is its ability to rapidly adapt to specific requirements. Manufacturers can easily tailor profiles to meet the exact dimensions and specifications of each application, ensuring a perfect fit every time.

Seamless Integration with Existing Systems

Custom plastic profiles are engineered to integrate seamlessly with existing systems, minimizing downtime and disruption during installation. This allows manufacturers to upgrade their equipment and processes without costly delays or production interruptions.

Capacity for Diverse Orders

Prototype Trials

Custom plastic profile extrusion offers the flexibility to accommodate small-scale prototype trials, allowing manufacturers to test new designs and concepts with minimal investment. This enables rapid iteration and refinement, leading to faster time-to-market for new products.

Large Production Runs

In addition to prototype trials, custom plastic profile extrusion has the capacity to handle large production runs with ease. With nine primary production lines and four co-extrusion lines, manufacturers can scale up production to meet high-volume demands without sacrificing quality or precision.

State-of-the-Art Production Lines

Primary Production Lines

The state-of-the-art production lines are equipped with the latest technology to ensure consistent quality and high throughput rates. This helps to meet tight deadlines and deliver superior products to our customers.

Co-Extrusion Lines

The co-extrusion lines allow the production of complex profiles with multiple layers, expanding design possibilities and enhancing product performance. This advanced technology creates custom solutions for even the most demanding applications.

Plastic Extrusion Design Engineering

Precision Design Capabilities

Experienced engineers have the expertise to design custom profiles with precision and accuracy. Using advanced CAD software and simulation tools, It optimizes profiles for performance, durability, and cost-effectiveness.

Innovation in Profile Development

Experienced engineers are constantly exploring new materials, processes, and techniques to push the boundaries of what’s possible in custom plastic profile extrusion.

Plastic Extrusion Tooling

Advanced Tool Room Facilities

The room is equipped with cutting-edge machining technologies, including 5-axis wire EDM and CNC machining centers. This allows high-quality tooling with precision and efficiency.

Tailored Tooling Solutions

It also offers customized tooling solutions to meet the unique requirements of each project. Whether it’s rapid prototyping or iterative design processes, tooling capabilities ensure the delivery of perfect solutions for your needs.

Plastic Extrusion Fabrication

Comprehensive Fabrication Services

In addition to extrusion, Fabrication services add value to your products. From punching and routering to drilling and printing, It has the expertise and equipment to handle all aspects of production.

Enhanced Product Finishing

The finishing services include surface treatments, coatings, and quality assurance measures to ensure that your products meet the highest standards of quality and performance. With attention to detail and commitment to excellence, you can trust Custom Plastic Profile Extrusion to deliver superior results every time.

Incorporating 3D Printing

Prototyping Capabilities

Our 3D printing capabilities enable rapid prototyping and iteration, allowing you to test new designs and concepts quickly and cost-effectively.

Customization and Personalization

With 3D printing, it can create custom profiles with unique features and designs, allowing you to differentiate your products and stand out in the market.

FAQs

Are custom plastic profiles suitable for small-scale projects?

Yes, custom plastic profiles are highly adaptable and can be tailored to meet the requirements of small prototype trials.

How quickly can custom plastic profiles be produced?

Production times vary depending on the complexity and volume of the order. However, manufacturers often offer rapid turnaround times to meet tight deadlines.

What materials can be used for custom plastic profile extrusion?

A wide range of thermoplastic materials can be used for custom profile extrusion, including PVC, ABS, HDPE, and more.

Are custom plastic profiles suitable for outdoor applications?

Yes, custom plastic profiles can be engineered to withstand harsh environmental conditions, making them ideal for outdoor use.

Can custom plastic profiles be recycled?

Yes, many thermoplastic materials used in custom profile extrusion are recyclable, contributing to sustainability efforts.

Conclusion

In conclusion, custom plastic profile extrusion is a versatile and efficient manufacturing process that revolutionizes the way we produce components and products. With its ability to ensure precise dimensions and tailor-made solutions, custom plastic profile extrusion offers numerous benefits for various industries. From flexible application to seamless integration with existing systems, this technology provides manufacturers with the tools they need to stay competitive in today’s market.

Ready to experience the benefits of custom plastic profile extrusion for your next project? Contact Lakeland Plastics today to bring your vision to reality with precision and excellence.

0 notes

Link

Under this contract, CHC Helikopter Service will provide crew change and transportation services for two key rigs: the Noble Invincible and the Deepsea Yantai. These critical missions will be supported by CHC’s Sikorsky S-92 aircraft, known for its exceptional performance and...

0 notes

Text

Machine de forage et de rodage en verre de quartz, Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 10 Premières Entreprises

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de Machine de forage et de rodage en verre de quartz 2024-2030”, publié par QYResearch, la taille du marché mondial de Machine de forage et de rodage en verre de quartz devrait atteindre 79 millions de dollars d'ici 2030, à un TCAC de 3.0% au cours de la période de prévision.

Figure 1. Taille du marché mondial de Machine de forage et de rodage en verre de quartz (en millions de dollars américains), 2019-2030

Figure 2. Classement et part de marché des 10 premiers acteurs mondiaux de Machine de forage et de rodage en verre de quartz (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

Selon QYResearch, les principaux fabricants mondiaux de Machine de forage et de rodage en verre de quartz comprennent Gehring, Shiba R&D, Sunnen, Engis, CNC Europe, Dezhou Guanlu Precision Machinery Co.,Ltd, Lapmaster Wolters, Saporiti Srl, Yangtze Optical Electronic Co.,Ltd., Dezhou Premach Machinery, etc. En 2023, les cinq premiers acteurs mondiaux détenaient une part d'environ 59.0% en termes de chiffre d'affaires.

According to QYResearch, the global key manufacturers of Quartz Glass Drilling and Honing Machine include Gehring, Shiba R&D, Sunnen, Engis, CNC Europe, Dezhou Guanlu Precision Machinery Co.,Ltd, Lapmaster Wolters, Saporiti Srl, Yangtze Optical Electronic Co.,Ltd., Dezhou Premach Machinery, etc. In 2023, the global top five players had a share approximately 59.0% in terms of revenue.

The market for quartz glass drilling and honing machines is influenced by several key drivers:

Overall, the market for quartz glass drilling and honing machines is driven by the expanding applications of quartz glass across high-tech industries, advancements in semiconductor technologies, optics, and optoelectronics, as well as continuous innovation in machining capabilities and automation.

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

0 notes

Text

Experience precision with our CNC Drilling Service in Qatar. Unlock unparalleled accuracy and efficiency in metal fabrication. Learn more at https://www.steelcoqatar.com/product/cnc-drilling-service-qatar.

2 notes

·

View notes

Text

Precision CNC Drilling Solutions at JBC Machine Services

Explore expert cnc drilling solutions at JBC Machine services. Our skilled team delivers accurate and efficient results for various drilling needs. Experience excellence in tailored services, ensuring top-notch precision in every project.

0 notes

Text

Best CNC Router for Home Business

CNC routers are computer-controlled machines that cut and engrave materials like wood, plastic, aluminum, and foam using end mills and engraving tools. They allow you to precisely cut designs and shapes from digital files for applications like sign making, woodworking, crafts, prototyping, and more.

Powered by automated g-code programming, CNC routers offer a precise and versatile solution for cutting a wide variety of 2D parts and designs.

For a home business, a Hobby CNC router can automate production, increase consistency, and allow you to take on larger jobs than would be possible by hand. However, choosing the right model is important based on your specific needs and budget. This guide will help you determine the best CNC router for your home business.

CNC Router for Home Business

When considering the purchase of a CNC mill or router for a small business, it is essential to identify the specific needs of your operations. Key factors to consider include the type of materials you plan on working with, the precision required, the volume of production, and budget constraints. A CNC mill is particularly beneficial for businesses that require high precision and versatility and can cut various materials, from metals to plastics. However, they are generally more expensive than CNC routers.

On the other hand, a CNC router is an ideal investment for businesses primarily working with softer materials like soft aluminum, wood, plastic, acrylic, MDF, PCB, or PVC. These machines are perfect for carving, engraving, or shaping tasks and are typically less expensive than CNC mills. Routers are also easier to learn and operate, making them an excellent choice for beginners or businesses with less technical experience.

CNC router machines are subtractive machines that perform the following:

Cutting

Milling

Drilling

Engraving

CNC routers are built to cut into a wide range of substrates:

Wood

Plastic

High-density foam

Aluminum

Acrylic

Plexiglass

Brass

Galvanized steel and other metals

Carbon fiber sheets

With a CNC router, you can work with all of these materials, increase your workshop’s capabilities, and expand your line of products and services. These machines, therefore, are an investment that can pay off in higher efficiency, product quality, and revenues.

Benefits of Using a CNC Router for Your Home Business

Precision – Accurate to within thousandths of an inch, ensuring quality parts.

Programming flexibility – Designs can be easily edited in CAD/CAM software.

Consistency – Every part will be dimensionally identical when the same program is run.

Speed – Automated cutting is much faster than manual methods for volume production.

Materials versatility – Routers can cut wood, plastic, aluminum, and more with tool changes.

Customization – Unique designs can be easily cut to order without extra setup fees.

Profit potential – New revenue streams emerge from CNC-made goods like signs, models, and gifts.

For any business producing consistent cut parts or customized designs, a desktop CNC router delivers an affordable automated manufacturing solution.

How to Use a CNC Router for Your Home Business

Design 2D vector graphics in CAD software or import DXF/SVG files.

Create toolpaths in CAM software to cut or engrave the design.

Secure material like wood or plastic onto the router bed using clamps or double-sided tape.

Transfer the cut program to the router controller via USB.

Select cutting tools like an endmill or engraving bit appropriate for the material.

Press start and let the machine automatically cut or engrave while unattended.

Once complete, remove parts and repeat for additional products as needed.

With some basic CAD/CAM training, a CNC router allows home businesses to automate production of consistent, customized goods right in their workshop.

0 notes

Text

The Raw Material have been challenged It will be change with our EndMilling

CNC milling services are an integral part of CNC machining and has gained immense traction over the years as it can be used for a wide range of parts. With CNC milling you can achieve high precision and tight tolerances regardless of a complex geometry. These machines used as high-speed milling cutters to shape the object into the desired shape. They are well-known for their ability to work with various metals and plastics, with each having their own physical and chemical properties which may pose challenges. Any CNC milling services provider must know the reaction and interaction of these machines with each of the materials formed. This is an important aspect which this post throws light on. Also, it highlights how CNC milling excels in working with maximum substrates. So stay tuned.

Commonly Milled Materials

This manufacturing technique works well with a diverse range of materials. Here are some important ones.

Metals: They have been the most popular choice of CNC milling services providers owing to their beneficial features. Also, they are preferred by most OEMs even when some are replaced by plastic. CNC milling has the ability to machine precise parts with tight tolerances, intricate designs, and smooth finishes and this is one reason these parts are used across industries such as automotive, aerospace, and heavy engineering. Working with metals, including steel, aluminum, brass, copper, and so on may seem easy. However, it requires attention to detail and considerations like cutting speeds, tool selection, and cooling methods. High-speed carbide tools are used to withstand the high demands of metal machining. Cooling and lubrication are crucial to dissipate heat generated during the process. This helps in preventing tool wear and tear, extending tool life.

Plastics: This is another popular choice for CNC milling, offering a delicate touch while maintaining accuracy. CNC parts made of acrylic, nylon, polycarbonate, and more are durable, lightweight, and visually appealing. While machining plastics, it is essential to manage heat generation to prevent warping or melting. Always, thermoplastics are used as they can withstand high temperatures. Proper chip evacuation and lower cutting speeds are significant in maintaining the material’s integrity. In addition to this, higher rake angle tools are used to minimize cutting forces and potential part distortion.

Composites: As the name implies, they are a fusion of different materials to enhance their properties. However, this presents unique challenges for machining techniques. Owing to the beneficial features of composites, such as strength-to-weight ratio, they are preferred in aerospace and sporting goods. Manufacturing with them requires a fine balance between material-specific considerations and achieving the required precision. Thus, advanced tools with diamond coatings are used when working with abrasive composites.

Ceramics: They are known for their electrical insulation, extreme hardness, and high-temperature resistance properties. CNC milling machines can achieve cutting through tough and abrasive materials like these. While they can be challenging to machine as they are just as brittle, they find use across industries, including aerospace and medical.

This section has covered the commonly CNC milled materials in detail. While material selection holds a great significance in CNC milling, it is equally important to pay attention to the tooling for CNC milling. The next section explains this aspect.

Essential Tooling for CNC Milling

The selection of cutting tools is crucial for successful CNC milling to get the best output. The following are some essential tools to consider for milling.

End Mills: They are commonly used for several milling operations from slotting to contouring. They are available in different sizes and shapes to accommodate multiple milling tasks.

Drills: These tools are mainly used for creating holes. There are different types of drills such as twist, center, and more. The size of the hole and accuracy are two important requisites when choosing drills for your application.

Face Mills: They are ideal for large surfaces. They remove material from the workpiece’s face using multiple cutting edges.

Carbide Inserts: They are replaceable and mounted on milling tools. Carbide inserts extend the tool life and allow for efficient machining.

Are you interested in CNC-milled parts using these materials or substrates? If yes, you must consult a leading CNC milling services provider like BDE, Inc. Over the years, they have been providing to their clients across industries. You can contact them to discuss your application requirements.

1 note

·

View note

Text

CNC Part Manufacturers: How to Choose the Best Partner for Your Production Needs

The manufacturing industry has seen significant advancements over the years, and one of the most transformative technologies is CNC (Computer Numerical Control) machining. CNC part manufacturers play a crucial role in producing high-precision components for various industries, including automotive, aerospace, medical, and electronics. As demand for precision parts continues to grow, choosing the right CNC part manufacturer becomes increasingly important. In this blog post, we’ll explore what CNC part manufacturers do, why their role is essential, and what to consider when selecting the best partner for your production needs.

What Do CNC Part Manufacturers Do?

CNC part manufacturers specialize in producing parts and components using CNC machines. These machines are computer-controlled tools that follow programmed instructions to precisely cut, shape, and finish materials such as metals, plastics, and composites. CNC machining is known for its ability to produce complex geometries with high accuracy and repeatability, making it an essential process for industries that require tight tolerances and consistent quality.

CNC part manufacturers typically offer a range of services, including:

Prototyping: Creating initial prototypes to test design concepts and functionality.

Mass Production: Producing large volumes of parts with consistent quality.

Custom Machining: Tailoring parts to specific customer requirements, often involving complex designs or unique materials.

Post-Processing: Providing additional services such as surface finishing, heat treatment, and assembly to complete the parts.

Why Choosing the Right CNC Part Manufacturer Matters

The quality of the parts produced by CNC part manufacturers directly affects the performance and reliability of the final product. Poorly manufactured parts can lead to product failures, costly recalls, and damage to your brand’s reputation. Therefore, selecting a reputable and experienced CNC part manufacturer is crucial for ensuring the success of your projects.

Key Considerations When Choosing CNC Part Manufacturers

Industry Experience

Experience is one of the most critical factors when choosing a CNC part manufacturer. Manufacturers with a proven track record in your industry are more likely to understand your specific needs and deliver parts that meet your exact specifications. Look for a manufacturer with experience in producing parts for similar applications, as they will be familiar with the challenges and standards required.

Capabilities and Equipment

Not all CNC part manufacturers are created equal. The range of capabilities and the type of equipment they use can vary significantly. It’s important to choose a manufacturer with state-of-the-art CNC machines capable of producing the precision and complexity required for your parts. Additionally, consider whether the manufacturer offers a variety of machining processes, such as milling, turning, drilling, and grinding, to meet your specific needs.

Material Expertise

Different industries require parts made from various materials, each with its own set of properties and challenges. A reputable CNC part manufacturer should have expertise in working with a wide range of materials, including metals like aluminum, steel, and titanium, as well as plastics and composites. They should also be able to advise you on the best material choices for your application based on factors such as strength, weight, and cost.

Quality Assurance

Quality is non-negotiable when it comes to CNC machined parts. Ask potential manufacturers about their quality control processes, including inspection and testing procedures. A good manufacturer will have rigorous quality assurance protocols in place, such as ISO 9001 certification, to ensure that every part meets the required specifications and tolerances. In addition, inquire about their defect rates and how they handle quality issues to ensure they can consistently deliver high-quality parts.

Lead Times and Production Capacity

In today’s fast-paced market, timely delivery is crucial. Choose a CNC part manufacturer that can meet your production deadlines without sacrificing quality. It’s also important to consider the manufacturer’s production capacity—can they handle large orders or scale production as needed? A manufacturer with flexible production capabilities will be better equipped to accommodate changes in your order size or schedule.

Cost and Value

While cost is always a consideration, it’s essential to look beyond just the price per part. Consider the overall value offered by the manufacturer, including quality, reliability, and service. A manufacturer that offers competitive pricing while maintaining high standards of quality and customer service will provide better long-term value. Be wary of manufacturers that offer significantly lower prices, as this could indicate corners are being cut on materials, processes, or quality control.

Communication and Customer Support

Effective communication is key to a successful partnership with a CNC part manufacturer. Choose a manufacturer that is responsive, transparent, and easy to work with. They should provide clear and regular updates on your order status and be proactive in addressing any issues or concerns. Strong customer support ensures that the manufacturing process runs smoothly and that any potential problems are resolved quickly.

Selecting the right CNC part manufacturer is a critical decision that can significantly impact the success of your projects. By considering factors such as industry experience, capabilities, material expertise, quality assurance, lead times, cost, and communication, you can find a manufacturer that meets your needs and delivers high-quality parts consistently.

Whether you’re looking to produce prototypes, custom parts, or large-scale production runs, partnering with a reliable and experienced CNC part manufacturer will ensure that your components meet the highest standards of precision and quality. Take the time to research and evaluate potential manufacturers, and you’ll be well on your way to achieving your production goals.

0 notes

Text

Machine Tooling Market - Forecast(2024 - 2030)

Machine Tooling Market Overview

The Machine Tooling Market is estimated to surpass $94.42 billion marks by 2026 growing at an estimated CAGR of more than 3.7% during the forecast period 2021 to 2026. Increasing demand for high efficiency in complex machining products is expected to drive the Machine Tooling Market. Rise in demand for low operating cost and high precision, along with technological advancement in production processes, is further resulting in the popularity of CNC machine tools. Moreover, development and launch of next-gen, cutting-edge machine products and solutions are the central focus areas for key players in this market. These players are continuously investing in R&D to create enhanced and sophisticated offerings to strengthen their portfolio and further entrench their position in the market.

Machine Tooling Market Report Coverage

The report: “Machine Tooling Market– Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the Machine Tooling Market.

By Type: CNC Machine Tools, Conventional Machine Tools

By Product Type: Metal Cutting Tools (Boring and Drilling, Milling, Finishing, Lathe, Machine Centers and Others), Metal Forming Tools (Rolling, Forging and Press, Extruding and Drawing, Punching and Blanking, Bending, Shearing, Casting and Others) and Special Machine Tools (EDM, EBM, PAM, LBM, USM, ECG, CM and Others)

By Sales Channel: Direct and Indirect

By End User Industry: Automotive, Healthcare, Mining and Metal, Aerospace and Defense, Construction, Electrical and Electronics, Energy and Power, Transportation and Others

By Geography - North America (U.S, Canada, Mexico), South America(Brazil, Argentina and others), Europe (Germany, UK, France, Italy, Spain, Russia and Others), APAC(China, Japan India, SK, Aus and Others), and RoW (Middle East and Africa).

Request Sample

Key Takeaways

End users in this market, typically prefer OEMs to provide maintenance support rather than going through a third party. Thus, driving a change in the market model prevalent in this segment.

CNC has various advantages over conventional machines. the various advantages of CNC machines, including high accuracy, safety, time efficiency, flexibility, and low maintenance, is further expected to drive the CNC machine tools market demand.

The core focus areas for leading players in this business are the technical advancement and introduction of next-gen, cutting-edge CNC machine products and solutions. In order to build enhanced and advanced offerings to improve their portfolio and further entrench their position in the industry, these players are actively investing in R&D.

Machine Tooling Market Segment Analysis - By Type

CNC Machine Tools significantly dominate the Machine tool sector accounting for nearly 80% of the market. CNC Machine Tool systems are generally categorised into Milling, Lathe, Drilling, Plasma Cutter, Grinder, Others. The rising demand for high performance in complex machining products is expected to boost the CNC sector. The growth in demand for low running costs and high accuracy, along with technical advances in manufacturing methods, is further contributing to the popularity of CNC machine tools. In addition, the increase in demand across industries particularly in the electronics and automotive sectors contributes positively to the development of the market for CNC machine tools. The core focus areas for leading players in this business are the technical advancement and introduction of next-gen, cutting-edge CNC machine products and solutions. In order to build enhanced and advanced offerings to improve their portfolio and further entrench their position in the industry, these players are actively investing in R&D. Nearly every OEM provides maintenance services to the end users. These end users prefer OEM led maintenance services rather than third parties due to the discounted maintenance services typically offered as well as reliability and improved component procurement policies. This is changing the business model typically utilized in the market.

Inquiry Before Buying

Machine Tooling Market Segment Analysis - By Product Type

The Milling segment held among the highest market share in 2020. Milling machines tools are primarily used in metal grinding processes across a variety of industries. The positive acceleration of the metalworking process industries in the world has ignited the market for milling machines tools. Milling machines tools are extremely flexible and can perform a wide range of functions, such as filling, spinning, chamfering, drilling, gear cutting, and so on. These devices can also render numerous incisions by using multiple cutters.

Moreover, Lathe segment is anticipated to witness significant market growth during the forecast period 2021-2026. Lathe is a tool that rotates every workpiece on its axis in order to execute a wide variety of operations. Automation is the key factor likely to fuel the expansion of the global demand for lathe machines tools. Manufacturers have begun to simplify their manufacturing procedures in order to improve efficiency. The incorporation of the Internet of Things (IoT) into manufacturing (Smart Manufacturing) is one of the latest market trends that will give the business sufficient momentum in the years ahead.

Machine Tooling Market Segment Analysis - By Geography

APAC accounted for the largest share of the Machine tool market. The significant demand from automotive and aerospace sector in China, India and South-East Asia, in particular, is driving market growth. Geographically, RoW (Middle East and Africa) region is anticipated to witness the significant market growth during the forecast period 2021-2026 with a CAGR of 5.22%. The market growth is due to the rising demand of the CNC machine tools from the end-users including automobile, food & beverage, aerospace, construction and others. Growing automotive production primarily in Kuwait, Jordan, and others is projected to boost the market growth. Israel is home to robust mining and manufacturing sector. The country’s manufacturing sector is booming with effective diamond cutting/polishing technologies, aviation and space products, and food processing. These provide promising growth prospects for the machine tool market in the country.

Schedule a Call

Machine Tooling Market Drivers

Rising Adoption of Internet of Things (IoT) Technologies to Fuel Growth

One of the most prominent machine tools market trends is expected to be the increasing uptake of IoT in the manufacturing sector. This will be a result of escalating demand for information and access to information. Furthermore, producers are looking to bring down their production costs, streamline processes, and raise the safety quotient in their units. As a result, there is growing investment in IoT by manufacturers for improved management and control, which is propelling the machine tool market, especially CNC Machine tools. For instance, it is predicted that by 2020, the manufacturing sector will receive an investment of USD 267 billion for IoT integration. Studies have shown that close to 31% of manufacturing operations are already IoT-enabled, which augurs well for this market.

Adoption of CNC Machine Tools in Medical Sector

The medical industry greatly benefits from the efficiency, speed, and accuracy of CNC machining. According to a report by Teton Machine, the number of Americans aged 65 and older is projected to double between 2019 and 2060 95 million. Due to the growth of aging population, the need for precision machining services in the medical industry is growing as well. CNC machines are capable of producing sophisticated surgical instruments, tiny screws and everything in between. In addition medical machined parts for the most complex devices require tight tolerances, which is capable through CNC machine tools. Adding to this, multi-tool and multi-axis machines, such as CNC Swiss turning centers, improve the manufacturing of medical parts with shorter cycle times and owing to the features allowing versatility during production. Moreover several medical equipment manufacturers such as Pulse systems, are focusing on adopting CNC machine tools for advancements in manufacturing. In 2019, Pulse Systems acquired additional CNC (computer numerical control) machine tools to support the company's rapid growth, and has expanded its facilities space to accommodate the newly-added capital equipment. Hence these rising adoption will drive the market growth in the forecast period 2021-2026.

Buy Now

Machine Tooling Market Challenges

High Maintenance Costs and Lack of Training to Hinder Growth of the Market

Generally, CNC machines are costlier than the manually-operated machines. However, with time, the cost is estimated to reduce effectively. Furthermore, to maintain the proper functioning of the machines, regular maintenance of the high-tech pieces is essential by the manufacturers. Apart from this, the focus in the current market is on deploying cheaper machine tools, especially in developing nations. While this saves on initial investment, these machine tools have higher long-term maintenance, parts replacement and other costs, apart from the limited functionality. Besides that appropriate training and machinists need to get acquainted with the professional skills necessary to operate these machines. Hence high maintenance costs and lack of skilled workers will restrict the market growth in the forecast period 2021-2026.

Machine Tooling Market Landscape

Product launches, acquisitions, and R&D activities are key strategies adopted by players in the Machine Tooling Market. Dalian, Amada, JTEKT, Trumpf, Shenyang Machine Tool (SMTCL), Philips Machine Tools, KRC Machine Tool Services, Optimation Technology Inc., Troy Industrial Services, MIC Group and others are considered to be the key players of the Machine Tooling Market.

Acquisitions/Technology Launches/Partnerships

In December 2019, DMG MORI, a leading machine tool manufacturer launched LASERTEC 125 3D hybrid, a new hybrid additive manufacturing system. The LASERTEC 125 is a 5-axis laser deposition welding (LDW) system designed for the maintenance, repair and production of significantly larger parts

IN February 2019, Okuma America Corporation, a world leading builder of CNC machine tools, partnered with Jergens, a superior manufacturer of workholding solutions for machine tools. This partnership was aimed to provide the best possible integrated solutions to the end-user. Such partnerships and Product launches positively impacts the market growth.

#Machine Tooling Market#Machine Tooling Market Share#Machine Tooling Market Size#Machine Tooling Market Forecast#Machine Tooling Market report#Machine Tooling Market Growth

0 notes