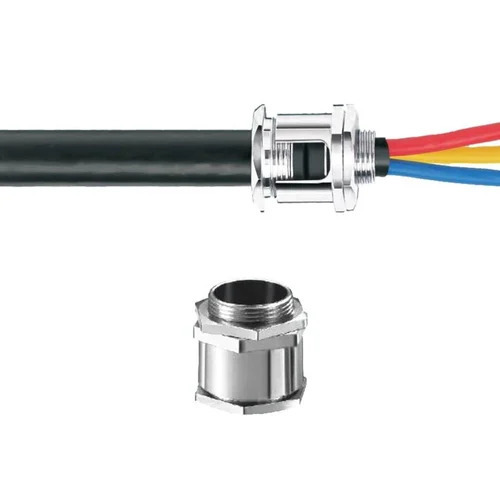

#Cable Gland Installation

Text

Atlas Metal offer products in a variety of metals like Brass, Zinc, Stainless Steel etc. and also we make customized products exactly in accordance with the specification of the customer and keep desire to provide best quality which satisfies customer’s expectations at a competitive price.

#Brass Components#Metal Industries#Pipe Fitting Manufacturers#Brass Fittings Manufacturer#Brass Pipe Fitting#Brass Pipe Fittings#Cable Gland Installation#Brass Plumbing Fittings#Brass Manufacturer

0 notes

Text

#LEDHighBayLightSupplierUAE

Prolux International LLC is one of the famous provider of LED High Bay Light Supplier UAE and are intended to illuminate rooms with high ceilings, as their name suggests. That normally implies having ceilings that are between 20 and 45 feet high. A high bay is a powerful light source that can brighten up a vast area by definition because a high-ceiling location has more room to fill, making it the ideal alternative for Outdoor LED lighting.

#led high bay light supplier#prolux international#uae#led lighting uae#led sports lighting supplier uae#explosion proof lighting manufacturer china#led high bay light supplier uae#explosion proof cable glands uae#solarlights#solarlightstockist#solarlightstockistuae#LED Stadium Light Supply and Installation Dubai

0 notes

Text

Why Earth Tag Washers Are Essential for Electrical Grounding

Introduction

Earth Tag Washers, also known as grounding or earthing washers, are critical components used in electrical installations to ensure effective grounding. They are typically installed with cable glands or other electrical equipment to provide a secure connection between the equipment and the earth (ground). This helps to safely discharge electrical current, preventing electrical shock hazards and equipment damage.

What Are Earth Tag Washers?

Earth tag washers are metal washers with a tab or tag that allows them to connect to grounding systems. They are used to bond electrical enclosures, cable glands, or conduits to the earth, ensuring that any stray electrical current is safely diverted. Earth tag washers are usually made from corrosion-resistant materials such as galvanized steel or brass to ensure durability and reliable conductivity.

Key Features of Earth Tag Washers

Electrical Grounding

The primary function of earth tag washers is to establish a reliable connection between electrical components and the grounding system, providing a safe path for electrical current.

Corrosion Resistance

Since these washers are often used in outdoor or harsh environments, they are designed with corrosion-resistant materials to ensure long-lasting performance.

Compatibility with Cable Glands

Earth tag washers are often used in conjunction with cable glands to ensure that the cable entry points into electrical enclosures are properly grounded, preventing electrical hazards.

Easy Installation

Earth tag washers are easy to install and can be added to existing setups without significant modifications. Their compact design allows them to be incorporated into tight spaces.

Applications of Earth Tag Washers

Electrical Enclosures

Earth tag washers are commonly used to bond electrical enclosures to the ground, ensuring that any static charge or electrical faults are safely discharged.

Cable Glands

These washers are often paired with cable glands to ground cables as they enter junction boxes or equipment, providing an additional layer of safety.

Industrial Machinery

In industries where electrical equipment is subject to vibrations, earth tag washers provide secure grounding connections that ensure the machinery operates safely.

Importance of Grounding in Electrical Systems

Grounding is a critical safety measure in electrical systems. Proper grounding protects against electrical faults, static buildup, and lightning strikes. Earth tag washers play a crucial role in this process by ensuring all electrical components are connected to the earth, minimizing the risk of electrical shock or equipment damage.

Conclusion

Earth tag washers are essential components in ensuring the safety and effectiveness of electrical systems. By providing reliable grounding, these washers help protect both people and equipment from electrical faults. Whether used with cable glands or electrical enclosures, earth tag washers are a simple but vital part of any grounding system.

0 notes

Text

Cable Gland Manufacturing in India: Driving Connectivity and Safety

Cable glands are essential components in electrical and instrumentation systems, serving as crucial elements for providing secure cable entry points while ensuring protection against environmental factors such as dust, moisture, and vibrations. In India, the manufacturing of cable glands has seen significant growth, with companies producing a wide range of high-quality products to meet domestic and international demands. This article explores the landscape of cable gland manufacturing in India, key players in the industry, technological advancements, market trends, and the importance of cable glands in ensuring connectivity and safety in various applications.

Overview of Cable Gland Manufacturing in India:

India has emerged as a prominent hub for cable gland manufacturing, with several companies specializing in the production of a diverse range of cable glands for different industries and applications. These manufacturers leverage advanced technologies, stringent quality standards, and skilled labor to produce reliable and efficient cable gland solutions that meet the requirements of both domestic and global markets.

Significance of Cable Glands:

Secure Cable Management: Cable glands provide a secure and reliable method for routing cables through enclosures, panels, or equipment while maintaining ingress protection against dust, water, and other contaminants.

Electrical Safety: By ensuring proper cable termination and grounding, cable glands help prevent electrical hazards such as short circuits and shocks, enhancing overall safety in electrical installations.

Environmental Protection: Cable glands offer protection against environmental factors like moisture, chemicals, and mechanical stress, ensuring the longevity and performance of electrical systems in diverse operating conditions.

Key Players in the Cable Gland Industry in India:

CMP Products India: CMP Products India is a leading manufacturer of cable glands, cable cleats, and associated products, known for its high-quality offerings and innovative solutions.

Rajputana Engineering Works: Rajputana Engineering Works specializes in the production of cable glands, conduit fittings, and accessories, catering to a wide range of industrial applications.

Dowells Cable Gland Pvt. Ltd.: Dowells Cable Gland Pvt. Ltd. is a well-established manufacturer of cable glands and electrical connectors, recognized for its reliability and product quality.

Hex Cable Accessories Pvt. Ltd.: Hex Cable Accessories Pvt. Ltd. is a trusted supplier of cable glands, lugs, and other electrical accessories, offering a comprehensive range of products for various industries.

Braco Electricals India Pvt. Ltd.: Braco Electricals India Pvt. Ltd. specializes in the manufacturing of cable glands, cable ties, and cable accessories, providing solutions for industrial and commercial applications.

Technological Advancements and Market Trends:

Material Innovations: Manufacturers are exploring advanced materials such as stainless steel, brass, and aluminum alloys to enhance the durability and performance of cable glands in challenging environments.

IP Ratings Compliance: Emphasis on designing cable glands that meet international Ingress Protection (IP) ratings to ensure reliable protection against dust and moisture ingress.

Customization and Specialization: Offering customized cable gland solutions tailored to specific industry requirements and applications, providing flexibility and adaptability in cable management.

Automation and Robotics: Integration of automation and robotics in manufacturing processes to improve efficiency, precision, and consistency in producing cable glands of high quality.

Global Expansion: Indian cable gland manufacturers are increasingly expanding their presence in international markets, leveraging competitive pricing and quality offerings to cater to a global customer base.

Importance of Cable Glands in Connectivity and Safety:

Cable glands are integral components in electrical installations across various sectors, ensuring reliable connectivity, cable management, and safety. By providing secure cable entry points, strain relief, and environmental protection, cable glands play a critical role in maintaining the integrity and efficiency of electrical systems, thereby reducing the risk of electrical faults, downtime, and safety hazards.

In conclusion, the cable gland manufacturing in India continues to thrive, driven by technological advancements, quality standards, and a focus on innovation. With a diverse range of products, customized solutions, and a commitment to meeting industry requirements, Indian cable gland manufacturers contribute significantly to ensuring connectivity and safety in electrical and instrumentation systems both domestically and globally. As the demand for reliable cable management solutions grows, the role of cable glands in facilitating secure and efficient cable routing remains paramount in enhancing the performance and longevity of electrical installations.

0 notes

Text

Cable Glands Market — Forecast(2024–2030)

Cable Glands Market Overview:

Cable Glands Market size is estimated to reach $3.9 billion by 2030 growing at a CAGR of 6.5% during the forecast period 2024–2030.

The cable glands market is witnessing a robust surge in demand, driven by the increasing need for secure and efficient cable management solutions across various industries. As businesses expand their infrastructure, the demand for reliable cable glands to ensure proper sealing and protection against environmental factors is on the rise, contributing to the cable glands market growth.

For Instance, as per the International Trade Administration, the 14th Five-Year Plan of China places a strong emphasis on new urbanization, energy, water, and transportation infrastructure projects. Estimates indicate that throughout the 14th Five-Year Plan period (2021–2025), total investments in new infrastructure will come to approximately $4.2 trillion. This growth has heightened the demand for essential components, such as cable glands, crucial for secure cable installations. This surge in infrastructure development is likely to drive demand for cable glands, essential components in ensuring secure and efficient cable installations.

Cable Glands Market — Report Coverage:

The “Cable Glands Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Cable Glands Market.

Attribute Segment

By Type

Hazardous Area Cable Glands

Industrial Cable Glands

By Materials

Brass

Stainless Steel

Plastic

Aluminum

Nylon

Nickel

Others

By Cable Type

Armored

Unarmored/Non-Armored

By Application

Control boxes

Skids

Motors

Lighting

Connector for electrical devices

Data Cable

By End-Use

Manufacturing & Processing

Oil & Gas

Mining

Aerospace

Chemicals

Marine

Poer & Utilities

Construction

Automation

Others

By Geography

North America (U.S., Canada and Mexico)

Europe (Germany, France, UK, Italy, Spain, Russia and Rest of Europe),

Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific),

South America (Brazil, Argentina, Chile, Colombia and Rest of South America)

Rest of the World (Middle East and Africa).

COVID-19 / Ukraine Crisis — Impact Analysis:

The COVID-19 pandemic has had a significant impact on the cable glands market. The global outbreak of the COVID-19 pandemic in 2020 led to a sharp decline in economic activities across various industries. This resulted in a decrease in the demand for cable glands, as many industries were forced to shut down their operations or reduce their production capacity.

The Ukraine crisis is expected to have a significant impact on the cable glands market. The crisis has disrupted supply chains and increased the cost of raw materials. This is expected to lead to higher prices for cable glands. The crisis is also expected to reduce demand for cable glands in some industries, such as construction. This is due to economic uncertainty and the decline in construction activity in some regions.

Sample Request

Key Takeaways:

Fastest Growth of APAC

Geographically, in the global Cable Glands Market share, APAC is analyzed to grow with the highest CAGR of 7.4% during the forecast period 2024–2030. The surging demand for cable glands in the APAC region is intricately tied to robust infrastructure development, notably in China, India, and Southeast Asian nations. Ongoing projects in power generation, telecommunications, and industrial facilities necessitate reliable cable management and protection, driving the need for these essential components. As the region continues its dynamic growth trajectory, the cable gland market is poised to play a pivotal role in supporting and facilitating the expanding infrastructure landscape. For instance, according to the International Energy Agency, China will be accountable for over 45% of the increase in renewable energy output between 2023 and 2025. These developments underscore a pivotal role in shaping the future of renewable energy and the growing market for cable glands in the APAC region.

• Unarmored is Register the Fastest Growth

Unarmored is analyzed to grow with the highest CAGR of 6.8% during the forecast period 2024–2030. The global market for unarmored cable glands, essential components in electrical enclosures, is experiencing steady growth. These glands establish reliable connections between cables and equipment, safeguarding against dust, water, and contaminants. Widely utilized for their protective qualities, unarmored cable glands contribute to the durability and efficiency of electrical systems worldwide. As industries expand and technological advancements continue, the demand for these glands is expected to rise, further propelling the global unarmored cable glands market.

• The Construction Segment is to Register the Highest Market Growth

According to the Cable Glands Market forecast, Construction held the largest market valuation reaching $237.6 million in 2023. The construction industry is experiencing a significant surge worldwide, leading to a higher demand for various construction materials and equipment. One such product in high demand is cable glands, which are essential for securing and protecting cables in construction projects. As the construction industry continues to boom, the cable glands market is expected to witness a steady increase in demand, reflecting the industry’s growth and development. This trend highlights the importance of cable management in ensuring efficient and safe construction practices. Additionally, according to the UK Government, the worldwide construction sector is expected to rise by more than 70% by 2025. As construction projects proliferate worldwide, the demand for reliable and efficient cable management solutions intensifies.

• Growing the demand for Automation Industry

The Cable Glands Market anticipates a rapid surge in the Automation segment, driven by escalating demand for automation within industrial applications. This robust growth trajectory is propelled by the need for efficient and streamlined processes in diverse industries. As automation becomes integral to industrial operations, cable glands play a pivotal role in ensuring secure and organized cable management, further fueling their demand. The market is poised to capitalize on this trend, offering innovative solutions that cater to the evolving automation landscape. This upward trajectory underscores the pivotal role of cable glands in facilitating the seamless integration of automated systems across various industrial sectors. For instance, according to the International Trade Administration, Japan is predicted to have 40% fewer workers overall by 2065. This will lead to a rise in the need for advanced industrial equipment and equipment as well as automated systems. This trend is poised to propel the Automation segment to high growth, particularly in industrial applications.

• Volatility in Raw Material Prices Hampers the Market Growth

Cable glands can be composed of stainless steel, brass, nickel, aluminum, or plastic, depending on the kind of use. Raw material costs are very variable while producing cable glands. Their prices are very dependent on the state of the market because these are essential metals. Cable glands are commonly made from basic materials like brass and aluminum. Fluctuations in material costs impact manufacturing expenses, posing a significant hurdle for market players. This uncertainty complicates pricing strategies and affects profit margins. To navigate these challenges successfully, companies must adopt resilient supply chain practices, explore alternative materials, and implement strategic pricing models. Adapting to the dynamic raw material landscape is essential for sustaining competitiveness in the Cable Glands market.

Inquiry Before Buying

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships and collaborations are key strategies adopted by players in the Cable Glands Market. The top 10 companies in this industry are listed below:

1. Eaton Corporation (TMCX II Armored Glands)

2. Emerson Electric Co (Rosemount™ General Purpose Cable Gland)

3. CMP Products Ltd (CMP Cable Glands)

4. Cortem S.p.A (Cortem NAVB series barrier cable gland)

5. Warom Technology, Inc. (DQM-II Series Explosion-proof Cable Glands)

6. Sealcon LLC (Sealcon Cable glands)

7. Jacob GmbH (Jacob Perfect cable gland)

8. Amphenol Corporation (Amphenol Cable Glands)

9. BARTEC Top Holding GmbH (Bartec Cable glands)

10. ABB Group (ABB RNCG Series Cable gland)

Buy Now

Scope of the Report:

Report Metric Details

Base Year Considered

2023

Forecast Period

2024–2030

CAGR

6.5%

Market Size in 2030

$3.9 billion

Segments Covered

By Type, Materials, Cable Type, Application, End-Use and Region.

Geographies Covered

North America (U.S., Canada and Mexico), Europe (Germany, France, UK, Italy, Spain, Russia and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia, New Zealand and Rest of Asia-Pacific), South America (Brazil, Argentina, Chile, Colombia and Rest of South America), Rest of the World (Middle East and Africa).

Key Market Players

1. Eaton Corporation

2. Emerson Electric Co

3. CMP Products Ltd

4. Cortem S.p.A

5. Warom Technology, Inc.

6. Sealcon LLC

7. Jacob GmbH

8. Amphenol Corporation

9. BARTEC Top Holding GmbH

10. ABB Group

For more Information and Communications Technology Market reports, please click here

0 notes

Text

Cable Glands: Essential Components for Secure Electrical Installations - A Guide by Trans Light Electricals LLC

In the world of electrical installations, safety and security are paramount. One crucial component that ensures the integrity of electrical systems is the cable gland. At Trans Light Electricals LLC, we specialize in providing high-quality cable glands designed to meet the demands of various industrial and commercial applications. In this post, we’ll explore what cable glands are, their importance, and how to select the right ones for your projects.

What Are Cable Glands?

Cable glands, often referred to as cable connectors or fittings, are devices that attach and secure the end of an electrical cable to equipment. Their primary purpose is to ensure that the electrical connections are safe, secure, and protected from external elements like moisture, dust, and mechanical stress. They are essential for maintaining the performance and longevity of electrical systems.

Why Are Cable Glands Important?

Sealing and Retention:

Cable glands provide a secure seal, preventing environmental contaminants from entering sensitive electrical equipment. This is crucial in outdoor and industrial environments where dust, moisture, or chemicals could damage the system.

Strain Relief:

Cable glands relieve mechanical stress on cables, preventing them from being pulled out or damaged due to tension or vibration. This ensures the longevity and safety of the connection.

Cable Protection:

By providing a protective barrier, cable glands shield cables from sharp edges or abrasion, reducing the risk of wear and tear over time.

Compliance and Safety:

High-quality cable glands help ensure that installations comply with industry standards and regulations, promoting safety and reliability.

Types of Cable Glands

At Trans Light Electricals LLC, we offer a wide range of cable glands to suit various applications. Some of the most common types include:

Metallic Cable Glands: Ideal for heavy-duty applications, metallic cable glands offer excellent durability and protection in harsh environments.

Non-Metallic Cable Glands: Made from plastic or other materials, these glands are lightweight, corrosion-resistant, and suitable for less demanding environments.

EMC Cable Glands: These are designed to provide electromagnetic compatibility, ensuring that the cable does not emit or absorb electromagnetic interference.

Flameproof Cable Glands: Specifically engineered for hazardous environments, these glands prevent the ignition of flammable gases or dust.

How to Choose the Right Cable Gland

Selecting the correct cable gland depends on several factors, including:

Cable Type and Diameter: Ensure the gland fits the cable size correctly for a secure seal.

Operating Environment: Consider the conditions in which the gland will be used, such as exposure to chemicals, extreme temperatures, or water.

Material: Choose the material based on the application’s needs, whether metallic for strength or non-metallic for resistance to corrosion.

Certification: For installations in hazardous areas, it’s vital to select cable glands that meet the necessary safety standards.

Why Choose Trans Light Electricals LLC?

At Trans Light Electricals LLC, we pride ourselves on being a leading cable gland supplier in the industry. Our products are sourced from reputable manufacturers and are designed to meet the highest standards of quality and safety. Whether you need cable glands for industrial, commercial, or residential applications, we have the solutions to ensure your installations are secure and reliable.

Trans Light Electricals LLC

Ras Al Khor Industrial Area – Ras Al Khor Industrial Area 2 – Dubai – United Arab Emirates

+97143399627

0 notes

Text

Best Overview of Cable Entry Systems & Accessories

Cable entry systems and accessories are integral components in the management and protection of cables in various electrical, electronic, and industrial applications. These systems are designed to facilitate the organized routing of cables through enclosures, walls, panels, or machinery, while also providing protection against environmental and mechanical stresses. The use of cable entry systems is critical in ensuring the safety, reliability, and efficiency of electrical installations across a wide range of industries.

What Are Cable Entry Systems?

Cable entry systems refer to assemblies or devices that allow cables to pass through barriers such as enclosures or walls while maintaining the integrity and safety of the installation. These systems include various components like entry frames, grommets, seals, cable glands, and strain relief devices. Each component plays a specific role in securing and protecting the cables, ensuring they are properly organized and shielded from potential hazards.

The primary purpose of cable entry systems is to create a secure and sealed entry point for cables. This prevents the ingress of dust, moisture, chemicals, and other contaminants that could damage the cables or interfere with their operation. Additionally, these systems provide mechanical protection by preventing cables from being pulled, bent, or subjected to vibrations that could lead to wear and tear over time.

Key Components of Cable Entry Systems

Cable entry systems are composed of several key components, each of which serves a specific function in ensuring the effective management and protection of cables. These components include:

Cable Glands:

Cable glands are devices that secure cables as they enter an enclosure, providing both mechanical retention and environmental sealing. They are designed to prevent the ingress of dust, moisture, and other contaminants while also providing strain relief to protect cables from mechanical stress. Cable glands are available in various materials, such as plastic, brass, and stainless steel, to suit different environmental conditions and cable types.

Entry Frames and Plates:

Entry frames and plates are modular components that allow multiple cables to be routed through a single entry point. They are typically installed into pre-cut openings in panels or enclosures, providing an organized and secure passage for cables. Entry frames often include grommets or seals that further enhance environmental protection and strain relief.

Grommets and Seals:

Grommets and seals are essential for creating a tight and secure fit around cables as they pass through entry frames or plates. Grommets are flexible rings that protect cables from sharp edges and prevent chafing, while seals ensure that no dust, moisture, or other contaminants can enter the enclosure. These components are particularly important in maintaining the integrity of installations in harsh environments.

Strain Relief Devices:

Strain relief devices are designed to prevent mechanical stress on cables, which can occur due to pulling, bending, or vibration. These devices secure the cable in place, preventing movement that could lead to damage. Strain relief is especially important in applications where cables are subject to frequent movement or need to maintain a fixed position relative to the enclosure or machinery.

Blind Plugs and Blanking Plates:

Blind plugs and blanking plates are used to seal off unused entry points in modular cable entry systems. This helps maintain the system's environmental protection by preventing dust, moisture, or other contaminants from entering the enclosure. These components also provide flexibility in system design, allowing for future expansion without compromising the current installation.

Types of Cable Entry Systems

Cable entry systems come in various types, each designed to meet specific application requirements. Some of the most common types include:

Split Cable Entry Systems:

Split cable entry systems are designed to allow cables with pre-terminated connectors to pass through an entry point without the need to remove the connectors. The system can be opened, the cable inserted, and then closed around the cable, making it ideal for retrofitting or adding new cables to an existing installation.

Brush Cable Entry Systems:

Brush cable entry systems use brush-like materials to allow cables to pass through while minimizing the ingress of dust and debris. These systems are commonly used in data centers or server rooms where it is important to maintain airflow and cooling efficiency while managing a large number of cables.

Membrane Cable Entry Systems:

Membrane cable entry systems feature flexible membranes that self-seal around cables when they are pushed through. These systems are ideal for applications where cables frequently need to be added or removed, as the membrane adapts to different cable sizes and configurations.

Multi-Entry Cable Glands:

Multi-entry cable glands are designed to accommodate multiple cables through a single entry point, offering sealing and strain relief for each individual cable. These glands are particularly useful in compact installations where space is limited.

Applications of Cable Entry Systems

Cable entry systems are used in a wide range of industries and applications, including:

Industrial Automation:

In industrial environments, cable entry systems protect cables from harsh conditions such as dust, moisture, and chemical exposure. They are essential for ensuring the reliability and safety of machinery and control systems.

Telecommunications and Data Centers:

In telecommunications and data centers, cable entry systems help manage large volumes of data and power cables. They prevent signal interference, ensure proper airflow, and protect cables from physical damage.

Transportation and Automotive:

In the automotive and transportation industries, cable entry systems protect wiring harnesses as they pass through vehicle bodywork, shielding them from mechanical damage, moisture, and other environmental factors.

Construction and Building Services:

In construction, cable entry systems are used to route electrical, data, and communication cables through walls, floors, and ceilings. They help maintain the integrity of fire-rated barriers and ensure compliance with building codes.

Marine and Offshore:

In marine environments, cable entry systems protect cables from saltwater, extreme temperatures, and mechanical stress. They are used on ships, offshore platforms, and other maritime structures.

Energy and Utilities:

Cable entry systems are used in power generation and distribution, including renewable energy installations. They protect cables from environmental conditions and ensure reliable operation of electrical systems.

Benefits of Cable Entry Systems & Accessories

The use of cable entry systems and accessories offers several key benefits:

Enhanced Safety:

Cable entry systems reduce the risk of electrical hazards by securely routing and protecting cables, preventing short circuits, fires, and electric shocks.

Improved Organization:

These systems help organize cables, reducing clutter and making maintenance and troubleshooting easier. This is particularly important in complex installations with numerous cables.

Environmental Protection:

Cable entry systems provide robust protection against environmental factors, extending the lifespan of cables and reducing the likelihood of damage.

Compliance with Standards:

Properly designed and installed cable entry systems help ensure compliance with industry standards and regulations, which is crucial for safety and reliability.

Cost Savings:

By preventing cable damage and reducing maintenance needs, cable entry systems can lead to significant cost savings over the life of an installation.

Conclusion

Cable entry systems and accessories are vital for the safe, organized, and efficient management of cables in various industrial and commercial applications. These systems protect cables from environmental and mechanical hazards, ensuring the reliability and longevity of electrical installations. Whether in industrial automation, telecommunications, transportation, or construction, cable entry systems play a crucial role in maintaining the integrity and performance of modern electrical systems.

0 notes

Text

Choosing the Right Cable Gland for Your Installation: A Guide to E1W, A2, and BW Cable Glands

When it comes to securing and sealing cables in electrical installations, cable glands are indispensable components. They protect cables from environmental damage, ensure safety, and maintain the integrity of the installation. At Raiden Industries, we offer a range of high-quality cable glands, including E1W cable glands, A2 cable glands, and BW cable glands, tailored to meet diverse installation requirements.

Understanding Different Types of Cable Glands

Choosing the right cable gland depends on the application, the type of cable being used, and the environment in which the installation takes place. Here's a breakdown of the three most common types of cable glands we offer at Raiden Industries:

E1W Cable Gland

Ideal for: Armored cables in outdoor or industrial settings.

Key Features: E1W cable glands are designed for use with armored cables in demanding environments. They provide an extra seal on the cable's inner sheath, offering enhanced protection against environmental factors such as dust, moisture, and chemicals. This makes E1W glands an excellent choice for outdoor applications or installations where robust sealing is required.

A2 Cable Gland

Ideal for: Unarmored cables in general-purpose indoor or outdoor applications.

Key Features: A2 cable glands are designed for use with unarmored cables, providing a secure grip and reliable sealing. These glands are perfect for general-purpose applications, offering simple and efficient cable termination in a wide range of environments, both indoors and outdoors.

BW Cable Gland

Ideal for: Armored cables in indoor environments.

Key Features: BW cable glands are suitable for armored cables used in indoor installations. They offer mechanical retention and earth continuity, ensuring a secure connection. BW cable glands are commonly used in building infrastructure, where protection against physical stress and maintaining electrical continuity are crucial.

Why the Right Cable Gland Matters

Using the appropriate cable gland for your installation is essential to ensure the longevity and safety of the electrical system. The wrong gland can compromise the protection of your cables, leading to issues such as water ingress, mechanical damage, or electrical failures. With Raiden Industries' range of E1W, A2, and BW cable glands, you can find the right solution for your specific needs, ensuring the safety and reliability of your installation.

Applications of Cable Glands

Industrial and Outdoor Installations: For heavy-duty environments, such as manufacturing plants or outdoor infrastructure, E1W cable glands offer the sealing and protection needed to withstand harsh conditions.

General Purpose Installations: A2 cable glands are versatile and can be used in both indoor and outdoor settings for unarmored cables, making them suitable for a wide range of general-purpose applications.

Indoor Electrical Systems: BW cable glands are the go-to solution for indoor installations that require the secure termination of armored cables, such as in commercial or residential buildings.

Trust Raiden Industries for Your Cable Gland Needs

At Raiden Industries, we are committed to delivering high-quality cable management solutions that ensure the safety and efficiency of your electrical installations. Whether you need E1W cable glands for heavy-duty applications, A2 cable glands for general use, or BW cable glands for indoor environments, we have the products and expertise to meet your needs.

Contact Raiden Industries for reliable cable glands that offer the protection and performance you need for any installation.

Website: Raiden Industries

0 notes

Text

Explosion Proof Equipment Market Trends & Outlook 2024

The Explosion proof equipment market report size is projected to reach to USD 9.9 billion by 2025, at a CAGR of 5.9% during the forecast period. Factors such as the increasing industrial safety measures and rising energy requirements are driving the explosion proof equipment industry.

The explosion proof equipment market for wireless connectivity services is expected to grow at a higher rate during the forecast period

The explosion proof equipment market for wireless connectivity services is projected to grow at a high growth rate during the forecast period. The growth of the segment can be attributed to its lower installation cost, requirement for cable-free operations, and reduction in space occupied and weight. Wireless devices can minimize the number of devices installed, such as cabling and other installation equipment leading to low installation expenditure and low labor costs.

Download PDF:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=108397700

The explosion proof equipment market for cable glands & accessories segment held the largest share of the market

The explosion proof equipment market for cable glands & accessories segment held the largest share of the market in 2019. Cable glands and accessories are increasingly used for mechanical retention, strain relief, and earth continuity.

The explosion proof equipment market in RoW is projected to grow at the highest CAGR during the forecast period.

The explosion proof equipment market in Rest of the World is expected to grow at the highest CAGR during the forecast period, due to the presence of the world’s largest oil & gas production, mining, and energy & power industries, which are highly prone to explosions in the region. The rising demand for protection in the oil & gas industry led the manufacturers to certify their products for use in explosive atmospheres.

Key Players: Explosion Proof Equipment Market

The major players in the explosion proof equipment market are Siemens (Germany), Honeywell International Inc. (US), ABB Ltd. (Switzerland), Rockwell Automation, Inc. (US), and Eaton Corporation Plc (Ireland).

Honeywell International, Inc.

Honey well International is a multinational company, founded in 1906 and headquartered in New Jersey, US. The company offers a variety of commercial and consumer products and engineering services.

ABB Ltd.

Founded in 1988 and headquartered in Zurich, Switzerland, ABB Ltd. is a multinational company founded after the merger of Allmanna Svenska Elektriska Aktiebola – ASEA (Sweden) and Brown, Boveri & Cie – BBC (Switzerland). ABB Ltd. is a global leader in power and automation technologies. The company operates through five business segments, such as electrification, motion, industrial automation, and robotics & discrete automation.

0 notes

Text

Brass Cable Glands: Reliable Protection for Industrial and Electrical Applications

Brass cable glands are indispensable for managing and protecting electrical cables in many industries. These fittings are durable and well-known for their safe and efficient connections to electrical systems. The combination of copper and zinc in brass gives it remarkable durability, resistance to corrosion, and tolerance for high temperatures; these qualities make it a perfect material for cable glands used in demanding settings.

Brass cable glands are strong and durable, lasting a long time and working reliably even when subjected to extreme conditions like vibration, impact, and mechanical stress.

Due to brass's natural resistance to corrosion, these cable glands are ideal for indoor and outdoor use, including those with frequent exposure to chemicals and water, such as maritime and industrial applications.

Brass cable glands are perfect for several industrial uses due to their high-temperature tolerance, allowing them to remain intact and functional in hot and cold environments.

Flexible and adaptable installation is made possible by the large range of sizes and configurations offered by brass cable glands, which can accommodate a variety of cable kinds and diameters.

The tight seal brass cable glands provide during installation makes them ideal for use in environments with dust, moisture, and other environmental elements. As a result, electrical systems are more secure and easier to maintain.

Industrial Machinery:

Brass cable glands are widely utilized in industrial machinery to safeguard electrical cables, guaranteeing the equipment's safe and effective performance.

Cable glands made of brass are perfect for usage in marine environments because they are resistant to corrosion and can withstand seawater and other harsh conditions.

Industries dealing with oil and gas, mining, and chemical processing use brass cable glands to operate safely in hazardous locations. These glands offer secure connections that help to prevent the intrusion of explosive gasses and dust.

Telecoms:

Crucial communication networks rely on the dependable connections provided by brass cable glands, which safeguard and organize cables in telecoms' infrastructure.

Brasil Cable Glands Production

Precision machining, casting, and finishing are steps in creating brass cable glands that guarantee long-lasting components that satisfy all industry standards. Thanks to improvements in production technology, brass cable glands are now the go-to for a wide variety of uses because of their high performance and dependability.

0 notes

Text

How to Use Industrial Cable Glands: A Comprehensive Guide

Explore the world of industrial cable glands with Atlas Metal Industries, a renowned manufacturer in the metal industry. Gain in-depth knowledge about cable gland types, materials, and installation procedures in our comprehensive blog. From armored to stainless steel cable glands, discover the perfect fit for your industrial applications. Atlas Metal, ensuring quality and reliability in every connection for over two decades.

#Atlas Metal#Cable Glands#Industrial Applications#Electrical Installations#MetalIndustry#Quality and Reliability#Armoured Cable Glands#Stainless Steel Cable Glands

0 notes

Text

Cable Accessories Supplier -royal projects

Royal Projects is a premier supplier of cable accessories, offering a diverse range of high-quality products. Their inventory includes cable lugs, connectors, glands, ties, heat shrink tubing, and markers. Known for durability and reliability, these accessories ensure safe and efficient electrical installations across various industries. Royal Projects' commitment to quality makes them a trusted choice for all cable accessory needs.

#Cable Accessories Suppliers#Cable Accessories Suppliers in Ahmedabad#Cable Accessories Suppliers in Gujarat#Cable Accessories Wholesalers#Cable Accessories Wholesalers in Ahmedabad#Cable Accessories Wholesalers in Gujarat

0 notes

Text

Best Suppliers & Dealers of Quality Brass Cable Glands in Dubai, UAE | Translight Electricals

Proper sealing and terminating of wiring and cable entrances are crucial. Cable glands not only offer explosion-proof enclosures but also reduce installation time while protecting against moisture and dust.

We offer high-quality brass cable glands that seal around cables effectively. Available in various materials, these glands should be chosen wisely to maintain standards and protection.

Features & Applications

Suitable for dry indoor use with all types of SWA cables.

Provides impact resistance and a strong holding force on the cable.

Ensures a high degree of entrance protection with additional sealing.

Functions as safety equipment in hazardous areas.

Trans Light Electricals offers the best suppliers and dealers of high-quality brass cable glands in Dubai, UAE, ensuring maximum protection from genuine brands.

1 note

·

View note

Text

Maximizing Efficiency with Cable Entry Systems and Accessories

Cable Entry Systems & Accessories: Streamlining Electrical Installations

Efficient cable management is essential in any electrical or industrial setup, where multiple cables need to be securely organized, protected, and routed. This is where Cable Entry Systems and Accessories come into play. These systems allow cables to pass through enclosures, panels, and machines while maintaining a high level of protection against environmental factors like dust, moisture, and mechanical stress.

In this post, we’ll explore the importance of cable entry systems, the available types, and the various accessories that enhance their functionality.

What are Cable Entry Systems?

Cable entry systems are designed to provide organized and secure entry points for cables into electrical enclosures, control panels, or equipment housings. They ensure that cables are not only neatly routed but also protected from external damage and strain. These systems are essential in maintaining the integrity of electrical installations in industries such as manufacturing, telecommunications, and energy.

Key Benefits of Cable Entry Systems

Protection: Cable entry systems provide protection against dust, water, and other environmental hazards. Many of these systems have high IP (Ingress Protection) ratings to ensure they can withstand harsh conditions.

Ease of Installation: These systems are designed to make installation quick and easy. They often feature pre-configured seals or modular designs, allowing for flexible cable routing and adjustments.

Safety: By securely holding cables in place and offering strain relief, cable entry systems help prevent electrical faults, wear, and potential accidents.

Efficiency: Proper cable management through these systems enhances the efficiency of electrical installations, reducing the need for costly repairs and downtime due to cable damage or mismanagement.

Types of Cable Entry Systems

Cable Glands: As part of a cable entry system, cable glands secure individual cables as they enter enclosures. They provide strain relief and environmental sealing, protecting the internal components from moisture, dust, or other contaminants.

Cable Entry Frames: These are modular systems that allow multiple cables to pass through a single entry point. Entry frames are ideal for applications where numerous cables need to be routed in an organized manner.

Brush Strips: Brush strips are used for low-density cable entry points, providing a flexible barrier for cables while offering a level of protection against dust and other particles. They are often used in server cabinets and IT installations.

Split Cable Entry Systems: These systems allow pre-terminated cables (cables with connectors already attached) to pass through enclosures without needing to cut and re-terminate them. The split design ensures ease of installation while maintaining a secure seal.

Cable Entry Accessories

In addition to cable entry systems, various accessories help to optimize the performance and functionality of the setup. Some common cable entry accessories include:

Strain Relief Clamps: These clamps provide additional strain relief to cables, ensuring that the cable does not experience excessive stress at the entry point. This reduces the risk of electrical failure and cable damage over time.

Sealing Plugs: Sealing plugs are used to fill unused entry points in a cable entry frame or panel, maintaining the integrity of the enclosure’s environmental protection.

Cable Ties and Holders: Cable ties and holders help organize cables inside enclosures, preventing them from becoming tangled or creating clutter. They contribute to both aesthetic neatness and operational efficiency.

Grommets: Cable grommets are rubber or plastic fittings that protect cables from sharp edges as they pass through holes or openings. They provide both a seal and mechanical protection, reducing wear and tear on cables.

Blind Plates: These are used to cover unused cable entry openings, maintaining the enclosure's IP rating and protecting against environmental hazards.

Applications of Cable Entry Systems

Manufacturing Plants: Cable entry systems are vital in large-scale industrial plants where machines and control panels require complex cabling.

Telecommunications: Telecom infrastructure, including data centers, uses cable entry systems to manage large volumes of cables efficiently.

Energy Sector: In renewable energy, oil, and gas sectors, cable entry systems ensure secure and protected installations in harsh environments.

Automotive Industry: Cable entry systems are employed in vehicles to manage electrical wiring securely.

Conclusion

Cable entry systems and accessories are indispensable in creating organized, safe, and efficient electrical installations. Whether you're managing a few cables or hundreds, selecting the right system and accessories ensures longevity and optimal performance in any environment. By securing and protecting cables, these systems prevent costly damage and maintain high standards of safety and performance.

0 notes

Text

Understanding the Different Types of Electrical Lugs and Their Uses

A cable lug is essential in electrical systems, providing a secure connection between cables and device terminals. It simplifies the assembly, maintenance, and repair processes, especially when a permanent connection is required, but a direct one is inconvenient or impossible. Whether you are looking for solutions from a lightning arrester manufacturer or a cable gland manufacturer in India, choosing the proper lugs is crucial for the success and safety of your electrical installations.

Here's a look at the different types of lugs and their applications.

Let’s explore!

Types of Electrical Lugs

Copper Lugs

Copper lugs are ideal for large gauge applications such as power draw or grounding. These lugs can be crimped, soldered, or welded onto cables, offering installation flexibility. They are made from high-grade electrolytic copper (ETP grade) and are available in various diameters and mounting holes, accommodating wire sizes from #8AWG to 1000MCM. Copper lugs are known for their excellent conductivity and durability, making them suitable for indoor and outdoor applications, including marine environments.

Uses: Connecting heavy gauge power cables to bus bars, relays, batteries, solar power inverters, and grounding devices. They provide efficient and reliable connections in power distribution and industrial machinery.

Aluminium Lugs

Aluminium lugs are manufactured from high-purity (99.6%) aluminum rods and are suitable for outdoor use due to their sealed palm ends. They are typically less expensive than copper lugs, making them a cost-effective solution for many wiring systems. These lugs come with jointing compounds and are sealed with end caps to prevent oxidation.

Uses: This lug is used in overhead transmission lines, substations, switchgear, and other applications where cost is a critical factor. Innovations in aluminum lugs have improved their safety and convenience, making them increasingly comparable to copper lugs.

Bimetallic Lugs

Bimetallic lugs are designed to connect aluminum conductors to copper busbars. They feature an aluminum barrel friction-welded to a copper palm, ensuring a high-quality connection. This design prevents galvanic corrosion, which can occur when different metals come into contact.

Uses: Solar plants, control panels, switchgear, and combiner boxes. Bimetallic lugs are essential in applications that transition between aluminum and copper components.

Specialized Lugs and Connectors

Crimping Lugs

Crimping lugs are used to connect cables securely by deforming the metal parts to hold each other in place. These lugs are commonly seen in automotive wire systems, electrical boxes, machinery, household appliances, and electronics. Insulated crimping lugs prevent accidental energy transfers and enhance safety.

Uses: Automotive battery connections, battery jumper cables, and various durable goods requiring secure electrical connections.

Mechanical Lugs

Mechanical lugs, or shear-off bolted connectors, use advanced technology to attach cable conductors. These lugs are suitable for underground and above-ground applications and are available in low-, medium-, and high-voltage versions.

Uses: Large-scale electrical installations in buildings, commercial facilities, and infrastructure projects. They are instrumental in applications requiring robust and reliable connections.

In a Nutshell

Electrical lugs are indispensable in ensuring secure and efficient connections in various applications. From power distribution to industrial machinery, the correct type of lug ensures reliable performance and safety. By understanding the different kinds of lugs and their specific uses, businesses can make informed decisions to optimize their electrical systems. As leading lugs manufacturers in India, we offer a comprehensive range of high-quality lugs to meet diverse needs, ensuring robust and efficient electrical connections.

Discover the perfect electrical connection solution with Axis India. Explore our wide range of high-quality lugs today.

About The Author:

Axis India stands at the forefront as a premier cable gland manufacturer in India and supplier of lightning arrestors and a wide array of Electrical Components, serving clients across 80+ countries worldwide. Whether you're seeking a quote or expert consultation, our dedicated team is ready to assist you.

0 notes