#Carton Box Stretch Wrapping Machine

Explore tagged Tumblr posts

Text

Eco Friendly Packaging: Smart Move for Brands That Care About the Planet

Eco friendly packaging is gaining traction nowadays because people are getting concerned about the harmful effects of some packaging materials that do not degrade naturally in the environment. When a company packages their products in a packaging that is environment friendly then it leaves a good impression on the client as it shows the company’s commitment to reducing environmental impact.

Importance of Packaging for Modern-Day Industries

All the consumer goods and consumer durables brands require good quality packaging that presents the product in a nice way in front of the customer. When a product is shipped using packaging materials, companies must remember that this packaging is the thing that a customer first sees even before the product. Apart from serving aesthetic purposes, the packaging material serves functional value as well by keeping the product safe during transit. Businesses must invest in quality packaging materials and supplies during packaging and dispatch of goods.

A Quick Look into the Catalogue of Packaging Materials and Their Importance

Plastic Packaging Materials: These are perhaps the most popular packaging materials as they are used in almost every industry from machinery to consumer durables. Liners, stretch films, bags, poly tubing, and heat seal, are some of the crucial plastic packaging materials that can be found in almost all industries. When it comes to films for wrapping goods there are many different choices available like hand stretch film, machine stretch film, shrink film, bundling film, etc.

Cartons and Boxes: This is another major category of packaging materials that is generally required for shipping delicate or soft goods that can get damaged easily during transit. When it comes to cartons there are many different choices available like heavy-duty cartons, tall and fat cartons, wine boxes, archive boxes, etc.

Adhesive Tapes and Dispensers: These are very crucial auxiliary packaging products that help in securing the goods inside packaging materials. Adhesives and tapes are required to seal boxes, stretch films or any other type of packaging so that the product does not fall out from the packaging during transit.

The world of packaging material is quite vast and hence one can get a lot of options as well when it comes to product packaging. Get a price quote from the wholesalers of packaging products for your business needs for better pricing.

Source

0 notes

Text

How One Small Change Turned Our Packing Room Into a Powerhouse

It started with a single complaint.

A customer emailed us saying, “Love the product. But the packaging? Not so much.” That wasn’t the first time we’d heard it—and it definitely wasn’t the last.

At first, we brushed it off. After all, we were a small but growing business. Our team was doing everything manually—stretch wrapping, taping, sealing—juggling volume with effort. We thought that was enough.

But then the returns started creeping up. Damaged items. Torn boxes. Poor presentation. And the worst part? We knew the product was solid. It just wasn’t being delivered that way.

Something had to give.

The Eye-Opener

One late evening, as I watched our packing team work, I noticed the fatigue in their hands. The stretch film tore too easily. Tape rollers jammed mid-seal. Shrink wrap was uneven. We were pouring energy into every package, and still, the results were inconsistent.

We didn’t need more people. We needed a better process.

So, we started searching for something simple—something that could ease the pressure and make our packaging more reliable. That’s when we found Durapak.

A Small Change with a Massive Impact

We didn’t revamp the whole warehouse overnight. We started small. Just one stretch film wrapping machine.

It wasn’t a huge investment—but the results felt revolutionary.

Instead of manually pulling and securing film around each box, we had smooth, automated rotations that wrapped each shipment with precision. No wrinkles. No wasted material. No strain.

What once took 5 minutes now took 30 seconds.

Encouraged, we added a shrink wrap machine and carton sealer to the mix. Each new piece of equipment from Durapak fit right into our workflow like it was meant to be there.

Productivity Went Through the Roof

Suddenly, the entire packing room felt different. Not just faster—better.

Shipments went out quicker, with zero rush or stress.

Material costs dropped, because machines used just the right amount every time.

Most importantly, our team could breathe. Their energy returned. So did their smiles.

And the results? Our customers noticed. The packaging was tighter, cleaner, and damage-proof. Unboxing felt like unwrapping something premium.

One of them even emailed: “Whoever’s packing your stuff now—give them a raise!”

The Bigger Picture

That one small change didn’t just fix a problem. It sparked a transformation.

What was once our most frustrating bottleneck is now our biggest strength. The packing room—once chaotic and slow—is now a powerhouse that drives our entire operation.

And all it took was trusting the right solution partner.

The Takeaway

If you're drowning in packaging delays, tired teams, and returns—it might not be your people or your product. It might just be the way you're packing.

We learned that you don’t need a massive overhaul to see massive results.

Sometimes, one small change is all it takes to build a powerhouse.

And for us, that change started with this.

0 notes

Text

Beyond Packaging: Environmentally Friendly Packaging is Nowadays Customers’ Choice

Logistics and packaging industries require a lot of packaging supplies for safely shipping products to different parts of the world. Environmentally friendly packaging is gaining quite the momentum since industries are trying to achieve sustainability goals. Also, most consumers like the change to more environment-friendly packaging and hence companies are also following customer preferences.

In Melbourne packaging supplies are offered by leading wholesale suppliers of different products like adhesive tapes, labels and markings, specialty tapes, vacuum sealers, etc. Stretch wraps are very important for packaging various products and keeping them free from scratches during transit. Nowadays the e-commerce industry is growing quite rapidly and hence reusable satchels are utilised widely for shipping many different types of products be it books or some beauty products.

Cartons are very important for shipping and packaging various types of products that are generally a bit larger in size and cannot be fit in satchels safely. Slotted cartons are very good for packaging goods and keeping them in warehouses as well since chances of any damage are significantly reduced and also transporting these is quite easy due to standardised size.

The leading suppliers of packaging products also offer various products for cleaning various commercial spaces like toilet tissue dispensers, face tissues and many other similar products. Sealing and ensuring that the packets and packaging are safely sealed is also a very important part of the process of logistics and hence wrap machines, vacuum sealers, automatic tape dispensers, etc are required. Sometimes large boxes are utilised for packaging various items and in such cases, corrugated cardboard sheets are required for keeping one thing from another so that there is no damage.

When it comes to packaging products and other similar products required for packaging one must choose quality. Browse through the large online catalogue of the leading wholesalers of various products and buy what is required for packing various products.

Source: https://paramount-packaging.blogspot.com/2025/03/beyond-packaging-environmentally.html

0 notes

Text

Boosting Warehouse Productivity: Must-Have Tools and Equipment for Efficient Operations

In the fast-paced world of warehousing, productivity is king. To remain competitive and meet customer demands, warehouses must adopt tools and equipment that streamline operations and maximize efficiency. Whether you're managing a small storage facility or a large distribution center, having the right resources can significantly enhance workflow, reduce downtime, and improve safety.

Here, we explore must-have tools and equipment that every warehouse needs to boost productivity.

1. Material Handling Equipment

Efficient material handling is the backbone of warehouse productivity. Investing in the right equipment can help streamline the movement of goods while reducing manual effort.

Forklifts: Essential for transporting heavy pallets and bulk materials.

Pallet Jacks: Perfect for quick and easy movement of smaller loads.

Conveyor Systems: Automate the transport of items across the warehouse, minimizing time and labor costs.

2. Storage Solutions

Organized storage not only saves time but also maximizes space utilization. Some popular storage solutions include:

Pallet Racking Systems: A durable and versatile solution for storing goods efficiently.

Wire Shelving: Ideal for lightweight inventory, offering visibility and easy access.

Bin and Tote Storage: Keeps small items neatly organized, reducing picking errors.

3. Inventory Management Software

Modern warehouses rely on technology to manage inventory accurately and efficiently. Inventory management software provides real-time tracking, reduces overstock or understock issues, and ensures smooth order fulfillment. Look for features such as barcode scanning, RFID compatibility, and reporting capabilities.

4. Packing and Shipping Tools

Efficient packing and shipping tools ensure orders are processed quickly and correctly, maintaining customer satisfaction. Must-have items include:

Stretch Wrap Machines: Secure goods on pallets for safe transit.

Carton Sealers: Automate box sealing for consistent results.

Label Printers: Streamline labeling processes with high-quality barcode and shipping label printing.

5. Warehouse Safety Equipment

Safety is paramount in any warehouse setting. Equip your facility with safety tools to minimize accidents and protect workers. Key items include:

Rack Protectors: Safeguard shelving units from forklift impacts.

Anti-Fatigue Mats: Enhance worker comfort during long shifts.

Personal Protective Equipment (PPE): Helmets, gloves, and safety glasses are essential for employee safety.

6. Automation Tools

Warehouse automation is a game-changer for efficiency. From robotic pickers to automated guided vehicles (AGVs), automation reduces errors and speeds up repetitive tasks. Investing in warehouse robotics or automated inventory systems can transform your operations.

Conclusion

Equipping your warehouse with the right tools and equipment is vital to boosting productivity, ensuring efficiency, and maintaining a safe work environment. Material handling equipment, organized storage systems, advanced inventory management software, and automation tools all play crucial roles in enhancing operations.

As the Warehouse efficiency products industry evolves, staying ahead requires strategic investments in technology and equipment that align with your specific needs. By upgrading your warehouse with these must-have tools, you can streamline processes, reduce costs, and meet growing customer expectations with ease.

1 note

·

View note

Text

Premium Box Wrapping and Shrink Wrapping Machines

Optimize your packaging operations with Millenium Packaging Solutions' top-of-the-line box wrapping and shrink wrapping machines. Our carton box stretch wrapping machines are engineered to securely wrap small and medium-sized cartons, shielding them from moisture and dust during transportation. Featuring a pneumatic top plate and an intuitive control panel, our machines deliver efficient and reliable shrink wrapping solutions across various industries. Partner with us to elevate your packaging efficiency and product protection.

0 notes

Text

Why Investing in a Packaging Machine is a Game Changer

In today’s fast-paced manufacturing and logistics industry, efficiency is key. Businesses looking to scale operations and improve product presentation can significantly benefit from industrial packaging machines. Whether for food, pharmaceuticals, or consumer goods, automating your packaging process ensures consistency, enhances product safety, and reduces labor costs.

If you're in the market for Industrial Packaging Machines, understanding what to look for and how to choose the right model is essential. This guide explores everything you need to know before making a purchase.

Types of Packaging Machines

Depending on your industry, various industrial packaging machines cater to specific needs. Some of the most popular options include:

1. Filling Machines

Ideal for liquid, powder, or granule-based products, filling machines ensure accurate portioning and prevent wastage.

2. Sealing Machines

Perfect for ensuring airtight packaging, these machines come in various forms, including vacuum sealers and heat sealers.

3. Wrapping Machines

From stretch wrappers to shrink-wrapping machines, these units protect and bundle products for transportation.

4. Labeling Machines

Consistency in branding is crucial, and labeling machines ensure every package is professionally marked with the necessary information.

5. Cartoning Machines

If your business involves boxing products, cartoning machines simplify the process, ensuring efficiency and precision.

Key Considerations When Buying a Packaging Machine

Purchasing a packaging machine for sale is a significant investment. Here are the crucial factors to consider:

1. Production Volume

Determine whether a semi-automatic or fully automated machine suits your business needs based on your daily production capacity.

2. Material Compatibility

Not all packaging machines work with every material. Ensure the machine you choose supports your packaging materials, whether plastic, glass, or cardboard.

3. Space Requirements

Consider the available space in your facility. Some industrial packaging machines require substantial floor space, while others are compact and adaptable.

4. Maintenance & Durability

Choose a machine that is easy to maintain, with readily available spare parts and reliable customer support in Australia.

5. Compliance & Safety Standards

Ensure the machine meets Australian industry regulations, including food safety and environmental guidelines.

Customer Testimonials

"Upgrading to an automatic sealing machine transformed our packaging efficiency. What used to take hours now gets done in minutes! Highly recommend investing in quality packaging machines in Australia." – Jason M., Food Manufacturer

"We switched to a fully automated filling and labeling machine, and the accuracy has improved tremendously. No more spillage or labeling errors!" – Linda S., Pharmaceutical Industry

FAQs About Packaging Machines

1. What is the lifespan of an industrial packaging machine?

With proper maintenance, most industrial packaging machines last 10-15 years, making them a long-term investment for your business.

2. Are used packaging machines a good option?

Second-hand machines can be cost-effective but ensure they are in good working condition and meet industry standards before purchasing.

3. How much does a packaging machine cost?

The price varies based on the type and automation level. Entry-level models start at a few thousand dollars, while advanced machines can go up to six figures.

4. Can packaging machines be customized?

Yes! Many suppliers offer customization to fit specific business needs, including speed, materials, and additional features.

Where to Find the Best Packaging Machines in Australia

Finding the right Bubble Wrap For Packing involves researching reputable suppliers who offer high-quality equipment, excellent after-sales service, and industry compliance. Many businesses opt for local distributors to ensure faster delivery, technical support, and compliance with Australian standards.

For companies seeking efficiency, consistency, and a competitive edge, investing in an industrial packaging machine is a smart move. Whether automating an existing process or scaling production, the right machine will make all the difference.

Final Thoughts

As demand for precision and speed in manufacturing continues to grow, investing in packaging machines in Australia can elevate your business. By understanding the types of machines available and evaluating key factors before purchasing, you can find the ideal packaging solution to enhance productivity and streamline operations.

0 notes

Text

Best Packaging Machine Supplier in tamilnadu

We are best Packaging Machine Supplier in tamilnadu, specializing in providing a wide range of client-centric and result-driven packaging solutions since 2021. Our goal is to become your one-stop destination for all your packaging machine requirements, whether they are specific or customized, ensuring that your business receives the most efficient and reliable packaging technology available

SERVICES & SOLUTIONS:

Welcome to alphatrade your ultimate destination,no matter yout industry ,we have the perfect machines for you. just tell us your needs , and we will recommend the best product at a right place . streamline your packaging process today with alpha trade

Types Of Solutions.

Stretch Wrapping Solutions

Sleeve Wrapping Solution

Pallet Strapping Solutions

Shrink Wrapping Solutions

Carton Box Sealing Solution

Strapping Solutions

Eol Automation Solutions

Robotics Solutions

Vacuum Packing Solution

Food Pack Cling Wrapping Solutions

Consumables

PRODUCTS :

Stretch Wrapping SolutionsAlphaTrade provides high-performance Stretch Wrapping solutions designed to secure and stabilize products for safe storage and transportation, ensuring minimal material usage and maximum efficiency.

Sleeve Wrapping SolutionOur Sleeve Wrapping solutions offer reliable and cost-effective packaging for a variety of products, providing a secure and protective wrap that enhances product visibility and presentation.

Pallet Strapping SolutionsAlphaTrade’s Pallet Strapping Solutions deliver robust, durable strapping to keep your products tightly secured during transportation and handling, reducing the risk of damage.

Shrink Wrapping SolutionsOur Shrink Wrapping solutions are engineered to offer a perfect fit around your products, providing excellent protection from dust, moisture, and tampering while ensuring an attractive finish.

Carton Box Sealing SolutionAlphaTrade’s Carton Box Sealing Solutions ensure fast, secure, and efficient sealing of boxes, enhancing the integrity of your packaging and improving workflow productivity.

Strapping SolutionsAlphaTrade's Strapping Solutions are ideal for securing packages of all shapes and sizes, ensuring maximum load stability and reducing the risk of product damage during transit.

EOL Automation SolutionsOur End-of-Line (EOL) Automation Solutions are designed to streamline packaging processes, enhance productivity, and reduce labor costs by automating critical packaging tasks.

Robotics SolutionsAlphaTrade’s Robotics Solutions bring cutting-edge automation to your packaging operations, improving speed, precision, and consistency while reducing human error and enhancing safety.

Vacuum Packing SolutionOur Vacuum Packing Solutions are perfect for extending shelf life and maintaining product quality, offering superior protection from contaminants, air, and moisture.

Food Pack Cling Wrapping SolutionsAlphaTrade offers specialized Food Pack Cling Wrapping solutions that provide freshness and protection, ensuring your food products stay safe, secure, and visually appealing.

ConsumablesWe provide high-quality Consumables, including films, tapes, and other materials, to support all your packaging needs, ensuring long-lasting durability and cost-effective solutions for various industries.

In conclusion,

AlphaTrade stands as a leading supplier of innovative and reliable industrial packaging solutions in Tamil Nadu, offering a comprehensive range of products and services tailored to meet the diverse needs of various industries. With a focus on efficiency, cost-effectiveness, and quality, AlphaTrade ensures that businesses can streamline their packaging processes, reduce operational costs, and enhance product protection. Whether you require customized solutions or standard products, AlphaTrade is committed to providing the best packaging technology to optimize your operations and drive success.

#bestpackagingmachinesupplier#industrialpackagingmachinesupplier#strappingsolutions#machinerydistributorsintamilnadu#packingmachinerymanufacturers

0 notes

Text

How the PR FG 800B Carton Stretch Wrapping Machine Can Improve Your Shipping Efficiency

In the fast-paced world of logistics and supply chain management, efficiency is the name of the game. With growing demand for faster deliveries and better protection of goods in transit, companies need reliable solutions to streamline their packaging processes. One such solution is the PR FG 800B Carton Stretch Wrapping Machine. This high-performance machine has revolutionized the way businesses handle shipping, offering automation, consistency, and enhanced product protection—all of which lead to improved shipping efficiency.

In this blog, we will explore how the PR FG 800B can improve your shipping operations, reduce costs, and increase overall productivity.

Understanding the PR FG 800B Carton Stretch Wrapping Machine

The PR FG 800B is a fully automated stretch wrapping machine designed to wrap cartons or boxes securely with stretch film. It’s ideal for industries that ship a high volume of products and require secure, efficient packaging solutions. Unlike manual wrapping, which is time-consuming and often inconsistent, the PR FG 800B ensures that every package is tightly and uniformly wrapped, minimizing the risk of damage during transit.

This machine comes with advanced features like adjustable wrapping parameters, pre-stretch film capability, and customizable speed settings, allowing businesses to tailor the wrapping process to their specific needs. With its user-friendly interface and robust design, the PR FG 800B is an essential tool for companies aiming to optimize their shipping efficiency.

Key Features of the PR FG 800B Carton Stretch Wrapping Machine

Before diving into how the PR FG 800B can improve your shipping efficiency, let's take a look at some of its standout features:

Fully Automated Operation: The PR FG 800B eliminates the need for manual labor in the wrapping process. With just the push of a button, the machine automatically wraps each carton to the exact specifications required. This automation leads to faster throughput and frees up employees to focus on other value-added tasks.

Pre-Stretch Film Technology: One of the most impressive features of the PR FG 800B is its pre-stretch capability. It can stretch the film up to 300%, meaning you use less film to achieve secure wrapping. This feature not only reduces material costs but also minimizes waste, making the machine an eco-friendly option for businesses.

Adjustable Wrapping Parameters: Every shipment is different, and the PR FG 800B allows you to customize the wrapping tension, speed, and number of wraps. This flexibility ensures that delicate products get the careful attention they need, while sturdier items receive a tight, secure wrap.

Compact and Robust Design: Designed to fit seamlessly into any production environment, the PR FG 800B is compact yet powerful. Its robust construction ensures long-lasting performance even in high-demand packaging operations.

User-Friendly Interface: The machine is equipped with an intuitive control panel that makes it easy to operate, even for workers with limited technical experience. Clear instructions and customizable presets allow for quick adjustments, ensuring minimal downtime.

Enhanced Safety Features: Safety is a top priority in any packaging operation. The PR FG 800B includes features like automatic film cutting and clamping to keep workers safe from sharp film edges. Additionally, it has built-in sensors that stop the machine if any obstructions are detected.

Benefits of Using the PR FG 800B for Your Shipping Operations

Now that we’ve covered the key features, let’s dive into the benefits of incorporating the PR FG 800B Carton Stretch Wrapping Machine into your shipping process.

1. Increased Productivity and Throughput

Automation is one of the primary reasons businesses turn to machines like the PR FG 800B. Manual wrapping can be slow and inconsistent, leading to bottlenecks in the shipping process. The PR FG 800B automates the wrapping process, enabling faster throughput. This means you can wrap more cartons in less time, increasing your overall productivity.

For companies dealing with large shipping volumes, time saved per package quickly adds up. Whether you are shipping hundreds or thousands of cartons per day, the PR FG 800B ensures each carton is securely wrapped in seconds, keeping your operations running smoothly.

2. Consistency and Improved Load Stability

One of the major issues with manual wrapping is inconsistency. Different employees may apply different amounts of tension or wrap the cartons in varying numbers of layers, leading to uneven protection. With the PR FG 800B, you get consistent results every time. The machine applies uniform tension and wraps each carton according to preset parameters, ensuring that every package is secure and protected.

Consistency in wrapping leads to improved load stability, reducing the risk of product damage during transit. When cartons are securely wrapped, they are less likely to shift or become damaged, improving customer satisfaction and reducing return rates.

3. Cost Savings on Stretch Film and Labor

The pre-stretch technology in the PR FG 800B is a game-changer when it comes to reducing material costs. By stretching the film up to 300%, you can significantly reduce the amount of stretch film needed to wrap each carton. This results in less film waste and lower packaging costs.

Additionally, since the machine handles the wrapping process automatically, there’s no need for as many workers to manually wrap cartons. This reduction in labor costs is especially beneficial for companies that need to wrap large volumes of goods every day. The machine's speed and efficiency allow your workforce to focus on more complex or strategic tasks, boosting overall productivity.

4. Reduced Shipping Damage and Returns

One of the hidden costs of inefficient packaging is the risk of shipping damage. When cartons are improperly wrapped, they are more likely to become damaged during transit. This not only leads to costly returns but also damages your brand’s reputation with customers. The PR FG 800B ensures that each carton is tightly and securely wrapped, minimizing the risk of damage during shipping.

By investing in high-quality stretch wrapping equipment, you can lower the chances of product damage, reduce return rates, and ultimately save money on replacement costs. This also means fewer disruptions in your supply chain due to damaged goods.

5. Enhanced Employee Safety

Manual wrapping, particularly for high volumes of goods, can lead to worker fatigue, repetitive strain injuries, and even accidents. The PR FG 800B significantly reduces these risks by automating the entire wrapping process. Workers no longer need to handle heavy rolls of film or operate in close proximity to sharp film cutters.

The machine’s built-in safety features, such as automatic film cutting and sensors, further ensure that employees are not exposed to unnecessary risks. This creates a safer working environment and helps prevent workplace injuries.

6. Environmental Benefits

Reducing waste and improving sustainability are top priorities for many businesses today. The PR FG 800B’s ability to stretch film efficiently helps companies reduce the amount of plastic used in their packaging operations. Less plastic means less waste, which is better for the environment. Some models of the PR FG 800B are also compatible with eco-friendly or recycled stretch films, making it easier for businesses to adopt greener packaging practices.

By minimizing material usage and lowering your carbon footprint, you can demonstrate your company’s commitment to sustainability—a factor that is increasingly important to consumers and business partners alike.

Is the PR FG 800B Right for Your Business?

The PR FG 800B Carton Stretch Wrapping Machine is a versatile solution that can benefit businesses across a wide range of industries, including manufacturing, retail, food and beverage, pharmaceuticals, and e-commerce. If your company regularly ships products in cartons or boxes, and you want to enhance your packaging process, reduce costs, and improve efficiency, the PR FG 800B is an investment worth considering.

Conclusion

Incorporating the PR FG 800B Carton Stretch Wrapping Machine into your shipping process offers numerous advantages, from increased productivity and consistency to cost savings and enhanced safety. By automating the wrapping process, this machine allows you to streamline your operations, reduce labor costs, and improve the protection of your products during transit. Furthermore, the machine’s eco-friendly features and reduced material usage contribute to your company’s sustainability goals.

If you’re looking to improve your shipping efficiency, reduce costs, and enhance product protection, the PR FG 800B is an excellent choice for your business.

Global Packaging Automation is a premier manufacturer and supplier of the PR FG 800B Carton Stretch Wrapping Machine in India, supporting businesses of all sizes across diverse industries. For inquiries or to make a purchase, contact us at +91 7738819711 or email us at [email protected]. If you're looking for high-quality equipment at competitive prices, Global Packaging Automation is your trusted partner. Click here to explore our extensive product range and learn more.

#Carton Stretch Wrapping Machine#strapping tool#global packaging#industrial packaging#packaging industry#packagingsolutions#PR FG 800B

0 notes

Text

Insights and Trends in the Global Industrial Packaging Market: Growth, Challenges, and Opportunities

Industrial Packaging: The Evolution of Packaging Materials Over the Years In Transportation Packaging Material Types: Paper, Plastic, Metal and Woven Sacks Paper has been one of the most widely used packaging materials for industrial products. Kraft paper and corrugated cardboard boxes are versatile materials that provide protection and allow easy printing of product information and branding. Their recyclable nature is also environment friendly. However, paper has limitations when it comes to moisture resistance and durability. Plastics like polyethylene, polypropylene and PET have gained substantial popularity in the past few decades. Rigid plastics effectively protect products from damage and moisture. They are lightweight and inexpensive. Flexible plastics in the form of bags, pouches and wraps mold well to products and reduce wastage of materials during packaging. Thermoformed plastic trays provide robust tamper-evident packaging solutions. However, different types of plastics require proper disposal methods as most are not bio-degradable. Metals like steel and aluminum sheets are especially suitable for harsh industrial environments. Metal drums, pails and cans resist dents and offer excellent barrier properties. Their recyclability is also an advantage. Nonetheless, metals add heaviness and rigidity that increases transportation costs. Woven sacks made from polypropylene or jute fibers are sturdy and cost-effective packs for granular, powdered or small parts. Rotomolding technology permits adding plastic liners inside bags to enhance moisture resistance. However, sacks are bulkier to handle and store compared to boxes or rigid containers. Packaging Machinery Automating Industrial Packaging Lines Automated packaging lines with machinery like filling machines, cartoners, wrapper, shrinkwrappers, palletizers and stretchwrappers have elevated production efficiencies. Robotic arms precisely place andassemble cartons. Volumetric filling technologies accurately dispense liquids and solids. Checkweighers maintain product weight uniformity. Centralized HMI systems monitor performance across all machines. Mobile and stationary stretch wrapping machines securely unitize packed loads for shipping. Automatic palletizers arrange boxes onto pallets at high speeds to optimize truck trailer space. Integrating digital printers onto lines customizes cartons with variable product/packaging details. Auto code date-printers track freshness and recalls/replenishments. Sophisticated vision systems verify codes, dates and package integrity. Barcode Scanning Enhancing Warehousing and Distribution Barcode scanning is integral to material management of inbound raw materials and outbound finished goods. Pallet tags and carton labels are scanned at each stage to update inventory levels and locations in warehouse management systems. Item IDs, quantities, production dates etc. are captured in databases for reports, shipments and traceability needs. Voice-directed picking via barcode scanners accurately directs warehouse workers to replenish materials across manufacturing and assembly lines. Scanners also guide put-away of finished goods while optimizing storage space utilization. During order fulfillment, scanners confirm orders are complete and accurate before dispatch. Two-dimensional barcodes like QR codes enable linking packaging to digital product brochures, instructions or assemblies online.

0 notes

Text

Fully Automatic Side Sealer with Shrink Tunnel Machine Manufacturer

Fully Automatic Side Sealer with Shrink Tunnel Machine Manufacturer – One of the first companies to import, produce, and export a wide range of packaging machinery is ACE Packaging Solutions. ACE Packaging Solutions offer a wide range of products, such as filling machines, cup and meal tray sealers, Fully Automatic Side Sealer with Shrink Tunnel Machine Manufacturer, L-SEALER, electromagnetic induction cappers, liquid packing machines, cling film wrapping sealers, cap closing machines, batch coders, stretch wrapping machines, shrink packaging machines, vacuum packaging machines, and filling machines. ACE Packaging Solutions apparel sector makes extensive use of the engineering products we offer.

Fully Automatic Side Sealer with Shrink Tunnel Machine Manufacturer

ACE Packaging Solutions Address PLOT NO 31 KHASRA NO 53 IPS Industrial Compound, Meerut Rd, Morta, Ghaziabad, Uttar Pradesh 201003

Mobile No. +91-9810264335 011-65394310

website –https://www.shrinkpackagingmachines.in/fully-automatic-side-sealer-shrink-tunnelmachine/

Shrink Wrapping Machine – Shrink Tunnel Machine – Manufacturer, Supplier Ghaziabad, India

Batch Coding Machine – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

Battery Powered Strapping Tool – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

blog/ 1 pages

Blog – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

carton-box-wrappers/ 1 pages

Carton Box Wrappers – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

carton-sealing-machine/ 1 pages

Carton Sealing Machine – Manufacturer, Supplier From Ghaziabad, India

category/

shrink-packaging-machine/ 1 pages

Shrink packaging machine Archives – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

contact-us/ 1 pages

Contact Us – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

features-of-l-sealer-machine/ 1 pages

What are the key components and features of an L-Sealer Machine? – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

foot-sealing-machine/ 1 pages

Foot Sealing Machine – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

fully-automatic-l-sealer/ 1 pages

Fully Automatic L-Sealer – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

fully-automatic-side-sealer-shrink-tunnelmachine/ 1 pages

Fully Automatic Side Sealer with Shrink Tunnel Machine – Manufacturer, Supplier From Ghaziabad, India

fully-automatic-strapping-machine/ 1 pages

Fully Automatic Strapping Machine – Manufacturer, Supplier From Ghaziabad, India

functions-of-shrink-packaging-machines/ 1 pages

What are the Functions of Shrink Packaging Machine? – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

hand-sealing-machine/ 1 pages

Hand Sealing Machine – Manufacturer, Supplier From Ghaziabad, India

how-does-a-strapping-machine-work/ 1 pages

How does a Strapping Machine Work? – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

how-pouch-sealing-machines-work/ 1 pages

How Pouch sealing Machines Work – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

#Fully Automatic Side Sealer with Shrink Tunnel Machine Manufacturer#Fully Automatic Side Sealer with Shrink Tunnel Machine#Shrink Wrapping Machine Manufacturers#Strapping Machine Manufacturers#Semi Automatic Strapping Machine Manufacturers#Shrink Packaging Machine Manufacturer#L Sealer Machine Manufacturers#Shrink Tunnel Machine Manufacturers

0 notes

Text

Protect Your Shipments with High-Quality Eco Friendly Products in Australia for Packaging

High-quality packaging providers must provide the greatest products since the retail and e-commerce industries depend on high-quality eco friendly products in Australia. This type of packaging is becoming more and more popular as customers consciously choose more eco-friendly items after learning about the harm that other packaging causes to the environment.

The greatest products are required by businesses that require dependable packaging solutions, and industries such as pallet wrap, stretch films, and adhesive tapes and dispensers offer a wide variety of items.

Eco-friendly tape is one of the most often utilised kinds of tape nowadays since, in addition to preserving shipments, it provides a distinctive branding opportunity. Companies must ensure that their goods are transported in a secure and stylish manner, which calls for product packaging. For this reason, efficient packaging is essential. Packing tape, labels with unique printing, boxes, and signage are examples of bespoke packaging products.

A Variety of Products from Top Packaging Suppliers

Pallet Wrap and Stretch Films: Use the proper stretch films and dispensers to safeguard the goods. Pallets may be simply and swiftly stabilised during travel by employing stretch film dispensers and manually wrapping them with stretch film. The ideal option for firms with large volume operations is to have a pallet wrapping machine and a stretch film machine.

Protective Packaging: Well-known businesses provide superior cushioning to stop harm, such as polyfoam and bubble wrap. To ensure their safety during handling and transit, items must be wrapped with protection. Other goods, including rolls of corrugated cardboard, offer a more flexible cover for bigger items, while protective film keeps surfaces from becoming scratched.

Adhesive tapes and dispensers are essential for fastening packages to prevent items from falling out of sealed cartons, packs, or packaging. Forza packaging tape works well for a variety of package sealing applications. Machine packaging tape is another well-liked choice since it provides reliable application and allows for process automation. Cloth tape's high stickiness and durability make it ideal for challenging tasks. For securing and bundling heavy items, reinforced fibreglass is a stronger material than filament tape.

Consult with the top suppliers of the goods needed to package different items and make bulk or specification-based orders.

Source

0 notes

Text

The Problem Wasn’t the Product. It Was Our Packaging

We were proud of our product.

It was well-designed, reliable, and priced right. Customers who got it—loved it. But too often, those customers came to us with a frustrated tone and a shared complaint:

“The product arrived damaged.”

At first, we shrugged it off—maybe a careless courier, maybe a freak incident. But when the complaints became consistent, and our return rate started creeping up, we had to ask the tough question:

What are we doing wrong?

We dug into our logistics. The product passed QC. Inventory systems were fine. Delivery timelines were met. But then we took a hard look at our packaging process—and the answer was right there.

When Good Isn’t Good Enough

Our team was manually wrapping each item, sealing boxes with hand-held tape guns, and relying on stretch film applied by feel, not precision. It looked okay when it left our warehouse—but by the time it reached the customer, shifts in transit often led to loose packaging, busted corners, or worse—open boxes.

It wasn’t the product failing. It was how we were protecting it.

And that realization hit hard.

If we wanted to maintain customer trust, we couldn’t just fix problems after they happened—we had to prevent them altogether.

Enter the Experts

We began looking for a solution that could help us seal, wrap, and protect our shipments better and faster. That's when we came across Durapak, a company that seemed to understand that good packaging isn’t just about looking neat—it’s about logistical integrity.

We explored their range—shrink wrapping machines, stretch film systems, carton sealers—each one built not only for speed, but for consistency and protection.

What stood out? Their machines were made to make packaging smarter, not just easier.

The Transformation We Didn't Know We Needed

After onboarding their shrink wrap and stretch film systems, we saw results within days. Packaging became tighter, cleaner, more uniform. Boxes felt like they were armored, not just packed.

Even better? Material usage dropped. Time per package? Cut nearly in half. Returns due to damage? Down by 80% within a month.

And the feedback? Well, let’s just say we stopped getting complaints—and started getting compliments.

Packaging as a Competitive Advantage

We used to treat packaging as a final step. A formality. But in reality, it was the first impression our customers had of our brand. It was the handshake before the unboxing.

Thanks to Durapak, we now see packaging as part of the product experience. It protects, reassures, and even delights. And that mindset shift has given us a clear edge.

The Takeaway

If you're confident in your product but still losing customers—don’t just look at what's inside the box. Look at the box itself. How it's wrapped. How it's sealed. How it shows up when it matters most.

Because sometimes, the problem isn’t the product.

It’s the packaging.

And trust us, there’s a fix for that—we found ours here.

0 notes

Text

The Rise of Packaging Items Like Corrugated Cardboard Box for Better Sustainability

Eco-friendly packaging like corrugated cardboard box is crucial for the majority of enterprises, whether they are manufacturing facilities, warehouses, godowns, food facilities, or any other kind of commercial or industrial facility. The top suppliers of packaging materials offer a wide variety of goods, including various kinds of sticky tapes and vacuum sealers, and are aware of the particular requirements of the sector.

Examining the Features of the Various Packaging Product Types

There are many different types of packaging items, each made to satisfy certain industrial needs. To ensure that expensive objects, such as electronics, do not break during transportation, foam packing and pallet sheets are essential. Pallet cushions are an essential item for shipping costly items on pallets since dust, splinters, and other debris can damage the items. Sheets of corrugated cardboard are used to create protective layers between objects. Products of all shapes and sizes may be safely packed in cartons and boxes, which come in a variety of sizes and strengths. Especially in retail and warehouse settings, corrugated trays and folders are perfect for organising and storing goods.

Leading providers of packaging goods serve the hospitality and food industries as well as the industrial and service sectors. Biodegradable wrap, plates and bowls, mugs of all kinds, and cutlery such as knives, spoons, forks, etc. are some of the products used to package and deliver meals to customers in an environmentally friendly way. Dispensing cartons, retail rolls, bags, sheets, tubes, wraps, and takeout bowls are examples of eco-friendly sustainable packaging that has grown in favour recently as environmental concerns have been more generally acknowledged.

The top producers of packaging materials also address cleaning issues, offering a variety of products to ensure cleanliness and safety in commercial and industrial settings. Roll-up hand towels, toilet tissue dispensers, and face tissues are among the materials needed for workplace cleanliness. The toilet or room is kept fresh and hygienic using products like odour control dispensers and antibacterial hand cleaners.

The rapid growth of the e-commerce sector in recent decades has made packing machines and dispensers indispensable for suppliers of goods sold online. Stretch wrap machines, vacuum sealers, and automatic tape dispensers are all made to manage heavy loads, increasing output and lowering labour expenses.

Look through the product sections of the websites of the top packaging product providers and purchase the items that you or your business need.

Source: https://paramount-packaging.blogspot.com/2025/02/the-rise-of-packaging-items-like.html

0 notes

Text

Secure and Simple: The Benefits of Pallet Shrink Wrap for Sale

In the dynamic world of logistics and shipping, the importance of secure and efficient packaging cannot be overstated. Pallet shrink wrap emerges as a hero in this realm, providing a simple yet highly effective solution for stabilizing and protecting goods during transportation. For businesses seeking reliable packaging solutions, exploring pallet shrink wrap for sale is a practical and cost-effective choice. In this article, we'll delve into the world of pallet shrink wrap, understanding its benefits, applications, and why it's a valuable investment for businesses in need of secure packaging.

Understanding Pallet Shrink Wrap:

Pallet shrink wrap, also known as stretch wrap or stretch film, is a thin, flexible plastic film commonly used to wrap and secure goods on pallets. The primary purpose of pallet shrink wrap is to provide stability to loads, preventing them from shifting or toppling during transit. This transparent and stretchable film adheres tightly to the items it encases, creating a secure unit that is easy to handle and protects against damage.

Benefits of Pallet Shrink Wrap:

Stability and Load Security: Pallet shrink wrap acts as a secure cocoon around palletized goods, keeping them stable and minimizing the risk of movement during handling and transportation. This stability is crucial for preventing damage and ensuring that goods arrive at their destination in the same condition as when they were shipped.

Protection Against Elements: The transparent nature of shrink wrap allows for easy inspection of goods while providing protection against the elements. Whether it's exposure to moisture, dust, or sunlight, shrink wrap acts as a protective barrier, preserving the integrity of the products it envelops.

Cost-Effective Packaging: Pallet shrink wrap is a cost-effective packaging solution. Its ability to tightly secure loads reduces the need for additional packaging materials such as straps or tapes. This not only saves on material costs but also streamlines the packaging process, contributing to overall cost efficiency.

Ease of Application: Shrink wrap is user-friendly and easy to apply, making it a practical choice for businesses of all sizes. Whether applied manually or with the help of automated machines, the process is efficient and requires minimal training. This ease of application enhances productivity in the packaging workflow.

Versatility in Packaging: Shrink wrap is highly versatile and can be used to package a wide range of products, from boxes and cartons to irregularly shaped items. Its flexibility allows for a snug fit around various load shapes and sizes, offering adaptability in the packaging process.

Tamper-Evident Packaging: The tight seal created by pallet shrink wrap serves as a tamper-evident feature. Any attempt to tamper with the load becomes immediately apparent, providing an additional layer of security for valuable or sensitive goods.

Improved Handling and Storage: The stability provided by shrink wrap not only benefits transportation but also facilitates easier handling and storage within warehouses. Pallets wrapped in shrink film can be safely stacked, optimizing storage space and ensuring efficient warehouse management.

Reduced Product Loss: By preventing goods from shifting or becoming damaged during transit, pallet shrink wrap helps reduce product loss. This is especially critical for businesses that deal with fragile or high-value items, where even minor damages can lead to significant financial losses.

Choosing the Right Pallet Shrink Wrap:

When exploring pallet shrink wrap for sale, it's important to consider the specific needs of your business. Here are key factors to keep in mind:

Film Thickness: Pallet shrink wrap is available in various thicknesses. Thicker films provide enhanced puncture resistance and load stability, making them suitable for heavier or irregularly shaped items.

Stretchability: The stretchability of the shrink wrap determines how well it conforms to the shape of the load. Higher stretchability allows for a snug fit and improved load stability.

Application Method: Pallet shrink wrap can be applied manually using handheld dispensers or automatically using stretch wrapping machines. Consider the volume of your packaging needs and choose the application method that aligns with your business requirements.

Transparent or Colored: While transparent shrink wrap allows for easy visual inspection of goods, colored options are available for additional security and product differentiation.

Pre-Stretch Feature: Some shrink wrap varieties come with a pre-stretch feature, which means the film is stretched during the manufacturing process. This can enhance the film's performance and reduce the amount of film needed for each pallet.

For More Info:-

Buy Stretch Wrap Roll UK

Machine Stretch Film Online UK

Shop Online Corner Edge Protector

Buy Machine Pallet Wrap Online

0 notes

Text

High-Quality Box Wrapping and Shrink Wrapping Machines

Enhance your packaging process with Millenium Packaging Solutions' advanced box wrapping and shrink wrapping machines. Our carton box stretch wrapping machines are designed to securely wrap small and medium-sized cartons, protecting them from moisture and dust during transit. Equipped with a pneumatic top plate and user-friendly control panel, our machines ensure efficient and reliable shrink wrapping for various industries. Contact us today to optimize your packaging solutions.

0 notes

Text

Rain-Proof Your Packaging: Strategies for Protecting Your Goods During Rainy Season

Introduction:

Rainy seasons can pose significant challenges for businesses involved in packaging and transportation. Ensuring the protection of goods from moisture damage becomes crucial to maintain their quality and preserve customer satisfaction. In some areas like Pune & Mumbai, where heavy rainfall is common, it is essential to implement effective strategies and partner with a reliable packaging company that specializes in rain-proof packaging solutions in Pune.

The Impact of Rainy Seasons on Packaging

The increased humidity and moisture levels during rainy seasons can lead to product damage, products get rusty, Corrugate boxes loose its strength, and compromised packaging aesthetic. Understanding the specific challenges and risks associated with rainy seasons is crucial for implementing effective protection strategies.

Innovative Packaging Systems for Rainy Seasons

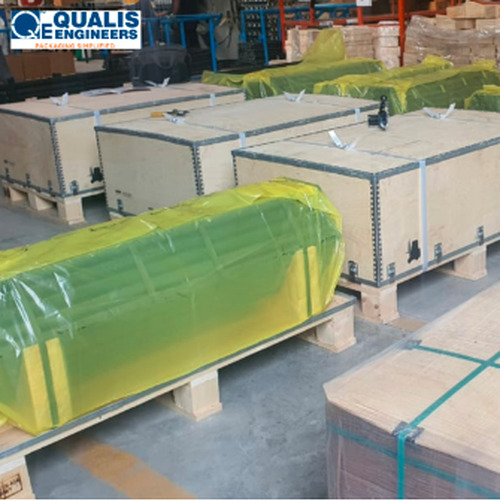

Qualis Engineers offer innovative packaging systems in Pune specifically tailored for rainy seasons. These systems include waterproof materials, moisture-resistant coatings, and advanced sealing techniques to protect goods from water ingress and damage.

Strategies for Ensuring Your Products Stay Dry and Undamaged

It is safe to say that there are no cost-effective, fully waterproof packaging options. However, there are strategies for making standard packaging more water-resistant and providing greater protection for your products. If the time of year, shipping destination, or both give you reason to believe your package may be delivered on a rainy day, try one or more of the following:

1. Ship in Corrugated Cartons

2. Use Aluminium Foil Bags / VCI bags

Usage of the VCi bags will prevent the castings or raw material in M S form .

3. Use of stretch film

Shipping cartons are not fully waterproof. We need to cover the carton box by stretch film to prevent it from the outer moisture and water drops in transit.

Also stretch film application will give strength to the whole packages during transit.

Products which can be used to protect your good during RainStretch Wrap Machine

A stretch wrap machine is a valuable asset for rain-proof packaging. It wraps goods tightly with stretch film, providing a secure and waterproof covering. This machine ensures consistent and efficient wrapping, saving time and effort compared to manual methods.

Shrink Wrap Machine

Stretch Wrap Hand Tools

Stretch wrap hand tools, such as dispensers and tensioners, are convenient and effective for manually wrapping goods with stretch film. These tools ensure proper tension and coverage, enhancing the rain-proofing of the packaging.

Conclusion

Protecting goods during rainy seasons is paramount to preserving their quality and ensuring customer satisfaction. By partnering with a dependable packaging company and implementing rain-proofing strategies, you can safeguard your goods against moisture damage. Choose innovative packaging systems, utilize moisture-resistant materials, reinforce sealing and cushioning techniques, and consider climate-controlled storage and transportation options. Rain-proof your packaging and deliver your goods with confidence, regardless of the weather conditions.

0 notes