#Cold Formed Steel Studs Framing

Text

Explore our range of cold formed steel studs and cold formed steel studs framing at Steel Network. Our cold formed steel framing solutions provide unmatched strength and versatility for your construction needs. Discover how our products can enhance your next project!

#steel stud framing#cold formed steel studs#cold formed steel studs framing#cold formed steel connections

0 notes

Text

Exploring the Benefits of Light Steel Framing Solutions

The Steel Smart System Structural Design Suite offers construction experts specialized software tools designed to swiftly and precisely create and detail light steel framing (LSF) studs and connectors. This suite empowers professionals with the resources they need to streamline the structural design process for LSF applications. For more details read the full blog!

#cfs design#light steel framing software#structural framing software#metal stud design software#cold formed steel design software

0 notes

Text

Light Gauge Steel Structure

Light Gauge Steel (LGS) structures, also known as Light Steel Framing (LSF), are an innovative and versatile construction technology that uses thin sheets of galvanized steel to form structural components. These structures are gaining popularity in the construction industry due to their numerous advantages over traditional materials like wood and concrete.

Characteristics and Components

LGS structures are typically composed of cold-formed steel sections, which are manufactured by bending and shaping steel sheets into desired profiles at room temperature. The most common profiles include C-sections and U-sections, which are used as studs, tracks, and joists. These components are assembled using screws, bolts, or welding, creating a robust and lightweight framework.

Advantages

Durability and Strength: Steel is inherently strong, non-combustible, and resistant to termites, rot, and mold. These characteristics make LGS structures particularly durable and capable of withstanding extreme weather conditions and seismic activities.

Lightweight: Compared to traditional materials, LGS structures are significantly lighter, which reduces the load on foundations and allows for easier transportation and handling. This lightweight nature also enables faster construction times and reduces labor costs.

Precision and Consistency: LGS components are manufactured with high precision, ensuring consistent quality and accuracy in construction. This precision allows for tighter tolerances and reduces the likelihood of errors during assembly.

Versatility and Flexibility: LGS systems are highly versatile and can be used in various building types, including residential, commercial, and industrial structures. They allow for flexible design options and can accommodate a wide range of architectural styles.

Sustainability: Steel is 100% recyclable, and the production process for LGS components generates minimal waste. This makes LGS structures an environmentally friendly option, contributing to sustainable construction practices.

Applications

LGS structures are used in a variety of applications, including:

Residential Buildings: From single-family homes to multi-story apartments, LGS provides a durable and cost-effective alternative to traditional wood framing.

Commercial Buildings: LGS is ideal for constructing commercial spaces such as offices, retail stores, and hotels due to its ability to create large open spaces without the need for internal columns.

Industrial Structures: The strength and flexibility of LGS make it suitable for warehouses, factories, and other industrial facilities.

Modular and Prefabricated Buildings: LGS components can be prefabricated in factories, allowing for rapid on-site assembly and reduced construction times.

Challenges and Considerations

While LGS structures offer many advantages, they also present some challenges. Thermal bridging can occur in steel structures, leading to heat loss and condensation issues. To mitigate this, adequate insulation and thermal break materials are essential. Additionally, proper corrosion protection, such as galvanization, is crucial to ensure the longevity of the steel components.

Conclusion

Light Gauge Steel structures represent a modern approach to construction, offering a combination of strength, durability, and sustainability. Their versatility and efficiency make them a valuable option in today's construction industry, addressing the demands for faster, cost-effective, and environmentally responsible building solutions. As technology and techniques continue to advance, LGS structures are likely to play an increasingly prominent role in the future of construction.

0 notes

Text

Steel Market — Forecast (2024–2030)

Steel market is analyzed to be $1,746.35 billion in 2023 and is projected to reach $2,105 billion in 2030. The market is estimated to grow with a CAGR of 4.13% during 2024-2030. Steel is an alloy that is made up of iron ore or scrap steel and carbon. In general, steels have various unique properties including being non-corrosive, rust-resistant and heavier than other metals such as aluminum. Therefore, steel is extensively used in various end-use industry verticals, including the manufacturing various transportation and automobile components, medical equipment, metal surgical implants, structural components and more, which in turn is boosting its market growth. In recent years, the steel market has experienced fluctuations driven by several factors. One significant trend in the steel market is the impact of trade policies and tariffs. Trade tensions between major steel-producing nations, such as the United States, China, and the European Union, have led to shifts in supply chains and pricing dynamics. Tariffs imposed on steel imports have affected the competitiveness of domestic producers and influenced global trade patterns. Additionally, sustainability concerns and environmental regulations have influenced market dynamics. Increasing awareness of carbon emissions and the environmental footprint of steel production has led to a growing demand for greener steel products. This has prompted investments in cleaner production technologies such as electric arc furnaces and the development of recycled steel. Moreover, technological advancements and innovations in steel manufacturing processes have enhanced efficiency and product quality. As a result, the steel market is poised for sustained growth as global economic recovery accelerates, with innovations in technology and sustainability shaping future trends.

Steel Market Report Coverage

The report: “Steel Industry – Forecast (2024-2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Steel Market Report.

By Type: Carbon Steel, (Low Carbon Steel, Medium Carbon Steel, High Carbon Steel), Stainless Steel (Austenitic Stainless Steels, Ferritic Stainless Steels, Martensitic Stainless Steels, Precipitation Hardening Grade Stainless Steels, Duplex Stainless Steels), Alloy Steel (Chromium Molybdenum Steel, Nickel-Chromium-Molybdenum Steel, Chromium Vanadium Steel, HSLA -Nickel-Chromium-Molybdenum Steel), Tool Steel (Water-hardening tool steels, Shock-resisting tool steels, Cold-work tool steels, Hot-work steels, High-speed tool steels, Others), Others

By Form: Bar, Rod, Tube, Pipe, Plate, Sheet, Structural, Others

By Application: Transportation (Road, Bridges, Barriers, Rail, Tracks, Rail Cars), Construction (Cool Metal (infrared reflecting) Roofing, Purlins, Beams, Pipe, Recyclable steel framing (studs), Desks/Furniture), Packaging (Canes, Bottles, Others), Water Projects (Levees/Dams/Locks), Energy (Renewable, Nuclear, Bio-fuels, Fossil, Electric Grid), Others

By Industry: Construction (Steel Skeletons, Concrete Walls, Pillars, Nails, Bolts, Screws, Others), Machinery (Bulldozers, Backhoe Leaders, Pipelayers, Others), Automotive and Transportation (Exhaust, Trim/Decorative, Engine, Chassis, Fasteners, Tubing For Fuel Lines), Kitchenware and Domestic Appliances (Small Household Appliances, Black Home Appliances, White Home Appliances), Electrical and Electronics (Motor Mount Brackets, Adapter Plates, Electronic Frames and Chassis, Brackets, Others), Healthcare (Orthopaedic Implants, Artificial Heart Valves, Bone Fixation, Catheters, Others), Energy (Scrubbers, Heat Exchangers, Others)

By Region: North America, South America, Europe, Asia-Pacific and Rest of the World

Request Sample

Key Takeaways

Steel Market Segment Analysis – By Type

In terms of type, the Steel Market is segmented into carbon steel, stainless steel, alloy steel, tool steel and others. In 2023, the Stainless-steel segment generated the greatest revenue of $361.94 billion and is projected to reach a revenue of $482.28 billion by 2030. Owing to the various benefits posed by stainless steel such as corrosion resistance, high and low temperature resistance, the ease of fabrication, strength, aesthetic appeal is one of the key factors for its adoption among various end-use industries, which in turn is boosting its market growth. The stainless-steel segment can be further classified as Austenitic stainless steels, Ferritic stainless steels, Martensitic stainless steels, Precipitation hardening grade stainless steel and Duplex stainless steels.

Steel Market Segment Analysis – By Form

By form, the steel market is segmented into bar, rod, tube, pipe, plate, sheet, structural and others. The bar segment accounted for the major market share in 2023, with a revenue of $554.58 billion, and is forecast to grow at a CAGR of 4.68% by 2030. The increasing demand for steel bar from various end-user industries such as building and construction, bridges, and many others, are driving the growth of the segment during the forecast period of 2024-2030.

Steel Market Segment Analysis – By Application

Steel Market is segmented by its application that includes transportation, construction, packaging, water projects, energy and others. The energy segment held the dominant market share, 31% of the whole market, in 2023, and is expected to maintain its dominance by 2030 with a CAGR of 4.69%. One of the major factors for the segment growth is the increasing awareness and focus towards renewable energy sources. Steel plays a crucial role in producing and distributing energy as well as improving energy efficiency. Renewable energy is further classified as Wind Towers and Foundation, Wind Turbines and Solar Parabolic Mirror Supports & Collectors.

Steel Market Segment Analysis – By Industry

The Steel finds its application across the industries such as construction, machinery, automotive and transportation, kitchenware and domestic appliance, electrical and electronics, healthcare, energy and others. Among them, the construction segment is the largest consumer of steel, as bearable structures can be manufactured easily at a low cost. The property of steel in its various forms and alloys makes it more flexible to cater the exclusive projects integrated with infrastructure. Moreover, the rapid industrialization and urbanization in various developing countries are fueling the segment growth in strengthening its dominant market position during the forecast period.

Buy Now

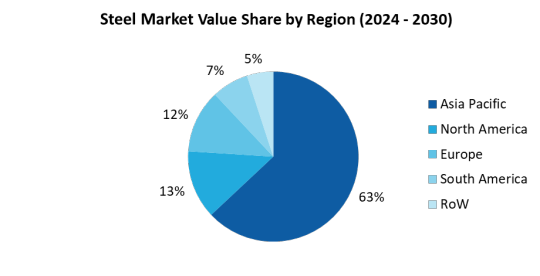

Steel Market Segment Analysis - By Geography/Country

The report comprises of the region wise study of the global market including North America, South America, Europe, Asia-Pacific and Rest of the World. Above all, Asia-Pacific region held the biggest share in 2023, up to 63% of the whole steel market owing to the rapidly expanding defense, machinery, automotive, and shipbuilding industries in the countries such as India, China, South Korea, and Japan. Foreign direct investment in energy and infrastructure is likely to provide opportunities for the market vendors. Coupled with favorable government regulations, growing infrastructure and construction activities in developing economies of the Asia-Pacific region are boosting the demand for the market.

Steel Market - Drivers

Growing Demand for Steel Across the Various Regions

Several factors have a significant impact on the overall development of the steel market. The major growth factor driving the Steel Market is the growing demand for steel across a variety of developing regions. For instance, Global crude steel production in January-November 2023 reached 1715.12 million metric tons, marking a marginal 0.5% year-on-year growth, per provisional data from the World Steel Association. November 2023 saw a production of 145.5 million metric tons, up by 3.3% from the previous year. China led the production with 952.14 million metric tons, followed by India and Japan, USA, Russia, South Korea, and Germany.

Construction and Infrastructure Development:

Construction activities, including residential, commercial, and infrastructure projects such as roads, bridges, and railways, are major drivers of steel demand. Urbanization and industrialization also contribute to the growth of the construction sector, thereby increasing the demand for steel products. For instance, as per Green Finance & Development Center, China Belt and Road Initiative (BRI) Investment Report 2023, engagement totalled about USD88.3 billion, with USD44.6 billion from investment and USD43.7 billion from construction contracts. Also, The US Department of Transportation allocates $3.2 billion in extra funding, alongside $4.3 billion from the Bipartisan Infrastructure Law for 2023. The Budget prioritizes $4.5 billion for the Capital Investment Grant program, aiming to bolster transit infrastructure for economic growth. As a result, the steel market is anticipated to thrive, propelled by heightened construction activities and the need for durable materials, reflecting a promising outlook for the industry.

Steel Market -Challenges

Environmental Regulations and Sustainability

The steel industry is facing mounting pressure to tackle environmental issues by cutting carbon emissions and enhancing sustainability efforts. Meeting stringent environmental regulations demands substantial investments in technology and infrastructure, presenting a formidable challenge for many companies. Despite the financial hurdles, embracing these changes can pave the way for a more sustainable and eco-friendly future for the industry.

Steel Market - Competitive Landscape

The companies referred in the study include Baosteel Co., Ltd., Posco Holding Inc, Nippon Steel Corporation, JFE Holdings, Tata Steel Limited, United States Steel Corporation, Anshan Iron and Steel Group Corporation, Hyundai Steel Co., Ltd., ThyssenKrupp AG, ArcelorMittal S.A., among others. Technology launches, acquisitions, and R&D activities are key strategies adopted by the key players in the Steel Market.

0 notes

Text

The Advantages of Light Gauge Steel Framing for Construction in Perth | Nextruss

Light gauge steel framing has become an increasingly popular choice for builders and construction companies in Perth looking for a versatile, durable, and sustainable framing solution. Compared to traditional timber framing, light gauge steel offers numerous benefits that make it well-suited for residential, commercial, and industrial projects across Western Australia.

At Nextruss Steel, our locally-based production facilities utilize advanced rollforming equipment to manufacture premium light gauge steel framing components. As leading suppliers of steel framing in Perth, we provide high quality cold-formed studs, tracks, and trusses optimized for strength, precision, and cost-competitiveness.

Discover the key benefits of using Nextruss Steel’s light gauge steel framing for your upcoming construction projects in WA:

Strength & Durability

Our lightweight steel framing meets Australian Standard AS3623 requirements for strength and durability. The galvanized steel resists termite damage, rotting, warping, and shrinking. Structures framed with our products can withstand harsh weather conditions, standing up to high winds and seismic activity.

The cold-formed steel we utilize has a high strength-to-weight ratio, making it light yet extremely sturdy. Our precision manufacturing processes create incredibly stable framing. The galvanized coating provides superior corrosion resistance compared to untreated steel.

Design Flexibility

With custom rollforming capabilities, we can manufacture framing to match complex or unique architectural plans. Light gauge steel enables curved walls, vaulted ceilings, and interesting angles for modern designs.

No matter the shape, size, or complexity – our steel framing solutions offer architects, builders, and engineers the design freedom to bring plans to life. We work closely with clients from the outset to develop optimized framing designs tailored to their specific project needs.

Rapid Construction

With prefabricated framing components produced precisely to required measurements, buildings framed with our light gauge steel can be constructed faster than conventional materials. This saves time and labour costs.

The ability to pre-cut all framing pieces to exact specifications based on plans results in faster assembly on-site. Because the steel framing is lightweight, it’s also easier to transport. Our production and logistics process is geared towards minimizing install time.

Bushfire Resistance

Steel is non-combustible, making it suitable for bushfire-prone areas across WA. Using our framing provides added peace of mind.

For regions where bushfire safety is a concern, light gauge steel framing offers protection. The non-combustible nature of steel prevents the spread of flames. This added security is invaluable for homeowners and businesses.

Sustainability

Steel is 100% recyclable. Our production process minimises waste, and steel requires less energy to produce than other building materials.

The recyclability and longevity of steel framing has clear sustainability benefits. Steel components can be continually reprocessed and reused. We utilize scrap steel feeds and green manufacturing practices to reduce environmental impact.

Cost-Effective

The total installed cost using our steel framing solutions is very cost-competitive in Perth. We offer discounted pricing for large wholesale orders.

With lower transportation costs and rapid on-site assembly, our light gauge steel framing can realize significant cost savings for builders. The minimal maintenance and longevity also provide excellent value over time. We offer helpful pricing resources.

Locally Produced

With our production facilities strategically located near Perth, we can deliver framing components faster and more affordably. Our local capabilities enable quick turnarounds.

By having end-to-end production based in WA, we control quality while providing better lead times and pricing. Our expertise in light gauge steel manufacturing ensures optimal solutions.

Industry Leadership

As a leading steel framing supplier in Perth with decades of experience, Nextruss Steel stays ahead of the latest building trends, technologies, and regulations.

Our continued investment in new equipment and research keeps us at the forefront of advancing steel framing. We actively participate in industry organizations to help shape the future of steel construction across Australia.

At Nextruss Steel, we partner with builders across Perth to deliver high quality light gauge steel framing purpose-built for their projects. Contact us today to discuss the advantages of steel construction for your next residential or commercial build.

#frames and trusses perth#steel frame company#steel frame manufacturer perth#steel frame manufacturers#steel frame suppliers#steel frame suppliers perth#steel framing perth#steel truss supplier perth#steel framing company#steel frame and truss manufacturers#steel frames#steel frame#steel frame house#trusses and frames#steel frame houses#steel frames and trusses#steel roof trusses perth#roof trusses perth#steel frame roof trusses#steel frame trusses#steel roof truss manufacturers#steel truss manufacturers#trusses suppliers perth#steel trusses#steel wall frames perth#steel framing supplier#steel frame homes#steel framed homes#steel framing#steel frame floor system

0 notes

Text

Things to know about Steel Wall Framing System

Unlike wood, which has to be cut and sized at the construction site, steel wall framing system is pre-fabricated. It can be manufactured to the exact lengths needed for a building, and can be shipped in large quantities.

Cold-formed steel is produced by roll formers, large machines that press cold steel into the desired shapes for construction purposes. Cold-formed steel is a strong, durable framing product that meets the highest sustainability requirements of all major green building standards and rating programs.

The lightweight nature of CFS framed walls can reduce building costs as well. It is often used in multi-story residential buildings and other high-rise structures where space is at a premium.

While CFS is strong enough to hold up to most lateral loads, it is not designed to support heavy cabinetry or wall hangings. These features require a different approach that involves extra planning, materials and expense.

Thermal conductivity of metal frames – not energy efficient

Although steel is strong, it is not an insulator and conducts heat 300 to 400 times faster than wood, which means that your home will be warmer in the winter than in the summer. This is due to a phenomenon called thermal bridging, in which heat moves quickly between studs and the wall insulation.

However, insulation can help mitigate this issue. By adding a layer of exterior EPS, XPS or Polyiso board, you can lower the amount of energy that passes through studs and insulation by about 55 percent.

0 notes

Text

Sheet Metal Welding

https://www.hsjfabrication.com/sheet-metal-welding/

Sheet metal welding has argon arc welding, laser welding, spot welding, carbon dioxide protection welding, stainless steel sheet welding, aluminium sheet welding manual arc welding, etc. With the advent of technology, the process of sheet metal welding has evolved over the years. As one of the professional sheet metal components companies, HSJ Metal Fabrication, understands the differences between the existing welding techniques. That’s why we can make a wise decision when it comes to picking the right welding technique for any projects from our customer.

What Is Sheet Metal Welding?

Sheet metal welding involves heating and melting sheet metal parts and joining them together to increase their strength or create a single integrated product. This process is widely used in various manufacturing industries, such as automotive, aerospace, construction, and equipment production. Common applications include welding metal frames, cabinets, HVAC systems, and other metal products.

At HSJ Metal Fabrication, we have expertise in different welding techniques, enabling us to make informed decisions when choosing the most suitable welding method for each project to meet our customer's requirements.

HSJ Sheet Metal Welding Highlights

Equipment List

5-Tig Welders, 300 amp, by Miller.

5-Tig Welder, 300 amp, by Airco.

2-Tig Welder, 250 amp, by Ltech.

2 Miller heliarc welder.

2-Tig Welder, 250 amp, Cobramatic for aluminum.

2-Tig Welder, 250 amp, Miller Syncrowave

2-Tig Welders, 330 amp, by Miller.

2-Mig Welder, Miller, 300 Amp.

2-Airco wire feed.

2-Miller CP300, wire feed.

2-Welder Airco.

2-Acme spot welder, 30" arm, water cooled, air timer.

2-TRW stud welding machine.

5-Gas powered field welder, Miller

5-Portable welder

Industry Area

Medical

Oil & Gas

Defense

Transportation

Packaging

Heating & Cooling

Building Materials & Construction

Engineering

Electrical Equipment & Electronics

Aerospace

Commercial Display

Industrial Equipment

Custom Sheet Metal Welding Tolerances

Size(mm)

Grade1

Grade2

Grade3

Grade4

Grade5

Gerneral Angle

0-30

±0.1

±0.2

±0.3

±0.4

±1

90degree, ±1

31-120

±0.15

±0.25

±0.4

±0.7

±2

121-250

±0.2

±0.3

±0.6

±1

±2

/

251-500

±0.3

±0.5

±1

±1.8

±2

Above 500

±0.5

±0.8

±1.5

±3

±3

HSJ Materials for Sheet Metal Welding

Aluminum (2A21/3003/5052/5083/6061/6082 /8011)

Carbon Steels(Q235,SPHC ,SPCC,SPCD ,SPCE ,ST,ST12,ST13,ST14,ST15,ST14-T )

Stainless Steel ( 304,304L ,312 ,316,317,321,347,904L,440,17-4ph,430 etc.)

Copper (C1020、C1100、C2100,2200,2300,2400)

Brass ( H62、H65、H68、H70、H80、H90、C2600、C2680、C2700、C5210、C5191、 C51000、QBe2.0、C1100、T2)

Other Non-Ferrous Alloys

Material

Features

Thickness(mm)

Electro-galvanised steel (SECC)

Fingerprint-resistant, with excellent corrosion resistance and good paintability, while maintaining the processability of cold rolled sheet

0.8, 1.0, 1.2, 1.5, 2.0

Cold rolled sheet (SPCC)

No rust resistance, surface plating or baking paint is required.

0.8, 1.0, 1.2, 1.5, 2.0, 3.0

Galvanised Steel Sheet (SGLD)

A multi-phase alloy containing aluminium and zinc rich material with beautiful appearance, scratch resistance, corrosion resistance and much higher capacity than SGCC.

0.8, 1.0, 1.2, 1.5, 2.0, 3.0

Aluminium sheet (AL)

Lower strength, excellent forming properties, good weldability and corrosion resistance, and good heat dissipation capability.

0.8, 1.0, 1.2, 1.5, 2.0, 2.5, 3.0, 4.0, 5.0

Hot-dip galvanized steel plate (SGCC

Beautiful appearance, there are two kinds of zinc flowers, small zinc flowers, it is difficult to see the zinc flowers; large zinc flowers can obviously see the kind of hexagonal flower blocks. It has corrosion resistance, paintability, formability, and spot welding.

0.8, 1.0, 1.2, 1.5, 2.0, 3.0

Benefits of Sheet Metal Welding

Save metal materials and reduce structural weight. Simplify processing and installation procedures and improve production efficiency.

The structural strength is high, and the joint sealing is good; it provides greater flexibility for structural design. The welding process is easy to realize mechanization and automation.

Custom Sheet Metal Fabrication Welding

HSJ Metal Fabrication Co., Ltd is a specialized sheet metal fabrication company located in Shenzhen, China. We offer industrial and commercial fabrication services, including OEM, ODM, and customized solutions for size, color, surface treatment, logo, assembly, or packing. Since 2015, we have been committed to providing dependable and excellent customer service for every project we undertake.

Choose HSJ for Sheet Metal Welding

Experienced and Reliable Sheet Metal Fabrication Company

Qualified Sheet Metal & Welding has been serving small and large clients for over 8 years. We have successfully completed thousands of projects for commercial, industrial, pharmaceutical, and aerospace clients from China and abroad. Our commitment to innovation and hard work has earned us a reputation as a reliable and experienced sheet metal fabrication company.

Customized Solutions for Your Sheet Metal Needs

At HSJ Metal Fabrication, we use the highest-quality materials, the best cutting-edge technologies, and the most efficient welding processes to ensure the accuracy and precision of our work. Our 20 years experienced engineer and professional service teams have successfully completed high-level customer requirements. We offer customized solutions for each client and ensure the most accurate and precise workmanship available in this field.

Associated with the Associated Builders & Contractors Association

We are affiliated with the Associated Builders & Contractors Association and are committed to providing the broadest range of sheet metal and welding services to the commercial, industrial, and pharmaceutical industries.

Contact us now for all your sheet metal needs!

Available Sheet Metal Welding Process

HSJ sheet metal welding comes with various types of sheet metal welding, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding.

Typical types of sheet metal welding processes including, MIG welding, TIG welding, resistance welding, projection welding, robotic MIG and TIG welding, and laser welding on various metallic and aluminum alloy surfaces as well as on stainless steel and iron.

MIG welding

MIG welding, also called MAG welding, is a continuous wire welding process where a shielding gas ensures firing bath protection. MIG or MAG welding is used where high productivity and high flexibility of use are required. While MIG welding requires the use of inert gas, MAG welding is carried out through an active gas. MIG welding can be also performed on thin metal, such as thin steel or aluminum.

TIG welding

TIG welding is one of the most popular welding methods since it provides high-quality components. Especially indicated to weld thin parts, it can be used for both continuous and spot welding.

Resistance welding

Resistance welding is a metal fusion welding technique where the material is heated by electrical resistance. Generally used to weld iron and steel, resistance welding guarantees high-quality standards on welded components while ensuring time and cost savings. If you want to learn more about resistance welding, we will explain everything to you.

Projection welding

Projection welding requires studs to be placed on the metals to be welded. During the metal welding process, the welding current is focused on the stud that heats to obtain complex welds, with final results that ensure excellent quality at low costs. Basically, projection welding is a type of resistance welding that uses projection.

Robotic TIG MIG MAG welding

Robotic welding is performed by programmable industrial robots. Mainly used in situations that require repeated welding, it guarantees repeated precision which is hard to achieve with manual welding. Greater precision and higher productivity are the main advantages of robotic welding.

Laser welding

Laser welding allows metals and metallic alloys to be welded, creating a thin and deep weld, with reduced heat deformations thanks to the reduced heat, even on materials that could not otherwise be welded. Precision, cleanness, minimal heat input, and fast manufacturing are just a few of the advantages of laser welding.

Welding metals: the metals that we process in Minifaber

The mentioned welding processes apply to a wide range of metals and sheet metal components that can be welded to create semi-finished and finished products. Through these processes, HSJ can provide welding of iron, aluminum, stainless steel, and copper.

Iron welding

Iron welding is widely employed in several industrial sectors. Thanks to a cutting-edge machinery and the extensive know-how raised through the years, Minifaber can provide iron welding services with the highest cleanness and precision. There are 5 different ways to carry out iron welding: HSJ can help you choose the right one!

Aluminum welding

Renowned for its ductility, lightness, and oxidation resistance, aluminum is employed in every sector in which these qualities are required, such as the aerospace sector and the transport sector. HSJ is focused on various types of aluminum welding: aluminum MIG welding, aluminum tig welding, and other welding processes to manufacture aluminum according to the desired output.

Stainless steel welding

Stainless steel is a special steel alloy that boasts important qualities such as rust resistance, corrosion resistance and high hygiene standards. For this reason, stainless steel is widely employed in the food industry. HSJ provides stainless steel welding services for any specific requirements and offers three different services of stainless steel welding.

Copper welding

Copper is employed in the electrical and electromechanical sectors for its high conductivity and ductility. Copper welding is among the services provided by Minifaber for national and international customers.

Metal Fabrication Welding Application

Computer enclosure

Electronic part

Sheet Metal Welding Related FAQs

How to weld thin metal?

TIG and MIG are both ideal when it comes to welding thinner metal sheets. However, for an extremely thin sheet of stainless steel and aluminum, the TIG method is preferred as it allows for better control over heat input.

What is the thinnest sheet metal that can be welded?

Which Weld Is stronger, MIG, TIG or Arc?

0 notes

Text

Timber frame structures: benefits and drawbacks

In most cases, "timber frame" refers to a system of panelized structural walls and floors made of small-section timber studs and covered in board products. The wood frame distributes vertical and horizontal loads to the foundations. It is often not used to refer to timber-engineered structural structures or post and beam buildings. A-Frame house plans have steeply sloped roof lines that slope down to the foundation line to resemble an "A" in the literal sense.

If the structural shell must build quickly, if the ground is very favourable, or if the design requires greater structural spans, timber frames may be the best alternative. Should be considered following benefits and drawbacks of timber frame construction.

Quickness of construction

Can build Prefabricated timber frames on site more quickly than an equivalent brick and block structure. As a result, interior trades like plastering and electrical wiring can start working earlier in the construction schedule because the interior will spend less time outside. If the structure covers in dry plasterboard, the moisture content of the timber frames must be allowed to stabilize after it is weatherproof. The time needed for mortar drying is typically shorter than this.

Modern rustic house plans use traditional style guidelines while giving them a slight twist to accommodate current trends and lifestyles.

However, timber frames could need more time for their design and manufacturing, resulting in a longer delay before work can start on site.

Brick and blockwork may need to wait while we can build timber frames in cold weather.

Quality

Off-site manufacturing can enable higher quality to obtain than in the less controlled settings of a construction site. The on-site erection of prefabricated timber frames is typically handled by the suppliers as well, allowing for completion in the controlled environment of the factory.

Beautiful house plans with a timber frame are what you should build. View floor plans to find inspiration for the construction of your ideal home.

Heat transfer efficiency

Compared to masonry structures with a thinner design, timber frame constructions often have higher thermal performance.

Timber frame construction has a lower thermal mass than masonry, allowing faster heating and cooling of the enclosed spaces.

Condensation

Condensation can form on surfaces or in the spaces between the layers of a structure's envelope, usually due to air transferring from the warm interior to the calm exterior and reaching its dew point within the fabric of the building.

Designers of wood frame constructions must add a vapour barrier between the lining of the inner wall and the insulation to prevent vapour from passing through, unlike cavity wall construction, which allows water to trickle down the inner face of the outer leaf and drain away.

The colours mutes in modern rustic homes.

Fire danger potential

Although masonry and steel frame structures can collapse if exposed to high temperatures for an extended period, there is a belief that timber frame constructions are more susceptible. However, when wood burns, the outer layers char and turn into charcoal, which acts as a heat-insulating material and does not burn. This demonstrates that the timber centre is protected from damage.

The boarding used to wrap the frame and fire stops put to restrict spread into the cavity can provide further fire protection for the structure.

If timber frames are correctly, and during construction, fire risk can grow before fire protection begins.

Conclusion

A long-lasting home produced by the designed building process, which also removes the need for months of back-and-forth travel to the construction site. Visit Trinity Building Systems if you are interested in the distinctively modern prefab home kits. Please make an appointment with the professionals and give them the reins.

#frame house plans#house plans timber frame#modern rustic homes#house plans modern rustic#modern prefab home kits

0 notes

Text

US Framing is a Wood Framing Contractor Specialized in Multifamily Homebuilding

US Framing is a leading wood framing contractor specializing in multifamily homebuilding. With over 40 years of experience, this company is able to provide a wide range of construction services for residential and commercial projects. US Framing partners with builders and contractors early in the construction process to provide support with planning, design, and sourcing materials. Read more great facts on apartment metal studs, click here.

The demand for framing contractors is driven by new home construction, so profitability largely depends on steady volumes of contracted work and cost control. While large companies often enjoy advantages such as geographic reach and relationships with high-volume homebuilders, small companies can compete based on their quality of service. About three-fourths of all US framing contractors are small businesses. The industry's primary focus is residential wood framing, although many companies also offer steel and precast concrete framing services. For more useful reference regarding contractor las vegas, have a peek here.

There are many different types of wood framing, and wood framing contractors can customize a structure to meet your needs. Wood framing is a sustainable building material. It releases less carbon than concrete and is less vulnerable to cold weather. Additionally, the cellular structure of wood helps hold warm air, which makes it an excellent insulator.

Wood framing contractors are highly skilled in cutting and measuring wood for a variety of structures. They can build anything from residential renovations to large-scale commercial buildings. As a result, they can handle virtually any type of construction. The materials are easy to work with and long-lasting, making them a great choice for construction projects.

Injuries to the hands are the most common type of injury for framers, accounting for the largest portion of all reported injuries. Another important body part that is injured is the foot, with approximately 530 injuries reported every year. As such, it is essential for wood framing contractors to wear appropriate personal protective equipment and stay protected.

Wood framing uses naturally shaped wooden poles to form the framework and support. It was first used in the 19th century in countries rich in softwood forests. Today, it is the standard way to build wooden houses. This construction method was popularized by platform framing, which uses several lightweight wall members known as studs. The studs usually extend from the sill to the plate.

Wall sheathing is usually made of plywood or laminate. It is applied to the framing prior to erection and eliminates the need for scaffolding. It also reduces manpower and expenses. Although wood framing does not require much material, some exterior sheathing is required for adequate bracing. Some construction codes require that the sheathing be stiff and durable. Please view this site https://www.hunker.com/13714098/how-to-serve-as-your-own-general-contractor for further details.

1 note

·

View note

Text

Secure your Home with World Class Cold-Formed Steel Studs Framing

Cold-formed steel is a reliable, durable, and lightweight construction material widely used in the foundation and framing of modern buildings and homes. When a building is constructed with cold-formed steel studs framing it is likely to be safe as this material requires very less to no maintenance. Another advantage of using cold-formed steel is that it is long-lasting, produces less waste, and reduces carbon emissions. They can also be easily reused, repurposed, and recycled which makes it an environment-friendly option as well.

They also protect your building from damages caused by Earthquakes, and they are water, fire, and pest-resistant. Secure your home with their steel stud framing.

#steel frame construction#cold formed steel studs#cold formed steel studs framing#steel stud framing

0 notes

Text

CFS Design & Importance of Using Software for This Purpose

CFS, or Cold-Formed Steel, is a method of constructing structural elements using thin-gauge steel sheets in construction applications like residential buildings, commercial structures, and industrial facilities. CFS design software plays a crucial role in achieving accuracy, efficiency, code compliance, visualization, documentation, and integration with other design tools. Advanced algorithms and mathematical models analyze the structural behavior of cold-formed steel members, resulting in more precise calculations and reliable designs. Software tools streamline the design process, automate repetitive tasks, and provide detailed compliance reports. Steel Smart System is a popular choice for CFS Floor Framing Design, helping construction professionals design and detail LSF studs and connectors quickly and accurately.

For more information, read the entire blog here - https://sites.google.com/view/steel-smart-system/blog/cfs-design-importance-of-using-software-for-this-purpose

0 notes

Text

Summary:

' I have lost a brother, and gained an enemy.

How is this fair?

How is this trial?

You’re all I’ve ever wanted:

All. '

Warnings: Angst / brotherly feels - One shot

Pairing: Thor x Loki

Authors Notes: I'm bringing this back in the hopes of refreshing some of my works from a03 on here for inspiration!

This fic is from 2013, so please pardon the dust as I begin my writing anew. It's set sometime before The Dark World and a little after the ending of the first Avengers film.

--

The winding hallway panned out before Thor, stunted rays of golden light feathered in from the windowed rooms beyond the halls stone walled confines. As he strode down them, Mjolnir loosely in his grip, there was no hesitation in the blonde’s step. No disconcertion or doubt or regret in his wake. No pride or pity. No punishment lay in wait for the actions to be brought forth in the once God-turned-King. He should have been busying himself with other issues. Other concerns. The trial awaited him, awaited them both. Just two days. Two. The thought ripped a low growl from the Norse God, causing him to pause in mid-step.

No one else had faith in Thors’ cause. In his request upon he and Loki’s return to Asguard many had advised Thor against any further involvement, against trying to save a soul destined for self-destruction and exile. Hard-headed oaf. Numb-skulled quim. Stubborn and stupid. Loki himself would have spoken those names aloud should he had heard of his brothers faith in him, surely. Of his brothers sole calling of the moment—his burden to bear. It had always, in short, been the younger boy. The now war-criminal-trickster-turned -prisoner with the serpent green hues and Cheshire grin: that was Thor’s weakness. The man who was still very much still just a wounded boy needing protection. Protection only a brother could provide. It sickened Thor to think that somehow he had failed. Somewhere along the lines he had simply not been enough. With Loki in lock down on the home front, all should have been over with, calmed; but Thor was at more of a conflict with himself than ever before. He had thought his brother dead. Thought his younger half lost, and in some way it had been easier. To not see your failures, see your mistakes and your undoing to be done—it had been…an ignorant bliss to the blonde. But like a ghost, very much so, Loki had returned. Captured, beaten, broken as he was, but very much alive he remained. Remained like some pent up diseased leper, hidden within the confines of his once home.

More responsibility, more burdens would fall upon our dear Asguardian King-to-be yet, however. It was clear in the Norse Gods appearance. He had lost a bit of his bulk personality-wise; his swaying ways, his poise of sorts. He remained quiet oddly, on most days, in dinner and in conversation. The rest of the Warriors had the courtesy to pay no mind, to follow their King with understanding and faith—but the toll it took had grown in the past weeks since Thor's return. Faith was being questioned, doubted—and Thor knew he was walking a thin line for all. He couldn’t bring himself to care. There was a task at hand he needed to fulfill to right himself. To right Asguard as a whole. In his mind he had let his brother fall to this shame, this sickness and insanity; Thor would have to lay him out before the court for his criminal war-crimes, let all that should be and will be simply…exist. Thor could not simply give in like such. He was an Odinson. A warrior under all pretenses of the name. He would fight—fight for the name whispered in the nights alongside laughter and musings as children. Fight for the name called out across training fields and slurred lovingly within merry drunken comedies. Loki. For Loki he would fight.

His boots clattered against the tile floors as his worn steps dragged along—heavy, burdened. Alone he had gone, down into the depths of the holding cells that existed deep within the Asguardian castle-like walls. Alone Thor had decided that not all was lost. Lost. Misguided. That is how he chose to think of his little brother. His responsibility. Alone he had thought. Alone he had fought for the smaller male’s freedom. Alone he would forever be on his fight.

The blonde Norse God was clad in very little, considering the occasion. A simple vest, studded with a stainless steel Armadillo-reminiscent war-wear chain mail. Grey. Dark. Cold. Almost colorless was the Gods golden frame and demeanor. Even his glacier hues and luminescent locks had somehow faded in the days passed since. Thor

turned toward a gold pleated frame. Cherry-wood graced the lining of the cell, vibrant and daring—fitting for such a prisoner. Prisoner. No, fitting—in fact—for his brother. A Prince. An heir. An Odinson. Thor flicked his hand over the lock of the room, the lavish cage that held his other. The key at his throat was heavy in sudden. The God clenched his jaw, ripping the thin lanyard from his throat and unlatching the series of barriers holding him from the sight he longed to see.

—

The room was encased to ensure that no amount of magic or trickery sustained within its walls could ever break free. A sad, sad sight in the face of Loki Laufeyson, to say the least. The muzzle around his jaw had been drawn far too tight. The metal clenched his mouth shut in an unbreakable, painful hold. He had tasted the metallic tinges of blood here and there during his arrival. He longed to speak; to burn, insult and strike with the power of his elements. A muzzle. Infuriating, it was. Like a domesticated animal to be trained—subjugated—taught its place. On Midguard at least he could be revered, even in his hiding. Here he was caged. Here he was the enemy—the freak—the traitor and the disease on a Kingdoms perfection.

The raven haired Odinson arched his aching back at the foot of his bed, chains rattling on his connected wrists at the motion. The sound echoed out across the room, his cell, his prison. He refused to let himself enjoy any of the luxuries Thor had ordered to him. Refused to sleep on the silken sheets laid out for him. Refused to dress himself in anything other than his tattered green and gold war-wear.

This room--a damned extravagance--was insulting to the Jotun born sorcerer. He would have rather a traitors cell. A barred cage. The trickster gave his shackles a small shake, the ringing remaining always in his ears. He pulled at the rings, feeling the vibration against his ankles and against his chamber bed. Like a dog. Like a damned animal. A soft hiss broke through his lips, stinging with the friction the metal springs and guiding that held his mouth shut, gave. The younger mans’ slender frame rippled, anger growing once more. He was not yet defeated. He refused to let himself remain at the hands of the All-Father and Thor. A small smirk perked up on the Gods lips at the thought of his not-brother. The Would-be and should-be King exiled, brought back, and forgiven. Yes, Loki knew Thor would be King. After his trial, after the ashes cleared from the air and Loki’s name no longer burdened his families…Thor would take the title like he should have, leaving Loki like he’d always been—Second best. Never to be an equal.

A soft whirl of fresh air blew around the trickster and he sat down beside the towering end-board of his bed. The door of his ‘cell’ revealed a flicker of light, cut off by a towering form with hues so opposing to his own. Loki’s teeth ground tighter; more metal slipping in at the corners of his mouth, the younger Prince’s expression remained stoic.

His tongue shifted against his canines. How he longed to speak, to thank his dear not-brother for the visit—nearly three weeks into his confinement. Thor truly knew how to show his affection, did he not? But Loki had waited. He had known his other would come for him in the end, as always.

—

Loki’s cypress greens flashed with a silver edge as he watched the blonde shut the door behind him, observing the soft ‘click’ of the locks sliding back into their place. Smart boy, the trickster mused in his thoughts. Seems like the standing of our trust runs both ways, Thor.

Thor slipped the key into the joint of his hip beneath his tight combat pant waistband. His eyes steadied themselves on the sight before him, no hesitance, no bracing. His steps were soft as he set Mjolnir down on the bedside before Loki, kneeling, examining. The smell of food met his sense, bitter and aged. He caught sight of the rotting plate and sighed. Loki was known for going weeks without food, pent up in the library or the study among his books, but his other looked ill now.

Deathly so.

Loki’s sharp cheekbones had hallowed. They sat like near razors pent up beneath his porcelain flesh. The raven haired man before Thor looked up to him with darkening eyes. Stains of purple and grey mottled his eyes in slight. Weeks. It had been weeks since their return. Thor had come late to his brothers side, he knew, and judging from the seething flickers in Loki’s glance, he did too. But there had been much to calm on the front…including his own mind. He could not have helped Loki then. He could barely help himself.

Thor slipped a finger along the curve of Loki’s jaw, causing the trickster to jerk back out of instinct.

“I mean you no harm, brother.” Thor hushed him, trying to hide the pain in his rejection with a low growl. His voice was worn, his expression even more so--much to the amusement of his other. The blonde ran the pad of his index over the soft metallic clutch that held the jaw confinement in place and pressed down.

Loki bit back a hiss at the pressure caused. A muffled curse flew from him at the sensation of the metal fixings biting into the corners of his mouth. The coils unraveled in agonizing slow, the pressure releasing him from its hold. His jaw pushed forward as the binding slipped from him. The Jotun sorcerer let his head lull back for a moment, licking the trickling blood from his lips as a rumbled laugh escaped his bruised lips; candy-apple red they were, even in the dim lighting.

”And I suppose that was your peace offering, Thor? A bit of freedom for the Jotun-freak, hmm?” Loki rose his shackled wrists up, stroking the bruising settling in on his cheeks. “If you were expecting my gratitude,” He continued, slender fingers rounding his chin. “I assure you--you will get none.” A smile played on the tricksters lips, small, almost innocent. His eyes flashed once more. Brightening.

”I do not expect that from you. Not after the weeks of confinement you-”

“Ah, yes. Weeks.” Loki straightened himself with a cough. “All the while the rest of the Kingdom and you, may I remind, went about their ways; celebrating and cheering on the soon-to-be-Kings coming reign and his war criminal catch.” There was no pause, no room for Thor to speak as Loki continued, chin tilting up, expression curious. “Surely this visit can not be consensual, not-brother?” A sneer ended his sentence as he lean back against the bed.

Thor stifled a recoil at his brothers words. Not-brother? It should have been expected, but that did not soften the blow the God of thunder felt in his chest. The restriction of his breath was small, but he knew visible all the more.

#thorki#thorki angst#thor: the dark world#mywriting#circa 2013 pls dont judge#thor#loki#brotherly feels and angst honestly#thorxloki

11 notes

·

View notes

Text

Light Gauge Steel Structures

Light Gauge Steel structures, also known as Light Steel Framing (LSF), are an innovative and versatile construction technology that uses thin sheets of galvanized steel to form structural components. These structures are gaining popularity in the construction industry due to their numerous advantages over traditional materials like wood and concrete.

Characteristics and Components

LGS structures are typically composed of cold-formed steel sections, which are manufactured by bending and shaping steel sheets into desired profiles at room temperature. The most common profiles include C-sections and U-sections, which are used as studs, tracks, and joists. These components are assembled using screws, bolts, or welding, creating a robust and lightweight framework.

Advantages

Durability and Strength: Steel is inherently strong, non-combustible, and resistant to termites, rot, and mold. These characteristics make LGS structures particularly durable and capable of withstanding extreme weather conditions and seismic activities.

Lightweight: Compared to traditional materials, LGS structures are significantly lighter, which reduces the load on foundations and allows for easier transportation and handling. This lightweight nature also enables faster construction times and reduces labor costs.

Precision and Consistency: LGS components are manufactured with high precision, ensuring consistent quality and accuracy in construction. This precision allows for tighter tolerances and reduces the likelihood of errors during assembly.

Versatility and Flexibility: LGS systems are highly versatile and can be used in various building types, including residential, commercial, and industrial structures. They allow for flexible design options and can accommodate a wide range of architectural styles.

Sustainability: Steel is 100% recyclable, and the production process for LGS components generates minimal waste. This makes LGS structures an environmentally friendly option, contributing to sustainable construction practices.

Applications

LGS structures are used in a variety of applications, including:

Residential Buildings: From single-family homes to multi-story apartments, LGS provides a durable and cost-effective alternative to traditional wood framing.

Commercial Buildings: LGS is ideal for constructing commercial spaces such as offices, retail stores, and hotels due to its ability to create large open spaces without the need for internal columns.

Industrial Structures: The strength and flexibility of LGS make it suitable for warehouses, factories, and other industrial facilities.

Modular and Prefabricated Buildings: LGS components can be prefabricated in factories, allowing for rapid on-site assembly and reduced construction times.

Challenges and Considerations

While LGS structures offer many advantages, they also present some challenges. Thermal bridging can occur in steel structures, leading to heat loss and condensation issues. To mitigate this, adequate insulation and thermal break materials are essential. Additionally, proper corrosion protection, such as galvanization, is crucial to ensure the longevity of the steel components.

Conclusion

Light Gauge Steel structures represent a modern approach to construction, offering a combination of strength, durability, and sustainability. Their versatility and efficiency make them a valuable option in today's construction industry, addressing the demands for faster, cost-effective, and environmentally responsible building solutions. As technology and techniques continue to advance, LGS structures are likely to play an increasingly prominent role in the future of construction.

0 notes

Text

Project Skeptic | Chapter 1

Read from the Start | Read on AO3

Summer 2019

The first thing that she realized was the taste of blood. It was subtle at first, a light dance across her tongue with a metallic edge. But then it was dry, dry enough to make her want to dart her tongue out against her lips and dull the throbbing edge. She had a headache, that was observation number two. Number three came in the form of the thick restraint against her wrists, burning and unrelenting.

You don’t ever trust a stranger, Emily. Her mothers’ words would echo through her mind like a steel drum against an empty corridor. When she was younger it never made any sense. The mailman was just as strange to her as someone in a dark hoodie with unkempt hair. If they didn’t offer up a handshake was she supposed to remain on high alert? Katherine Junk would be spiteful right about now. Spiteful or worried.

Emily pulled her head back, drawing in a sharp breath as an undeniable ache pulsed against her spine. She was in a chair, one that creaked and groaned under her weight. Her consciousness was barely there but started to spark; there was a fire nearby, she could smell it and feel its heat on the side of her face. The room had a sweet and floral scent to it.

“Good morning, Sunshine.”

Loud. God that voice was loud and oh so familiar. Emily wasn’t fully there, her heartbeat deafening in her ears as she made a jumble of noise past her lips. Her whole body was stiff, and she blinked a few times to get used to the coloring of her surroundings, dark and rustic, and she could swear up and down that there was a Christmas tree situated in the corner. It had multi-colored lights and way too much tinsel. It had been meticulously applied branch by branch.

“I hit you pretty hard there, huh?” The voice was calling attention and Emily blinked three more times before focusing. The figure was, in fact, shaded in a deep orange that flickered against the floor sporadically. She was dressed casually, normally. Not like someone who would kidnap a person; a dark green sweater and jeans that contrasted from her deep ginger hair. Her eyes, even in the light from the fire, were sparkling like broken waves. “You’re okay though, you’re strong.”

Emily drew in an easier breath and clenched her jaw, which was sore too. Claire, Callie maybe even Chelsea Emily’s mind was searching for a name to the face. It was her next-door neighbor; she can remember the conversations they’ve had at the mailboxes and the golden lettering on their forest green door. She recalls that this woman has a wife, a music producer that’s too grumpy for her own good, but her name. God, what was her name?

“What’s going on?” Emily asked, swallowing the bloodied taste in her mouth. Her voice was dry enough to be unrecognizable. “Where am I?”

“That’s classified, I’m afraid. But we’ll get to that depending on how well you take this.”

“Take what? Being kidnapped?” She let out a small groan and rolled her neck again. “Who are you?”

She couldn’t remember much; the walk home from work, the elevator ride up with her neighbor nodding and asking her about her plans for the rest of summer. Emily explained she would work like she always did and struggled to find her keys in her bag. She remembers an earth-shattering pain in her temple and a warm sensation before everything went dark.

The woman let out a deep sigh as if Emily was inconveniencing her. Maybe she was at this point. She sat down on the edge of a leather reading chair that was positioned right across from the wooden seat that Emily was fastened to. It had a large studded back and reminded Emily of something that would accompany a glass of scotch and imported cigar wrapped in gold.

“I’m Chloe, I didn’t’ technically kidnap you, and this is a secret organization dedicated to keeping the holiday season sacred.” She had rushed out her words like a band-aid and Emily wasn’t sure if this woman was completely nuts or if she wasn’t exactly hearing her right over the pounding in her ears.

None of this registered, however, so Emily simply said, “But it’s only June.”

“Oh, I know,” Chloe slumped back in her seat completely, letting her hands hang over the sides of the chair. “We’re so behind schedule. Recruitment was supposed to be in May but being so close to you proved very difficult. There’s a lot we have to catch you up on, Emily.”

“Can you-?” Emily tugged at her restraints, trying not to flinch too hard at the stinging pain that moved through her skin as she shifted. The woman lifted her eyebrows and moved forward, almost as if she had forgotten entirely.

“Yeah, sorry about this. We’re not usually so violent but it’s not every day that you refuse orders from the big guy. You know, don’t you? You work for some big television company.”

Chloe talked too fast, Emily decided. She had an innocent edge about her, and at this point, she didn’t’ care if she had to keep the conversation up. She reached to the side table and pulled a golden crafted letter opener, gently trying to saw through the rope. It came undone easily and Emily let out a relieved breath she didn’t’ know she was harboring. She rubbed the raw skin, eyes searching the room.

It looked like the inside of a cabin that her family used to rent by the lake, from the stone figures all the way to the throw that was draped over the edge of the chair Chloe sat in. It was too eerie, too familiar. There wasn’t a door, that same flutter bubbling in Emily’s chest.

“You’re taking this remarkably well.”

“You hit me in the head. I’m afraid I don’t’ believe you.”

She was scared to move her fingers up to her temple. She was sure it was sticky. She could practically feel the blood that has soaked into the collar of her shirt. Instead, she resided into staring into blue eyes that looked silver.

“Do you believe in Santa, Emily?”

Did she? It was a loaded question. The fiction of it all was ripped away violently when she woke up to her mother’s hand wedged under her pillow when she lost her first tooth. She was a light sleeper. Emily remembered crying as she asked her mom about a bunny who hid eggs and a man who delivered toys in exchanged for burnt cookies and room temperature milk.

“You stopped believing when you were six years old. After that Christmas didn’t’ feel the same anymore, and your mom would let you pick out what you wanted at the store, didn’t’ she?” Chloe asked, “You knew what was under the tree every single year until the tree vanished completely and was replaced by a card with a fifty-dollar bill in it.”

Emily slumped back in her seat, because yes, that was exactly what happened. It didn’t’ feel so sad when her mother told her she was going on a cruise instead of sticking around and dealing with the stress of the holiday season. The way Chloe told the story deflated her. A story that she hadn’t talked about, not even to Aubrey.

“Say you are telling the truth,” Emily started “Say you’re apart of a secret organization that rotates around Christmas… what do I have to do with it?”

The younger woman wasn’t sure why she was entertaining the idea. It might be the pounding in the side of her head or the fact that her bubbly little neighbor had a complete backstory on how her Christmases had played out, but she simply dug her fingers into her sore shoulder and looked at Chloe was expectancy.

“The world is changing, Emily. It’s growing bigger, some would even argue better, by each day. For the past five years it’s been too much for one man with a couple of reindeer to handle, you know? The old guys retired.”

“Is he now?”

There was sarcasm leaking past her voice. It wasn’t intended, but it spilled out like a pool of steam over fresh hot chocolate. This room smelled too much like cinnamon, Emily decided.

“He is. And when he’s away he trusts in this organization, Project Skeptic, to deliver presents, grant wishes, and keep the Christmas spirit alive.” Emily swallowed roughly. Her mouth still tasted metallic and Chloe’s words hadn’t yet settled with her. “We’ve kept an eye on you, Emily. We know that all you want is to get that feeling back.”

December 2019

Emily pressed her stomach to the cold of the wooden floor, it’s edge soaking through her jumpsuit in a simple motion. It was the type of cold that she remembered as a child when her bed was given to her older cousin from Kansas and she drooled all over her pillow. She hadn’t even bothered to wash it before throwing it into the trash. Emily had slept on the hardwood flooring for two weeks.

Now she was struggling to hold her breath, letting it catch in her throat as she stared up at the windowpane above her. The sheer white curtains caught the light of a passing car, one that stalled- she could hear the crunch of tires against gravel and practically smell the gasoline that rested in the tank. She pressed her cheek close to the laminate and listened. It eventually pulled away, breath short as she was bathed in darkness once more.

Emily brought her frame back up to a standing position, careful not to let her form show in the large bay window; the house was normal, a large pre-lit Christmas tree that was filled with family ornaments made from Styrofoam cups, the angel on top that seemed to stare her down, and the plate of cookies that were stacked high enough to not only feed one reindeer but twelve.

She didn’t dwell too much on her surroundings. Sometimes it was different. The house wasn’t as decorated, or the tree was a live one. Very seldom was it just a barren wasteland with nothing more than cold granite countertops and a fire that was unlit.

Emily reached against her belt, pulling a simple laser pointer from its leather confines. She felt blindly for the little switch, the thing smooth under her fingertips. She pointed it at the ground, drawing a neat little line with its electric blue light. She could almost taste the charge in the air as she squatted down, reaching her grasp into the clutches of the glow.

This type of technology had scared Emily at first; a simple laser pointer that created a hole in the void to grasp Christmas presents that had already been pre-made. Now it was like second nature, a warmth engulfing her skin as she unshelled packages wrapped in paper with little candy canes and bushels of holly.

Emily learned not to question the size or weight, or the elegantly written Santa on the paper. Instead, she questioned other things: How many parents were in the house? Did the kids have a habit of staying awake? How full was the moon and how visible would it make her?

There was a subtle growl that cut through her little atmosphere like a butter knife through a grilled steak. It leaked grease and edged a deep feeling in the pit of Emily’s stomach. Were there any dogs?

She moved her hand over the line of electricity and plunged herself into innate darkness once more, slowly standing as her palms faced the floor. She could hear the rumble in the German shepherd’s chest, practically feel it close to the wooden floor. Its jowls dripped, hot saliva fell in thick strands.

Emily kept her eyes on the animal as it took a step forward. It was blacker than brown, and its eyes caught the green lights of the tree behind her. If it wasn't cheap plastic, the scent would be seeping into her clothing. The dog licked his gums, stepping closer.

Before she could protect her throat, the lights flashed on. They were almost worse than being mauled by a house pet. Her fingers moved against her stare to block out the stage glow, to blink away the afterlight that dominated her vision. There was an alarm too, a loud one that should signal fire but instead brought defeat.

“Emily!”

She let out a deep groan before anything else, slumping her shoulders and shaking her head. Even through the light, she could see everyone rushing around, could hear the door that stood next to the windowpane open and close- a simple little house rigged to produce nightmares.

“We have talked about this,” Chloe let the door fall behind her, “You need to check your compact before you get into the house that way you’ll know if-“

“There are any animals on the perimeter, I know.”

“If you know, then why didn’t’ you?”

Chloe didn’t’ wait for her to answer, instead, she clicked her tongue and had her follow from the faux room and into a standard hallway. Standard in the way that Emily could walk into any building on Wall Street and come in contact with the same generic paintings of beach scenes to make it feel a little less frigid in the winter. The red fire alarms stood out against tan colored walls. Chloe Beale looked ragged and tired.

“As much as I love you, Emily, you’re not going in on your own.” She finally said, breaking the silence. “Do you even have your compact?”

Did she? Emily felt against her waist and she did. It was easy to run her fingers along the extensive little device. It held everything she needed; the ages of the children in the house, what they wanted, if there was any unexpected company like a guard dog- even if it was simulated.

“Of course, I do, Chlo” Emily stopped in the middle of the empty corridor, pressing her fingers against the woman’s elbow. The Kevlar on her black jumpsuit was cool under her touch. “You know how I operate. We’ve been through this training a million times. I’m just… nervous, I guess. A lot is riding on this. Making and breaking Christmas.”

Chloe’s cerulean eyes softened at this. She looked tired. Her skin was pale under the neon lights and her jaw was clenched- nothing like it had been before, the stress of the holidays edging against her frame and making it stiff. “You’re telling me. This is my block- hell, it’s my city. But it’s no excuse to forget what you’ve learned.” She tapped the compact with her fingers. “What we’ve taught you. Right?”

Emily allowed herself to smile softly at Chloe. “Right,”

“Go get changed. We’re meeting 007 tonight for dinner.”

“Oh, Chloe I am not third-wheeling with you and your wife again.” Emily all but whined “She hogs all the noodles. Besides, don’t you two ever get tired of me tagging along?”

Chloe rolled her eyes in a dramatic fashion, crossing her arms over her chest. She looked intimidating in the small hallway. “First of all, Beca is the youngest of three, she’d bite your hand off for those noodles. And second of all, no we don’t get sick of you hanging around because you’re family now.”

“You don’t have to take pity on me,” Emily scoffed playfully “Just because my girlfriend is halfway across the country on business 90% of the time does not mean you have to suffer through me at the end of the couch during movie night.”

“We invited you, end of story. Go, get cleaned up.”

Emily saw no benefit in arguing with Chloe Beale. She was already high strung enough as it was, her back straight and eyes always trained on the little clipboard of hers. It sent a quick twinge of guilt through Emily, forgetting her compact like that didn’t help anyone- especially not the crew that set the whole elaborate thing up in the first place. Fake snow and a rabid hologram of German Shepards.

Everything that Emily would have chalked up to insanity seven months ago. Seven long months of working her day job, only to slip into a dingy warehouse on the east side of town. Scanning a badge, she hid among old candy wrappers and half-used Chapstick. No one would go searching in there.

The training had been embedded in her head, by Chloe herself, mostly. She sat in a classroom with unlimited servings of hot chocolate stirred with candy canes. Something she quickly grew tired of- cringing away from the sugary drink now. She had taken the defense courses and the Child Protocol lectures. But her anxiety continued to spike in rebellion, Christmas approaching fast.

Her phone buzzed in her back pocket, Chloe narrowing her eyes “You can carry your phone, but not your compact?”

Emily ignored the comment and stared at the screen. “Oh, Shit.”

“There a problem?” Chloe asked.

“Nothing major, my mother just informed me that we’re having Christmas at my house this year.”

Her voice was calm, but a flutter of anxiety licked at the back of her mind. That was one of the first things that they had taught her- no connections, plenty of excuses. Most of the people here didn’t’ have anyone depending on them for the holiday season. No obliged trips to church or brunches consisting of runny eggs.

For the past two years Aubrey had to work through Christmas and Emily would travel a few miles out of the city to be with her family for a few hours before she facetimed her girlfriend and they shared a long call littered with apologies, and Emily explaining that it was just a day.

“Oh,” Chloe sounded out evenly “You know what, no big deal. I’ve hidden this from Beca our whole marriage. Some would say it’s concerning how oblivious she is.”

Emily hummed in agreeance. Chloe was shockingly calm about the situation- about having to sneak out right after dinner on Christmas eve. About breaking into houses until the sun rose behind morning clouds.

Chloe must have sensed her worry, giving her shoulder a squeeze. “It’ll be fine Em. Now, go get changed. She’s probably taken out half the restaurant at this point.”

16 notes

·

View notes

Text

TRP Flag: Lysonde Riverblade - Lady; Aerialist; Dancer; Knife-thrower’s Girl

Directory Information:

Race: Sin’dorei

Class: Performer

Age: Adult

Eye Color: Mint green

Height: 5′9″

Body Shape: 147 lbs. (Athletic)

Birthplace: Dawnstar Village

Residence: Silvermoon City

Additional Information:

Pronunciation: “Lihs-ahnd”

House: Riverblade (née Stormfall)

Nickname: Lys

Piercings: Two gold studs per earlobe. Left ear tragus with ruby stud.

Tattoos: Elaborate art nouveau blackwork on right thigh from hip to knee.

Scars: Slash on upper left arm.

Affiliations: Dalaran infirmary, Armies of Legionfall

Vitality: Healthy and happy!

Languages: Thalassian, Common, Orcish

Personality Traits:

Lawful (4) < Chaotic (16)

Altruistic (17) > Selfish (3)

Gentle (18) > Brutal (2)

Cautious (5) < Impulsive (15)

Swords (8) < Spells (12)

Extroverted (16) > Introverted (4)

Physical Description:

Stout of form with skin the color of rich clay, Lysonde faces the world with the polite smile of a woman who will not take your shit or anyone else's. Freckles decorate her skin, concentrated on her cheeks and shoulders and collar bones. Heavy mahogany-tinted curls tumble to the middle of her back. She walks with an acrobat's grace and bared limbs reveal lean muscles. An elaborate tattoo of architecture-inspired curves and diamond-tipped spires marks the outside of her right thigh from hip to knee in soft black ink.

Despite her no-nonsense demeanor, she's often caught smiling or laughing, and dresses in the wild colors and patchwork mix of fabric common to flower children and carnival followers. She sports a substantial iridescent topaz ring on her left hand, stacked atop a diamond-set wedding band.

History:

- She's a known performer for the Succulent Tart troupe and spotted more and more often at charity events.

- Elves in Lordaeron at the time of the fall of the city may have seen her before.

- Frequenters of traveling shows and carnivals might have spotted her performing aerial rope acrobatics and dances, as well as acting as a knife thrower's assistant in her younger years.

Those actually involved in the carnival circuit have probably heard rumors of her as a tramp who sleeps with patrons and steals their money, an unreliable dreamer who skips performances whenever she feels like it, or a cold-hearted maneater with a taste for rich men.

At First Glance:

Smells like...

A light perfume of amber, vanilla, and tiger lily.

Dark-skinned elf.

Contrary to available skin-tone choices in the game, this character has tawny brown skin. She also has a substantial scattering of freckles.

Shiny!

Sporting a topaz ring on her left hand, stacked atop a diamond wedding band.

* Fancy!

Wearing a lovely gold and pale yellow gown with fiery orange beading decoration.

Other Information (OOC): I like big words and I cannot lie. http://lysonde.tumblr.com

Inventory:

Ruby Stud Earring

Jewelry Earrings

“A single, small ruby stud earring.”

Shell Necklace

Jewelry Necklace

“A spiral shell wrapped in wire and capped with three raw crystals. A hinged top hides a miniature black panther figurine inside the hollow of the shell.”

Rosewood Bead Necklace

Jewelry Necklace

“A multi-stranded necklace of hand-polished rosewood beads which produce a lovely rose scent when warmed against the skin.”

Med-kit

Container