#light steel framing software

Text

Solutions for Light Steel Framing Design with SteelSmart System

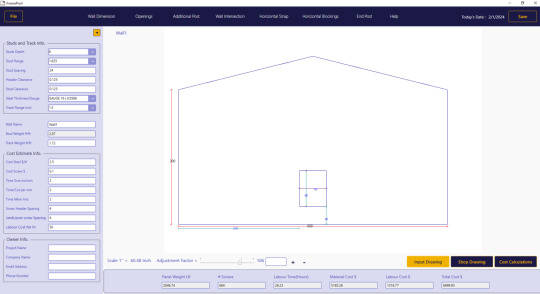

Explore the Light Steel Framing Software by SteelSmart System, engineered to streamline the design and analysis of light steel framing projects. This software offers a comprehensive suite of tools tailored for precision, efficiency, and innovation in structural engineering. With advanced features, users can optimize their designs, ensuring compliance with industry standards and enhancing project outcomes. Visit their website to discover the full potential of their Framing Software and elevate your engineering solutions.

0 notes

Audio

For the last 20 years, Steel Smart System has been offering the best light steel framing software in the market for structural engineers and light steel framing contractors. Visit their website for more information and to place the order - https://www.steelsmartsystem.com/steelsmart-system-light-steel-framing-design-software/

0 notes

Text

Make Use Of Light Gauge Steel Design Software Without Having 3D Modeling Skills

Did you know? Now you no longer need to have a thorough understanding of CAD design or acquire specialized 3D modeling abilities. With your basic knowledge of evaluating architectural dimensions and structural standards, you can easily enter your data into our light gauge steel design software program. After that, FrameProX instantly generates detailed shop drawings along with comprehensive cost calculation, for constructing the particular wall.

#light gauge steel design software#light gauge steel framing#3d modeling software construction#3d modeling software for buildings#3d steel detailing software#architecture 3d modeling software#building construction software#best steel detailing software#building structural analysis software

1 note

·

View note

Text

@haematophiliac

02:12 on the clock.

The pair had been working together in silence, leaning over the autopsy table for nearly two hours. This was not an unusual place to find Executive Proton and Admin Jax-- in fact, the two of them regularly worked alongside one another in the basement levels of the executive's workshop.

Whenever Fragmentation Syndrome was involved anything pertaining to a Rocket member, individuals with previous experience handling the condition were pulled and assigned to the issue at hand. In this scenario, a grunt had been inflicted with the anomalous syndrome, and was showing symptoms for the past 72 hours. Fragmentation develops quickly-- and aggressively. Without intervention, it can devastate any body, either organic or artificial.

Autopsying these bodies was vital in order to better understand the condition, and in order to prevent further spread. Of course, the ongoing treatments that Executive Proton received for his own illness, was paramount as well.

Of course, he was still very symptomatic, despite being stable.

And unfortunately, when one anomaly meets another, reactions occur.

The room had been silent, until Proton's scalpel cut into the vagus nerve of the cadaver. Once steel cut through the delicate strand, an awful, screeching sound erupted, and Proton's arm was rendered temporarily useless-- within seconds, the body in front of the pair distorted, as did the executive's arm. Frozen in place, Proton twitches some, that horrid screeching piercing his cranium, and causing the man to hunch over as he made an awful sound of his own. It only lasts for a moment-- but in that moment, some of the exposed organs and muscle tissue on the cadaver simply-- pixelate and vanish.

Cussing under his breath, Proton leans up-- and then turns his head to Jax. His own movements were still lagging, like that of outdated software.

❝ Well that was fucked up. ❞

His frame flickers, just like the dingey yellow lights overhead, and he lowers his hand down from his face. Proton smiles, his calmness rather unnerving. His voice is off, more akin to a radio signal.

❝ Jaaax? Are you oͦᵏkͣaͣaͣaͣʸay? ❞

#➤ 《 𝟗𝟎 𝐃𝐚𝐲𝐬 𝐃𝐞𝐥𝐢𝐧𝐪𝐮𝐞𝐧𝐭; 𝐆𝐞𝐭 𝐓𝐡𝐞 𝐑𝐞𝐩𝐨 𝐓𝐫𝐞𝐚𝐭𝐦𝐞𝐧𝐭 》 In Character#➤ 《 𝐒𝐞𝐫𝐩𝐞𝐧𝐭 𝐁𝐞𝐧𝐞𝐚𝐭𝐡 𝐓𝐡𝐞 𝐒𝐡𝐫𝐢𝐧𝐞 》 Verse One#haematophiliac

2 notes

·

View notes

Text

warehouses, dead malls, and backrooms, oh my

I was the only one in my department who showed up on time for work today. I thought I would have to process and label all 12 tractor trailers worth of boxes myself. There were various dudes there, but I was the only one who knew how to work the computers (the work computers are my level of expertise... I swear they run on 1998 software... frames and all. Who else remembers websites and programs with frames?). I was thankful when another person arrived 45 minutes late. She didn’t know how to log out of my username and into hers... I told her use Ctrl-Alt-Del to bring up the screen... she didn’t know what Ctrl-Alt-Del was.

So being in a dark grey-on-grey steel on concrete warehouse with hardly anyone around.... being someone who worked at Sears before that as even in 2004-2005 was slowly sliding into bankruptcy. Who walked through aging next-to-abandoned malls in the Early 90s (which was supposed to be the heyday of malls but some did not do so well). Who commuted to college via Boston’s aged creaky subway and would sometimes be at a stop underground by myself. And having been a child who sometimes accompanied my father, who fixed elevators and escalators in Boston to office buildings and museums after closing... (and who recently had one of my long time tumblr followers who actually interacted with my posts blog get apparently hacked, be emptied out, turned white, with only one post up which I’m sure they didn’t make: “Hypnosis for Businessmen”)...

I’ve been digging “The Backrooms” lately. Yes, late to the party, have had a lot going on. But I’m on the older person divide who doesn’t like the ones with more sci-fi elements added to it. The scary part IS a cavernous mandmade space with no one but you to wander around in it. Rooms emptied out except for maybe a stack of chairs. The eerie feeling of shadows, of knowing you are alone but feeling not alone somehow without anywhere to hide or feel comfortable in, without knowing what to do or having anything to do. Except wander wander wander until you find another level that looks different but is equally so very empty. A lack of clocks and windows to tell you what time it is. The only light being unnatural, florescent, buzzing. Post capitalism hellscape. The younger kids don’t get the extensional horror of it all yet, I think... or else have so short of an attention span they need to add to it.

4 notes

·

View notes

Text

The Art of Crafting a Wedding Tent: A Comprehensive Step-by-Step Guide

When planning an outdoor wedding, the tent is more than just a shelter; it’s the heart of the celebration, setting the stage for unforgettable memories. As leading Tent Manufacturers and Suppliers in Indore, understanding the meticulous process behind crafting these tents ensures the delivery of durable, stylish, and functional structures. From material selection to final assembly, here’s an inside look at how wedding tents are manufactured to perfection.

1. Material Selection: Laying the Foundation for Quality

The first step in crafting a top-tier wedding tent is selecting the right materials. Two fabrics dominate the industry: canvas and PVC (Polyvinyl Chloride), each bringing unique qualities to the table.

Canvas: Loved for its natural, rustic appeal, canvas is breathable and eco-friendly, making it ideal for outdoor weddings. However, it requires waterproofing treatments to handle weather conditions.

PVC Texture: For a smooth, present day see, PVC is the go-to alternative. Its weather-resistant and waterproof properties make it perfect for unpredictable climates. It’s also lightweight, allowing for both clear and opaque tent designs.

The tent's framework is equally important, typically made from corrosion-resistant aluminum or galvanized steel. These materials ensure the structure is lightweight yet sturdy, offering the stability required for large wedding gatherings.

2. Design and Customization: Tailoring the Tent to Perfection

Once the materials are chosen, the plan stage starts. Wedding tents can be customized to match the theme and scale of any event, making this stage crucial for creating the perfect ambiance.

Pole Tents: Featuring dramatic peaks supported by central poles, these tents are perfect for large, luxurious weddings, especially when paired with the Best Royal Wedding Furniture Set.

Frame Tents: Without center poles, these offer a flexible layout, allowing for elegant decor such as Wedding Flower Stage Decoration and spacious seating arrangements.

Clear-Span Tents: Ideal for maximizing space, these tents have no interior poles, making them the perfect choice for grand events that require a seamless, unobstructed flow.

With the help of CAD (Computer-Aided Design) software, manufacturers create custom designs that include essential features like windows, doorways, and decorative elements such as a Pink and White Wedding Gate, perfectly enhancing the overall aesthetic.

3. Precision Cutting and Sewing: Ensuring a Seamless Fit

Once the design is finalized, the fabric is cut to exact specifications. Precision is key here—laser cutters or automated machines ensure that each piece fits together flawlessly. This accuracy prevents any issues during assembly and guarantees a clean, professional look.

After cutting, the fabric pieces are sewn together using specialized machines. For fabrics like PVC, heat sealing is used instead of traditional stitching to create watertight seals, ensuring the tent remains leak-proof even in harsh weather conditions.

4. Crafting the Metal Frame: The Skeleton of the Tent

The frame of the tent forms its structural backbone. Aluminum or steel tubes are cut, bent, and welded into shape using high-tech machinery. These components are designed to easily interlock, allowing for quick assembly and disassembly on-site.

If the tent design includes clear sections, such as transparent windows or a decorative Wedding Flower Stage Decoration, clear PVC panels are added at this stage to allow natural light to fill the tent while maintaining a luxurious look.

5. Rigorous Quality Control: Ensuring Perfection

Before the tent is shipped, it goes through a rigorous quality control process. Each tent is fully set up in a designated testing area to ensure:

Fabric Integrity: Checking for any defects like holes or stitching errors.

Structural Strength: Ensuring the frame is strong enough to support the tent under various conditions.

Weather Resistance: Simulating wind and rain to ensure the tent is ready for outdoor use.

Adjustments are made as needed, ensuring the final product meets industry standards for Luxuries Tent Manufacturers and Suppliers in Indore.

6. Packaging and Shipping: Delivering the Dream Tent

Once the tent passes all quality checks, it’s carefully packaged for shipping. The fabric is folded and stored in waterproof containers, while the metal framework is securely bundled to avoid any damage during transport.

Whether shipped directly to the customer or a rental facility, manufacturers often provide on-site setup services or detailed assembly instructions, making the process hassle-free for event planners and coordinators.

Conclusion: The Craftsmanship Behind Wedding Tents

Crafting a wedding tent is an intricate blend of design, engineering, and craftsmanship. From choosing the highest-quality materials to ensuring every seam and joint is flawless, the process results in a tent that is both functional and stunning. For outdoor weddings, these tents become more than just shelters—they are the backdrop for life’s most cherished moments.

At Ranka Tent Suppliers, we pride ourselves on being the premier Tent Manufacturers and Suppliers in Indore. Whether you're in need of a tent with a Pink and White Wedding Gate, a Best Royal Wedding Furniture Set, or stunning Wedding Flower Stage Decoration, we ensure your event is covered with style and grace. By understanding the manufacturing process, you can be confident that your tent will provide the perfect setting for your special day, ensuring your celebration is sheltered in luxury and elegance.

#tent supplier#wedding tent suppliers#luxuries tent manufacturers and supplier in indore#best royal wedding furniture set

0 notes

Text

Best Swimming Pool Construction Guide: Step-by-Step Process

Building a swimming pool can be a rewarding experience, offering both relaxation and value to your property. Whether you're a homeowner looking to enhance your outdoor space or a contractor guiding a project, constructing a pool requires careful planning and precision. This guide will take you through the key stages of pool construction, ensuring that the process is smooth and successful.

1. Planning and Design

The initial phase of pool construction involves comprehensive planning. The design of your pool should reflect both functional needs and aesthetic desires. Consider the following factors:

Size and Shape: Determine the dimensions that fit your space and budget. Common shapes include rectangular, circular, or custom free-form designs.

Pool Type: Decide between inground (most common for luxury and longevity) and above-ground pools (budget-friendly and quicker to install).

Materials: Options include concrete, fiberglass, or vinyl-lined pools. Concrete offers versatility in shape, while fiberglass requires less maintenance.

Purpose: Whether for relaxation, exercise, or aesthetics, tailor the design accordingly.

Budget: Outline all potential expenses, including installation, landscaping, and future maintenance.

Working with a professional designer or using 3D modeling software can help visualize the final layout and determine any necessary permits.

2. Obtaining Permits and Site Preparation

Before any construction begins, obtaining the necessary permits is crucial. Local building codes often regulate pool size, placement, and safety features such as fencing. Failure to obtain the necessary permits can lead to fines or cause project delays.

Site Survey

Once the permits are secured, conduct a site survey to:

- Assess the terrain and soil conditions.

- Determine any possible utility lines or obstructions.

- Verify property lines.

Excavation

Excavation marks the first physical stage of construction. Heavy machinery is used to dig the pool’s hole based on the specifications outlined during the planning phase. The excavation depth should match the pool design, taking into account the shallow and deep ends.

3. Forming the Pool Structure

Once the site is prepared, it’s time to form the structure. Pool construction typically involves three primary methods.

Concrete Pools: A framework of rebar (steel rods) is laid to form the shape, and shotcrete or gunite (sprayed concrete) is applied. This is the most customizable and durable option, though it requires longer construction time.

Fiberglass Pools: A pre-formed fiberglass shell is installed into the hole. This type of pool is faster to install and requires less maintenance.

Vinyl-Lined Pools: A supporting structure is built, and a flexible vinyl liner is installed inside the frame. This is a more affordable option, though the liner needs replacement every 5-10 years.

Plumbing Installation

At this stage, plumbing lines for water circulation, drainage, and filtration are laid. Proper installation of the pipes ensures efficient water movement and long-term functionality.

4. Electrical Work

The pool’s electrical system controls lighting, filtration, and heating. Safety is paramount during this step, so it’s advisable to hire a licensed electrician who understands the specific requirements for pool installations. They will install:

Pool Lights: For aesthetic and functional purposes.

Pump Systems: To ensure efficient water circulation.

Heaters: If the pool is to be heated, electrical connections for the heating system are set up.

5. Installing the Pool Finish

The next step involves finishing the interior of the pool. The type of material you chose in the planning stage will determine the process:

Concrete Pools: A smooth plaster finish is applied, or more premium options such as tiles or aggregate can be used. These finishes add both style and durability.

Fiberglass Pools: The fiberglass shell arrives pre-finished, so no additional work is required.

Vinyl Pools: The vinyl liner is secured and smoothed, ensuring no wrinkles or air bubbles are present.

This is where your pool begins to take shape and reveal its final appearance.

6. Decking and Landscaping

After the pool structure is completed, focus shifts to the surrounding area. The decking provides a transition between your pool and the landscape, as well as a functional space for lounging or entertainment. Popular decking materials include:

Concrete: Durable and versatile, it can be textured or stained for aesthetic appeal.

Pavers: Offer a natural look and can be arranged in different patterns.

Wood: Offers a warm, natural aesthetic, but it demands more frequent maintenance.

Once the deck is in place, landscaping can enhance the pool area. Adding plants, lighting, and outdoor furniture can transform the pool into a stunning backyard oasis.

7. Filling the Pool and Final Inspection

With the construction complete, it’s time to fill the pool. Water trucks can be hired for larger pools, or it can be filled using a hose, depending on the size. The pool must be filled to the appropriate water level to allow the filtration and circulation systems to function correctly.

Inspection

A final inspection by the relevant authorities ensures the pool meets all safety regulations, including proper fencing, gate locks, and the correct functioning of all systems.

8. Maintenance and Care

A well-maintained pool lasts longer and ensures the water remains clean and safe. Regular maintenance tasks include:

Cleaning: Regularly skim the water’s surface, vacuum the pool floor, and maintain clean filters to ensure clear, debris-free water.

Water Chemistry Management: Regularly test and adjust chlorine, pH, and alkalinity levels to maintain optimal water quality.

Pump and Filter Checks: Ensure the pump and filter are running smoothly.

It’s also advisable to winterize your pool if you live in a colder climate.

Conclusion

Building a swimming pool is an exciting yet intricate project that requires careful planning, execution, and attention to detail. By following this step-by-step construction guide, you can create a beautiful, functional pool that adds value and enjoyment to your property.

0 notes

Text

LSF Software is designed for efficient light steel framing solutions, providing users with powerful tools for design, analysis, and project management. With an intuitive interface and advanced features, LSF Software streamlines the workflow for engineers and architects, ensuring accuracy and compliance in every project. Experience enhanced productivity and innovation in light steel construction with our cutting-edge software.

0 notes

Text

VU 55-inch Vibe Series QLED TV ‘True-View’ of Performance

For the first time, the VU brand has unveiled a television with an integrated soundbar, unrivalled picture quality, and excellent sound quality. However, does it meet high expectations for sound and visual quality? This post extensively evaluates every aspect of the VU 55-inch Vibe Series QLED TV, from performance to design.

As such, individuals should stay in touch with us as they read through this blog post regarding the Vu 55-inch QLED TV and determine whether there are any legitimate causes for us to be enthusiastic about it.

Style of the VU 55-inch Vibe Series QLED TV

The Vu 55-inch QLED TV has a sleek body and modern style; the VU 55-inch Vibe Series QLED TV is undoubtedly eye-catching. It appears more stylish than others because it has nearly no bezels around the corners. An integrated soundbar with prominent VU lettering is integrated into the lightweight yet sturdy body created by the steel frame and plastic back mix. It looks tidy when put on a level surface thanks to its stylish and sturdy legs, and a wall installation is an option if you want to save even more space. Connector ports are segregated on the back to ensure easy access and neatness.

In-Box Accessories

1-TV Unit

Remote Control

Power Cord

User Manual

Table Mount Stand

VESA Wall Mount Bracket

2 AAA Batteries

Picture Quality of VU 55-inch Vibe Series QLED TV

The VU Vibe Series televisions 55 inches are very promising regarding image quality; they have great contrasts and a wide range of colours. The IPS panel makes it possible to watch from any direction, losing not more than 15 to 20 per cent brightness, thus making them the best in their category. It improves dark scenes and bright lights, enhancing the picture's details. MEMC technology eliminates quickly moving images, providing smooth switching for fast-moving shots. There may be slight banding in highlights of HDR content, but this is still acceptable for an affordable television set.

Software & Hardware of VU 55-inch Vibe Series QLED TV

The VU Vibe TV boasts a Google OS with a built-in Chromecast and a similar carousel interface to other Android TV devices. This allows easy access to a wide range of streaming services and apps.

Connectivity Inputs

4 HDMI ports

2 HDMI 2.1 ports, including eARC

4K at 40 Hz refresh rate

1 USB 3.0 port and 1 USB 2.0 port

Bluetooth support

Dual-band Wi-Fi

Pros & Cons

Pros

The Dynamic contrast of this VU 55-inch TV gives a VA panel type of experience.

Dynamic Range is better than many budget TV brands

The Audio Quality of VU Vibe TV is phenomenal

Cons

The VU 55-inch TV has no Dolby Vision.

The Banding is slightly visible in bright scenes.

Verdict of Vu 55-inch QLED TV

Is the Vibe of the VU 55-inch TV worth the hype? The answer lies in the dynamic range, audio quality, casual gaming, and overall gaming experience that this TV offers in the budgeted price range. Read our in-depth review on the main blog to learn more about its features.

Read more: VM one Technologies

0 notes

Text

Top Benefits of Using Structural Framing Software for Design

When tackling the complexities of light steel and cold-formed steel floor framing, using specialized software can revolutionize your design approach. Managing design tasks manually can be both time-consuming and error-prone. With Light Steel Framing Software, many tasks are automated, making the design process more streamlined. This software enables quick model generation and effortless adjustments, which reduces the need for extensive manual calculations and updates. As a result, you can complete projects faster and with greater efficiency.

Designing floor systems using Floor Framing Design software offers precise and detailed design capabilities. This software helps ensure that each component is accurately sized and positioned, adhering to all necessary specifications. Accuracy is crucial in structural design significantly enhances this aspect by automating many of the calculations and design checks. Structural framing software design often involves intricate calculations that can be challenging to perform manually. Advanced software handles these calculations quickly and accurately, allowing you to focus on other aspects of the project. This not only speeds up the design process but also provides a solid foundation for making well-informed decisions.

Incorporating framing software into your design process can greatly benefit your approach to light steel and CFS floor framing. Steel Smart System provides innovative software solutions designed to streamline structural framing tasks. Their tools are designed to optimize light steel and CFS floor framing design, improving both efficiency and precision in your designs. To learn more and enhance your design capabilities, read the full blog:

0 notes

Text

The All New iPhone 16 Rumors

As tech enthusiasts eagerly anticipate Apple's next flagship smartphone, rumors and leaks about the iPhone 16 are circulating widely. While the official launch is still months away, here's a compilation of the most intriguing rumors about the upcoming iPhone 16.

Design and Build

One of the most persistent rumors suggests a significant redesign for the iPhone 16. Apple is reportedly experimenting with a titanium frame, replacing the stainless steel used in previous models. This change could result in a lighter, more durable phone. Additionally, the iPhone 16 is rumored to feature a completely portless design, relying entirely on wireless charging and data transfer. This would mark a significant departure from the Lightning port, which has been a staple of the iPhone lineup for years.

Display

The display of the iPhone 16 is expected to see some notable improvements. Rumors point to a ProMotion display with a 120Hz refresh rate across all models, not just the Pro variants. This would make for smoother scrolling and a more responsive user experience. There are also whispers of an under-display Face ID, which could eliminate the need for the notch and offer a truly edge-to-edge display.

Camera Enhancements

Apple has consistently pushed the boundaries of smartphone photography, and the iPhone 16 is no exception. Speculations include a periscope lens for improved optical zoom capabilities, allowing for clearer and more detailed long-distance shots. Additionally, improvements in low-light photography and video recording are expected, thanks to advanced computational photography techniques and larger sensors.

Performance and Battery Life

The iPhone 16 is rumored to be powered by the A18 Bionic chip, which promises even greater performance and efficiency. This next-generation processor is expected to deliver faster processing speeds and better graphics performance, making it ideal for gaming and demanding applications. Coupled with a larger battery, the iPhone 16 could offer longer battery life, addressing a common concern among iPhone users.

Software and Features

On the software side, iOS 18 is expected to introduce several new features and enhancements. There are rumors of improved AR capabilities, leveraging the power of the new hardware to offer more immersive experiences. Additionally, Apple may introduce new privacy features, continuing its commitment to user data protection.

Pricing and Availability

While pricing details are always a subject of much speculation, the iPhone 16 is expected to follow a similar pricing structure to its predecessors. However, with the introduction of new materials and technologies, there could be a slight increase in price. The official announcement is anticipated in September, with pre-orders likely to start shortly after the launch event.

Conclusion

The iPhone 16 is shaping up to be another groundbreaking release from Apple. With rumors of a bold new design, significant camera enhancements, and cutting-edge technology, it promises to set new standards in the smartphone industry. As always, these rumors should be taken with a grain of salt until the official announcement, but the anticipation and excitement are already building among Apple fans worldwide.

0 notes

Text

Build a Modern and Strong Building with Quality Steel Framing Solutions

When buying various steel framing solutions, it is best to choose the leading companies. Steel frames are being used more often in the construction of commercial and industrial buildings because of their strength and ability to withstand bad weather. Steel is also used because its greater weight-bearing capacity enables trusses to span greater distances. These days, metal frames and trusses are utilised in both residential and commercial buildings since they last longer. In addition, steel is more resilient to weather and lasts longer than other building materials for many years.

The majority of industrial buildings constructed in the contemporary era employ light gauge steel framing because of its exceptional strength and ability to serve as both primary and secondary structural elements. Similarly, light steel floor joists are becoming more and more common these days due to their greater stability and related cost benefits. Moreover, steel is weatherproof, so using it for joists is always a smart decision. The best companies that offer floor joists utilise 3D BIM software to generate the design first and provide the job with a reg 126 certificate for compliance.

Views on the Various Steel Frames Used in the Present-Day Construction Industry:

Metal Trusses and Frames: Metal trusses are a crucial part that can support a substantial weight over extended distance. The top producers understand the concept and provide specially designed 3D models before embarking on the project.

Prefab Steel Frame: Because these frames are manufactured in a special facility, they are perfect for erecting prefab homes or commercial structures.

Steel Wall Frames: These are great since they last a lot longer than wood, so you can expect a longer-term return on investment. Steel is also significantly more often used because of its excellent strength-to-weight ratio.

Steel Stud Frame: Steel stud frames provide an unrivalled level of structural strength, making them a solid foundation for a wide range of building uses. To finish the task, experts obtain the customer's approval of the design before creating the frame.

Buildings such as residences, offices, warehouses, and factories require steel frames, trusses, and joists. Ask the leading companies that design and manufacture steel frames, trusses, and joists for a quote on your project.

Source - https://metalframingsystems.blogspot.com/2024/06/build-modern-and-strong-building-with.html

0 notes

Text

Day 66

One of like. 4 frames I managed to make in 2 hours lol. Ahh the pain of learning a new software...

I looked up how to use a traditional flint and steel.. No I won't have it be very realistic because it's an animation. So no. Not gonna have the ancestor light a torch realistically.

oh what's this? (i talked more about this project before privating most of it. time will tell if it gets finished.)

1 note

·

View note

Text

Revolutionizing Architecture with Tensile Membrane Structures: Dream Works India

In the dynamic world of architecture and construction, tensile membrane structures stand out as an innovative solution that merges aesthetics with functionality. Dream Works India, a leader in this field, harnesses the potential of these cutting-edge structures to create spaces that are not only visually stunning but also durable and versatile. In this article, we explore the transformative capabilities of tensile membrane structures and how Dream Works India is redefining architectural excellence.

What Are Tensile Membrane Structures?

Tensile membrane structures are architectural forms that use a fabric or membrane held in tension to create lightweight, flexible, and strong coverings. These structures are supported by a combination of steel cables, masts, or rigid frames, allowing for large, unobstructed spans and unique, eye-catching shapes.

Key Features of Tensile Membrane Structures:

Lightweight Design: These structures use minimal materials to cover vast areas, making them significantly lighter than traditional construction methods.

Versatility: The flexible nature of the membranes allows for a wide range of shapes and applications, from canopies and pavilions to complete building envelopes.

Durability: Modern tensile membranes are crafted from advanced materials like PTFE (polytetrafluoroethylene) and PVC-coated polyester, which are known for their strength and resistance to weathering.

Aesthetic Appeal: The sleek and modern look of tensile structures can enhance the visual impact of any project, creating iconic and memorable spaces.

Quick Installation: The construction process for tensile membrane structures is faster compared to conventional methods, reducing labor and time costs.

Dream Works India: Pioneers in Tensile Membrane Structures

At Dream Works India, we are passionate about pushing the boundaries of architectural design. Our expertise in tensile membrane structures allows us to deliver innovative solutions that meet the highest standards of quality and performance. Here's how we stand out in the industry:

Innovative Design and Engineering

Dream Works India excels in transforming conceptual designs into reality. Our team of architects and engineers collaborates closely with clients to develop bespoke solutions that align with their vision and functional requirements. We employ advanced design software and modeling techniques to ensure precision and excellence in every project.

High-Quality Materials and Technology

We use the finest materials to manufacture our tensile membranes, ensuring they are durable, lightweight, and capable of withstanding extreme weather conditions. Our PTFE and PVC-coated fabrics are known for their long lifespan and minimal maintenance requirements. Additionally, we integrate the latest construction technologies to optimize the performance and sustainability of our structures.

Sustainable and Eco-Friendly Solutions

Sustainability is a core value at Dream Works India. Our tensile membrane structures are designed to enhance natural lighting and ventilation, reducing the need for artificial lighting and HVAC systems. This not only lowers energy consumption but also creates healthier, more comfortable environments. Furthermore, we prioritize the use of recyclable and eco-friendly materials in our designs.

Comprehensive Project Management

From the initial design phase to the final installation, Dream Works India offers comprehensive project management services. We handle every aspect of the project, including design, fabrication, installation, and maintenance, ensuring a seamless and hassle-free experience for our clients.

Applications of Tensile Membrane Structures

The versatility of tensile membrane structures makes them suitable for a wide range of applications. Here are some of the most popular uses:

1. Sports Facilities

Tensile membrane structures are ideal for covering large sports arenas and stadiums. They provide protection from the elements while allowing for natural light, creating a comfortable environment for spectators and athletes alike.

2. Commercial Spaces

From shopping malls to exhibition halls, tensile structures can enhance the functionality and aesthetic appeal of commercial buildings. They offer expansive, column-free spaces that can accommodate a variety of activities and events.

3. Public Spaces

Parks, plazas, and outdoor event spaces can benefit from the shade and shelter provided by tensile membranes. These structures can be designed to complement the surrounding environment and serve as striking focal points in public areas.

4. Transportation Hubs

Airports, bus stations, and train terminals can use tensile membrane structures to create spacious, well-lit, and weather-resistant waiting areas for passengers. The open design of these structures facilitates easy movement and provides a welcoming atmosphere.

5. Residential and Recreational Use

Tensile membrane structures can also be used in residential settings to create unique outdoor living spaces, such as covered patios and pool enclosures. Their aesthetic flexibility allows for the integration of modern design elements into traditional home settings.

Notable Projects by Dream Works India

Dream Works India has an impressive portfolio of tensile membrane structures projects across various sectors. Here are a few examples that showcase our expertise and creativity:

1. Sunset Pavilion

Located in a popular urban park, the Sunset Pavilion is a testament to our design and engineering capabilities. The structure features a dramatic, sweeping canopy that provides shade and a stunning visual anchor for the park. Its organic form seamlessly blends with the natural surroundings, offering a serene space for visitors to relax and enjoy.

2. Metro Sports Arena

For the Metro Sports Arena, we designed and installed a massive tensile membrane roof that covers the entire seating area. This structure ensures spectators are protected from the sun and rain, while the open sides maintain excellent ventilation and a sense of connection to the outdoors.

3. Luxury Resort Canopy

At a prestigious luxury resort, we created an elegant poolside canopy that combines functionality with modern design. The tensile membrane provides ample shade for guests, enhancing their comfort and the resort's overall aesthetic appeal.

4. Shopping Mall Atrium

Our work on the central atrium of a major shopping mall involved creating a series of interconnected tensile membranes that cover the expansive space. These structures allow natural light to flood the atrium while providing a striking architectural feature that draws visitors in.

The Future of Tensile Membrane Structures

As the demand for sustainable and innovative architectural solutions grows, tensile membrane structures are set to play a pivotal role in the future of construction. Here are some trends and advancements we anticipate:

1. Smart and Adaptive Technologies

Integration with smart technologies will enable tensile structures to adapt to changing environmental conditions. For example, responsive shading systems could adjust the membrane’s opacity based on the sun’s intensity, enhancing energy efficiency and user comfort.

2. Enhanced Material Properties

Ongoing research in membrane materials is likely to yield fabrics with improved performance characteristics, such as greater durability, fire resistance, and self-cleaning capabilities. These advancements will expand the potential applications and longevity of tensile structures.

3. Greater Emphasis on Sustainability

With a growing focus on green building practices, tensile membrane structures will continue to evolve towards even more eco-friendly designs. This includes the use of biodegradable materials and innovative ways to integrate renewable energy sources into the structures.

Why Choose Dream Works India?

Choosing Dream Works India for your tensile membrane structure project means partnering with a company that is dedicated to excellence, innovation, and customer satisfaction. Here’s why clients trust us:

Expertise and Experience: With years of experience in the industry, we possess the knowledge and skills to handle complex and challenging projects.

Customization: We offer tailored solutions that meet the specific needs and goals of our clients, ensuring every project is unique and impactful.

Quality Assurance: We maintain rigorous quality control processes to guarantee the highest standards of durability and performance in our structures.

Client-Centric Approach: Our focus on customer satisfaction drives everything we do, from initial consultation to final installation.

Conclusion

Dream Works India is your go-to partner for innovative and high-quality tensile membrane structures. Our dedication to excellence, sustainable practices, and client satisfaction sets us apart in the industry.

Explore the endless possibilities of tensile membrane structures with Dream Works India and transform your space into a work of architectural art. Whether you're looking to create a functional shelter or an iconic architectural feature, we have the expertise and creativity to bring your vision to life.

For more information or to discuss your project needs, visit our website or contact us today. Together, let's shape the future of architecture with tensile membrane structures.

0 notes

Text

Reliable Steel Assembly Drawing Services Provider in Oklahoma, USA

CAD Outsourcing specialize in providing top Steel Assembly Drawing Services to facilitate smooth fabrication and erection processes. We also offers AutoCAD 3D Assembly Drawing Services, Steel Erection Drawing Services, Fabrication Assembly Drawing Services, Solidworks Assembly Drawing Services and Joist Steel Detailing Services. Our team of experts has extensive experience in creating accurate and detailed drawings using Revit, AutoCAD, Tekla Structures, Inventor, and SolidWorks. By hiring our skilled Steel Detailers, you can streamline your fabrication process and ensure timely project delivery. With our CAD services, you can reduce costs, improve efficiency and increase customer satisfaction. Contact us today to learn more about how we can support your Steel Assembly Drawing needs.

Types of Tekla Structural Steel Detailing Outsourcing Services:

- AutoCAD 3D Assembly Drawing Services

- Steel Erection Drawing Services

- Fabrication Assembly Drawing Services

- Solidworks Assembly Drawing Services

- Joist Steel Detailing Services

- Cold Formed Steel Structural Fabrication Drawing Services

- Hot Rolled Steel Framing Detailing Services

- Light Gauge Metal Frame Detailing Services

We offer our Steel Assembly Drawing Services Oklahoma and covered other cities: Iowa, South Dakota, North Dakota, Minnesota, Georgia, Missouri, Indiana, Kansas and Chicago.

Visit Us:https://www.cadoutsourcing.net/shop-drawing-services/oklahoma-shop-drawings-service.html

Portfolio:https://www.cadoutsourcing.net/shop-drawing-services/steel-shop-drawings-assembly-drawings.html

Software Expertise:AutoDesk AutoCAD, Revit, Tekla Structures, STAAD.Pro, SOLIDWORKS, ZWCAD, AutoDesk Navisworks, 3Ds Max, Inventor, Showcase, ReCap, Infraworks 360, Civil 3D.

For more Details:Website: https://www.cadoutsourcing.net/shop-drawing-services/steel-detailing-fabricating.html

Experience excellence with CAD Outsourcing Consultant. Contact us today for all your Tekla Steel Assembly Drawing Services needs.

Check Out my Latest Article "Why do you need to Hire Tekla Steel Detailer for your Structural Engineering Projects?" is now available on

#AssemblyDrawing#SteelFabrication#SolidworksAssemblyDrawing#ErectionDrawing#SteelDetailing#Detailing#CADServices#Building#Architecture#Structure#BIM#B1M#Engineering#Construction#CadOutsourcing#CAD#CADD#CADDesign#Architect#Engineer#CADDraftman#BIMModeler#CadOutsourcingCompany#CADDrawing#CADDrafting#AutoCAD#Revit#TeklaStructures#Inventor#SolidWorks

1 note

·

View note

Text

Behind the Scenes: How Luxurious Wedding Tents Are Manufactured

Wedding tents have evolved from simple functional shelters to symbols of grandeur, offering elegant and lavish spaces that transform any venue into a dreamlike setting. But have you ever wondered what goes into manufacturing these stunning structures? At Ranka Tent Suppliers, one of the leading Tent Manufacturers and Suppliers in Indore, we take pride in our state-of-the-art manufacturing process. We bring together design, craftsmanship, and technology to create the perfect tent for your big day. Let’s take a journey behind the scenes and discover how luxurious wedding tents are made.

Step 1: Understanding Client Needs

The handle starts with a nitty gritty interview with the client.Every wedding is unique, and so are the needs of the couple. Our design team sits down with clients to discuss their vision, style preferences, event theme, and the venue's layout. Whether it’s a romantic outdoor garden wedding or a glamorous evening affair, we ensure that the tent design aligns with the overall aesthetic of the event. For couples opting for luxury, we also incorporate special elements like the Best Royal Wedding Furniture Set to create a truly regal atmosphere.

Step 2: Innovative Design and Customization

Once we have a clear understanding of the client's vision, our plan group gets to work.Luxurious wedding tents are not just about size and structure—they are about creating a personalized experience. Using cutting-edge design software, we develop customized layouts, incorporating everything from fabric choices to structural elements. The design process also considers how the tent will integrate with other key features such as furniture, flower arrangements, and stage decorations, ensuring a harmonious flow.

Step 3: Premium Material Selection

The key to manufacturing high-end wedding tents lies in the quality of materials used. As luxury tent manufacturers and suppliers in Indore, we source only premium fabrics and durable materials that ensure the tent is not only beautiful but also robust. For the canopy, we use high-grade waterproof and UV-resistant fabrics that withstand varying weather conditions while maintaining an elegant drape. The tent’s frame, typically constructed from high-quality aluminium or steel, offers the stability needed to accommodate large gatherings without compromising on style.

Step 4: Precision Manufacturing

Once the plan and materials are finalised, the fabricating stage starts. At Ranka Tent Suppliers, we employ skilled craftsmen and technicians who work meticulously to create each tent. The frame is precision-engineered to ensure a sturdy and safe structure. Our advanced sewing machines ensure that fabric panels are cut and stitched with exacting precision, avoiding any wrinkles or imperfections. Every tent is crafted to be modular, allowing it to be easily assembled, expanded, or customized on-site, ensuring flexibility for different venue requirements.

Step 5: Attention to Aesthetic Detailing

What sets lavish wedding tents apart is the consideration to detail. After the basic structure is created, our artisans focus on the finishing touches that elevate the tent’s appearance. From intricate drapery to custom linings and decorative trims, no detail is too small. We offer various aesthetic elements such as chandeliers, fairy lights, and floral hangings to enhance the beauty of the tent’s interior. These details are crafted with an eye for elegance, ensuring that the final product exudes luxury and sophistication. Incorporating a Best Royal Wedding Furniture Set within the tent helps elevate the grandeur, offering a regal ambiance for the wedding celebration.

Step 6: Rigorous Quality Testing

Before any tent leaves our facility, it undergoes a series of quality checks to ensure that it meets the highest standards. As one of the leading tent dealers and exporters in India, we test for durability, structural integrity, and weather resistance. Each tent is also checked for ease of assembly and disassembly, ensuring that the installation process at the event site is seamless and hassle-free.

Step 7: Delivery and Installation

The last arrange in the handle is conveying and setting up the tent at the occasion area.Our logistics team ensures that the tent arrives safely and on time. The setup is done by trained professionals who carefully assemble the tent, ensuring that it is perfectly aligned with the venue layout. Whether it’s on a beach, in a garden, or in a cityscape, our tents are installed with precision, creating a captivating environment for the wedding celebration.

Step 8: Post-Event Support and Sustainability

Once the event is over, our team is responsible for efficiently dismantling the tent. We also ensure that the materials used are sustainably sourced and can be reused for future events. As part of our commitment to sustainability, we continually research eco-friendly materials and practices to minimize waste and our environmental footprint. This ensures that our role as a luxury tent manufacturer and supplier in Indore aligns with environmental goals while delivering top-notch service.

Why Choose Ranka Tent Suppliers?

At Ranka Tent Suppliers, we believe that a wedding tent is more than just a structure—it is the canvas upon which dreams are painted. As trusted tent manufacturers and suppliers in Indore, we blend tradition with modern technology to craft tents that are as unique as the events they host. Our commitment to quality, consideration to detail, and development have made us a driving title in sumptuous tent fabricating.

From concept to creation, every step in the manufacturing process is designed to ensure that our clients receive a tent that not only meets but exceeds their expectations. Our dedication to craftsmanship and customer satisfaction has made us a trusted partner for weddings across India and beyond.

Whether you’re planning an intimate gathering or a grand celebration, Ranka Tent Suppliers is here to bring your vision to life with stunning, luxurious wedding tents. Let us offer assistance to make your extraordinary day indeed more extraordinary!

0 notes