#ControlStrategies

Explore tagged Tumblr posts

Text

Active Suspension Systems: Enhancing Ride Comfort with Chassis Controls

Introduction

Vehicle dynamics, safety, and comfort have all seen substantial improvements as a result of the development of automotive technology. Suspension systems are one area that has made impressive improvement. Active suspension systems have been more popular recently because of their capacity to improve ride comfort through complex chassis controls. Traditional passive suspension systems have been in use for decades. This article gives a basic overview of active suspension systems, emphasizing their operation, advantages, and effects on the driving experience as a whole.

Understanding Suspension Systems

Any vehicle’s suspension systems, which control how the tires interact with the road surface, are an essential component. They perform a number of vital tasks:

Ride Comfort: Suspension systems minimize vibrations and shocks transferred to the vehicle’s occupants by absorbing and dampening the forces generated by uneven road conditions.

Vehicle Stability: Suspension systems aid in maintaining tire contact with the ground, ensuring the best possible traction and stability during cornering, braking, and accelerating.

Handling: Suspension systems have an impact on how a vehicle handles, including how responsive it is to driver inputs and how stable it is on the road as a whole.

Types of Suspension Systems

Passive and active suspension systems are the two main categories.

Passive Suspension Systems: For suspension, passive systems rely on fixed mechanical parts like springs and shock absorbers. They provide a simple and dependable solution but do not adjust to shifting traffic patterns or driving circumstances.

Active Suspension Systems: Active systems, on the other hand, use cutting-edge technology and sensors to continuously and instantly alter the suspension parameters. Active suspensions can give a superior balance of ride comfort and handling performance because of their adjustability.

How Active Suspension Systems Work?

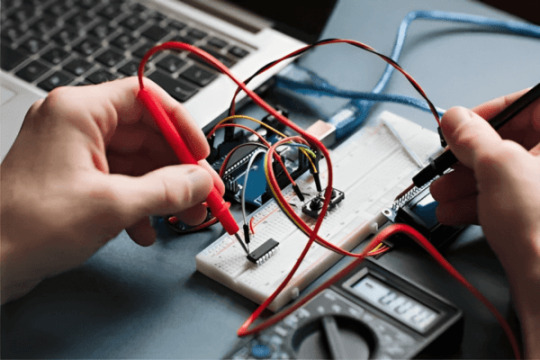

Active suspension systems use a variety of sensors to track the motion of the car as well as outside elements including the road’s condition, the driver’s input, and the speed of the car. The central control unit receives real-time data from these sensors and modifies the suspension settings as necessary. The following are some of the essential parts and procedures of active suspension systems:

Sensors: Accelerometers, wheel speed sensors, height sensors, and other types of sensors can be used as these. They continuously gather information about the movements of the vehicle and outside variables.

Control Unit: A centralized control unit analyses sensor data and quickly decides how to change the suspension settings.

Actuators: To modify the suspension’s properties, such as changing the damping rates or the ride height, electric or hydraulic actuators are utilized.

Adaptive Algorithms: Complex algorithms known as adaptive algorithms determine the ideal suspension settings based on input from the driver, sensor data, and predetermined performance standards. These algorithms make sure that the suspension system reacts to shifting circumstances swiftly and successfully.

Benefits of Active Suspension Systems

Compared to passive suspension systems, active suspension systems provide the following benefits:

Improved Ride Comfort: Active systems can instantly correct road irregularities, giving passengers a smoother and more comfortable ride.

Better Handling: These systems have the capacity to modify the suspension settings to enhance grip and stability during turns, which improves handling and control.

Customizable Driving Modes: Multiple driving modes are available on many active suspension systems, allowing drivers to adjust the characteristics of their cars to suit their tastes. These modes range from a relaxing “soft” mode to a sporty “firm” mode.

Safety: In difficult driving circumstances, active suspensions can increase vehicle stability and lower the risk of accidents.

Advantages of Active Suspension Systems

Through chassis controls, active suspension systems have many benefits that considerably improve ride comfort. These technologies are made to adjust and improve the suspension settings of a car in real time, making driving more comfortable and pleasant. Here are a few significant benefits of active suspension systems:

Improved Ride Comfort: Better Ride Comfort Road irregularities, bumps, and vibrations are expertly reduced by active suspension systems. They can give riders a smoother, more comfortable ride by continuously modifying the suspension parameters. This benefit stands out more on bumpy or uneven roadways.

Improved Handling and Stability: Active suspension systems have the capacity to dynamically change damping rates and other suspension properties. As a result, the vehicle is more stable when cornering, braking, and accelerating. The suspension can adjust to various driving situations, improving performance and safety.

Reduced Body Roll: By keeping the car level and ensuring that all tires have optimal traction on the road, these systems can reduce body roll during corners. This boosts driver confidence and comfort while also improving handling.

Customizable Driving Modes: Multiple driving modes are available in many vehicles with suspension systems, allowing the driver to select between various comfort and performance levels. For instance, a “Comfort” mode might prioritize a comfortable and smooth ride, whereas a “Sport” mode might tighten the suspension for a sportier driving experience.

Adaptive Response to Changing Conditions: Active suspension systems are fitted with sensors that continuously monitor a number of variables, such as the road’s conditions, the vehicle’s speed, and the driver’s input. The control unit processes this data and modifies the suspension settings as necessary. The suspension is always tuned for the current driving situation thanks to its adaptability.

Enhanced Off-Road Capability: Active suspension systems can be very helpful in off-road cars. In addition to improving off-road traction and articulation, they can adapt to adverse terrain to provide a smoother, more controllable ride.

Future Integration with Autonomous Driving: Active suspension systems are positioned to play a significant part in autonomous vehicles in the future integration with autonomous driving. They can assist in making up for a lack of human reactions and anticipation by maintaining ideal vehicle dynamics while constantly reacting to shifting road circumstances.

Disadvantages of Active Suspension Systems

While suspension systems have many benefits for improving ride comfort and driving performance, they also have significant drawbacks and difficulties. When assessing the installation of such systems, it’s critical to take into account the following disadvantages:

Cost: Compared to conventional passive suspensions, suspension systems are more complex and technologically advanced. Due to the greater manufacturing and maintenance expenses caused by this complexity, active suspension-equipped automobiles are more expensive to buy and maintain.

Reliability Concerns: Active suspension systems are dependent on a large number of sensors, control units, and electrical parts. Any of these parts going bad can result in suspension issues and possibly a worsened ride quality. It is essential to guarantee these systems’ dependability.

Weight: The vehicle’s active suspension parts, including the sensors, actuators, and control units, are heavier. Even while improvements in materials and design have somewhat lessened this problem, the extra weight can still have a negative impact on handling and fuel economy.

Complexity for Do-It-Yourself Repairs: Active suspension systems can be challenging for car owners who enjoy working on their own repairs and customizations. DIY updates and maintenance on these systems are more challenging, if not impossible, due to their complexity.

Limited Availability: Active suspension systems are still optional and frequently found only in more expensive or luxurious versions. Because of this restricted accessibility, many drivers are unable to take advantage of suspension systems’ advantages.

Adaptation Delay: Active suspension systems are intended to quickly react to shifting road conditions, however, there may be a little delay in their response. The system’s capacity to react to sudden, unforeseen risks or barriers may be hampered by this delay.

Potential for Less Tactile Sensation: According to some auto enthusiasts, active suspension systems have the potential to give drivers less tactile sensation through the steering wheel and chassis. For individuals who prefer spirited driving, this could make it harder to feel connected to the road, making driving less fun.

Conclusion:

In conclusion, active suspension systems represent a remarkable advancement in automotive technology, offering a range of benefits that significantly enhance ride comfort and vehicle performance through chassis controls. These systems are designed to adapt and optimize suspension settings in real-time, providing a smoother, safer, and more enjoyable driving experience.

The advantages of suspension systems include improved ride comfort by minimizing the impact of road imperfections and vibrations, enhanced handling and stability, reduced body roll, customizable driving modes, adaptive responses to changing conditions, decreased noise and vibration in the cabin, increased traction and safety, and even the potential for longer tire life. Furthermore, these systems are well-suited for off-road applications and hold promise in the context of autonomous driving.

However, it’s important to acknowledge the disadvantages and challenges associated with suspension systems, including their higher cost, maintenance complexity, reliability concerns, added weight, limited availability, potential for over-complication, energy consumption, adaptation delay, and the perception of reduced feedback for driving enthusiasts.

Ultimately, the adoption of active suspension systems should be considered carefully, taking into account the specific needs and preferences of both automakers and consumers. As technology continues to advance, active suspension systems are likely to evolve and become more widespread, further enhancing the driving experience and setting new standards for ride comfort and chassis control in the automotive industry.

#gearchanger#dorleco#controlsystem#ADAS#ControlStrategies#stroke#automotive#controlunit#PowertrainControl#Anti-lock Braking System

0 notes

Text

Scent Control: 3 Effective Steps for Deer Hunting

Controlling scent to beat a buck's nose is possible. It just takes a smart scent-eliminator strategy that employs the proper equipment and a good attitude toward getting everything as right as you can. It's definitely a process, and it requires extra effort, but getting around a deer's number-one defense is absolutely worth it — especially if you're targeting mature bucks. Here's how to eliminate your scent in three easy steps. As you can probably imagine, the first step in scent control involves the wind.

1. Plan and Work the Wind

The best defense against watching a whitetail bouncing away from your stand through the foliage is to play the wind. That's the first lesson they teach in remedial deer hunting. Any deer that gets downwind of you has a much better chance of busting you.

A deer passing upwind, however, doesn't have a chance to wind you. I've messed around with bird dogs for a fair share of my adult life and I'm always amazed at how a good upland dog won't catch a whiff of a downed rooster even from a few feet away if the wind is blowing the scent away from them. A deer is no different

Set your stands and blinds accordingly and you'll have a good start, but it's not enough to consider how the wind will blow at your ambush sites. How you get there matters as well. A lot, in fact. And if you walk past the best bedding area on the property and let your wind blow right through it, you'll spend your evening stand time counting squirrels. Plan your exit and entrance routes around the wind as well. Like I said, it's a lot of work but it's worth it.

2. Add Scent Control Clothing and Boots to Your Strategy

There has been a lot of money spent on scent-control camo clothing and scent-eliminator sprays on the promise of taking oblivious Booners. Scent-control clothing does offer advantages and there are some excellent products on the market, but you need to use such clothing as a part of your overall scent-controlstrategy. Most important, you need to follow all of the manufacturer's directions carefully. I've met with a lot of the people who have designed those clothes, and they know a lot more about how they function than we do. Trust me on that.

Trail camera

Use them correctly, and pair them with knee-high rubber boots. Remember those bird dogs I mentioned? One way I can trick them is by using knee-high rubber boots and spraying them down very liberally with scent-eliminator sprays while I set up blind retrieves. Normally, a dog that doesn't have sludge between his ears will quickly learn to follow your tracks to the spot you either placed the dummy or tossed it, essentially hacking the training drill with his snout. When you use knee-high boots and treat them correctly, you can watch a seasoned bird dog run right past your scent trail without picking it up.

This applies to deer as well, and it matters most on your way into and out of your stand. Every time you walk through the woods you leave yourself open to contamination, and that has a cumulative effect. A deer that crosses your fresh trail and realizes he is now sharing the woods with a predator is a lot harder to kill than one who doesn't recognize the threat.

If you think this step doesn't matter, you're missing out. I can remember in my early days of deer hunting when all we did was play the wind, and it was always a bummer to see a deer heading toward where I had walked in because I knew they were going to turn around and walk out. And they did, nearly every single time.

3. Use Active Scent Control

The last step to beating a buck's nose is employing ozone odor-eliminator technology as part of your strategy. There are a lot of armchair scientists who claim ozone can't work in the woods, but they don't really understand how it works. Ozone is a natural bleaching agent, which occurs in the environment during thunderstorms. It's an unstable molecule that seeks to cling to other molecules, and when it does, it renders them scentless. It also happens to be heavier than the atmosphere, meaning it sinks. That's why the air smells clean after a storm.

An in-field ozone generator, mounted over your head and aimed downwind will take care of almost all of the new scent you're creating while you're sitting (you're always creating scent). Ozone technology has been around since the 1800s. Among its many benefits is the fact that you can control where it goes and the amount you need to nearly erase your scent.

I spent a couple of years trying to disprove its effectiveness on hard-hunted public land and finally gave up. It works well. Really well. An in-field ozone generator doesn't always keep a perfectly downwind deer from catching a whiff of something suspicious, but their reaction is always that of a deer that seems to think a predator is a lot farther away than he really is. They don't stomp and snort, and take the whole herd away with them. Instead, deer stick their noses into the air and look around for a bit before simply walking off. A lot of times, they walk right by.

0 notes

Text

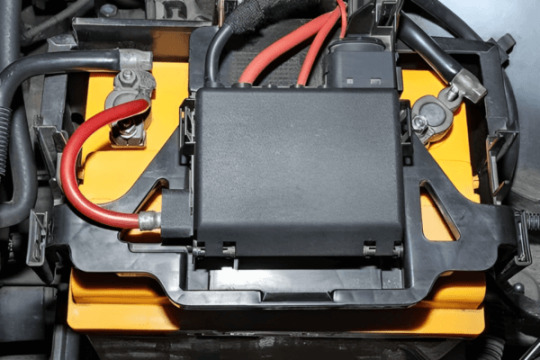

Energy Management in Electric Fleets

Introduction

The efficient and economical functioning of electric vehicles (EVs) within a fleet is dependent on energy management in electric fleets. Understanding and optimizing energy management is crucial given the rapid adoption of EVs across a variety of industries, including public transportation, delivery services, and corporate fleets. An overview of the main ideas and tactics in energy management for electric fleets will be given in this introduction.

1. Understanding Electric Fleets:

A collection of electric cars employed for delivery, service, or other tasks make up an electric fleet.

Battery electric cars (BEVs), plug-in hybrid electric vehicles (PHEVs), which combine electricity and conventional fuels, and hydrogen fuel cell vehicles are examples of electric vehicles.

2. Benefits of Electric Fleets:

Reduced greenhouse gas emissions: Depending on the kind, EVs may have minimal or no tailpipe emissions.

Lower running costs: Fuelling costs are reduced because electricity is typically less expensive than gasoline or diesel.

Savings on maintenance: Electric cars typically have fewer moving parts and need less maintenance.

3. Elements of energy management:

Charging Infrastructure: Establishing an effective charging infrastructure is an essential component of energy management. This entails picking the appropriate charging stations, placing them optimally, and making sure that the vehicles in the fleet can use them.

Route Planning and Optimization: Optimal routes can be planned by using software tools and algorithms that take into account variables including vehicle range, the availability of charging stations, and traffic conditions. By doing this, energy usage is reduced and efficiency is increased.

Battery Management: Battery management is essential to extending the life and performance of electric vehicle batteries. Controlling temperature, preventing deep discharges, and improving charging and discharging patterns are all part of this.

Energy Monitoring: Fleet managers may monitor energy usage, range, and other performance indicators in real time by installing telematics and energy monitoring systems in their cars.

4. Important Energy Management Techniques

Time-of-Use (TOU) Charging: Charging automobiles during times when power prices are lower, such as off-peak hours, can significantly minimize operating expenses.

Fleet Electrification Strategy: Based on variables like daily mileage and accessibility to charging infrastructure, determine which vehicles in the fleet are appropriate for electrification.

Regenerative Braking: Utilize regenerative braking technologies to recover energy during braking, which is subsequently applied to refuel the battery.

Smart Charging: Implement smart charging strategies that enable load control and prioritize charging in accordance with vehicle requirements and energy availability.

5. Fleet Education and Training:

To guarantee effective energy management, drivers and fleet managers must receive the proper training. Best practices for EV operation should be known by drivers, and fleet management should be knowledgeable about the software and infrastructure available for charging.

6. Data Analysis and Continuous Improvement:

To find areas for improvement, periodically review data gathered from the fleet’s EVs and charging infrastructure. Making decisions about fleet replacement or expansion, as well as modifying charging schedules and route optimization, may all fall under this category.

Advantages of Energy Management in Electric Fleets

A variety of benefits that energy management in electric fleets provides make it a crucial part of running and optimizing electric vehicle (EV) fleets. These benefits help fleet operators as well as further economic and environmental objectives. Here are a few significant benefits:

1. Cost Savings:

Lower Fuel Costs: Compared to gasoline or diesel, electricity is often more affordable. In the long run, fleet operators will find that EVs are cost-effective since they provide significant fuel cost reductions.

Reduced Maintenance Expenses: Compared to vehicles powered by internal combustion engines, electric vehicles have fewer moving parts, which over time results in lower maintenance and repair expenses.

2. Operating Costs Are Lower:

Lower Total Cost of Ownership (TCO): Compared to conventional vehicles, EVs frequently offer a lower TCO when fuel and maintenance costs are taken into account.

Energy management allows fleet managers to more effectively estimate and control their energy expenses as compared to the erratic prices of fossil fuels.

3. Environmental advantages

Reduced Greenhouse Gas Emissions: EVs emit almost no tailpipe emissions, lowering the fleet’s carbon footprint and aiding in the fight against global warming.

Improved Air Quality: Since electric cars have zero exhaust emissions, they help to minimize local air pollution in cities.

4. Energy Efficiency:

Higher Energy Efficiency: Compared to vehicles powered by internal combustion engines, electric vehicles are intrinsically more energy efficient. By making sure that energy is used efficiently and reducing waste, energy management systems can further maximize this efficiency.

5. Range Optimization:

Route Planning: By taking into account variables like battery range and the accessibility of charging infrastructure, energy management tools and software can optimize routes to make sure that EVs can finish their missions without running out of power.

Reduced Range Anxiety: Effective energy management lowers the possibility that vehicles will run out of power while in use, which helps to lessen driver stress and boost fleet dependability.

6. Flexibility and Load Balancing:

Load management: By scheduling charging during off-peak times, energy management systems can ease the load on the electrical grid and benefit from lower electricity prices.

Integration for Vehicle-to-Grid (V2G): Bi-directional charging is made possible by some energy management systems, allowing EVs to discharge energy back into the grid as necessary and possibly earning money for fleet managers.

7. Fleet Performance Monitoring:

Real-time data: Energy management systems offer data on energy use, battery health, and vehicle performance in real-time, enabling fleet managers to make wise decisions and optimize operations.

8. Compliance and Sustainability Goals:

Meeting Regulations: To cut emissions and encourage the usage of electric vehicles, many areas and governments are putting laws into place. Fleets can comply with these legal standards with the aid of efficient energy management.

Corporate Social Responsibility: Business Social Responsibility Utilizing electric fleets helps fleet operators improve their reputation and image by advancing environmental and corporate social responsibility goals.

Disadvantages of Energy Management in Electric Fleets

While energy management in electric fleets has many benefits, there are also drawbacks and difficulties that fleet managers may run across. To successfully handle and eliminate these potential downsides, it is crucial to be aware of them. The following are some drawbacks:

1. Upfront Costs:

Investing in an energy management system and switching to electric vehicles might be expensive upfront because you have to buy the cars, set up the charging stations, and integrate the software. Some fleet operators may find these expenditures prohibitive, however, they are frequently made up for in the long run by savings.

2. Limited range and inadequate infrastructure for charging

Range Anxiety: Drivers of electric vehicles may experience anxiety because they worry about running out of battery power while driving because their range is often less than that of conventional automobiles.

Charging Infrastructure Gaps: It may be difficult to provide fleet vehicles with convenient and timely charging in some areas due to a limited or uneven distribution of charging infrastructure

3. Charging Time:

Refueling a conventional vehicle with gasoline or diesel can take much less time than charging an electric vehicle. The productivity of the fleet may be impacted by this downtime, particularly if cars must be charged throughout the working day.

4. Battery Degradation:

5. Variability in Energy Costs:

Energy costs might vary based on location and time of use, despite the fact that electricity is often less expensive than gasoline or fuel. To save energy expenditures, fleet managers must carefully control where and when to charge their vehicles.

6. Limited Vehicle Options:

The types of activities that can be electrified may be limited due to the lack of electric vehicle models that are suitable for particular fleet needs (such as heavy-duty trucks or specialty vehicles).

7. Dependence on Grid Reliability:

Electric fleets are dependent on an electrical system that is reliable. The necessity for backup power options or grid stability enhancements is highlighted when there are grid interruptions or power outages that impede charging and vehicle operations.

8. Environmental Impact of Battery Production:

Conclusion:

Energy management in electric fleets is a critical and evolving discipline that holds great promise for the transportation industry and the broader effort to reduce greenhouse gas emissions. As the world shifts toward cleaner and more sustainable energy sources, the electrification of fleets plays a pivotal role in achieving environmental, economic, and operational goals.

In conclusion, energy management in electric fleets represents a significant opportunity for organizations to reduce their environmental footprint, cut operating costs, and contribute to a more sustainable and efficient transportation ecosystem. While challenges exist, the benefits of electrifying fleets are substantial and far-reaching, making it a strategic and environmentally responsible choice for the future of fleet management.

#EnergyManagement#ElectricFleets#gearchanger#dorleco#controlsystem#ADAS#ControlStrategies#stroke#automotive#controlunit#PowertrainControl#Anti-lock Braking System

0 notes

Text

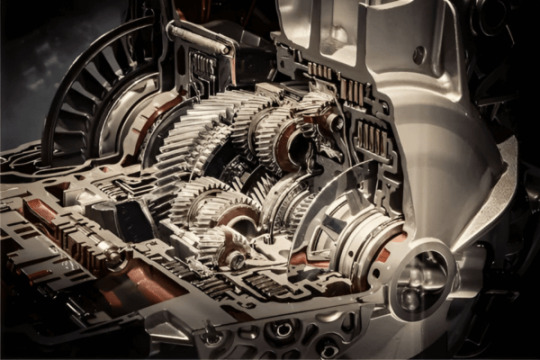

Shift-by-Wire Technology: Future of Transmission Control

Introduction:

The automobile sector has seen a tremendous transition over the years because of a constant pursuit of innovation and efficiency. The introduction of Shift-by-Wire Technology, a revolutionary method of transmission control, is one of the most encouraging recent advancements. By switching out conventional mechanical linkages for electronic interfaces, SBW ushers in a new era of superior automobile design. Let’s examine how Shift-by-Wire Technology is poised to transform the way we travel by making our cars smarter, safer, and more environmentally friendly as we set out on this adventure through the world of SBW technology.

Transmission Control’s Evolution:

The gear changer and transmission itself have typically been physically connected in car transmissions. Although these mechanical linkages have been helpful to us, they have certain drawbacks. They can be unwieldy, prone to damage, and frequently incapable of meeting the demands of contemporary driving.

Introducing Shift-by-Wire

Electronic signals are used in place of mechanical connections thanks to SBW. Drivers now engage their vehicle’s transmission through electronic interfaces as opposed to physically pulling a lever or shifting a gear selector. There is a plethora of opportunities created by the switch to digital control.

Smoothness and Precision: Shift-by-Wire Technology provides unmatched precision in gear selection. Shifts are made faster, smoother, and more precise with electronic signals. A seamless and comfortable driving experience is available to drivers.

Adaptive Intelligence: SBW systems provide a great degree of adaptability. They can be combined with artificial intelligence (AI) algorithms and advanced driver assistance systems (ADAS) to enable autonomous gear selection based on traffic circumstances, load, and even driver conduct. Performance and fuel efficiency are also improved by this adaptive intelligence.

Reduced Mechanical Complexity: SBW simplifies the transmission system by getting rid of mechanical links. This results in fewer maintenance expenses and also frees up room within the car, opening up creative interior design possibilities.

Eco-Friendly Driving: Shift-by-Wire Technology enables the best gear selection, enhancing fuel economy and cutting pollutants. Due to SBW’s improved ability to integrate electric motors with conventional transmissions, electric and hybrid vehicles stand to gain even more from it.

Improved Safety: SBW technology can have safety features including stopping unintentional gear changes and giving feedback to the driver in dangerous circumstances. All road users benefit from safer driving thanks to this.

The Future of Autonomous Driving: Shift-by-Wire Technology is a key enabler as we get closer to autonomous driving. It makes it possible for autonomous systems to be integrated seamlessly, guaranteeing that cars can easily switch between manual and autonomous driving modes.

Advantages of Shift-by-Wire Technology

Shift-by-wire technology, which is generally used in automatic transmissions, is the use of electrical controls to handle gear shifting in a vehicle. Comparing this technology to conventional mechanical systems, the following benefits are available:

Precision and Smoothness: Shifts are smoother and more seamless thanks to the precision that shift-by-wire systems provide for controlling gear changes. As a result, driving may be more relaxing and enjoyable.

Reduced Mechanical Wear: Shift-by-wire systems often endure less wear and tear over time because there are fewer mechanical components involved. Transmissions may survive longer as a result, and maintenance expenses may go down.

Integration with Advanced Driver-Assistance Systems (ADAS): Shift-by-wire technology is easily linked with advanced driver assistance systems (ADAS), enhancing the performance of features like adaptive cruise control and lane-keeping assistance. Additionally, it can support the advancement of automated driving technologies.

User Experience and Customization: Automakers can create unique shift-by-wire interfaces that let drivers choose from a variety of driving modes (such as sport, eco, or comfort) or even tailor their shifting preferences. Drivers now have more control, which improves the user experience overall.

Weight and Space Savings: Compared to conventional mechanical connections, shift-by-wire systems frequently take up less room and weigh less. Vehicles may end up being lighter as a result, which would improve handling and fuel economy.

Remote diagnostics: Shift-by-wire technologies enable automakers to remotely monitor and diagnose problems, enabling more rapid and effective maintenance and repair procedures.

Reduced Vibration and Noise: By doing away with physical links, shift-by-wire systems can lessen the vibration and noise that comes with changing gears, making the cabin atmosphere quieter and more comfortable.

Disadvantages of Shift-by-Wire Technology

Shift-by-wire technology offers several advantages, as mentioned earlier, but it also comes with some potential disadvantages and challenges:

Reliability Concerns: Electronic systems are prone to malfunctions or breakdowns, which raises reliability issues. A shift-by-wire system failure could cause problems with gear selection and possibly put the car in an unsafe situation.

Cost: Compared to conventional mechanical connections, shift-by-wire systems are typically more complex and expensive to construct and repair. Both automakers and consumers may incur higher up-front expenditures as a result of this.

Maintenance and Repairs: When shift-by-wire systems do need maintenance or repairs, sophisticated diagnostic tools, and qualified specialists are frequently required. Owners of vehicles may incur increased maintenance costs and lengthier downtime as a result.

Power Dependency: Shift-by-wire systems require electricity to run in order to function. Drivers may not be able to change gears in the event of an electrical system breakdown or power outage, thereby raising safety issues.

Adaptation Challenges: Some drivers might favor the responsiveness and control of vintage mechanical shifters. Drivers may need some time to adjust to shift-by-wire systems, and there may be opposition to this change.

Cybersecurity Risks: Shift-by-wire systems could be subject to hackers as they grow more linked and incorporated into car networks. To avoid unauthorized access or alteration, it is essential to ensure the security of these systems.

Complexity: Shift-by-wire systems’ complexity can make it more difficult to diagnose and remedy problems with them, thereby driving up repair costs and lengthening the time it takes to resolve problems.

Conclusion:

In conclusion, shift-by-wire technology is a significant development for the automotive sector, offering a number of noteworthy benefits, such as precise control, seamless gear changes, integration with cutting-edge driver assistance systems, customizability options, weight and space savings, safety features, adaptability to driving conditions, remote diagnostics, decreased noise and vibration, and contemporary design. These advantages improve driving convenience, fuel economy, security, and general vehicle performance.

However, it’s crucial to be aware of the potential drawbacks and difficulties brought on by shift-by-wire technology, such as concerns about reliability, higher costs, maintenance hassles, power dependence, adaptation problems, cybersecurity risks, environmental effects, compatibility issues, and the requirement for redundancy and fail-safe systems.

As manufacturers conduct extensive research, development, and testing to reduce these drawbacks, the use of shift-by-wire systems is expanding. It is expected that many of these issues will be resolved as technology develops and becomes more mature, and shift-by-wire technology will spread throughout the automobile sector, providing better driving experiences and increased vehicle performance.

#ShiftbyWireTechnology#gearchanger#dorleco#controlsystem#ADAS#ControlStrategies#stroke#automotive#controlunit#PowertrainControl#Anti-lock Braking System

0 notes

Text

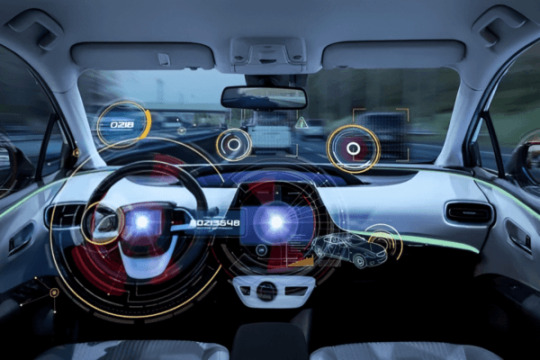

BCM Connectivity and Integration in Connected Vehicles

Introduction:

As a result of incorporating cutting-edge technologies to improve safety, convenience, and the overall driving experience, connected vehicles have completely changed the automobile industry. The Body Control Module (BCM), a central electronic component in charge of managing and controlling numerous systems and functions inside the body of the vehicle, is an essential component of connected automobiles. In order to ensure flawless communication between various car components, external devices, and distant networks, BCM connectivity and integration are essential. An introduction to BCM integration and connectivity in connected vehicles is given in this article.

Body Control Module (BCM):

The BCM, also referred to as the body control module, is the “brain” of a vehicle’s body. It is a key electronic control component in charge of organizing and operating a number of features, such as lighting, climate control, power windows, door locks, wipers, and more. The BCM has developed into a focal point for both internal and external communication in contemporary connected automobiles.

Connectivity in BCM: To improve their functionality, connected cars use a variety of communication technologies, including:

Intra-vehicle BCM connectivity: The BCM interfaces and communicates with a number of vehicle subsystems, including the infotainment system, the transmission control module, and the engine control module (ECM). With the help of this intra-vehicle connectivity, various systems can be coordinated for maximum effectiveness.

External Connectivity: BCMs in connected cars are fitted with interfaces for external connection, such as Ethernet, LIN (Local Interconnect Network), CAN (Controller Area Network), and others. These interfaces make it easier to communicate with networks, sensors, and other external devices.

Wireless Connectivity: BCMs frequently come with Wi-Fi, Bluetooth, and cellular connectivity to support remote connectivity and over-the-air (OTA) updates. This enables automakers to provide software updates, keep tabs on the condition of their vehicles, and provide remote services like monitoring and diagnostics.

Integration is a crucial component of BCM functionality in connected vehicles, which includes:

Sensor Integration: BCMs combine data from a variety of in-vehicle sensors, such as temperature, proximity, and ambient light sensors. The BCM uses this information to make quick judgments about things like adaptive lighting and climate management.

Infotainment Integration: BCMs connect to the infotainment system, enabling users to control connectivity, entertainment, and navigation functions from a single interface. Access to entertainment and information is made simple for users thanks to this connection.

Telematics Integration: BCMs are crucial components of telematics systems, enabling communication from the car to the cloud. Services like remote diagnostics, car tracking for stolen vehicles, and emergency help are made possible by this interface.

ADAS Integration: BCMs can work with radar sensors, cameras, and other ADAS parts to provide functions like adaptive cruise control, lane-keeping assistance, and collision avoidance.

Over-the-Air (OTA) Updates: By integrating with OTA update systems, manufacturers are able to remotely distribute software updates and BCM enhancements, boosting vehicle functionality, security, and performance.

Advantages of BCM Connectivity and Integration in Connected Vehicles

Modern connected automobiles rely heavily on connectivity and integration of the Body Control Module (BCM), which has a number of benefits that improve the driving experience, safety, and general operation of the vehicle. The following are some major benefits of BCM integration and connectivity in connected vehicles:

Enhanced User Experience:

Convenience: Through a user-friendly interface, such as infotainment systems or smartphone apps, BCM integration enables centralized control of different vehicle operations. Drivers may access and handle car functions more easily as a result of the user experience being made simpler.

Vehicle maintenance and diagnostics

Remote diagnostics: BCM connectivity permits continuous tracking of the condition and operation of the vehicle. In order to minimize downtime and potential breakdowns, automakers and service providers can remotely identify problems and proactively plan maintenance or repairs.

Security and Safety:

Theft Prevention: By using BCM integration, enhanced security features like remote car tracking and vehicle immobilization in the event of theft can be implemented, improving vehicle security.

Emergency Services: The BCM can immediately alert emergency services in the event of an accident, providing vital location and collision information to hasten relief.

OTA (over-the-air) updates:

Efficiency in Energy:

Adaptive Systems: To reduce energy consumption, BCMs can connect with a variety of vehicle systems, including lighting, climate control, and power management. This may lead to improved internal combustion engine fuel economy and increased range for electric vehicles.

ADAS, or advanced driver assistance systems

Integration with ADAS: By enabling features like adaptive cruise control, lane-keeping assistance, and automatic emergency braking, BCMs play a critical role in tying ADAS sensors and systems together. These devices enhance driving assistance and safety.

Data Insights:

Data Collection: BCM-equipped connected cars can gather a ton of information about driver behavior, vehicle performance, and road and traffic conditions. To enhance traffic control, safety features, and vehicle design, this data can be examined.

Remote Control and Monitoring:

Remote Start and Pre-conditioning: Remote Engine Start, Cabin Heating/Cooling, and Charging Control via Smartphone Apps: BCM connectivity improves user comfort by enabling remote engine starting, cabin heating/cooling, and charging control.

Vehicle tracking: Vehicle owners have the ability to track their vehicles remotely, which can be handy for fleet managers tracking company vehicles or parents monitoring teen drivers.

Disadvantages of BCM Connectivity and Integration in Connected Vehicles

There are many benefits to connecting and integrating BCMs (Body Control Modules) into connected automobiles, but there are also some possible drawbacks and difficulties with this technology. To achieve a complete comprehension of the subject, it is crucial to take into account the following disadvantages:

Security Concerns:

Cyber security Risks: A car may be more susceptible to hacks the more connected it is. Hackers might take advantage of BCM flaws to take over vital auto systems and possibly cause accidents or car theft.

Privacy Concerns:

Data Privacy: Connected cars gather a ton of information, such as where you are, how you drive, and your personal preferences. There are worries about how automakers, other service providers, or hackers might use, share, or otherwise misuse this data.

Reliability and Complexity:

System Complexity: The complexity of the electronic systems in cars rises as they become more integrated and networked. This complexity may result in greater difficulties in identifying and fixing problems, which could raise maintenance expenses.

Drive while distracted:

Advanced entertainment and networking systems in cars can be distracting for drivers if they are not created with safety in mind. Accidents and decreased road safety might result from this distraction.

Age-old Technology

Rapid technological advancements: The technological environment is always changing. In a few years, what is cutting edge now can become antiquated, potentially leaving vehicle owners with dated equipment.

Insufficient Network Coverage

Rural and Remote Areas: Some linked features may not function as intended in locations with weak or no network connection, which reduces their utility.

Data Overload:

Data Management: Both manufacturers and users may experience data overload due to the large volume of data created by connected automobiles. It might be quite difficult to process and use this data in a meaningful way.

Legal and Regulatory Obstacles:

Conclusion:

In conclusion, BCM connectivity and integration of BCMs (Body Control Modules) in connected vehicles offer a variety of benefits and opportunities that can dramatically improve driving functionality, safety, and enjoyment. These benefits include a better user experience, better diagnostics and upkeep for vehicles, increased safety and security, energy efficiency gains, personalization features, and aid for advanced driver assistance systems (ADAS).

However, it’s important to recognize the potential drawbacks and difficulties brought on by this technology, such as cyber security dangers, data privacy issues, increased complexity, reliance on network connectivity, higher vehicle expenses, and complex regulatory and legal issues. To guarantee that connected vehicles continue to be secure, safe, and considerate of user privacy, it is necessary to carefully analyze these issues and take proactive measures.

As the automotive sector keeps innovating and perfecting BCM connectivity

#BodyControlModule#dorleco#controlsystem#ControlStrategies#stroke#automotive#controlunit#PowertrainControl#Anti-lock Braking System#ADAS

0 notes

Text

Thermal Management in Vehicle MCUs

Introduction

Modern automobile electronics must carefully consider thermal management when designing and maintaining their Microcontroller Units (MCUs). Managing the heat generated by these components is crucial for their dependability and endurance as cars become more dependent on electronic control units for a variety of activities.

An overview of vehicle MCU thermal management is provided below:

1. Role of MCUs in Vehicles:

2. Heat Generation in MCUs:

MCUs produce heat during operation as a result of the passage of electric current via their parts. The amount of heat produced by an MCU increases as its processing power and the number of jobs it completes increase. External causes like power loss in connected sensors or actuators can also produce heat.

3. The significance of thermal management:

A number of factors make efficient thermal management essential:

Reliability: Excessive heat can shorten an electronic component’s lifespan and cause premature failure, which could result in major system failures.

Performance: High temperatures can have a significant impact on MCU performance, resulting in sluggishness, unpredictable behavior, or system breakdowns.

Safety: The proper operation of the MCU is crucial in safety-critical systems (such as braking or steering control). Safety can be compromised by overheating.

Fuel Efficiency: The overall energy efficiency of a vehicle is also impacted by heat generation. To save on fuel, effective thermal control might be beneficial.

4. Thermal Management Techniques:

Heat Sinks: Heat sinks are passive cooling solutions that dissipate heat away from the MCU. They consist of metal fins or plates that increase the surface area for heat dissipation. Heat sinks can be attached directly to the MCU package.

Fans and Liquid Cooling: In some cases, active cooling methods like fans or liquid cooling systems may be used to further enhance heat dissipation. Liquid cooling systems circulate a coolant (e.g., water or glycol) to transfer heat away from the MCU.

Thermal Interface Materials (TIMs): TIMs are substances (e.g., thermal paste or pads) placed between the MCU and heat sinks to improve thermal conductivity and ensure efficient heat transfer.

Design Considerations: Good design principles, such as placing MCUs in locations with sufficient airflow and reducing adjacent heat sources, are the foundation of effective thermal management.

5. Environmental considerations:

Vehicle MCUs must operate in a variety of environmental conditions, from bitter cold to sweltering heat. Thermal management systems should be designed to account for these variations.

6. Monitoring and control:

7. Challenges and Future Trends:

The demand for powerful MCUs rises as vehicles become more electric and driverless. This makes it difficult to control heat in electronic systems that are increasingly compact and tightly packed. These issues are being addressed by new technology including wide-band gap semiconductors and enhanced cooling methods.

Significance of Thermal Management in Vehicle MCUs

It is impossible to emphasize the importance of heat management in vehicle Microcontroller Units (MCUs) since it is essential to the reliable and secure operation of contemporary automobiles. The following are the main justifications for why heat management is crucial in car MCUs:

Reliability and Durability: Overheating can drastically shorten the life of electronic parts, especially MCUs. Effective thermal management prolongs the life of crucial vehicle systems and lowers the risk of component failure by helping to maintain the operating temperature within acceptable limits.

Preventing Performance Degradation: MCUs may experience performance degradation as a result of high operating temperatures. As a result, there can be system crashes, abnormal behavior, or reduced response times. In order to maintain MCUs’ performance capabilities, proper thermal management makes sure that they run within the designated temperature ranges.

Safety-Critical Functions: Many automotive systems, including the anti-lock braking system (ABS), airbag deployment, and stability control, rely on MCUs for safety-critical operations. These systems’ capacity to perform properly can be compromised by overheating MCUs, which could result in mishaps or present a safety risk.

Fuel Economy: More effective thermal management results in automobiles using less fuel. MCUs and other electronic components perform more effectively and use less energy and fuel when their ideal operating temperatures are maintained.

Consistent System Operation: System operation that is consistent and predictable is made possible by keeping MCUs in a steady temperature environment. Temperature changes can result in performance changes, which can have an impact on both the general driving experience and the safety of the vehicle.

Prevention of Thermal Runaway: Thermal runaway, in which the MCU’s temperature continues to grow uncontrolled, can occur as a result of overheating in extreme circumstances. This is a serious safety risk and may cause catastrophic failure. Thermal runaway situations are avoided with the aid of efficient thermal management systems.

Optimal Performance of Advanced Features: Modern vehicles include modern technologies like infotainment systems, advanced driver-assistance systems (ADAS), and autonomous driving capabilities, all of which depend on potent MCUs for optimal performance. These cutting-edge features are guaranteed to perform at their full potential without interruptions thanks to effective thermal control.

Drawbacks of Thermal Management in Vehicle MCUs:

While it is essential for good operation and minimizing overheating, thermal management in vehicle Microcontroller Units (MCUs) has some downsides and difficulties. The following are some disadvantages of heat management in car MCUs:

Cost and Complexity: Setting up efficient thermal management systems can be time-consuming and expensive. The complexity of vehicle electronic systems rises along with hardware expenses when heat sinks, fans, heat pipes, and other cooling techniques are used.

Space Constraints: Vehicles frequently have a small amount of room for heat management components. It can be difficult to integrate cooling solutions without sacrificing other important parts or cabin space.

Weight: Cooling solutions increase the vehicle’s weight, which might affect its handling and fuel economy. Weight control is considerably more important for electric vehicles (EVs) to maximize range.

Power Consumption: Fans and other active cooling techniques use electricity. In particular for electric or hybrid vehicles, this may have an impact on the vehicle’s total energy efficiency.

Maintenance: Cooling elements like fans and heat sinks may need upkeep and are subject to wear and tear. In order to avoid cooling system failures, it is crucial to guarantee the long-term dependability of these components.

Noise and Vibration: Active cooling systems, such as fans, can cause noise and vibration within the car, which may interfere with the comfort of the passengers and the driver.

Integration Difficulty: Including power distribution and communication networks in the overall vehicle architecture, and integrating thermal management systems can be difficult and may call for additional engineering work.

Thermal inertia: Thermal management systems may not react immediately to temperature changes due to thermal inertia. It may be difficult to deal with this lag when there are sudden fluctuations in temperature.

Conclusion:

Finally, it should be noted that proper heat management in vehicle Microcontroller Units (MCUs) is a crucial factor in contemporary automobile design. Although crucial for preserving the dependability, effectiveness, and safety of vehicle electronic systems, it has its own set of difficulties and trade-offs. To ensure the general operation and lifetime of vehicle MCUs and the systems they control, it is crucial to strike a balance between the advantages and disadvantages of thermal management.

There are disadvantages to take into account, though, such as complexity, expense, space limitations, weight, power consumption, maintenance, and environmental impact. Engineers and vehicle makers must carefully weigh these drawbacks against the advantages of thermal management. Addressing these issues will be more crucial as electronic systems in vehicles become more dependent on them and as electrification and autonomous technology develop.

In conclusion, the importance of thermal management in vehicle MCUs cannot be overstated because it supports the efficiency, safety, and dependability of modern cars. A key component of automotive engineering is navigating the trade-offs and difficulties of thermal management to ensure that vehicles satisfy the requirements of today’s advanced electronic systems and environmental considerations.

#MCUs#thermalmanagement#dorleco#controlsystem#ControlStrategies#stroke#automotive#controlunit#PowertrainControl#Anti-lock Braking System#ADAS

0 notes

Text

Regenerative Braking Systems and Control Strategies

Introduction

Regenerative braking is a cutting-edge technique applied to various transportation systems, including trains, some industrial machines, and electric and hybrid cars. During braking or deceleration, it enables the recovery and conversion of kinetic energy into electrical energy. This method also lessens the wear and tear on conventional friction braking systems while increasing energy efficiency. The foundations of regenerative braking systems and the control techniques that make them effective will be covered in this introduction.

Regenerative braking fundamentals: Regenerative braking systems make use of the idea of energy conservation. Kinetic energy is often lost as heat while a vehicle or machine slows down thanks to conventional friction brakes. A regenerative braking system, on the other hand, takes advantage of this kinetic energy and transforms it into electrical energy that can either be stored in batteries or used to drive the car’s electric motor.

Regenerative braking system components include:

Key elements of a typical regenerative braking system include the following:

Electric motor/generator: This part has two functions. It works as a motor to give propulsion during acceleration, and it works as a generator to turn kinetic energy into electricity during braking.

Energy Storage: Depending on the application, the electrical energy produced during regenerative braking is stored in batteries or capacitors.

Control System: The management of energy flow between the motor/generator, the energy storage system, and the vehicle’s traction system depends heavily on the control unit.

Control Strategies:

To optimize the advantages of regenerative braking, effective control systems are crucial. Here are some typical methods of control:

Torque Blending: This technique effortlessly integrates friction and regenerative braking. It estimates the necessary braking force and divides it between the regenerative system and friction brakes to provide effective deceleration while reducing friction brake wear.

Prioritizing Regeneration: When the battery is not fully charged, regenerative braking may occasionally take precedence over friction braking. Based on variables like the battery’s state of charge and the need for deceleration, the control system chooses when to utilize regenerative braking and when to use conventional brakes.

Regenerative Braking Modes: Various regenerative braking modes, such as “high” and “low” settings, are available in many automobiles. Low regenerative braking simulates ordinary coasting whereas high regenerative braking offers more vigorous deceleration and energy recovery.

Prediction Control: To enhance regenerative braking, advanced control systems can use prediction algorithms based on traffic patterns, road conditions, and driver behavior. Regenerative braking, for instance, might be enhanced as you approach a downhill part or decreased as you near a traffic light.

Benefits of Regenerative Braking Systems:

Improved energy efficiency and range for electric and hybrid vehicles.

Reduced wear and maintenance costs on friction brakes.

Enhanced braking control and stability.

Lower emissions and reduced environmental impact.

Increased sustainability and energy recovery.

Advantages of Regenerative Braking Systems and Control Strategies

Across a variety of transportation modes, regenerative braking systems and the accompanying control mechanisms offer several noteworthy benefits. Here are several major advantages:

Enhancing Energy Efficiency: By using regenerative braking, kinetic energy can be transformed into electrical energy that can be saved and used again. This procedure improves the machine or vehicle’s overall energy efficiency, particularly in stop-and-go traffic or applications requiring frequent brakes.

Extended Range for Electric Vehicles (EVs): Regenerative braking is a technique used in electric and hybrid cars to collect and store energy that would otherwise be lost as heat. The vehicle’s range can be increased and the requirement for regular recharging decreased by using the recovered energy to power it.

Reduced Operating Costs: Traditional friction brakes need regular maintenance and repair since they deteriorate over time. Over the course of vehicles or pieces of equipment’s lifecycle, regenerative braking lessens wear and tear on these parts.

Enhanced Braking Control: The braking force can be precisely controlled using regenerative braking devices. Particularly in slick circumstances, this level of control can increase braking stability and lower the chance of sliding. Additionally, it enables a smooth and controlled deceleration.

Reduced Environmental Impact: Regenerative braking systems reduce energy demand from the grid and greenhouse gas emissions by recovering and reusing energy that would otherwise be lost as heat. The environmental impact of electric and hybrid vehicles is lowered as a result.

Predictive and Adaptive Control: Regenerative braking can be optimized based on variables including road gradient, traffic patterns, and the driver’s input using advanced control techniques that can adapt to driving conditions and driver behavior. For optimum effectiveness, predictive algorithms can foresee when to activate regenerative braking.

Renewable energy and energy recovery: By recovering and reusing energy that would otherwise be lost, regenerative braking is in line with sustainability objectives. This helps to advance a more environmentally friendly strategy for industrial and transportation applications.

Disadvantages of Regenerative Braking Systems and Control Strategies

Although regenerative braking systems and control methods have many benefits, they also have drawbacks and difficulties. Here are a few negative aspects of these systems:

Initial Cost: Installing regenerative braking systems can be expensive, particularly when retrofitting older machinery or cars. Electric motors, energy storage devices (such as batteries), and control electronics are all included in the price. Adoption may be hampered by this up-front cost, especially for industries or customers with tight budgets.

Complexity: Regenerative braking systems make the design and control systems of a vehicle or piece of equipment more complex. To control the energy flow between the motor/generator, the energy storage system, and the traction system, more parts and software are needed. This intricacy may make maintenance and problem-solving more difficult.

Space and Weight Restrictions: Batteries and capacitors, which are part of regenerative braking systems, add weight to the machine or vehicle. The payload capacity may be reduced, and the performance of the vehicle as a whole may be impacted. Additionally, fitting these components into tight industrial gear or smaller vehicles might be difficult.

Limited Energy Recovery: Regenerative braking efficiency is influenced by driving habits and road conditions. The amount of energy recovered may be constrained in circumstances where there is little braking or deceleration. For instance, compared to city driving with numerous stops and starts, interstate driving at constant speeds offers less opportunity for regenerative braking.

Compatibility and Standardization: Control schemes and regenerative braking systems are not standardized across all automakers and vehicle classes. Consumers and fleet operators may find it difficult to transition between different brands or models due to compatibility and interoperability difficulties.

Regenerative Braking Noise: In some situations, regenerative braking systems may emit distinctive noises that drivers or passengers may find odd or bothersome. These noises are distinct from the usual noise made by conventional braking systems.

Limitations of Regenerative Braking: Regenerative braking works best at low speeds and during moderate to vigorous braking. It might not offer much energy recovery during emergency stops or high-speed braking.

Conclusion:

In conclusion, regenerative braking systems and the control strategies that go along with them constitute a significant improvement in the world of industrial machinery and transportation. These technologies provide a number of advantages, including increased energy efficiency, increased electric vehicle range, decreased running costs, improved braking control, and little environmental impact. They support energy conservation, support sustainable industrial and transportation practices, and are consistent with sustainability objectives.

Regenerative braking systems do, however, have some drawbacks, including high initial costs, complexity, weight restrictions, energy conversion losses, and maintenance issues. To enable the widespread acceptance and ongoing development of regenerative braking technology, several issues must be resolved.

As technology continues to evolve, we can expect regenerative braking systems to become more sophisticated and efficient, addressing some of the current limitations. Moreover, standardization and interoperability efforts will be crucial to ensure that regenerative braking solutions are accessible and compatible across various manufacturers and industries.

In the years to come, regenerative braking systems and control strategies are likely to play an increasingly vital role in reducing energy consumption, greenhouse gas emissions, and overall operating costs while enhancing the overall performance and sustainability of vehicles and machinery.

#RegenerativeBrakingSystems#Electricmotor#dorleco#controlsystem#ControlStrategies#stroke#automotive#controlunit#PowertrainControl#Anti-lock Braking System#ADAS

0 notes