#ControlValves

Explore tagged Tumblr posts

Text

Buy High-Quality Valves from China

Get high-quality valves made in China for your fluid handling needs. From self-lubricated plug valves to concentric butterfly valves, our selection ensures precise control and reliable performance in every application.

#HighQualityValves#ValvesMadeInChina#FluidHandling#PlugValves#ButterflyValves#BallValves#GlobeValves#ControlValves#ValveSuppliers#ChinaManufacturers

0 notes

Text

PVC Ball Valves - Efficient and Leak Free

PVC Ball Valves - Designed for efficiency and leak-free performance, these valves are the perfect solution for all your flow control needs. PVC Ball Valves provide reliable and precise control, ensuring your system runs smoothly and effectively. Experience the difference in quality and performance with our PVC Ball Valves today!

Visit Website - https://petronthermoplast.com/pvc-ball-valve/?utm_source=Raveena_SEO&utm_medium=Raveena_Organic

Contact No. - +91-8218684097

Request for Quotation - [email protected]

ITEM CODE - VEEAV112E, VEEAV212E, VEEAV400E

Delivery - Worldwide

#PVCBallValves#FlowControl#Efficiency#LeakFree#ballvalve#valve#fitting#valvesupplier#waterindustry#controlvalves#safetyvalve

0 notes

Text

CONTROL VALVES VS BALL VALVES: KEY DIFFERENCES

Differences between control valves and ball valves, including their unique features, applications.

That is why when selecting the Ball valves, it is crucial to work with the best Ball valves Supplier. Not only do these suppliers offer a good valve product but also give a professional recommendation on the right valve for the right application.

One of the primary and significant responsibilities of a reliable Valve Stockist is to ensure that both control and ball valves are available when needed. If you are targeting the Middle Eastern market, you can seek the services of a Valve Stockist in UAE.

#BallValves#BallValvesSupplier#ControlValves#Controlvalvessuppliers#ValveManufacturers#valveselectioncriteria#ValveStockist#ValveStockistinUAE#ValveSuppliers#valvescomparison

0 notes

Text

ANBI Group is one of the leading Valve suppliers in Dubai, UAE. Visit www.anbisolutions.com for more products.

#anbionline#anbigroup#valves#valve#gatevalve#engineering#pumps#ballvalve#oilandgas#hydraulics#flange#fitting#construction#controlvalves#butterflyvalve#industry#pneumatic#fittings#actuators#plumbing#industrial#flexiblehose#hydraulicpump#castings#filter#butterfly#work#hydraulicparts

1 note

·

View note

Text

Control valves are essential components in various industrial processes, regulating fluid flow by adjusting the aperture within a piping system. Comprising several key elements, control valves typically include a valve body housing the moving

0 notes

Text

Control valve supplier in Dubai

UAE Valves is one of the top Control Valve Supplier in Dubai. A control valve is a mechanical device used in various industrial processes to regulate the flow of fluids, such as gas, steam, or liquid, through a pipeline or duct. It achieves this regulation by adjusting the size of the flow passage according to signals received from a controller.

Control valves are crucial components in systems requiring precise control of flow rate, pressure, temperature, or liquid level. They are widely used in industries such as oil and gas, chemical processing, power generation, and water treatment.

Working Principle:

The working principle of a control valve is straightforward. In an industrial setting, a control valve adjusts the size of an opening to control the flow of fluid through a pipeline. When the valve is fully open, it allows maximum flow, and when fully closed, it stops the flow completely. Between these extremes, the valve can be precisely adjusted to allow a specific amount of fluid to pass through.

This adjustment is typically performed automatically based on signals from a controller, which monitors conditions such as pressure, temperature, or flow rate. Essentially, a control valve acts like a gatekeeper, regulating the flow of fluid to meet the system's requirements.

Parts of a Control Valve:

Valve Body: The main structure that contains the fluid and through which the fluid flows.

Actuator: A device that moves or controls the valve's mechanism, often powered by air, electricity, or hydraulic fluid.

Closure Element: The component that makes contact with the seat to restrict or allow flow.

Trim: Internal components such as the plug, seat, and stem that modulate the flow.

Seat: A surface against which the closure element seals to stop flow.

Positioner: A device that adjusts the valve actuator's position based on control signals.

Bonnet: The top part of the valve body that houses the stem and provides a seal.

Yoke: A support structure that holds the actuator in place and connects it to the valve body.

Stem: A rod that connects the actuator to the closure element and transmits motion.

Packing: Material that provides a seal around the stem to prevent fluid leakage.

Advantages:

Precisely controls the amount of fluid passing through a system.

Maintains the desired pressure levels within the system.

Helps maintain a stable temperature by regulating fluid flow.

Reduces energy consumption by optimizing fluid flow.

Enhances system performance by maintaining consistent operating conditions.

Prevents system overpressure and potential hazards.

Easily adjustable for various operating conditions.

Allows for control from a distance and integration into automated systems.

Designed for durability and ease of maintenance.

Ensures consistent production quality by maintaining optimal conditions.

Meets industry standards and regulatory requirements.

Industries Using Control Valves:

Control valves are used across numerous industries, including nuclear power, oil and gas, power generation, manufacturing and process industries, automotive, aerospace, mining and minerals processing, water treatment and distribution, pulp and paper, refining, marine, renewable energy, chemical and petrochemical, and steel and metal processing. These valves play a critical role in ensuring operational efficiency, safety, and compliance within these diverse sectors.

Types of Control Valves:

Three-way control valve

Cage type control valve

Double seat control valve

O type shutoff control valve

Single seat control valve

Water control valve

Globe control valve

Angle type control valve

We are a Control Valve Supplier in Dubai, supplying valves in the following descriptions:

Available Materials: Stainless Steel (SS316, SS304), Ductile Iron, Super Duplex (F51, F53, F55), Cast Iron (WCB, WCC, WC6), LCC, LCB

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Medium: Air, Water, Chemical, Steam, Oil

Operations: Electro Pneumatic Operated and Pneumatic Operated

Size: 1/2” – 24”

Ends: Butt Weld, Flanged, Threaded, Socket Weld

Electric Actuator Details:

Torque: 3 – 9 nm

Operating Pressure: 8 Bar

Port Connection: NPT 1.4”

Mounting Base: ISO 5211

Temperature: -20°C to +80°C

Configuration of a Pneumatic Actuator:

Torque: 3 – 9000 nm

Operating Pressure: 8 Bar

Port Connection: NPT 1.4”

Mounting Base: ISO 5211

Temperature: -20°C to +80°C

Temperature Ranges:

Standard: -4°F to 200°F (-20°C to 93°C)

Low: -40°F to 176°F (-40°C to 80°C)

High: 0°F to 300°F (-18°C to 149°C)

Visit us: https://www.uaevalves.com/product-category/control-valve/

3 notes

·

View notes

Text

Precise Control Starts Here – BR.W61P Series Single Seat Control Valve

In industrial automation, precision and reliability aren’t optional—they’re essential. The BR.W61P Series Single Seat Control Valve is designed to deliver accurate flow control with a streamlined structure and dependable performance.

🔩 Highlights of BR.W61P Series:

High Precision Regulation: Ideal for controlling liquids, steam, or gases with excellent responsiveness.

Compact Single Seat Design: Reduces leakage and simplifies maintenance for consistent long-term use.

Versatile Applications: Perfect for chemical processing, energy systems, and general industrial automation.

Efficient and Reliable: Built for performance in demanding working conditions.

For smart flow control you can count on, the BR.W61P Series delivers control without compromise.

0 notes

Text

Graphite, PTFE & Grafoil Gland Packing for Gate, Globe & Control Valves

Valves play a critical role in controlling fluid flow, and gland packing ensures they remain leak-proof even under extreme pressure and temperature. Among the most trusted sealing materials are Graphite, PTFE (Teflon), and Grafoil – each with specific advantages tailored for different valve types and industrial conditions.

At Udhhyog, Delhi’s top gland packing supplier and valve manufacturer, we provide high-performance sealing solutions for gate, globe, and control valves, serving industries like steam, chemical, water treatment, and power generation.

This article breaks down the properties and applications of graphite, PTFE, and Grafoil gland packing and provides specifications for their ideal use in valves.

What is Gland Packing?

Gland packing is a sealing material inserted around the valve stem inside a chamber known as the stuffing box. It prevents leakage by forming a tight seal when compressed using a gland follower and gland flange.

Used in:

Gate Valves

Globe Valves

Control Valves

Steam Valves

Graphite Gland Packing

✅ Features:

Withstands high temperatures up to 550°C

Resistant to chemicals, steam, and pressure

Flexible and easy to install

✅ Applications:

Steam valves

Power plants

Oil and gas pipelines

Chemical reactors

✅ Advantages:

Excellent thermal stability

High pressure resistance (up to 250 bar)

Cost-effective long-term sealing

PTFE Gland Packing

✅ Features:

Chemically inert and non-reactive

Temperature resistance up to 260°C

Low coefficient of friction

✅ Applications:

Globe and control valves

Acidic or alkaline chemical lines

Pharmaceutical and food-grade processing

✅ Advantages:

Ideal for corrosive environments

Non-stick, low wear

Prevents chemical contamination

Grafoil Gland Packing

Grafoil is a pure graphite-based material with no binders, making it perfect for nuclear and high-purity applications.

✅ Features:

Withstands extreme temperatures (up to 650°C)

High compressibility and resilience

Fire-safe and non-oxidizing

✅ Applications:

Nuclear plants

Superheated steam systems

Refineries and chemical plants

✅ Advantages:

Long-lasting under thermal cycling

Superior sealing under fluctuating pressure

Excellent in steam and high-purity services

Comparison Table: Graphite vs PTFE vs Grafoil

PropertyGraphitePTFEGrafoilMax Temp550°C260°C650°CPressure RangeUp to 250 barUp to 150 barUp to 300 barChemical ResistanceHigh (except oxidizers)ExcellentExcellentSteam CompatibilityYesNoYesFlexibilityMediumHighHighApplication RangeBroadSpecialty chemicalsHigh-purity & nuclear

Gland Packing in Gate, Globe & Control Valves

🔸 Gate Valve Gland Packing

Operates fully open/closed

Uses graphite or Grafoil to handle high temps/pressure

🔸 Globe Valve Gland Packing

Requires flexible sealing for throttling

Ideal with PTFE or graphite packing

🔸 Control Valve Gland Packing

Needs low-friction, high-resilience material

Best with PTFE or Grafoil for dynamic applications

Valve Sizes & Gland Packing Availability at Udhhyog

Available for valves from 15mm to 300mm:

Cross-section sizes: 3mm, 6mm, 10mm, 12mm, 16mm, 19mm

Packing materials: Graphite, Grafoil, PTFE, Carbon fiber

Types: Preformed rings, spiral wound, compression rolls

Valve Types & Material Compatibility

Valve TypeGraphitePTFEGrafoilGate Valve✅❌✅Globe Valve✅✅✅Control Valve✅✅✅Steam Valve✅❌✅Chemical Valve✅✅✅

Why Choose Udhhyog – Valve Packing Experts in Delhi

🏭 Custom Valve & Packing Solutions

We offer gland valve kits, stuffing box rings, and complete valve + packing assemblies.

🔧 Premium Packing Materials

Only certified materials from verified suppliers – Grafoil, PTFE, Graphite.

📦 Stock Ready for All Valve Sizes

Available in bulk quantities for OEMs and industries.

🧠 Technical Guidance & Sizing Help

Our engineers assist with material selection, pressure class, and sizing.

🚚 Fast Delivery Across North India

Serving Delhi, NCR, Punjab, Haryana, UP, Himachal Pradesh, and J&K.

Gland Packing Pricing in Delhi (Udhhyog Rates)

MaterialSize (mm)Price Range (INR/kg or meter)Graphite6–25₹450 – ₹900PTFE6–19₹500 – ₹1,000Grafoil6–25₹1,200 – ₹2,000

📌 Prices vary by quantity, grade, and size. Contact Udhhyog for bulk or customized gland sets.

Conclusion

Selecting the right gland packing material for your valve type and fluid service is essential for long-lasting performance and safety. Whether you're dealing with high-pressure steam, aggressive chemicals, or precision control systems, the correct choice between Graphite, PTFE, or Grafoil can make all the difference.

Trust Udhhyog as your go-to supplier for gland packing and valve sealing solutions in Delhi.

Contact Udhhyog Today

📞 Call now or Visit Udhhyog Website for detailed product catalogs, technical support, and price quotes.

#GlandPacking#GraphitePacking#PTFEPacking#GrafoilPacking#ValveSealing#ControlValve#GateValve#GlobeValve#Udhhyog#ValveSupplierDelhi#IndustrialSealing#SteamValvePacking

1 note

·

View note

Text

Graphite, PTFE & Grafoil Gland Packing for Gate, Globe & Control Valves

Valves play a critical role in controlling fluid flow, and gland packing ensures they remain leak-proof even under extreme pressure and temperature. Among the most trusted sealing materials are Graphite, PTFE (Teflon), and Grafoil – each with specific advantages tailored for different valve types and industrial conditions.

At Udhhyog, Delhi’s top gland packing supplier and valve manufacturer, we provide high-performance sealing solutions for gate, globe, and control valves, serving industries like steam, chemical, water treatment, and power generation.

This article breaks down the properties and applications of graphite, PTFE, and Grafoil gland packing and provides specifications for their ideal use in valves.

What is Gland Packing?

Gland packing is a sealing material inserted around the valve stem inside a chamber known as the stuffing box. It prevents leakage by forming a tight seal when compressed using a gland follower and gland flange.

Used in:

Gate Valves

Globe Valves

Control Valves

Steam Valves

Graphite Gland Packing

✅ Features:

Withstands high temperatures up to 550°C

Resistant to chemicals, steam, and pressure

Flexible and easy to install

✅ Applications:

Steam valves

Power plants

Oil and gas pipelines

Chemical reactors

✅ Advantages:

Excellent thermal stability

High pressure resistance (up to 250 bar)

Cost-effective long-term sealing

PTFE Gland Packing

✅ Features:

Chemically inert and non-reactive

Temperature resistance up to 260°C

Low coefficient of friction

✅ Applications:

Globe and control valves

Acidic or alkaline chemical lines

Pharmaceutical and food-grade processing

✅ Advantages:

Ideal for corrosive environments

Non-stick, low wear

Prevents chemical contamination

Grafoil Gland Packing

Grafoil is a pure graphite-based material with no binders, making it perfect for nuclear and high-purity applications.

✅ Features:

Withstands extreme temperatures (up to 650°C)

High compressibility and resilience

Fire-safe and non-oxidizing

✅ Applications:

Nuclear plants

Superheated steam systems

Refineries and chemical plants

✅ Advantages:

Long-lasting under thermal cycling

Superior sealing under fluctuating pressure

Excellent in steam and high-purity services

Comparison Table: Graphite vs PTFE vs Grafoil

PropertyGraphitePTFEGrafoilMax Temp550°C260°C650°CPressure RangeUp to 250 barUp to 150 barUp to 300 barChemical ResistanceHigh (except oxidizers)ExcellentExcellentSteam CompatibilityYesNoYesFlexibilityMediumHighHighApplication RangeBroadSpecialty chemicalsHigh-purity & nuclear

Gland Packing in Gate, Globe & Control Valves

🔸 Gate Valve Gland Packing

Operates fully open/closed

Uses graphite or Grafoil to handle high temps/pressure

🔸 Globe Valve Gland Packing

Requires flexible sealing for throttling

Ideal with PTFE or graphite packing

🔸 Control Valve Gland Packing

Needs low-friction, high-resilience material

Best with PTFE or Grafoil for dynamic applications

Valve Sizes & Gland Packing Availability at Udhhyog

Available for valves from 15mm to 300mm:

Cross-section sizes: 3mm, 6mm, 10mm, 12mm, 16mm, 19mm

Packing materials: Graphite, Grafoil, PTFE, Carbon fiber

Types: Preformed rings, spiral wound, compression rolls

Valve Types & Material Compatibility

Valve TypeGraphitePTFEGrafoilGate Valve✅❌✅Globe Valve✅✅✅Control Valve✅✅✅Steam Valve✅❌✅Chemical Valve✅✅✅

Why Choose Udhhyog – Valve Packing Experts in Delhi

🏭 Custom Valve & Packing Solutions

We offer gland valve kits, stuffing box rings, and complete valve + packing assemblies.

🔧 Premium Packing Materials

Only certified materials from verified suppliers – Grafoil, PTFE, Graphite.

📦 Stock Ready for All Valve Sizes

Available in bulk quantities for OEMs and industries.

🧠 Technical Guidance & Sizing Help

Our engineers assist with material selection, pressure class, and sizing.

🚚 Fast Delivery Across North India

Serving Delhi, NCR, Punjab, Haryana, UP, Himachal Pradesh, and J&K.

Gland Packing Pricing in Delhi (Udhhyog Rates)

MaterialSize (mm)Price Range (INR/kg or meter)Graphite6–25₹450 – ₹900PTFE6–19₹500 – ₹1,000Grafoil6–25₹1,200 – ₹2,000

📌 Prices vary by quantity, grade, and size. Contact Udhhyog for bulk or customized gland sets.

Conclusion

Selecting the right gland packing material for your valve type and fluid service is essential for long-lasting performance and safety. Whether you're dealing with high-pressure steam, aggressive chemicals, or precision control systems, the correct choice between Graphite, PTFE, or Grafoil can make all the difference.

Trust Udhhyog as your go-to supplier for gland packing and valve sealing solutions in Delhi.

Contact Udhhyog Today

📞 Call now or Visit Udhhyog Website for detailed product catalogs, technical support, and price quotes.

#GlandPacking#GraphitePacking#PTFEPacking#GrafoilPacking#ValveSealing#ControlValve#GateValve#GlobeValve#Udhhyog#ValveSupplierDelhi#IndustrialSealing#SteamValvePacking

0 notes

Text

Graphite, PTFE & Grafoil Gland Packing for Gate, Globe & Control Valves

Valves play a critical role in controlling fluid flow, and gland packing ensures they remain leak-proof even under extreme pressure and temperature. Among the most trusted sealing materials are Graphite, PTFE (Teflon), and Grafoil – each with specific advantages tailored for different valve types and industrial conditions.

At Udhhyog, Delhi’s top gland packing supplier and valve manufacturer, we provide high-performance sealing solutions for gate, globe, and control valves, serving industries like steam, chemical, water treatment, and power generation.

This article breaks down the properties and applications of graphite, PTFE, and Grafoil gland packing and provides specifications for their ideal use in valves.

What is Gland Packing?

Gland packing is a sealing material inserted around the valve stem inside a chamber known as the stuffing box. It prevents leakage by forming a tight seal when compressed using a gland follower and gland flange.

Used in:

Gate Valves

Globe Valves

Control Valves

Steam Valves

Graphite Gland Packing

✅ Features:

Withstands high temperatures up to 550°C

Resistant to chemicals, steam, and pressure

Flexible and easy to install

✅ Applications:

Steam valves

Power plants

Oil and gas pipelines

Chemical reactors

✅ Advantages:

Excellent thermal stability

High pressure resistance (up to 250 bar)

Cost-effective long-term sealing

PTFE Gland Packing

✅ Features:

Chemically inert and non-reactive

Temperature resistance up to 260°C

Low coefficient of friction

✅ Applications:

Globe and control valves

Acidic or alkaline chemical lines

Pharmaceutical and food-grade processing

✅ Advantages:

Ideal for corrosive environments

Non-stick, low wear

Prevents chemical contamination

Grafoil Gland Packing

Grafoil is a pure graphite-based material with no binders, making it perfect for nuclear and high-purity applications.

✅ Features:

Withstands extreme temperatures (up to 650°C)

High compressibility and resilience

Fire-safe and non-oxidizing

✅ Applications:

Nuclear plants

Superheated steam systems

Refineries and chemical plants

✅ Advantages:

Long-lasting under thermal cycling

Superior sealing under fluctuating pressure

Excellent in steam and high-purity services

Comparison Table: Graphite vs PTFE vs Grafoil

PropertyGraphitePTFEGrafoilMax Temp550°C260°C650°CPressure RangeUp to 250 barUp to 150 barUp to 300 barChemical ResistanceHigh (except oxidizers)ExcellentExcellentSteam CompatibilityYesNoYesFlexibilityMediumHighHighApplication RangeBroadSpecialty chemicalsHigh-purity & nuclear

Gland Packing in Gate, Globe & Control Valves

🔸 Gate Valve Gland Packing

Operates fully open/closed

Uses graphite or Grafoil to handle high temps/pressure

🔸 Globe Valve Gland Packing

Requires flexible sealing for throttling

Ideal with PTFE or graphite packing

🔸 Control Valve Gland Packing

Needs low-friction, high-resilience material

Best with PTFE or Grafoil for dynamic applications

Valve Sizes & Gland Packing Availability at Udhhyog

Available for valves from 15mm to 300mm:

Cross-section sizes: 3mm, 6mm, 10mm, 12mm, 16mm, 19mm

Packing materials: Graphite, Grafoil, PTFE, Carbon fiber

Types: Preformed rings, spiral wound, compression rolls

Valve Types & Material Compatibility

Valve TypeGraphitePTFEGrafoilGate Valve✅❌✅Globe Valve✅✅✅Control Valve✅✅✅Steam Valve✅❌✅Chemical Valve✅✅✅

Why Choose Udhhyog – Valve Packing Experts in Delhi

🏭 Custom Valve & Packing Solutions

We offer gland valve kits, stuffing box rings, and complete valve + packing assemblies.

🔧 Premium Packing Materials

Only certified materials from verified suppliers – Grafoil, PTFE, Graphite.

📦 Stock Ready for All Valve Sizes

Available in bulk quantities for OEMs and industries.

🧠 Technical Guidance & Sizing Help

Our engineers assist with material selection, pressure class, and sizing.

🚚 Fast Delivery Across North India

Serving Delhi, NCR, Punjab, Haryana, UP, Himachal Pradesh, and J&K.

Gland Packing Pricing in Delhi (Udhhyog Rates)

MaterialSize (mm)Price Range (INR/kg or meter)Graphite6–25₹450 – ₹900PTFE6–19₹500 – ₹1,000Grafoil6–25₹1,200 – ₹2,000

📌 Prices vary by quantity, grade, and size. Contact Udhhyog for bulk or customized gland sets.

Conclusion

Selecting the right gland packing material for your valve type and fluid service is essential for long-lasting performance and safety. Whether you're dealing with high-pressure steam, aggressive chemicals, or precision control systems, the correct choice between Graphite, PTFE, or Grafoil can make all the difference.

Trust Udhhyog as your go-to supplier for gland packing and valve sealing solutions in Delhi.

Contact Udhhyog Today

📞 Call now or Visit Udhhyog Website for detailed product catalogs, technical support, and price quotes.

#GlandPacking#GraphitePacking#PTFEPacking#GrafoilPacking#ValveSealing#ControlValve#GateValve#GlobeValve#Udhhyog#ValveSupplierDelhi#IndustrialSealing#SteamValvePacking

0 notes

Text

Van điều khiển là gì? Có những loại van điều khiển nào?

Trong các ngành công nghiệp hiện đại, van điều khiển đóng một vai trò vô cùng quan trọng, giúp điều tiết và kiểm soát lưu lượng của các chất lỏng hoặc khí trong các hệ thống. Hãy cùng Tuấn Hưng Phát Valve khám phá về van điều khiển, các loại van điều khiển phổ biến, và ứng dụng của chúng trong các ngành công nghiệp.

Van Điều Khiển Là Gì?

Van điều khiển (tiếng Anh là Control Valve) là một thiết bị cơ khí được sử dụng để điều tiết, kiểm soát hoặc tự động điều chỉnh lưu lượng của chất lỏng, khí, hơi, hoặc các chất khác trong hệ thống ống dẫn. Việc điều khiển van có thể được thực hiện thông qua các tín hiệu điện, khí nén hoặc thủy lực. Van điều khiển giúp tự động hóa quá trình đóng mở mà không cần sự can thiệp trực tiếp của con người.

Nguyên Lý Hoạt Động

Van điều khiển hoạt động dựa trên các tín hiệu đầu vào được truyền đến bộ điều khiển. Bộ điều khiển sẽ phân tích các tín hiệu này và điều khiển cơ chế đóng mở của van sao cho phù hợp với yêu cầu của hệ thống. Van điều khiển có thể được sử dụng để điều chỉnh lưu lượng của nước, hơi, khí, dầu, hóa chất, và nhiều chất khác.

Các Loại Van Điều Khiển

Tại thị trường Việt Nam, van điều khiển chủ yếu được chia thành hai loại chính: van điều khiển on/off và van điều khiển tuyến tính. Mỗi loại có đặc điểm và ứng dụng khác nhau, phù hợp với nhu cầu của từng hệ thống.

1. Van Điều Khiển On/Off

Van điều khiển on/off là loại van có khả năng đóng mở hoàn toàn. Khi được cấp tín hiệu, van sẽ đóng chặt hoặc mở hoàn toàn mà không có sự điều chỉnh linh hoạt về góc độ. Van điều khiển on/off rất phù hợp với các ứng dụng yêu cầu chỉ có hai trạng thái, ví dụ như trong các hệ thống điều khiển bơm hoặc trong các ứng dụng đơn giản mà không yêu cầu điều chỉnh lưu lượng chính xác.

2. Van Điều Khiển Tuyến Tính

Van điều khiển tuyến tính cho phép điều chỉnh lưu lượng qua van một cách linh hoạt, bằng cách điều khiển van ở nhiều góc độ khác nhau. Điều này giúp kiểm soát chính xác lưu lượng của chất lỏng hoặc khí trong hệ thống. Van điều khiển tuyến tính được sử dụng trong các ứng dụng yêu cầu điều khiển chính xác và liên tục, như trong các hệ thống điều khiển quá trình công nghiệp.

Các Dạng Điều Khiển Van Điều Khiển

Bên cạnh việc phân chia theo chức năng điều khiển, van điều khiển cũng có thể được phân chia theo dạng điều khiển, bao gồm:

1. Van Điều Khiển Điện

Van điều khiển điện sử dụng động cơ điện để vận hành van, đóng mở khi được cấp điện năng. Van có thể được điều khiển thông qua các tín hiệu điện như 4-20mA hoặc 0-10V. Đây là loại van điều khiển phổ biến trong các hệ thống tự động hóa trong các ngành công nghiệp điện, hóa chất, thực phẩm và nước sạch.

2. Van Điều Khiển Khí Nén

Van điều khiển khí nén sử dụng bộ truyền động khí nén để điều khiển việc đóng mở van. Các tín hiệu khí nén sẽ được điều khiển thông qua bộ điều khiển khí nén, làm van thay đổi trạng thái. Loại van này thường được sử dụng trong các hệ thống yêu cầu tốc độ và độ chính xác cao, ví dụ như trong các hệ thống kiểm soát chất lỏng trong các nhà máy chế biến.

Lợi Ích Khi Sử Dụng Van Điều Khiển

Việc sử dụng van điều khiển đem lại nhiều lợi ích cho các hệ thống công nghiệp:

Tăng hiệu quả và độ chính xác: Van điều khiển giúp điều chỉnh lưu lượng một cách chính xác, từ đó giúp hệ thống hoạt động hiệu quả và tiết kiệm năng lượng.

Tự động hóa quá trình: Van điều khiển giúp giảm bớt sự can thiệp của con người, tự động hóa quá trình đóng mở van và điều chỉnh lưu lượng, giúp giảm thiểu sai sót và tăng năng suất.

Dễ dàng điều chỉnh: Nhờ vào khả năng điều chỉnh linh hoạt của các loại van điều khiển tuyến tính, người vận hành có thể dễ dàng điều chỉnh lưu lượng và áp suất trong hệ thống.

Ứng dụng đa dạng: Van điều khiển được sử dụng rộng rãi trong nhiều lĩnh vực khác nhau như cấp nước, xử lý nước thải, công nghiệp hóa chất, và công nghiệp thực phẩm.

Các Ứng Dụng Của Van Điều Khiển

Van điều khiển có mặt trong hầu hết các ngành công nghiệp hiện nay. Một số ứng dụng phổ biến của van điều khiển bao gồm:

1. Ngành Công Nghiệp Nước

Trong ngành công nghiệp cấp nước và xử lý nước thải, van điều khiển giúp điều chỉnh lưu lượng nước, đảm bảo việc cung cấp nước ổn định cho các khu vực sinh hoạt và công nghiệp. Van điều khiển cũng giúp điều tiết lưu lượng trong các hệ thống xử lý nước thải, duy trì chất lượng nước trong các bể xử lý.

2. Ngành Công Nghiệp Dầu Khí

Trong ngành công nghiệp dầu khí, van điều khiển được sử dụng để điều khiển lưu lượng dầu và khí trong các đường ống dẫn. Các hệ thống van điều khiển giúp kiểm soát áp suất và lưu lượng, đồng thời bảo vệ các thiết bị trong hệ thống khỏi hư hỏng.

3. Ngành Công Nghiệp Hóa Chất

Van điều khiển cũng được sử dụng trong các nhà máy sản xuất hóa chất, giúp điều chỉnh lượng hóa chất đưa vào các phản ứng hóa học. Điều này giúp đảm bảo sự chính xác trong các quá trình sản xuất và kiểm soát chất lượng sản phẩm.

4. Ngành Công Nghiệp Thực Phẩm

Trong ngành công nghiệp thực phẩm và đồ uống, van điều khiển giúp kiểm soát quá trình cấp nguyên liệu, pha chế, và đóng gói. Việc điều chỉnh lưu lượng chính xác giúp duy trì chất lượng sản phẩm.

Kết Luận

Van điều khiển là một phần không thể thiếu trong các hệ thống công nghiệp hiện đại. Nhờ vào khả năng điều chỉnh lưu lượng linh hoạt và tự động, van điều khiển giúp các hệ thống hoạt động hiệu quả, tiết kiệm năng lượng và giảm thiểu sự can thiệp của con người. Dù là van điều khiển điện hay van điều khiển khí nén, việc lựa chọn đúng loại van cho từng ứng dụng cụ thể sẽ mang lại hiệu quả tối ưu.

Hy vọng bài viết này đã cung cấp cho bạn những kiến thức hữu ích về van điều khiển. Nếu bạn đang tìm kiếm các giải pháp van điều khiển chất lượng, đừng quên tham khảo Tuấn Hưng Phát Valve – đơn vị chuyên cung cấp các sản phẩm van điều khiển uy tín và chất lượng cao.

0 notes

Text

Honeywell V5011N1073 1 1/4 Inch Body PDTC Equal Percentage 18.7CV | PartsHnC

The Honeywell V5011N1073 Precision Direct Tension Control valve has a 1 1/4-inch body and is designed to provide precise and proportional fluid flow control in HVAC systems. This valve, which has an 18.7 Cv and an equal % flow characteristic, is frequently employed in HVAC applications where precise fluid flow control is essential. The best possible control over temperature and pressure is made possible by the PDTC function, which guarantees accurate modulation in response to variations in control signals. Installed in a variety of HVAC equipment, including heating systems and air handling units, the V5011N1073 enhances the system's overall performance and energy efficiency by facilitating controlled and efficient fluid flow. It also helps HVAC systems maintain stable pressure and temperature levels.

0 notes

Text

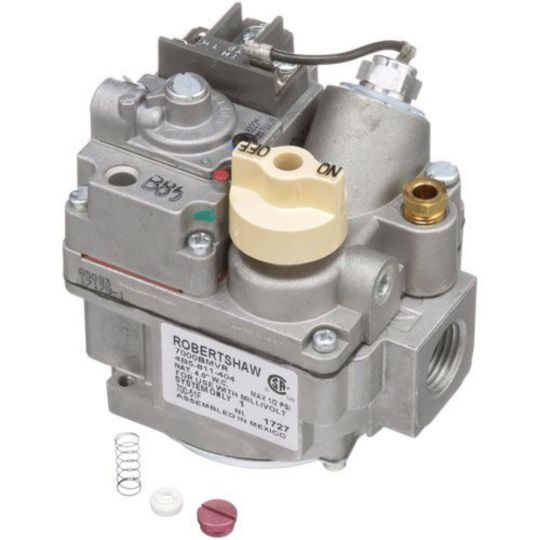

Keating 023627 Control Valve 1/2" | PartsFe

Order Keating 023627 Control Valve 1/2" today! Shop Restaurant Equipment Parts & Accessories at PartsFe with same-day shipping, available at the best prices.

0 notes

Text

ANBI Group is one of the leading Valve suppliers in Dubai, UAE. Visit www.anbisolutions.com for more products.

#anbionline#anbigroup#valves#valve#gatevalve#engineering#pumps#ballvalve#oilandgas#hydraulics#flange#fitting#construction#controlvalves#butterflyvalve#industry#pneumatic#fittings#actuators#plumbing#industrial#flexiblehose#hydraulicpump#castings#filter#butterfly#work#hydraulicparts

0 notes

Text

Essential applications of control valves across industries

Control valves are indispensable components across various industries, where they enable precise control and optimization of processes, contribute to operational efficiency, and ensure compliance with safety and quality standards. Their versatility and reliability make them essential for the smooth functioning of industrial operations worldwide.

0 notes

Text

Keating 023627 Control Valve 1/2" | PartsFe

Order Keating 023627 Control Valve 1/2" today! Shop Restaurant Equipment Parts & Accessories at PartsFe with same-day shipping, available at the best prices.

0 notes