#Copper Clad Laminate (CCL) Market

Text

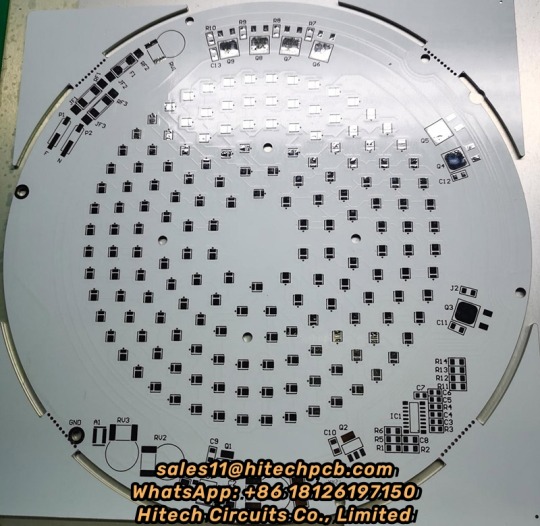

Aluminium PCB

1. What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Aluminum LED PCB with White Solder Mask

The retail price of Aluminum LED lights has dropped dramatically in recent years, while the energy efficiency and brightness of LED lights have improved. These technological advances have led some to predict annual growth of 45% over the next five years. With the development of the LED industry, the demand for LED PCBS and solder masks is also increasing. Solder shield is a protective coating applied to exposed printed circuit boards. The exposed PCB board is covered with a mask to prevent accidental solder bridging during PCB assembly and to protect the PCB from the environment. Solder masks are traditionally green, and are expected to withstand the high temperatures that occur in reflow soldering, as different colors such as blue, red, or black will occasionally appear. Increased production of Hitch Aluminum LED PCB requires increased whiteness and color stability of the mask. Aluminum LED PCB commonly used LPI welding color is white and black, of which white welding color is the most commonly used to achieve high brightness and perfect light reflection. White Aluminum LED PCB ensures no darkening and will not affect the color temperature of LED smd. At the same time, it also helps to increase the life of LED applications. Looking for reliable Aluminum LED PCB suppliers, Hitech is a good choice.

6. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

7. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability

Aluminum-based printed boards are obviously much more stable in size than those made of insulating materials. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

(4) Other reasons

Aluminum based printed board, with shielding effect; Instead of brittle ceramic substrate; Safe use of surface mounting technology; Reducing the real effective area of the printed board; Instead of radiator and other components, improve the heat resistance and physical properties of products; Reduce production costs and labor.

8. Why choose Aluminum LED PCB from Hitechpcb? What are the advantages of Aluminum LED PCB?

(1) Good heat dissipation performance: Aluminum LED PCB can reduce the thermal resistance to the minimum, has a smaller thermal resistance, thermal expansion coefficient is closer to copper foil, so that Aluminum LED PCB has excellent thermal conductivity and heat dissipation performance, reduce the module operating temperature, prolong the service life.

High current load: Using the same thickness, the same line width, Aluminum LED PCB substrate can carry higher current.

(2) Good machinability: can replace ceramic substrate, better mechanical endurance. At the same time, high strength and toughness, can realize large area printed board manufacturing and component mounting.

(3) Good electromagnetic shielding: In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum LED PCB can act as a shield plate, play the role of shielding electromagnetic wave

(4) Environmental protection: The Aluminum LED PCB used in the raw material is non-toxic and can be recycled. Meet RoHs requirements.

(5)Light weight: Aluminum LED PCB has a surprisingly light weight with excellent strength and elasticity, which is very convenient.

Hitech Circuits can provide high quality and affordable Aluminum LED PCB products for you.

9. Technical requirements for Aluminum LED PCB

The main technical requirements are:

1. Dimensional requirements: including panel size and deviation, thickness and deviation, perpendicularity and warpage; Appearance, including cracks, scratches, burrs and delimitation, aluminum oxide film, etc.

2. Performance requirements, including peel strength, surface resistively, minimum breakdown voltage, dielectric constant, combustion and thermal resistance requirements.

10. Special test method for Aluminum-based copper clad plates

One is the measurement method of dielectric constant and dielectric loss factor. It is the series resonance method with variable Q value. The sample and tuned capacitor are connected to the high-frequency circuit in series to measure the Q value of the series circuit.

The other is the measurement method of thermal resistance, which is calculated by the ratio of temperature difference and heat conduction between different temperature measurement points.

11. The Aluminum LED PCB manufacturing process in Hitechpcba

(1)Substrate cutting

a. cutting process: material → cutting

b. Note: ① Check the size of the first piece; ② Pay attention to Aluminum surface scratching and copper surface scratching; ③ Pay attention to the layering of the board edge and the tip.

(2)Plate drilling

a, drilling process: pin → drilling → inspection plate

b, matters needing attention: ① check the number of drilling holes, the size of the empty chestnut chain; ② Check the plate burr, hole deviation; ③ Avoid scratching the substrate; ④ Check and replace the drill nozzle.

(3) Imaging transfer

a, graphic imaging process: grinding plate → film → exposure → development

b, precautions: ① Check whether there is an open circuit after development; ② Pay attention to the poor line caused by the board wipe; ③ There can be no air residual exposure to prevent poor exposure; ④ Whether there is deviation in developing counterpoint; ⑤ After exposure, the development should be done at rest for more than 15 minutes.

(4)Solder mask and Silkscreen process

a, kill row silk printing resistance welding, character process: screen printing → pre-baking → exposure → development → character

b, matters needing attention: ① Check whether there is foreign body on the board; ② Pay attention to the cleaning of the net board; ③ Pre-bake for more than 30 minutes after screen printing, to avoid bubbles in the line; ④ Pay attention to the thickness and uniformity of screen printing; ⑤ After the pre-baked plate to completely mutual cooling, avoid touching film or damage to the ink surface gloss.

(5)E-test or flying probe test

a, test process: line test → withstand voltage test

b, precautions: ① How to distinguish after the test how to store qualified and unqualified products.

(6)FQC, FQA, packaging, shipping

a. Process: FQC→FQA→ Packaging → shipping

b. Note: ① FQC should pay attention to the confirmation of the appearance of the finished Aluminum LED PCB in the process of eye inspection and make a reasonable distinction; ② FQA does spot check and verify the inspection standards of FQC; ③ We should confirm the number of packages to avoid mixed plates, wrong plates and package

12. Application of Aluminum LED PCB

1. Audio devices: input, output amplifier, balance amplifier, audio amplifier, preamplifier, power amplifier.

2. Power Supply: switching voltage regulator, DC/AC converter, SW voltage regulator, etc.

3. Communication electronic equipment: high frequency amplifier, filter, transmitter circuit

4. Office automation equipment: motor drive, etc

5. Automobile: electronic regulator, ignition device, power controller, etc.

6. Computer :CPU board, floppy disk drive, power equipment, etc.

7. Power module: converter, solid relay, rectifier bridge, etc

8. Lamps and lighting: A variety of colorful LED energy-saving lamps are well received by the market, and Aluminum LED PCB used in LED lights has also begun to be applied on a large scale.

13. Aluminum LED PCB Storage Conditions

Aluminum LED PCB are generally stored in a dark and dry environment. Most Aluminum LED tube lighting metal core pcb are prone to dampness, yellowing, and blackening. Generally, they should be used within 48 hours after opening the vacuum package.

14. Specification for the manufacture of Aluminum LED PCB

a. Aluminum LED PCB is often used in power devices, power density is high, so the copper foil is thicker. If copper foils over 3oz are used, the etching of thick copper foils requires engineered line width compensation, otherwise the line width will be out of tolerance after etching.

b. The aluminum base surface of aluminum substrate must be protected by protective film in advance during PCB processing, otherwise, some chemicals will etch the aluminum base surface, resulting in appearance damage. And the protective film is easy to be hurt, resulting in gaps, which requires the whole PCB processing process must be inserted.

c. The hardness of the milling cutter used by the glass fiber board gong board is relatively small, and the hardness of the milling cutter used by the aluminum substrate is large. In the process of manufacturing glass fiber board milling cutter speed, while the production of aluminum substrate is at least two thirds slower.

d, computer milling glass fiber board is just the use of the machine's own cooling system, but the processing of aluminum substrate must be in addition to alcohol heat dissipation for the gong head.

15. Aluminum LED PCB circuit fabrication

(1) Mechanical processing: Drilling of aluminum substrate can be done, but no burr is allowed on the edge of the inner hole after drilling, which will affect the pressure test. Milling the shape is very difficult. And punching shape, need to use advanced mold, mold production is very skilled, as one of the difficulties of aluminum substrate. After shape punching, the edge should be very neat, without any burr, and do not hurt the welding resistance layer on the edge of the plate. Usually the use of soldier die, hole from the line, shape from the aluminum surface, circuit board punching force is cut down, and so on are skills. After punching the shape, the warpage of the board should be less than 0.5%.

(2) The whole production process is not allowed to wipe the aluminum base surface: aluminum base touch, or by a certain chemical will produce surface discoloration, blackening, which is absolutely unacceptable, re-polishing aluminum base some customers do not receive, so the whole process does not touch the aluminum base surface is one of the difficulties in the production of aluminum base plate. Some enterprises use passivation process, some in hot air leveling (spray tin) before and after each pasted protective film.

(3) Over-high voltage test: the aluminum base board of the communication power supply shall be tested at 100% high voltage. Some customers require direct current or alternating current. The voltage shall be 1500V or 1600V, and the time shall be 5 seconds or 10 seconds. Dirt on the board, holes and aluminum edge burr, line saw tooth, damage to any little insulation layer will lead to high voltage test fire, leakage, breakdown. Pressure test board stratification, foaming, are rejected.

1 note

·

View note

Text

What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

6. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability

Aluminum-based printed boards are obviously much more stable in size than those made of insulating materials. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

(4) Other reasons

Aluminum based printed board, with shielding effect; Instead of brittle ceramic substrate; Safe use of surface mounting technology; Reducing the real effective area of the printed board; Instead of radiator and other components, improve the heat resistance and physical properties of products; Reduce production costs and labor.

7. Why choose Aluminum LED PCB from Hitechpcb? What are the advantages of Aluminum LED PCB?

(1) Good heat dissipation performance: Aluminum LED PCB can reduce the thermal resistance to the minimum, has a smaller thermal resistance, thermal expansion coefficient is closer to copper foil, so that Aluminum LED PCB has excellent thermal conductivity and heat dissipation performance, reduce the module operating temperature, prolong the service life.

High current load: Using the same thickness, the same line width, Aluminum LED PCB substrate can carry higher current.

(2) Good machinability: can replace ceramic substrate, better mechanical endurance. At the same time, high strength and toughness, can realize large area printed board manufacturing and component mounting.

(3) Good electromagnetic shielding: In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum LED PCB can act as a shield plate, play the role of shielding electromagnetic wave

(4) Environmental protection: The Aluminum LED PCB used in the raw material is non-toxic and can be recycled. Meet RoHs requirements.

(5)Light weight: Aluminum LED PCB has a surprisingly light weight with excellent strength and elasticity, which is very convenient.

Hitech Circuits can provide high quality and affordable Aluminum LED PCB products for you.

0 notes

Text

0 notes

Link

"The worldwide Copper Clad Laminate (CCL) and Prepreg market research has many advantages for busine

0 notes

Link

0 notes

Link

0 notes

Text

Printed Circuit Board Laminate Market: Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2022 – 2027

Lamination is a method of permanently joining materials together using heat, pressure, welding, or adhesives. This process enhances a material’s strength, durability, appearance, stability, and other qualities. Lamination of a circuit with a non-conductive material is known as printed circuit board (PCB) laminate. Pads, conductive tracks, and other features etched from copper sheets bonded onto a non-conductive substrate are used to link and support electronic components on PCB laminates. One copper layer PCBs, two copper layer PCBs, or outer and inner layer PCBs are all common uses for PCB laminations.

Request a Sample Report Here: https://crediblemarkets.com/sample-request/printed-circuit-board-laminate-market-385549

Printed Circuit Board Laminate Market: By Type

FR-4

High-Performance FR-4

High Tg Epoxy

BT Epoxy

Polyimide

Copper Clad (CCL)

Teflon

Printed Circuit Board Laminate Market: By Applications

Automotive

Communications

Industrial Electronics

Consumer Electronics

Aerospace & Defense

Others

Printed Circuit Board Laminate Market: Key Players

Ventec International Group

Isola

Elite Material Co., Ltd.

Rogers Corporation

SHENZHEN CATOS TECHNOLOGY CO., LIMITED

Shengyi Technology Co., Ltd.

Zhejiang huazheng electronic group co.,ltd.

Mica-AVA (Far East) Industrial Ltd

AGC Nelco

Taconic

Potential Advantages:

A thorough examination of current trends and forecasts for the PCB laminate market is offered.

The study examines the market’s competitive landscape, including growth trends, structure, driving forces, scope, opportunities, and challenges.

It involves a thorough examination of the important segments in order to shed light on market dynamics.

Porter’s Five Forces study exposes the buying and selling power of buyers and suppliers, as well as providing insights into the market’s competitive structure, allowing for more effective growth strategies and better decision-making.

Direct Buy This Report now@ https://crediblemarkets.com/reports/purchase/printed-circuit-board-laminate-market-385549?utf8=%E2%9C%93&license_type=single_user

Contact Us:

Credible Markets

99 Wall Street 2124 New York, NY 10005

Email- [email protected]

0 notes

Text

Printed Circuit Board Laminate Market: Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2021 – 2027

Lamination is a method of permanently joining materials together using heat, pressure, welding, or adhesives. This process enhances a material’s strength, durability, appearance, stability, and other qualities. Lamination of a circuit with a non-conductive material is known as printed circuit board (PCB) laminate. Pads, conductive tracks, and other features etched from copper sheets bonded onto a non-conductive substrate are used to link and support electronic components on PCB laminates. One copper layer PCBs, two copper layer PCBs, or outer and inner layer PCBs are all common uses for PCB laminations.

Request a Sample Report Here: https://crediblemarkets.com/sample-request/printed-circuit-board-laminate-market-385549

Printed Circuit Board Laminate Market: By Type

FR-4

High-Performance FR-4

High Tg Epoxy

BT Epoxy

Polyimide

Copper Clad (CCL)

Teflon

Printed Circuit Board Laminate Market: By Applications

Automotive

Communications

Industrial Electronics

Consumer Electronics

Aerospace & Defense

Others

Printed Circuit Board Laminate Market: Key Players

Ventec International Group

Isola

Elite Material Co., Ltd.

Rogers Corporation

SHENZHEN CATOS TECHNOLOGY CO., LIMITED

Shengyi Technology Co., Ltd.

Zhejiang huazheng electronic group co.,ltd.

Mica-AVA (Far East) Industrial Ltd

AGC Nelco

Taconic

Potential Advantages:

A thorough examination of current trends and forecasts for the PCB laminate market is offered.

The study examines the market’s competitive landscape, including growth trends, structure, driving forces, scope, opportunities, and challenges.

It involves a thorough examination of the important segments in order to shed light on market dynamics.

Porter’s Five Forces study exposes the buying and selling power of buyers and suppliers, as well as providing insights into the market’s competitive structure, allowing for more effective growth strategies and better decision-making.

Direct Buy This Report now@ https://crediblemarkets.com/reports/purchase/printed-circuit-board-laminate-market-385549?utf8=%E2%9C%93&license_type=single_user

Contact Us:

Credible Markets

99 Wall Street 2124 New York, NY 10005

Email- [email protected]

0 notes

Text

Copper Clad Laminate (CCL) and Prepreg Market 2022-2028 Size, Share, Trend, Key Palyers with Products

Copper Clad Laminate (CCL) and Prepreg Market 2022-2028

A New Market Study, Titled “Copper Clad Laminate (CCL) and Prepreg Market Upcoming Trends, Growth Drivers and Challenges” has been featured on fusionmarketresearch.

Description

This global study of the Copper Clad Laminate (CCL) and Prepreg market offers an overview of the existing market trends, drivers, restrictions, and metrics and also offers a viewpoint for important segments. The report also tracks product and services demand growth forecasts for the market. There is also to the study approach a detailed segmental review. A regional study of the global Copper Clad Laminate (CCL) and Prepreg industry is also carried out in North America, Latin America, Asia-Pacific, Europe, and the Near East & Africa. The report mentions growth parameters in the regional markets along with major players dominating the regional growth.

Request Free Sample Report @ https://www.fusionmarketresearch.com/sample_request/2021-2030-Report-on-Global-Copper-Clad-Laminate-(CCL)-and-Prepreg-Market/69024

This research covers COVID-19 impacts on the upstream, midstream and downstream industries. Moreover, this research provides an in-depth market evaluation by highlighting information on various aspects covering market dynamics like drivers, barriers, opportunities, threats, and industry news & trends. In the end, this report also provides in-depth analysis and professional advices on how to face the post COIVD-19 period.

The research methodology used to estimate and forecast this market begins by capturing the revenues of the key players and their shares in the market. Various secondary sources such as press releases, annual reports, non-profit organizations, industry associations, governmental agencies and customs data, have been used to identify and collect information useful for this extensive commercial study of the market. Calculations based on this led to the overall market size. After arriving at the overall market size, the total market has been split into several segments and subsegments, which have then been verified through primary research by conducting extensive interviews with industry experts such as CEOs, VPs, directors, and executives. The data triangulation and market breakdown procedures have been employed to complete the overall market engineering process and arrive at the exact statistics for all segments and subsegments.

Leading players of Copper Clad Laminate (CCL) and Prepreg including:

Kingboard Laminates Group

SYTECH

Panasonic

Nan Ya Plastic

EMC

ITEQ

DOOSAN

TUC

GDM International Technology Ltd.

Hitachi Chemical

Isola

Nanya New Material Technology Co., Ltd.

Rogers Corporation

Wazam New Materials

Chang Chun Group

Mitsubishi

Guangdong Goworld Lamination Plant

Ventec International Group

Sumitomo

AGC (Park Electro)

Market split by Type, can be divided into:

Copper Clad Laminate (CCL)

Prepreg

Market split by Application, can be divided into:

Consumer Electronics

Vehicle Electronics

Industrial/Medical

Military/Space

Market split by Sales Channel, can be divided into:

Direct Channel

Distribution Channel

Market segment by Region/Country including:

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Spain etc.)

Asia-Pacific (China, Japan, Korea, India, Australia and Southeast Asia etc.)

South America (Brazil, Argentina and Colombia etc.)

Middle East & Africa (South Africa, UAE and Saudi Arabia etc.)

Ask Queries @ https://www.fusionmarketresearch.com/enquiry.php/2021-2030-Report-on-Global-Copper-Clad-Laminate-(CCL)-and-Prepreg-Market/69024

Table of Contents

Chapter 1 Copper Clad Laminate (CCL) and Prepreg Market Overview

1.1 Copper Clad Laminate (CCL) and Prepreg Definition

1.2 Global Copper Clad Laminate (CCL) and Prepreg Market Size Status and Outlook (2015-2030)

1.3 Global Copper Clad Laminate (CCL) and Prepreg Market Size Comparison by Region (2015-2030)

1.4 Global Copper Clad Laminate (CCL) and Prepreg Market Size Comparison by Type (2015-2030)

1.5 Global Copper Clad Laminate (CCL) and Prepreg Market Size Comparison by Application (2015-2030)

1.6 Global Copper Clad Laminate (CCL) and Prepreg Market Size Comparison by Sales Channel (2015-2030)

1.7 Copper Clad Laminate (CCL) and Prepreg Market Dynamics (COVID-19 Impacts)

1.7.1 Market Drivers/Opportunities

1.7.2 Market Challenges/Risks

1.7.3 Market News (Mergers/Acquisitions/Expansion)

1.7.4 COVID-19 Impacts on Current Market

1.7.5 Post-Strategies of COVID-19 Outbreak

Chapter 2 Copper Clad Laminate (CCL) and Prepreg Market Segment Analysis by Player

2.1 Global Copper Clad Laminate (CCL) and Prepreg Sales and Market Share by Player (2018-2020)

2.2 Global Copper Clad Laminate (CCL) and Prepreg Revenue and Market Share by Player (2018-2020)

2.3 Global Copper Clad Laminate (CCL) and Prepreg Average Price by Player (2018-2020)

2.4 Players Competition Situation & Trends

2.5 Conclusion of Segment by Player

Chapter 3 Copper Clad Laminate (CCL) and Prepreg Market Segment Analysis by Type

3.1 Global Copper Clad Laminate (CCL) and Prepreg Market by Type

3.1.1 Copper Clad Laminate (CCL)

3.1.2 Prepreg

3.2 Global Copper Clad Laminate (CCL) and Prepreg Sales and Market Share by Type (2015-2020)

3.3 Global Copper Clad Laminate (CCL) and Prepreg Revenue and Market Share by Type (2015-2020)

3.4 Global Copper Clad Laminate (CCL) and Prepreg Average Price by Type (2015-2020)

3.5 Leading Players of Copper Clad Laminate (CCL) and Prepreg by Type in 2020

3.6 Conclusion of Segment by Type

Chapter 4 Copper Clad Laminate (CCL) and Prepreg Market Segment Analysis by Application

4.1 Global Copper Clad Laminate (CCL) and Prepreg Market by Application

4.1.1 Consumer Electronics

4.1.2 Vehicle Electronics

4.1.3 Industrial/Medical

4.1.4 Military/Space

4.2 Global Copper Clad Laminate (CCL) and Prepreg Revenue and Market Share by Application (2015-2020)

4.3 Leading Consumers of Copper Clad Laminate (CCL) and Prepreg by Application in 2020

4.4 Conclusion of Segment by Application

Continue…

ABOUT US:

Fusion Market Research is one of the largest collections of market research reports from numerous publishers. We have a team of industry specialists providing unbiased insights on reports to best meet the requirements of our clients. We offer a comprehensive collection of competitive market research reports from a number of global leaders across industry segments.

CONTACT US

Phone:

+ (210) 775-2636 (USA)

+ (91) 853 060 7487

0 notes

Text

The best material of thin PCB--BT FR4

With the thinning, multilayering, and increase of substrate-mounted components, especially the development of semiconductor mounting technologies such as BGA. MCM, the substrate is required to have high Tg, high heat resistance and low thermal expansion rate, so as to improve the interconnection of the board. And installation reliability; at the same time, with the development of communication technology and the improvement of computing processing speed, the dielectric properties of substrates have also begun to attract people's attention, requiring them to have lower dielectric constant and lower dielectric loss to meet signal transmission Speed and efficiency.To get more news about BT PCB, you can visit pcbmake official website.

BT (Bismaleimide-triazine) resin-based copper clad laminate (hereinafter referred to as BT board) has high Tg, excellent dielectric properties, low thermal expansion and other properties, making it a popular high-density interconnect (HDD). It has been widely used in multilayer PCBs and packaging substrates.

"BT" is the chemical trade name of a resin produced by Japan's Mitsubishi Gas Chemical Company. The resin is synthesized from bismaleimide (Bismaleimid, referred to as BMI) and cyanate ester (abbreviated as CE) resin. . As early as 1972, Ling Gas Chemical Company began the research on BT resin. By 1977, BT board began to be used in chip packaging soil, and then they continued in-depth research. By the end of the 1990s, more than a dozen varieties had been developed. , Different products can be made to meet different needs, such as high-performance copper clad laminate, chip carrier board, high-frequency application copper clad laminate, BT resin for packaging, resin-coated copper foil, etc. The demand for this type of sheet in the market is growing day by day.According to the survey results of the sales of various domestic glass cloth-based sheets in 1999 by Japan's JPCA, the sales of BT resin-based sheets are second only to FR-4 boards. , Reaching 36 billion yen.

Because of the importance of BT resin substrate, it has been listed in some authoritative standards in the world, such as EC 249-2-1994 as "No.18" board, IPG4101-1997 as "30" board: MIL-S- 13949H is defined as "GMr board, and the product standard formulated by JIS for this type of product is JS C-6494-1994. my country's national standard GB/T 4721-1992 also defines it as BT" board.

At present, BT boards on the market are dominated by products of Mitsubishi Gas Chemical Company. Only in recent years have some CCL manufacturers launch their BT boards, such as ISOLA and Hitachi Chemical. In China, the industrial production of BT boards is currently blank. However, with the development of the electronics industry and many foreign electronics industry manufacturers investing and building factories in mainland China, the demand for high-performance copper clad laminates in the domestic market is increasing. At present, there are already Research institutes have begun research on BT resin. For example, the BT resin developed by Wuxi Chemical Industry Research Institute has reached a certain level in performance, and Guangdong Shengyi Technology Co., Ltd. has also begun research on this type of sheet.

0 notes

Text

Different Growing Trends across Global PTFE CCL Market Outlook: Ken Research

Different Growing Trends across Global PTFE CCL Market Outlook: Ken Research

PTFE (Polytetrafluoroethylene) has properties like chemical resistance, flexibility, thermal resistance and low friction owing to which it is used in applications across various industries like aerospace, electronics and electrical, consumer goods and building & construction. CCL is a basic material of PCB which is laminated with copper clads and forms a basis of many electrical components. PTFE…

View On WordPress

#Global PTFE CCL Industry#Global PTFE CCL Industry Research Report#Global PTFE CCL Market#Global PTFE CCL Market Analysis#Global PTFE CCL Market Forecast#Global PTFE CCL Market Growth#Global PTFE CCL Market Outlook#Global PTFE CCL Market Research Report#Global PTFE CCL Market Revenue#Global PTFE CCL Market Share#Global PTFE CCL Market Size#Global PTFE CCL Market Trends#PTFE CCL Market

0 notes

Text

Global World Copper Clad Laminate Market Growth Drivers, Opportunities and Challenges 2025

Summary – A new 2015-2023 World Copper Clad Laminate Market Research Report by Product Type, End-User / Application and Regions / Countries-” has been featured on WiseGuyReports.

Summary

Copper clad laminate (CCL), a base material for electronics industry and an important raw material for the manufacturing of printed circuit board (PCB), is widely used in electronic products, including TV, radio, computer, and mobile communications.

ALSO READ: https://wiseguyreports.wordpress.com/2020/07/24/copper-clad-laminate-2020-global-industry-overview-companies-trend-and-forecast-to-2025/

This report includes market status and forecast of global and major regions, with introduction of vendors, regions, product types and end industries; and this report counts product types and end industries in global and major regions.

Market Segment as follows:

By Region / Countries

North America (U.S., Canada, Mexico)

Europe (Germany, U.K., France, Italy, Russia, Spain etc)

South America (Brazil, Argentina etc)

Middle East & Africa (Saudi Arabia, South Africa etc)

By Type

Paper board

Composite substrate

Normal FR4

High Tg FR-4

Halogen-free board

Special board

Others

By End-User / Application

Computer

Communication

Consumer Electronics

Vehicle electronics

Industrial & Medical

Military & Space

Package

By Company

KBL

SYTECH

Nan Ya plastic

Panasonic

ITEQ

EMC

Isola

DOOSAN

GDM

Hitachi Chemical

TUC

JinBao

Grace Electron

Shanghai Nanya

Ding Hao

GOWORLD

Chaohua

WEIHUA

...FOR MORE DETAILS: https://www.wiseguyreports.com/reports/2628172-2015-2023-world-copper-clad-laminate-market-research-report-by-product

About Us:

Wise Guy Reports is part of the Wise Guy Research Consultants Pvt. Ltd. and offers premium progressive statistical surveying, market research reports, analysis & forecast data for industries and governments around the globe.

Contact Us:

NORAH TRENT

Ph: +162-825-80070 (US)

Ph: +44 203 500 2763 (UK

0 notes

Text

Acute Growth of Special Copper Clad Laminate Market Opportunity Assessments 2019-2025

The Global Special Copper Clad Laminate Market Report 2019 aims to deliver an explicit evaluation of the market. Special copper clad laminates are mainly high-speed/high-frequency boards and package substrates, including: BT/epoxy glass fiber board, modified FR-4 (low CTE and low Dk/Df), PPO modified epoxy board, BT-like board , PTFE board, hydrocarbon board, PI / fiberglass board. Special CCL applications: IC carrier board, high speed digital, RF wireless, space, test The global Special Copper Clad Laminate market was xx million US$ in 2018 and is expected to xx million US$ by the end of 2025, growing at a CAGR of xx% between 2019 and 2025.

The report offers sweeping insights extracted by thoroughly analyzing historical and current developments in the market. It also provides par excellence futuristic estimations for various vital factors including Special Copper Clad Laminate market size, share, net profit, sales, revenue, and growth rate.

The market competition by top manufacturers/players, with sales volume, price (USD/Unit), revenue (Million USD) and market share for each manufacturer/player

The report covers the market study and projection of Special Copper Clad Laminate market on a territorial along with worldwide point . The report establishes subjective and quantitative valuation by industry examiners, direct information, help from industry specialists alongside their latest verbatim and every industry producers through the market value chain. The examination specialists have also evaluated the by and large sales and income creation of this specific market. Moreover, this report additionally conveys broad examination of basic market drift, many key essentials while overseeing macro-economic indicators, combined with market enhancements according to each section.

Get more information, Ask for Free Sample Copy of this Report@ https://www.acquiremarketresearch.com/sample-request/78173/

Some of the most prominent Key Vendors: Rogers, Mitsubishi Gas, Hitachi Chemical, Isola, Park Electrochemical, Panasonic Electrician, Doosan Electronics, TACONIC, NAN YA PLASTICS, SYTECH, Taiwan Union Technology Corporation (TUC)

Regions covered in the market report: North America (United States, Canada and Mexico), Europe (Germany, France, UK, Russia and Italy), Asia-Pacific (China, Japan, Korea, India and Southeast Asia), South America (Brazil, Argentina, Colombia etc.), Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

Key questions answered in this report

• What will the market size be in 2025 and what will the growth rate be?

• What are the key market trends?

• What is driving this market?

• What are the challenges to Special Copper Clad Laminate market growth?

• Who are the key vendors in this market space?

• What are the Special Copper Clad Laminate market opportunities and threats faced by the key vendors?

• What are the strengths and weaknesses of the key vendors?

For detailed information regarding Special Copper Clad Laminate market, Contact Us: https://www.acquiremarketresearch.com/industry-reports/special-copper-clad-laminate-market/78173/

Applications Segment Analysis: IC Carrier Board, High Speed Digital, RF Wireless, Space, Test

Product Segment Analysis: BT/epoxy fiberglass cloth board, Modified FR-4 (low CTE and low Dk/Df), PPO modified epoxy board, BT-like board, PTFE board, Hydrocarbon board, PI/glass fiber cloth board

Reasons to Purchase this Report

• Analyzing outlook of the Special Copper Clad Laminate market with the recent trends and Porter’s five forces analysis

• Market dynamics which essentially consider the factors, which are impelling the present market scenario, along with growth opportunities of the market in the years to come

• Market segmentation analysis, including qualitative and quantitative research incorporating the impact of economic and non-economic aspects

• Regional and country level analysis integrating the demand and supply forces that are influencing the growth of the Special Copper Clad Laminate market

• Competitive landscape involving the market share of major players, along with the key strategies adopted for development in the past five years

• Comprehensive company profiles covering the product offerings, key financial information,

Our experts and analysts evaluate the vendors in the Special Copper Clad Laminate market and provide understandings to articulate current and future market trends, innovation, customer expectations and competitive forces. The overviews, SWOT analysis and strategies of each vendor in the market provide understanding about the Special Copper Clad Laminate market forces and how those can be oppressed to create future opportunities.

0 notes

Text

Copper Clad Laminate (CCL) Market Analysis (2020-2027) | ITEQ, Panasonic, Nan Ya plastic

Latest Global Copper Clad Laminate (CCL) Market research report is an in-depth study of the industry including basic structures. This report features market revenue, share, development and market size. Also accentuate Copper Clad Laminate (CCL) industry contribution, product picture and provision. It examines a competitive summary of worldwide market forecast between period 2020 to 2025.

The Global Copper Clad Laminate (CCL) market report gives information covering market competition, creation, revenue, export, import, supply, utilization, market overview, market examination by applications and market impact factors analysis. These reports are resulting with market intelligence, economy and value. The report offers operational advisory and business intelligence on ‘Copper Clad Laminate (CCL) Market’, emphasizing on emerging business models, problematic advancements alongside point of reference investigation and achievement contextual analyses. It additionally covers the demand-supply gap, difficulties and specialty sections in the ecosystem

Get Free Sample Copy for more Professional and Technical insights at: https://www.globalinforeports.com/request-sample/1093658

Leading Players are:

ITEQ, Panasonic, Nan Ya plastic, SYTECH, KBL, Isola, DOOSAN, JinBao, TUC, Hitachi Chemical, GDM

The Copper Clad Laminate (CCL) report uttered an entire view of this market by substituting it when it comes to application as well as region. Trends examines regional segmentation integrates prospective and present requirement for them from the North America, Europe, Asia Pacific, South America, Middle East & Africa. The report covers the major applications of industry in the leading region.

Major Types are:

Normal FR4

Composite substrate

Paper board

High Tg FR-4

Halogen-free board

Special board

Others

Major Applications are:

Industrial & Medical

Vehicle electronics

Consumer Electronics

Communication

Computer

Military & Space

Package

Avail Discount on Report @ https://www.globalinforeports.com/check-discount/1093658

This Report will address some of the most important questions which are listed below:

Which is the main local/country for the development of the market? What is the anticipated growth rate of the leading regions during the forecast period?

What is the market size of the Copper Clad Laminate (CCL) market at the worldwide level?

Which mode of distribution channel is most preferred by the manufacturers of Copper Clad Laminate (CCL)?

What the key factors driving, inhibiting the growth of the market and what is the degree of impact of the drivers and restraints?

What is the impact of the regulations on the growth of the Copper Clad Laminate (CCL) market?

How are the emerging markets for Copper Clad Laminate (CCL) expected to act in the coming years?

Who are the major players working in the global Copper Clad Laminate (CCL) market? What is the present market position of the key players? Who are the rising players in this industry?

The Copper Clad Laminate (CCL) report stipulates economic scenarios with all the thing value, the principal area, benefits, distributions, limitations, creation, petition, market enhancement, and figure and so forth. The Copper Clad Laminate (CCL) report introduces speculation attainability evaluation, a task SWOT investigation, and venture yield evaluation.

Have Any Query? Ask Our Industry Experts @ https://www.globalinforeports.com/send-an-enquiry/1093658

Customization of this Report: This Copper Clad Laminate (CCL) report could be customized to the customer's requirements. Please contact our sales professional ([email protected]), we will ensure you obtain the report which works for your needs.

0 notes

Link

0 notes

Text

Asia Pacific Copper Clad Laminate (CCL) Market Report (2014-2024) - Market Size, Share, Price, Trend and Forecast

Asia Pacific Copper Clad Laminate (CCL) Market Report (2014-2024) – Market Size, Share, Price, Trend and Forecast

Asia Pacific Copper Clad Laminate (CCL) Market Report (2014-2024) – Market Size, Share, Price, Trend and Forecast

Abstract:

The Asia Pacific Copper Clad Laminate (CCL) market size is $XX million USD in 2018 with XX CAGR from 2014 to 2018, and it is expected to reach $XX million USD by the end of 2024 with a CAGR of XX% from 2019 to 2024.

This report is an essential reference…

View On WordPress

#Anti-Shock Trousers Market Analysis#Anti-Shock Trousers Market Forecast#Anti-Shock Trousers Market Share#Anti-Shock Trousers Market Size#Anti-Shock Trousers Market Trend#Anti-Shock Trousers Price

0 notes