#CrusherBackingCompound

Explore tagged Tumblr posts

Text

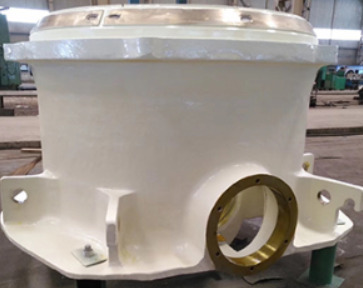

Crusher wear parts --Cone Crusher Main Frame

All of our cone crusher main frame is backed by our Quality Guarantee and are shipped only after meeting our rigorous quality standards. We are committed to meeting your replacement parts need in a professional and efficient manner. We have a larger inventory of wear parts for immediate deliveries. 100% drawing, same wear parts, but 1/3 price.

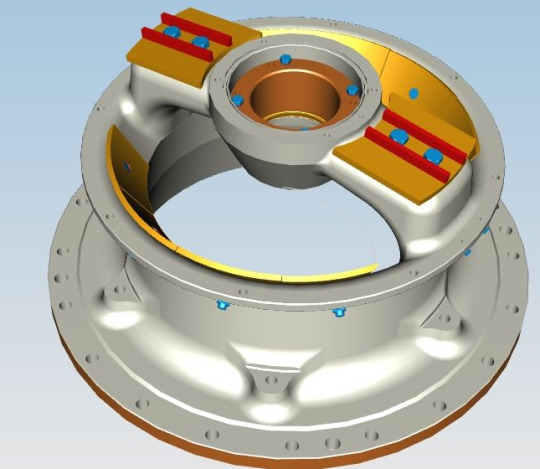

Our Cone Crusher Adjustment Rings Casting Details

• Hardness: 276-341 HB

• Minimum Tempering Temperature: 538 ℃

Benefits

Why Choose BDI Machinery Cone Crusher Main Frame?

• Over 30 years of casting experience

• Custom-fit for greater performance and easier replacement

• Cheaper price with better quality

• Design improvements increase crusher efficiency and prevent premature erosion

• Large inventory of Main Frame in stock for immediate deliveries

• Professional sales and after-sales to service for you

#CrusherWearParts#CrusherSpareParts#BallMillliners#BucketTeeth#ForgedSteelBalls#CrusherBackingCompound#ReverseEngineeringServices#WearParts#ConeCrusher#ManganeseSteel#StoneCrusher#EarthmovingMachine

0 notes

Text

crusher wear parts | BDI

BDI Wear Parts is a dynamic, fast-growing company with years of experience in the production, application and supply of crusher wear parts, spare parts, ball mill liners, bucket teeth, screen media, idler, and forged steel balls. We supply and ship parts across the globe to the USA, Canada, Europe, Australia, Africa and other countries.

BDI leverages its deep technical, industry and supply chain experience to help our customers improve their performance. Our service goes far beyond providing wear parts. We take great pride in helping our customers reduce costs, increase parts availability, minimize downtime and provide great after-sales service.

BDI’s experienced staff source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

Our very strong focus on providing high quality parts and applications advice enables BDI to help our customers continuously reduce capital and operational costs and improve production reliability. We take great pride in very positive feedback our customers provide us. This is the secret to our growth and our successful partnerships with our customers.

#CrusherWearParts #CrusherSpareParts #BallMillliners #BucketTeeth #ForgedSteelBalls #CrusherBackingCompound #ReverseEngineeringServices #LogwasherParts #WearParts #Cutting #EdgesCrushing #ScreeningEquipment #Quarry #Mining #ManganeseSteel #ConeCrusher #JawCrusher #ImpactCrusher #StoneCrusher #CrushingEquipment #CrusherReplacementParts #Earthmoving #EarthmovingMachine #HeavyEquipment #Aggregate #constructioIndustrial #AftermarketBucketTeeth #ExcavatorReplacement #identifyingExcavator #bucketTeeth #excavator

0 notes

Text

crusher wear parts | BDI

We have many case histories in which wear life increase of 60% are common, and some in which wear life increased up to 200%. BDI wear parts offers cone crusher liners styles than other manufacturers. Each of these designs has been developed for a customer seeking to improve cone crusher performance. Any type of crusher wear parts can get in best price Contact me in 1-647-898-7506 or [email protected]

www.bdiwearparts.com

#crusherbackingcompound #quarry #mining #conecrusherwearparts #crusher #crusherreplacementparts #heavyequipment #crushing #Aggregate #Reverseengineeringservices #construction

0 notes