#Cubic Block Graphite Heat Exchanger

Text

Graphite

Omega graphite is a well-known company for Manufacturers and suppliers of graphite in Mumbai, India graphite is widely used in various industrial applications due to its unique properties, including high thermal conductivity, chemical resistance, and low friction. Graphite equipment, such as heat exchangers, absorbers, and distillation columns, can provide excellent performance in demanding environments where corrosion resistance and thermal efficiency are critical.

Call Us: +919820045787 | Email Us: [email protected] | Visit Our Website: https://www.omegagraphite.com/

#Graphite#Graphite Heat Exchanger#Graphite Condensers#Graphite Cooler#Cubic Block Graphite Heat Exchanger#Cylindrical Block Graphite Heat Exchanger

0 notes

Text

Graphite block heat exchanger

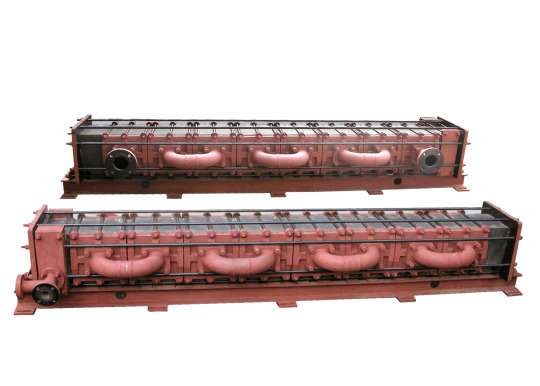

Graphite block heat exchangers are suitable for the heating, cooling, evaporation, condensation, and absorption of highly corrosive liquid chemicals. It is one of the most versatile types of impervious graphite heat exchangers. The process and service channels are formed by drilling rows of holes horizontally and vertically through graphite blocks. Heat is transferred by conduction through the impervious graphite left between the rows of holes that separate the media. Graphite block heat exchangers consist of a stack of blocks enclosed in a steel shell.

Why Use Graphite in Heat Exchangers?

Due to its thermal and physical properties, graphite is an excellent heat transfer medium. These are some of its advantages:

Exceptional thermal conductivity

Easily machined

Capable of withstanding system stresses

Superior corrosion resistance

Low coefficient of thermal expansion (CTE)

High operational safety

Long service life

Benefits Of Graphite Block Heat Exchanger

High corrosion resistance of Graphilor® 3

Compactness

Robustness

Modular design

Easy maintenance

Long lifetime

Service and maintenance in the US with two strategically located facilities

Manufacturing plant in the US

Materials

Impervious graphite: GAB GPX1, GPX1T or GPX2

Shell, Pressure plates and flanges: carbon steel or stainless steel

Tie rods, nuts, bolts, washers, springs: stainless steel

PTFE gaskets between the blocks

Design

Totally modular design: number of blocks, size of blocks and number of passes can be adjusted

Different drilling diameters on process and service sides

Maximum block diameter: 900 mm

Graphite nozzles on product side

Thermal expansion compensation ensured by tie rods and helical springs

Key Features

Design pressure: -1 barg (full vacuum) to +10 barg (145 psig)

Design temperature: -60 to +200°C (-76 to 392°F)

Heat transfer area: up to 163 m2 (1755 ft2)

Design: according to European PED, ASME code, Chinese Pressure Vessel code and other national pressure vessel codes on request

Key Benefits

Outstanding corrosion resistance on one side or on both sides

Good heat transfer performance thanks to adjustable cross sections on both sides

Large transfer areas and comparatively low pressure drop on the product side

Easy disassembly and ability to mechanically clean each block

Impregnation before machining ensures resin free surfaces

Single or double-row drillings on product side

High operational safety

Sturdy and modular design

Short lead time

Long lifetime

Optional features

Removable headers for easy mechanical cleaning

Rubber lined, glass lined or PTFE lined shell for corrosive fluids on shell side

Protection against abrasion

Sight glass

Main applications

Cooling, condensation, heating, evaporation and absorption of ultra-corrosive chemicals

Heat transfer between two ultra-corrosive chemicals

Best suited for single purpose units

Types of Graphite Heat Exchangers for Corrosive Environments

Graphite heat exchangers are available in many designs and configurations to suit different heat transfer processes. These include:

Shell and Tube Graphite Heat Exchangers

Imperative shell and tube heat exchangers are engineered for superior reliability and longevity. When compared to other graphite heat exchangers, they offer exceptional performance and a low initial cost, resulting in an excellent lifetime return on investment. The large cross-sectional area makes them ideal for low pressure and fouling applications.

Multi-Blox Graphite Heat Exchangers

Our Multi-BloxTM heat exchanger features some of the longest graphite composite blocks in the industry. The design reduces the need for gaskets, eliminates leak paths, and minimises point loading. With a maximum operating pressure of 150 PSIG, they are designed for non-stop service.

Cubic Block Graphite Heat Exchangers

The most efficient cubic block heat exchangers on the market with the highest heat transfer capabilities in the smallest area are available from us. They are easy to clean and maintain, and they are exceptionally durable. They are therefore ideal for interchange service and high-fouling applications.

To find out more about this article, please click here : https://sa179tubes.com/graphite-block-heat-exchanger/

#sa179 #satubes #steelpipe #steeltubes #SA179Tubes #SA179TUBES

0 notes

Link

The Global Heat Exchanger Market is anticipated to reach USD 33.01 billion by 2026 according to a new study published by Polaris Market Research. Heat exchanger is a very dynamic industry concerning raw materials, equipment manufacturing and end-use industries. A heat exchanger primarily works on the principle of convection and conduction for making transfer of thermal energy in the required processes. New technological developments and increased demand for energy-efficiency in almost every industrial and commercial sector around the globe has been a force majeure for the global heat exchangers market.

This industrial equipment is available of different types such as shell & tube, plate & frame, graphite and other heat exchangers types. Each type of heat exchanger includes its own set of pros and cons and is generally compared on the basis of purchase cost, installation cost, operating cost, and maintenance cost. Some of the primary criteria for choosing a particular type of heat exchanger includes operating pressure & temperature, application, available utilities, characteristics of the fluids, plot plan & layout constraints, considerations for future expansions, and mechanical considerations.

Request for sample copy of this report @ https://www.polarismarketresearch.com/industry-analysis/heat-exchangers-market/request-for-sample

The global market has significantly evolved around the technological efficiency of the products, their raw materials and government initiatives for energy efficiency across the world. The change in consumer preference towards utilization of energy-efficient products, buildings and construction has also played a significant part in this gain.

Manufacturing practices in chemicals & petrochemical plants and up gradations of plants and facilities has also resulted in reduced carbon emissions contributing to the global climate mandates. Reduction of volatile organic compounds in environment and specific regulations adopted specifically in European, American and Asian countries such as China has greatly affected the sustainability factor.

The heat exchanger market has also evolved in terms of advanced & innovative products for better & sustainable thermal efficiency in many operating utilities such as power generation by making use of renewable sources.

Asia Pacific industry is projected to be the largest market for the equipment sale in terms of revenue and volume both. The shift from western industrialization to the Asia Pacific has been the primary factor for driving this regional industry. The business operators or primarily the manufacturers have become increasingly and exceptionally globalized to make out higher value for cost and, simultaneously, compete to fulfill the rapidly emerging expertise in the Asian market. North America is yet another potential market with an established manufacturing base.

The industry is highly fragmented in nature with many significant market players worldwide. Some of the global key manufacturers include Alfa Laval AB, Hughes Anderson, Kelvion Holdings GmbH, Koch Heat Transfer Co., SPX Corporation, HRS Heat Exchangers Ltd., Xylem Inc., AOI Heat Transfer Inc., and Hindustan Dorr-Oliver Ltd

Key Segment Outlook

Product Type

Shell & tube

Plate & frame

Air cooled

Extended surface

Heat sinks

Regenerative

Printed circuit heat exchanger (PCHE)

Others

U- tube heat exchanger

Straight Tube (1 Pass Tube Side)

Straight Tube (2 Pass Tube Side)

Gasket plate & frame heat exchangers

Welded plate & frame heat exchangers

Brazed heat exchangers

Materials Segments

Carbon steel

Stainless steel

Nickel

Others

Graphite Shell & Tube Segments

Cubic Heat Exchangers

Graphite Block Heat Exchangers

Polytube Graphite Shell & Tube Block Heat Exchangers

Application

Pulp & Paper

Automotive

Healthcare

Chemical

Electronics

Petrochemicals and Oil & Gas

Food & beverage

HVACR

Others

Region

North America

Europe

Asia-Pacific

Latin America

Middle East and Africa

U.S.

Canada

Germany

UK

France

Rest of Europe

China

India

Japan

South Korea

Rest of Asia-Pacific

Brazil

Mexico

Rest of Latin America

Request for Discount on This Report @ https://www.polarismarketresearch.com/industry-analysis/heat-exchangers-market/request-for-discount-pricing

About Polaris Market Research

Polaris Market Research is a global market research and consulting company. The company specializes in providing exceptional market intelligence and in-depth business research services for our clientele spread across different enterprises. We at Polaris are obliged to serve our diverse customer base present across the industries of healthcare, technology, semi-conductors and chemicals among various other industries present around the world

Contact us

Polaris Market Research

Phone: 1-646-568-9980

Email: [email protected]

Web: www.polarismarketresearch.com

0 notes

Text

Heat Exchanger Market Industry Analysis, Size, Share, Growth, Trends, and Forecast 2026

The global Heat Exchanger Market is anticipated to reach USD 33.01 billion by 2026 according to a new study published by Polaris Market Research. Heat exchanger is a very dynamic industry concerning raw materials, equipment manufacturing and end-use industries. A heat exchanger primarily works on the principle of convection and conduction for making transfer of thermal energy in the required processes. New technological developments and increased demand for energy-efficiency in almost every industrial and commercial sector around the globe has been a force majeure for the global heat exchangers market.

This industrial equipment is available of different types such as shell & tube, plate & frame, graphite and other heat exchangers types. Each type of heat exchanger includes its own set of pros and cons and is generally compared on the basis of purchase cost, installation cost, operating cost, and maintenance cost. Some of the primary criteria for choosing a particular type of heat exchanger includes operating pressure & temperature, application, available utilities, characteristics of the fluids, plot plan & layout constraints, considerations for future expansions, and mechanical considerations.

Get Sample Copy @: https://www.polarismarketresearch.com/industry-analysis/heat-exchangers-market/request-for-sample

The global market has significantly evolved around the technological efficiency of the products, their raw materials and government initiatives for energy efficiency across the world. The change in consumer preference towards utilization of energy-efficient products, buildings and construction has also played a significant part in this gain.

Manufacturing practices in chemicals & petrochemical plants and up gradations of plants and facilities has also resulted in reduced carbon emissions contributing to the global climate mandates. Reduction of volatile organic compounds in environment and specific regulations adopted specifically in European, American and Asian countries such as China has greatly affected the sustainability factor.

The heat exchanger market has also evolved in terms of advanced & innovative products for better & sustainable thermal efficiency in many operating utilities such as power generation by making use of renewable sources.

Asia Pacific industry is projected to be the largest market for the equipment sale in terms of revenue and volume both. The shift from western industrialization to the Asia Pacific has been the primary factor for driving this regional industry. The business operators or primarily the manufacturers have become increasingly and exceptionally globalized to make out higher value for cost and, simultaneously, compete to fulfill the rapidly emerging expertise in the Asian market. North America is yet another potential market with an established manufacturing base.

The industry is highly fragmented in nature with many significant market players worldwide. Some of the global key manufacturers include Alfa Laval AB, Hughes Anderson, Kelvion Holdings GmbH, Koch Heat Transfer Co., SPX Corporation, HRS Heat Exchangers Ltd., Xylem Inc., AOI Heat Transfer Inc., and Hindustan Dorr-Oliver Ltd.

Any Special Requirement | Speak to our Industry Expert @: https://www.polarismarketresearch.com/industry-analysis/heat-exchangers-market/speak-to-analyst

Key Segment Outlook

Product Type

U- tube heat exchanger

Straight Tube (1 Pass Tube Side)

Straight Tube (2 Pass Tube Side)

Gasket plate & frame heat exchangers

Welded plate & frame heat exchangers

Brazed heat exchangers

Materials Segments

Carbon steel

Stainless steel

Nickel

Others

Graphite Shell & Tube Segments

Cubic Heat Exchangers

Graphite Block Heat Exchangers

Polytube Graphite Shell & Tube Block Heat Exchangers

Application

Pulp & Paper

Automotive

Healthcare

Chemical

Electronics

Petrochemicals and Oil & Gas

Food & beverage

HVACR

Others

Region

S.

Canada

Germany

UK

France

Rest of Europe

China

India

Japan

South Korea

Rest of Asia-Pacific

Brazil

Mexico

Rest of Latin America

Purchase This Report @: https://www.polarismarketresearch.com/checkouts/3231

About Polaris Market Research

Polaris Market Research is a global market research and consulting company. The company specializes in providing exceptional market intelligence and in-depth business research services for our clientele spread across different enterprises.

Contact Us:

Polaris Market Research

Phone: 1–646–568–9980

Email: [email protected]

Web: www.polarismarketresearch.com

0 notes

Text

Heat Exchanger Market : Industry Perspective, Comprehensive Analysis

Heat Exchanger Market : Industry Perspective, Comprehensive Analysis

The report “Heat Exchangers Market [By Product Type (Shell & Tube (U-Tube, Straight Tube (1 & 2 Pass Tube Side)), Plate & Frame (Gasket, Welded, Brazed), Air Cooled, Extended Surface, Heat Sinks, Regenerative, Printed Circuit (PCHE)); By Material of Construction (Carbon Steel, Stainless Steel, Nickel, Others); By Graphite Heat Exchanger (Cubic, Graphite Block, Polytube Graphite Shell & Tube…

View On WordPress

0 notes

Text

Cubic Block Graphite Heat Exchanger

omega graphite is a Leading company for Manufacturers and suppliers of Cubic Block Graphite Heat Exchanger, Cubic block type graphite heat exchangers consist of cube-shaped graphite blocks assembled and bolted together. Each cubic block consists of two sets of holes, one set of holes axially carrying the corrosive process to adjacent blocks. We are the best manufacturer, supplier of cubic block type graphite heat exchangers in Mumbai, India, UAE and Saudi Arabia, Brazil. media while another set of holes runs perpendicular to the axial holes carrying the service media. Heat transfer occurs by conduction through the graphite material that separates the two sets of pores. Cubic block heat exchangers are available in horizontal and vertical mounting designs.

Call Us: +919820045787 | Email Us: [email protected] | Visit Our Website: https://www.omegagraphite.com/

#graphite#cubic block graphite heat exchanger#cylindrical block graphite heat exchanger#shell & tube graphite heat exchanger#graphite powder#graphite condensers

0 notes

Text

#Graphite#Graphite Heat Exchanger#Graphite Condensers#Graphite Cooler#Cubic Block Graphite Heat Exchanger#Cylindrical Block Graphite Heat Exchanger#Shell & Tube Graphite Heat Exchanger#Graphite Reboilers

0 notes

Text

#Graphite#Graphite Heat Exchanger#Graphite Condensers#Graphite Cooler#Cubic Block Graphite Heat Exchanger#Cylindrical Block Graphite Heat Exchanger#Shell & Tube Graphite Heat Exchanger#Graphite Reboilers

0 notes

Text

#Graphite#Graphite Heat Exchanger#Graphite Condensers#Graphite Cooler#Cubic Block Graphite Heat Exchanger#Cylindrical Block Graphite Heat Exchanger#Shell & Tube Graphite Heat Exchanger#Graphite Reboilers

0 notes

Text

Cubic Block Type Graphite Heat Exchangers

#Graphite#Graphite Heat Exchanger#Graphite Condensers#Graphite Cooler#Cubic Block Graphite Heat Exchanger#Cylindrical Block Graphite Heat Exchanger#Shell & Tube Graphite Heat Exchanger#Graphite Reboilers

0 notes

Text

Unveiling the Power of Graphite: Exploring Our No.1 Omega Graphite Company's Innovations

Welcome to the blog of Our No.1 Omega Graphite Company! Here, we delve into the world of graphite and its myriad applications, showcasing our expertise as leading manufacturers in the industry. From cutting-edge Graphite Heat Exchangers to essential Graphite Condensers and beyond, we are dedicated to pushing the boundaries of what this remarkable material can achieve.

Graphite Heat Exchangers: Revolutionizing heat transfer with our innovative designs, our Graphite Heat Exchangers offer unparalleled efficiency and durability. Whether it's Cubic Block or Cylindrical Block configurations, we provide solutions tailored to meet your specific needs.

Graphite Condensers and Coolers: Our Graphite Condensers and Coolers set the standard for reliability and performance in demanding environments. Designed to withstand corrosive substances and extreme temperatures, they ensure optimal operation and minimal maintenance.

Shell & Tube Graphite Heat Exchangers: Combining versatility with efficiency, our Shell & Tube Graphite Heat Exchangers excel in diverse applications, from chemical processing to pharmaceutical production. With customizable configurations, we provide solutions that adapt to your workflow seamlessly.

Graphite Reboilers and Falling Film Evaporators: Enhancing process efficiency and productivity, our Graphite Reboilers and Falling Film Evaporators offer superior heat transfer capabilities, enabling precise control over evaporation processes.

Specialized Solutions: Beyond traditional heat exchangers and evaporators, we offer a range of specialized solutions to address unique challenges in industries such as chemical processing and petrochemical refining. From HCL Absorbers to Sulphuric Acid Dilutors and Dilution Coolers, our comprehensive portfolio caters to diverse requirements.

Graphite Ejectors and HCL Synthesis Plants: Leveraging our expertise in graphite technology, we deliver advanced solutions for gas handling and synthesis processes. Our Graphite Ejectors and HCL Synthesis Plants optimize efficiency while ensuring safety and reliability.

Graphite Distillation Columns and Accessories: Enabling precise separation and purification processes, our Graphite Distillation Columns and Accessories meet the highest standards of quality and performance. From tubes and fittings to pumps, we provide complete solutions for your distillation needs.

Global Presence: With a strong presence in India, Mumbai, Saudi Arabia, UAE, Brazil, and beyond, we serve customers worldwide with dedication and excellence. Our commitment to quality, innovation, and customer satisfaction drives us to continually exceed expectations.

At Our No.1 Omega Graphite Company, we are passionate about harnessing the potential of graphite to empower industries and drive progress. Join us on this journey as we continue to innovate and redefine possibilities in graphite technology.

Stay tuned for more insights, updates, and success stories from the forefront of graphite manufacturing. Together, let's unlock the full potential of this remarkable material and shape a brighter future for generations to come.

For inquiries and partnerships, please contact us at [Contact Us At: [email protected] | 9820045787 | https://www.omegagraphite.com].

#Graphite#Graphite Heat Exchanger#Graphite Condensers#Graphite Cooler#Cubic Block Graphite Heat Exchanger#Cylindrical Block Graphite Heat Exchanger#Shell & Tube Graphite Heat Exchanger#Graphite Reboilers#Falling Film Evaporators#HCL Absorber#Sulphuric Acid Dilutor#Sulphuric Acid Dilution Coolers#Graphite Ejectors#HCL Synthesis Plant#Graphite Distillation Column#Graphite Tubes#Graphite Fittings#Graphite Pump

0 notes

Text

#Graphite#Graphite Heat Exchanger#Graphite Condensers#Graphite Cooler#Cubic Block Graphite Heat Exchanger#Cylindrical Block Graphite Heat Exchanger#Shell & Tube Graphite Heat Exchanger#Graphite Reboilers

0 notes

Text

#Graphite#Graphite Heat Exchanger#Graphite Condensers#Graphite Cooler#Cubic Block Graphite Heat Exchanger#Cylindrical Block Graphite Heat Exchanger#Shell & Tube Graphite Heat Exchanger#Graphite Reboilers

0 notes

Text

Innovating Heat Transfer Solutions with Omega Graphite: Your Partner for Graphite Excellence

Welcome to the official blog of Omega Graphite, a leading manufacturer of premium graphite products catering to a diverse range of industries across India, Mumbai, UAE, Saudi Arabia, and Brazil. With a commitment to innovation and quality, we specialize in providing cutting-edge solutions for heat transfer applications, including graphite heat exchangers, condensers, coolers, and much more. Join us as we explore the capabilities of graphite and its pivotal role in industrial processes.

Our Product Portfolio

At Omega Graphite, we offer a comprehensive range of graphite products designed to optimize heat transfer efficiency and reliability. Here's an overview of our extensive product portfolio:

Graphite Heat Exchangers: Engineered to withstand extreme temperatures and corrosive environments, our graphite heat exchangers ensure efficient heat transfer in various chemical processing, pharmaceutical, and petrochemical applications.

Graphite Condensers: Designed for condensing vapors into liquids, our graphite condensers offer superior thermal conductivity and resistance to thermal shock, making them ideal for cooling and distillation processes.

Graphite Coolers: Utilizing the exceptional heat dissipation properties of graphite, our coolers are capable of efficiently dissipating heat from industrial equipment and processes, ensuring optimal performance and reliability.

Cubic Block Graphite Heat Exchangers: Featuring a unique cubic block design, our graphite heat exchangers provide enhanced surface area for improved heat transfer efficiency, resulting in reduced energy consumption and operating costs.

Cylindrical Block Graphite Heat Exchangers: With their cylindrical block configuration, our graphite heat exchangers offer efficient heat exchange in compact, space-saving designs, suitable for a wide range of applications.

Shell & Tube Graphite Heat Exchangers: Combining the versatility of shell and tube designs with the superior thermal conductivity of graphite, our heat exchangers deliver optimal heat transfer performance in diverse industrial processes.

Graphite Reboilers: Engineered for use in distillation and evaporation systems, our graphite reboilers ensure efficient vaporization of liquids by providing consistent heat transfer, contributing to higher productivity and product quality.

HCL Synthesis Plant: Our graphite products play a crucial role in HCL synthesis plants, where they are used in various process equipment such as reactors, heat exchangers, and distillation columns, facilitating the production of high-purity hydrochloric acid.

Graphite Distillation Columns: Tailored to meet the stringent requirements of distillation processes, our graphite distillation columns offer exceptional resistance to corrosion and thermal shock, ensuring reliable separation of chemical components.

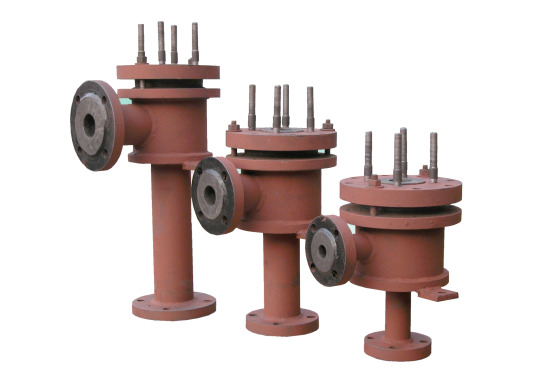

Graphite Tubes and Fittings: We offer a wide range of graphite tubes and fittings, including piping, elbows, tees, and flanges, designed to provide seamless integration and compatibility with graphite heat exchangers and process equipment.

Graphite Pump: Our graphite pumps are engineered to handle corrosive and abrasive fluids with ease, making them suitable for a wide range of industrial applications, including chemical processing, wastewater treatment, and mining.

Why Choose Omega Graphite?

Expertise and Innovation: With years of experience and expertise in graphite technology, we continuously innovate and develop advanced solutions to meet the evolving needs of our customers.

Quality Assurance: We adhere to stringent quality standards throughout the manufacturing process to ensure that our products meet the highest levels of performance, reliability, and safety.

Global Presence: With strategic locations in India, Mumbai, UAE, Saudi Arabia, and Brazil, we provide localized support and timely delivery to customers worldwide, fostering strong partnerships and lasting relationships.

Customer-Centric Approach: At Omega Graphite, customer satisfaction is our top priority. We work closely with our clients to understand their specific requirements and provide customized solutions that meet or exceed their expectations.

Stay tuned to our blog for insightful articles, industry trends, and product updates. For inquiries or assistance, feel free to contact us. Omega Graphite—Your Trusted Partner for Innovative Heat Transfer Solutions.

Contact Us At: [email protected] | 9820045787 | https://www.omegagraphite.com

#Graphite#Graphite Heat Exchanger#Graphite Condensers#Graphite Cooler#Cubic Block Graphite Heat Exchanger#Cylindrical Block Graphite Heat Exchanger#Shell & Tube Graphite Heat Exchanger#Graphite Reboilers

0 notes

Text

#Graphite#Graphite Heat Exchanger#Graphite Condensers#Graphite Cooler#Cubic Block Graphite Heat Exchanger#Cylindrical Block Graphite Heat Exchanger#Shell & Tube Graphite Heat Exchanger#Graphite Reboilers

0 notes

Text

0 notes