#DefectDetection

Text

Enhance quality control with Loopr IQ Inspect, the leading visual defect detection solution. Streamline your procedures and improve product quality effortlessly.

0 notes

Text

How AI and Machine Learning are Transforming Defect Detection in Manufacturing

In manufacturing, AI and machine learning have emerged as game changers, notably in defect identification. These technologies change traditional quality control approaches by increasing precision and efficiency.

1. Enhanced Accuracy Through AI: AI systems excel in detecting even little variations or flaws in manufactured items. AI-powered systems may detect abnormalities with unprecedented precision by evaluating massive volumes of data, reducing false positives and negatives.

2. Speed and Efficiency: Machine learning techniques allow for rapid processing of inspection data, considerably lowering the time necessary for fault identification. This speed not only increases output, but also allows manufacturers to handle concerns quickly, reducing manufacturing delays.

3. Adaptability to Complex Scenarios: AI-powered defect detection systems are adaptable to a variety of industrial settings and product kinds. AI may adjust its approach to specific industrial requirements, such as detecting faults in complex electrical components or structural issues in car parts.

4. Predictive Maintenance and Optimization: Aside from finding flaws, AI may anticipate possible problems before they exist. Manufacturers can use predictive maintenance models to solve machinery or process defects ahead of time, increasing production efficiency and minimizing downtime.

5. Continuous Improvement and Innovation: AI and machine learning algorithms improve over time as they continue to learn from data. This recurrent learning process enables manufacturers to constantly improve defect detection technologies, staying ahead of changing quality requirements.

At last, AI and machine learning have the potential to change industrial defect detection. These technologies not only improve precision and efficiency, but also give producers the potential to attain greater levels of product quality and reliability. As more sectors adopt AI-powered solutions, the future of defect detection in manufacturing appears bright, with improvements positioned to boost innovation and competitiveness in global marketplaces.

By incorporating AI into defect detection systems, manufacturers may place themselves at the cutting edge of technological innovation, assuring rigorous quality control and operational excellence in an increasingly complicated industrial world.

0 notes

Text

What Is AOI? Automated Optical Inspection In PCB

Automated Optical Inspection (AOI) is a critical technology in PCB manufacturing. It uses high-resolution cameras and sophisticated software to rapidly and accurately inspect for defects such as misalignments, missing components, and soldering issues. By automating the inspection process, AOI ensures consistent quality, reduces human error, and increases production speed. Read more https://viewmm.com/en/aoi/

0 notes

Text

Non-Destructive Testing: Trends, Challenges, and Future Outlook of the Global Market

The global non-destructive testing market size is anticipated to reach USD 34,148.1 million by 2030, registering a CAGR of 7.9% from 2023 to 2030, according to a new report by Grand View Research, Inc. The market is expected to experience substantial growth during the forecast period. This growth can be attributed to the increasing manufacturing activities in both developing and developed nations.

Non-destructive Testing Market Report Highlights

The market is expected to exhibit a CAGR of 7.9% over the next eight years owing to a rise in manufacturing-related activities, globally

The services segment accounted for the largest revenue share of over 75.0% in 2022. The high upfront cost of non-destructive equipment coupled with technical complexities involved in their deployment/installation is the major reason influencing end-users to outsource their non-destructive testing operations

Rapid industrialization, especially in developing economies has significantly contributed to the growth of the market

The manufacturing vertical segment was the dominant segment in 2022 and is expected to witness a healthy CAGR of 9.3% over the forecast period owing to the increased manufacturing activities primarily in Asia Pacific.

North America dominated the market in 2022 and accounted for the largest revenue share of more than 36.0%, owing to the extensive adoption of NDT techniques in the region

For More Details or Sample Copy please visit link @: Non-destructive Testing Market Report

The application of non-destructive testing (NDT) plays a crucial role in precise fault detection, effectively reducing the probability of product/component failures and associated repair costs. NDT also accelerates the manufacturing process by eliminating potential faults beforehand. The market is expected to be driven by the advancements in non-destructive testing methods, as these technological improvements ensure accurate fault detection and significantly reduce the complexity of testing procedures.

The ultrasonic testing segment is projected to experience substantial growth, which can be attributed to factors such as the equipment's user-friendly nature, the presence of skilled technicians, and the precise detection of faults. Furthermore, the manufacturing segment is anticipated to extensively adopt NDT techniques during the forecast period due to the growing awareness of their benefits and applications.

#NonDestructiveTesting#NDT#StructuralSafety#TestingTechnologies#IndustrialInspection#DefectDetection#MaterialsTesting#UltrasonicTesting#RadiographicTesting#VisualInspection#NDTMethods#NDTEquipment#NDTServices#SafetyStandards#RiskAssessment#QualityControl#NDTIndustry

0 notes

Text

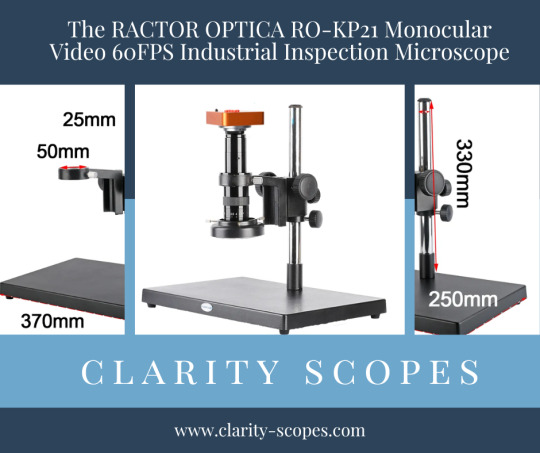

Upgrade your inspection processes with the RACTOR OPTICA RO-KP21 Monocular Video 60FPS Industrial Inspection Microscope. And now, for a limited time only, enjoy our exclusive 15% Spring Sales Offer! Don't miss out on this fantastic opportunity to save while revolutionizing your inspection capabilities.

Visit our website now to learn more about the RACTOR OPTICA RO-KP21 and take advantage of our 15% Spring Sales Offer.

🌐 Visit our website at RACTOR OPTICA RO-KP21 Monocular Video 60FPS Industrial inspection Micr – Clarity Scopes (clarity-scopes.com)... for more details.

✅ Limited time offer, so act fast!

#IndustrialInspection#Microscope#QualityControl#Precision#Efficiency#Technology#Manufacturing#Engineering#Innovation#Productivity#DigitalIntegration#VisualPrecision#DefectDetection#IndustrialAutomation#OpticalInstruments#InspectionTools#QualityAssurance#ResearchAndDevelopment#HighDefinitionImaging#AdvancedTechnology

0 notes

Text

Enhancing Quality Control with Automated Optical Inspection Systems

Automated Optical Inspection (AOI) systems revolutionize quality control processes in manufacturing industries.

https://www.globalinsightservices.com/request-sample/GIS10138

These systems utilize high-resolution cameras and advanced image processing algorithms to detect defects in products with incredible precision and speed. By automating the inspection process, AOI systems eliminate human error and ensure consistent and reliable results, leading to improved product quality and reduced production costs. With their ability to detect defects such as scratches, chips, misalignments, and missing components, AOI systems play a crucial role in maintaining high standards throughout the manufacturing process.

#AOI #QualityControl #Manufacturing #Automation #DefectDetection #ImageProcessing #Precision #Speed #ProductQuality #CostReduction #Efficiency #Consistency #Technology #Innovation #ManufacturingIndustry

0 notes

Text

Navigating Precision: The Rise of Semiconductor Metrology and Inspection Market

In the ever-evolving realm of semiconductor technology, precision is paramount. The Semiconductor Metrology and Inspection Market stands at the forefront, embracing cutting-edge techniques to ensure the quality and efficiency of semiconductor production. With the surge in demand for smaller, faster, and more powerful chips, the market witnesses a proliferation of advanced metrology and inspection solutions, catering to the intricate needs of semiconductor manufacturers worldwide.

From nanoscale measurements to defect detection, the Semiconductor Metrology and Inspection Market is driven by innovation and technological prowess. As the industry delves deeper into the realms of nanotechnology and quantum computing, the demand for highly accurate metrology tools skyrockets. Advanced imaging techniques, such as electron microscopy and atomic force microscopy, coupled with AI-driven analytics, redefine the landscape, enabling unprecedented levels of precision and efficiency in semiconductor fabrication processes.

In a landscape where every nanometer counts, reliability is non-negotiable. The Semiconductor Metrology and Inspection Market is characterized by a relentless pursuit of perfection, as manufacturers strive to eliminate defects and optimize yields. Real-time monitoring, augmented reality overlays, and predictive analytics emerge as game-changers, empowering semiconductor fabs to maintain stringent quality standards while maximizing productivity. With the advent of 5G, IoT, and AI applications, the market witnesses a paradigm shift towards next-generation metrology solutions, fueling the relentless march towards technological excellence.

#SemiconductorTech #MetrologyInnovation #PrecisionMatters #Nanotechnology #AIinManufacturing #QualityAssurance #TechTrends #QuantumComputing #Industry40 #InnovationHub #SmartManufacturing #NanoscaleImaging #DefectDetection #RealTimeAnalytics #FutureTech

0 notes

Photo

Webinar Deep Learning in Machine Vision http://ehelpdesk.tk/wp-content/uploads/2020/02/logo-header.png [ad_1] This webinar gives users of mach... #androiddevelopment #angular #bildverarbeitung #c #classification #cnn #convolutionalneuralnetworks #css #dataanalysis #datascience #deeplearning #deeplearningnetwork #defectdetection #development #docker #halcon #industrialimaging #industriellebildverarbeitung #iosdevelopment #java #javascript #klassifikation #machinelearning #machinevision #maschinellessehen #mvtecsoftware #mvtecsoftwaregmbh #node.js #objectdetection #pretrainednetworks #python #react #semanticsegmentation #unity #visionsoftware #webdevelopment

0 notes

Text

@defectdetective continued from [x]

Seeing Connor try to get through the day was almost to much to watch. Ace shook his head in disbelief.

“All that for grabbing a pen? Do you honestly have a death wish?” He sighs, rushing quickly to Connor’s side. “Come on. Lets get you down to the infirmary and I’ll patch you back up.”

“How long until your replacement biocomponent comes?” Ace asks, carefully helping Connor to his feet, a hand pressing softly to the smaller male’s wound to prevent any more Thirium from being lost.

0 notes

Text

Check me out on the my sideblog @defectdetective

0 notes