#Disc Springs Market Report

Explore tagged Tumblr posts

Text

Disc Springs Market Set to Reach $787.7 Million by 2035: Growth Driven by Applications Across Various Industries

The global disc springs market is projected to grow significantly, reaching $787.7 million by 2035, up from $398.1 million in 2024, according to recent research by DataString Consulting. This growth is primarily driven by the increasing adoption of disc springs in key industries such as industrial machinery, automotive, aerospace, and power generation. Disc springs are increasingly being utilized in pneumatic systems, safety valves, clutch assemblies, and electrical contacts, which are driving their widespread application and market growth.

Key Drivers of Market Growth

Disc springs are particularly valued in industrial machinery for their robustness and high fatigue resistance. These springs are critical for efficient power transmission and counteracting vibration in rotating machinery. Load-bearing machines, such as cranes and forklifts, rely on disc springs in their hydraulic systems to absorb shock loads and minimize operational jerks. Leading industrial companies like Siemens and Caterpillar are known for incorporating high-quality disc springs into their products to ensure optimal performance and longevity.

In the automotive industry, disc springs are integral components in clutch assemblies and safety systems. Their ability to maintain a constant load ensures smooth power transmission, making them essential for automotive giants like Toyota and Volkswagen. The compact design and high load capacity of disc springs also make them vital for safety systems, including braking and steering mechanisms.

Furthermore, technological advancements have increased the demand for disc springs in industries where heat expansion and contraction present challenges, such as automotive engineering, aerospace, and power generation. Disc springs are highly resistant to fatigue and can withstand extreme temperatures, making them an ideal choice for systems that must endure thermal expansion.

Industry Leadership and Competitive Strategies

The global disc springs market is highly competitive, with top players from key demand hubs such as the U.S., Germany, and China. Prominent players in the industry include Schneider Electric SE, Rotor Clip Company Inc., Mubea, Borrelly Spring Washers, Associated Spring, Lesjfors AB, Disc Springs Australia, Bauer Springs Inc., Seeger-Orbis, MW Industries Inc., Teller Springs, and Peterson Spring.

Some of the strategies employed by these companies include:

Mubea Disc Springs: Focuses on maintaining high material quality standards and offering tailor-made solutions for diverse industrial applications.

Belleville Springs Limited: Expands its product range to meet the needs of challenging industries, such as oil and gas, and customizes products based on client specifications.

Stork Springs: Develops high-fatigue life disc springs to enhance performance and durability, particularly in automotive applications.

Associated Spring Raymond: Innovates new disc spring designs that can withstand high electrical loads, catering to advanced electronic devices.

Market Expansion and Regional Insights

The disc springs market is expected to experience substantial growth between 2025 and 2030, driven by factors such as increasing demand from the automotive industry, advancements in manufacturing technologies, and a growing focus on maintenance in heavy machinery. North America is poised to be a significant market for disc springs, with the U.S. leading the way due to its diverse industrial applications. Technological advancements in materials science have improved the quality of disc springs, resulting in greater adoption across sectors like energy production and automotive.

In Canada, stringent regulatory standards are boosting the demand for high-performance disc springs, particularly in the oil and gas sector. The competitive landscape in the region is strong, with numerous players actively contributing to the growth of the market.

Conclusion

The disc springs market is undergoing rapid expansion, driven by their increasing application in various industries such as automotive, manufacturing, energy, and more. As technological advancements continue to shape the market, disc springs will play a pivotal role in ensuring the efficiency, durability, and safety of critical systems in diverse sectors worldwide.

For more detailed insights into the market dynamics and growth opportunities, visit DataString Consulting's Disc Springs Market Research Report.

About DataString Consulting

DataString Consulting specializes in providing strategic insights, market research, and business intelligence solutions for both B2C and B2B markets. With over 30 years of combined experience, the company's leadership team helps businesses formulate strategies, expand their market reach, and navigate competitive landscapes. Their customized strategies identify emerging trends and uncover new opportunities, accelerating the path from product development to market success.

0 notes

Text

Disc Spring Market Report: Unlocking Growth Potential and Addressing Challenges

United States of America – Date – 21/05/2025 - The Insight Partners is proud to announce its newest market report, "Disc Spring Market: An In-depth Analysis of the Disc Spring Market". The report provides a holistic view of the Disc Spring market and describes the current scenario as well as growth estimates for Disc Spring during the forecast period.

Overview of Disc Spring Markets

There has been some development in the Disc Spring market, such as growth and decline, shifting dynamics, etc. This report provides insight into the driving forces behind this change: technological advancements, regulatory changes, and changes in consumer preference.

Key findings and insights

Market Size and Growth

Historical Data: The Disc Spring market is estimated to reach CAGR of 5.4% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.These estimates provide valuable insights into the market's dynamics and can inform future projections.

Key Factors Affecting the Disc Spring Market

The Disc Spring market is influenced by a combination of industrial demand, material science, and economic factors:

Growth in End-Use Industries: This is the primary driver for the disc spring market.

Automotive Industry: A major consumer, disc springs are used in clutches, brakes, automatic transmission clutch assemblies, suspension systems, and pre-loading thrust bearings. The increasing production of both conventional and electric vehicles (where they are used in battery packs and other electrical components for consistent pressure) fuels demand.

Industrial Machinery and Equipment: Critical for various machines, including presses, pumps, valves, and heavy machinery, where they ensure consistent pressure, absorb shock, and dampen vibrations, enhancing operational efficiency and extending equipment lifespan.

Construction and Mining: Used in heavy equipment, braking systems, and various structural components where high load capacity and durability are essential.

Aerospace & Defense: Demand for lightweight, high-performance, and reliable components in aircraft, spacecraft, and defense equipment drives the use of disc springs in critical systems.

Energy Sector (Traditional and Renewable): Utilized in power generation equipment, circuit breakers, and increasingly in renewable energy applications like wind turbines (for pitch control systems and braking mechanisms).

Spotting Emerging Trends

Changing Consumer Preferences

While disc springs are industrial components, "consumer preferences" in this context refer to the evolving demands and priorities of industrial buyers and end-users of the products containing disc springs:

Demand for Higher Reliability and Longer Lifespan: Industrial customers prioritize components that reduce downtime, maintenance costs, and replacement frequency. This drives a strong preference for disc springs with enhanced fatigue life, robust materials, and consistent performance over extended periods.

Emphasis on Compact and Lightweight Solutions: Across industries (automotive, aerospace, electronics), there's a continuous drive for miniaturization and weight reduction to improve efficiency (fuel economy, battery range), reduce material costs, and enable more compact product designs. This directly fuels the demand for disc springs due to their high force-to-space ratio.

Regulatory Changes

Regulatory changes significantly impact the Disc Spring market, primarily concerning safety, performance, and environmental compliance:

Industry-Specific Performance and Safety Standards: Stricter standards in industries like automotive (e.g., for braking systems, transmissions), aerospace (e.g., material certification, fatigue life), and machinery (e.g., for safety mechanisms, load-bearing capacities) directly influence the design, material selection, and testing requirements for disc springs. Compliance with international standards (e.g., ISO, DIN EN) is often mandatory for market access.

Growth Opportunities

The Disc Spring market is set for significant growth driven by several key opportunities:

Growth in Electric Vehicles (EVs): The rapid global expansion of the EV market presents a substantial opportunity. Disc springs are crucial in EV applications, including battery pack clamping, braking systems, and various electrical components requiring constant force and vibration dampening. The demand for lightweight and highly reliable components in EVs will further boost this segment.

Increasing Industrial Automation and Robotics: The continuous global trend towards industrial automation and the proliferation of robotics in manufacturing processes necessitate high-precision, reliable mechanical components. Disc springs are vital in robotic joints, grippers, and automated machinery for precise force application and backlash control.

Conclusion

The Disc Spring Market: Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast Disc Spring 2023-2031 report provides much-needed insight for a company willing to set up its operations in the Disc Spring market. Since an in-depth analysis of competitive dynamics, the environment, and probable growth path are given in the report, a stakeholder can move ahead with fact-based decision-making in favor of market achievements and enhancement of business opportunities.

About The Insight Partners

The Insight Partners is among the leading market research and consulting firms in the world. We take pride in delivering exclusive reports along with sophisticated strategic and tactical insights into the industry. Reports are generated through a combination of primary and secondary research, solely aimed at giving our clientele a knowledge-based insight into the market and domain. This is done to assist clients in making wiser business decisions. A holistic perspective in every study undertaken forms an integral part of our research methodology and makes the report unique and reliable.

0 notes

Text

Industrial Brakes Market Expected to Witness a Sustainable Growth over 2025 | Global Market Vision

The industrial brakes market is experiencing steady growth, driven by increasing automation, stringent safety regulations, and advancements in braking technologies. Industrial brakes are essential components in various sectors, including manufacturing, mining, construction, marine, and aerospace, where they ensure the safe and efficient operation of machinery by controlling motion and providing stopping power.

The market encompasses a range of brake types, such as hydraulic, pneumatic, mechanical, electromagnetic, and spring brakes, each catering to specific applications and performance requirements. Applications of industrial brakes include holding brakes, dynamic and emergency braking, and tension control, which are critical in processes that demand precision and safety.

Technological advancements have led to the integration of smart features in braking systems, such as sensors and Internet of Things (IoT) capabilities, enabling real-time monitoring, predictive maintenance, and enhanced control. These innovations contribute to reduced downtime and improved operational efficiency.

Get Full PDF Sample Copy of Report (Including Full TOC, List of Tables & Figures, Chart) @ https://futuremarketconsulting.com/request-sample/53433

Key Market Players:

Akebono Brake Industry Co. Ltd.

Altra Industrial Motion Corp.

Eaton Corporation plc

Aplicacion Nuevas Technologias Antec S.A.

Carlisle Brake & Friction

Coremo Ocmea S.p.A

Pintsch Bubenzer GmbH

Ringspann GmbH

SIBRE Siegerland Bremsen GmbH

Magnetek Inc.

Dellner Brakes AB.

By Product (Disc Brake, Drum Brake);

By Distribution Channel (Direct, Indirect);

By Actuation Type (Mechanical, Hydraulic, Pneumatic, Electrical, Other Brakes);

By Application (Holding Brakes, Dynamic & Emergency Brakes, Tension Brakes);

By Industry (Manufacturing, Metal & Mining, Construction, Marine & Shipping, Other Industries);

Key Target Audience:

• Industrial Brakes manufacturers and other stakeholders

• Organizations, forums and alliances related to Industrial Brakes distribution

• Government bodies such as regulating authorities and policy makers

• Market research organizations and consulting companies

The study is useful in providing answers to several critical questions that are important for industry stakeholders such as Industrial Brakes manufacturers, customers and policy makers. The study would also help them to target the growing segments over the coming years, thereby aiding the stakeholders in taking investment decisions and facilitating their expansion.

The following are the major objectives of the study.

To define, describe, and forecast the global Industrial Brakes market size on the basis of grade, application, type, and region

To provide detailed information regarding the significant factors influencing the growth of the market (drivers, restraints, opportunities, and industry-specific challenges)

To analyze the opportunities in the market for stakeholders and details of a competitive landscape for market leaders

To forecast the market size, in terms of value and volume, with respect to five main regions, namely, North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa

To strategically profile key players and comprehensively analyze their market shares and core competencies

To track and analyze competitive developments such as joint ventures, mergers & acquisitions, new product developments, and research & developments (R&D) in the Industrial Brakes market

During this research study, major players operating in the Industrial Brakes market in various regions have been identified, and their offerings, regional presence, and distribution channels have been analyzed through in-depth discussions. Top-down and bottom-up approaches have been used to determine the overall market size. Sizes of the other individual markets have been estimated using the percentage splits obtained through secondary sources such as Hoovers, Bloomberg BusinessWeek, and Factiva, along with primary respondents. The entire procedure includes the study of the annual and financial reports of the top market players and extensive interviews with industry experts such as CEOs, VPs, directors, and marketing executives for key insights (both qualitative and quantitative) pertaining to the market. The figure below shows the breakdown of the primaries on the basis of the company type, designation, and region considered during the research study.

Frequently asked questions

How much is the global Industrial Brakes market worth?

What was the value of the Industrial Brakes market in 2021?

At what CAGR is the Industrial Brakes market projected to grow in the forecast period (2022-2028)?

What is the leading segment in the market?

What is the key factor driving the market?

Which are the leading players in the market?

Which country held the highest market share in the market?

Which factors are expected to drive the adoption of the product?

Buy Exclusive Report @: https://futuremarketconsulting.com/buy-now/53433

NOTE: Our analysts monitoring the situation across the globe explains that the market will generate remunerative prospects for producers post the COVID-19 crisis. The report aims to provide an additional illustration of the latest scenario, economic slowdown, and COVID-19 impact on the overall industry.

Related Repots:

0 notes

Text

Global Connected Cow and Farm Market Growth, Insights and Forecast by 2032 | Reed Intelligence

Connected Cow and Farm Market Insights

Reed Intelligence has recently added a new report to its vast depository titled Global Connected Cow and Farm Market. The report studies vital factors about the Global Connected Cow and Farm Market that are essential to be understood by existing as well as new market players. The report highlights the essential elements such as market share, profitability, production, sales, manufacturing, advertising, technological advancements, key market players, regional segmentation, and many more crucial aspects related to the Connected Cow and Farm Market.

Get Free Sample Report PDF @ https://reedintelligence.com/market-analysis/global-connected-cow-and-farm-market/request-sample

Connected Cow and Farm Market Share by Key Players

JOSKINBauer Group (BSA)Evers AgroMajor EquipmentAgometerFliegl AgrartechnikVredoVeenhuis MachinesPel Tuote OySCHOUTEN MACHINESClaydon Yield-o-MeterBomech

Important factors like strategic developments, government regulations, market analysis, end users, target audience, distribution network, branding, product portfolio, market share, threats and barriers, growth drivers, latest trends in the industry are also mentioned.

Connected Cow and Farm Market Segmentation

The report on Global Connected Cow and Farm Market provides detailed segmentation by type, applications, and regions. Each segment provides information about the production and manufacturing during the forecast period of 2024-2032. The application segment highlights the applications and operational processes of the industry. Understanding these segments will help identify the importance of the various factors aiding to the market growth.

The report is segmented as follows:

Segment by Type

Disc

Spring Tines

Other

Segment by Application

Private Farms

Commercial Farms

Connected Cow and Farm Market Segmentation by Region

North America

U.S.

Canada

Europe

Germany

UK

France

Asia Pacific

China

India

Japan

Australia

South Korea

Latin America

Brazil

Middle East & Africa

UAE

Kingdom of Saudi Arabia

South Africa

Get Detailed Segmentation @ https://reedintelligence.com/market-analysis/global-connected-cow-and-farm-market/segmentation

The market research report on the Global Connected Cow and Farm Market has been carefully curated after studying and observing various factors that determine the growth, such as environmental, economic, social, technological and political status of the regions mentioned. Thorough analysis of the data regarding revenue, production, and manufacturers gives out a clear picture of the global scenario of the Connected Cow and Farm Market. The data will also help key players and new entrants understand the potential of investments in the Global Connected Cow and Farm Market.

Key Highlights

It provides valuable insights into the Global Connected Cow and Farm Market.

Provides information for the years 2024-2032. Important factors related to the market are mentioned.

Technological advancements, government regulations, and recent developments are highlighted.

This report will study advertising and marketing strategies, market trends, and analysis.

Growth analysis and predictions until the year 2032.

Statistical analysis of the key players in the market is highlighted.

Extensively researched market overview.

Buy Connected Cow and Farm Market Research Report @ https://reedintelligence.com/market-analysis/global-connected-cow-and-farm-market/buy-now

Contact Us:

Email: [email protected]

#Connected Cow and Farm Market Size#Connected Cow and Farm Market Share#Connected Cow and Farm Market Growth#Connected Cow and Farm Market Trends#Connected Cow and Farm Market Players

0 notes

Text

Air Brake System Market worth $3.4 billion by 2028

According to a research report "Air Brake System Market by Type (Disc & Drum), Component (Compressor, Governor, Tank, Air Dryer, Foot Valve, Brake Chamber, & Slack Adjuster), Rolling Stock, Vehicle Type (Rigid Body, Heavy-Duty, Semi-Trailer, & Bus), Region - Global Forecast to 2028" published by MarketsandMarkets, the global air brake system market is projected to grow from USD 3.1 billion in 2023 to USD 3.4 billion by 2028 at a CAGR of 2.2% from 2023 to 2028.

Browse 272 market data Tables and 48 Figures spread through 267 Pages and in-depth TOC on "Air Brake System Market by Type (Disc & Drum), Component (Compressor, Governor, Tank, Air Dryer, Foot Valve, Brake Chamber, & Slack Adjuster), Rolling Stock, Vehicle Type (Rigid Body, Heavy-Duty, Semi-Trailer, & Bus), Region - Global Forecast to 2028" The growth in air brake systems is primarily driven due to a rise in heavy commercial vehicle production, driven by technological advancements, safety concerns, and government regulations. For instance, FMVSS 121 (US) or CMVSS 121 (Canada) monitors performance and equipment requirements for braking systems on vehicles equipped with air brake systems. Similarly, air brake regulations are observed under Heavy Vehicle National Law (HVNL) in Australia. Air brakes are preferred in commercial vehicles over hydraulic brakes for their safety features and fail-safe measures.

Download PDF Brochure @

“Heavy-duty truck to be the largest market for air brake systems”

Heavy-duty trucks include class 7 and class 8 trucks in which class 7 weighing approximately 12 to 14 tons, whereas class 8 trucks weighing upto approximately 15 t0 36 tons. According to OICA and MarketsandMarkets analysis, the production of heavy-duty trucks accounted for the maximum of the total truck production for all the regions, including North America, Asia Pacific, Rest of the World, and Europe in 2022 and is expected to dominate during the forecast period. Asia Pacific is the largest market for heavy duty trucks which contributes around ~59% of total heavy duty production at global level. Further, at global level production of heavy duty trucks is around 40% of total commercial vehicle production. Most heavy trucks have air brake systems due to their high load-carrying capacity. The main distinction between the air brake systems for rigid trucks and heavy-duty trucks lies in their load-carrying capacity and number of components. Fleet operators favor heavy-duty trucks for their strong weight-bearing capacity and engine power. The increasing development of economies in Asia and other regions is expected to drive the demand for heavy-duty trucks in the future. As a result, the heavy-duty truck segment is projected to be the largest market for air brake systems in terms of vehicle type.

“Brake chamber is estimated to hold the largest market share in the on-highway air brake system during the forecast period.”

Brake chambers hold the largest market share in global air brake systems for on-highway vehicles. Air brake chambers are metallic containers situated at each wheel, which, when forced by compressed air, convert into mechanical force to stop the commercial vehicle. There are two kinds of air brake chambers, namely, service and spring brake chambers. A service brake chamber contains a flexible rubber disc called a diaphragm, a pushrod metal rod, and a return spring. When the brake pedal is pressed, compressed air fills the service brake chamber causing the brakes to apply.

As the brake chamber is placed at the end of the wheel, the number of axles decides the number of brake chambers in each commercial vehicle. Each axle has two brake chambers in a vehicle. Hence, the number of brake chambers increases with the GVWR of the commercial vehicle. The number of brake chambers in each vehicle may vary with each region, as the average number of axles in each region is different for heavy-duty vehicles and buses. North America and Europe have more multi-axle heavy trucks than Asia Oceania. Hence, the average number of brake chambers in buses in India is four, while in European countries, it is six. Asia Pacific holds the largest market share in the brake chamber market. The demand for brake chambers is related to the number of multi-axle commercial vehicles, as each axle requires two brake chambers. Further, growing commercial vehicle production will also drive the demand for the brake chamber market.

“Europe accounted for the second largest global air brake system market.”

Europe is estimated to be the second-largest market for air brake systems after Asia Pacific. Countries such as France, Germany, UK, and Spain have a higher production of commercial vehicles. The growth of air brake systems in Europe can be attributed to factors such as the growing production of heavy-duty trucks and stringent government regulations related to active safety. As per ACEB, road freight transport is a crucial way of trade and commerce in the European region. Trucks are responsible for >70% of freight transportation over the land in this region. As maximum transportation is conducted through these heavy trucks, it leads to fatal accidents in this region. According to European Union, out of total road fatalities in the EU in 2019, 14% and 2% died due to heavy good vehicle and bus crashes, respectively. Thus, the European Commission has implemented various braking system regulations for heavy commercial vehicles to avoid fatalities from heavy commercial vehicle crashes. For instance, European union mandates to install rollover stability control system in heavy trucks weighing above 3.5 tons.

Further, the inclusion of additional safety-related components to withstand the government braking-related mandates makes the price of the air brake system comparatively higher in Europe than in Asia-Oceania and North America. Additionally, Europe’s disc brake installation rate is the highest due to the shortest stopping braking distance for commercial vehicles. The above factors imply European commercial vehicles’ importance and safety standards. Thus, rising commercial vehicle production and adopting advanced technologies related to air brake systems by OEMs is anticipated to drive the growth of air brake systems in Europe.

Key Market Players

The air brake system market is primarily dominated by globally established players such as Knorr- Bremse AG (Germany),Meritor, Inc. (US), Haldex (Sweden), ZF Friedrichshafen AG (Germany), and Wabtec Corporation (US). These companies consistently develop new products, adopt expansion strategies, and undertake collaborations, partnerships, and mergers & acquisitions to gain traction across different regions in this air brake system market.

Request Free Sample Report @ https://www.marketsandmarkets.com/requestsampleNew.asp?id=163805421

0 notes

Text

Industrial Brakes Market Share, Size, Future Demand, and Emerging Trends

A frictional tool known as an industrial brake is used to stop an inertia-spinning load or to keep a part in a stable position. The inertia load is typically brought on by several rotating components that must be stopped.

They convert the kinetic energy from friction between two surfaces into heat, which slows everything down. Employing industrial brakes in various industrial machinery sets them apart from automotive breaks.

Industrial brakes operate in all weather conditions, need less maintenance since they have fewer moving parts, and are simple to adapt for different purposes. These factors will probably increase the need for industrial brakes globally in the upcoming years.

Browse detailed - Industrial Brakes Market Revenue Estimation and Growth Forecast Report

Types of Industrial Brakes

The industrial brakes sector is divided into types based on their application, including mechanically, electrically, hydraulically, pneumatically, and other methods.

• Mechanically Applied Brakes

These brakes operate, when two surfaces to rub against one another and creating frictional forces. The frictional surfaces' surface area and the applied actuation force significantly impact a brake's stopping power or capacity. The working surfaces experience high friction and wear.

• Hydraulically Applied Brakes

A hydraulic brake is a configuration of braking mechanisms that transfers pressure from the regulating mechanism to the braking mechanism using brake fluid, generally containing glycol ethers or diethylene glycol. Additionally, the majority of brakes in the industrial brakes market are hydraulically operated.

• Pneumatically Applied Brakes

Practically every field of mechanical engineering uses disc brakes that are directly pneumatically applied. Here, compressed air generates the actuating force, while spring force releases the brake.

• Electrically Applied Brakes

Electronic brakes employ an electrical current or magnetic actuation force to slow down or stop the rotation of a spinning component. They are utilized in applications requiring quick response times and accurate tension management in industrial and automotive braking systems.

0 notes

Text

Tractor Implements In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

Tractor Implements Market: Global opportunity analysis and industry forecast

Tractor implements refers to the agricultural machines that are attached to a tractor. The tractor implements are used for various operation in the agricultural field like land preparation, harvesting, sowing, seeding, baling, irrigation and others. The tractor implements are categorized into three mounting locations that is front, mid and rear. The most common front mounted implement on the tractor is tractor loader. The common mid position tractor implement is the mower deck while the common rear mounted implement is the tractor rear blade. The other tractor implements include tractor blades, landscape rakes, spreaders, tillovators, sprayers, quick hitchers, disc mowers, rotary tedders and other such tractor implements. There are two types of tractor implements on the basis of their operation that is powered and unpowered. The powered tractor implement requires mechanical and electrical power for their movement while the unpowered tractor implements are operated normally.

Top impacting factors: Market Scenario Analysis, Trends , Drivers and Impact Analysis

The increasing demand for the food production technologies and technologically advanced agricultural machineries is one of the major factor driving the growth of the tractor implements market. The increasing demand for irrigation and crop protection owing to the increasing availability of machinery for harvesting, sowing, seeding and others is expected to boost the growth tractor implements market. Further, the demand for the tractor implements in the 4 wheel drive is accounted to be high compared to the 2 wheel tractors due to its power and attaching of combined implements in front and rear position simultaneously act as the major growth driver for the tractor implement market. Moreover, the increase in government promotion in agricultural tractor implements and subsidies for the farmers in the Asia-Pacific region countries are expected to boost the tractor implements market. The increasing demand for the mechanized farming techniques by investing in tractor implements is driving the market of tractor implements. However, thehigh agricultural implements expenses can hamper the growth of the market.

New product launches to flourish the market

The launch of new generation technologically advanced products can boost the growth of the market. In the past few years, many such products having unique features were launched in the market. On July 2018, one of the global leader in tractor implements John Deere has launched a heavy duty rigid type spring tyne cultivator. The spring tyne cultivator is used to remove the weeds from the soil and helps in loosening the soil. Further, Agristar company has launched tractor implement Agristar Power Harrow 615 PH in 2018. It uses advanced metal blades for breaking and smoothing of soil surfaces.

High demand form applications :

The different types of tractor implements can be used along with the tractor for various applications in agricultural field. The tractor implements include rotavator, cultivator, harrow, trailer, rear blades and other such implements. The rotavator is the tractor implement that is used for soil cultivation. The rotavator is modern agricultural machinery that is used to churn, break and aerate the soil in order to increase the oxygen count in the soil. The rotavators consists of rear blades that are connected to the motor that break the soil when the blades spin. Further, one of the tractor implement cultivator is used to break the soil into fine particles. The cultivator is used for sowing seeds before the beginning of the cropping process. Moreover , plough is a tractor implement that is used in prevention of weeds by breaking the soil particles deep inside the ground.

Full Report With TOC:-https://www.alliedmarketresearch.com/tractor-implements-market-A09968

0 notes

Text

Spring Washers Market - Future Growth Prospects for the Global Leaders

The latest market report published by Credence Research, Inc. “Global Spring Washers Market: Growth, Future Prospects, and Competitive Analysis, 2016 – 2028. The global spring washers market has witnessed steady growth in recent years and is expected to grow at a CAGR of 5.80% between 2023 and 2030. The market was valued at USD XX billion in 2022 and is expected to reach USD XX Billion in 2030.

Spring washers, also known as disc springs or Belleville washers, are mechanical devices designed to exert a spring force when compressed. They are typically thin, circular washers with a slightly conical shape. The unique design of spring washers allows them to store and release energy, making them ideal for specific applications where vibration, thermal expansion, or bolt loosening can occur.

Spring washers are a vital component of many industrial applications, ensuring the proper distribution of tension and load across fastened joints. The dynamics within the spring washers market have been intriguing, as various factors contribute to its growth and development. One significant dynamic is the increasing demand for spring washers in automotive manufacturing. With the rising production of vehicles worldwide, manufacturers require reliable fastening solutions that can withstand high vibrations and maintain optimal performance under extreme conditions. This surge in demand has prompted key players in the industry to invest heavily in research and development activities, aiming to produce advanced spring washers with enhanced durability and efficiency.

Types of Spring Washers:

Belleville Spring Washers

Belleville spring washers, named after their inventor Julien Belleville, are the most common type of spring washers. They have a conical shape and are widely used in engineering and mechanical applications. Belleville washers can be stacked in series to increase the amount of force they exert, making them versatile for various load requirements.

Wave Spring Washers

Wave spring washers, also known as wave washers, have a wavy or corrugated design. They offer a lower spring rate compared to Belleville washers, making them suitable for applications with limited space. Wave washers are commonly used in electrical devices, bearing preload applications, and various other assemblies.

Curved Spring Washers

Curved spring washers, as the name suggests, have a curved shape with a higher load capacity. They are suitable for applications that require a higher degree of deflection and strength, such as heavy machinery and automotive assemblies.

Applications of Spring Washers:

Spring washers find applications in a wide range of industries due to their unique capabilities. Some of the key applications include:

Automotive Industry

In the automotive sector, spring washers are used to prevent fastener loosening caused by vibrations and constant movement. They play a vital role in ensuring the safety and reliability of automotive components.

Construction and Infrastructure

In construction and infrastructure projects, spring washers are utilized to maintain the integrity of structures subject to heavy loads, wind, and seismic forces. They provide a secure connection and prevent bolt slippage.

Manufacturing and Machinery

In manufacturing processes, spring washers help maintain proper tension in assembly joints, reducing the need for frequent re-tightening of fasteners. This contributes to increased efficiency and productivity.

Aerospace and Defense

The aerospace and defense industries rely on spring washers to withstand extreme conditions and maintain the performance of critical components in aircraft, spacecraft, and military equipment.

Browse 200 pages report Spring Washers Market By Type (Belleville, Bowed/Curved, Finger, Adjustable Spacers Other) By Application (Automotive, Equipment, Others) - Growth, Future Prospects & Competitive Analysis, 2016 – 2030)- https://www.credenceresearch.com/report/spring-washers-market

Advantages of Using Spring Washers

Using spring washers offers several advantages:

Vibration Damping: Spring washers absorb and dampen vibrations, reducing wear and tear on components.

Temperature Resistance: They can withstand high temperatures, making them suitable for applications in challenging environments.

Cost-Effective Solution: Spring washers are relatively inexpensive, providing a cost-effective means of ensuring joint integrity.

Easy Installation: They are simple to install and require minimal maintenance, saving time and effort during assembly.

Why to Buy This Report-

The report provides a qualitative as well as quantitative analysis of the global Spring Washers Market by segments, current trends, drivers, restraints, opportunities, challenges, and market dynamics with the historical period from 2016-2020, the base year- 2021, and the projection period 2022-2028.

The report includes information on the competitive landscape, such as how the market's top competitors operate at the global, regional, and country levels.

Major nations in each region with their import/export statistics

The global Spring Washers Market report also includes the analysis of the market at a global, regional, and country-level along with key market trends, major players analysis, market growth strategies, and key application areas.

Browse Full Report: https://www.credenceresearch.com/report/spring-washers-market

Visit: https://www.credenceresearch.com/

Related Report: https://www.credenceresearch.com/report/hydrostatic-transmission-market

Related Report: https://www.credenceresearch.com/report/events-and-exhibitions-market

Browse Our Blog: https://www.linkedin.com/pulse/spring-washers-market-rising-trends-research-outlook-2022-2030-singh

Browse Our Blog: https://medium.com/@priyanshi_97937/spring-washers-market-to-grow-steadily-over-cagr-of-5-80-dfa53546ccb7

About Us -

Credence Research is a viable intelligence and market research platform that provides quantitative B2B research to more than 10,000 clients worldwide and is built on the Give principle. The company is a market research and consulting firm serving governments, non-legislative associations, non-profit organizations, and various organizations worldwide. We help our clients improve their execution in a lasting way and understand their most imperative objectives. For nearly a century, we’ve built a company well-prepared for this task.

Contact Us:

Office No 3 Second Floor, Abhilasha Bhawan, Pinto Park, Gwalior [M.P] 474005 India

0 notes

Photo

Coming in April!

NEW 2020 1080p HD masters JOSIE AND THE PUSSYCATS IN OUTER SPACE

Run Time 352:00

Subtitles English SDH

Audio Specs DTS HD-Master Audio 2.0 - English, MONO - English

Aspect Ratio 1.33:1 4x3 FULL FRAME

Product Color COLOR

Disc Configuration 2 BD 50

Rock stars Josie and the Pussycats are out of this world...literally! When the bumbling Alexandra accidentally launches Josie and the gang into outer space, they travel through the galaxy searching for a path back to Earth. Along the way, they meet cat people, robot monsters, evil dictators, space pirates and plenty of strange creatures, including their new companion Bleep, voiced by Hanna-Barbera legend Don Messick. Fortunately, everyone’s a fan of Josie and the Pussycats, including aliens! Rocket through the universe with your favorite superstars as they save the day, sing some songs and have a hip-happenin’ good time in a 2-disc, 16-episode Josie and the Pussycats in Outer Space complete series collection that hits all the right notes!

NEW 2021 1080p HD Master Sourced from 4K scan of preservation film elements!

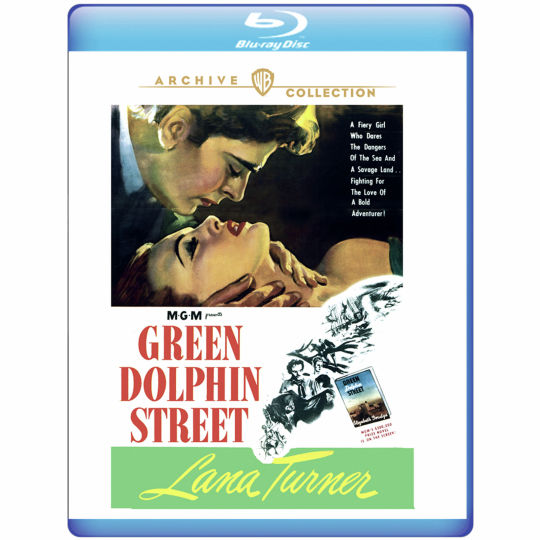

GREEN DOLPHIN STREET

Run Time 141:00

Subtitles English SDH

Audio Specs: DTS HD-Master Audio 2.0 - English, MONO - English

Aspect Ratio: 1.37:1 4x3 FULL FRAME

Product Color BLACK & WHITE

Disc Configuration BD 50

Special Features: Lux Radio Theater Broadcast; Theatrical Trailer (HD)

The Academy Award® winner about star-crossed love that spans the years – and the globe. After her triumph as the lunchroom temptress in the crime classic The Postman Always Rings Twice, Lana Turner expanded her range with Green Dolphin Street. Set in 19th century Europe and New Zealand, this sweeping romance tells the story of two beautiful sisters, one headstrong (Turner) and one gentle (Donna Reed), and of the man (Richard Hart) who marries one even though he loves the other. The film’s riptides of emotion are matched by breathtaking physical tumult: a fierce Maori uprising plus a catastrophic earthquake and tidal wave that earned the film a 1947 Oscar® for special effects. With its dramatic story and spectacular visuals, Green Dolphin Street drew huge audiences for epic moviemaking, being one of the top-ten box office hits of the year.

NEW 2021 1080p HD Master Sourced from 4K scan of Nitrate preservation elements!

BROADWAY MELODY OF 1940

Run Time 102:00

Subtitles English SDH

Audio Specs: DTS HD-Master Audio 2.0 - English, MONO - English

Aspect Ratio: 1.37:1 4x3 FULL FRAME

Product Color BLACK & WHITE

Disc Configuration BD 50

Special Features: Making-of Featurette: "Begin the Beguine" (hosted by Ann Miller); "Our Gang Comedies: The Big Premiere"; MGM Cartoon: "The Milky Way" ; Original Theatrical Trailer (HD)

The job – a career breakthrough – is supposed to go to hoofer Johnny Brett, but a mix-up in names gives it to his partner. Another example of Broadway hopes dashed? Not when Johnny is played by Fred Astaire. Sparkling Cole Porter songs, clever comedy and dance legends Astaire and Eleanor Powell make the final Broadway Melody (co-starring George Murphy) a film to remember. Powell’s nautical “All Ashore" routine (a/k/a I Am the Captain”), Astaire’s blissful “I’ve Got My Eyes on You” and Fred & Eleanor's elaborate routine to Cole Porter's classic "I Concentrate On You" are more than enough to please any fan. But they’re just a warm-up for the leads to tap one finale number into immortality: “Begin the Beguine,” introduced by Frank Sinatra in That’s Entertainment! with, “You can wait around and hope, but you’ll never see the likes of this again.”

NEW 2021 1080p HD Master Sourced from a new 4K restoration of the last-known surviving nitrate Technicolor print!

DOCTOR X (1932)

Run Time 76:00

Subtitles English SDH

Audio Specs: DTS HD-Master Audio 2.0 - English, MONO - English

Aspect Ratio: 1.37:1 4x3 FULL FRAME

Product Color COLOR; BLACK & WHITE

Disc Configuration BD 50

Special Features: Alternate B&W version of feature; DOCTOR X (HD): UCLA Before & After Restoration featurette (HD); New documentary: "Monsters and Mayhem: The Horror Films of Michael Curtiz (HD); New feature commentary by author/film historian Alan K. Rode; Archival feature commentary by Scott MacQueen, head of preservation, UCLA Film and Television Archive. Original B&W Theatrical Trailer (HD)

Is there a (mad) doctor in the house? “Yes!” shrieks Doctor X, filmed in rare two-strip Technicolor®. An eminent scientist aims to solve a murder spree by re-creating the crimes in a lab filled with all the dials, gizmos, bubbling beakers and crackling electrostatic charges essential to the genre. Lionel Atwill is Doctor Xavier, pre-King Kong scream queen Fay Wray is a distressed damsel and Lee Tracy snaps newshound patter, all under the direction of renowned Michael Curtiz. The new two-color Technicolor master was restored by UCLA Film and Television Archive and The Film Foundation in association with Warner Bros. Entertainment. Funding provided by the Hobson/Lucas Foundation. Also includes the separately filmed B&W version (which has been restored and restored from its original nitrate camera negative) originally intended for small U.S. markets and International distribution, and which has been out of distribution for over 30 years.

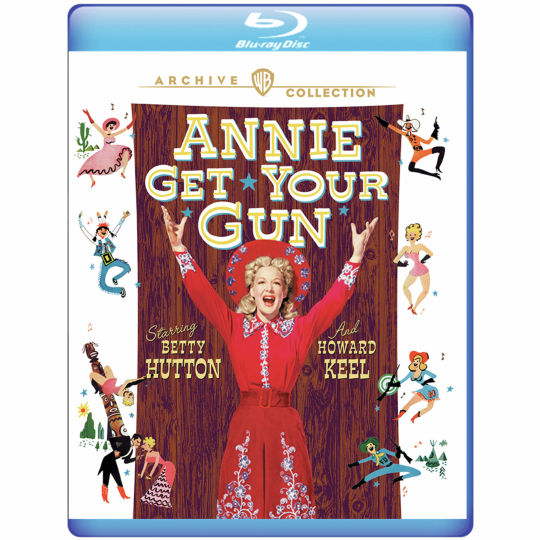

NEW 2021 1080p HD Master Sourced from 4K scan of original nitrate Technicolor negatives!

ANNIE GET YOUR GUN (1950)

Run Time 107:00

Subtitles English SDH

Sound Quality DTS HD-Master Audio 2.0 - English

Aspect Ratio 1.37:1 4x3 FULL FRAME

Product Color COLOR

Disc Configuration BD 50

Special Features: Susan Lucci retrospective & intro piece (from 2000 DVD release); Outtakes: Let’s Go West Again-Betty Hutton, Doin’ What Comes Natur’lly-Judy Garland, I’m an Indian, Too-Judy Garland, Colonel Buffalo Bill with Howard Keel and Frank Morgan; Stereo audio pre-recording session tracks including There’s No Business Like Show Business featuring Judy Garland; Theatrical Re-issue Trailer (HD)

Betty Hutton (as Annie Oakley) and Howard Keel (as Frank Butler) star in this sharpshootin’ funfest based on the 1,147-performance Broadway smash boasting Irving Berlin’s beloved score, including “Doin’ What Comes Natur’lly,” “I Got the Sun in the Morning” and the anthemic “There’s No Business Like Show Business.” As produced by Arthur Freed, directed by George Sidney, and seen and heard in this new remastered HD presentation, this lavish, spirited production showcases songs and performances with bull’s-eye precision, earning an Oscar®* for adaptation scoring. The story is a brawling boy-meets-girl-meets-buckshot rivalry. But love finally triumphs when Annie proves that, yes, you can get a man with a gun!

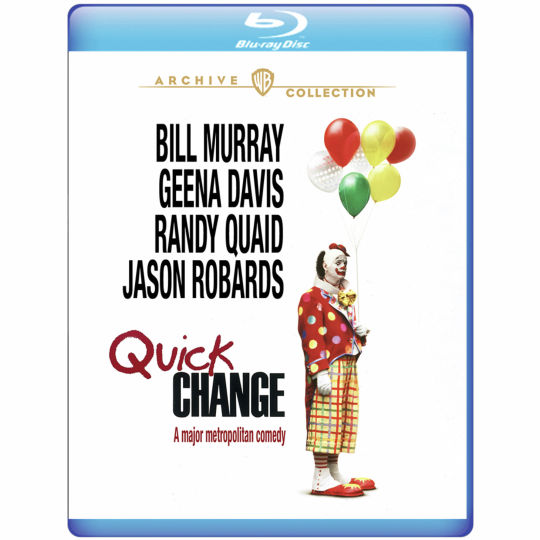

NEW 2021 1080p HD Master! QUICK CHANGE (1990)

Run Time 88:00

Subtitles English SDH

Sound Quality DTS HD-Master Audio 2.0 - English

Aspect Ratio 1.85:1, 16 X 9 WIDESCREEN

Product Color COLOR

Disc Configuration BD 25

Special Feature: Theatrical Trailer

The star of Caddyshack, Ghostbusters and Groundhog Day headlines and codirects this uproarious Big Apple heist-and-pursuit caper. Bill Murray plays Grimm, a frazzled urbanite who disguises himself as a clown – and sets out to rob a bank. Geena Davis and Randy Quaid play accomplices in Grimm’s daring scheme and Jason Robards is the blustery cop caught up in Grimm’s “Clown Day Afternoon.” Swiping a million bucks is a snap compared to getting out of town. Grimm and cohorts commandeer a car, a cab, a bus, a baggage tram and a plane (and encounter future stars Stanley Tucci and Tony Shalhoub in hilarious supporting roles) to make what becomes a less-than-merry escape. But for comedy lovers, Quick Change is a ticket to ride!

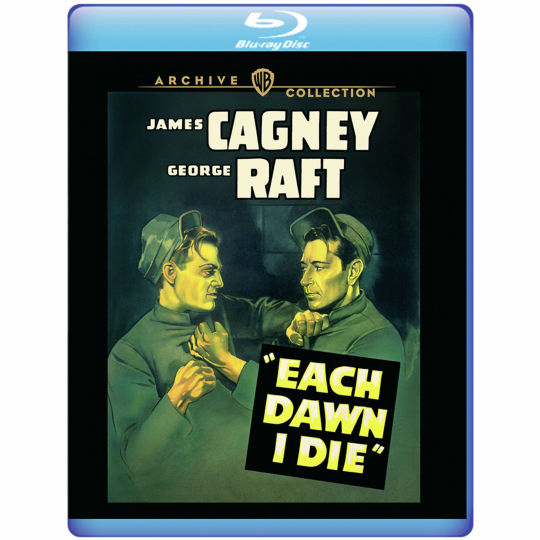

NEW 2021 1080p HD Master Sourced from 4K scan of best surviving nitrate preservation elements! EACH DAWN I DIE (1939)

Run Time 92:00

Subtitles English SDH

Audio Specs: DTS HD-Master Audio 2.0 - English, MONO - English

Aspect Ratio: 1.37:1 4x3 FULL FRAME

Product Color BLACK & WHITE

Disc Configuration BD 50

Special Features: Warner Night at the Movies including 1939 Short Subjects Gallery: Vintage Newsreel, WB Technicolor Short: "A Day at Santa Anita", WB Cartoon: "Detouring America"; Restrospective featurette: "Stool Pigeons and Pine Overcoats: The Language of Gangster Films" ; Feature Commentary by Film Historian Haden Guest; Breakdowns of 1939: Studio Blooper Reel; WB Cartoon: "Each Dawn I Crow"; Radio show w/George Raft & Franchot Tone; Trailer for "Wings of the Navy" and Original Theatrical Trailer for Each Dawn I Die (HD)

Framed for manslaughter after he breaks a story about city corruption, reporter Frank Ross is sure he’ll prove his innocence and walk out of prison a free man. But that’s not how the system works at Rocky Point Penitentiary. There, cellblock guards are vicious, the jute-mill labor is endless, and the powers Ross fought on the outside conspire to keep him in. Frank’s hope is turned to hopelessness. And he’s starting to crack. Two of the screen’s famed tough guys star in this prison movie that casts a reform-minded eye on the brutalizing effects of life in the slammer. James Cagney “hits a white-hot peak as [Ross,] the embittered, stir-crazy fall guy” (Leonard Maltin’s Movie Guide). And George Raft (Cagney’s friend since their vaudeville days) portrays racketeer Hood Stacey, who may hold the key to springing Ross.

NEW 2021 1080p HD Master Sourced from 4K scan of best surviving preservation elements!

ANOTHER THIN MAN (1939)

Run Time 102:00

Subtitles English SDH

Audio Specs: DTS HD-Master Audio 2.0 - English, MONO - English

Aspect Ratio: 1.37:1 4x3 FULL FRAME

Product Color BLACK & WHITE

Disc Configuration BD 50

Special Features: M-G-M Musical Short: Love on Tap; Classic M-G-M Cartoon: The Bookworm

Dum-Dum, Wacky, Creeps, Fingers: They’re just a few of the hoodlums in the world of amateur sleuths and professional bon vivants Nick and Nora Charles. And now there’s a new hood: parenthood. A birthday – make that boithday – party that some of da boys hold for infant Nick Jr. is part of the fun in this third film in the witty series. The case begins when the Charles family arrives for a weekend with a Long Island industrialist who fears someone wants to kill him. Sure enough, his fears come true. Nick (William Powell) is among the suspects. Asta scrams with what may be the murder weapon. And Nora (Myrna Loy) has her own ideas about the case and sneaks off to a nightclub to ferret out a clue. “Madam, how long have you been leading this double life?” Nick asks. “Just since we’ve been married,” she replies.

24 notes

·

View notes

Text

Disc Spring Market Report: Unlocking Growth Potential and Addressing Challenges

United States of America – Date – 21/05/2025 - The Insight Partners is proud to announce its newest market report, "Disc Spring Market: An In-depth Analysis of the Disc Spring Market". The report provides a holistic view of the Disc Spring market and describes the current scenario as well as growth estimates for Disc Spring during the forecast period.

Overview of Disc Spring Markets

There has been some development in the Disc Spring market, such as growth and decline, shifting dynamics, etc. This report provides insight into the driving forces behind this change: technological advancements, regulatory changes, and changes in consumer preference.

Key findings and insights

Market Size and Growth

Historical Data: The Disc Spring market is estimated to reach CAGR of 5.4% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.These estimates provide valuable insights into the market's dynamics and can inform future projections.

Key Factors Affecting the Disc Spring Market

The Disc Spring market is influenced by a combination of industrial demand, material science, and economic factors:

Growth in End-Use Industries: This is the primary driver for the disc spring market.

Automotive Industry: A major consumer, disc springs are used in clutches, brakes, automatic transmission clutch assemblies, suspension systems, and pre-loading thrust bearings. The increasing production of both conventional and electric vehicles (where they are used in battery packs and other electrical components for consistent pressure) fuels demand.

Industrial Machinery and Equipment: Critical for various machines, including presses, pumps, valves, and heavy machinery, where they ensure consistent pressure, absorb shock, and dampen vibrations, enhancing operational efficiency and extending equipment lifespan.

Construction and Mining: Used in heavy equipment, braking systems, and various structural components where high load capacity and durability are essential.

Aerospace & Defense: Demand for lightweight, high-performance, and reliable components in aircraft, spacecraft, and defense equipment drives the use of disc springs in critical systems.

Energy Sector (Traditional and Renewable): Utilized in power generation equipment, circuit breakers, and increasingly in renewable energy applications like wind turbines (for pitch control systems and braking mechanisms).

Spotting Emerging Trends

Changing Consumer Preferences

While disc springs are industrial components, "consumer preferences" in this context refer to the evolving demands and priorities of industrial buyers and end-users of the products containing disc springs:

Demand for Higher Reliability and Longer Lifespan: Industrial customers prioritize components that reduce downtime, maintenance costs, and replacement frequency. This drives a strong preference for disc springs with enhanced fatigue life, robust materials, and consistent performance over extended periods.

Emphasis on Compact and Lightweight Solutions: Across industries (automotive, aerospace, electronics), there's a continuous drive for miniaturization and weight reduction to improve efficiency (fuel economy, battery range), reduce material costs, and enable more compact product designs. This directly fuels the demand for disc springs due to their high force-to-space ratio.

Regulatory Changes

Regulatory changes significantly impact the Disc Spring market, primarily concerning safety, performance, and environmental compliance:

Industry-Specific Performance and Safety Standards: Stricter standards in industries like automotive (e.g., for braking systems, transmissions), aerospace (e.g., material certification, fatigue life), and machinery (e.g., for safety mechanisms, load-bearing capacities) directly influence the design, material selection, and testing requirements for disc springs. Compliance with international standards (e.g., ISO, DIN EN) is often mandatory for market access.

Growth Opportunities

The Disc Spring market is set for significant growth driven by several key opportunities:

Growth in Electric Vehicles (EVs): The rapid global expansion of the EV market presents a substantial opportunity. Disc springs are crucial in EV applications, including battery pack clamping, braking systems, and various electrical components requiring constant force and vibration dampening. The demand for lightweight and highly reliable components in EVs will further boost this segment.

Increasing Industrial Automation and Robotics: The continuous global trend towards industrial automation and the proliferation of robotics in manufacturing processes necessitate high-precision, reliable mechanical components. Disc springs are vital in robotic joints, grippers, and automated machinery for precise force application and backlash control.

Conclusion

The Disc Spring Market: Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast Disc Spring 2023-2031 report provides much-needed insight for a company willing to set up its operations in the Disc Spring market. Since an in-depth analysis of competitive dynamics, the environment, and probable growth path are given in the report, a stakeholder can move ahead with fact-based decision-making in favor of market achievements and enhancement of business opportunities.

About The Insight Partners

The Insight Partners is among the leading market research and consulting firms in the world. We take pride in delivering exclusive reports along with sophisticated strategic and tactical insights into the industry. Reports are generated through a combination of primary and secondary research, solely aimed at giving our clientele a knowledge-based insight into the market and domain. This is done to assist clients in making wiser business decisions. A holistic perspective in every study undertaken forms an integral part of our research methodology and makes the report unique and reliable.

0 notes

Text

Predictive Maintenance as a Service for Cement Industry: An Overview

These processes & machines need to occur in tandem, without intervals, to create high-quality cement. Unplanned downtime in even one of these machines can unleash havoc on the ongoing process, not just endangering efficiency & quality but also health & safety of personnel on-site.

The cement manufacturing industry is one of the oldest and most critical manufacturing industries for the global civilization. It has witnessed unparalleled growth at the heart of most economic developments and international growth this decade. Fortune Insights report says, the global cement market will grow from $326.80 billion in 2021 to $458.64 billion in 2028, a steep 5.1% globally. It is then no wonder that cement plants face pressure for process and asset maintenance.

CEMENT MANUFACTURING PROCESS & NEED FOR PREDICTIVE MAINTENANCE

Cement manufacturing is one of the most complex continuous manufacturing processes, with multiple ingredients & steps involved. Here is an overview of the entire process wrt machines used at each stage:

Predictive Maintenance checklist for cement industry:

Extractors: Used to Quarry the raw materials, i.e. limestone & clay

Crushers used to crush high rock piles into coarse powders called raw meal

Blenders & Mixers mix the crushed raw meal in the right proportions

Grinders to further grind the raw material to free different minerals in the ore

A rotary kiln where the raw meal is heated up to 1450 degrees & then cooled

Assembly belts & conveyors to carry the cement for packing & dispatching to customers

These processes & machines need to occur in tandem, without intervals, to create high-quality cement. Unplanned downtime in even one of these machines can unleash havoc on the ongoing process, not just endangering efficiency & quality but also health & safety of personnel on-site.

Common causes for machine downtime in a cement plant

Loose nuts, bolts, springs, plates, spring rods, flywheel, bearings, shaft, coupling housing, hammer rotor

Motor failure, Conveyor belt, breakage, bearing failure, stretching rod breakage, breakage of separator blade

Fan bearing breakage, fan unbalance

Gear knocking, gear tooth wear, gear deformation, gear spitting and spalling

Axle spindle breakage, crusher bearings failure, slip tape breakage

Disc liner shift

Rolling mill cracks, tubing failure, pump failure, spoke breakage

Grate plate breakage

Why asset maintenance in cement plants is a necessity?

Asset maintenance in cement plants is critical because:

Extensive repair & replacement costs

Chances of industrial safety hazards & accidents

Over maintenance of equipment, causes wear & tear

Harsh operating environment

Dynamic environment, needing proactive decision making

Enable remote monitoring & control for agility & resilience to

How can Predictive Maintenance as a Service help?

With the stakes so high and a constantly changing environment, real-time machine diagnostics are necessary to empower plant managers with the correct data. IIoT can enable this by enabling a 360-degree view of interconnected assets across the plant. Predictive maintenance as a service allows plant managers in cement managers to move away from reactive measures like reactive maintenance and preventive maintenance to a predictive one, where critical machines don’t have to be pulled down unless there is a specific anomaly.

At a grass root level, predictive maintenance as a service by IU for cement plants can be implemented by putting sensors at strategic positions on the machines. Vibration analysis of mechanical equipment components like Air Compressors, Belt drives or Conveyors, Fans and blowers, Kiln rollers, Motor bearings & Vertical and horizontal mills can help predict anomalies.

The Predictive Maintenance as a service solution by Infinite Uptime involves collecting data, analysis & computing of the triaxial vibrations, temperature and noise of the mechanical equipment on edge at real-time via a patented edge computing system. The data then is monitored & analyzed in real-time, and a machine health score is assigned. A machine with a lower health score is flagged to the plant supervisor or plant engineer with a diagnostic assessment of the probable cause for the anomaly and a recommendation on improving the same. Not just that, if not considered severe yet, but still significant; the fault is continuously monitored, with relevant parameters like temperature, vibration etc., to assure that it does not aggravate the status quo. This information can be made available in real-time to the appropriate people at their fingertips. An access-based dashboard ensures that you get access to the most relevant machine data for the plant from single machine access for a plant operator to multiple machines across the plant access for a plant head and a multi-plant machine score for a manufacturing head. Let’s look at a

case study

around how we helped a top Indian cement manufacturer reduce 250 hours of downtime.

Conclusion

Today, the cement industry is on the cusp of digital transformation, fueled by rising demand and cut-throat competition and increasingly stringent regulations. The pressure on the cement industry’s assets, processes, and people to be on the top of their game has never been higher. In such a scenario, Predictive Maintenance as a Service for your cement plant can help avoid machine failures and the associated unplanned downtime and the quality of the output cement and the OEE (Overall Equipment Effectiveness) of the cement plants. It improves machine availability and performance, also saving costs for repairs & spare parts. But most importantly, it arms you with resilience & agility during unpredictable times via remote monitoring and proactive maintenance when needed the most.

This blog is referenced from : https://www.infinite-uptime.com/predictive-maintenance-as-a-service-for-cement-industry-an-overview/

0 notes

Text

Preparing for the future of EHRs

Electronic health records (EHRs) first replaced paper medical records in the 1960s, and the technology has since progressed from punch cards, magnetic tape, and floppy discs to today’s cloud computing. The format of taking a patient’s medical history has also changed, from problem-oriented medical records to the more modern subjective, objective, assessment, and plan (SOAP) note. Despite this progress, the full potential of EHRs remains elusive for clinicians, consumers, health systems, and the health care system as a whole.

As the EHR market continues to consolidate, cloud adoption increases, and additional 21st Century Cures Act requirements go into effect later this year, health care organizations should be considering the future of EHRs. To better understand how EHRs should evolve to meet changing needs, the Deloitte Center for Health Solutions conducted a survey of 38 US-based College of Healthcare Information Management Executive (CHIME) members in the spring of 2022 and interviewed 13 EHR experts from 10 organizations including health care provider organizations, EHR companies, startup companies, and government agencies in the summer of 2022. The survey was designed to learn how EHRs can strive to:

Achieve equitable health outcomes for all consumers with a focus on wellness and prevention,

Enable clinicians to meaningfully connect with their patients and practice effectively and efficiently,

Help health systems better serve their patient populations and communities while continuing to operate well financially, and

Allow public health departments, researchers, and other stakeholders to access and use relevant data.

Our research found that many users want their EHRs to do more. Nineteen percent of the CHIME survey respondents were dissatisfied or very dissatisfied with their organization’s EHR system, with another 11% neither satisfied nor dissatisfied. Even respondents who were satisfied (70%) stated that aspects of their current EHR system wouldn’t be able to meet future needs. Interviewees noted that allowing clinicians to chart the way they want has always faced tension with the need for EHRs to satisfy other requirements (e.g., billing and regulatory reporting).

As we think about how EHRs should evolve out of necessity, it helps to understand what health care might look like in the next decade. Deloitte’s vision for the Future of HealthTM predicts that key drivers such as consumerism, data-sharing, and data interoperability will transform the health care industry by 2030. Consumers will seek out convenience and will be more focused on prevention and well-being. More advanced technologies will enable new capabilities. Are today’s EHRs prepared to help health systems meet this new future?

Health care organizations have realized the initial benefits of digitizing records, but health care leaders should prepare for the next generation of EHRs. Many of our interviewees felt that change is already underway, particularly with the opportunities that cloud native EHRs and a platform ecosystem approach can provide. Health systems should think more holistically about EHRs within the context of their current digital technology investments and identify what capabilities could improve the experience for consumers and clinicians. They also should develop a plan to test new capabilities and workflows, potentially with health care and technology partners.

Convenient, consumer-centric EHR systems

Interviewees noted that health care consumers want both convenient access to health care and good relationships with their physicians. But if they had to choose one, they would choose convenience. To help address this, more than half of the survey respondents are interested in adopting tools that would improve the consumer experience by reducing the time and burden of accessing care. In fact, 61% of the respondents plan to invest in patient communication tools, such as telehealth and messaging capabilities, with their health care team over the next three to five years (figure 1). Online appointment scheduling and virtual registration are other consumer-specific capabilities that organizations are looking to invest in during this timeframe.

To address some of these pain points, Geisinger Health System is streamlining its patient registration process using biometrics. Patient wait times are shorter because the patients are checked in faster and no longer required to share their date of birth, social security number, or medical record number at each appointment. This solution can also reduce the burden on front-office staff and reduce patient misidentification and fraud.8 Nearly 80% of patients who were offered facial biometrics chose to enroll in the program, demonstrating its appeal to consumers, likely due in part to consumers’ comfort level with similar technology on their smartphones.

Unsurprisingly, interviewees noted that EHRs and patient portals are not intuitive enough, and improvements are needed for both clinicians and consumers. Clinicians in particular find documentation burdensome. While interviewees agreed that keyboard shortcuts and macros can help alleviate some of the data entry issues, broader changes should be made. Finding information is not always easy, and even if the capability is there, figuring out how to use it (e.g., sharing data and making it actionable) can be difficult.

Leveraging user experience design is important, but interviewees also touched on using human-centered design (HCD) and equity-centered design in the development of future EHRs (see sidebar, “Visualizing patient asthma history using HCD processes,” for more information.). That means designing EHRs with an understanding that not all end users are the same—even if they fit under the same persona category. It’s also important to recognize why different users are using the system (including researchers and administrators pulling reports for payers, regulators, public health agencies, etc.), invite a diverse set of users into the discussion from the beginning of the process, and provide more education and training on the EHR and some aspects of human- and equity-centered design.

Visualizing patient asthma history using HCD processes

The Children’s Hospital of Philadelphia (CHOP) developed an interactive visualization of patient asthma history using HCD processes.11 Embedded in the EHR and using Fast Healthcare Interoperability Resources (FHIR), the tool was used in a pediatric emergency department. CHOP found that using the asthma timeline application resulted in a reduction in time on task, number of screens, and cognitive load as well as high user satisfaction.

In ensuring that EHRs serve future health care needs, it also falls on developers to think about how to “build humanity into our systems.” There are a few examples of this including, empathetic chatbots that respond with “I’m sorry that this has happened to you” instead of “Thank you for your feedback.” Another solution is allowing patients to record their names to be stored in the EHR to help clinicians pronounce their patients’ names properly, thus helping health care professionals practice culturally humble care and rebuild patient trust. Ensuring patient portals are available in different languages to improve equitable access to patient health information is another potential solution.

Approaching EHRs with human- and equity-centered design approaches could lead to a host of improved outcomes. A few of the improvements include, reduced time spent documenting, a better understanding of the patient’s medical history, a stronger patient/clinician relationship, less clinician burnout, more engaged health care consumers, and less stress in sometimes difficult health care interactions.

Interviewees also noted that a focus on prevention and wellness will be essential moving forward. As John Glaser writes, “the electronic health record must transition from an emphasis on a person’s medical record to an emphasis on a person’s plan for health.” Rather than recording what a patient is encountering, the EHR should help the clinician plan a course of action to improve the patient’s health or keep them healthy. This could include a library of care plans, personalized algorithms, care team support, interoperability, decision support, and analytics, and support the transition to value-based care. A person with well-managed diabetes, for example, would have a different care plan than that of a person with diabetes who needs more support. Survey respondents seemed keen on this idea as two-thirds of respondents are looking to enhance clinical decision support and advanced diagnostics for their clinicians in the next three to five years. In addition, 50% of respondents plan to invest in advanced analytics and machine learning that suggest a course of treatment and automate.

Preparing for a new generation of EHRs

Will the future of EHRs include ambient listening systems? Holograms? Hospitals at home? Many interviewees felt that change is afoot, with the possibility of a new generation of EHRs arising soon. In preparation for this, health systems should:

Analyze clinician care delivery workflows to find opportunities for improvement. Prioritize those that improve efficiency and clinician satisfaction. Determine if an emerging technology capability can help address the issue.

Identify key consumer activities that are not yet addressed. Evaluate and prioritize initiatives to meet these needs.

Automate or eliminate manual or nonvalue add tasks in the front/back office.

Understand your EHR vendor’s roadmap for embedding machine learning, AI, and automation, and compare it to your organization’s priorities.

Develop a strategic plan that allows for initial, iterative testing of new capabilities, workflow, and automation with new health care and technology partners.

Future EHR solutions should be designed to cater to the needs of all users—especially the needs of consumers and clinicians. These solutions also should leverage the latest technology such as cloud native, platform ecosystems to improve consumers’ health and wellness.

Technical Doctor's insight:

Contact Details : [email protected] or 877-910-0004 www.technicaldr.com

0 notes

Link

The global Disc Springs market was valued at 480.91 Million USD in 2021 and will grow with a CAGR of 5.16% from 2021 to 2027, based on the newly published report. The prime objective of this report is to provide the insights on the post COVID-19 impact which will help market players in this field evaluate their business approaches. Also, this report covers market segmentation by major market Vendors, types, applications/end users and geography(North America, East Asia, Europe, South Asia, Southeast Asia, Middle East, Africa, Oceania, South America).

#Disc Springs Market#Disc Springs Market Size#Disc Springs Market Share#Disc Springs Market Growth#Disc Springs Market Trends

0 notes

Text

Disc Springs Market 2021 | Business Opportunity, Growth Strategies & Forecast Report By 2027

The Global Disc Springs Market Report, in its latest update, highlights the significant impacts and the recent strategically changes under the present socio-economic scenario. The Disc Springs industry growth avenues are deeply supported by exhaustive research by the top analysts of the industry. The report starts with the executive summary, followed by a value chain and Marketing channels study. The report then estimates the CAGR and Market revenue of the global and regional segments.

Base Year: 2020

Estimated Year: 2021

Forecast Till: 2027

The report classifies the market into different segments based on type and product. These segments are studied in detail, incorporating the market estimates and forecasts at regional and country levels. The segment analysis is helpful in understanding the growth areas and potential opportunities of the market.

Get | Download FREE Sample Report of Global Disc Springs Market @ https://www.decisiondatabases.com/contact/download-sample-1513

A special section is dedicated to the analysis of the impact of the COVID-19 pandemic on the growth of the Disc Springs market. The impact is closely studied in terms of production, import, export, and supply.

The report covers the complete competitive landscape of the Worldwide Disc Springs market with company profiles of key players such as:

Schnorr GmbH

Mubea

Century Spring Corp

Lesjöfors

Hagens Fjedre A/S

Igus

Bauer Springs

SPIROL International Corporation

Tohatsu

International Industrial Springs (IIS)

Daemar Inc

Scherdel

Circlips Australia

MW Industries, Inc. (MWI)

Bellevile Spring

Want to add more Company Profiles to the Report? Write your Customized Requirements to us @ https://www.decisiondatabases.com/contact/get-custom-research-1513

Disc Springs Market Analysis by Type:

Standard Materials

Corrosion-resistant Materials

Thermally Stable Materials

Others

Disc Springs Market Analysis by Application:

Plant Construction

Power Station Construction

Machine Construction

Others

Disc Springs Market Analysis by Geography:

North America (USA, Canada, and Mexico)

Europe (Germany, UK, France, Italy, Russia, Spain, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South-East Asia, Rest of Asia-Pacific)

Latin America (Brazil, Argentina, Peru, Chile, Rest of Latin America)

The Middle East and Africa (Saudi Arabia, UAE, Israel, South Africa, Rest of the Middle East and Africa)

Key questions answered in the report:

What is the expected growth of the Disc Springs market between 2022 to 2027?

Which application and type segment holds the maximum share in the Global Disc Springs market?

Which regional Disc Springs market shows the highest growth CAGR between 2022 to 2027?

What are the opportunities and challenges currently faced by the Disc Springs market?

Who are the leading market players and what are their Strengths, Weakness, Opportunities, and Threats (SWOT)?

What business strategies are the competitors considering to stay in the Disc Springs market?

Purchase the Complete Global Disc Springs Market Research Report @ https://www.decisiondatabases.com/contact/buy-now-1513

About Us: