#Drive-In Pallet Rack Systems

Explore tagged Tumblr posts

Text

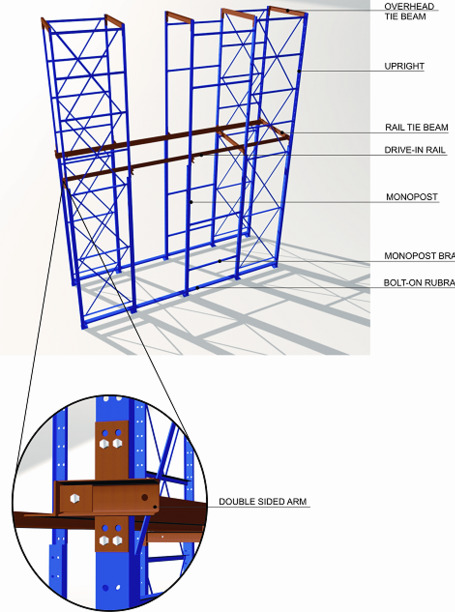

Drive-In Racking System | Drive-Through Racking System I Camara Industries, Inc

Drive-In Rack and Drive-Through Rack Systems are Ideal for high-volume, low-SKU applications . Lane depth can reach over 10 pallets deep and are a practical way to redeem pallet efficiency by using this high density storage system method. Contact Camara Industries, Inc to learn about our cost-effective drive in racking systems and start improving your storage capacity!

#Rack Drive#Drive In Racking System#Drive-Thru Pallet Rack Systems#Drive-In Rack#Drive-In Pallet Rack Systems#Drive-Thru Rack#Cold Warehouse Storage#Structural Drive-In Rack#Structural Drive-Through Rack

0 notes

Text

Mobile Pallet Racking System: Maximizing Storage Efficiency

In the field of modern warehousing optimizing space is paramount. A Mobile Pallet Racking System provides a dynamic solution. It combines high-density storage and easy accessibility. This innovative system amplifies warehouse operations. It uses mobile bases to move pallet racks along tracks. This creates flexible aisles only when necessary.

What is a Mobile Pallet Racking System?

It is a storage solution where pallet racks are mounted on mobile bases. These bases come with wheels or tracks. They can be moved electronically or manually. This allows access to a specific Pathway, while the rest of the system remains compacted.

Key Features of Mobile Pallet Racking Systems :

Storage with High Density

Make use of all available space by decreasing the number of aisles. It is an ideal solution for facilities with storage capacity constraints.

Ease of Access

Mobile mechanisms allow the opening of aisles when you want. They make sure the stock retrieval is efficient.

Handling Heavier Loads

These systems are intended to manage pallets of a heavy-duty nature. They are ideal for industrial applications.

Advanced controls

Systems are equipped with electronic controls. Additionally, they have safety features such as motion detectors to avoid accidents or collisions.

Configurations that Can Be Customized

Systems are available in designs that are single or double-depth. These are to meet specific storage requirements.

Benefits of Utilizing a Mobile Pallet Racking System:

Space Optimization: Utilize up to 80% of warehouse space. Improved Inventory Management: Accessing specific pallets is easy. Ensures streamlined inventory handling.

Cost Savings: The need for extra warehouse space is reduced. This is accomplished by maximizing the existing capacity.

Enhanced Security: Locking mechanisms limit access. Those features protect goods of high value.

Applications of Mobile Pallet Racking Systems :

1. Cold storage facilities.

2. Manufacturing plants.

3. Distribution centers.

4. Warehouses with space limitations.

Conclusion :

Mobile Pallet Racking System is an innovative storage solution. It is designed to enhance efficiency in warehouses. Productivity is also enhanced. This system is a compact design. Combined with flexible access it makes it an excellent choice. Businesses can use it to optimize storage space. Functionality is not compromised. Invest in a mobile pallet racking system. The system can transform your warehouse operations. It also meets the demands of a modern high-density storage environment.

#warehouses#drive-in racking system#mezzanine floor structure manufacturers#business#metalstorage#industrial storage racks in noida#industrial racks for warehouses#slotted angle racks manufacturers#modular mezzanine floor in pune#mobile pallet racking system

0 notes

Text

#Drive-In Pallet Racking is installed in warehouses and distribution centers that need a cost effective#high density storage solution for their products.Drive-in systems can be designed to store 2 to 10 pallets deep per lane. Because of its de#drive-in pallet rack is a first in#last out (FILO) storage system.

0 notes

Text

The Drive-In Racking system is an excellent solution for maximizing warehouse storage in high-density environments. Designed for storing large quantities of similar products, this system allows forklifts to drive directly into the rack structure, enabling deep storage of pallets in lanes. With no need for individual access aisles for each pallet, Drive-In Racking optimizes space by allowing more goods to be stored in a smaller area. It’s ideal for industries with high-volume, low-rotation products, such as cold storage and food processing. Eurorack’s Drive-In Racking is built to handle heavy loads while ensuring stability and safety.

#drive in racking system#pallet racking system#drive in racks#drive thru racking system#storage racking system#heavy duty racks#eurorack#warehouse racking system#eurorack drive in racks

1 note

·

View note

Text

Compactor Storage Systems Manufacturer In Pune – Max Space

Max Space Racking Systems is a leading compactor storage systems manufacturer in Pune. Explore our space-saving solutions for efficient storage. In a world where efficient storage solutions are paramount, Max Space Racking Systems emerges as a trusted compactor storage systems manufacturer in Pune, India. Compactor storage systems are a vital component of modern storage solutions. They offer a space-saving and highly organized way to store a wide range of items, from documents and files to goods in warehouses and distribution centers.

#Compactor Storage Systems Manufacturer in Pune#Design & Manufacturing Of Racking System in Pune#Vertical Carousels Manufacturer in Pune#vertically stacked trays or shelves in Pune#Pallet Shuttle Systems Manufacturer in Pune#Selective Pallet Racks Manufacturer in Pune#Drive-in Racks Manufacturer in Pune#Multi Tier Racks Manufacturer in Pune#Shelving Racks Manufacturer#FIFO Racks Manufacturer#Cantilever#Racks Manufacturer#Racks for Bobbin / Rolls Manufacturer

0 notes

Text

Boost Your Storage Space with the Best Racking Systems in Dubai

As the organizations in Dubai are concerned, they always look forward for innovative solutions that increase the efficiency factor. A well-designed racking system would be the key that could bring a transformation in how the goods were placed, organized, and accessed. Through this blog, we explore the various types of racking systems in Dubai for businesses to enhance storage space with streamlined operations.

The Need For Racking System In Dubai

In a city such as Dubai, where space often seems limited and businesses are spreading fast, an efficient storage system is inevitable. A racking system in Dubai enables companies to maximize available space by making vertical storage areas highly accessible and organized storage zones.

A racking system helps businesses store more goods within a smaller footprint, reduces clutter, and improves productivity. A retail store, warehouse, or manufacturing facility cannot improve overall efficiency without implementing a racking system.

Types of Racking Systems for Maximum Storage

There is no one-size-fits-all for racking systems, and Dubai business owners have the privilege of making a choice from among thousands of options. Below are some of the most popular types of racking systems that businesses use to increase their storage capacity:

1. Selective Pallet Racking

Selective pallet racking is the most common warehouse storage solution that is applied in Dubai warehouses. It is highly effective for direct access to each pallet for any kind of business undertaking a massive and frequently used inventory. Selective racking is highly cost-effective since it requires no complicated technology for installation. It also serves the warehouses and big stores.

2. Drive-In Racking

The racking system is most suited to companies engaged in bulk storage of commodities as it allows the entry of forklifts into racking lanes so that goods can be accommodated in a much smaller and denser volume. It is an efficient storage mechanism especially suited for holding big quantities of identical products.

3. Push-Back Racking

Dubai-based push-back racking systems give flexibility to businesses which need to store with high density as well as easy accessibility. The racking system makes use of a car system which goes back by sliding on the rails while goods can be loaded at the front while older stock pushes back at the rear end. This push-back racking is applied in many warehouses and distribution centers offering greater storage density and product rotation.

4. Cantilever Racking

Cantilever racking is an excellent solution for businesses that store long, bulky, or irregularly shaped items. This racking system uses arms that extend from a vertical structure, providing open, easy access to materials like pipes, wood, and metal. It is perfect for industries such as construction, manufacturing, and retail.

5. Mezzanine Racking

Mezzanine racking is ideal in Dubai, which is where the vertical space is a bit of a problem. It provides another level or platform, mostly in warehouses, for storage purposes. This type of racking system is highly customizable and will help a business double its storage space without having to find additional floor space.

Benefits of Storage Racks in Dubai

The strategic use of storage racks in Dubai provides numerous benefits to businesses of all sizes. Some of the main advantages include:

Increased Storage Capacity: The most important benefit of any racking system is that it enables businesses to store more products within the same area. Maximizing vertical space allows businesses to reclaim essential floor area for more efficient operations and activities.

Improves the Inventory Management System: With an organized racking system, the company will store its goods in a very logical and accessible way. Thus, the organization of its inventory will increase, which in turn leads to quick retrieval time and minimum chances of mistakes.

Improved Safety: When installed and serviced properly, racking reduces the number of accidents caused by ill-maintained goods stored. This applies to any warehouse or factory that operates heavy machinery.

Maximized Efficiency: Storage racks Dubai help businesses streamline their operations, making it easier to access goods quickly and efficiently. This leads to faster order fulfillment, reduced downtime, and improved workflow.

Customizing Your Racking System for Optimal Results

Maximizing vertical space allows businesses to reclaim essential floor area for more efficient operations and activities.Customization options are available for businesses looking to maximize storage efficiency.

For example, businesses that deal with a wide variety of products might benefit from adjustable shelving units that can be tailored to suit different sizes. Alternatively, if your business relies on heavy machinery or equipment, high-density racking systems can be designed to accommodate these requirements.

The Future of Storage Solutions in Dubai

As Dubai grows into a global business and trade hub, the demand for efficient storage solutions will only grow. Investing in the best racking system in Dubai will keep your business competitive and future-ready.

The evolution of storage systems also brings in smarter technologies, such as automated racking systems and RFID tracking, that further optimize storage management and improve accuracy.

Conclusion

In conclusion, the perfect racking system is an investment that brings long-term benefits to your business. This includes improving efficiency and capacity for increased storage. That is the way to deal with storage racks in Dubai. And as businesses continue growing and spaces are becoming limited, the racking system continues to be critical in providing optimal solutions for storage space.At Cosmictech, we understand the specific storage challenges businesses face in Dubai. Design your storage to maximum space usage, safety, and efficiency. Contact us today and let's help you build your storage capabilities with the best racking systems in Dubai.

0 notes

Text

Why Pallet Racking Systems Are the Backbone of Organized Warehouses?

In any warehouse, space is money — and Pallet Racking Systems help you use that space wisely. Designed for stacking goods vertically, these racks improve accessibility, boost efficiency, and keep your floor clutter-free.

Whether you're managing bulk items, packaged goods, or high-frequency stock, pallet racking systems give you the flexibility to organize inventory by type, weight, or movement speed. They not only support better stock control but also reduce the risk of damage and delays during order picking.

At Sigma Racks, we manufacture heavy-duty pallet racks that are built to handle industrial loads without compromising on safety or durability. Our racks are designed using automated machines for precision and consistency, and we offer customized layouts based on your product flow and warehouse size.

From selective and drive-in systems to push-back and double-deep setups, we help you choose the right configuration to match your operational needs. The result? Faster access, optimized space, and smoother workflows.

If you’re struggling with disorganized storage or underutilized vertical space, it’s time to upgrade your warehouse with pallet racking systems that do more than just hold pallets — they hold your business together.

#pallet racking systems#warehouse pallet racks#industrial pallet racks#heavy duty pallet racking#pallet storage solutions#pallet racking manufacturer

1 note

·

View note

Text

warehouse racking manufacturers

PRK Steel Pvt. Ltd. is widely recognized as one of the best manufacturers and suppliers of warehouse racking systems in India. With years of expertise and a strong commitment to quality, PRK Steel delivers innovative and customized racking solutions tailored to meet the diverse needs of modern warehouses and industrial storage facilities.

Their comprehensive range includes pallet racks, cantilever racks, drive-in racks, long span shelving, and multi-tier systems—all designed for maximum space utilization, strength, and durability. PRK Steel uses high-grade raw materials and advanced manufacturing techniques to ensure each product adheres to international quality standards.

read more:

0 notes

Text

Revolutionizing Storage: The Advantages of Push Back Racking Systems

Push Back Racking Systems have transformed the landscape of storage and inventory management, offering an unparalleled efficiency in maximizing warehouse space. Unlike traditional racks, Push Back Racks can store up to six pallets deep, boosting storage capacity by 25-30% more than selective racking systems. This leap in efficiency is achieved through an innovative design: pallets rest on wheeled carts that glide along inclined rails, enabling deep storage without necessitating multiple aisles.

See More: https://camaraindustries.com/revolutionizing-storage-the-advantages-of-push-back-racking-systems/

0 notes

Text

How Metal Buildings Can Be Customized for Warehousing and Distribution Centers

Meta Title: Custom Metal Buildings for Warehousing & Distribution

Meta Description: Learn how metal buildings can be tailored for warehouses and distribution centers, offering flexibility, durability, and cost-effective solutions.

Categories: Construction, Good Reads, Steel Building Insider, Steel Buildings A-Z

Building Types: Industrial, Storage, Storage Units, Warehouse, Workshop, Commercial

Speed, space, and scalability. These aren’t just buzzwords—they’re mission-critical requirements for modern warehouse and distribution facilities. Whether you're building a regional fulfillment hub, a last-mile delivery depot, or a custom logistics center, you need a structure that works as hard as your operation does.

That’s why smart companies are turning to Armstrong Steel. As a direct manufacturer of pre-engineered steel buildings, we deliver faster timelines, lower long-term costs, and structural flexibility that traditional construction simply can’t compete with. Our buildings are engineered to streamline your logistics operations from the ground up—and designed to grow alongside your business.

Why Steel Buildings Are Built for Logistics

Warehousing today isn’t about just stacking pallets—it’s about flow. Movement. Throughput. From receiving bays to automated storage and outbound lanes, your building needs to support operational efficiency without bottlenecks.

Armstrong steel buildings are designed for exactly that. With wide clear-span interiors, high eave heights, customizable loading dock placements, and expansion-ready framing, we give you the foundation to move goods, equipment, and teams with purpose and precision.

And unlike conventional construction, our kits arrive on your job site pre-cut, pre-drilled, and ready for fast erection—minimizing disruption and helping you go operational sooner.

Design for the Operation You Run—Not a One-Size-Fits-All Shell

Every warehouse build starts with a deep dive into how your business functions. That means asking the right questions:

What’s the flow of goods from inbound to outbound?

How much space do you need for racking, staging, or assembly?

Will you be using forklifts, conveyors, or overhead cranes?

Is vertical storage a priority?

Do you anticipate adding space later on?

Our team collaborates with you to design a structure that supports these workflows now—while also making future changes fast and affordable. From bay spacing to roof pitch to insulation specs, every Armstrong building is engineered around your real-world use case.

Go Vertical with Confidence

Warehouse land is expensive. Going vertical is how you maximize it.

Armstrong Steel buildings are engineered to support tall eave heights—30, 40, even 60 feet or more—without sacrificing interior flexibility. That means you can install multi-level racking, integrate mezzanines, or prep for automated storage/retrieval systems right from day one.

And because our buildings are column-free across wide spans, you get full access to every cubic foot—no wasted space, no layout restrictions.

Clear-Span Interiors. Zero Obstructions.

No columns. No interference. No compromises.

Armstrong’s clear-span framing systems eliminate interior supports, giving you open, uninterrupted space to design your floor plan however you need it. Rearrange zones, expand product lines, add assembly stations—our structure won’t get in your way.

Need separate climate zones, pick-and-pack stations, or equipment corridors? You’ve got the freedom to build them exactly where you want, without having to redesign your entire layout.

Integrated Loading, Shipping & Receiving Access

Logistics lives and dies by the loading dock.

Armstrong Steel buildings can be configured with multiple overhead doors, dock-high access points, and drive-through bays exactly where you need them. Whether you’re accommodating 53' trailers or cross-docking small parcel deliveries, we help you place entry points to reduce turnaround time and maximize flow.

Our design consultants coordinate with your layout to ensure traffic patterns, vehicle staging, and access points support real efficiency—not just architectural symmetry.

Build Today. Expand Tomorrow.

Need 20,000 square feet now, but planning for 60,000 next year?

Armstrong buildings are modular by design. Our pre-engineered connections and panelized systems allow you to add bays, extend length, or even add hybrid-use areas like cold storage, break rooms, or controlled-environment chambers—without tearing down or rebuilding from scratch.

Your initial structure can be framed with expansion in mind, making future growth seamless and cost-effective.

Smarter Climate Control, Lower Operating Costs

Warehouses are big—and big spaces can bleed money on climate control if they’re not designed right.

That’s why Armstrong Steel offers smart building envelope options including:

High R-value insulation systems to stabilize internal temps

Ridge vents and solar exhaust fans to improve air circulation

Reflective roof panels to reduce heat gain

Optional wall light panels and skylights to cut lighting costs

Whether you’re storing dry goods, sensitive components, or perishable items, we help you control internal conditions without blowing your operating budget.

Engineered Strength. Every Time.

Armstrong buildings aren’t just fast and flexible—they’re strong.

We account for every variable: live loads, wind uplift, snow accumulation, seismic zones, and site-specific weather exposure. Your structure is engineered to last—with built-in durability that outperforms wood, tilt-wall, and conventional steel alternatives.

And because we manufacture every component in-house, we maintain tight tolerances and deliver exact-fit pieces—reducing on-site rework and maximizing structural reliability.

The Armstrong Advantage

From your first phone call to the final bolt, we’re in your corner.

We don’t outsource design. We don’t resell someone else’s package. We work directly with you—business owner to building consultant—to make sure your warehouse or distribution center is built right, from day one.

You’ll get:

A dedicated project consultant

Custom-engineered drawings and foundation plans

Pre-punched, pre-cut framing for precise assembly

U.S.-sourced steel with proven performance

Industry-leading warranties and structural support

Start Your Warehouse Build the Right Way

Armstrong Steel has delivered thousands of precision metal building kits across North America—each one built to meet the real-world needs of logistics operators, warehousing professionals, and commercial developers.

If you're ready to build smarter, faster, and stronger, we're here to help.

Call 1-800-345-4610 to speak with a building consultant Or click ‘Price My Building’ on our website to get a fast, customized quote

0 notes

Text

Boost Shelf Load Capacity with Jugmug’s High-Speed Stiffener Machines

In the modern warehousing and logistics sector, efficient storage systems are the backbone of operations. Every component, from beams to panels and stiffeners, must be precisely engineered to ensure structural integrity and load-bearing capacity. At the core of this reliability is the Shelf Stiffener – a critical component that strengthens shelving units to support heavier loads without deformation.

Jugmug RollForming, a trusted name in roll forming solutions, delivers high-speed shelf stiffener roll forming machines that empower manufacturers to meet industry demands with accuracy, consistency, and speed. Whether it’s for industrial racking systems, warehouse storage units, or retail shelving, Jugmug’s machines are designed to enhance structural stability and efficiency.

Why Shelf Stiffeners Matter in Storage Systems

Shelf stiffeners are metal profiles that provide additional support to the base of shelves or panels, preventing sagging or bending under heavy loads. They are especially vital in:

Heavy-duty racking systems

Industrial shelving

Retail display shelves

Warehouse storage units

By integrating stiffeners, shelves can safely bear more weight, ensure worker safety, and prolong product lifespan.

Challenges Faced by Manufacturers

Manufacturers of shelving systems face several challenges:

High-volume production demands

Need for dimensional accuracy

Consistency in profile shape and strength

Adaptability to different sizes and materials

Competitive pricing pressures

This is where Jugmug RollForming steps in with its automated, high-speed shelf stiffener roll forming machines, offering a perfect balance of performance, flexibility, and cost-efficiency.

Jugmug RollForming: Revolutionizing Shelf Stiffener Manufacturing

With years of experience in roll forming technology, Jugmug RollForming has carved a niche in manufacturing custom roll forming lines for industrial applications. Their shelf stiffener roll forming machines are engineered with precision to meet the diverse needs of manufacturers worldwide.

Key Features of Jugmug’s Shelf Stiffener Roll Forming Machines

High-Speed Production

Time is money in manufacturing. Jugmug’s machines operate at high line speeds, ensuring increased output without compromising on quality.

Consistent Profile Accuracy

With servo feeding, precision roll tools, and hydraulic cutting, every shelf stiffener produced is dimensionally consistent – essential for perfect shelf assembly.

Customizable Design Options

Jugmug offers complete flexibility in terms of:

Profile shapes (hat, omega, channel, or custom)

Material thickness (typically 0.6mm to 2.5mm)

Width variations

Punching configurations

Heavy-Duty Frame & Construction

Built with high-grade materials, these machines are suitable for 24/7 industrial operations, with minimal maintenance and downtime.

Hydraulic & Servo Automation

From decoiling to punching, forming, and cutting, every stage is automated for seamless, uninterrupted production.

Touchscreen HMI and PLC Control

Operators can manage settings, monitor output, and troubleshoot with ease using user-friendly PLC control panels.

Technical Specifications (Typical Configuration)

Material: Galvanized Steel, CRCA, SS

Thickness: 0.6 mm to 2.5 mm

Line Speed: Up to 25–40 meters/min

Roll Stations: 10–18 (depending on profile)

Drive System: Gearbox or Chain Drive

Punching: Hydraulic or Mechanical (inline/offline)

Cutting: Post-cut or flying cut-off

Power Supply: 3 Phase, 415V, 50Hz

Note: Specifications can be customized based on client needs.

Applications of Jugmug’s Shelf Stiffener Profiles

Heavy Load Shelves – For storing large equipment, tools, or inventory

Pallet Racking Support – Stiffeners act as reinforcement for cross beams

Retail Display Shelving – Enhances aesthetics and load strength

Cold Storage Systems – Suitable for moisture-resistant steel profiles

Benefits of Choosing Jugmug RollForming

Turnkey Solutions

Jugmug provides complete roll forming lines, including:

Decoilers

Punching Press

Roll Forming Mill

Cutting Units

Run-out Tables

Global Reach

Serving clients across India, the Middle East, Africa, and Southeast Asia, Jugmug ensures timely delivery, support, and spares.

After-Sales Support

From installation to training and troubleshooting, Jugmug’s engineers offer end-to-end support, ensuring smooth operations at client facilities.

Custom Engineering Expertise

Whether you need to integrate with an existing line or develop a new solution from scratch, Jugmug’s team of engineers ensures your machine is tailored to your production needs.

Why Manufacturers Prefer Jugmug for Shelf Stiffener Machines

Proven track record in industrial roll forming

Heavy-duty machine construction for long service life

Energy-efficient systems with low operational costs

Quick setup and changeover features

High ROI due to speed, accuracy, and automation

Final Thoughts

For businesses in the storage, warehousing, retail shelving, or racking industry, investing in the right manufacturing technology is critical. Jugmug RollForming’s Shelf Stiffener Roll Forming Machines offer the perfect combination of speed, reliability, and customizability, helping manufacturers improve product quality and boost operational efficiency.

If you’re looking to maximize shelf load capacity and stay ahead in a competitive market, Jugmug RollForming delivers the innovation you need.

0 notes

Text

Why a Drive-In Freezer Is a Game-Changer for Your Cold Storage Needs

by International Coolers

When it comes to industrial cold storage, space, efficiency, and temperature control aren't just conveniences—they're necessities. That’s where the drive-in freezer earns its reputation.

Whether you're managing a food distribution warehouse, pharmaceutical logistics, or high-volume storage for perishable goods, a drive-in freezer provides the heavy-duty solution you need. And at International Coolers, we specialize in tailoring these systems to meet global industry demands.

🚛 What Is a Drive-In Freezer?

A drive-in freezer is a specialized cold storage unit designed to allow forklifts or pallet jacks to drive directly into the storage space. Unlike standard walk-in units, this design allows deep storage with minimized aisle space—perfect for high-density, palletized inventory.

Key Features:

❄️ Ultra-low temperature operation

🧊 High-density racking system

🚪 Reinforced insulated panel doors

🚚 Forklift accessibility for seamless logistics

📦 Space-efficient design for bulk storage

🌍 Why International Coolers?

We serve clients worldwide with custom freezer solutions engineered for performance, durability, and energy savings. Our drive-in freezers are trusted across industries that demand consistency under extreme conditions.

Here’s what sets us apart:

🔧 Custom sizes, voltages & racking solutions

🌱 Energy-efficient cooling systems

🏗️ On-site consultation & installation

🔒 Reliable sealing & insulation to prevent temperature fluctuations

🌎 Global delivery and support

🧠 When Should You Invest in a Drive-In Freezer?

You manage a large volume of perishable products

You want to maximize storage space

You need quick access for shipping & receiving

You operate in industries like food & beverage, pharmaceuticals, meat processing, or cold chain logistics

📩 Get a Custom Quote Today

Whether you're scaling your storage or building from scratch, our expert engineers at International Coolers are here to help. Let’s future-proof your business with a drive-in freezer solution that’s built to last.

🔗 Visit our website to learn more 📞 Contact us directly or DM us here for a quick consultation.

#DriveInFreezer #ColdStorage #InternationalCoolers #IndustrialFreezer #FrozenLogistics #CommercialFreezer #FreezerWarehouse #ColdChain #WalkInFreezer #FrozenFoodIndustry

#DriveInFreezer#ColdStorage#InternationalCoolers#IndustrialFreezer#FrozenLogistics#CommercialFreezer#FreezerWarehouse#ColdChain#WalkInFreezer#FrozenFoodIndustry

1 note

·

View note

Text

Design & Manufacturing of Racking System in Pune | Max Space Rack

At Max Space Racking System, our expertise lies in designing and manufacturing high-quality racking systems in Pune. We are dedicated to optimizing your space and streamlining your operations for maximum efficiency.

#Design & Manufacturing Of Racking System in Pune#Compactor Storage Systems Manufacturer in Pune#Vertical Carousels Manufacturer in Pune#vertically stacked trays or shelves in Pune#Pallet Shuttle Systems Manufacturer in Pune#Selective Pallet Racks Manufacturer in Pune#Drive-in Racks Manufacturer in Pune#Multi Tier Racks Manufacturer in Pune#Shelving Racks Manufacturer#FIFO Racks Manufacturer

0 notes

Text

What Equipment Powers The Future Of Automated Material Movement

The logistics world is rapidly changing. Today, warehouses, factories, and distribution centers are heavily dependent on automation. This transition is about much more than speed, however; it’s also about safety, precision and cost-cutting.

At the center of this revolution is some formidable hardware. These machines are not only moving things. They can think, talk and respond in real time.

The future of moving stuff is smart machines that can never take a break. What instrumental technology is driving this shift, and what role does each play in automated loading and unloading the telco supply chain?

Mobile Robots Without Supervision (AMRS):

Autonomous Mobile Robots (AMRs) are blazing the trail in new-age logistics. These robots can move materials around a warehouse floor without the need for tracks or wires. They rely on sensors, cameras and maps to navigate.

Indeed, they’re designed to adjust to shifts in layout or traffic because of that. Which is why they’re great for busy bees. AMRs can be programmed to transport tools, parts and even entire orders between stations.

What’s more, they dodge people and obstacles by themselves. Thanks to onboard AI, they can even make real-time decisions. Unlike conventional conveyor belts, the AMRs require no fixed paths.

So, they save time on setup and can tweak them as necessary. From e-commerce to manufacturing, including perishable food, such robots offer flexibility and speed.

And, as a bonus, they free up human labor to be used for more dangerous and repetitive work. That reduces the risk of injury while enabling a smoother operation.

AS/RS (Automated Storage And Retrieval Systems)

Automated Storage and Retrieval Systems (AS/RS) bring intelligent storage to the material supply and handling of work-in-process materials. These systems employ cranes, shuttles or robotic arms to store and retrieve items.

Warehouse software records everything. The right item is delivered quickly as soon as an order arrives. This eliminates the requirement for laborious manual picking, an activity that is inherently slow and prone to human error.

AS/RS equipment operates in the vertical as well. So, companies can stick them in tall racks and save space on the floor. That’s great for warehouses where every foot matters.

And these automated material handling solutions (here and here as well) can increase the accuracy of your inventory. They monitor inventory in real time and cut down on overstock and missed items.

And they don’t stop. Which means swifter shipping times and better customer service. They may be an investment up front, but what you’ll save in the long run is worth it. The warehouses of the future will not operate without them.

Everything You Need To Know About Automatic Guided Vehicles (AGVS)

Automated Guided Vehicles, known as AGVs, are similar to robot forklifts. They move pallets, bins, or containers to and from the loading area. AGVs, in contrast to AMRs, often depend on wires, magnets, or lasers for guidance. This makes them even more appropriate for predictable environments.

AGVs are great on the factory floor and large distribution centers. They are stable and can carry heavy burdens without tiring. Their paths can be programmed for repetitive tasks, such as shuttling materials between different production lines.

They cut down on traffic jams at active facilities and ensure that goods are always in motion. With the further implementation of Industry 4.0 by enterprises, AGVs will remain a mainstay of smart logistics.

Robotic Arms, Pick And Place And The Precision Experts

It’s not just a car factory involved any longer. Now, they are influential players in warehouses and fulfillment centers. These machines do pick, packing, sorting and even palletizing.

With vision systems and gripping tools, they can also identify and grab objects with great precision. They don’t mind working with products in various shapes and sizes.

These robots excel in e-commerce. They process hundreds of orders an hour and no one ever complains. By reading bar codes and sensing product attributes, they grab the right one every time.

Some systems apply machine learning and get better with time. Which means the more they work, the smarter they become. Robotic arms also help take the strain off of labor.

Conclusion

Automated moving things is no longer a trend — it’s the future of supply chains. From AMRs to robot arms, these tools are remaking the way businesses store, move and deliver goods.

Each machine is somebody’s miracle cure. Together, they create a smart, responsive system, which both saves money and increases productivity.

As new technology continues to develop this equipment will only become more sophisticated. Companies that want to keep up need to adopt these tools now. The future is not to those who move faster, but those who move smarter.

0 notes

Text

A Real-World Example of Cost Savings with 3PL Services

In today’s dynamic and competitive logistics landscape, businesses are constantly looking for smarter ways to optimise their operations and reduce costs. This is where partnering with a reliable 3PL logistics company like Jeena & Company can deliver tangible value. Through a combination of operational expertise and upgraded infrastructure, a 3PL logistics company helps businesses streamline their supply chain while ensuring scalability and efficiency.

Let’s take a real-world example of how Jeena & Company recently helped its clients achieve significant cost savings through strategic warehouse upgrades and improved 3PL services.

At the core of this success is Jeena’s newly upgraded warehouse infrastructure, designed to boost efficiency, save costs, and improve overall customer experience. By investing in advanced storage solutions and seamless handling systems, Jeena and Company redefined the meaning of smart warehousing in the logistics industry. Our warehouses cater to a wide range of industries, including pharmaceuticals, FMCG, health & wellness, fitness, fashion, cosmetics, and luxury retail. From shampoos and healthcare products to gym equipment and high-end luxury items, our smart warehousing solutions are equipped to handle diverse product categories with precision and care.

Here’s a look at what’s new:

Heavy-duty Racking Jeena has increased its warehouse storage capacity by a notable 20%, adding 1,040 pallet positions to the existing 4,616. This upgrade ensures that more goods can be stored efficiently, reducing the need for frequent inventory movement and enabling bulk storage at lower costs.

Multi-Tier Shelving To cater to the growing demands for varied storage solutions, 16,000 new bin locations have been introduced. These bins allow for organised, space-saving storage, especially for SKUs with smaller volume. This flexibility has been a game-changer for clients with diverse inventory needs, offering them better inventory management at a lower operational cost.

Spiral Chute for Small Parcel Handling Speed and safety in handling smaller packages are often overlooked, but not at Jeena. The addition of a spiral chute ensures the seamless movement of small consignments between floors. This means faster packing and delivery times with reduced manpower involvement—another critical contributor to cost savings.

These upgrades may sound like operational enhancements, but in practice, they’ve resulted in direct financial benefits for customers. Reduced storage and labour costs, faster order fulfilment, better inventory accuracy, and scalability without the need for capital investment are some of the key outcomes delivered by Jeena.

When clients opt for Jeena’s services, they don’t just hire a warehouse—they partner with a logistics partner that anticipates future needs, adapts quickly, and invests in solutions that directly impact the client’s bottom line. As a 3PL logistics company committed to customer success, Jeena has proven that small infrastructure changes can lead to big savings.

In summary, choosing the right 3PL logistics company can lead to substantial cost efficiencies. Jeena & Company’s warehouse upgrades are a prime example of how forward-thinking logistics solutions drive operational excellence. With state-of-the-art warehouse facilities in Mumbai and now in Pune as well, businesses benefit from strategic locations that enhance distribution and reduce transit time. Companies no longer need to carry the burden of managing logistics in-house. By outsourcing to a trusted 3PL logistics company, they gain access to expertise, innovation, and infrastructure that fuel growth while saving money.

Looking to simplify your logistics and amplify savings? Choose Jeena & Company—where innovation meets reliability in every shipment. Share your logistics needs at [email protected] or visit us at www.Jeena.com.

To Know More: https://jeena.com/a-real-world-example-of-cost-savings-with-3pl-services/

0 notes

Text

Top Mistakes to Avoid When Choosing Warehouse Racking Systems

It's important to select the right warehouse racking system to store inventory, make sure it's safe and increase efficiency. Organizing inventory, ensuring safety and improving operational efficiency are all benefits of these systems. However, many businesses make bad choices, install or plan these systems, which leads to productivity and safety problems in the future.

In this blog, we’ll explore the top mistakes to avoid when choosing Warehouse Racking Systems, so you can build a storage setup that’s both scalable and secure.

1. Not Considering Load Requirements

A common error is failing to estimate the weight and type of products being stored. The choice of Warehouse Racking Systems without a proper load analysis can result in structural failure or overengineering that can result in high costs. In addition to calculating the average and peak loads per level and per bay, as well as dynamic loading factors for moving items, every Storage Rack Safety standard should be considered as well.

2. Ignoring Floor Space and Ceiling Height

Installing racks without understanding your warehouse dimensions leads to wasted vertical or horizontal space. Modern Racking Systems should be tailored to your exact layout. Skipping this step often results in racks that either block pathways or fail to utilize the available height. A poorly designed racking layout may even increase operational delays.

3. Overlooking Future Scalability

Often businesses plan by considering their current inventory. However, good Racking Systems should be capable of adjusting as the company grows. Whenever possible, choose modular racks that can be expanded, added levels or converted into different types of racks such as mezzanines or cantilevers racks. In order to plan properly, warehouse rack installation must be scalable and forward-looking.

4. Choosing the Wrong Rack Type

From selective pallet racks to drive-in or push-back systems, each type serves a different need. Selecting the wrong one could slow down your picking process or reduce density. Make sure the Warehouse Racking Systems you choose match your inventory rotation, item size, and picking speed. Understanding Industrial Racks Selection is key to efficiency.

5. Ignoring Safety Features

Neglecting safety features is a dangerous oversight. Rack end protectors, column guards, beam locks, and anti-collapse mesh should be considered essential — not optional. A safe Warehouse Storage System reduces accident risk and increases employee confidence. Implementing Safety Standards should be a top priority.

6. Poor Installation Practices

If the racks are poorly installed, they will not perform as well as well-designed racks will, Uneven floors, improper anchoring, and misaligned beams can pose safety hazards; Always utilize experienced professionals to install your Warehouse Racking Systems and ensure compliance with local codes and load specifications; Prioritize the installation of certified storage racks.

7. Skipping Regular Inspections and Maintenance

Once installed, Warehouse Racks need periodic checks. Over time, bolts loosen, uprights can get hit, and loads might shift. A regular inspection schedule keeps your system safe and compliant. Following a storage rack maintenance checklist helps prevent long-term failures.

8. Not Integrating with Warehouse Flow

Your racking should support — not disrupt — your warehouse's workflow. Poor layout planning can lead to bottlenecks, excess travel time, or difficulty accessing fast-moving stock. Align Warehouse Racking Systems with receiving, staging, and dispatch zones. A well-planned warehouse storage solution supports operational flow.

Final Thoughts

You will ensure that your Industrial Racks continue to serve your business for many years to come by avoiding these mistakes. A dynamic asset can be created with the right planning, professional guidance, and proactive maintenance. Investing wisely in your warehouse will maximize space, improve safety, and optimize every square foot.

By taking the time to assess your needs and investing wisely, you will maximize your warehouse's potential.

Need help planning your racking setup? Speak with expert consultants and explore scalable warehouse racking systems that match your exact operational needs.

#warehouseracking#warehouserackingsystem#racksforwarehouse#warehouserackinstallation#racking mistakes

1 note

·

View note