#EPDM rubber sheets

Explore tagged Tumblr posts

Text

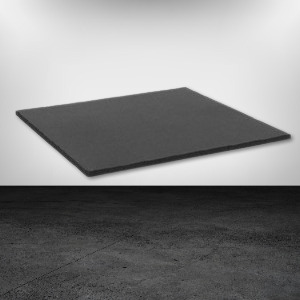

EPDM rubber sheets offer a unique combination of strength, flexibility, and resistance to harsh environments, making them the ideal material for a wide range of applications. Whether you're looking for weatherproof solutions, sound insulation, or durable gaskets, EPDM sheets can meet your needs.

EPDM Rubber Sheets Manufacturer

Choosing the right EPDM rubber sheet manufacturer is crucial for ensuring quality and performance. Look for a manufacturer with a proven track record of excellence, offering

EPDM Rubber Sheets Manufacturers

Several reputable manufacturers supply high-quality EPDM rubber sheets. Here are a few popular options:

EPDM Rubber Sheets Dealers

For convenient access to EPDM rubber sheets, consider purchasing from trusted dealers.

#EPDM rubber sheets#EPDM Rubber Sheets Manufacturer#EPDM Rubber Sheets Manufacturers#EPDM Rubber Sheets Dealers

0 notes

Text

0 notes

Text

EPDM RUBBER SHEETS - MATC: Mustafa Ashqar Trading LLC

EPDM Rubber Sheets are known for their excellent resistance to weathering, ozone, and chemicals, making them suitable for a wide range of applications, particularly in outdoor and industrial environments. For more visit, https://mustafaashkar.com/product/epdm-rubber-sheets/

0 notes

Text

Buy Nitrile Rubber Rolls - Wholesale Rubber Depot

Is nitrile rubber expensive?

The cost of nitrile rubber (NBR) can vary, and whether it is considered expensive or not depends on several factors, including your specific needs, budget, and the context in which you are using it. Here are some points to consider:

Relative Cost: Nitrile rubber is generally more affordable than some specialized elastomers like silicone rubber or fluorocarbon rubber (Viton). So, in comparison to these materials, NBR might be considered relatively cost-effective.

Application: Whether NBR is expensive or not depends on the application. For some industrial or commercial applications, the cost of NBR may be justified due to its durability, resistance to oils and chemicals, and other desirable properties. In such cases, it may not be considered expensive when weighed against its performance.

Volume: The cost per unit of nitrile rubber tends to decrease when purchased in larger quantities. If you need a small amount, it may appear relatively more expensive on a per-unit basis.

Quality and Grade: Different grades of NBR are available, and higher-quality grades often come at a higher price. The choice of grade depends on the specific requirements of your application.

Market Conditions: The price of NBR can fluctuate due to market conditions, so what might be considered expensive at one time could become more affordable at another.

Alternatives: It's also essential to consider alternatives when evaluating the cost of NBR. If there are suitable alternatives that are more cost-effective for your application, then NBR might be relatively expensive in comparison.

In summary, whether nitrile rubber is expensive or not is a relative judgment and depends on various factors, including your specific needs, budget constraints, and the properties of NBR that make it suitable for your application. It's advisable to compare prices from multiple suppliers, consider your specific requirements, and assess the long-term benefits of using NBR to determine its cost-effectiveness for your situation.

#rubber material wholesale#buy nitrile rubber rolls#rubber product wholesaler#white epdm rubber wholesale#nitrile white rubber sheet#epdm rubber rolls wholesale#neoprene rubber 40 duro

0 notes

Text

Our rubber flooring solution for playgrounds is safe and aesthetically beautiful. Additionally, we offer other alternative flooring options for playgrounds.

#rubber floor mats#rubber flooring#rubber mats#rubber matting#rubber sheets#rubber uk#epdm rubber flooring

0 notes

Text

Our rubber flooring solution for playgrounds is safe and aesthetically beautiful. Additionally, we offer other alternative flooring options for playgrounds.

#rubber mats#rubber matting#rubber floor mats#rubber flooring#epdm rubber flooring#epdm flooring#rubber sheets#rubber uk

0 notes

Text

Exploring Rubber Sheet Manufacturing and Advanced Additives in India

India has become a key player in the global rubber industry, largely due to its expanding network of high-quality rubber sheet manufacturers. These manufacturers produce a wide range of rubber sheets tailored for applications in automotive, construction, electronics, pharmaceuticals, and general engineering sectors.

Rubber sheet production involves precise blending of rubber materials and additives to meet performance criteria like resistance to heat, oil, abrasion, and chemicals. Among the many variants produced, silicone rubber compound remains a top choice for demanding environments due to its superior thermal and chemical stability.

The Role of Rubber Sheet Manufacturers

Rubber sheet manufacturers in India operate advanced facilities capable of producing both standardized and custom-designed rubber sheets. These include natural rubber sheets, EPDM sheets, nitrile sheets, neoprene sheets, and silicone rubber sheets. The sheets are used for gaskets, flooring, insulation, anti-vibration pads, and sealing applications.

With a focus on precision, durability, and compliance with global standards, Indian manufacturers serve both domestic markets and international clients across Europe, the Middle East, and Southeast Asia.

Silicone Rubber Compound: A Versatile Material

One of the standout materials in the rubber industry is silicone rubber compound. It is known for maintaining elasticity and functionality in extreme temperatures, high UV exposure, and chemical-prone environments. Silicone rubber compound is used in applications where hygiene, flexibility, and reliability are non-negotiable—such as food processing, pharmaceuticals, and electronics.

Many rubber sheet manufacturers in India offer silicone-based rubber sheets in both solid and sponge forms, catering to niche markets that demand precision and high performance.

Rubber Masterbatches: Enhancing Manufacturing Efficiency

A key innovation that has revolutionized rubber production is the use of rubber masterbatches. These are pre-mixed blends of rubber-compatible additives, offering consistent quality and improved dispersion during sheet production. With rubber masterbatches, manufacturers achieve better process control, reduced production time, and minimal material loss.

Indian rubber manufacturers use custom rubber masterbatches to meet the specific needs of clients in sectors like railways, defense, healthcare, and oil & gas.

Why India Leads in Rubber Sheet Manufacturing

India’s advantage in rubber manufacturing is driven by several strengths:

Advanced technology and R&D

Skilled labor and material expertise

Global quality standards (ISO, RoHS, FDA-compliance)

Strong export capabilities

Growing demand for sustainable and recyclable rubber products

With these factors, Indian rubber sheet manufacturers are meeting the rising global demand for high-quality rubber solutions at competitive pricing.

Conclusion

From high-performance silicone rubber compounds to efficient production through rubber masterbatches, India’s rubber sheet manufacturers are helping global industries operate more safely, reliably, and efficiently. Their ability to combine traditional expertise with modern innovation is positioning India as a global hub for advanced rubber solutions.

0 notes

Text

Waterproof Membrane Sheet for Long-Lasting Roof Protection

When it comes to safeguarding buildings from water infiltration, a Waterproof Membrane Sheet remains one of the most dependable and widely adopted solutions in the construction industry. These thin layers of material are specifically engineered to prevent water from penetrating roofing structures, thereby extending their life and reducing maintenance costs.

Why Roofs Fail Without Proper Waterproofing

Roofs are the first line of defense against the elements. Over time, exposure to rain, UV rays, temperature shifts, and environmental pollutants can weaken unprotected surfaces. Without effective Waterproofing Products, water seeps into cracks and crevices, leading to structural damage, mold growth, and insulation degradation.

🔍 Expert Insight: "About 80% of building envelope problems are due to water infiltration, most commonly through the roof," says Rajesh Desai, a structural consultant with over 15 years in urban infrastructure design.

What Is a Waterproof Membrane Sheet?

A Waterproof Membrane Sheet is a barrier layer installed on rooftops, terraces, or substructures to block water penetration. These membranes are typically made from bituminous materials, PVC, TPO (Thermoplastic Polyolefin), or EPDM (Ethylene Propylene Diene Monomer). Their flexibility, durability, and resistance to environmental stress make them ideal for both new constructions and renovation projects.

Key Features to Look For:

UV and weather resistance

High tensile strength

Thermal insulation compatibility

Ease of application on various substrates

Advantages of Using Waterproof Membrane Sheets

Longevity: Offers 15–25 years of protection, reducing the need for frequent repairs.

Energy Efficiency: Reflective membranes can help maintain internal temperatures and lower energy bills.

Adaptability: Can be applied to complex shapes and various roofing types including sloped, flat, or domed.

Cost-Effective: Though the upfront cost may be higher, long-term savings on repairs and energy bills are substantial.

📢 Testimonial "Since installing the membrane sheet three years ago, our industrial unit hasn’t experienced a single leak—even during monsoon season," notes Meenakshi Rao, Facility Manager, Pune.

Common Types of Waterproofing Products for Roofs

Bituminous Membranes: Asphalt-based, great for low-slope roofs.

Liquid-Applied Membranes: Suitable for complex roof geometries.

Thermoplastic Membranes (PVC/TPO): High UV resistance and longevity.

Rubber-Based Sheets (EPDM): Extremely flexible and durable in cold climates.

Each of these Waterproofing Products offers unique benefits, and the choice often depends on the roof's design, location, and intended lifespan.

FAQs

Q: Can membrane sheets be installed over old roofs? Yes. Many Waterproof Membrane Sheets are designed to adhere to existing surfaces, making them ideal for refurbishment projects.

Q: How long does installation typically take? For an average-sized roof, installation can be completed in 2–5 days, depending on complexity and weather conditions.

Q: Are these sheets environmentally friendly? Modern membranes like TPO and EPDM are recyclable and often meet LEED or green building standards.

How to Ensure Proper Installation

To maximize performance, membranes should be installed by trained professionals using the right primers, sealants, and overlaps. Poor installation often leads to premature failures, defeating the purpose of investing in premium Waterproofing Products.

🧰 Pro Tip: Always insist on a post-installation flood test. This test involves temporarily ponding water on the membrane to ensure there are no leaks before the top layer is installed.

Final Thoughts

A Waterproof Membrane Sheet isn’t just an add-on; it’s a foundational component for sustainable and secure construction. Whether you're safeguarding a home, warehouse, or commercial space, investing in the right Waterproofing Products ensures peace of mind and long-term durability.

#Waterproof Membrane Sheet#Caulking#Waterproofing Products#Waterproofing Products Australia#Waterproofing Supplies

0 notes

Text

Essential Waterproofing Techniques to Prevent Roof Leakage: A Guide to Protecting Your Home

When keeping your home safe from the weather, the roof is your first line of defence. However, with the wear and tear of a roof, weather, and neglect, your roof will leak at some point. This is where waterproofing comes into play.

Waterproofing techniques will not only help deter water from damaging your roof, but they will also help prolong the life of your roof. If your roof is flat or sloped, being aware of the best waterproofing techniques and hiring the best waterproof expert can save you an expensive repair down the road.

Why Waterproofing Matters

When a roof doesn’t have a proper waterproofing system, your home or building could suffer extensive damage afterwards. Water entering a home due to roof leaks can damage the roof structure, the inside of the walls, the insulation, and the ceilings.

Water entering the living space makes it unhealthy and will cost you thousands of dollars to repair. In regions experiencing significant snowfall or rainfall, the chances of a roof leak increase dramatically. This is why you need to invest in waterproofing services near you to make a roof time- and weather-proof.

Essential Waterproofing Techniques

Let’s discuss the essential waterproofing techniques to prevent roof leakage:

1. Liquid Applied Membranes

Sheet membranes are one of the most common methods of waterproofing flat roofs. They are commonly made from elastomeric or polyurethane materials. Liquid-applied membranes create a seamless, flexible, and waterproof barrier when applied to the roof surface.

Liquid-applied membranes can withstand the elements after being applied, and installation involves simple procedures, which is why many homeowners prefer them. Liquid-applied membranes work so well for flat roofs because they form an even surface and do not allow for ponding water. They are also UV resistant and will not break down after prolonged exposure.

2. Bituminous Coatings

Bituminous coatings are another common waterproofing product. Bituminous coatings are primarily made with asphalt but may also have other elements that will harden and provide a hard, water-tight coating. They are a good option for many types of roofing materials, particularly flat roofs, and are excellent at preventing overwhelming amounts of water from penetrating the roof material. Bituminous coatings can be applied to roofing by liquid application, which will form a coating after hardening, that is thick and acts as a protective layer. The application is deemed best suited for labor-intensive roofing types because they are more suited for extreme climate applications (high rain or snow).

3. EPDM (Ethylene Propylene Diene Monomer)

EPDM is a rubber membrane commonly used in the waterproofing of flat roofs. It is extremely flexible, highly durable, and ultraviolet resistant; therefore, it can be very effective in waterproofing roofs in extreme weather situations. EPDM membranes are supplied in large sheets and bonded to the roof surface, which provides unbroken, watertight protection against water intrusion.

This product provides huge benefits because of its longevity; EPDM roofs can have a lifespan of more than 30 years with proper maintenance. With the flat roofs we tend to pond, EPDM can be your best option.

4. Torch-on Felt Membranes

Membranes with torch-on felt flexible waterproofing systems are suitable for waterproofing pitched roofs and flat roofs as well. The system works by making contact with the torch and heating the underside of the membrane, and exposing it to the roof surface.

The adhesive is activated with heat and forms a strong bond with the roof material. Torch-on membranes are very durable, can withstand high temperatures, and will work acceptably in general climates. They also provide excellent waterproofing capabilities, preventing leaks.

5. Green Roofing Systems

For homeowners who are committed to green living, a green roof can be functional as well as visually appealing. Green roof systems consist of vegetative material planted in soil that insulates as well as retains water. The last layer of the roof system is a waterproof membrane that is intended to prevent water from penetrating the roof structure under the soil finish.

This method is used extensively in commercial buildings and is now being embraced more by residential homes. A green roof can do more than prevent leaks as an added benefit, it can also provide energy savings because it works as a natural insulating layer.

Choosing the Best Waterproofing Company

When waterproofing your roof, ensure you hire a trustworthy waterproofing company with the training and experience. Here is what you should look for when hiring a waterproof contractor:

Experience: Choose a company with a well-known reputation for waterproofing roofs, especially if you have a flat roof or require specialty treatments.-

Licensing and Insurance: Verify that the waterproofing company is licensed and insured to work on roofing and waterproofing. This protects you from liability if an accident takes place in the course of work.

Reputability: Read online reviews and get references from friends or family. Good contractors will have feedback and happy customers.

Warranty: A reputable waterproofing company will provide warranties on work. This guarantees that if something happens with water intrusion in the future, you can get the waterproofing fixed at no additional cost.

Conclusion

Gest best Rightcliq Waterproofing services for extremely important to avoid roof leakage and protect your home. No matter what type of roof you have, flat or sloped, investing in waterproofing and hiring the expert waterproofing contractors could save you lots of money over the next few years.

From liquid membranes to bituminous coatings to EPDM, there are many options available to suit your needs. Don't waste your time or money waiting for a leak. Contact a reputable waterproofing company like RightCliq and give your roof the protection and care it deserves.

Resource : https://rightcliqservices.blogspot.com/2025/06/essential-waterproofing-techniques-to.html

0 notes

Text

EPDM Rubber Sheet: The Versatile and Reliable Choice for Various Applications

When it comes to rubber sheets, one material stands out for its exceptional versatility, durability, and performance - EPDM rubber. Ethylene Propylene Diene Monomer (EPDM) rubber is a synthetic elastomer widely used in a variety of industrial and commercial applications. Its unique properties make it an ideal choice for sealing, insulating, and protecting various surfaces and environments.

In this comprehensive guide, we will delve into the world of EPDM rubber sheets, exploring their characteristics, benefits, applications, and why they have become a go-to option for engineers, architects, and professionals across different industries.

What is EPDM Rubber?

EPDM rubber is a type of synthetic rubber derived from ethylene, propylene, and a diene monomer. The addition of the diene monomer allows for cross-linking during vulcanization, enhancing the material's overall strength and resilience. This makes EPDM rubber highly durable and resistant to weather, heat, ozone, and other environmental factors.

Characteristics of EPDM Rubber Sheets

EPDM rubber sheets boast a remarkable set of characteristics that set them apart from other rubber materials:

Weather Resistance: EPDM rubber exhibits exceptional resistance to weathering, UV rays, and ozone exposure. This makes it perfect for outdoor applications where exposure to harsh environmental conditions is a concern.

Temperature Tolerance: EPDM rubber can withstand a wide temperature range, from -40°C to 120°C (-40°F to 248°F), without compromising its flexibility or performance. This makes it suitable for both hot and cold environments.

Chemical Resistance: EPDM rubber is highly resistant to a variety of chemicals, including acids, alkalis, and polar substances. This property makes it ideal for applications where contact with corrosive materials is possible.

Electrical Insulation: The excellent electrical insulating properties of EPDM rubber make it valuable in the electrical and electronics industry, where it is used for cable insulation, gaskets, and other applications.

Tear and Abrasion Resistance: EPDM rubber offers exceptional tear and abrasion resistance, ensuring its longevity and reliability even in high-stress environments.

Flexibility: Despite its robustness, EPDM rubber remains flexible, allowing it to conform to irregular shapes and surfaces, making it ideal for various sealing applications.

Waterproofing: EPDM rubber's water-resistant properties make it the preferred choice for roofing, pond liners, and other applications requiring effective waterproofing solutions.

The AIDA Approach to EPDM Rubber Sheets

Attention - Why Choose EPDM Rubber Sheets?

When it comes to choosing the right material for your project, EPDM rubber sheets should be at the top of your list. The impressive combination of weather resistance, temperature tolerance, chemical resistance, and electrical insulation sets EPDM rubber apart from other rubber materials. Whether you need a reliable sealing solution, a durable roofing membrane, or an electrical insulator, EPDM rubber sheets have got you covered.

Interest - The Many Applications of EPDM Rubber Sheets

The versatility of EPDM rubber sheets opens up a world of applications across various industries. Let's explore some of the most common uses:

1. Roofing Applications

EPDM rubber sheets are widely used in the construction industry for roofing applications. The material's exceptional waterproofing and weather-resistant properties make it an ideal choice for flat roofs, green roofs, and even traditional sloped roofs. EPDM roofing membranes are easy to install, highly durable, and can withstand extreme weather conditions, making them a popular choice for both residential and commercial buildings.

2. Automotive Seals and Gaskets

In the automotive industry, EPDM rubber is commonly used for manufacturing seals and gaskets. The material's ability to resist heat, chemicals, and weathering ensures that these automotive components maintain their integrity and prevent leaks and vibrations.

3. Electrical Insulation

EPDM rubber's excellent electrical insulating properties make it a preferred material for cable insulation and various electrical components. It helps protect wires and cables from environmental factors, ensuring safety and optimal performance.

4. HVAC Systems

In the heating, ventilation, and air conditioning (HVAC) industry, EPDM rubber is utilized for gaskets, O-rings, and seals. Its resistance to extreme temperatures and chemicals ensures that HVAC systems operate efficiently and reliably.

5. Pond Liners

EPDM rubber sheets are widely used as pond liners due to their exceptional waterproofing capabilities. They provide a durable and flexible solution for creating water features and natural-looking ponds in various landscaping projects.

6. Industrial Hoses

EPDM rubber is an excellent material for manufacturing industrial hoses due to its high-temperature tolerance, chemical resistance, and flexibility. These hoses find applications in the transport of water, steam, chemicals, and other substances.

Desire - Advantages of Choosing EPDM Rubber Sheets

Choosing EPDM rubber sheets for your projects comes with a host of advantages:

Longevity: EPDM rubber sheets have an extended service life, making them a cost-effective solution in the long run.

Minimal Maintenance: The durable nature of EPDM rubber reduces the need for frequent maintenance, saving time and resources.

Environmentally Friendly: EPDM rubber is a sustainable material that can be recycled and repurposed, contributing to environmental conservation efforts.

Easy Installation: EPDM rubber sheets are relatively easy to install, further reducing project timelines and costs.

Flexibility and Versatility: The flexibility and versatility of EPDM rubber allow it to adapt to various applications and project requirements.

Energy Efficiency: EPDM roofing membranes contribute to energy efficiency by reflecting sunlight and reducing cooling costs.

Action - Making the Right Choice

When choosing EPDM rubber sheets for your projects, consider the following factors:

Application: Identify the specific application and requirements of your project to select the appropriate EPDM rubber sheet type.

Thickness: Choose the right thickness based on the level of protection and insulation needed for your project.

Quality: Opt for high-quality EPDM rubber sheets from reputable suppliers to ensure superior performance and longevity.

Installation: If you are not familiar with EPDM rubber installation, seek professional help to ensure proper application and maximum efficiency.

Maintenance: Although EPDM rubber requires minimal maintenance, periodic inspections are essential to address any potential issues promptly.

Conclusion

In conclusion, EPDM rubber sheets stand as a testament to the remarkable capabilities of synthetic rubber materials. Their exceptional weather resistance, temperature tolerance, chemical resistance, and electrical insulation properties make them an incredibly versatile and reliable choice for various applications.

Whether you need a durable roofing solution, a reliable sealing material, or an electrical insulator, EPDM rubber sheets have got you covered. Their longevity, minimal maintenance requirements, and energy-efficient properties make them a cost-effective and environmentally friendly option.

So, the next time you embark on a project that demands performance and durability, consider EPDM rubber sheets as your go-to choice. Experience the advantages of this remarkable material and ensure the success of your project with EPDM rubber sheets.

0 notes

Text

EPDM Rubber Gasket Suppliers in Hyderabad

If you’re hunting for EPDM Rubber Gasket suppliers in Hyderabad, you’ve landed in the right spot! Poly Projects is among the top EPDM Rubber Gasket manufacturers in Hyderabad known for quality, durability, and customized solutions that fit your exact needs.

What’s so special about EPDM Rubber Gaskets anyway?

Made from Ethylene Propylene Diene Monomer (EPDM) — a fancy name for a rubber that’s tough as nails.

They resist heat, UV rays, and weather like champs.

Perfect for sealing windows, doors, pipes, and machines — basically, wherever you need to keep stuff airtight or watertight.

Why Poly Projects?

We deliver the best EPDM Rubber Gasket products with precision.

Custom sizes and shapes to match your project.

Quick and reliable delivery — no waiting weeks.

Affordable prices without cutting corners on quality.

Not just EPDM Rubber Gaskets!

We also supply:

Polycarbonate Roofing Sheets — let the sunshine in, but keep the rain out.

Galvanized Iron Color Coated Sheets — strength meets style.

UPVC Sheets / Windows — durability that lasts.

Silicon Sealant — perfect for extra tight seals.

Self Drill Screws — strong fastening guaranteed.

Car Parking Sheds, Canopy, Sky Light Duct Covering

Swimming Pool Covering — complete outdoor protection solutions.

Who uses our products?

Builders, architects, contractors, and homeowners all across Hyderabad and Telangana rely on us for quality materials that stand the test of time.

Why trust us?

Top-notch manufacturing with strict quality control.

Environmentally friendly materials.

Expert advice and support whenever you need it.

Thousands of happy clients and growing!

Ready to seal the deal with the best EPDM Rubber Gasket suppliers in Hyderabad? 📞 Call us now at 92909 12888 🌐 Visit polyprojects.in for more info.

#EPDM Rubber Gasket Manufacturers in Hyderabad#EPDM Rubber Gasket Suppliers in Hyderabad#EPDM Rubber Gasket Hyderabad#Best EPDM Rubber Gasket#Top EPDM Rubber Gasket Suppliers#Durable EPDM Rubber Gasket Hyderabad#Custom EPDM Rubber Gaskets#Industrial EPDM Gasket Suppliers Hyderabad#EPDM Gasket for Construction#Weather Resistant EPDM Rubber Gasket#Affordable EPDM Rubber Gasket Hyderabad#EPDM Sealing Gaskets Hyderabad#Polycarbonate Roofing Sheets Hyderabad#Galvanized Iron Color Coated Sheets#UPVC Sheets and Windows Suppliers#Silicon Sealant Suppliers Hyderabad#Self Drill Screws Manufacturer#Car Parking Sheds Hyderabad#Canopy Suppliers Hyderabad#Sky Light Duct Covering Supplier#Swimming Pool Covering Hyderabad

0 notes

Text

Find the top epdm waterproofing rubber membrane sheeting price, manufacturers and suppliers- Duratuf

Are you trying to find the best epdm waterproofing rubber membrane sheeting price, manufacturers and suppliers? Locate us in Mexico that provide premium EPDM sheets at affordable prices. Perfect for industrial waterproofing, ponds, and roofing. Obtain long-lasting, weatherproof solutions right now! For the best prices and large orders, get in touch with reliable suppliers right now. Examine costs and get high-quality EPDM sheets in Mexico!

Get Offers on Bulk Orders!

0 notes

Text

Rubber Gasket: The Silent Sealant Behind Durable Designs

Introduction

In industrial manufacturing, home construction, automotive design, or plumbing, the role of a rubber gasket cannot be overstated. While they may appear insignificant, these components ensure airtight, watertight, and dust-tight seals that maintain system integrity, reduce energy loss, and extend product life.

Let’s explore the comprehensive world of rubber gaskets, their importance, the wide array of types available, and how to choose the best one for your needs.

1. Why Are Rubber Gaskets Essential in Modern Engineering?

At its core, a rubber gasket serves one fundamental purpose: sealing the gap between two surfaces to prevent leakage or contamination. These surfaces may expand, contract, or vibrate due to pressure or temperature changes. A rubber gasket accommodates such movements while maintaining a strong seal.

Without a proper gasket, even the most advanced machines or perfectly aligned window frames can develop leaks or inefficiencies.

2. Exploring Key Types of Rubber Gaskets

Understanding gasket types is critical in choosing the right one. Let’s review the most commonly used types:

a. Rubber Gasket Sheet

Ideal for custom-cut solutions, a rubber gasket sheet can be sliced into specific dimensions for industrial machinery, pipe flanges, or HVAC systems.

b. Rubber Window Gasket

These are precision-made strips or frames that seal gaps in window and door assemblies. A rubber window gasket enhances insulation and keeps out rain, dust, and noise.

c. Silicone Rubber Gasket

Famed for its flexibility, a silicone rubber gasket resists both high and low temperatures. It’s perfect for medical, food-grade, and electrical use where hygiene and stability are key.

d. EPDM Rubber Gasket

Known for outstanding resistance to UV light, ozone, and weathering, the EPDM rubber gasket is ideal for rooftops, solar panels, and building facades.

e. Rubber Flange Gasket

Used in pipelines, rubber flange gaskets seal joints between metal flanges, preventing leaks in plumbing, fire systems, or oil transmission lines.

3. Specialized Applications Across Sectors

Rubber gaskets are used in everything from household appliances to rocket engines. Their adaptability makes them a preferred solution across sectors:

Construction: Rubber gasket for aluminum windows is essential for sealing frame joints against water infiltration and air leakage.

Automotive: From door seals to engine cylinder heads, gaskets reduce noise, vibration, and leakage.

Electronics: Gaskets in control panels and enclosures prevent dust, water, and electrical interference.

Oil & Gas: Seals in this sector need chemical resistance, pressure endurance, and long life—hence the use of high temperature rubber gasket and rubber flange gasket.

Marine: Boats and underwater structures rely on waterproof rubber gasket materials that prevent seawater corrosion.

4. Choosing the Ideal Gasket for Your Application

Here’s a breakdown to help you choose wisely:NeedRecommended GasketUV and ozone resistanceEPDM rubber gasketHigh heat resistanceHigh temperature rubber gasketWatertight sealingWaterproof rubber gasketCustom fitCustom rubber gasketsGeneral sealingRubber gasket sheetWindow/door framesRubber window gasket

Choosing the wrong type could lead to system failure or premature wear. Always align your choice with the environmental demands and application.

5. Rubber Gasket for Aluminum Windows: A Perfect Match

Modern aluminum windows offer strength and aesthetics but require airtight sealing. A rubber gasket for aluminum windows bridges the structural gap and offers multiple advantages:

Weatherproofing: Protects against rain and dust.

Thermal insulation: Prevents heat or cold transfer through gaps.

Noise reduction: Diminishes outdoor sound for interior calm.

Vibration absorption: Especially helpful in high-rise buildings with wind sway.

Architects now often request custom rubber gaskets designed to perfectly fit non-standard or slim-profile window systems.

6. How Custom Rubber Gaskets Solve Design Challenges

While off-the-shelf gaskets work in many situations, custom applications benefit from custom rubber gaskets tailored to unique designs or environments. These are CNC-cut or molded based on exact dimensions, thickness, and materials.

Common requests include:

Odd geometries (oval, complex edge cuts)

Food-safe grades for industrial kitchens

Chemical-resistant options for labs

Flame-retardant seals for electric vehicles

Custom solutions avoid over-compression or loose fits that might compromise performance.

7. The Importance of Temperature and Weather Resistance

In many environments, a standard rubber gasket may fail due to extremes in temperature, pressure, or chemical exposure. That’s where specialized options excel:

A high temperature rubber gasket made from silicone or Viton resists heat up to 250°C, perfect for boilers or engines.

Weatherproof rubber gasket options, such as EPDM, resist UV radiation, ozone, and fluctuating climates.

For marine or plumbing use, a waterproof rubber gasket offers airtight protection against constant moisture.

Using the wrong material could cause expansion, hardening, or cracking over time.

8. Common Issues and How to Avoid Them

Improper gasket use leads to common sealing failures. Here’s how to prevent them:ProblemSolutionGasket hardens or cracksUse temperature-specific rubber like siliconeLeakage from windowsReplace worn rubber window gasket with EPDMGasket gets brittle in sunlightUse UV-resistant EPDM rubber gasketPoor fit causing vibrationInstall custom rubber gaskets sized accuratelyFrequent water seepageUpgrade to weatherproof or waterproof rubber gasket

Maintenance also plays a role. Clean gaskets regularly with mild soap and water, and inspect for signs of wear or shrinkage every few months.

9. Where to Buy Rubber Gaskets

From local hardware stores to specialized suppliers, rubber gaskets are widely available. However, for technical applications, it's wise to source from manufacturers who provide certifications and custom rubber gaskets tailored to industry standards.

If you're using rubber gasket for aluminum windows or industrial machines, working with experts ensures material integrity and precise sizing.

10. The Future of Rubber Gaskets: Smart and Sustainable

With the rise of green building and smart systems, rubber gaskets are evolving too:

Eco-friendly gaskets: Made from recycled or biodegradable rubber.

Sensor-integrated gaskets: For detecting leaks or pressure changes in real-time.

Long-life formulations: New compounds last over 15 years in tough conditions.

Whether in aerospace or home renovation, the rubber gasket is no longer just a filler — it's a critical component of sustainable and smart engineering.

FAQs – Rubber Gaskets

Q1. Can I use a rubber gasket outdoors? A: Yes, but you should use an EPDM rubber gasket or weatherproof rubber gasket to ensure durability in outdoor conditions.

Q2. What is the difference between silicone and EPDM rubber gaskets? A: Silicone handles high temperatures better, while EPDM is ideal for UV and outdoor weather resistance.

Q3. Are rubber gaskets waterproof? A: Yes. Waterproof rubber gaskets are specifically designed to seal out water even under high pressure or immersion.

Q4. How do I know if I need a custom gasket? A: If you’re sealing irregular shapes, require FDA or flame-retardant standards, or need exact fit, opt for custom rubber gaskets.

Q5. What is a rubber flange gasket used for? A: It’s used between flanged pipes or fittings to seal and prevent leakage in industrial piping systems.

Q6. How often should rubber gaskets be replaced? A: It depends on usage, but most gaskets last 5–10 years. Inspect them yearly for signs of cracking or compression loss.

Conclusion

Rubber gaskets might seem like a minor detail in the larger picture of construction or engineering, but they are crucial to system performance, safety, and longevity. Whether you're sealing aluminum windows, installing a heavy-duty machine, or designing a weatherproof enclosure, the right rubber gasket can make all the difference.

Choose wisely between rubber window gasket, EPDM rubber gasket, high temperature rubber gasket, or custom rubber gaskets depending on your needs. And when in doubt, consult with experts or manufacturers to ensure a secure, long-lasting seal.

Contact us today to find the perfect soundproofing solution for your space.

0 notes

Text

Rubber Sheet Manufacturer

Shree Rubber Works is a trusted rubber sheet manufacturer, known for delivering outstanding durability, flexibility, and performance. Offered in a variety of materials—including natural rubber, neoprene, EPDM, nitrile, and silicone—our rubber sheets are perfectly suited for applications such as gaskets, flooring, insulation, electrical matting, and sealing solutions.

0 notes

Text

Best Rubber Manufacturing Companies in India You Should Know About

India stands as one of the leading producers and exporters of rubber and rubber-based products globally. With a thriving manufacturing ecosystem and access to raw materials, the country has developed a strong reputation for delivering high-quality rubber goods across various sectors, including automotive, aerospace, construction, electronics, agriculture, and healthcare.

If you're looking to collaborate with a reliable rubber manufacturing company in India, this comprehensive guide introduces the top industry leaders known for their product excellence, innovation, and global reach.

Why Partner with a Rubber Manufacturing Company in India?

Collaborating with Indian rubber manufacturers offers several strategic advantages:

Cost-Effective Production: Competitive labor and raw material costs help reduce overall manufacturing expenses.

Advanced Technology: Indian companies are increasingly investing in state-of-the-art equipment and R&D for high-precision manufacturing.

Compliance with Global Standards: Many firms operate under international certifications such as ISO, REACH, and ROHS.

Customization and Scalability: Manufacturers in India cater to both mass production and customized component requirements.

Whether you're a global OEM or an emerging brand in need of rubber components, India provides a robust supply chain backed by quality manufacturing.

Best Rubber Manufacturing Companies in India

Here’s a curated list of top rubber products manufacturing companies in India, recognized for their quality, scale, and customer commitment:

1. GRP Limited (Gujarat Reclaim and Rubber Products Ltd.)

Headquarters: Mumbai, Maharashtra Established: 1974

GRP Limited is a pioneer in the manufacturing of reclaimed rubber and polymer composites. With operations in over 50 countries, it is well-regarded for sustainable rubber processing and a broad product portfolio.

Key Products:

Reclaimed Rubber

Rubber Composites

Industrial Rubber Sheets

Notable Strength: Industry leader in eco-friendly rubber manufacturing with an extensive global presence.

2. TVS Rubber (Sundaram Industries)

Headquarters: Madurai, Tamil Nadu Established: 1943

A part of the renowned TVS Group, TVS Rubber specializes in high-quality rubber components for the automotive, industrial, and defense sectors.

Key Products:

Molded Rubber Components

Anti-Vibration Mounts

Rubber-to-Metal Bonded Parts

Notable Strength: Trusted OEM partner for global automotive brands, backed by decades of experience and international certifications.

3. Hindustan Rubber and Plastic Industries

Headquarters: Mumbai, Maharashtra Established: 1976

This company is known for manufacturing custom-molded rubber products used in automotive, infrastructure, and industrial sectors.

Key Products:

Rubber Gaskets

Seals and O-Rings

Bellows and Diaphragms

Notable Strength: Strong focus on quality control and precision engineering, aligned with global performance standards.

4. Zenith Rubber Pvt. Ltd.

Headquarters: Mumbai, Maharashtra Established: 1965

Zenith Rubber is one of India’s largest exporters of industrial rubber sheets. It is known for its wide range of products that meet international benchmarks.

Key Products:

Industrial Rubber Sheets

Flooring Mats

Rubber Hoses and Tubing

Notable Strength: Export presence in over 40 countries and significant expertise in sheet rubber manufacturing.

5. Sri Sai Rubber Products

Headquarters: Hyderabad, Telangana Established: 1989

Sri Sai Rubber Products specializes in both molded and extruded rubber components for clients in railways, electrical, and heavy machinery sectors.

Key Products:

Rubber Bushes

Extruded Profiles

Silicone and EPDM Components

Notable Strength: Known for delivering customized rubber solutions with quick lead times and consistent quality.

6. Metro Rubber Corporation

Headquarters: Kolkata, West Bengal Established: 1980

Metro Rubber offers a versatile range of industrial rubber products for domestic and international markets.

Key Products:

Rubber Expansion Joints

Gaskets and Seals

Rubber Linings

Notable Strength: Renowned for customized product development and reliable industrial-grade solutions.

7. Jain Rubber Products

Headquarters: Jaipur, Rajasthan Established: 1984

Jain Rubber Products is a trusted manufacturer of molded rubber components and high-performance elastomer products.

Key Products:

Rubber Grommets

Anti-Vibration Pads

Seals and Caps

Notable Strength: Combines innovation with material science expertise to cater to a wide industrial base.

8. Rubber Products India (RPI)

Headquarters: Pune, Maharashtra Established: 1990

RPI supplies a comprehensive range of molded rubber components for OEMs in automotive and electronics industries.

Key Products:

Rubber Bushings and Gaskets

Silicone and Nitrile Rubber Parts

Custom Molded Components

Notable Strength: ISO-certified manufacturing with in-house testing, prototyping, and rapid production capabilities.

9. Swastika Constant Care

Headquarters: Vadodara, Gujarat Established: 2005

Swastika specializes in rubber and silicone components for healthcare, pharmaceutical, and food industries.

Key Products:

Silicone Tubing

Rubber Stoppers

Medical-Grade O-Rings

Notable Strength: Expertise in FDA-compliant production, serving niche, high-regulation industries.

10. Super Seals India Ltd.

Headquarters: Chennai, Tamil Nadu Established: 1987

Super Seals is a key manufacturer of EPDM profiles and sealing solutions, especially for automotive and rail applications.

Key Products:

Automotive Door Seals

Rail Coach Profiles

EPDM Extruded Components

Notable Strength: Advanced infrastructure and a solid reputation in high-performance sealing systems.

Final Thoughts

India's rubber manufacturing industry is a blend of innovation, scale, and technical expertise. From bulk production to highly customized rubber solutions, these companies demonstrate why India is a preferred sourcing hub for rubber components worldwide.

Partnering with a trusted rubber manufacturing company in India can help you secure consistent quality, cost-effective solutions, and flexible production capabilities tailored to your industry requirements.

Looking to Source Rubber Components from India?

Digital platforms like FindingMFG connect global buyers with verified Indian manufacturers, offering seamless sourcing, quotation management, and quality assurance in one place. It’s a reliable gateway to collaborate with trusted rubber product suppliers from across the country

0 notes

Text

Professional Roof Waterproofing Services to Stop Leaks Fast

Let’s be real—if your roof is leaking, it’s not just annoying. It’s a ticking time bomb. One good downpour, and suddenly you’re dealing with water stains, mould, damaged ceilings, or worse—a full-blown roof collapse. And here's the kicker: most of it could be avoided with proper roof waterproofing services.

In this guide, I’ll walk you through everything you need to know about keeping your roof sealed, safe, and leak-free. No fluff. No jargon. Just straight talk about protecting your home (or business) before it's too late.

Why Roof Waterproofing Services Matter

Think of your roof like your phone screen. Once there’s a crack, even a tiny one, the damage spreads fast. Similarly, a small leak in your roof doesn’t stay small for long. That’s where professional roof waterproofing services come in. These services don’t just patch leaks—they prevent them from happening in the first place.

Roof waterproofing is about creating a moisture-proof barrier. It blocks rain, humidity, and seepage from creeping in and turning your concrete, wood, or steel roof into a breeding ground for structural damage.

Signs You Need Roof Waterproofing (Now, Not Later)

You don’t need to be a contractor to spot the red flags. Here are signs your roof is screaming for waterproofing:

Water stains on ceilings or walls

Mould or mildew smells in your attic

Paint or plaster peeling near the roofline

Visible cracks or holes in roofing material

Leaks during or after rain

If you're seeing even one of these, it's time to bring in experts for roof waterproofing services—fast.

Types of Roof Waterproofing Techniques

Not all waterproofing methods are created equal. The right one depends on your roof type, climate, and budget. Here's a no-nonsense breakdown:

Bituminous Membrane Waterproofing

This method involves applying a thick, durable membrane (bitumen-based) over the roof. Ideal for flat or low-sloped roofs. It’s cost-effective, easy to apply, and lasts years.

Liquid Waterproofing

Think of it like painting on protection. This is a liquid sealant applied in layers that dries into a flexible waterproof layer. Great for irregular surfaces or tight corners.

Polyurethane Waterproofing

Extremely strong and flexible. Polyurethane membranes can cover small cracks and resist weather extremes. On the pricier side, but worth it for durability.

Cementitious Waterproofing

Common in Pakistan and other developing regions. It’s easy to apply and ideal for internal areas like bathrooms or kitchens—but not so great for roofs exposed to direct weather.

EPDM Rubber Roofing

A synthetic rubber sheet that’s rolled out and fixed onto the roof. Super resilient and used in commercial buildings.

Which one should you pick? That’s where a quality provider of roof waterproofing services steps in—they’ll assess and recommend the best fit.

Benefits of Professional Roof Waterproofing Services

Let’s get one thing straight. DIY fixes won’t cut it long-term. Here’s why going pro saves you time, money, and stress:

Stops Current Leaks Cold Professionals don’t guess. They detect the root cause and stop the leak where it starts.

Prevents Future Damage With high-grade materials and proper application, you’re not just fixing today’s issue—you’re blocking next season’s too.

Increases Roof Lifespan A well-waterproofed roof can last years longer than one left exposed to weather damage.

Boosts Property Value Thinking of selling your house? A waterproofed roof is a big tick for buyers.

Saves Money

Sure, it’s an upfront cost. But compare that to interior repairs, mould removal, and roof replacements… suddenly, waterproofing looks like a bargain.

How to Choose the Right Roof Waterproofing Services Provider

Not all contractors are created equal. Here’s how to pick someone legit:

Check reviews or ask for references

Ensure they offer warranty-backed work

Ask about the materials they use (cheap stuff doesn’t last)

Look for experience, not just low pricing

Make sure they inspect the full roof before quoting

Want a shortcut? Go with providers who specialise specifically in roof waterproofing services, not just generic “contractors.”

Common Mistakes to Avoid

Too many people wait until it's too late. Here are the most common mistakes we see:

Ignoring small leaks – They always grow.

Relying on temporary fixes – Silicone fillers and tape are not long-term solutions.

Hiring cheap labour – Bad application means you’ll be paying double in a yea

Skipping regular inspections – Prevention is always cheaper than repair.

Roof Waterproofing for Homes vs. Commercial Buildings

While the core idea is the same, the scale and materials differ.

For homes:

Aesthetic matters

Smaller surface area

Often sloped roofs

Cost-conscious solutions preferred

For commercial buildings:

Flat roofs more common

Large-scale waterproofing systems

Heavy-duty solutions like bituminous or rubber-based membranes

Professional roof waterproofing services can tailor the solution based on your space—whether it’s a small house or a multi-storey plaza.

Cost of Roof Waterproofing in Pakistan

Let’s talk numbers. In Pakistan, the cost of roof waterproofing services typically ranges from:

Rs. 30 – Rs. 100 per square foot depending on material

Labour charges may vary by city (Lahore, Karachi, Islamabad)

Additional costs for roof prep, crack repair, and cleaning

Always get a detailed quote upfront. Cheap rates often hide shortcuts or inferior materials.

Maintenance Tips After Waterproofing

Once your roof is sealed, your job isn't over. Here's how to keep it protected:

Schedule inspections before and after monsoon season

Clear leaves and debris from gutters and roof edges

Reapply waterproof coating every 4–5 years (based on material)

Watch for early signs of wear, especially after heavy storms

FAQs: Roof Waterproofing Services

Q: How long does roof waterproofing last?

A: Depends on the material—typically 5 to 15 years with proper maintenance.

Q: Can I waterproof the roof myself?

A: Not recommended. Without proper tools and experience, DIY solutions rarely last and often make the issue worse.

Q: When is the best time for waterproofing?

A: Dry season is ideal. Avoid applying during or right before monsoon.

Q: Will waterproofing fix existing damage?

A: It stops future leaks but won’t fix structural damage already caused. You’ll need repair + waterproofing in such cases.

Q: How do I know if my contractor did a good job?

A: Ask for before/after pictures, inspect the roof after rain, and make sure they give a warranty.

0 notes