#ERP modules

Explore tagged Tumblr posts

Text

Empower Your Manufacturing Journey: SS ERP MFG (Pharmaceuticals) Product Management Module

Optimizing Product Lifecycle Management for Pharmaceutical Manufacturers

Welcome to the Product Management Module of SS ERP MFG (Pharmaceuticals), a pivotal tool designed to streamline product-related processes and enhance operational efficiency for pharmaceutical manufacturing companies. Developed by Synthegrate Solutions’ esteemed Research and Development (R&D) Department, this module underscores our commitment to innovation and excellence, empowering businesses to optimize their product lifecycle management and drive growth in today’s competitive market.

Unlocking Manufacturing Potential: SS ERP MFG (Pharmaceuticals) Product Management Module

At the heart of the Product Management Module lies a comprehensive suite of features tailored to meet the diverse needs of pharmaceutical manufacturing enterprises:

The Products List Section: Centralizes product information, providing users with a single source of truth for product specifications, pricing, and availability, thereby streamlining inventory management and ensuring accurate order fulfillment.

The Product Add Section: Facilitates the seamless addition of new products to the inventory, accelerating time-to-market and enabling businesses to quickly respond to changing market demands and customer preferences.

The Update Price Section: Dynamically adjusts product pricing in response to market fluctuations, competitive pressures, and changing cost structures, maximizing profitability and capitalizing on market opportunities.

The Print Label Section: Generates and prints product labels directly from the ERP system, enhancing brand visibility, improving product traceability, and ensuring compliance with regulatory requirements.

The Variation Section: Manages product variations efficiently, simplifying inventory management and enhancing customer satisfaction by offering a wider range of options to meet diverse preferences.

The Import Products Section and The Import Opening Stock: Streamlines the process of importing product data and opening stock levels from external sources, minimizing data entry errors and improving data accuracy.

The Selling Price Group, The Products Units, The Products Categories, The Products Brands, and The Products Warranties: Provide robust tools for managing pricing strategies, unit conversions, product categorization, brand associations, and warranty information, enabling companies to tailor their product offerings to meet market demands and customer preferences.

Why SS ERP MFG (Pharmaceuticals) Product Management Module Matters

Beyond its operational benefits, the Product Management Module plays a crucial role in facilitating strategic decision-making and optimizing resource allocation for pharmaceutical manufacturers. With comprehensive reporting capabilities, users can generate detailed insights into product performance, inventory levels, and pricing trends, empowering businesses to make informed decisions, capitalize on opportunities, and mitigate risks effectively.

In conclusion, the Product Management Module represents a significant advancement in Synthegrate Solutions’ commitment to empowering pharmaceutical manufacturers with innovative solutions. By providing robust tools for managing products, pricing, variations, and inventory, this module enables businesses to streamline operations, enhance customer satisfaction, and drive business growth. With its intuitive interface, extensive features, and seamless integration capabilities, the Product Management Module exemplifies Synthegrate Solutions’ dedication to delivering value-driven solutions that empower pharmaceutical enterprises to thrive in today’s competitive landscape.

youtube

0 notes

Text

Off-the-Shelf ERP Software vs. Custom: Which is Right for Your Business?

Choosing the right ERP system is crucial for optimizing your business operations. Custom ERP software offers tailored features and scalability but comes with higher costs and longer implementation times. In contrast, off-the-shelf ERP solutions are more affordable and quicker to deploy but may lack specific customizations. PiERP bridges this gap by offering both custom and off-the-shelf cloud-based ERP solutions, ensuring flexibility to meet unique business needs. Whether you need a specialized system or a ready-to-use solution, PiERP’s scalable and adaptable options enhance productivity, streamline operations, and support sustainable growth, making it a valuable partner for your business success. For more details, visit: https://pierp.software/blogs/off-the-shelf-erp-software-vs-custom-which-is-right-for-your-business

#erp software#erp solution#erp systems#enterprise resource planning software#cloud based ERP solutions#ERP modules

0 notes

Text

ERP modules

Lighthouse ERP stands as a masterful solution provider, unveiling the power and functionality of its comprehensive module solutions designed to propel manufacturing excellence to new heights. With a strategic emphasis on Enterprise Resource Planning (ERP) modules, Lighthouse ERP addresses the intricate needs of the manufacturing industry, offering a suite of tools that seamlessly integrate and optimize diverse aspects of operational workflows. This mastery in ERP modules establishes Lighthouse ERP as a trailblazer, empowering manufacturers with the tools they need to navigate complexities and achieve unparalleled operational efficiency.

At the heart of Lighthouse ERP's prowess lies its meticulous attention to ERP modules that cover the entire spectrum of manufacturing operations. These modules act as specialized components, each dedicated to a specific function within the manufacturing ecosystem. The beauty of Lighthouse ERP's approach lies in its recognition of the multifaceted nature of manufacturing, acknowledging that a one-size-fits-all solution is not sufficient for addressing the unique challenges that manufacturers face.

One of the cornerstones of Lighthouse ERP's mastery is its Manufacturing Resource Planning (MRP) module. This module revolutionizes production planning and scheduling by optimizing the allocation of resources, minimizing downtime, and enhancing overall production efficiency. The MRP module is a linchpin for manufacturers seeking to achieve precision in their operations, ensuring that resources are utilized efficiently and production schedules are aligned with market demands.

Supply Chain Management (SCM) is another area where Lighthouse ERP's module solutions shine. The SCM module enables manufacturers to orchestrate and optimize every aspect of their supply chain, from procurement and inventory management to distribution. With real-time visibility into the entire supply chain, manufacturers can make data-driven decisions, reduce lead times, and foster resilience in the face of dynamic market conditions.

Lighthouse ERP's Quality Management module is a testament to its commitment to manufacturing excellence. This module integrates seamlessly into the manufacturing process, providing tools for real-time monitoring, automated quality checks, and compliance tracking. By upholding the highest standards in product quality, manufacturers can mitigate the risk of defects, enhance brand reputation, and instill confidence in customers.

Financial Management is a critical aspect of manufacturing operations, and Lighthouse ERP's module solutions in this domain ensure comprehensive control and visibility. From tracking project costs to managing revenue streams and ensuring compliance, the Financial Management module empowers manufacturers to make informed financial decisions, contributing to the overall sustainability and profitability of the business.

The Human Resources (HR) module in Lighthouse ERP's arsenal addresses the people-centric aspects of manufacturing operations. By managing employee data, tracking performance, and facilitating workforce planning, the HR module ensures that manufacturers have the human capital required to drive success. This module contributes to fostering a positive organizational culture and aligning human resources with strategic business objectives.

Lighthouse ERP's mastery extends to Customer Relationship Management (CRM), recognizing the significance of customer interactions in the manufacturing landscape. The CRM module enables manufacturers to manage customer relationships, track interactions, and gain insights into customer preferences. By incorporating a customer-centric approach, manufacturers can enhance customer satisfaction and loyalty, contributing to long-term business success.

In conclusion, Lighthouse ERP's mastery in unveiling the power and functionality of comprehensive module solutions for manufacturing excellence is a testament to its commitment to innovation and operational efficiency. By providing specialized ERP modules that cater to the intricate needs of the manufacturing industry, Lighthouse ERP empowers manufacturers to navigate the complexities of their operations with precision and achieve excellence in an ever-evolving business landscape.

0 notes

Text

ERP Software Benefits for Private Label Manufacturing

Technology is changing with each passing day, and hence you get an upgraded/advanced version of the ongoing software/tools. Private labeling manufacturing is one of those manufacturing forms that has been helping process manufacturing companies for decades. Various challenges in private-label manufacturing need to be addressed with an ERP system.

Here are some of the benefits of using ERP software that can help solve all the challenges in private-label manufacturing;

Benefits of ERP Software for Private Labeling

Streamline Operations

ERP software integrates and centralizes various private labeling processes such as inventory management, production planning, order processing, and financial management. This streamlining of operations can lead to increased efficiency and reduced manual data entry.

Improved Inventory Management

Private label manufacturers must deal with a wide range of SKUs and inventory items. ERP software helps in tracking inventory levels in real-time, managing stock levels, and reducing carrying costs by preventing overstock or stockouts.

Enhanced Demand Forecasting

ERP systems often include modules for demand forecasting, it can also help private label manufacturers manage customer demand. It also helps in managing inventory and production scheduling.

Cost Control

ERP software provides better visibility into cost structures. It allows for cost tracking at various stages of production, helping companies identify cost-saving opportunities and optimize their pricing strategies.

Data Analytics

ERP software provides exact insights with valuable data and reports on various aspects of the business. Advanced analytics tools within ERP can provide insights for informed decision-making, performance tracking, and identifying areas of improvement.

Scalability

With ERP software, you can grow the business, accommodating increasing production volumes and complexity. This scalability helps private label manufacturers continue to meet the needs of expanding all the operations in an organization.

Improved Communication

Private manufacturers need to collaborate and communicate efficiently. With an ERP system, it is easier to communicate with real-time updates on production progress, order status, and inventory levels can improve client relationships.

Lot Traceability

Lot tracking is one of the most important tasks in private manufacturing. An ERP system supports traceability tracking requirements by tracking the origin of materials and components used in production, that particularly important in industries with strict traceability regulations.

Integration Capabilities

ERP software helps in integrating with other businesses, such as CRM and e-commerce platforms, creating a seamless and improving overall business efficiency.

Next Steps!

ERP software is helping private label manufacturers with a comprehensive and integrated solution for managing their operations, right from production, supply chain, inventory management, and other operations. It can also improve efficiency, cost control, and overall business performance, helping businesses deliver high-quality private-label products to their clients.

0 notes

Text

What's New in Odoo 17: The most expected features

Explore the Exciting New Features of Odoo 17: Get a sneak peek into the anticipated enhancements and innovations in the upcoming Odoo version. Discover what Odoo 17 has in store for your business

#odoo 17#odoo erp#expected features#Odoo Software#Odoo CRM#Erp modules#Open erp#Odoo erp software#odoo erp software#erp solution#erp software#cloud based enterprise resource planning

0 notes

Text

Digitizing Business Process

Save on Your Business Operation costs by Digitizing Business Processes We can help you Go Digital with: *Cloud ERP on Google *Business Email(Google Workspace) *Domain & Hosting *Website Designing & Digital Marketing For more information visit us @ https://proerp.in/

#clouderp#erpsoftwares#cloud erp solutions#cloud erp software#cloud computing#erp modules#erpcrm#erpsoftware#best erp softare#erp software providers#top erp systems#erp system#erp solution#sales crm#purchase management#inventory management

0 notes

Text

How ERP Software for Engineering Companies Improves Operational Efficiency

In today's competitive market, engineering companies are under immense pressure to deliver innovative solutions, maintain cost-efficiency, and meet tight deadlines—all while ensuring the highest standards of quality. As the engineering industry becomes more complex and digitally driven, operational efficiency has become a key metric for success. One of the most transformative tools driving this change is ERP (Enterprise Resource Planning) software.

For companies seeking to streamline their operations, ERP software for engineering companies provides a centralized platform that integrates every function—ranging from procurement, design, production, finance, HR, and project management. In India, especially in industrial hubs like Delhi, the demand for such software is growing rapidly. Let us explore how ERP systems significantly enhance operational efficiency and why choosing the right ERP software company in India is vital for engineering enterprises.

Centralized Data Management: The Foundation of Efficiency

One of the major challenges engineering companies face is managing vast amounts of data across departments. Manual entries and siloed systems often lead to redundancies, errors, and miscommunication. With ERP software for engineering companies in India, organizations gain access to a unified database that connects all operational areas.

Real-time data availability ensures that everyone, from the design team to procurement and finance, is working with the latest information. This reduces rework, improves collaboration, and speeds up decision-making, thereby increasing efficiency.

Streamlined Project Management

Engineering projects involve numerous stages—from planning and design to execution and maintenance. Tracking timelines, resources, costs, and deliverables manually or via disparate systems often results in delays and budget overruns.

Modern engineering ERP software companies in Delhi provide robust project management modules that allow firms to plan, schedule, and monitor projects in real time. This includes milestone tracking, Gantt charts, resource allocation, and budget forecasting. Managers can gain visibility into bottlenecks early on and reallocate resources efficiently, ensuring timely delivery.

Automation of Core Processes

Automating routine tasks is one of the key advantages of implementing ERP software. From generating purchase orders and invoices to managing payroll and inventory, ERP eliminates the need for repetitive manual work. This not only saves time but also minimizes human error.

The best ERP software provider in India will offer customizable automation workflows tailored to the specific needs of engineering companies. For instance, when a material stock reaches a minimum threshold, the ERP system can automatically generate a requisition and notify the purchasing team. This ensures zero downtime due to material shortages.

Enhanced Resource Planning and Allocation

Resource planning is crucial in engineering projects where labour, materials, and machinery must be utilized efficiently. A good ERP software for engineering companies provides detailed insights into resource availability, utilization rates, and project requirements.

By analysing this data, companies can better allocate resources, avoid overbooking, and reduce idle time. This leads to significant cost savings and ensures optimal productivity across the board.

youtube

Integration with CAD and Design Tools

Many ERP solution providers in Delhi now offer integration with design and CAD software. This is particularly useful for engineering firms where design data is often needed for procurement, costing, and production.

When ERP is integrated with CAD, design changes automatically reflect across related departments. This seamless flow of information eliminates miscommunication and ensures that downstream processes such as procurement and manufacturing are aligned with the latest design specifications.

Real-time Cost and Budget Management

Keeping engineering projects within budget is a continuous challenge. Unexpected costs can arise at any stage, and without proper monitoring, they can spiral out of control. ERP software providers in India equip engineering companies with real-time budget tracking tools.

From initial cost estimation to actual expenditure, companies can monitor every aspect of the financials. Alerts can be configured for budget deviations, helping management take corrective action promptly. This financial control is a cornerstone of operational efficiency and long-term profitability.

Improved Compliance and Documentation

Engineering companies must adhere to various compliance standards, certifications, and audit requirements. Maintaining accurate documentation and audit trails is critical. ERP systems automate compliance tracking and generate necessary documentation on demand.

By partnering with trusted ERP software companies in Delhi, engineering firms can ensure they meet industry standards with minimal administrative overhead. Features like document versioning, digital signatures, and compliance checklists help organizations stay audit-ready at all times.

Scalable and Future-ready Solutions

One of the biggest advantages of working with a reputed engineering ERP software company in Delhi is access to scalable solutions. As engineering businesses grow, their operational complexities increase. Modern ERP systems are modular and scalable, allowing businesses to add new functionalities as needed without disrupting existing operations.

Moreover, cloud-based ERP solutions offer flexibility, remote access, and lower infrastructure costs. These are especially beneficial for engineering companies that operate across multiple locations or work on-site with clients.

Enhanced Customer Satisfaction

Efficient operations lead to improved delivery timelines, better quality products, and faster customer service—all of which directly impact customer satisfaction. With ERP, engineering companies can maintain accurate production schedules, meet delivery deadlines, and respond to customer queries with real-time information.

By choosing the right ERP software for engineering companies in India, firms not only improve internal operations but also build a strong reputation for reliability and professionalism among their clients.

Choosing the Right ERP Partner

With the growing number of ERP solution providers in India, selecting the right partner is crucial. Here are a few factors to consider:

Domain Expertise: Choose a vendor with experience in the engineering sector.

Customization: The software should be tailored to suit your specific workflows.

Scalability: Ensure the ERP solution grows with your business.

Support & Training: Opt for companies that provide ongoing support and employee training.

Integration Capabilities: Check whether the ERP can integrate with your existing systems, including CAD tools, financial software, etc.

Trusted ERP software companies in Delhi like Shantitechnology (STERP) stand out because they offer deep industry knowledge, scalable platforms, and dedicated customer support—making them ideal partners for engineering businesses seeking to transform operations.

youtube

Final Thoughts

In a rapidly evolving business landscape, engineering companies must adopt smart technologies to stay ahead. ERP software is not just an IT solution—it is a strategic tool that can redefine how engineering firms manage their projects, people, and performance.

From streamlining project workflows and automating routine tasks to enhancing collaboration and boosting resource efficiency, ERP solutions deliver measurable gains across the organization. For those looking to make a digital leap, partnering with a top-rated ERP software company in India can be the difference between stagnation and scalable success.

Looking for a reliable ERP partner? Shantitechnology (STERP) is among the leading ERP solution providers in Delhi, offering tailored ERP software for engineering companies to help you boost productivity, reduce costs, and grow sustainably. Contact us today to learn more!

#Engineering ERP software company#ERP software for engineering companies in India#ERP solution providers#ERP software for engineering companies#ERP software companies#ERP software providers in India#Gujarat#Maharashtra#Madhyapradesh#ERP solution providers in India#ERP for manufacturing company#Delhi#Hyderabad#ERP Software#Custom ERP#ERP software company#Manufacturing enterprise resource planning software#Bengaluru#ERP software company in India#Engineering ERP Software Company#Best ERP software provider in India#Manufacturing ERP software company#Manufacturing enterprise resource planning#ERP modules for manufacturing industry#Best ERP for manufacturing industry#India#Youtube

2 notes

·

View notes

Text

2 notes

·

View notes

Text

https://www.futureelectronics.com/p/semiconductors--Led-lighting-components--led-driver-modules-rev--constant-current-acdc-led-drivers/ess010w-0500-18-erp-power-3119364

Led driver power supply, LED Dimming Modules, LED driver replacement

100 - 277Vac, 9W, 500mA, 10-18V, [0-10V, TRI...], IP64 LED Driver

#Constant Current AC/DC LED Drivers#ESS010W-0500-18#ERP Power#power supply#LED Dimming Modules#LED driver replacement#circuit#high power led driver#high voltage#components#driver replacement#LED driver circuit board

3 notes

·

View notes

Text

Smarter Schools Start with Smarter Operations

From managing buses to cafeteria lines, OpenEduCat simplifies everything. With ERP modules for campus, canteen, transport, placement, and parent engagement, schools can ditch the manual mess and focus on what matters — education.

Read more: https://openeducat.org/blog/our-blog-1/post/effortless-operations-a-deep-dive-into-modern-erp-management-features-142#scrollTop=0

#From managing buses to cafeteria lines#OpenEduCat simplifies everything. With ERP modules for campus#canteen#transport#placement#and parent engagement

0 notes

Text

Top 10 Must-Have Odoo Modules For Your Business Success

🚀 Boost Your Business Efficiency with Odoo Modules! Discover how Odoo's modular approach can streamline your operations: ✔️𝗦𝗮𝗹𝗲𝘀 𝗠𝗮𝗻𝗮𝗴𝗲𝗺𝗲𝗻𝘁: Elevate Your Sales Strategy ✔️𝗦𝗲𝗿𝘃𝗶𝗰𝗲𝘀: Enhance Service Delivery ✔️𝗜𝗻𝘃𝗲𝗻𝘁𝗼𝗿𝘆 𝗠𝗮𝗻𝗮𝗴𝗲𝗺𝗲𝗻𝘁: Master Stock Control ✔️𝗔𝗰𝗰𝗼𝘂𝗻𝘁𝗶𝗻𝗴: Financial Precision and Control ✔️𝗣𝗿𝗼𝗷𝗲𝗰𝘁 𝗠𝗮𝗻𝗮𝗴𝗲𝗺𝗲𝗻𝘁: Deliver on Time, Every Time ✔️𝗛𝘂𝗺𝗮𝗻 𝗥𝗲𝘀𝗼𝘂𝗿𝗰𝗲𝘀: Empower Your Workforce ✔️𝗠𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗶𝗻𝗴: Tailor Production to Demand ✔️𝗪𝗲𝗯𝘀𝗶𝘁𝗲 𝗮𝗻𝗱 𝗲𝗖𝗼𝗺𝗺𝗲𝗿𝗰𝗲: Expand Your Digital Presence ✔️𝗠𝗮𝗿𝗸𝗲𝘁𝗶𝗻𝗴 𝗔𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻: Drive Engagement and Growth ✔️𝗣𝗿𝗼𝗱𝘂𝗰𝘁𝗶𝘃𝗶𝘁𝘆 𝗠𝗮𝗻𝗮𝗴𝗲𝗺𝗲𝗻𝘁: Boost Operational Efficiency

Read in detail - https://www.candidroot.com/blog/our-candidroot-blog-1/odoo-modules-for-your-business-success-779

#odoo#odoo modules#erp experts#business transformation#business efficiency#digital transformation#odoo erp#erp#erp system#erpsoftware

0 notes

Text

Powerful Financial Accounting and CRM All-in-One Platform

ECUENTA is your all-in-one solution for smarter business management. With our powerful Sales, Purchase, and Product modules, you can streamline every aspect of your operations. Manage sales efficiently by tracking orders, generating smart invoices, and monitoring payments effortlessly. Simplify your purchasing process with tools to manage suppliers and maintain optimal inventory levels. Organize your product catalogue easily, ensuring everything is categorized and updated. Whether you're a growing business or an established enterprise, ECUENTA helps you save time, reduce errors, and make informed decisions – all from one easy-to-use platform.

#product module#bulk product import#global VAT update#sales module#sales module in ERP#purchase module#Management inventory tracking#accounting software

0 notes

Text

Powerful Financial Accounting and CRM All-in-One Platform

ECUENTA is your all-in-one solution for smarter business management. With our powerful Sales, Purchase, and Product modules, you can streamline every aspect of your operations. Manage sales efficiently by tracking orders, generating smart invoices, and monitoring payments effortlessly. Simplify your purchasing process with tools to manage suppliers and maintain optimal inventory levels. Organize your product catalogue easily, ensuring everything is categorized and updated. Whether you're a growing business or an established enterprise, ECUENTA helps you save time, reduce errors, and make informed decisions – all from one easy-to-use platform.

#product module#bulk product import#global VAT update#sales module#sales module in ERP#purchase module#Management inventory tracking#accounting software

0 notes

Text

How do manufacturing ERP modules impact business productivity?

With a process manufacturing ERP, organizations can manage their business more efficiently. The different modules of ERP like procurement & purchasing, manufacturing, financial management, inventory management, supply chain, and more can help in streamlining and automating business processes. It also serves as a shared database for all financial and operational information from across the company impacting a boost in business productivity.

So, let us discuss how these modules of ERP can impact business productivity in all aspects;

Improved Visibility

Being a single source of management, the ERP modules create a centralized database for all the tasks in an organization. Anyone can access information from any department as per the requirements, fostering coordination, collaboration, and improved visibility in the processes.

Enhanced Communication

Process manufacturing companies often find communication gaps between departments, teams, and individuals. With efficient process manufacturing ERP and its modules, it is easier to create a smooth channel of communication removing redundancies, inefficiencies, and missed opportunities for collaboration. It helps in bringing open channels and creating transparency.

Efficient Data Collection and Analysis

Data collection and analysis is yet one of the most crucial tasks any process manufacturing organization needs to focus on. With ERP software it is easy to facilitate the modern, data-focused facility and all the benefits that this unprecedented amount of information and insights. It helps in driving more informed, effective decision-making in all the operations like maintenance, purchase operations, procurement, supply chain, and more.

Overall Cost Reductions

Among all the above benefits, ERP modules like financial management and others can help in overall cost reductions and analyzing costs in every other process. It helps in reducing unnecessary expenses, bringing efficiency, and boosting overall productivity.

Quality Control and Compliance

Process manufacturers often follow strict regulatory requirements to ensure product quality and compliance. The ERP system provides industry compliance by integrating compliance requirements into production workflows. It enables efficient quality checks, ensuring that the team operates with the latest legislation.

Conclusion

The process manufacturing ERP modules can help organizations streamline and strengthen their processes. With its data-driven technology, it can help process manufacturers keep plant operations up and smoothen the running processes. So, are you using an ERP system to manage your process manufacturing operations? If yes, is it providing you with all the modules of ERP that can help smoothen the functioning of all the processes? If not, this is the correct time to choose an industry-specific process manufacturing ERP software and streamline growth and productivity in all aspects.

0 notes

Text

Power Your Business with Singapore’s Best Odoo Development Companies Elevate your business with Singapore’s leading Odoo development companies, offering customized ERP solutions for 2025 and beyond. These specialists provide expert implementation, seamless integrations with e-commerce and payment systems, and tailored module development to match your unique workflows. With their ongoing support and migration expertise, you can ensure your Odoo ERP runs smoothly, driving efficiency and scalability. Whether you’re a startup or an enterprise, partner with the best to unlock your business’s full potential today!

#Odoo development Singapore#Odoo ERP#ERP implementation#custom Odoo modules#Odoo integration#Odoo migration

0 notes

Text

A Quick Guide to SAP Business One for the Manufacturing Industry – Modules & Implementation

SAP for Manufacturing Industry can significantly accelerate time-to-market (TTM), boost production efficiency, and cut down operational expenses. In simple terms, SAP ERP empowers manufacturing companies by bringing automation and adaptability across various operations. Consequently, manufacturers can utilize available resources more effectively while maximizing productivity.

Globally, the manufacturing sector plays a pivotal role in shaping our everyday lives. To keep up with rising product demands, manufacturers are constantly on the lookout for efficient and scalable solutions. This is where SAP ERP comes into the picture, offering transformative automation for the industry. In this blog, we’ll explore the pivotal role SAP plays in the manufacturing sector, its various modules, and the key benefits it brings. But first, let’s understand:

What is SAP for Manufacturing?

As with many other key industries, automation and digital transformation are reshaping the future of manufacturing. These forward-looking trends help businesses address complex challenges like shrinking delivery timelines, evolving consumer demands, and disrupted supply chains. The SAP Business One manufacturing solution steps in as a powerful enabler, making operations more agile and future-ready.

SAP is a comprehensive and scalable Enterprise Resource Planning (ERP) platform, offering robust features, modular integration, and high adaptability for both small and large enterprises. Its intuitive design simplifies usage while drastically reducing implementation time. SAP manufacturing modules empower real-time monitoring of the production lifecycle, ensuring better oversight and control.

Through built-in intelligence, integration, and analytics tools, SAP’s digital manufacturing suite refines processes for peak performance. For a successful implementation, partnering with a trusted global SAP provider is essential.

Problems Facing Manufacturing Industries

The manufacturing domain is evolving rapidly, but rising competition and global uncertainties pose several hurdles. Here are the primary challenges manufacturers face:

Prediction of Demand

Forecasting demand remains a major concern. The absence of real-time data analytics tools leads to inaccurate estimates, making it difficult for manufacturers to align supply with market needs.

Efficiency Issues

Managing remote production facilities presents its own set of hurdles. Many manufacturers struggle to maintain cost-efficiency and consistent output quality, occasionally compromising on standards.

Lead Management

Prioritizing and managing sales leads effectively is a pain point. Due to the lack of a strategic lead management approach, all leads are often treated uniformly, resulting in missed opportunities.

Inventory Management

Manual stock tracking invites errors and inefficiencies. This outdated approach can lead to stock-outs or excessive inventory levels, both of which hinder operations.

ROI Challenges

Maximizing Return on Investment (ROI) quickly is a universal industry goal. However, manufacturers often encounter numerous roadblocks in their quest for faster, sustainable gains.

This is where SAP ERP Solutions proves invaluable, empowering manufacturers to overcome these barriers with greater ease.

How SAP Helps in Manufacturing Industries

SAP ERP offers numerous advantages tailored to the manufacturing ecosystem. Whether it's inventory control or multi-level bill of materials management, SAP is an indispensable tool. Here are some of the top ways SAP supports the industry:

Streamlined, end-to-end automation

Optimal resource utilization

Decreased turnaround time and operational costs

Real-time feedback and insights

Secure tracking of all functions

These advantages translate into elevated productivity and operational excellence. Let’s now dive into the core SAP Manufacturing ERP Modules that make this possible.

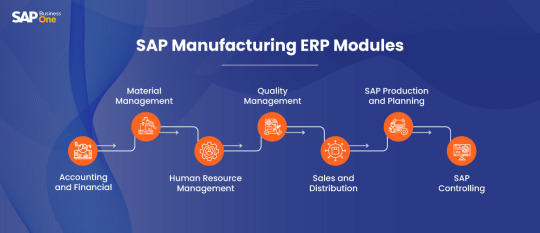

SAP Manufacturing ERP Modules

SAP offers a mix of functional and technical modules, each delivering powerful results for the manufacturing process:

1. Accounting and Financial

Manages financial transactions and audit trails efficiently across all business sizes. Integrates all financial data in one dashboard for quick, accurate decision-making.

2. Material Management

Ensures raw material availability by streamlining procurement, storage, and inventory processes. Also supports automated invoice creation and vendor interactions.

3. Human Resource Management

Manages workforce operations with care and structure, boosting employee engagement and overall efficiency. Critical for fostering a productive workplace culture.

4. Quality Management

Maintains quality standards at every stage—from raw material intake to final product delivery. Ensures compliance with industry norms.

5. Sales and Distribution

Tracks sales orders and delivery schedules with ease, while aiding inventory and revenue forecasting. A vital tool for smooth distribution.

6. Production and Planning

Offers centralized planning by leveraging real-time data, streamlining sales, operations, and material requirements efficiently.

7. SAP Controlling

Provides oversight and real-time monitoring of business processes. Supports budgeting, forecasting, and performance tracking.

Each of these modules plays a significant role in helping manufacturers optimize operations and achieve growth.

Benefits of SAP Manufacturing

Here are the standout business benefits manufacturers can gain by adopting SAP Business One:

Better Traceability of Stocks

Minimizes manual tracking errors by maintaining accurate stock levels and providing insights into expiring components.

Improved Inventory Management

Automates and organizes warehouse logistics through advanced tools like bin location tracking for greater visibility and control.

Unified Data Access

Eliminates siloed systems by consolidating all critical data into one accessible platform, improving cross-departmental efficiency.

Smarter Planning

MRP Wizard enables scenario planning for procurement and production to ensure better preparedness and decision-making.

Enhanced Customer Satisfaction

Automates order processing and query handling, offering faster response times and more personalized service.

SAP ERP Supports Multiple Manufacturing Types

SAP solutions can be tailored for various manufacturing models:

Process Manufacturing – e.g., pharmaceuticals, chemicals, F&B

Repetitive Manufacturing – e.g., electronics, automotive parts

Discrete Manufacturing – e.g., toys, furniture, appliances

Features of SAP Business One for Manufacturing

SAP B1 offers a range of manufacturing-centric features, including:

Warehouse Management – Optimize stock movement and reduce surpluses.

Machine Planning – Minimize overspending and maximize ROI.

Production Planning – Integrated with PLC and dependent operations.

Costing Tools – Accurate margin analysis and forecasting.

Key Product Costing – Use HANA to drive structured cost calculations.

Production Management – Real-time status updates and cross-functional reporting.

Planning & Consumption – Support for JIT and FIFO strategies.

Quality Control – Built-in compliance tools and automatic certifications.

Production Cycle Monitoring – End-to-end tracking and optimization.

SAP for Small Manufacturing Businesses

Small manufacturers can benefit immensely from SAP’s automated, scalable ecosystem. It helps manage all aspects—production, inventory, procurement, and sales—within a single, intuitive platform.

SAP Digital Manufacturing

SAP Digital Manufacturing Cloud enhances operations by providing:

Performance Visibility – Unified analytics to assess productivity.

Process Transparency – Real-time data integration via MOM.

Consistent Reporting – Actionable insights for instant decisions.

Adaptive Manufacturing – Flexibility to meet diverse market demands.

Resource Efficiency – Minimized downtime and optimized output.

Key Functional Areas of SAP in Manufacturing

Major functionalities include:

Financial operations (A/R, A/P, cash flow)

Inventory & SCM (lot tracking, raw materials)

Real-time shop floor control and costing

BI tools for workflow and attendance tracking

BOMs, routing, logistics, and CRM integration

Why You Should Adopt SAP for Manufacturing

SAP Business One offers:

Streamlined operations with real-time insights

Automation across functions, boosting agility

Enhanced supply chain and customer management

Seamless warehouse and eCommerce integration

Long-term scalability and efficiency

Why Choose Silver Touch for SAP Implementation?

Silver Touch Technologies is a seasoned SAP Business One partner. Here’s what sets us apart:

Deep domain knowledge and process consulting

End-to-end SAP solution planning and execution

Custom add-ons tailored to your operations

Integration with MES and legacy systems

Trusted by SMEs and large enterprises globally

24x7 technical support as a certified SAP Partner

Conclusion: SAP in Manufacturing

In conclusion, SAP ERP is a transformative solution for small and mid-sized manufacturing businesses. It supports intelligent, connected, and scalable manufacturing with features designed for modern industrial needs. Partnering with a reliable SAP provider like Silver Touch ensures your manufacturing unit is ready for the future.

Source - https://sap.silvertouch.com/blog/sap-business-one-for-manufacturing

#SAP Business One Manufacturing#SAP Business One Manufacturing Industry#SAP Business One manufacturing solution#SAP Manufacturing ERP Modules

0 notes