#Electric vehicle powertrain management

Text

How does an engine contribute to a car's powertrain?

The powertrain in a vehicle is the system responsible for generating power and delivering it to the wheels to propel the vehicle forward. The operation of a powertrain can vary depending on whether the vehicle is powered by an internal combustion engine (ICE) or an electric motor (in the case of electric vehicles). Here's a general overview of how a powertrain works in both types of vehicles:

Internal Combustion Engine (ICE) Vehicle - Combustion Process: In an ICE vehicle, the powertrain starts with the combustion process in the engine. Fuel (gasoline or diesel) mixes with air in the combustion chamber and is ignited by spark plugs (in gasoline engines) or compression (in diesel engines).

Power Generation: The combustion process generates energy in the form of mechanical power, causing pistons to move up and down within the cylinders of the engine. This motion drives the crankshaft, converting linear motion into rotational motion.

Transmission: The rotational motion from the crankshaft is transmitted to the transmission, which consists of gears that allow the driver to select different ratios (speeds). This enables the engine to operate efficiently across a range of vehicle speeds.

Drivetrain: The transmission sends power to the drivetrain components, including the driveshaft, differential, and axles, which transfer power to the wheels. The differential allows the wheels to rotate at different speeds, enabling smooth turns.

Wheel Movement: The power transmitted through the drivetrain causes the wheels to rotate, propelling the vehicle forward or backward depending on the gear selection and throttle input from the driver.

Electric Vehicle (EV) -

Battery Pack: The primary source of power for the EV, storing electricity in chemical form.Powers the electric motor and provides electricity for all electronic devices within the EV.

Battery Management System (BMS): Monitors battery cell conditions, including voltage, current, temperature, and state of charge (SoC).It protects the battery against overcharging, deep discharging, and overheating and helps balance the charge across cells. Ensures optimal performance and longevity of the battery by regulating its environment.

Inverter: Converts DC from the battery pack into AC to drive the electric motor.Adjusts the frequency and amplitude of the AC output to control the motor’s speed and torque. Critical for translating electrical energy into mechanical energy efficiently.

Onboard Charger: Facilitates the conversion of external AC (from the grid) to DC to charge the battery pack. Integrated within the vehicle, allowing for charging from standard electrical outlets or specialized EV charging stations. Manages charging rate based on battery status to ensure safe and efficient charging.

DC-DC Converter: Steps down the high-voltage DC from the battery pack to the lower-voltage DC needed for the vehicle's auxiliary systems, such as lighting, infotainment, and climate control. Ensures compatibility between the high-voltage battery system and low-voltage electronic components.

Electric Motor: Converts electrical energy into mechanical energy to propel the vehicle. It can be of various types, such as induction motors or permanent magnet synchronous motors, each offering different efficiencies and characteristics. Typically provides instant torque, resulting in rapid acceleration.

Vehicle Control Unit (VCU): The central computer or electronic control unit (ECU) that governs the EV's systems. Processes inputs from the vehicle’s sensors and driver inputs to manage power delivery, regenerative braking, and vehicle dynamics. Ensures optimal performance, energy efficiency, and safety.

Power Distribution Unit (PDU): Manages electrical power distribution from the battery to the EV’s various systems. Ensures that components such as the electric motor, onboard charger, and DC-DC converter receive the power they need to operate efficiently. Protects the vehicle's electrical systems by regulating current flow and preventing electrical faults.

In both ICE vehicles and EVs, the powertrain's components work together to convert energy into motion, enabling the vehicle to move efficiently and effectively. However, the specific technologies and processes involved differ significantly between the two propulsion systems.

#electric powertrain technology#conventional powertrain#Electric vehicle components#revolo hybrid car kit#ev powertrain development services#software (SW) platforms for all Electric vehicles components#Battery Management Systems#Inverter#Smart Charger#VCU solutions

3 notes

·

View notes

Text

Pioneering the Future of Transportation: Innovative Car Engine Technologies

The automotive industry is undergoing a revolutionary transformation, driven by innovative car engine technologies that are shaping the future of nationwide car shipping. These advancements are crucial in improving vehicle performance, efficiency, and sustainability, paving the way for a new era of mobility.

As environmental concerns and regulatory pressures mount, automakers are investing heavily in developing cutting-edge engine solutions that not only enhance performance but also reduce emissions and improve fuel economy.

Emerging Car Engine Solutions

1. Electric Powertrains

One of the most significant innovations in car engine technology is the rapid development of electric powertrains. Major automakers are investing heavily in electric vehicle (EV) production, aiming to become global leaders in electric mobility by 2030. Electric powertrains offer several advantages:

Zero direct emissions, contributing to reduced air pollution

Higher energy efficiency compared to traditional internal combustion engines

Instant torque delivery, providing improved acceleration and performance

By 2030, it is expected that 55 percent of all cars sold in Europe will be fully electric, highlighting the growing importance of this technology.

2. Advanced Internal Combustion Engines

While electric vehicles are gaining traction, innovative internal combustion engine designs are also being developed to improve efficiency and reduce emissions. These advancements include:

Variable compression ratio engines that adjust compression based on driving conditions

Homogeneous charge compression ignition (HCCI) engines that combine the best features of gasoline and diesel engines

These technologies aim to squeeze more power and efficiency out of traditional fuel sources, providing a bridge between conventional and fully electric vehicles.

3. Hybrid Powertrains

Hybrid powertrains, which combine internal combustion engines with electric motors, continue to evolve and offer a balance between traditional and electric technologies. Advanced hybrid systems provide:

Improved fuel efficiency through regenerative braking and electric-only operation at low speeds

Reduced emissions while maintaining long-range capabilities

Enhanced performance through the combination of electric and combustion power

4. Hydrogen Fuel Cell Technology

While still in the early stages of adoption, hydrogen fuel cell technology is gaining attention as a potential alternative to battery-electric vehicles. Fuel cell engines offer:

Zero emissions, producing only water vapor as a byproduct

Faster refueling times compared to battery charging

Longer range capabilities, especially for larger vehicles from the nationwide auto transport companies and long-distance transportation

The Future of Automotive Innovation

The continued development of advanced car engine technologies is set to transform the automotive landscape dramatically. As these innovations progress, we can expect to see:

Enhanced Vehicle Intelligence: The integration of AI and machine learning in engine management systems will lead to smarter, more responsive vehicles. For instance, BMW Group and NVIDIA Corporation's collaboration aims to integrate AI computing platforms into vehicles, enabling advanced autonomous driving capabilities and intelligent engine control features.

Improved Connectivity: The automotive industry is moving towards a more connected future. Ford Motor Company and Amazon Web Services (AWS) are developing a cloud-based platform for next-generation connected vehicles, enabling features like over-the-air software updates and predictive maintenance for engine systems.

Sustainable Transportation Solutions: With a focus on electric powertrains, hydrogen fuel cells, and more efficient combustion engines, the automotive industry is actively working towards reducing its environmental impact. This shift is expected to accelerate, with more automakers committing to sustainable practices and products.

Enhanced Performance and Efficiency: The combination of advanced engine control systems and innovative powertrain technologies will result in vehicles that are not only more efficient but also offer improved performance across various driving conditions.

Automakers are playing a crucial role in driving these innovations forward. Companies like General Motors, Volvo, Aston Martin, and Jaguar Land Rover are planning to manufacture only electric cars in the foreseeable future, demonstrating their commitment to sustainable mobility solutions.

Additionally, collaborative efforts between automakers, engine suppliers, research institutions, and government agencies are facilitating technology innovation, standardization, and scale economies that drive down costs and accelerate the adoption of cleaner, more efficient engines.

The future of auto transport services in california is being shaped by remarkable advancements in car engine technologies. From electric powertrains to advanced internal combustion engines and hydrogen fuel cells, these innovations are not only enhancing vehicle performance and efficiency but also contributing to a more sustainable automotive ecosystem.

As we move forward, the continued collaboration between automakers, nationwide car carriers, and automotive industries will be essential in realizing the full potential of these groundbreaking technologies, ultimately transforming the way we travel and interact with our vehicles.

The automotive engine market is expected to grow from USD 94 billion in 2022 to USD 130.63 billion by 2028, with a CAGR of 5.48%. This growth underscores the importance of innovative engine technologies in shaping the future of the best nationwide auto transport.

As these technologies continue to evolve, they will not only revolutionize the driving experience but also play a crucial role in addressing global environmental challenges and creating a more sustainable future for mobility.

vimeo

7 notes

·

View notes

Text

Audi announce new simulator driver as they take next step in F1 power unit development

Audi have signed Swiss racing pro Neel Jani as their new simulator driver as they take the next step in developing a power unit for their Formula 1 project. Jani, 39, is a former test and reserve driver for Red Bull Racing and, as a member of the Porsche factory team, he won the FIA World Endurance Championship in 2016 as well as the famous 24-hour race at Le Mans.

German brand Audi announced last summer that they would enter F1 from 2026, when new regulations come in, and would be building their own power unit. They soon struck a deal to take over the Sauber works team – currently Alfa Romeo – for their entry.

BARRETTO: How Sauber are preparing for Audi’s arrival – and keeping the pressure on in the midfield battle

Plenty of preparation has gone into the project, with the likes of Andreas Seidl leaving McLaren in December to join as the new Sauber CEO while former McLaren technical director James Key will join the team in September.

Jani, who has also driven in GP2 and Formula E, will now have his own important role to play for Audi as he supports the development of the power unit with his vast experience. An update of the dynamic driving simulator for the work on the F1 hybrid powertrain is also being run at Audi’s Neuberg site in parallel.

Audi have signed Neel Jani as a simulator driver to aid in the development of their F1 power unit

“I am delighted to accompany Audi on their way into Formula 1,” said Jani. “It is both an honor and a great responsibility to be involved in a project of this magnitude at an early stage.

“I am sure that with my experience from Formula 1 and [sportscar] projects I can forge good links between theory and practice.”

Oliver Hoffman, Member of the Board of Management for Technical Development of Audi AG, added: “Just like in production development, simulation plays a major role in our Formula 1 project.

“Our simulator is an important tool for the power unit development. It requires a development driver who, in addition to a grasp of technology, brings versatile experience to the project, especially in terms of energy management in racing conditions.”

Audi have also stated that, since the end of 2022, testing of a one-cylinder engine has been delivering “valuable results” for the development of the power unit. The manufacturer added that the continuing concept phase is laying the groundwork of the power unit for 2026, when the new regulations will provide for increasing electrification.

This feature is currently not available because you need to provide consent to functional cookies. Please update your cookie preferences

Explainer: F1 sustainable fuels

The electric motor will deliver nearly the same output as the internal combustion engine and the 1.6-litre turbo engines will be powered by sustainable synthetic fuel.

“At the moment, we are mainly focused on fundamental concept questions with high relevance to performance,” said Adam Baker, CEO of Audi Formula Racing GmbH.

READ MORE: 'It's the next revolution' – Tech chief Pat Symonds explains why Formula 1 is leading the push for sustainable fuels

“However, in evaluating various technical solutions we rely not only on digital methods. Know-how, experience and practically relevant development are indispensable elements of drawing the right conclusions from the simulation.

"With that combination, we can assess various operating strategies at an early stage and pave the way for efficient energy management of the power unit.”

Audi have also said the first hybrid power unit, consisting of the internal combustion engine, electric motor, battery and control electronics, is planned to be run on their dyno before the year is out. That will then provide the basis for the future vehicle concept going forward.

via Formula 1 News https://www.formula1.com

#F1#Audi announce new simulator driver as they take next step in F1 power unit development#Formula 1

4 notes

·

View notes

Text

A list of Automotive Engineering Service Companies in Germany

Bertrandt AG, https://www.bertrandt.com/. Bertrandt operates in digital engineering, physical engineering, and electrical systems/electronics segments. Its Designing function includes designing of all the elements of the automotive.

Alten Group, https://www.alten.com/. ALTEN Group supports the development strategy of its customers in the fields of innovation, R&D and technological information systems. Created 30 years ago, the Group has become a world leader in Engineering and Technology consulting. 24 700 highly qualified engineers carry out studies and conception projects for the Technical and Information Systems Divisions of major customers in the industrial, telecommunications and Service sectors.

L&T Technology Services Limited, https://www.ltts.com/. LTTS’ expertise in engineering design, product development, smart manufacturing, and digitalization touches every area of our lives — from the moment we wake up to when we go to bed. With 90 Innovation and R&D design centers globally, we specialize in disruptive technology spaces such as EACV, Med Tech, 5G, AI and Digital Products, Digital Manufacturing, and Sustainability.

FEV Group GmbH, https://www.fev.com/. FEV is into the design and development of internal combustion engines, conventional, electric, and alternative vehicle drive systems, energy technology, and a major supplier of advanced testing and instrumentation products and services to some of the world’s largest powertrain OEMs. Founded in 1978 by Prof. Franz Pischinger, today the company employs worldwide highly skilled research and development specialists on several continents.

Harman International, https://www.harman.com/. HARMAN designs and engineers connected products and solutions for automakers, consumers, and enterprises worldwide, including connected car systems, audio and visual products, enterprise automation solutions; and services supporting the Internet of Things.

EDAG Engineering GmbH, https://www.edag.com/de/. EDAG is into vehicle development, plant planning and construction, and process optimization.

HCL Technologies Limited, http://www.hcltech.com/. HCL Technologies Limited is an Indian multinational information technology services and consulting company headquartered in Noida. It emerged as an independent company in 1991 when HCL entered into the software services business. The company has offices in 52 countries and over 210,966 employees.

Cientra GmbH, https://www.cientra.com/. Cientra expertise across VLSI, ASIC, FPGA, SoC engineering, and IoT accelerate our delivery of customized solutions to the Consumer, Aviation, Semiconductors, Telecom, Wireless, and Automotive industries across their product lifecycle.

Akka Technologies, https://www.akka-technologies.com/. AKKA supports the world’s leading industry players in their digital transformation and throughout their entire product life cycle.

IAV GmbHb, https://www.iav.com/en/. IAV develops the mobility of the future. Regardless of the specific manufacturer, our engineering proves itself in vehicles and technologies all over the world.

Altran Technologies, https://www.altran.com/in/en/. Altran expertise from strategy and design to managing operations in the fields of cloud, data artificial intelligence, connectivity, software, digital engineering, and platforms.

Capgemini Engineering, https://capgemini-engineering.com/de/de/. Capgemini Engineering is a technology and innovation consultancy across sectors including Aeronautics, Space, Defense, Naval, Automotive, Rail, Infrastructure & Transportation, Energy, Utilities & Chemicals, Life Sciences, Communications, Semiconductor & Electronics, Industrial & Consumer, Software & Internet.

2 notes

·

View notes

Text

BMW Powers Up Indonesia with the Stunning i5 Touring e-Wagon

BMW Group Indonesia has officially introduced the first electric wagon in the country, the BMW i5 Touring. This marks a significant milestone for the company as it continues to expand its hybrid and electric vehicle lineup. According to Lars Nielsen, Managing Director of BMW Group Asia, the launch of the BMW i5 Touring is a testament to BMW’s commitment to providing sustainable, cutting-edge technology while enhancing user convenience. With a progressive design and advanced features, the i5 Touring is set to make a lasting impression in the Indonesian automotive market.

A Future-Forward Design

The BMW i5 Touring isn't just about aesthetics—it’s about merging modern design with practical functionality. The car’s sleek, elongated body embodies the classic wagon style while exuding a strong and dynamic presence on the road. It is designed to offer maximum space for both passengers and cargo, making it an ideal choice for families or individuals needing extra room for long trips or bulky items.

The i5 Touring measures 5,060 mm in length, 1,900 mm in width, and 1,515 mm in height, which translates into ample interior volume, particularly in the cargo area. This spacious design ensures that the i5 Touring is not only stylish but also highly functional, capable of accommodating the needs of modern drivers who value both aesthetics and practicality.

Exterior Highlights

On the outside, the BMW i5 Touring continues BMW’s tradition of sharp, eye-catching design elements. The car features BMW’s signature double headlights, paired with the iconic kidney grille, giving it a bold and sporty look. The design is further enhanced by sharply cut rear windows and a wider, more aggressive stance, ensuring that the i5 Touring commands attention wherever it goes.

The bold lines and striking proportions of the i5 Touring make it stand out, while also contributing to its aerodynamic efficiency. This combination of form and function is a hallmark of BMW’s design philosophy, ensuring that the vehicle not only looks good but performs exceptionally well on the road.

Interior Comfort and Advanced Technology

Inside the i5 Touring, the focus is clearly on the driver. The interior is built around BMW’s Curved Display system, which includes a 12.3-inch information display and a 14.9-inch control display. These screens seamlessly integrate into the dashboard, providing a futuristic, driver-centric experience.

Premium materials are used throughout the cabin, creating a luxurious yet sporty ambiance. The flat-bottomed steering wheel and sports seats add to the dynamic feel of the interior, making every drive comfortable and engaging. The i5 Touring’s interior is a perfect blend of elegance and functionality, offering both comfort and cutting-edge technology.

Lars Nielsen emphasized the technological innovations found in the i5 Touring, noting that the car is equipped with the latest digital advancements. These include advanced auto-driving and parking functions, which not only enhance the convenience of driving but also contribute to the car’s overall sustainability throughout its lifecycle. BMW’s commitment to sustainability is evident in every aspect of the i5 Touring, from its electric powertrain to its eco-friendly materials and manufacturing processes.

Impressive Cargo Space

One of the standout features of the i5 Touring is its impressive cargo capacity. The car’s trunk can expand to accommodate up to 1,700 liters of cargo, making it ideal for those who need extra space for long trips or larger items. Whether you’re going on a family vacation or simply need to transport bulky equipment, the i5 Touring has you covered.

This generous cargo space, combined with the car’s spacious interior, makes the i5 Touring a practical choice for families or anyone who values versatility in their vehicle. BMW has designed the i5 Touring to meet the needs of modern drivers, offering both style and substance in a single package.

Advanced Safety and Driving Assistance

Safety is a top priority in the BMW i5 Touring, and the car comes equipped with a range of advanced safety features and semi-automatic driving systems. One of the key highlights is BMW’s Driving Assistant Professional, which enhances the car’s lane-keeping and parking capabilities. This system makes driving easier, safer, and more precise, reducing the likelihood of human error and ensuring a more relaxed driving experience.

BMW’s state-of-the-art Advanced Driver Assistance Systems (ADAS) further contribute to the i5 Touring’s safety credentials. These systems provide real-time support to the driver, helping to reduce the risk of accidents in a variety of road conditions. Whether you’re navigating busy city streets or cruising on the highway, the i5 Touring’s safety features are designed to keep you and your passengers safe.

Power and Performance

The BMW i5 Touring is available in the eDrive40 variant, which delivers impressive performance numbers. Powered by an electric motor, the car produces 340 horsepower and 430 Nm of torque. This allows the i5 Touring to accelerate from 0 to 100 km/h in just 6.1 seconds, making it one of the fastest electric wagons in its class. The car also boasts a top speed of 193 km/h, ensuring that it offers both speed and efficiency.

BMW has engineered the i5 Touring to deliver a dynamic driving experience, with responsive handling and smooth acceleration. The electric motor provides instant torque, giving the car a powerful yet refined feel on the road. Whether you’re navigating tight city streets or enjoying a long highway drive, the i5 Touring is designed to offer a thrilling driving experience.

Long-Range Battery

The BMW i5 Touring is equipped with an 84.3 kWh battery pack, which provides an impressive driving range of up to 500 km on a single charge (based on the WLTP cycle). This long-range capability makes the i5 Touring a practical choice for both daily commutes and longer trips, eliminating the need for frequent charging stops.

Charging the i5 Touring is also convenient, thanks to its ability to charge via an 11 kW AC charger or a 205 kW DC fast charger. The DC fast charger can significantly reduce charging times, allowing drivers to quickly get back on the road with minimal downtime. This combination of long-range capability and fast charging options makes the i5 Touring a highly practical electric vehicle for a variety of driving needs.

Price and Availability

The BMW i5 Touring eDrive40 is now available in Indonesia, with a starting price of IDR 2.227 billion (off the road in DKI Jakarta). Customers can place orders for the i5 Touring at any authorized BMW dealership across the country. With its combination of cutting-edge technology, impressive performance, and spacious design, the i5 Touring is set to be a popular choice among Indonesian drivers looking for a premium electric vehicle.

In conclusion, the BMW i5 Touring is more than just an electric wagon—it’s a statement of BMW’s commitment to innovation, sustainability, and driving pleasure. With its progressive design, advanced technology, and impressive performance, the i5 Touring is poised to become a leader in the electric vehicle market in Indonesia. Whether you’re looking for a stylish family car or a dynamic driving experience, the BMW i5 Touring offers the best of both worlds.

For more updated information about the automotive market, the latest cars & bikes, Please visit our website https://www.autoini.com

#indonesia#vehicle#autoini#jakarta#automobile#automotive#cars#latest car#bmw#suv#luxury suv#autos#electric suv#electric cars#concept car#bali

0 notes

Text

Fueling the Future: Key Trends in the Automotive Fuel Tank Market

The automotive fuel tank market is evolving rapidly, driven by innovations in materials, design, and environmental regulations. According to Mordor Intelligence, The Automotive Fuel Tank Market is projected to be valued at USD 19.23 billion in 2024 and is expected to grow to USD 24.31 billion by 2029, with a compound annual growth rate (CAGR) of 4.80% during the forecast period (2024-2029). The demand for more efficient, lightweight, and eco-friendly fuel tank solutions is pushing manufacturers to explore new technologies and materials, transforming the industry.

Key Trends Shaping the Automotive Fuel Tank Market

Shift Toward Lightweight Materials One of the most significant trends in the automotive fuel tank market is the increasing use of lightweight materials such as plastic and composite materials. Traditional steel fuel tanks are gradually being replaced by plastic variants, which offer reduced weight, improved fuel efficiency, and better corrosion resistance. The use of high-density polyethylene (HDPE) in fuel tank production is particularly notable, as it offers flexibility, durability, and cost-effectiveness, helping automakers meet stringent fuel efficiency and emission standards.

Focus on Emission Regulations and Fuel Efficiency The automotive industry is under increasing pressure to comply with global emissions regulations, such as the Corporate Average Fuel Economy (CAFE) standards and Euro 6 emission norms. These regulations aim to reduce greenhouse gas emissions and improve fuel efficiency. As a result, manufacturers are developing fuel tanks that can withstand higher pressures, store alternative fuels, and incorporate features that minimize fuel evaporation. Evaporative emission control systems (EVAP) are becoming more common, helping to curb emissions and meet regulatory requirements.

Rising Demand for Alternative Fuels The push for alternative fuels such as compressed natural gas (CNG), liquefied petroleum gas (LPG), and hydrogen is reshaping the fuel tank industry. Specially designed fuel tanks are required to safely store and transport these fuels, leading to the development of reinforced composite tanks and multi-layer plastic tanks. As governments and consumers increasingly adopt cleaner fuels, the demand for alternative fuel tanks is expected to rise, presenting new opportunities for market growth.

Growth of Hybrid and Electric Vehicles The rise of hybrid and electric vehicles (EVs) is impacting the automotive fuel tank market. While EVs do not require traditional fuel tanks, hybrid vehicles still rely on fuel storage systems. However, the size and capacity of fuel tanks in hybrid vehicles are often smaller due to the presence of electric powertrains. This has led to a shift in the design and production of fuel tanks, focusing on compact, lightweight solutions that can fit into the limited space available in hybrid vehicles. Although the increasing penetration of EVs may slow the overall growth of the fuel tank market, hybrid vehicles will continue to drive demand for fuel storage systems.

Technological Advancements in Fuel Tank Design Innovations in fuel tank design are also shaping the market. Modern fuel tanks are being designed with advanced features such as modular fuel tank systems, which allow for easier installation and maintenance. Additionally, the integration of fuel level sensors, pressure management systems, and anti-leakage technologies is improving the overall performance and safety of fuel tanks. Manufacturers are investing in research and development to create more efficient and reliable fuel storage solutions that meet the needs of modern vehicles.

Regional Growth and Emerging Markets The Asia-Pacific region, particularly China, India, and Japan, is expected to experience significant growth in the automotive fuel tank market due to the rising demand for vehicles and increasing fuel efficiency regulations. North America and Europe are also witnessing growth, driven by the shift toward lightweight materials and alternative fuel adoption. Emerging markets in Latin America and Africa are presenting opportunities for manufacturers to expand their presence as vehicle ownership rises in these regions.

Conclusion

The automotive fuel tank market is set for steady growth in the coming years, driven by advancements in materials, environmental regulations, and the rising demand for alternative fuels. As the industry focuses on improving fuel efficiency, reducing emissions, and integrating new technologies, manufacturers must adapt to meet the evolving needs of the automotive sector. Lightweight, durable, and eco-friendly fuel tank solutions will be key to sustaining market growth, while innovations in design and technology will continue to shape the future of the industry.

With increasing investments in research and development and the global push for cleaner, more efficient transportation solutions, the automotive fuel tank market holds significant opportunities for growth and innovation. https://www.mordorintelligence.com/industry-reports/automotive-fuel-tank-market

#automotive fuel tank market#automotive fuel tank market size#automotive fuel tank market share#automotive fuel tank market forecast#automotive fuel tank market analysis

0 notes

Text

IAA TRANSPORTATION will kick off on 17th September

On 17th September, 2024,IAA TRANSPORTATION,the world's leading event for the logistics,commercial vehicle and transportation industries,will kick off.AEAUTO will make a shining debut on this stage where elites in the field of transportation and mobility gather together to plan a sustainable and pioneering future.AEAUTO will also present many cutting-edge products at BOOTH: Halle 21 D68.

AEAUTO appeared at this exhibition with the latest product:

EPS(Electric Power Steering System)

It can provide efficient and precise assistance for vehicle steering,improve driving experience while ensuring driving safety,and make vehicle control easier.

DC EV Charger

This is a charger designed specifically for electric vehicles.It performs well in charging speed and stability,and can provide electric vehicles with efficient energy supply to meet the needs of fast charging in different scenarios.

AC EV Charger

It provides a reliable solution for daily charging of electric vehicles,with good compatibility and safety,and can be used in scenarios such as homes and public parking lots.

EV conversion kit

It provides great convenience for the transformation of traditional vehicles to electric vehicles,allowing traditional vehicles to easily achieve the transformation to electric vehicles by installing this kit and adapt to the travel needs of the new era.

Powertrain system

As the core guarantee for the efficient operation of the vehicle,it has efficient power transmission and stable performance,which enables the vehicle to exert the best power output under various working conditions.

Electric Mixer truck loading system

It brings new possibilities for transportation operations in the field of electric mixer trucks,optimizes the loading process,improves operating efficiency,and injects new vitality into the development of related industries.

To make it easier for you to get to the trade fair,we have provided the following information on the main routes:

From the central train station(Hauptbahnhof)to Messe/Nord:

Take tram lines 8 and 18(stops include"Kröpcke"and"Aegidientorplatz").

From the city center to Messe/Ost:

Take tram lines 6 or 16(stops include"Kröpcke"and"Tierärztliche Hochschule").

From Hannover Airport to Hannover Central Station:

Take the city rail(S-Bahn)line S5(between Terminals B and C).

At this exhibition, AEAUTO General Manager Henry, technical expert Dale, and Sales Director Simon will be present at the exhibition. Each of them has profound experience and unique insights in their respective fields. This is definitely a rare opportunity to have in-depth exchanges with industry elites. You can discuss with us the latest developments in the industry, whether it is cutting-edge technology development trends or changes in the market structure. At the same time, we can also take this opportunity to jointly promote the development of related project cooperation, work together to move towards a broader development space, and jointly explore new opportunities and possibilities.

AEAUTO will communicate and cooperate with industry colleagues in the 21st exhibition area of the IAA TRANSPORTATION exhibition to showcase its innovative achievements.People from all walks of life are welcome to visit the AEAUTO booth to witness the charm of these innovative products and explore the bright future of the transportation industry.

0 notes

Text

Automotive Power Electronics Market - Forecast(2024–2030)

Automotive Power Electronics Market Overview

Automotive Power Electronics Market Size is valued at $5.4 Billion by 2030, and is anticipated to grow at a CAGR of 4.2% during the forecast period 2024 -2030. The automotive power #electronics market is experiencing significant growth, driven #primarily by the increasing demand for #electric vehicles (EVs). This surge is fueled by a global shift towards sustainable transportation and stringent emission #regulations. The rapid #technological advancements in #semiconductor materials and power management solutions are enhancing the efficiency and performance of automotive power electronics, thereby #accelerating market expansion.

Additionally, consumer preferences are evolving towards vehicles that offer better energy efficiency, safety, and convenience, all of which are enabled by sophisticated power electronic systems. Manufacturers are investing heavily in research and development to innovate and stay competitive in this dynamic market. Furthermore, government incentives and subsidies for EVs are further propelling the adoption of automotive power electronics. This market trajectory is expected to continue its upward trend, as the integration of power electronics in vehicles becomes more prevalent, aligning with the broader goals of energy conservation and environmental sustainability.

Sample Report:

COVID-19/Russia-Ukraine War Impact

The COVID-19 pandemic significantly disrupted the automotive power electronics market, initially causing production halts and supply chain disruptions. As factories shut down and demand for vehicles plummeted, manufacturers faced challenges in maintaining operations and meeting financial targets. However, the pandemic also accelerated the adoption of electric vehicles (EVs), driven by increased awareness of environmental issues and government incentives. This shift spurred innovations in power electronics, essential for EVs’ efficiency and performance. Consequently, despite short-term setbacks, the industry experienced a renewed focus on developing advanced power electronics solutions, paving the way for long-term growth and resilience in a post-pandemic era.

The Russo-Ukraine War has significantly impacted the automotive power electronics sector, primarily through disruptions in the supply chain and fluctuations in raw material prices. The conflict has caused instability in the region, affecting the production and transportation of essential components like semiconductors and rare earth metals, crucial for power electronics. This disruption has led to increased costs and delays, compelling manufacturers to seek alternative sources and adjust their supply chains. Additionally, the economic sanctions imposed on Russia have further strained international trade relations, exacerbating the challenges faced by the automotive industry. Consequently, companies are re-evaluating their strategies to mitigate risks and ensure resilience in their operations, focusing on diversifying suppliers and investing in local manufacturing capabilities to reduce dependency on geopolitically sensitive regions.

Inquiry Before Buying:

Automotive Power Electronics Market

The report “Automotive Power Electronics Market Forecast (2024–2030)”, by Industry ARC, covers an in-depth analysis of the following segments of the Automotive Power Electronics Market:

By Component: Microcontroller Unit, Power Integrated Circuit, Sensors, Others

By Vehicle Type: Passenger Cars, Commercial Vehicles

By Electric Vehicle Type: Battery Electric Vehicles, Hybrid Electric Vehicles, Plug-In Hybrid Electric Vehicles

By Application: Powertrain & Chassis, Body Electronics, Safety & Security, Infotainment & Telematics, Energy Management System, Battery Management System

By Geography: North America (USA, Canada, and Mexico), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, Indonesia, Malaysia, and Rest of APAC), and Rest of the World (Middle East, and Africa)

Key Takeaways

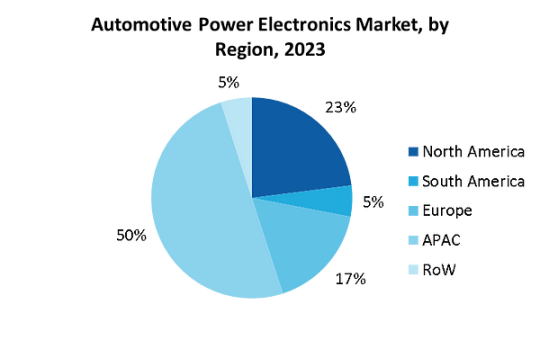

Asia-Pacific dominated the Automotive Power Electronics market with a share of around 50% in the year 2023.

The automotive industry’s need to meet stricter safety regulations and reduce emissions, coupled with rising consumer demand for electric vehicles, will propel the growth of the automotive power electronics market throughout the forecast period.

Apart from this, thrust to equip vehicles with advanced power solutions is driving the growth of Automotive Power Electronics market during the forecast period 2024–2030.

For More Details on This Report — Request for Sample

Automotive Power Electronics Market Segment Analysis — By Vehicle Type

The demand for automotive power electronics in passenger cars is escalating due to government initiatives promoting the integration of advanced electronics. This surge is driven by policies aimed at enhancing vehicle efficiency, safety, and environmental performance. For instance, in March 2024, the European Union introduced new regulations mandating the inclusion of advanced driver-assistance systems (ADAS) in all new cars, significantly boosting the need for sophisticated power electronics. Similarly, the U.S. government has increased funding for electric vehicle (EV) infrastructure, encouraging automakers to incorporate more power-efficient electronic components. Additionally, China’s recent tax incentives for electric and hybrid vehicles, announced in January 2024, have accelerated the adoption of power electronics to improve performance and range. These initiatives are fostering innovation and production of cutting-edge electronic components, such as inverters and onboard chargers, essential for modern passenger cars. As a result, automotive manufacturers are increasingly investing in power electronics to comply with regulations, meet consumer expectations, and gain a competitive edge in the evolving market.

Schedule a Call :

Automotive Power Electronics Market Segment Analysis — By Electric Vehicle Type

The demand for automotive power electronics in hybrid electric cars is rapidly increasing due to the global imperative to decarbonize the transport sector and reduce reliance on fossil fuels. Governments worldwide are implementing stringent regulations and incentives to promote the adoption of hybrid and electric vehicles. In January 2024, the European Union introduced enhanced subsidies for hybrid vehicle purchases, coupled with stricter emission standards, significantly boosting the market for power electronics. Similarly, the U.S. launched the “Clean Transport Initiative” in April 2023, providing substantial tax breaks and grants for hybrid car manufacturers to innovate and scale up production. Additionally, Japan’s latest energy policy, announced in February 2024, includes a comprehensive plan to phase out internal combustion engines, further propelling the demand for hybrid vehicles equipped with advanced power electronics. These components, such as power inverters, converters, and battery management systems, are essential for enhancing the efficiency and performance of hybrid electric cars. As a result, automotive companies are accelerating investments in power electronics technology to meet regulatory requirements, cater to consumer preferences, and contribute to a sustainable future.

Automotive Power Electronics Market Segment Analysis — By Geography

On the basis of geography, Asia-Pacific held the highest segmental market share of around 50% in 2023, The Asia-Pacific region is the largest market for automotive power electronics, driven by high vehicle production rates and the increasing adoption of advanced electronics in automobiles. Countries like China, Japan, and South Korea are leading in vehicle manufacturing, with major automakers integrating sophisticated power electronic components to enhance vehicle efficiency and performance. For example, in March 2024, Toyota introduced a new hybrid model equipped with cutting-edge power electronics, significantly improving energy management and fuel efficiency. Similarly, BYD in China launched an electric vehicle series in February 2024, featuring advanced inverters and converters, which contribute to extended driving ranges and faster charging times. These innovations reflect the region’s robust focus on technological advancements and sustainable transportation solutions. The strategic partnerships between automotive giants and technology firms, such as Hyundai’s collaboration with LG Electronics to develop next-generation battery management systems in April 2023, further underscore the region’s leadership in this sector. This confluence of high production volumes and technological integration ensures that the Asia-Pacific market remains at the forefront of automotive power electronics development.

Buy Now:

Automotive Power Electronics Market Drivers

The rising market for the electric vehicles is the key factor driving the growth of Global Automotive Power Electronics market

The growing demand for automotive power electronics is being significantly driven by the expanding electric vehicle (EV) market. As global initiatives to reduce carbon emissions intensify, consumers and manufacturers alike are shifting towards EVs, which rely heavily on power electronics for various critical functions. These components, including inverters, converters, and battery management systems, are essential for optimizing the performance, efficiency, and range of electric vehicles. Automakers are ramping up production of EVs, incorporating advanced power electronics to meet regulatory standards and consumer expectations for sustainability and high performance. The technological advancements in power electronics are also enabling faster charging, improved energy management, and enhanced vehicle safety, further boosting their demand. Consequently, the automotive industry is experiencing a surge in innovation and investment in power electronics to support the burgeoning EV market, positioning it as a pivotal element in the future of transportation.

Automotive Power Electronics Market Challenges

The high cost of electric vehicles is expected to restrain the market growth

The high cost of electric vehicles (EVs) negatively impacts the automotive power electronics market by limiting consumer adoption and market growth. Despite the technological advancements and environmental benefits of EVs, their higher price compared to traditional vehicles remains a significant barrier. This cost premium is largely due to expensive components such as batteries and advanced power electronics systems, including inverters and converters, which are essential for EV functionality. As a result, potential buyers are often deterred by the initial investment required, slowing the transition to electric mobility. Consequently, manufacturers face challenges in achieving economies of scale, which further drives up costs. This cyclical issue restricts market expansion and inhibits broader implementation of power electronics innovations, ultimately stalling progress towards widespread EV adoption and the associated benefits of reduced emissions and improved energy efficiency in the automotive sector.

Automotive Power Electronics Industry Outlook

Product launches, mergers and acquisitions, joint ventures and geographical expansions are key strategies adopted by players in the Automotive Power Electronics Market. The key companies in the Automotive Power Electronics Market are:

STMicroelectronics N.V.

Infineon Technologies AG

Fuji Electric Co., Ltd.

NXP Semiconductors N.V.

Renesas Electronics Corporation

Toshiba Corporation

Mitsubishi Electric

Huawei Digital Power

Robert Bosch GmbH

Hitachi Energy

Recent Developments

In May 2022, STMicroelectronics joined forces with Microsoft to make development of highly secure IoT devices easier.

In March 2023, Infineon Technologies announced the acquisition of GaN Systems, a global leader in gallium nitride (GaN)-based power conversion solutions. This move strengthened Infineon’s position in the market.

For more Automotive Market reports, please click here

0 notes

Text

Electric Vehicle Propulsion Systems: How Does MCU Drive Efficiency?

September 4, 2024

by dorleco

with no comment

eMOBILITY CONTROLS

Edit

Introduction

The Electric Vehicle Propulsion System of an electric vehicle is made up of various components that combine to transform electrical energy into motion to move the vehicle. Increasing the efficiency of the EV requires the Motor Control Unit (MCU). Let’s take a closer look at how the MCU of an EV propulsion system increases efficiency:

1. Motor Planning and Control:

The MCU controls factors including voltage, current, and frequency to manage the operation of the electric motor to maintain optimal performance and efficiency. It minimizes energy loss by ensuring that the motor runs within its most efficient range.

2. Regenerative Braking Control:

When braking and accelerating, the car can regain energy thanks to regenerative braking. It is under MCU management. Based on input from the driver and the condition of the road, it determines the proper amount of regenerative braking force to maximize energy recovery and boost efficiency.

3. Battery Control:

Optimizing battery management is critical to the overall functionality of the system. The MCU keeps an eye on the battery’s temperature, condition, and charge level. It maximizes battery performance and lifespan by reducing overcharging and over-discharging and by modifying charging and discharging rates by this data.

4. Temperature Control:

Overheating can cause components in an EV to lose some of their effectiveness. To prevent overheating, the MCU regulates power supply and monitors the temperature of essential components including the battery and electric motor. This ensures that the parts stay within their designated temperature limits and continue to work correctly.

5. Powertrain Coordination:

When an EV has many motors, like separate motors for the front and rear axles, the MCU regulates the power transmission between the motors. In particular, all-wheel drive (AWD) electric cars (EVs) ensure the optimal power distribution for optimal traction and efficiency.

6. Adaptive Algorithms:

Adaptive control algorithms are found in many MCUs, which respond instantly to changing driving conditions. These algorithms consider variables including load, vehicle speed, and road conditions. The MCU regulates power supply and motor performance to optimum economy in a range of driving scenarios.

Advantages of Electric Vehicle Propulsion Systems

There are various advantages when comparing the propulsion of electric vehicles to those of traditional internal combustion engine (ICE) vehicles. The driving efficiency of electric vehicles (EVs) is one of their primary benefits, and the Motor Control Unit (MCU) has a significant impact on this. The following are advantages of electric vehicle (EV) propulsion systems, and the MCU increases their efficiency:

1. Energy Effectiveness:

EVs are inherently more energy-efficient than ICE vehicles. The MCU plays a major role in optimizing the process of converting electrical energy from the battery into mechanical energy to propel the vehicle.

It regulates the electric motor’s performance to ensure that it maximizes energy conversion while consuming the least amount of energy.

2. Efficiency and Instant Torque:

Electric motors can accelerate quickly and provide torque instantly. To maximize efficiency and responsiveness and create a driving experience that is both efficient and enjoyable, the MCU ensures that the motor receives power accurately.

3. Battery Management:

The MCU monitors and controls the battery’s charging and discharging rates optimally. It protects against overcharging and severe discharge, two situations that might reduce the battery’s useful life.

The MCU supports the battery’s continuous ability to store energy by preserving ideal working conditions.

4. Temperature Regulation:

Efficient thermal management is critical to EV efficiency. The MCU monitors critical component temperatures and modifies power delivery as needed to avoid overheating.

Ensuring that the motor, battery, and power electronics operate within acceptable temperature limits, enhances their efficiency and longevity.

5. Intelligent Control Systems:

Adaptive control algorithms are found in many MCUs, which respond instantly to changing driving conditions. They adjust power delivery and engine performance based on factors like load, road conditions, and vehicle speed.

These adaptable algorithms optimize performance in a range of driving scenarios.

6. Updates and Enhancements to Software:

The MCU’s software can be updated progressively with manufacturer updates to increase efficiency. These upgrades could improve functionality, effectiveness, and modifications according to data and user input.

7. Combined Powertrain:

An essential component of the integrated powertrain in an EV is the MCU, which permits precise coordination between the electric motor, power electronics, and other components. This integration makes the system more effective.

Disadvantages of Electric Vehicle Propulsion Systems

In addition to their many advantages, electric vehicle (EV) propulsion technology has several serious disadvantages. It’s important to keep in mind that many of these flaws are being fixed and enhanced as EV technology develops. The Motor Control Unit (MCU) helps to somewhat offset some of these disadvantages, particularly about driving efficiency. The following are some issues with electric vehicle propulsion systems and the MCU’s fixes for them:

1. Limited Range:

One of the primary disadvantages of EVs is their limited driving range on a single charge. The MCU can optimize the power supply of the electric motor, resulting in efficient energy use and an increase in the vehicle’s range.

With accurate power output regulation and adaptive algorithms, the MCU contributes to maximizing the miles per kilowatt-hour (kWh) of energy stored in the battery, extending the total range.

2. Infrastructure for Charging:

Locating infrastructure for EV charging that is both comfortable and easily accessible may prove to be challenging. The MCU can assist with fast charging by maximizing charging rates, reducing charging times, and alerting drivers to charging stations that are close by.

3. Charging Time:

It could take longer to charge an electric vehicle (EV) than it does to refuel with gasoline or diesel. The MCU can regulate charging to lessen overheating and battery degeneration, allowing for a safe and efficient battery charging process.

4. Initial Cost:

When comparing EVs to traditional ICE cars, an EV’s initial cost is typically higher. However, by optimizing energy use and prolonging the life of essential components like the battery, the MCU can eventually contribute to cost savings.

5. Performance in Cold Weather:

Cold weather may cause electric vehicles to function less well and have a shorter range due to its effect on battery efficiency. By controlling the battery’s temperature using thermal management techniques, the MCU can lessen the negative effects of cold weather on efficiency.

6. Charging accessibility:

Due to restricted access to charging infrastructure, EV owners may find it challenging to conveniently charge their vehicles in some places. The MCU can help by optimizing the use of available charging resources and offering recommendations for efficient charging schedules based on the accessibility of charging stations.

7. Effects of Battery Production on the Environment:

The process used to make lithium-ion batteries, which are used in EVs, may have negative environmental implications. The MCU can help solve this issue by prolonging battery life and reducing the need for battery replacements by improving battery usage and charging practices.

8. Discarding and reusing:

EV battery recycling and disposal can be difficult processes. The MCU may be able to prolong the batteries’ usable life and lessen the requirement for early removal by controlling their life and health.

Conclusion:

To sum up, electric vehicle (EV) propulsion technologies offer a viable and environmentally friendly option to traditional internal combustion engine cars. A Motor Control Unit (MCU), which is essential for effectiveness and overall performance, is required for these systems.

Longer driving distances, more energy efficiency, and a reduced environmental impact are the outcomes of the MCU’s contribution to driving efficiency, notwithstanding the advantages and disadvantages of electric vehicle propulsion systems. As technology advances, these solutions should become much more accessible and effective, making EVs a more appealing and ecologically beneficial mode of transportation.

#autonomousVehicle#electricvehicle#EVPropulsion#Vehiclecontrolunit#VCU#EVSoftwareservices#CANKeypads#CANDisplays

0 notes

Text

Electric Vehicle Relay Market is Estimated to Witness High Growth Owing to Rising Adoption of Electric Vehicles

The electric vehicle relay market has been gaining significant traction over the past few years owing to the rising adoption of electric vehicles across the globe. Electric vehicle relays play a vital role in the overall functioning of electric vehicles by controlling various electrical systems and loads within the vehicle. Relays help in protecting circuits and offer greater operational efficiency. They find widespread use in charging systems, battery management systems, powertrain systems and other auxiliary functions within electric vehicles. The growing demand for eco-friendly vehicles coupled with stringent emission norms imposed by regulatory bodies around the world has propelled the sales of electric vehicles in recent years. This, in turn, has stimulated the demand for electric vehicle relays significantly.

The global electric vehicle relay market is estimated to be valued at USD 12.09 Bn in 2024 and is expected to reach USD 30.45 Bn by 2031, exhibiting a compound annual growth rate (CAGR) of 14.1% from 2024 to 2031.

Key Takeaways

Key players operating in the electric vehicle relay market are AEC (American Electronic Components, Inc.), Continental AG, Denso Corporation, Eaton Corporation, Fujitsu Limited, Hella GmbH & Co. KGaA, Hyundai Mobis, Infineon Technologies AG, Littelfuse Inc., Mitsubishi Electric Corporation, Panasonic Corporation, Robert Bosch GmbH, Schneider Electric SE, TE Connectivity Ltd., and Valeo SA.

Key opportunities in the Electric Vehicle Relay Market Growth include development of new products with advanced features suited for autonomous electric vehicles and focus on expanding presence in emerging nations in Asia Pacific and Latin America.

Major electric vehicle manufacturers are focusing on expanding their global footprint by setting up manufacturing plants across different regions. For instance, Tesla is setting up a new electric vehicle gigafactory in Berlin, Germany. Similarly, SAIC Motor Corporation and Volkswagen are also expanding their electric vehicle production capacities globally which will drive the demand for electric vehicle relays.

Market drivers

The rapid surge in electric vehicle sales across the world has been a major driver for the electric vehicle relay market. Stringent regulations aimed at curbing vehicular emissions and policies promoting electric vehicle adoption by governments worldwide have accelerated the sales of Electric Vehicle Relay Market Size and Trends substantially over the past few years. According to the International Energy Agency (IEA), the global stock of electric passenger vehicles reached 10 million in 2020, growing by 43% from 2019. This rapid rise in electric vehicle deployment is expected to drive the demand for electric vehicle relays significantly over the coming years.

PEST Analysis

Political: Government regulations and subsidies are influencing the electric vehicle relay market growth. Many countries are supporting the adoption of electric vehicles to reduce carbon emissions from fuel-powered vehicles through various incentives and regulations.

Economic: Lower operating costs of electric vehicles compared to fuel vehicles is driving consumers to opt for electric vehicles. Additionally, fluctuations in oil prices are also impacting the demand for electric vehicles.

Social: Increasing awareness about environmental pollution and focus on sustainable transportation are positively impacting the sales of electric vehicles. Consumers are willing to pay more for electric vehicles due to their low carbon footprint.

Technological: Advancements in relay technologies, such as improvements in communication protocols and power electronics, are enhancing the performance of electric vehicle relays. Electronic relays are replacing mechanical relays in vehicles to reduce complexity and enable controlled switching of large loads with quick response times.

Geographical regions where market in terms of value is concentrated

Asia Pacific dominated the electric vehicle relay market share in terms of value in 2024 due to the high production and sales of electric vehicles in China. China is the largest manufacturer as well as consumer of electric vehicles globally, which drives the relay market in the country.

The fastest growing region for the electric vehicle relay market

Europe is expected to witness the highest growth in the electric vehicle relay market during the forecast period. This is attributed to the stringent emission regulations and rising fuel costs in the region which are compelling automakers as well as customers to shift towards electric vehicles for transportation. The presence of major automobile companies and their focus on developing electric vehicles will further support the market growth in Europe.

Get more insights on Electric Vehicle Relay Market

For Deeper Insights, Find the Report in the Language that You want

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )

#Coherent Market Insights#Electric Vehicle Relay Market#Electric Vehicle Relay#Automotive Relay#High-Voltage Relay#DC Relay#Contactor#Power Electronics#Electric Vehicle Components#Automotive Electrical Systems#Electrical Engineering

0 notes

Text

One-Stop Printed Circuit Board Fab & Assembly Solutions for Automotive Industry

Automotive PCB Assembly Manufacturing Services

Automotive PCB Assembly Manufacturing Services

What is Automotive PCB?

Automotive circuit boards include central control circuit boards, ignition control circuit boards, power amplifier circuit boards, audio-visual media player boards, etc. according to their function and region. Due to brand manufacturers, electronic buses, etc., many circuit modules and backplanes do not have a unified standard name.

With the increasing demand of consumers for the functionality, safety, comfort, and entertainment of automobiles, especially for autonomous driving, the proportion of hybrid electric vehicles and pure electric vehicles in new energy vehicles has also increased by a considerable amount. The demand for PCB circuit board products for new energy vehicles has also increased.

What Types of PCBs are Found in Automotive Electronics?

Electric vehicles have consistent, essential, and innovative requirements. Today, Tesla is leading the wave of innovation. However, innovations in electric vehicle manufacturing and design require durable, reliable, and rugged PCB applications. Therefore, this is difficult to do without professiopnal automotive PCB manufacturers. High-performance automotive PCB requirements can significantly withstand harsh driving conditions and could be a catalyst for innovation in the growing new energy drive systems.

Electric vehicle PCB demand mainly comes from powertrain-related equipment (vehicles, battery management systems (BMS), voltage conversion systems (DC-DC, inverters, etc.), and other high and low voltage devices). In addition, mmWave radar is an important sensing device for realizing intelligent and autonomous driving and has obvious advantages compared with other sensors.

High power copper plated PCB is one of the most widely good to use PCB applications in emerging industries. Flexible PCBs, HDI PCBs, and LED PCBs are good to use in AC/DC power converters, audio and video, digital displays, braking systems, automatic dimming, electronic mirror controls, automotive lighting, engine timing systems, and remote diagnostic systems.

Common Uses of PCBs in Automobiles

Circuit boards commonly found in automobiles are ones utilized for safety features. These are the boards that also require the utmost in reliability.

In particular, the circuit used for airbag deployment rate / crash sensors are invaluable in dissipating static electricity and triggering the airbag's deployment at the exact moment when it’s needed.

Other critical safety features often requiring high-reliability PCBs include anti-lock brake systems and sensors that would trigger such features.

More vehicle functions powered by boards include power converters, fluid monitors, engine timing, LED lighting, power distribution systems, on-board and remote diagnostics, security systems, and other sensors for non-critical situations (gas, tire pressure, and so on).

Audio/video equipment, touchscreens, and GPS systems are found in most modern automobiles and make use of boards to connect all the electrical components.

Automotive PCB Technologies

Our automotive customers select us for our expertise in advanced technologies. Technologies we have the capability to provide include the list below, as single-sided, double-sided, and multi-layer boards.

Metal Core PCBs

Metal core PCBs are good to use in circuits where a lot of heat appears. Similarly, heat needs to dissipate quickly so as not to damage components. During the operation of the circuit board, heat comes due to some electronic components.

The purpose of metal is to transfer heat from critical circuit board components to less important areas, such as the backing of a metal heat sink or the metal core. Therefore, these PCBs are easy to thermally manage.

Heavy Copper PCBs

When printed circuit boards were first put into practical use, the electrolytic copper foil was almost always good to use as a conductor material. The technique of forming metal by electroplating is electroforming, or electroforming for short.

Since thin copper foil is easy to produce inexpensively by the electroforming process, electrolytic copper foil eventually became the standard conductor material for printed circuit boards. Furthermore, it was good to use in large quantities.

HDI Automotive PCB Manufacturers

HDI PCB technology is also known as 'microvia', and sometimes as 'sequential build-up' or simply 'build-up' technology. We refer to it as HDI, following the approach of the IPC standard that defined it.

It come on on the use of via holes less than 150µm (0.006in) in diameter that can go to adjacent layers of a PCB without having to go through all layers, smaller then are easy to drill mechanically. It is commonly called a "microvia" and can be buried (buried microvia) or sealed (blind microvia).

Microvias come on by laser-drilling and through-plating vias between each pair of adjacent copper layers before they are glued together to make the finished PCB. When the end result is a via hole that only connects between internal copper layers, it is a buried microvia.

Rigid PCBs

FR4 rigid PCBs offer no flexibility and are often used for video screens and rear-view cameras. They are not ideal for high vibration placements or tight form fitting spaces.

Flex PCBs

Because of their flexible & durable nature, these PCBs can be used in automobile corners and bends. They’re made of polyester films, polyimide, or plastic.

Rigid-Flex board

The combination of the rigid board and the flexible board can not only provide the support of the rigid board but also have the bending characteristics of the flexible board. Therefore, it can meet the requirements of three-dimensional assembly.

Flexible-rigid boards are the most complex connecting structures in EA. A simple GZHP has one rigid and one flexible layer. Complex GBPs can have 20 or more connecting sets of oneway and two-way GBPs between rigid external PBs.

The creation of GPP and GZHP is due to the need to miniaturize EA; the disproportion between the volume and mass of ERP (unpackaged and surface-mounted components) placed on rigid PCBs and the volume and mass of rigid PCBs.

Ceramic Substrate Board

Ceramic substrate board is best for manufacturing single- and double-sided printed circuit boards with vias such as aluminum oxide and nitride. Generally, the technology has advantages over traditional thin-film and thick-film technologies for manufacturing ceramic printed circuit boards.

Single and double-sided printed circuit boards made using this technology come by high resolution, high electrical conductivity, solderability, and weldability along the switching tracks.

The manufactured ceramic printed circuit boards can be good to use for the manufacture of hybrid electronic circuits, in the field of the auto industry, optoelectronics, and microwave technology.

Why Choose Hitechpcba as PCB Assembly Solutions for the Automotive Industry

Automotive PCB assembly is a specialized process that requires experience and knowledge in order to produce high-quality results. There are many steps involved in the assembly process, and each one must be performed with precision and care. If even one step is done incorrectly, it can affect the performance and reliability of the finished product. Here are some reasons why choosing our automotive PCB assembly services is the best decision for your business:

1. Our PCBs meet the minimum tolerance requirements for RoHS, REACH and Conflict Minerals. We also have a variety of green certification programs, including ENIG, HAL and HASL.

2. We understand the importance of quality and reliability in PCBs, and we work hard to ensure that our products meet or exceed industry standards.

3. We have extensive experience in this field, and our team is composed of skilled and experienced engineers. We understand the unique challenges and requirements that this market demands. We use the latest technologies and equipment to ensure that our automotive PCB assembly services are of the highest quality.

4. We use only the highest quality components and materials in our PCB assembly process. This ensures the durability and reliability of your products. Our PCBAs can withstand heavy current loads. They are able to do this because of their excellent thermal conductivity, which helps dissipate heat and protect the components around them.

5. We have a comprehensive quality assurance system in place that guarantees the accuracy and consistency of your products.

At our company, we take great pride in the fact that we source all of our materials from trusted and reliable suppliers. We believe that this is what sets us apart from our competitors, and it’s something that we’re really proud of. We understand that our customers rely on us to provide them with high-quality products, and by working with only the best suppliers, we can ensure that we always deliver on our promise.

0 notes

Text

Honda to join forces with Aston Martin from 2026

Honda to join forces with Aston Martin from 2026

By Balazs Szabo on 24 May 2023, 08:57

Ahead of the Monaco Grand Prix, Aston Martin has today announced that it will be entering into a works partnership with Honda from the 2026 F1 season onwards.

Honda returned to the sport in 2018 when it started supplying powertrains to Toro Rosso (now Scuderia Alpha Tauri) in 2018 before moving up the ladder to supply engines to Red Bull Racing in 2019.

The partnership culminated in a world championship in 2021 when Max Verstappen secured his first title in the Honda-powered Red Bull Racing car with the success repeated last year when the Milton Keynes-based squad clinched both the Drivers’ and Constructors’ Championships.

The announcement also means that Aston Martin’s long-time partnership with Mercedes is set to come to an end. The Anglo-German manufacturer has been the engine supplier of the Silverstone-based team since 2009 with the partnership set to continue until the end of the current power unit era. It means that Aston Martin will use the Mercedes-developed power units, plus the gearbox and rear suspension until the end of 2025.

“One of the key reasons for our decision to take up the new challenge in F1 is that the world’s pinnacle form of racing is striving to become a sustainable racing series, which is in line with the direction Honda is aiming toward carbon neutrality, and it will become a platform which will facilitate the development of our electrification technologies,” said Honda CEO Toshihiro Mibe.

“Honda is a company that has a history of growing by taking on challenges and winning world-class races. With the new 2026 regulations, the key for winning will be a compact, lightweight, and high-power electric motor with a high-performance battery capable of handling high and swift power output, as well as the energy management technology.

“We believe that the technologies and know-how gained from this new challenge can potentially be applied directly to our future mass production electric vehicles, such as an electric flagship sports model, and electrification technologies in various areas, including eVTOL which is currently under research and development.

“Honda and our new partner, the Aston Martin F1 Team, share the same sincere attitude and determination to win, so starting with the 2026 season, we will work together and strive for the Championship title as Aston Martin Aramco Honda.

Aston Martin owner Lawrence Stroll said: “We share a mutual drive, determination, and relentless ambition to succeed on track. Honda is a global titan and its success in motorsport is longstanding and incredibly impressive.”

Koji Watanabe, President of Honda Racing Corporation – the racing division of Honda which will run the project – added: “In the midst of major changes in our business and the motorsports environment leading toward the transition to a carbon neutral society, we have re-established HRC as an optimal platform to sustain and further evolve motorsport activities as a Honda strength. We will establish sustainable operational structures for our racing activities and continue to deliver more dreams and excitement for motorsports fans all around the world.”

Group CEO of Aston Martin Performance Technologies Martin Whitmarsh added: “The new 2026 F1 power unit regulations are a huge and important change, but one which we are confident we can navigate successfully together. Jointly with our strategic partner Aramco, we can look forward to open collaboration towards a common goal.

“Our future works partnership with Honda is one of the last parts of the jigsaw puzzle slotting into place for Aston Martin’s ambitious plans in Formula 1. Finally, I would like to pay tribute to our current power unit supplier who we will continue to partner with for the next few seasons.”

via F1Technical.net . Motorsport news https://www.f1technical.net/news/

2 notes

·

View notes

Text

Eco-Friendly Fleet Management: Top 15 Strategies for Sustainability

The trucking industry, a vital cog in global supply chains, is under increasing pressure to reduce its environmental impact. While the transition to electric vehicles and alternative fuels is gaining traction, numerous strategies can be implemented today to make fleets more sustainable.

This article delves into 15 practices adopted by eco-conscious fleets, showcasing their commitment to environmental responsibility.

Optimizing Vehicle Performance

Researching and Adopting Latest Technologies: Leading fleets stay at the forefront of technological advancements, continuously evaluating new products and solutions to enhance sustainability. This can include exploring electric vehicle options, advanced telematics systems, and fuel-efficient components like aerodynamic add-ons, tire management systems, and engine optimization technologies.

Purchasing Fuel-Efficient Trucks: Investing in modern, fuel-efficient trucks with low emissions is a cornerstone of green fleet operations. By maintaining a young fleet and selecting models with advanced features like hybrid powertrains or regenerative braking, companies can significantly reduce their environmental footprint.

Vehicle Specification Optimization: Tailoring truck specifications to specific operational needs is crucial for maximizing fuel efficiency. Factors such as engine size, transmission type, aerodynamics, and tire selection are carefully considered. For example, downsizing engines, selecting low-rolling-resistance tires, and optimizing axle ratios can yield substantial fuel savings.

Enhancing Aerodynamics: Reducing aerodynamic drag can yield substantial fuel savings. Green fleets often implement aerodynamic add-ons like cab extenders, side fairings, and trailer skirts. Additionally, using aerodynamically optimized trailer designs and gap reducers can further improve fuel efficiency.

Minimizing Idle Time: Unnecessary idling consumes fuel and increases emissions. Top fleets aiming for sustainbility employ various strategies, including auxiliary power units, battery-powered cab HVAC systems, solar panels, and driver training to minimize idle time. Implementing idle reduction policies and using telematics to monitor idle time can also be effective.