#Electromechanical Components

Explore tagged Tumblr posts

Text

youtube

#SMB Connectors#eteily#tech#technologies#RF connector#Coaxial Connectors#SMB Connector Series#SMB Plug & Jack#plug connector#Crimp SMB#Electromechanical Components#SMB Cable#SMB RF Coaxial Connector#high quality SMB Plug#RF components#SMB Hermetic Connector#SMC and CMS connectors#Youtube

0 notes

Text

Future Electronics to Host Future Tech Day in Hefei, China

Future Electronics, a global leader in electronics distribution, is excited to announce the upcoming "Future Tech Day" portion of the 2024 China Tech Day series—focusing on the automotive industry. The event will take place on Wednesday, September 25th in Hefei, with another session planned in Hangzhou later this year.

#Future Electronics#(SDCs)#Power#MCUs#FPGA#LCDs#Wireless#Lighting#electronic components#Capacitors#Film Capacitors#Analog#development tools#electromechanical

3 notes

·

View notes

Text

1 note

·

View note

Text

Future Electronics' full Advanced Engineering with sharing of engineering ideas

Future Electronics’ Advanced Engineering Group provides in-depth engineering services. Founded in 1968, Future Electronics is a global leader in the electronic components industry. Future Electronics' award-winning customer service, global supply chain programs and industry-leading engineering design services have made the company a strategic partner of choice.

#Future Electronics#(SDCs)#Power#MCUs#FPGA#LCDs#Wireless#Lighting#electronic components#Capacitors#Film Capacitors#Analog#development tools#electromechanical

1 note

·

View note

Text

Future Electronics, recognized their partnership with Infineon

Future Electronics and Infineon Technologies recently hosted a webinar, which taught attendees about the benefits and use cases of Infineon’s cutting-edge memory solutions.

#Future Electronics#(SDCs)#Power#MCUs#FPGA#LCDs#Wireless#Lighting#electronic components#Capacitors#Film Capacitors#Analog#development tools#electromechanical

1 note

·

View note

Text

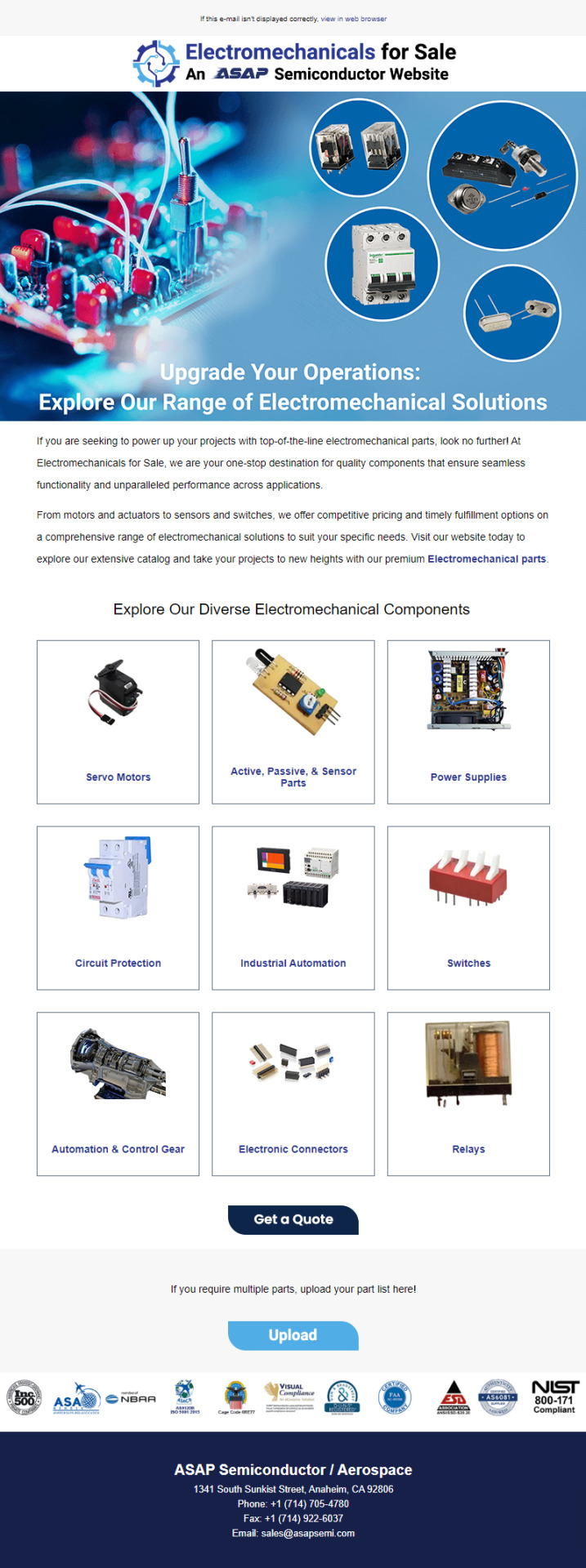

Quality You Can Trust: Elevate Your Projects with Our Electromechanical Parts!

Electromechanicals for Sale are premier supplier of electromechanical components and industrial automation spare parts. Explore our extensive catalog of electromechanical parts and components. As the premier supplier, we offer industrial automation spare parts and components for all your needs such as Servo Motors Active, Passive, & Sensor Parts, Power Supplies, Circuit Protection, Industrial Automation, Switches Automation, Control Gear, Electronic Connectors Relays and more. We supply electromechanical parts for leading manufacturers of Industrial automation.

Here at Electromechanicals for sale, quality is of the utmost importance. All parts found on our website trace back to leading automation spare parts suppliers and manufacturers that we trust, and countless listings undergo varying levels of testing, inspection, and document verification prior to shipment.

#Electromechanical Parts#Industrial Automation#Electronic components#Electronic industry#Industrial Lighting#Marine Electronics#Electronics Component Connectors#Electrical Switches & Relay#Circuit Board Accessories

1 note

·

View note

Text

Slot Evolution

Explore the evolution of slot machines from the 1960s electromechanical Money Honey to the advanced video slots of the 1970s and 1980s. Discover how technological advancements transformed gameplay and added excitement to casinos.

Slot machines have come a long way since their inception in the late 19th century. As the 20th century progressed, technological advancements brought about significant changes in the design, functionality, and complexity of these popular gambling devices. From the electromechanical innovations of the 1960s to the introduction of video slots in the 1970s and 1980s, each decade has seen remarkable…

View On WordPress

#1970s slots#1980s slots#20th century slots#Bally Technologies#bonus rounds#casino attractions#Casino Evolution#Casino Games#digital slot machines#electrical components#electromechanical slots#enhanced gameplay#Fortune Coin Company#gambling advancements#gambling devices#gambling entertainment#gambling technology#gaming innovations#interactive slot games#mechanical slots#modern slot machines#Money Honey#multiple paylines#reel-spinning mechanisms#slot machine advancements#slot machine design#slot machine development#slot machine evolution#slot machine evolution history#slot machine features

0 notes

Text

DC Fans DC Axial Fan, 30x30x6mm, 12VDC, 3.6CFM, 0.96W, 32.1dBA, 10500RPM, Hypro

#electromechanical circuit breakers#electromechanical circuit breaker#uk electronics components#electrical switch#electronic components online

0 notes

Text

Future Electronics Invites Employees to Annual Holiday Luncheon

This festive event wraps up Future Electronics’ Spirit of the Holidays initiative. Throughout December, the company will be hosting a series of fun moments to give back to employees and gather food, toys, and monetary donations for those less fortunate.

#Future Electronics#(SDCs)#Power#MCUs#FPGA#LCDs#Wireless#Lighting#electronic components#Capacitors#Film Capacitors#Analog#development tools#electromechanical

1 note

·

View note

Text

Future Electronics, a distributor of electronic components founded in 1968

Future Electronics, a leading global distributor of electronic components, recently received Diodes Incorporated’s Best Global Distributor Award for 2023.

#Future Electronics#Power#MCUs#FPGA#LCDs#Wireless#Lighting#electronic components#Capacitors#Film Capacitors#Analog#development tools#electromechanical

1 note

·

View note

Text

Understanding the Role of Busbars, Circuit Breakers, and Relays in Switchgear

In the world of electrical distribution and control systems, switchgear plays a pivotal role in managing, protecting, and isolating electrical circuits and equipment. Within a switchgear assembly, components like busbars, circuit breakers, and relays are essential for ensuring efficient operation and maximum safety. Understanding the role of each of these components can help professionals and businesses make better decisions when designing or upgrading their electrical systems.

What Is Switchgear?

Switchgear is a general term that encompasses a wide range of electrical disconnect switches, fuses, circuit breakers, and associated equipment used to control, protect, and isolate electrical equipment. These systems are critical for both high-voltage and low-voltage applications and are commonly found in industrial plants, commercial buildings, power plants, and substations.

1. Busbars: The Power Distribution Backbone

Busbars are metallic strips or bars — typically made of copper or aluminum — that conduct electricity within a switchgear or distribution board. Their main function is to distribute electrical power to multiple circuits from a single input source.

Key Functions:

· Efficient Power Distribution: Busbars act as a central hub for distributing power to various outgoing circuits.

· Compact Design: Helps in reducing the overall footprint of the switchgear.

· Heat Dissipation: Designed to handle high currents while minimizing heat build-up.

Applications:

· Power distribution panels

· Switchboards and MCCs (Motor Control Centers)

· Panelboards and switchgear cubicles

2. Circuit Breakers: Protection from Overcurrent

Circuit breakers are automatic electrical switches designed to protect electrical circuits from damage due to overcurrent or short circuits. Unlike fuses, circuit breakers can be reset manually or automatically after tripping.

Key Functions:

· Fault Interruption: Instantly disconnects the circuit during faults to prevent damage or fire.

· Manual Switching: Can be used to manually turn circuits on or off during maintenance.

· Safety Compliance: Ensures that systems meet international safety standards (IEC, ANSI, etc.)

Types of Circuit Breakers:

· MCB (Miniature Circuit Breaker): Used for low-power applications

· MCCB (Molded Case Circuit Breaker): Handles higher loads than MCBs

· ACB (Air Circuit Breaker): Used for high-current circuits in industrial settings

3. Relays: The Sensing and Control Brains

Relays are electromechanical or solid-state devices that detect faults and send signals to circuit breakers or other control devices to disconnect the circuit. They are the “brains” behind the automatic protection mechanism of the switchgear.

Key Functions:

· Fault Detection: Monitors voltage, current, and other parameters to detect anomalies.

· Triggering Action: Sends signals to trip the circuit breaker when necessary.

· Automation and Coordination: Works in coordination with other protection devices to ensure selective tripping.

Types of Relays:

Overcurrent Relays

Differential Relays

Distance Relays

Earth Fault Relays

Why These Components Matter

Together, busbars, circuit breakers, and relays form the core of any switchgear system. When properly selected and configured:

· Downtime is minimized

· Equipment lifespan is extended

· Operational safety is enhanced

· Energy efficiency is improved

In an era where electrical reliability is non-negotiable, understanding these components isn’t just for engineers — it’s essential knowledge for decision-makers in any industry reliant on power.

Conclusion

Whether you’re designing a new electrical panel or upgrading an old one, choosing high-quality busbars, circuit breakers, and relays is critical to the safety and efficiency of your entire system. At AL Taqwa Oman, we specialize in premium-grade switchgear accessories that meet global standards and deliver unmatched performance.

Need help finding the right accessories for your panel? Contact our experts today and power your systems with confidence.

#electrical#electrical equipment#electrical supplies#switchgear#oman#electricity#busbar#relay#circuit breaker

8 notes

·

View notes

Text

Low Voltage Relays Explained: Types, Functions, and Applications

In the complex world of electrical systems, relays play a crucial role in ensuring safety, efficiency, and automation. Among these, low voltage relays stand out as versatile components that manage and protect circuits operating below 1000 volts. Whether in industrial automation, residential power distribution, or commercial infrastructure, these devices act as the nerve center of electrical control and protection.

In this comprehensive guide, we will break down what low voltage relays are, explore their types, explain their functions, and highlight their diverse applications across industries.

What Are Low Voltage Relays?

A low voltage relay is an electrically operated switch that uses a small control voltage (typically below 1000V AC or DC) to switch larger electrical loads on and off. These relays act as intermediaries between control circuits and power circuits, providing isolation, control, and protection.

Unlike manual switches, relays automate the process of circuit management, responding to electrical signals, fault conditions, or system commands without human intervention.

Types of Low Voltage Relays

Low voltage relays come in several forms, each tailored to specific tasks within an electrical system. Here are the main types:

1. Electromechanical Relays (EMRs)

· Use a coil and a movable armature to open or close contacts.

· Provide physical isolation between input and output.

· Common in traditional control panels and basic automation.

2. Solid-State Relays (SSRs)

· Use semiconductors (like thyristors or triacs) instead of mechanical contacts.

· Offer silent operation, faster switching, and longer lifespan.

· Ideal for high-speed applications and environments requiring low maintenance.

3. Overload Relays

· Specifically designed to protect motors and equipment from sustained overcurrent.

· Available as thermal overload relays (using bimetallic strips) or electronic overload relays (using sensors and processors).

4. Time Delay Relays

Provide a deliberate time lag between the relay receiving a signal and switching.

Used in motor control circuits, lighting systems, and sequential operations.

5. Overcurrent and Short-Circuit Relays

· Detect and react to current exceeding preset thresholds.

· Essential for system protection against faults and overloads.

6. Voltage Monitoring Relays

· Monitor voltage levels and trip when voltages fall below or rise above safe limits.

· Protect sensitive devices from under voltage and overvoltage conditions.

Functions of Low Voltage Relays

Low voltage relays serve multiple vital functions in electrical systems:

1. Switching and Control

Relays control the opening and closing of power circuits in response to low voltage signals from controllers, timers, or sensors. This enables remote and automated control of large electrical loads.

2. Protection

Relays detect abnormal conditions like overloads, overcurrent, under voltage, and phase failures. When such conditions arise, they disconnect the affected circuit to prevent equipment damage or fire hazards.

3. Isolation

They electrically isolate control circuits (usually low voltage, low current) from power circuits (high voltage, high current), ensuring safety and reducing interference.

4. Signal Amplification

A small control signal (from a PLC, sensor, or microcontroller) can trigger a relay to switch much larger loads, effectively amplifying the control power.

5. Automation and Sequencing

In complex systems, relays help sequence operations by ensuring that processes occur in the correct order and at the right time intervals.

Applications of Low Voltage Relays

Low voltage relays are the backbone of automation and protection in various industries. Here are some key application areas:

Industrial Automation

· Control of motors, pumps, conveyor belts, and production lines.

· Use in programmable logic controllers (PLCs) and distributed control systems (DCS).

Power Distribution Systems

· Protect electrical panels from overload and short circuits.

· Monitor voltage and current levels in distribution boards.

Building Automation

· Lighting control systems.

· HVAC (heating, ventilation, and air conditioning) systems.

· Elevator and escalator controls.

Renewable Energy Systems

· Manage and protect solar inverters, battery banks, and wind turbines.

· Automatically disconnect faulty sections to prevent system-wide failures.

Data Centers and IT Infrastructure

· Ensure stable power supply to servers and networking equipment.

· Protect sensitive electronics from voltage fluctuations.

Transportation

· Railways, metros, and automotive applications for control and safety circuits.

Home Appliances

· Found in washing machines, microwave ovens, and HVAC units to automate functions and provide protection.

Advantages of Using Low Voltage Relays

· Enhanced Safety: Isolate control and power circuits, reducing electrical shock risks.

· Automation Ready: Easily integrated into automated systems for smarter operation.

· Cost-Effective Protection: Safeguard expensive equipment from damage due to electrical faults.

· Versatile: Available in many forms to suit different voltage levels, currents, and response times.

· Reduced Maintenance: Especially with solid-state relays, which have no moving parts.

Future Trends: Smart Relays and IoT Integration

As industries move toward smart grids and Industry 4.0, low voltage relays are also evolving:

· Digital relays offer programmable settings, self-testing, and event recording.

· IoT-enabled relays can send status updates and alerts to centralized monitoring systems.

· Energy-efficient designs reduce power consumption while providing reliable protection.

Conclusion

Low voltage relays are indispensable in modern electrical engineering, seamlessly combining protection, control, and automation. From safeguarding your home appliances to managing the power in a sprawling industrial plant, these devices ensure that electrical systems run smoothly and safely.

Understanding the different types, functions, and applications of low voltage relays empowers system designers, engineers, and even DIY enthusiasts to build safer and more efficient electrical setups.

As technology advances, the role of these small but mighty devices will only grow, driving the future of safe, smart, and automated power systems.

9 notes

·

View notes

Text

The Role of Relays and Timers in Industrial Automation Systems

In the world of industrial automation, efficiency, safety, and precision are crucial. Among the many components that contribute to a well-functioning automated system, relays and timers play a foundational role. These devices act as control elements that manage the flow of electricity, signal processes, and coordinate timing sequences — ensuring that operations run smoothly and safely.

In this article, we’ll explore how relays and timers work, their types, applications in automation systems, and how high-quality products — like those offered by Enza Electric — can enhance performance and reliability in industrial settings.

What Are Relays?

A relay is an electromechanical or electronic switch used to control a circuit by a separate low-power signal or multiple signals. In industrial automation, relays act as a bridge between the control system and the equipment being operated — allowing machines to be turned on or off automatically.

Types of Relays Commonly Used in Automation:

Electromechanical Relays (EMRs): Use physical moving parts; reliable and easy to maintain.

Solid-State Relays (SSRs): No moving parts; faster switching, longer lifespan, and better for high-speed applications.

Thermal Overload Relays: Protect motors and equipment from overheating.

Control Relays: Designed for controlling multiple contacts simultaneously in automation systems.

What Are Timers?

Timers are devices used to delay or repeat electrical signals at predetermined intervals. They help synchronize tasks, automate sequences, and provide controlled outputs over time — critical for complex industrial processes.

Common Timer Functions:

On-delay and off-delay timing

Interval timing

Cyclic or repeat cycle operation

Flashing and sequencing operations

Types of Timers:

Analog Timers: Manual dial settings, simple and cost-effective.

Digital Timers: Offer precise programming, displays, and flexible timing ranges.

Programmable Timers: Ideal for complex automation routines requiring multiple sequences.

Key Roles in Industrial Automation Systems

1. Process Control and Sequencing

Relays and timers enable automated machines to follow a specific sequence — turning motors, lights, or pumps on and off in a logical order. For example, a conveyor system can use a relay-timer combination to control material flow with millisecond precision.

2. Safety and Protection

Relays protect systems by interrupting circuits in case of faults. Combined with timers, they can ensure delay before activating emergency stop functions, preventing false triggers and increasing worker safety.

3. Load Management

In high-demand industrial environments, relays help manage load distribution by selectively energizing or de-energizing machinery. Timers assist in staggered starts, reducing power surges.

4. Energy Efficiency

By automating start/stop functions and managing operation durations, timers help reduce unnecessary energy use. Relays ensure only the necessary loads are powered, minimizing wastage.

5. System Monitoring and Feedback

In smart automation, relays provide feedback signals to the control system. Timers assist with diagnostics by creating intervals for testing or data collection.

Benefits of Using High-Quality Relays and Timers

Choosing the right components significantly impacts system performance and longevity. Enza Electric’s relays and timers are engineered with:

High durability for tough industrial environments

Precision timing for reliable operation

Easy installation and compact designs

Compliance with international safety and quality standards

By integrating Enza’s low-voltage solutions, businesses in the GCC, MENA, and Africa regions benefit from cost-effective, scalable automation that supports both current needs and future expansion.

Common Applications in Industrial Sectors

Manufacturing Plants: Control of motors, robotic arms, and production lines.

HVAC Systems: Timed control of fans, compressors, and dampers.

Water Treatment Facilities: Sequenced operation of pumps and valves.

Packaging Machinery: Relay and timer-based coordination of packing, sealing, and labeling.

Food and Beverage Industry: Process automation with hygiene-compliant controls.

Final Thoughts

Relays and timers are the silent operators behind the success of industrial automation systems. From process optimization to enhanced safety and energy management, these components are indispensable.

When sourced from a trusted manufacturer like Enza Electric, businesses are not only investing in reliable hardware but also in the longevity, scalability, and safety of their entire operation.

Ready to Power Your Automation?

Explore Enza Electric’s wide range of relays, timers, and other low-voltage switchgear solutions designed to meet the evolving demands of modern industries. Visit www.enzaelectric.com to learn more or request a quote today.

9 notes

·

View notes

Text

hardtoswallowpills.png the reason headphone jacks were removed from cellphones is not ‘force people to use bluetooth’— analog headphone jacks are an electromechanical weak point and big in terms of modern components

They killed the headphone jack to achieve a thinner body and drastically improve the water resistance. There is a reason the iphone started touting how waterproof their phones are at the same time they killed the jack

Oh and they absolutely want to sell you bluetooth headphones, so a win win win scenario for them

#i know way too much about manufacturing#i could vent more about how manufacturing actually works#because it helps explain a lot of the bullshit surrounding commodities

8 notes

·

View notes

Text

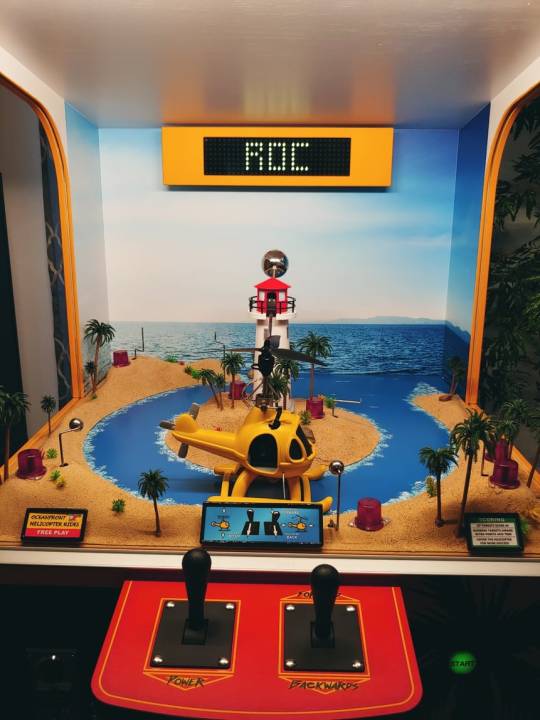

There's a company making remakes of old Electromechanical Arcade games with modern electronic components and while it's too pricey for me right now at ~$4,500 I can appreciate them and I think they look well made.. I especially like the cabinet stylings.. 💜🕹️😁👍🏻

#arcade#electromechanical#vintage gaming#retro style#retro gaming#retro arcade#arcade aesthetic#retro#aesthetic

3 notes

·

View notes