#EngineModeling

Explore tagged Tumblr posts

Text

Role of embedded systems in VCU design

December 22, 2023

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

INTRODUCTION

Modern automobiles’ Vehicle Control Units (VCUs) are designed and function largely thanks to embedded technologies. The vehicle control unit (VCU) is an essential part that controls the engine, transmission, brakes, and other subsystems of a car. Embedded systems make the following contributions to VCU design:

1. Integration of Sensors:

VCUs’ embedded systems are in charge of combining data from numerous sensors located throughout the car. This comprises data from accelerometers, gyroscopes, wheel speed sensors, engine sensors, and other sensors that supply the VCU with the necessary information to make judgments.

2. Data Processing and Control:

The VCU’s embedded processors analyze incoming sensor data to make judgments regarding the vehicle’s functioning in real-time. To maintain maximum performance and safety, this entails regulating engine settings, controlling transmission shifts, and monitoring brake systems.

3. Communication Protocols:

VCUs frequently have to interface with other electronic control units (ECUs) in the car, like the ABS, Transmission Control Unit (TCU), and Engine Control Unit (ECU). The implementation of communication protocols is handled by embedded systems, guaranteeing smooth data transfer between various subsystems.

4. Identification and Repair of Faults:

To implement diagnostic functions within the VCU, embedded systems are essential. In addition to detecting defects or malfunctions, they monitor the condition of numerous car systems and components and produce diagnostic trouble codes (DTCs) to assist personnel in locating and resolving problems during maintenance.

5. Power Management:

Within the VCU, embedded systems are involved in controlling the power distribution. To maximize energy efficiency, they control power usage and make sure that various components receive the proper power supply.

6. Functional Safety:

Safety in automobile systems is of utmost importance. VCU embedded systems are made to adhere to functional safety requirements like ISO 26262. They put safety measures and redundancies in place to guarantee that crucial operations carry on dependably even in the event of errors or malfunctions.

7. Software Updates and Upgrades:

Over-the-air (OTA) updates are made possible by embedded systems, which let manufacturers update the VCU’s software remotely to improve performance, add new features, or fix security flaws without the need to physically visit a service center.

8. ADAS (Advanced Driver Assistance Systems) Integration:

Benefits of embedded systems in VCU design

The integration of technologies into Vehicle Control Units (VCUs) has several advantages that enhance the overall effectiveness, security, and functionality of contemporary automobiles. Here are a few main benefits:

1. Real-Time Processing:

Fast and real-time processing capabilities of embedded systems enable VCUs to make snap judgments based on sensor data. For vital operations like stability control, braking, and engine control, this is essential.

2. Optimized Performance:

Engine performance, gearbox shifts, and brake systems are just a few of the vehicle aspects that can be optimized with the usage of embedded systems. This results in enhanced response, fuel efficiency, and general vehicle performance.

3. Integration of Complex Functions:

Advanced driver assistance systems (ADAS) and engine control are only two of the many tasks that VCUs frequently oversee. The integration of these intricate tasks is made easier by embedded systems, which guarantee smooth communication between the many components in the car.

4. Reduced Size and Weight:

The general decrease in the size and weight of VCUs is facilitated by the lightweight and compact nature of embedded systems. This is especially crucial for the automotive sector, where weight and space constraints are essential for both fuel economy and vehicle design.

5. Energy Efficiency:

Power management within the VCU design is made possible by embedded systems, which guarantee that every component gets the appropriate power while consuming the least amount of energy possible. As a result, the car’s overall energy efficiency is increased.

6. Stability and Reliability:

7. Diagnostic Capabilities:

Advanced diagnostic capabilities are offered by the embedded systems found in VCUs. They provide diagnostic trouble codes (DTCs), which help in the prompt detection and fixing of problems during maintenance, and they continuously check the condition of the car’s parts.

8. Adaptability and Flexibility:

Manufacturers may add new features, enhance performance, and fix security flaws in embedded systems by using software updates and upgrades, all without having to physically alter the VCU design.

9. Cost-Effectiveness:

Embedding technologies in VCUs can help reduce expenses throughout the vehicle’s lifecycle, even though there may be early development expenditures. Long-term cost savings may result from the capacity to remotely update software, quickly identify problems, and enhance performance without requiring hardware modifications.

10. Compliance with Standards:

Industry norms and laws, including functional safety requirements (such as ISO 26262), can be met by embedded systems in VCUs. This guarantees that automobiles fulfill the safety and performance standards set forth by regulatory agencies.

Drawbacks of embedded systems in VCU design

Although embedded systems are essential to the functioning and design of vehicle control units (VCUs), using them has some disadvantages. To overcome obstacles and improve the overall performance and dependability of automotive systems, it is critical to take these limits into account. Among the disadvantages are:

1. Software Complexity:

Embedded systems in VCUs can execute extremely complicated applications. Complex software can be difficult to manage and debug, and mistakes or flaws in the software can have serious effects on a vehicle’s performance and safety.

2. Security Issues:

The likelihood of cybersecurity risks rises as cars get more interconnected. Embedded systems are vulnerable to hacking and unauthorized access, endangering the privacy and safety of car users. Strong cybersecurity defenses are essential.

3. Limited Upgradability:

Although some embedded systems support software upgrades, there may be hardware constraints preventing the addition of new technologies. Hardware component upgrades can be difficult and expensive, and they may result in obsolescence problems.

4. Rigid Design:

Particular functionality is frequently considered when designing embedded systems. Without making considerable changes to the hardware or software architecture, it could be difficult to adjust to new specifications or technological advancements.

5. Cost of Development and Maintenance:

It can be costly to develop and maintain embedded systems for VCU designs. Higher total vehicle expenses may result from the initial development expense as well as the requirement for continuing maintenance and updates.

6. Vendor Dependency:

When purchasing embedded system components, automakers may have to rely on particular vendors or suppliers. This reliance may reduce adaptability and heighten susceptibility to disturbances in the supply chain or modifications in vendor associations.

7. Limited Processing Capacity:

Embedded systems’ processing capacity may become a limiting issue as vehicle functionalities get more sophisticated. High computing demands could place a burden on embedded processors, particularly when it comes to complicated AI algorithms and autonomous driving.

8. Integration Challenges:

It can be difficult to integrate embedded systems with other electronic components found in vehicles. Careful management of compatibility problems and communication protocols is necessary to guarantee smooth operation and avoid system conflicts.

9. Environmental Challenges:

Extreme temperatures and vibrations are examples of harsh environmental conditions that can affect an embedded system’s dependability. For automotive applications, it is essential to make sure these systems are resilient to these kinds of situations.

10. Long Development Cycles:

Because of the rigorous testing and certification procedures, embedded system development cycles for automotive applications might be lengthy. The newest technology may not be implemented as soon as planned as a result of this.

Conclusion:

In conclusion, the role of embedded systems in Vehicle Control Unit (VCU design) design is paramount, contributing significantly to the efficiency, safety, and overall performance of modern vehicles. Embedded systems serve as the technological backbone that enables the integration, processing, and control of diverse functions within the VCU design. From the real-time processing of sensor data to seamless communication between different subsystems, embedded systems play a pivotal role in shaping the behavior of the vehicle.

The benefits of embedded systems in VCU design are evident in the optimization of performance, energy efficiency, and adaptability. These systems allow for the integration of complex functions, ensuring that vehicles operate with precision and responsiveness. The ability to implement diagnostic features enhances reliability, while over-the-air updates and upgrades contribute to long-term cost-effectiveness and the incorporation of new technologies.

However, it’s essential to acknowledge certain drawbacks associated with embedded systems, such as software complexity, security concerns, and potential limitations in upgradability. Addressing these challenges is crucial for ensuring the continued advancement and resilience of embedded systems in VCU design.

As technology evolves, ongoing research and development efforts are focused on mitigating drawbacks, improving cybersecurity measures, enhancing processing power, and increasing adaptability to meet the evolving demands of the automotive industry. In essence, embedded systems in VCU design represent a dynamic and evolving field that continues to shape the future of intelligent and connected vehicles, balancing innovation with the need for robust safety and reliability standards.

Read next…..

0 notes

Text

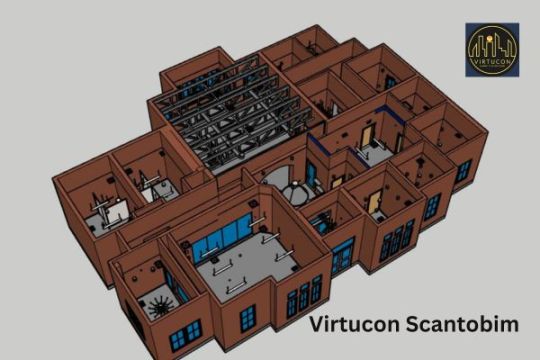

Virtucon Scantobim

Introduction Virtucon Engineering LLC operates under the trade name Virtucon Scan to BIM, offering specialized services in the field. offers innovative, unique, and smart design, engineering, and technology solutions. We are a BIM, and CAD services provider with expertise in scan to BIM, point cloud to Revit, and scan to 2d As-built drawings. Servicing clients across the AEC industry & helping to improve their efficiency & profitability of the business.

We always focus on customer satisfaction, deadlines, accuracy, and a clear vision for building long-term relationships to ensure that our customers all over the world are satisfied. Our clients are from the USA, Canada, UK, Europe and Asian countries.

We believe in

Unmatched quality and price.

Accurate model with fast turnaround time- Our Expert team converts point cloud into a 3d model urgent basis.

Providing complete CAD & BIM solutions to the AEC industry.

The easiest way of communication.

Highly qualified and experienced architects, engineers, and technicians to complete any complex project.

1 note

·

View note

Text

As of my last knowledge update in January 2022, I don't have access to real-time data or projections for specific markets, including the Vehicle Control Unit (VCU) market, beyond that date. Market conditions and growth rates are subject to change, and the statement you provided appears to be a forward-looking prediction.

To obtain the most accurate and up-to-date information regarding the Vehicle Control Unit market and its projected growth rates by 2030, I recommend checking recent industry reports, market analyses, and forecasts from reputable sources. These sources may include market research firms, automotive industry publications, and relevant government or industry association reports.

When researching market trends and growth projections, consider consulting reports and analyses from sources such as:

Market Research Firms:

Gartner

Frost & Sullivan

MarketsandMarkets

Grand View Research

Automotive Industry Associations:

Society of Automotive Engineers (SAE)

International Organization of Motor Vehicle Manufacturers (OICA)

Automotive Research Association of India (ARAI)

European Automobile Manufacturers' Association (ACEA)

Reputable Business News Outlets:

Bloomberg

Reuters

The Wall Street Journal

Government Reports and Publications:

Depending on your region, government agencies related to transportation and commerce may provide relevant reports and data.

Always verify the credibility of the sources you consult and ensure that the information is current and applicable to your specific needs. Market conditions and projections can be influenced by various factors, including technological advancements, regulatory changes, and shifts in consumer preferences.

Vehicle Control Unit Market to Witness Highest CAGR Growth By 2030

The Global Vehicle Control Unit Market Size Report | Industry & Forecast Forecast Year published by Insight Partners presents a complete analysis of the worldwide Vehicle Control Unit market and the impact of COVID-19 on the market. The study is enriched by business-oriented factors that influence growth prospects, challenges companies might face, and trends that businesses must have to escalate…

View On WordPress

#Vehicle Control Unit#VCU#AutomotiveIndustry#EngineModeling#Dorleco#Engineers#VehicleControlUnit#DataValidation

1 note

·

View note

Text

Cosmo

The path we pursue is always new. The Cosmo is a smooth-running car with a sophisticated styling and a high-performance engine and mechanism. Adults choose the Cosmo because of their desire to cherish their own thoughts.

4-door hardtop GENTEEL-X LIMITED VERSION (automatic 4-speed)

●Car Name/Model: Mazda E-HBES

●EngineModel: FE 4-cylinder OHC/1998 cc

●Maximum output (net) = 97ps/5000rpm

●Maximum torque = 15.8kg-m/3500rpm

●Fuel supply system = EGI

10 mode Fuel economy: 9.8km/ℓ (Ministry of Transport approved value)

Length x width x height = 4665 x 1690 x 1360 (mm)

3 notes

·

View notes

Video

instagram

Stirling engine model. - - - #stirlingengine #stirling #engineidea #engine #modelengine #enginemodel #enginestyle #electronicsidea #electronicsgeek #electronicsengineering (at Busan, South Korea) https://www.instagram.com/p/CDlaJ7aDVuX/?igshid=1mltla75k57z

#stirlingengine#stirling#engineidea#engine#modelengine#enginemodel#enginestyle#electronicsidea#electronicsgeek#electronicsengineering

1 note

·

View note

Text

Watch "Adjustable Speed Stirling Engine Model - EngineDIY" on YouTube

0 notes

Photo

Supply 6261-11-3200 095000-6140 Fuel Injector. Enginemodel: Komatsu SAA6D140E-5 Engine. Application: PC800-8 PC850-8 https://www.instagram.com/p/CPCy9NprRFZ/?utm_medium=tumblr

0 notes

Video

Very very nice engine. 🆒🆒🆒- repost @electronicsbuddy - #electronicsbuddy #electronicsidea #electronicsengineering #electronicsprojects #electronicsdiy #electronicslovers #electronicsproject #electronicsengineer #diyelectronics #diyprojects #diy #engineidea #enginework #engine #enginemodel #engineering #chemical https://www.instagram.com/p/B_z48gClOkL/?igshid=piktpc347c91

#electronicsbuddy#electronicsidea#electronicsengineering#electronicsprojects#electronicsdiy#electronicslovers#electronicsproject#electronicsengineer#diyelectronics#diyprojects#diy#engineidea#enginework#engine#enginemodel#engineering#chemical

0 notes

Photo

Stirling Engine Car Model Stirling Motor Model Kit #smallengines #tinyengine #enginemodel #stirlingmodel #stirling #diykits #sciencekits #trialnerror #funhobbies #hobbylife #modellife https://buff.ly/2ypBmlh

#trialnerror#tinyengine#hobbylife#stirlingmodel#modellife#enginemodel#diykits#smallengines#sciencekits#funhobbies#stirling

0 notes

Text

What is the role of a Vehicle control unit in managing fuel consumption in a vehicle?

The Vehicle Control Unit (VCU) plays a pivotal role in managing fuel consumption in a vehicle by controlling various aspects of the combustion process and optimizing the engine's efficiency. Here are the key functions of the VCU related to fuel consumption management:

Air-Fuel Ratio Control:

The VCU continuously monitors the air-fuel mixture entering the engine cylinders. By adjusting the injection duration and timing of fuel injectors, the VCU ensures that the engine receives the optimal air-fuel ratio for combustion. Maintaining the correct ratio is crucial for maximizing fuel efficiency.

Injection Timing Control:

The VCU determines the precise moment when fuel injectors should release fuel into the combustion chamber. By adjusting the injection timing, the VCU optimizes the combustion process, promoting efficient fuel utilization and power generation.

Idle Speed Control:

The VCU manages the engine's idle speed, ensuring it remains stable and efficient during periods of inactivity. Proper idle speed control helps minimize unnecessary fuel consumption when the vehicle is stationary.

Ignition Timing Control:

The VCU controls the timing of the spark that ignites the air-fuel mixture in the engine cylinders. Optimizing ignition timing enhances combustion efficiency, power output, and fuel economy.

Variable Valve Timing (VVT) Control:

In engines equipped with variable valve timing systems, the VCU adjusts the timing of the intake and exhaust valves. This allows for better control over airflow, optimizing combustion and improving fuel efficiency across different driving conditions.

Throttle Control:

The VCU manages the opening and closing of the throttle valve to regulate the amount of air entering the engine. This control is essential for maintaining the desired air-fuel ratio under various operating conditions, contributing to fuel efficiency.

Feedback Systems and Sensors:

The VCU continuously receives data from various sensors, such as oxygen sensors and mass airflow sensors, providing real-time information about the combustion process and exhaust emissions. This feedback allows the VCU to make immediate adjustments to optimize fuel delivery and combustion efficiency.

Economy and Power Modes:

Some VCUs are programmed with multiple operating modes, including economy and power modes. In economy mode, the VCU prioritizes fuel efficiency, adjusting parameters to conserve fuel during steady-state cruising. In power mode, the focus may shift towards performance.

Adaptive Learning:

Modern VCUs often incorporate adaptive learning algorithms. These algorithms analyze driving patterns and adjust fuel delivery and ignition timing over time to optimize efficiency based on the driver's behavior and environmental conditions.

By actively managing these parameters, the VCU contributes significantly to fuel efficiency, helping vehicles meet emission standards and providing drivers with optimal performance while minimizing fuel consumption. Advances in engine control technology continue to enhance the precision and adaptability of these systems for improved overall efficiency.

0 notes

Text

Technology Advancement in the Automotive Industry

December 20, 2023

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

A vehicle build facility is where the Automotive Industry, such as cars, trucks, or motorbikes, are assembled. It is also referred to as an automotive assembly factory or manufacturing plant. This procedure entails assembling different components, including the engine, chassis, body, and interior, to construct a completely functional car. In the automotive business, vehicle build facilities are essential to mass production.

Key elements and phases commonly seen in the Automotive Industry are as follows:

Body Shop: This is the location where the chassis or frame of the car is put together. The many parts that make up the vehicle’s construction are frequently joined together by automated technology and welding robots.

Paint Shop: The body is taken to the paint shop once it has been constructed. This is where the car goes through a lot of procedures like cleaning, priming, painting, and sealing. For precise painting, sophisticated robotic technologies are frequently employed.

Assembly Line: The vehicle’s components are assembled sequentially on the assembly line, which is an important step in the process. Installing individual pieces, including the engine, transmission, exhaust system, interior components, and more, is the responsibility of each station on the assembly line.

Quality Control: To guarantee that every vehicle satisfies the necessary criteria, quality control inspections are conducted at various stages of the assembly process. Both automatic systems and human inspection may be used in this.

Testing: To guarantee the functionality and safety of the vehicle, some facilities carry out a variety of tests. Functionality tests, road tests, and quality control inspections could be part of this.

Packaging and Shipping: The completed cars are ready for shipping once they pass all inspections and testing. This includes packaging, placing into transport cars, and delivering to retail locations or warehouses.

Benefits of Technology Advancement in the Automotive Industry

The Automotive Industry, the economy, and society at large can all profit from a vehicle build facility, also known as an automotive assembly plant. Here are a few main benefits:

Economic Impact: By generating jobs and promoting economic growth, vehicle manufacturing plants have a major positive economic impact. The automotive sector employs a large number of people, not just in assembly plants but also in other sectors like logistics, suppliers, and support services.

Mass Production Efficiency: Assembly plants facilitate mass production, which makes it possible to manufacture a huge number of vehicles efficiently and economically. Because of the economies of scale that follow, cars are now more reasonably priced for consumers.

Standardization and Quality Control: Production plants for automobiles use strict quality control procedures along with standardized procedures. This guarantees uniformity in the production process and contributes to upholding high standards for the automobiles that are manufactured.

Innovation and Technology Integration: State-of-the-art innovations and technology are frequently implemented in automotive assembly facilities. This involves the application of automation, robotics, and sophisticated production methods that improve productivity, accuracy, and the capacity to add new features and materials to automobiles.

Supply Chain Integration: Component and material providers are part of a larger supply chain that includes auto assembly factories. Through improved coordination and optimization of the whole production process, this integration shortens lead times and guarantees a consistent supply of parts.

Local and International Trade: The ability to produce automobiles in a certain area promotes both local and international trade. Completed automobiles can be exported to other nations, fostering economic interdependence and improving international trade balances.

Technological Developments: The Automotive Industry’s vehicle manufacturing facilities frequently spearhead technological developments. New technology, safety features, and environmental benefits in automobiles are the result of research and development activities at these institutions.

Environmental Aspects: A few contemporary auto manufacturing plants use eco-friendly and sustainable methods. The automotive sector may become more environmentally friendly by using energy-efficient operations, reducing waste, and using recycled materials.

Consumer Access to Diverse Models: A large selection of car models with varying features, styles, and price points are made available to consumers through mass production in auto manufacturing plants. This range meets the varying needs and tastes of customers.

Regional Development: By drawing in associated sectors, establishing a network of suppliers, and encouraging the expansion of auxiliary services like retail, maintenance, and transportation, the construction of vehicle build facilities can promote regional development.

Drawbacks of Technology Advancement in the Automotive Industry

Although car manufacturing plants have many advantages, they are not without problems and disadvantages. The following are a few possible downsides:

Environmental influence: The production of vehicles can have a big influence on the environment through energy use, emissions, and trash production. The entire environmental impact of vehicle manufacturing is still an issue, despite efforts to adopt sustainable procedures.

Resource Intensity: A significant amount of energy, water, and raw materials are needed in the manufacturing of automobiles. These resources’ extraction and processing have the potential to deplete natural resources and worsen the environment.

Supply Chain Vulnerabilities: The manufacturing of automobiles may be disrupted due to global supply chain interdependence. Production schedules may be impacted by occurrences like supply chain problems, natural disasters, or geopolitical unrest that cause delays and shortages of essential components.

High Initial Capital Expense: Setting up and running a car manufacturing plant costs a large sum of money initially. Land, infrastructure, technology, and labor development can come at a high cost.

Labor Issues: Strikes, disagreements, and worker unhappiness can pose a threat to labor-intensive businesses such as car manufacturing. Production schedules may be thrown off, and overall productivity may suffer.

Technological Obsolescence: Some production technologies may become outdated due to the quick speed at which technology is developing in the Automotive Industry. To stay competitive and adopt the newest advancements, research and development must be continuously funded.

Market Volatility: The state of the economy, consumer inclinations, and legislative shifts can all have an impact on the Automotive Industry sector. The production volume and profitability of automobile manufacturing facilities can be impacted by changes in the demand for certain car models or economic downturns.

Energy Consumption: The production of automobiles is still very energy-intensive, although efforts to adopt more energy-efficient procedures. The Automotive Industry’s total carbon footprint is influenced by its reliance on non-renewable energy sources.

Waste Generation: Materials, chemicals, and by-products are just a few of the wastes that are produced during the manufacturing process. To reduce the influence on the environment, proper waste management and disposal are essential. However, there may be obstacles in the way of implementing efficient waste reduction and recycling strategies.

Land Use and Urbanization: Large land parcels are frequently needed for vehicle construction facilities, which might result in urbanization and the possible displacement of natural habitats. This may have effects on the biodiversity and ecosystems in the area.

Conclusion:

In conclusion, vehicle build facilities play a pivotal role in the automotive industry, contributing significantly to economic growth, technological advancement, and global trade. The mass production capabilities of these facilities make automobiles more accessible to consumers, fostering diversity in vehicle models and features. Despite these advantages, challenges and drawbacks exist, ranging from environmental concerns and resource intensity to labor issues and market fluctuations.

To address these challenges, the automotive industry is increasingly focusing on sustainable practices, technological innovation, and supply chain resilience. Efforts to reduce environmental impact, improve energy efficiency, and adopt eco-friendly manufacturing processes are underway. Additionally, advancements in automation and robotics contribute to increased precision, efficiency, and safety on the assembly line.

As the Automotive Industry evolves, continued attention to environmental sustainability, responsible resource management, and the well-being of the workforce will be essential. Balancing economic interests with environmental and social considerations is key to the long-term success and resilience of vehicle-building facilities in an ever-changing global landscape. The ongoing commitment to research and development, coupled with regulatory frameworks that encourage responsible practices, will shape the future of vehicle manufacturing, ensuring a harmonious coexistence with the environment and society at large.

#TechnologyAdvancement#AutomotiveIndustry#EngineModeling#Dorleco#Engineers#Powertrain#DataValidation#vcu#Vehiclecontrolunit

0 notes

Text

V-Model development techniques to design

December 15, 2023

by dorleco

with no comment

Control Systems

Edit

Introduction

The V-Model sometimes referred to as the Verification and Validation Model or the V-Cycle, is a software development technique that places a strong emphasis on testing at every stage of the process. It is a variation of the Waterfall approach that is frequently applied in the development of critical systems when exhaustive testing is essential. The two primary stages of the V-Model are carried out in the following order:

1. Verification (the V’s left side):

a.Requirements analysis: –

– Recognize and record the needs of the client.

– Determine software and system needs based on input from customers.

b. System Design: Using the requirements as a guide, create a high-level design specification.

– Describe the general architecture of the system.

c. Architecture: – Construct a thorough system architecture.

– Specify how system components interface with one another.

d. Module Design: – Divide the system into more manageable, smaller components.

– Establish thorough requirements for every module.

e. Implementation (Coding): Using the comprehensive module requirements as a guide, write code.

f. Unit Testing:

– Verify the accuracy of each module.

– Find and address errors at the module level.

2. Validation (the V’s right side):

a. Integration testing: –

Integrate modules and test them collectively to make sure they function as a unit.

– Find and correct errors about how the modules interact with one another.

b. System Testing: –

Check that the system satisfies the criteria by testing the system as a whole.

– Find and address system-level flaws.

c. UAT, or user acceptance testing:

– Confirm with end users that the solution satisfies their needs by validating it.

d. Deployment:

Upon successful testing, move the system into production.

Verify that all required paperwork has been completed.

e. Maintenance and Support: –

Provide continuous assistance, resolve any problems that occur in the live environment, and apply any updates that are required.

Key principles and techniques associated with the V-Model:

The V-Model includes several essential ideas and methods that direct its use in software development. The following are the key ideas and methods related to the V-Model:

Early Testing:

Principle: Early in the development life cycle, testing activities are started.

Technique: To ensure that faults are found and fixed as soon as feasible, test preparation and execution begin early on, using unit testing.

Phased and Incremental Approach:

Principle: There are different phases for development and testing.

Technique: Testing activities are scheduled by the stages that the development process is separated into. Partially functional systems can be delivered for testing and validation through incremental development.

Traceability:

Principle: Requirements and related tests should have a distinct, traceable relationship.

Feedback Loops:

Principle: Between the stages of development and testing, ongoing feedback is crucial.

Methodology: During testing, flaws are reported back to the development team so they can be fixed. This loop of iterative feedback aids in raising the software’s quality.

Documentation:

Idea: Thorough documentation is essential for all phases of testing and development.

The technique involves creating and keeping up-to-date detailed documentation for the requirements, design, test cases, and test plans. Throughout the system’s life cycle, this documentation acts as a reference and aids in understanding.

Parallel Development and Testing:

The concept of concurrent development and testing states that both processes take place simultaneously.

Approach: As the development stage advances, the corresponding phase’s testing is also in progress. By taking a parallel method, problems can be found and fixed sooner, which lowers the possibility of significant flaws developing later.

Clearly defined roles and duties:

The development and testing teams’ roles and duties should be well-defined.

Method: Give teams or people distinct tasks for every stage of the V-Model. This guarantees responsibility and makes it apparent who is in charge of what.

User Participation:

Principle: Acceptance and validation depend on user participation.

Method: To make sure the system satisfies users’ needs and expectations, involve users in the User Acceptance Testing (UAT) stage.

Configuration Management:

Principle: Oversee and regulate modifications to the software and related materials.

Technique: Use configuration management procedures to maintain version control, track modifications, and make sure that the development and testing processes are consistent.

Comprehensive Testing:

Principle: Every facet of the system should be tested.

Technique: To verify the accuracy and dependability of the program, plan and carry out a variety of tests, such as unit, integration, system, and user acceptability testing.

Drawbacks of Key principles and techniques associated with the V-Model

The V-Model has some disadvantages even if it provides an organized method for software development with integrated testing. The following are some restrictions and disadvantages related to the main ideas and methods of the V-Model:

Rigidity and Inflexibility:

Cons: The V-Model may be inflexible and less flexible when it comes to requirements modifications. It makes the difficult assumption that needs are well-defined and constant, which makes it difficult to adapt to changes as the project is being developed.

Late Visibility of the System:

Cons: The system’s complete visibility isn’t apparent until much later in the development life cycle. This might result in misinterpretations of user needs or delayed discovery of design faults, which increases the difficulty and expense of problem-solving.

Limited User Involvement:

The User Acceptance Testing (UAT) phase is usually the only time that users are involved. This may lead to the identification of important problems or misconceptions at a later stage of the process when it will cost more to make adjustments.

Reliance on Forward Planning:

Limitation: A good grasp of requirements and early preparation are critical to the V-Model’s success. Delays and major obstacles may arise if the needs alter or the original planning is faulty.

Sequential Nature:

Cons: The V-Model has a sequential path whereby the accomplishment of one phase is contingent upon the conclusion of the preceding phase. This may result in a lengthier development period overall, particularly if modifications are needed after the project has begun.

Limited Flexibility for Iterative Development:

Cons: The V-Model is not a good fit for incremental or iterative development methodologies. It might not work well with contemporary agile approaches, which place a strong emphasis on adaptability and quick response to changing needs.

Overemphasis on Testing:

Assumption of Well-Defined Requirements:

Cons: The V-Model assumes that requirements are clear-cut and constant from the start. In actuality, needs frequently change, and modifications might be required as the project is being developed.

Minimal Client Engagement:

Cons: Communication with clients or stakeholders is frequently restricted to the requirements phase and the user acceptance testing phase. This could lead to a deficiency in continuous feedback and communication during the development process.

Having Trouble Managing Complicated Projects:

Drawback: When working on large, complex projects with requirements that are not fully understood up front, the V-Model may encounter difficulties. In certain situations, a more adaptable and iterative strategy can be more suitable.

Conclusion:

To sum up, the fundamental ideas and methods behind the V-Model offer an organized and methodical approach to software development that prioritizes early testing and traceability. But it’s important to take into account the V-Model’s advantages as well as disadvantages:

It’s important to take the project’s needs stability, the organization’s general development strategy, and the nature of the project into account while selecting the V-Model. The V-Model can be useful in situations where a systematic, methodical, and well-documented development process is necessary and if needs changes are either small or well managed, albeit it may not be appropriate for every project. However, alternative approaches like Agile can be better suitable for projects that need greater adaptation and flexibility.

0 notes

Text

Powertrain Component Modelling and Sizing

December 1, 2023

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

One of the most important aspects of designing a vehicle’s Powertrain Component system is modeling and sizing its components. The performance, efficiency, and general functioning of a vehicle are largely dependent on its powertrain, which normally consists of the engine, transmission, and other related parts. This is a summary of the procedure:

1. Define Vehicle Requirements:

Determine the kind of vehicle (e.g., a truck, an electric car, or a passenger car) and its intended purpose.

Establish the necessary performance parameters, including top speed, acceleration, and towing capacity.

Take into account legal restrictions, pollution guidelines, and fuel economy objectives.

2. Powertrain Architecture:

Decide on the kind of Powertrain Component architecture, such as fuel cell, hybrid, electric, or internal combustion engine.

Describe how the various parts of the powertrain interact with one another and the flow of energy through the system.

3. Component Modeling:

Model the engine’s performance attributes, such as torque, power, and fuel consumption, using simulation tools.

Think about things like heat management, pollution, and engine economy.

4. Transmission Modeling:

To optimize gear ratios for both performance and fuel efficiency, model the transmission system.

Take into account variables including driveability, shift times, and gearbox efficiency.

Modeling of electric motors and batteries (for hybrid and electric cars):

Model the torque-speed characteristics of an electric motor.

Model the battery system taking output power, voltage, and capacity into account.

5. Control System Modeling:

Control power distribution, energy flow, and overall system performance by putting control algorithms into practice.

Think about things like torque vectoring, energy regeneration, and vehicle stability control.

6. Optimization and Sizing:

Component Dimensioning

Based on the needs of the vehicle, determine the proper dimensions and specifications for each powertrain component.

Optimize variables including battery capacity, electric motor power, and engine displacement.

7. Compatibility & Integration:

Make sure every part of the powertrain functions as a unit.

Think of things like packing limitations, weight distribution, and heat control.

8. Performance Validation:

Simulation:

To verify the Powertrain Component system’s overall performance under varied operating situations, use simulation tools.

Based on the outcomes of the simulation, iterate and improve the design.

Prototype Testing:

Construct working prototypes to verify the simulation results in real-world settings.

Adjust the powertrain’s parts in light of test results.

9. Cost Analysis:

Take into account the financial effects of the selected powertrain components.

Cost issues should be balanced with performance and efficiency.

10 . Iterative Process:

The development of powertrains frequently involves iterations. Adjust the design in light of comments, simulation results, and testing.

11. Compliance and Documentation:

Keep records of the testing outcomes, design decisions, and specifications.

Verify adherence to pertinent laws and guidelines.

Benefits of Powertrain Component Modelling and Sizing

There are many advantages to Powertrain Component modeling and sizing powertrain when developing a vehicle. Here are a few main benefits:

1. Optimizing Performance:

Engineers can simulate and evaluate the operation of individual Powertrain Component parts as well as the system as a whole thanks to modeling.

By matching components appropriately, sizing guarantees the best possible performance in terms of power output, efficiency, and general functionality.

2. Efficiency Improvement:

Engineers are able to find ways to increase fuel economy, decrease energy losses, and improve efficiency by precisely simulating the components of the powertrain.

Accurate component sizing helps prevent over- or undersizing, maximizing the Powertrain Component for the vehicle’s unique needs.

3. Cost Reduction:

Engineers can determine the most economical configuration of Powertrain Component parts through simulation and sizing.

Reducing over-specification can result in material, manufacturing, and total vehicle production cost savings.

4. Emissions Reduction:

Precise modeling enables combustion process optimization, which lowers emissions from internal combustion engines.

5. Predictive analysis:

Without the use of actual prototypes, modeling allows engineers to forecast how the Powertrain Component will behave under different operating circumstances.

This capacity to identify problems ahead of time expedites the design process and enables the early detection and resolution of possible problems.

6. customization for Particular Uses:

Powertrain customization for various vehicle kinds and uses is made easier by modeling and sizing.

The powertrain can be designed to satisfy specific requirements, whether the vehicle is intended for a heavy-duty truck, fuel-efficient commuter car, or high-performance sports car.

7. Optimized Energy Management (for Hybrid and Electric Vehicles):

Modeling helps to optimize the energy management strategy in hybrid and electric vehicles. This includes managing battery charging and discharging, regenerative braking, and overall power distribution.

The car can attain the required range and performance if the electric components are sized properly.

8. Reduced Development Time:

Compared to conventional trial-and-error techniques, simulation-based design enables Powertrain Component iteration and refinement more quickly.

This shortens the vehicle’s total development time.

9. Improved Reliability and Durability:

Engineers may examine the mechanical and thermal strains on powertrain parts through simulation, ensuring that the parts are built to last in practical situations.

Appropriate component sizing helps prevent premature wear and failure.

10. Regulatory Compliance:

Engineers may create powertrains that adhere to safety, fuel economy, and pollution regulations by using modeling.

Manufacturers are able to prevent expensive recalls and redesigns because of this proactive approach.

Drawbacks of Powertrain Component Modelling and Sizing

Although there are many advantages to powertrain component modeling and sizing, these procedures can also have disadvantages and difficulties. To provide a balanced awareness of the overall design and development process, it is necessary to be aware of these limits. Here are a few disadvantages:

1. Model Complexity:

It can be difficult and time-consuming to create realistic models for every component in the powertrain and how they interact. A thorough understanding of the components’ thermodynamic and physical characteristics is necessary for detailed modeling.

2. Data Validation and Accuracy:

The quality of the input data and the reliability of the mathematical models utilized have a significant impact on the accuracy of the simulation results. Real-world testing, which can be costly and time-consuming, is necessary for the validation of these models.

3. Integration Challenges:

Especially in hybrid and electric vehicles where several technologies (e.g., engines, electric motors, batteries) must work together flawlessly, integrating various powertrain components into a cohesive system can be challenging.

4. Dynamic Operating Conditions:

Powertrains function in a variety of dynamic environments. Extreme climatic conditions, abrupt load fluctuations, and transitory behaviors may be too complicated for modeling and sizing to adequately reflect.

5. Limited Scope of Simulation:

Assumptions and simplifications form the foundation of simulations. Simulations may not adequately account for certain features of real-world driving situations, such as road conditions and traffic fluctuation.

6. Initial Cost of Simulation Software:

Investing in and using sophisticated simulation tools can be expensive. Modern modeling software may be difficult for small or startup businesses with tight finances to obtain.

7. Human Factors and Driving Experience:

Although modeling frequently concentrates on technical details, it could leave out important parts or the subjective driving experience. It’s possible that aspects like vibration, loudness, and comfort aren’t given enough attention.

8. Fast Technical Developments:

9. Uncertainty in Input Parameters:

There can be a lot of uncertainty in a lot of the input parameters used in modeling, including environmental factors, traffic circumstances, and driver behavior. The precision of forecasts may be impacted by these uncertainties.

Conclusion:

In conclusion, powertrain component modeling and sizing play a pivotal role in the design and development of modern vehicles, offering a range of benefits and presenting certain challenges. The ability to simulate and optimize the performance of individual components and the entire powertrain system contributes to improved efficiency, reduced emissions, and cost-effective solutions. By tailoring the powertrain to specific vehicle requirements, engineers can achieve optimal performance and meet regulatory standards.

However, it’s important to acknowledge the complexities and limitations associated with this approach. The intricate nature of modeling, challenges in data accuracy and validation, and the dynamic operating conditions of vehicles pose hurdles to achieving a perfect simulation. Integrating various powertrain technologies, adapting to rapid industry changes, and addressing uncertainties in input parameters further add to the complexity.

The balance between simulation and real-world testing is crucial. While modeling provides valuable insights and accelerates the design process, physical testing remains essential for validating simulation results and ensuring the reliability and safety of the powertrain under diverse conditions.

As the automotive industry continues to evolve, powertrain modeling and sizing will likely play an increasingly integral role, especially with advancements in electric and autonomous vehicle technologies. Continued research, collaboration, and the establishment of standards can address some of the current challenges, fostering innovation and efficiency in the design and development of future vehicle powertrains. In essence, powertrain component modeling and sizing are powerful tools when used judiciously, guiding engineers toward the creation of vehicles that are not only technologically advanced but also sustainable, reliable, and well-suited to diverse user needs.

0 notes

Video

DIY engine.😏😏😏#- - Credit @engineidea - - -#diy #diyproject #electronicsidea #stirling #stirlingengine #modelengine #enginemodel #engineidea #engine #mechanicalengineering #mechanical #enginework #enginestyle #engineering (at Surat, Gujarat) https://www.instagram.com/p/B9rWgXpFqpx/?igshid=17oemef0lxxu0

#diy#diyproject#electronicsidea#stirling#stirlingengine#modelengine#enginemodel#engineidea#engine#mechanicalengineering#mechanical#enginework#enginestyle#engineering

0 notes