#Epoxy Powder Coating Paint

Explore tagged Tumblr posts

Text

Industrial Coatings Market to be Worth $129.8 Billion by 2032

Meticulous Research®—a leading global market research company, published a research report titled ‘Industrial Coatings Market—Global Opportunity Analysis and Industry Forecast (2025-2032)’. According to this latest publication, the industrial coatings market is projected to reach $129.8 billion by 2032, at a CAGR of 3.4% from 2025–2032.

The industrial coatings market is experiencing growth driven by the rapid expansion of the automotive industry, large-scale infrastructure projects in developing countries, stringent environmental regulations aimed at reducing VOC emissions, and increased demand in the industrial sector for extending product lifespan and minimizing maintenance. However, this growth is hindered by the longer drying times associated with waterborne coatings and rising raw material costs.

In addition, the advancement in polymers and nanotechnology and the increasing demand for powder coating in marine applications are potential growth opportunities for market players. The market faces substantial challenges, including supply chain disruptions. Moreover, prominent technology trends in the industrial coatings market include smart coatings, sustainable materials, and additive manufacturing.

Key Players:

The industrial coatings market is characterized by a moderately competitive scenario due to the presence of many large- and small-sized global, regional, and local players. The key players operating in the industrial coatings market are BASF SE (Germany), Akzo Nobel N.V. (Netherlands), The Sherwin-Williams Company (U.S.), Axalta Coating Systems, LLC (U.S.), Kansai Paint Co., Ltd. (Japan), PPG Industries, Inc. (U.S.), Nippon Paint Holdings Co., Ltd. (Japan), Hempel A/S (Denmark), Teknos Group Oy (Finland), Beckers Group (Germany), Chugoku Marine Paints, Ltd. (Japan), Jotun A/S (Norway), RPM International Inc. (U.S.), Barpimo S.A. (Spain), and DAW SE (Germany).

The industrial coatings market is segmented based on type, resin type, and end-use industry. The report also evaluates industry competitors and analyzes the industrial coatings market at the regional and country levels.

Among the types studied in this report, the solvent-borne coating segment is anticipated to dominate the industrial coatings market in 2025. The growing adoption of solvent-based coatings in diverse applications, including automotive, architectural, and industrial finishes, along with established supply chains for raw materials, additives, and equipment, highlights the segment’s leading position in the industrial coatings market. Furthermore, the cost-effectiveness of solvent-based coatings compared to water-based alternatives reinforces its market dominance.

Among the resin types studied in this report, the epoxy segment is anticipated to dominate the industrial coatings market in 2025. Epoxy coatings are designed to be non-toxic and low-VOC, enhancing safety for both workers and the environment. The rising demand for corrosion protection in harsh environments, along with their growing application in industries such as automotive, marine, and aerospace, are key factors driving the segment's dominant position in the industrial coatings market.

Among the end-use industries studied in this report, the automotive segment is anticipated to dominate the industrial coatings market in 2025. The increased production volume in the automotive industry, the expansion of the automotive sector in China and India, and the growing use of industrial coatings to protect vehicle surfaces from corrosion, scratches, chips, and other damage are key factors contributing to the segment’s dominant position in the industrial coatings market.

Geographic Review

This research report analyzes major geographies and provides a comprehensive analysis of North America (U.S., Canada), Europe (Germany, U.K., France, Italy, Spain, Netherlands, and Rest of Europe), Asia-Pacific (Japan, China, India, South Korea, Australia & New Zealand, Indonesia, Thailand, and Rest of Asia-Pacific), Latin America (Brazil, Mexico, and Rest of Latin America), and the Middle East & Africa (UAE, South Africa, Israel, and Rest of Middle East & Africa).

Among the geographies studied in this report, Asia-Pacific is anticipated to dominate the industrial coatings market in 2025. Rapid industrialization in Asian countries, the expanding automotive sector in the region, increased government investment, incentives to promote industrial development, and large-scale infrastructure projects are significant factors driving the market's dominant position in the industrial coatings sector.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=6052

Key Questions Answered in the Report:

What is the value of revenue generated by the sale of type, resin type, and end-use industry?

At what rate is the global demand for industrial coatings projected to grow for the next five to seven years?

What is the historical market size and growth rate for the industrial coatings market?

What are the major factors impacting the growth of this market at global and regional levels?

What are the major opportunities for existing players and new entrants in the market?

Which offering segments create major traction in this market?

What are the key geographical trends in this market? Which regions/countries are expected to offer significant growth opportunities for the manufacturers operating in the industrial coatings market?

Who are the major players in the industrial coatings market? What are their specific product offerings in this market?

What recent developments have taken place in the industrial coatings market? What impact have these strategic developments created on the market?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Industrial Coatings Market#Marine Paint#Industrial Painting#Industrial Floor Coatings#Industrial Epoxy#Automotive Paints#Automotive Powder Coating#Industrial Powder Coating

0 notes

Text

Sea-Shield After Care Products

Welcome to the Sea-Shield After Care Products Collection, your number one choice for high-quality aftercare goods made especially for boat repair and maintenance. We provide a wide selection of Sea-Shield coatings, rust stain removers, and boat soaps in our collection, all of which have been professionally produced to maintain your boat's durability and perfect condition.

Why Choose Sea-Shield After Care Products

Yacht crew and boat enthusiasts both choose Sea-Shield Coatings because of our dedication to providing high-quality and innovative boat maintenance products. Our selection includes everything you need to maintain the best possible appearance and performance from your boat or yacht, no matter your level of experience as a skipper or sailor.

Above all, our collection of boat soaps provides mild yet effective cleaning options designed to meet the specific needs of maritime surfaces. Our boat soaps have been developed to remove filth, grime, and salt residue from boats without removing necessary protective coatings, leaving the finish looking brand new and shining.

Rust Stain Remover, Boat Repair Soaps, and More

We provide an effective rust stain remover that removes unattractive rust stains from metal surfaces on your yacht and boat soaps. The specially formulated composition of our rust stain remover allows it to deeply penetrate and remove rust spots without harming the surrounding surface, restoring the elegance and soundness of the metal parts of your boat.

Check out our selection of Sea-Shield coatings to improve longevity and provide additional protection from the elements on your boat. Our coatings offer exceptional protection against corrosion, UV rays, and environmental damage since they have been developed using cutting-edge technology. Your boat's durability and worthiness are preserved for years to come with Sea-Shield coatings, providing you peace of mind that it is protected from the resentful boat environment.

Shop Our After-Care Products Today at Sea-Shield Coating.

Explore our collection today and discover the difference that Sea-Shield Coatings can make in your boat’s surface shine and maintenance routine. We offer everything you need to maintain the finest possible look and performance for your boat, season after season, from boat soaps to rust stain removers to Sea-Shield coatings.

#boating product#boat#yacht#ceramic coating#yacht paint polish#yacht product#glass polishing#boating#aftercare#marine shield coating#fur coat#sea shield#metal coating#powder coating#epoxy coating

1 note

·

View note

Text

Everything you should know about powder coating finishes?

Types of Powder Coating Finishes

Epoxy Coatings: Known for their excellent adhesion, hardness, and chemical resistance, epoxy coatings are ideal for indoor applications. However, they may yellow with UV exposure, making them less suitable for outdoor use.

Polyester Coatings: Offering superior UV resistance, polyester coatings are perfect for outdoor applications. They are flexible, impact-resistant, and available in a variety of colors and gloss levels.

Hybrid Coatings: Combining the benefits of epoxy and polyester, hybrid coatings provide good chemical and corrosion resistance along with better UV stability than pure epoxies.

Acrylic Coatings: These coatings are known for their excellent gloss retention, weather resistance, and aesthetic appeal. They are commonly used for automotive and architectural applications.

Benefits of Powder Coating

Durability: Powder coatings are highly resistant to chipping, scratching, and fading, providing long-lasting protection for the underlying metal.

Environmental Friendliness: Unlike liquid paints, powder coatings contain no solvents and release negligible amounts of volatile organic compounds (VOCs) into the atmosphere, making them an eco-friendly choice.

Cost-Effectiveness: The efficiency of the powder coating process, with minimal waste and the ability to recycle overspray, makes it a cost-effective finishing option.

Variety: Powder coatings can achieve a wide range of finishes, including smooth, textured, matte, and high-gloss. They are also available in an extensive array of colors, making customization easy.

What is Powder Coating? Powder coating is a dry finishing process that involves the application of a fine, free-flowing, thermoplastic or thermoset powder onto a surface. This powder is electrostatically charged and sprayed onto the object, which is then cured under heat to form a smooth, hard finish. This method is known for its durability, resistance to corrosion, and ability to produce a wide range of colors and textures.

Applications of Powder Coating Powder coating is used in various industries, including automotive, aerospace, electronics, architecture, and home appliances. Its ability to provide a robust and attractive finish makes it a preferred choice for everything from car parts and machinery to furniture and consumer goods.

Conclusion Asiam Coater excels. in delivering exceptional powder coating finishes tailored to meet specific requirements. Their expertise ensures that products not only look great but also withstand the test of time, providing superior performance and aesthetics. With a commitment to quality and sustainability, Asian Coater stands out as a leader in the powder coating industry.

For more Information:- Contact us:-+91–8882531837 Email:[email protected] Address:-F-516, UDSIDC, MG Road Industrial Area, Phase -II, Ghaziabad — 201015

3 notes

·

View notes

Text

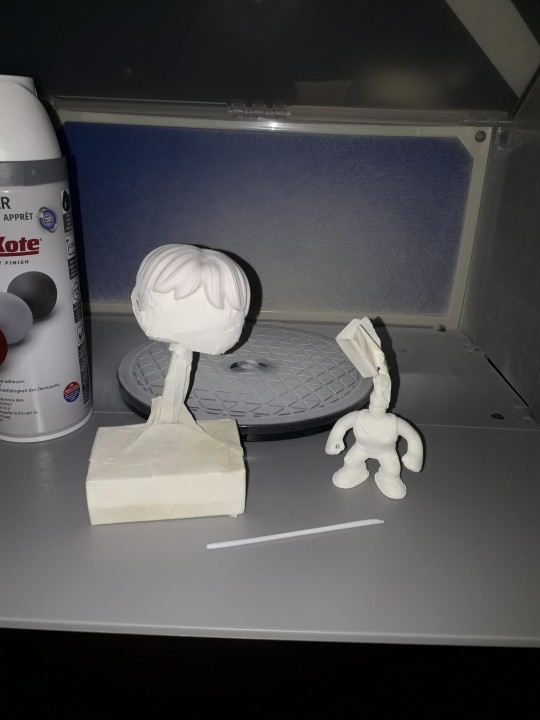

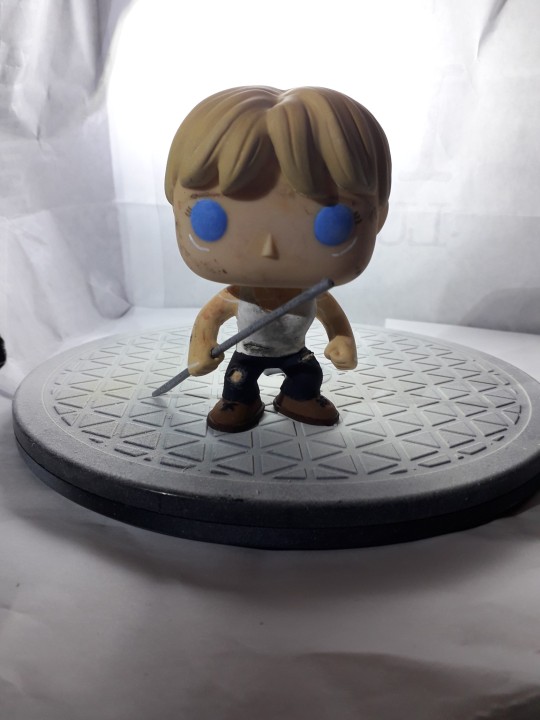

How to Build Your Own 'Augmented Super Wife Supersoldier From The Future' Funko Pop.

A Semi-Coherent Guide By RC.

This is a long one. A loooooooong one.

I meant to do this like two and a half years ago, but in the spirit of keeping this fandom's head above water, and the fact I'm at the hospital (nothing serious!) with nothing to do for the next couple of hours, I'm doing it now.

So if, like me, you are still bitter that Grace and Dani didn't get official Funkos, or official *anything* due to manufacturer short-sightedness, why not say 'fuck it' and build yer own?

This rambling tutorial will attempt to demonstrate how to build Grace from the 'when they start to kill me, run' scene.

Like, literally that bit 😋.

Anywho. Let's do this!

You will need:

- Funko Pop DIY (female)

- Polymer clay (eg. Sculpy, Fimo, CosClay). I'd advise against cheapo no-name alternatives purely because in my experience the baking times/temperatures stated are absolute garbo. Also, polymer clay will give off quite gnarly fumes while curing, so better to use a trusted source. But if cheapo's all ya got, it's all ya got.

Other modeling materials you might consider instead of polymer clay include...

Epoxy clay (eg. Milliput, Apoxie Sculpt, The Army Painter 'Green Stuff', even something like J-B Weld or similar 2 part plumber's/repair putty).

Plain ol' air drying clay (eg. DAS, FimoAir, Gedeo).

You could even whip up a batch of 'cold porcelain', or an oven cure salt dough from ingredients you probably already have at home. Make sure you clear coat any salt dough creations properly after curing as over time ambient moisture may mess with it.

Each option above has its own pros and cons. Do your research if you aren't sure. Me? I used Fimo.

*ahem* Carrying on...

- Masking tape

- Hobby knife

- Pin vice

- Kebab skewer (wooden), or styrene rod

- Paint brushes

- Primer (plus dust mask if you're using a rattle can indoors)

- Sandpaper (around 400 grit oughta do it but you could probably go 200 either side of that and get a good result)

- Acrylic paints (optional: Posca PC-1MR pens in black and white for fine detail).

- Crafter's heat gun, or a hairdryer

- Varnish/clear coat.

Optional extras: Airbrush, spray booth/cardboard box, rotary tool, oven thermometer, artist's/cake decorating turntable, UV resin, silver leafing pen, jeweller's files, jeweller's wire, acetone, superglue or 5 minute epoxy, a lil piece of sponge, pearl mica powder, scavenged Funko Pop head 😈.

Step One: Grab your Funko DIY and separate the head from body using heat to soften the vinyl enough to wangle it off the neck post. Shoving it in a mug of hot water for a few minutes should do the trick. Make sure to dry out the head as much as possible. Last thing you want is mould growing inside it. This is Terminator, not The Last Of Us 😉. Alternatively you could use your heat gun/hairdryer, but I explain in Step Six why the water bath approach is a better option (imho) at this early stage.

(You are giving this entire thing a quick read through before you start, right? I dunno about the rest of you but I like to have at least a basic idea of the work ahead before I get stuck in. Saves finding out you're missing a necessary tool/material at an inopportune moment and all).

Stop rambling, RC. Sorry. It's easier to be succinct when you haven't lost half your photos 🤦♀️. Moving on...

If you don't wanna attempt to sculpt the hair yourself you can, as I did, take a kitbashing approach instead of using the supplied DIY head. Grab one of the many commercially available Funkos with a decent approximation of the hairstyle you want and then go Step One on em. Buy 'pre-loved', buy BNIB, dig one out of a dumpster, steal one from your lil cousin, it doesn't matter. Procure as your time/budget/situation dictates. Improvise where necessary.

Sorry, Ron. I need your floppy hair. I do not need your clothes.

Or your boots. Or your motorcycle.

...😋

Step Two: Take the body of the Funko DIY and mark out the position of the tank top and the cuffs of the jeans. These will be used as guides for when you add the clay.

At this point I used a pin vice to drill the hole thru the fist for the rebar. If you're a crazy person you could use a rotary tool with an appropriately sized bit attached.

To make the rebar I fashioned a mould from a drinking straw and filled it with UV resin. Because I'm awkward. A wooden kebab skewer, or some hobbyist's styrene rod (eg. Evergreen Scale Models) would work just as well. Just cut it to size, paint it silver and you're golden. I used a metallic leafing pen. You use whatever you've got handy. Doesn't have to be shiny. A flat grey acrylic would work just fine.

Use jeweller's files and sandpaper to make small adjustments to the hand hole and rebar respectively in order to get a good press fit. There's always glue if you overdo it 😉. But don't add the rebar to the model just yet, as you're gonna need room to manoeuvre for the next bit.

Step Three: How do you make it look like your figure is wearing clothes when you don't have much real estate to work with?

You fake it, that's how.

You do not need to model an entire set of clothes! It's an arse ache, and we're all about working smarter not harder on the RC channel.

So, take your modeling compound of choice, roll a chunk of it out to the desired thickness, and then cut into strips, say 2-3mm wide. Use your best judgement here.

Now, using the jeans as our example, wrap a strip around the bottom of the leg where the cuff would sit. Cut off any excess and blend out the join. Just give it a lil rub and it's like it was never there. Like magic! You should have a nice defined edge at the bottom, just above the foot. Now see the top edge of your lil clay strip? Well, you wanna start pushing and flattening the clay to blend the edge right out so it fades back into the body.

Repeat for the other leg, and the bottom of the tank top. The straps are relatively simple, tho the bits that pass under the arms can be fiddly due to lack of space. Use a hobby knife to shape and crisp up those edges and then blend out the extraneous edge. Same thing with the neckline.

Run a strip around each foot to form the soles of the boots, and a lil 'x' on the top of the feet to give the impression of laces.

For the rips in the clothing you can simply gouge out a little of the clay. If there isn't any on that part of the model (the knee for example) roll out a little wormy dealie (for you North of the Border fans 😉), position it as needed, blend out the edges, then gouge as required.

If you're playing on hardcore mode, this might be the time to start piling clay on the Funko DIY head and sculpting the hair. You may prefer to leave it til the head's re-attached tho. It depends on the material you're using. If you don't think it'll stand up to a bit of manhandling while pushing the head back onto the body, save this step til that bit's done.

Cure according to the clay manufacturer's instructions. The vinyl will not melt at the temperatures required to cure polymer clay, but if you don't wanna risk it or you don't wanna use your food oven to cook plastic, with all the gnarly fumes and stuff, I've given you plenty of air dry and/or non toxic alternatives. Consistent temperature is key with polymer clay. Undercooked, it's quite brittle. An oven thermometer comes in handy here if you've got one.

Step Four: Primetime!!! Some like to brush on primer, which is fine if you're painting a fence or throwing gesso on a canvas. Not so fine if you're painting a figurine imho. I mean, unless it's Cassandra from Doctor Who. A good rattle can of spray paint is what you want ideally, but again, it's about what you can afford/wangle/manage with your crafting space, so feel free to ignore me and brush away!

First rule of Primer Club: several light coats are better than one heavy coat. Second rule of Primer Club: knock each coat back a lil with sandpaper before applying the next one. Third rule of Primer Club: sit your rattle can in a warm water bath for five minutes before shaking it up to improve flow.

You can get primer specifically for plastics but while I would recommend it, it's not absolutely necessary.

A scavenged head may need masking off if the base colour already matches the skin colour of your character. Save yourself a bit of painting innit. You can get really tight, clean edges against the hairline with a hobby knife. If the hairstyle, hair colour, and skin colour match straight outta the box? Congrats! Why are you even reading this? 😜.

That thing in the background is a portable spray booth (that other thing is a turntable). A cardboard box is also a portable spray booth if you want it to be. Only thing it doesn't have is an extractor fan. So put on a dust mask, and open a window or work outside.

The DIY figure comes primed outta the box, so if you're using the DIY head and are planning on sculpting the hair after re-attachment you don't need to prime it. Unless you want to.

Step Five: Time to paint that shizz. You don't need me to walk you thru this bit, right?

Right?...

Masking is your friend if you don't trust your ability to freehand with a brush. If you're masking over a part you've already painted and are afraid of pulling the paint off, you can knock the level of tack on the tape down by sticking it to yourself (or your clothes) a couple of times before applying it. Some prefer to add a light layer of clear coat to 'lock in' the underlying paint. It's like a real life 'save point'. Some people do both. Some use masking fluid. Some use silly putty/blu-tac/plasticine. Play around, see what works. You do you.

I painted Grace's eyes blue coz Grace is extra and so am I. I threw a lil bit of pearl powder in there to add a subtle shimmer, as I thought going full metallic blue might be a bit too extra.

Lady Funkos have eyelashes. Don't forget the eyelashes.

(I nearly forgot the eyelashes).

A fine tipped Posca pen comes in handy here if you've got one.

Ditto the eyebrows, tho those aren't just for the ladies obvs.

For Grace's augmentation scars, again I recommend a Posca pen but a brush will do.

DO NOT PAINT THE NECK POST. Don't even varnish the neck post. Keep that bitch masked up until you're ready to reattach the head. Like, you can get away with painting the very bottom if you're worried the bare plastic will show even with the head attached, but that's it. Any more will be making a rod for your own back.

You have a choice now. Whether to weather your figure. I chose to add that extra level of detail as it made sense to me. Use a combination of dark washes, dry brushing, and/or sponge stipling to add dirt, blood etc. If ya want.

When you're happy with your paint job, give everything (except the neck post!!!!) a couple of layers of clear coat.

Step Six: When it comes to reattaching the head you probably don't wanna be dunking anything in water by this point, just in case. So we're gonna soften the neck post (and around the base of the head if necessary) with hot air instead. Use a hairdryer if you don't have a heat gun. DO NOT use an industrial or decorator's heat gun for the love o' god. That shit's meant for stripping paint, not gently warming vinyl figurines. It'd be like using a nuke to shake a cherry tree, and you'd likely burn yourself. A hairdryer is more than capable of doing the job.

Why did we not use the hairdryer for Step One? To be honest there's nothing stopping you if that's what you wanna do, but as you don't have direct access to the bits that need softening at that point you will have to wait for the heat to penetrate. You could be doing other things in that time by letting a water bath do the work for you.

Now, however, you do have direct access, so you'll probably find you only need to blast the hot air for 10 seconds or so.

Step Seven: So, you've got the head re-attached, and your paint job is finished and clear coated. That means it's time to add the rebar. If you went a bit too far with the drilling or sanding now's the time to get your glue on. As an final extra touch you can spiral some thin jeweller's wire around the length of the rebar to make it look more rebar-y. I didn't do this bit as the wire I had in my possession at the time was too thick for my tastes.

But whether you opt for that or not, congratulations on making your very own Grace Funko Pop!

I'm still planning on making security guard and future war versions of Grace, and at least one version of Dani. Yeah, I've been saying that for the last two years, but it's still absolutely happening, trust me.

Anyway. That'll do it. If you have any questions, or you need further explanations or recommendations etc. y'all know where to find me.

8 notes

·

View notes

Text

Refinish Paint Market Size, Share, Top Key Players, Growth, Trend and Forecast Till 2034

The Global Refinish Paint Market was valued at USD 8.7 billion in 2024 and is projected to experience a steady growth rate of 4.5% CAGR from 2025 to 2034. The market expansion is primarily fueled by the growth of the automotive aftermarket service industry, driven by increasing vehicle ownership worldwide. As more people own vehicles, there is a notable rise in the demand for services such as repainting, dent repair, and surface refinishing. Consumers are increasingly focused on maintaining the aesthetic appeal and resale value of their vehicles, driving the need for high-quality refinish paints. Additionally, the growth in vehicle customization and the need for frequent collision repairs are contributing to the rise in demand for refinish coatings. In parallel, rising environmental awareness and the push for more eco-friendly solutions are prompting a shift toward low-VOC and water-based paint options.

Get sample copy of this research report @ https://www.gminsights.com/request-sample/detail/7382

A major trend in the refinish paint market is the growing demand for premium finish coatings. Consumers are more inclined to invest in coatings that not only enhance the look of their vehicles but also offer superior durability. Premium finishes, known for their smooth textures, high gloss, and resistance to environmental factors, have become especially popular in high-end vehicles. Matte, metallic, and pearlescent coatings are trending in the luxury and custom vehicle markets, where appearance is of utmost importance. These high-quality finishes provide a level of sophistication that appeals to consumers willing to pay more for longevity and visual appeal.

In terms of resin types, the market is divided into epoxy, acrylic, polyurethane, and others, with polyurethane taking the lead. The polyurethane segment alone accounted for USD 3.4 billion in 2024, owing to its excellent durability, flexibility, and superior finish quality. This resin type is highly regarded for its ability to withstand UV rays, chemical exposure, and abrasions, making it ideal for automotive applications. Polyurethane coatings are also prized for their glossy appearance and long-lasting protection, which meets both aesthetic and practical needs in the refinish market.

Technology-wise, the refinish paint market can be broken down into waterborne, powder coatings, and solvent-borne categories. Solvent-borne coatings represent the largest share, holding 49% of the market. Their fast-drying properties, excellent adhesion to various surfaces, and ability to perform well in harsh environmental conditions make them highly favored. These coatings are particularly popular in automotive refinishing, where the demand for smooth finishes and versatility is crucial. Solvent-borne coatings' durable nature and reliability have solidified their position as the preferred choice in advanced automotive refinishing techniques.

Browse complete summary of this research report @ https://www.gminsights.com/industry-analysis/refinish-paint-market

In the U.S. market, the demand for refinish paint is strong, with a market value of USD 2.1 billion in 2024. The U.S. has a large base of vehicle owners, which contributes to the continuous demand for high-quality refinish coatings. The growing trend in vehicle customization, an increase in collision repairs, and the rising number of accidents are all driving factors. Moreover, stringent environmental regulations are pushing for more eco-friendly, low-VOC paint options, which further influence the growth trajectory of the market in the U.S.

About Global Market Insights

Global Market Insights Inc., headquartered in Delaware, U.S., is a global market research and consulting service provider, offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with penetrative insights and actionable market data specially designed and presented to aid strategic decision making. These exhaustive reports are designed via a proprietary research methodology and are available for key industries such as chemicals, advanced materials, technology, renewable energy, and biotechnology.

Contact Us:

Aashit Tiwari

Corporate Sales, USA

Global Market Insights Inc.

Toll Free: +1-888-689-0688

USA: +1-302-846-7766

Europe: +44-742-759-8484

APAC: +65-3129-7718

Email: [email protected]

0 notes

Text

Industrial Coating Market Drivers Include Demand for Corrosion-Resistant Finishes in Infrastructure

Infrastructure development across the globe has created a surging demand for protective materials that extend the service life of vital assets. One of the primary forces fueling the Industrial Coating Market is the increasing need for corrosion-resistant finishes, especially in high-value infrastructure projects. With bridges, highways, pipelines, and industrial plants requiring long-term protection against harsh environmental conditions, coating manufacturers are prioritizing product performance, longevity, and compliance with environmental standards.

Growing Need for Durable Infrastructure

Aging infrastructure across North America and Europe, combined with robust new project investments in Asia-Pacific and the Middle East, is creating massive growth opportunities for corrosion-resistant coatings. These coatings are not only necessary for safeguarding steel and concrete from degradation but are also crucial in reducing maintenance costs and preventing structural failures. Municipalities and private-sector stakeholders are investing heavily in technologies that ensure durability over decades rather than years.

Key Application Areas Driving Demand

Corrosion-resistant coatings are particularly essential in industries such as:

Transportation Infrastructure: Railways, bridges, and tunnels exposed to moisture and temperature extremes.

Water and Wastewater Management: Pipelines and storage tanks frequently face rust and contamination risks.

Oil & Gas: Offshore rigs, refineries, and distribution lines that require chemical-resistant coatings.

Construction and Industrial Buildings: High-rise structures, warehouses, and manufacturing facilities facing pollution and UV damage.

Each sector places distinct performance requirements on coatings, pushing the development of innovative formulations tailored to specific environments.

Technology Advancements Enhancing Corrosion Resistance

Modern industrial coatings are far more advanced than traditional solvent-based paints. Key innovations contributing to enhanced corrosion resistance include:

Epoxy and Polyurethane Blends: Offering superior barrier protection and chemical resistance.

Zinc-Rich Primers: Providing cathodic protection to steel structures.

Powder Coatings: Delivering solvent-free application with exceptional abrasion resistance.

Water-Based Systems: Supporting sustainability while maintaining performance.

Smart coating technologies that detect early corrosion signs and respond dynamically are also being developed, highlighting the fusion of materials science and digital monitoring.

Regulatory Environment as a Secondary Driver

While corrosion protection remains the core focus, regulatory guidelines surrounding environmental and worker safety are influencing coating compositions. The demand for low-VOC (volatile organic compound) formulations is reshaping R&D efforts, requiring high-performance solutions without sacrificing ecological responsibility. This trend aligns with government mandates across the EU, the U.S., and parts of Asia pushing for greener infrastructure.

Economic Impacts and Cost Justifications

While advanced corrosion-resistant coatings can have higher upfront costs, their long-term economic benefits are well-documented. Preventing corrosion-related damage not only reduces repair costs but also avoids operational downtime—critical in industrial and transport settings. Many governments and large corporations now include lifecycle coating cost assessments in their budgeting frameworks.

Regional Spotlight: Growth in Asia-Pacific

Rapid industrialization and urbanization in countries like China, India, and Indonesia are driving a significant portion of the market demand. Government-backed infrastructure megaprojects, including highways, metro systems, and water treatment plants, have boosted the consumption of industrial coatings. Moreover, the region’s climate, which includes high humidity and salinity in coastal zones, demands robust corrosion-resistant materials.

Competitive Landscape and Manufacturer Strategies

Global leaders in the industrial coating sector are emphasizing durability and compliance. Strategies include:

Increased R&D in anti-corrosive and environmentally friendly products

Expansion of regional production facilities for faster delivery

Collaborations with infrastructure contractors to tailor coating solutions

Training programs for applicators to ensure performance consistency

Brands that can provide high-performing, sustainable coatings at scale are poised to capture major market share over the coming years.

Looking Ahead

The market for corrosion-resistant coatings is expected to remain robust as governments invest in climate-resilient infrastructure. The combination of material science innovations and sustainability pressures will continue to shape the future of industrial coatings.

In the next article, we’ll explore how eco-friendly, low-VOC paint system innovations are becoming one of the most transformative trends in the industrial coating landscape—aligning with global sustainability objectives.

#IndustrialCoatingMarket#CorrosionResistance#InfrastructureDevelopment#ProtectiveCoatings#ConstructionMaterials#SustainableSolutions#SmartCoatings#IndustrialPaints#VOCCompliance#EngineeringInnovation

0 notes

Text

Enhance Epoxy & Polyurethane Systems with Molecular Sieve Powder

Sorbchem India's Activated Molecular Sieve Powder is a dehydrated synthetic powder derived from 3A and 4A molecular sieves. Its foamless structure effectively removes moisture and air bubbles in epoxy and polyurethane coatings, paints, resins, and adhesives. By acting as a moisture scavenger, it enhances product quality, extends shelf life, and prevents CO₂ formation in polyurethane systems.

For more information

Contact +91 9879203377,

Email us- [email protected]

Website- https://www.sorbchemindia.com/products/molecular-sieves-powder

#MolecularSievePowder#ZeolitePowder#SorbchemIndia#ActivatedZeolite#3AMolecularSieve#4AMolecularSieve#EpoxyAdditives#MoistureScavenger#PolymerMoistureControl#MoistureAdsorption#ShelfLifeExtension#PolyurethaneFlooring#EpoxyFlooring#PolyurethaneCoatings

1 note

·

View note

Text

Innovative Coatings for Alloy Steel Chains: Boosting Rust Protection & Performance

Alloy steel chains play a crucial role in heavy lifting, rigging, construction, mining, and transport industries. However, even the strongest chains can suffer from wear and corrosion, especially when exposed to moisture, chemicals, or extreme environments. This is where coating technology steps in. Innovative coatings are helping alloy steel chains last longer, resist rust, and perform better in tough conditions.

Why Coatings Matter in Alloy Steel Chains

Alloy steel chains are built for strength, but they are still vulnerable to:

Rust and corrosion from water, chemicals, or salty air.

Surface wear from friction and heavy loads.

Environmental stress like extreme heat or cold.

Without proper protection, these factors can weaken chains, reduce their load-bearing capacity, and shorten their service life. Coatings act as a barrier to these elements, enhancing both safety and lifespan.

Common Coating Challenges in Industrial Use

Before diving into innovations, it's important to understand the limitations of traditional coatings:

Zinc plating offers some rust resistance but may wear off quickly.

Painted coatings can chip or peel under mechanical stress.

Basic galvanization helps with corrosion but doesn’t always handle abrasion well.

Industries need coatings that are not only rust-resistant but also durable, flexible, and environmentally safe.

1. Hot-Dip Galvanizing (HDG): A Classic with Upgrades

Hot-dip galvanizing remains a popular choice for alloy steel chains. Chains are dipped in molten zinc, forming a protective layer.

Benefits:

Excellent corrosion resistance

Self-healing properties on small scratches

Cost-effective for outdoor and marine use

Innovations: Modern HDG includes additives that improve adhesion, surface finish, and longevity in acidic or high-salt conditions.

2. Epoxy-Based Powder Coating: Durable and Protective

Epoxy powder coating involves applying a dry powder to the chain, which is then baked to create a hard, protective film.

Benefits:

Strong resistance to chemicals and water

Smooth, hard finish that reduces friction

Available in color coding for load identification

Innovations: New formulas include UV-blocking properties and flexible layers that resist cracking under repeated stress.

3. Ceramic Coatings: Ultra-Hard Protection

Ceramic-based coatings are a newer innovation designed to provide top-tier protection in high-wear environments.

Benefits:

Extreme hardness and abrasion resistance

High heat tolerance (ideal for mining or smelting operations)

Chemical and corrosion resistance

Use Case: Ceramic coatings are often used in mining and offshore drilling where chain exposure to harsh grit or chemicals is common.

4. PTFE (Teflon) Coatings: Low Friction & High Protection

PTFE or Teflon coatings are known for their slick, non-stick surface and chemical resistance.

Benefits:

Low friction for smooth chain movement

Resistant to oil, grease, solvents, and weather

Lightweight coating that doesn't add bulk

Applications: Ideal for environments where chains are exposed to grease, moisture, or continuous motion like conveyor systems.

5. Nano-Coatings: The Future of Chain Protection

Nano-coatings use microscopic particles to create a thin but highly protective layer over metal surfaces.

Benefits:

Invisible protection with zero added weight

Water-repellent and self-cleaning properties

Long-lasting barrier without flaking or peeling

Trends: Nanotechnology is being used in military and aerospace sectors and is now entering industrial lifting and rigging.

6. Duplex Coatings: Combining Two Layers for Superior Results

Duplex coatings combine galvanization with a topcoat (like powder coating or epoxy), offering dual protection.

Benefits:

Enhanced corrosion resistance

Better adhesion and impact protection

Longer maintenance intervals

Common Combo: Hot-dip galvanizing + powder coating is a popular duplex choice in coastal and marine applications.

Environmental & Regulatory Considerations

With increasing environmental regulations, coatings must also be:

Non-toxic and free of heavy metals

VOC-compliant (volatile organic compounds)

Safe for human handling in manufacturing and field use

Eco-friendly coatings are gaining popularity, with water-based and bio-polymer solutions now under development.

How to Choose the Right Coating for Your Chain

When selecting a coating, consider:

Operating environment: Is it wet, hot, salty, or chemical-heavy?

Chain use frequency: Daily, seasonal, or occasional use?

Load requirements: Will coatings affect weight tolerances or flexibility?

Maintenance schedule: Do you need longer intervals between inspections?

Consulting your chain supplier or coating expert can help match the right protection to your workload.

Innovative coatings are revolutionizing how alloy steel chains perform under pressure. Whether you're lifting cargo in coastal zones, mining underground, or moving loads in high-heat environments, the right coating can significantly extend chain life and improve safety. From epoxy to ceramic, PTFE to nano layers, these advancements not only protect your investment but also reduce downtime and risk. Investing in coated alloy chains is a smart move for any operation demanding strength, reliability, and resilience.

0 notes

Text

Top Uses of Pigment Powder for Stunning DIY Projects

Looking to add vibrant color, creativity, and a professional touch to your DIY projects? Pigment powder is the perfect solution. This versatile coloring agent has become a must-have in the world of arts, crafts, and home improvement. Whether you’re a seasoned artisan or a weekend crafter, pigment powder offers endless possibilities to elevate your creative efforts. At Touchwood Design, we understand the magic that color brings to any project. Let’s explore the top uses of Pigment Powder and how you can incorporate it into your own creations.

What is Pigment Powder?

Pigment powder is a finely ground, dry substance made from natural or synthetic materials used to add color to various mediums. Unlike dyes, which dissolve in liquids, pigment powders remain suspended, providing a richer, more opaque finish. They're available in a wide range of hues, metallics, and pearlescent shades.

Top Uses of Pigment Powder for DIY Projects

1. Resin Art and Furniture Coating

Pigment powder is a favorite in resin-based projects. From colorful coasters to epoxy river tables, adding pigment powder to resin creates stunning visual effects. At Touchwood Design, we often use pigment powder in resin tables to produce captivating swirls and metallic finishes.

2. Candle Making

Want your homemade candles to stand out? Adding a small amount of pigment powder to your wax can result in bold or pastel shades. Make sure to use pigment powders that are safe for burning to avoid releasing toxins.

3. Soap Crafting

Natural mica pigment powders are a go-to for coloring handmade soaps. They provide vibrant, skin-safe hues that don’t fade over time. Whether you're making cold-process or melt-and-pour soap, pigment powder blends beautifully without clumping.

4. Clay and Polymer Creations

Crafters love using pigment powder to add shimmer and detail to polymer clay or air-dry clay. Brush it onto molds before pouring or mix it directly into the clay for a marbled effect.

5. Painting and Fine Art

Mixing pigment powder with acrylic mediums, oils, or watercolors allows artists to create custom colors with unmatched vibrancy. It also works well in mixed media and abstract art forms.

6. Concrete and Cement Decor

Yes, even concrete can benefit from a splash of color. Add pigment powder to concrete mixes to create colorful stepping stones, countertops, and planters.

7. Nail Art and Makeup

Cosmetic-grade pigment powders are widely used in nail salons and homemade beauty products. From holographic nails to highlighter palettes, the possibilities are endless.

8. Wood Finishing and Staining

Combine pigment powder with wood stains or oils to enhance grain patterns and bring out the natural beauty of timber. Our experts at Touchwood Design often recommend this technique for bespoke furniture pieces.

How to Use Pigment Powder Safely and Effectively

Start with a small amount and build up to the desired color intensity.

Mix thoroughly to avoid uneven coloring.

Wear gloves and a mask when handling to avoid inhalation or staining your hands.

Use a compatible medium such as resin, wax, or acrylics depending on your project type.

Choosing the Right Pigment Powder

Not all pigment powders are created equal. When selecting the best pigment powder for your DIY projects, consider the following:

Color fastness: Ensure it won't fade over time.

Compatibility: Choose pigments based on the medium (resin, soap, wood, etc.).

Safety: Use cosmetic-grade pigment for skin or body applications.

At Touchwood Design, we prioritize high-quality pigments that are safe, long-lasting, and environmentally friendly.

Frequently Asked Questions (FAQs)

Q1: Can pigment powder be used in food or edible items? A: No. Unless it is food-grade, pigment powder should never be used in edible products.

Q2: What's the difference between pigment powder and mica powder? A: Mica powder is a type of pigment powder made from natural minerals that add shimmer. Pigment powder, in general, includes both matte and metallic versions.

Q3: How long does pigment powder last? A: Stored in a cool, dry place, pigment powder can last for several years without losing its vibrancy.

Q4: Can I mix different pigment powders together? A: Absolutely! Mixing different pigment powders can create custom shades and effects tailored to your project.

Q5: Is pigment powder safe for children’s crafts? A: Choose non-toxic and child-safe versions, and always supervise use.

Final Thoughts

From resin artwork to wood staining, pigment powder adds flair and functionality to any DIY venture. Its ability to transform basic materials into vibrant masterpieces makes it an essential part of every craftsperson’s toolkit. At Touchwood Design, we embrace innovation, quality, and creativity in every piece we create—and pigment powder plays a big part in that journey.

Ready to Get Started?

Unlock the full potential of your DIY creativity with premium-quality pigment powder. Browse our Touchwood Design Collection to find inspiring furniture, helpful resources, and tools to bring your colorful ideas to life. Create with confidence. Create with color. Create with Touchwood Design.

0 notes

Text

Electric Ovens, Industrial Ovens, Industrial Batch Oven, Drying Ovens, Haryan, India

Involved Manufacturer, Exporter and Supplier Of Industrial Batch Ovens, Industrial Ovens, Batch Ovens, Electric Industrial Oven, Heating Oven, Welding Ovens, haryana, India.

Industrial Oven, Industrial Ovens, Industrial Batch Ovens, Industrial Ovens, Batch Ovens, Infrared Oven, Electric Industrial Oven, Tray Drying Oven, Trolley Type Oven, High Temperature Oven, Drum Heating Oven, Flame Proof Drum Heating Oven, Varnish Baking Oven, Radiator Core Baking Oven, Air Circulation Oven, Forced Air Circulation Oven, Electric Drying Oven, Tray Dryer, Electric Tray Dryer, Stainless Steel Tray Dryer, Oil Fired Oven, Gas Fired Oven, Bench Oven, Chamber Oven, Box Oven, Heating Oven, Tempering Oven, Aluminium Ageing Oven, Composite Curing Oven, Walk In Ovens, Garment Curing Oven, Electric Motor Drying Oven, Top Loading Ovens, Polyurethane Curing Oven, Motor Winding Baking Oven, Bearing Heating Oven, Ageing Oven, Industrial Hot Air Oven, Heat Shrink Oven, PU Wheel Heating Oven, Post Curing Oven, Transformer Heating Oven, Die Preheating Oven, Rubber Curing Oven, Electrical Heated Oven, Clean Room Oven, Geomet Coating Oven, Dacromet Coating Oven, Teflon Coating Oven, Moisture Drying Oven, Plastic Annealing Oven, Lacquer Curing Oven, Halar Coating Oven, PTFE and PFA Coating Oven, Conveyorized Ovens, Belt Conveyor Oven, Flat Belt Conveyorized Oven, Infrared Conveyor Oven, Gas Fired Continuous Oven, Oil Fired Continuous Oven, Over Head Conveyorized Oven, Triple Decker Conveyorized Oven, Powder Coating Plants, Powder Painting Plants, Paint Baking Oven, Powder Coating Oven, Paint Curing Oven, Enamel Paint Baking Oven, Epoxy Curing Oven, Paint Booth, Powder Coating Booth, Water Wash Paint Booth, Dry Paint Booth, Down Draft Paint Booth, Side Draft Paint Booth, Welding Ovens, Portable Electrode Drying Oven, Stationary Mother Electrode Baking Ovens, SAW Flux Baking Oven Top Loading, SAW Flux Baking Oven Front Loading, Mumbai, Maharashtra, India.

0 notes

Text

Construction Paints And Coatings Market is driven by Infrastructure Development

The Global Construction Paints And Coatings Market is estimated to be valued at US$ 214.64 Bn in 2025 and is expected to exhibit a CAGR of 6.64% over the forecast period 2025 to 2032. The construction paints and coatings market encompasses a diverse portfolio of protective and decorative finishes applied to buildings and infrastructure projects worldwide. These products range from waterborne and solvent-borne coatings to powder, epoxy, and polyurethane systems designed to enhance aesthetic appeal, corrosion resistance, and durability. Construction coatings offer advantages such as weather protection, UV resistance, mold and mildew prevention, and energy efficiency through reflective technologies. Construction Paints And Coatings Market Insights is growing need for sustainable and low-VOC formulations is reshaping product innovation, while advancements in nanotechnology and self-cleaning surfaces further drive market evolution. Architects, contractors, and homeowners rely on these solutions to extend the lifespan of structures and reduce maintenance costs. As urbanization accelerates and infrastructure spending rises, demand for high-performance coatings across residential, commercial, and industrial segments continues to grow.

Get more insights on,Construction Paints & Coatings Market

#Coherent Market Insights#Construction Paints & Coatings#Construction Paints & Coatings Market Insights#Construction Paints & Coatings Market#Powder Coatings#Waterborne Coatings

0 notes

Text

High-Quality Epoxy Powder Coating Paint in Faridabad | Nivera Paints

Nivera Paints offers durable and efficient epoxy powder coating paint in Faridabad, perfect for industrial and protective applications with excellent corrosion and chemical resistance. For More Info Contact Us : ☎️ 9911017299 🌐 www.niverapaints.com ✉️ [email protected]

0 notes

Text

Complete Guide to Industrial Painting and Coating Solutions

In the world of manufacturing, construction, and infrastructure, protecting surfaces against corrosion, abrasion, and environmental damage is a top priority. Industrial painting and coating solutions serve as a critical line of defense, enhancing both the longevity and performance of metal, concrete, and other industrial surfaces.

Whether you're operating a manufacturing facility, managing a warehouse, or maintaining structural assets, understanding the fundamentals of industrial painting and coating can save you significant costs in the long run. In this guide, we’ll break down the essentials—and show you how partnering with experienced professionals can make all the difference.

What Is Industrial Painting and Coating?

Industrial painting and coating involves the application of protective layers (primers, sealants, paints, or specialized coatings) to industrial equipment, structures, or surfaces to shield them from harsh operating environments. Unlike residential painting, industrial coatings are formulated for high durability and performance under extreme conditions—chemical exposure, UV radiation, humidity, and high temperatures.

Key Benefits of Industrial Painting and Coating

Corrosion Protection

Steel and metal structures are especially vulnerable to rust and corrosion. Industrial coatings form a barrier that protects metal from moisture and oxygen exposure.

Improved Aesthetics

Coatings enhance visual appeal and help maintain brand consistency in factories, warehouses, and commercial spaces.

Extended Lifespan

Surfaces treated with industrial coatings last significantly longer, reducing maintenance frequency and replacement costs.

Chemical and Heat Resistance

Many coatings are specially engineered to resist acids, alkalis, solvents, and high temperatures in chemical or manufacturing environments.

Safety Compliance

Anti-slip, fire-resistant, or anti-static coatings can help meet workplace safety standards and regulations.

Common Types of Industrial Coatings

Epoxy Coatings

Known for excellent adhesion and chemical resistance, often used in flooring and tanks.

Polyurethane Coatings

Offers flexibility and UV resistance—ideal for outdoor applications.

Zinc-Rich Primers

Provide galvanic protection for steel surfaces exposed to corrosive conditions.

Powder Coating

Durable, eco-friendly finish for metal parts with minimal VOC emissions.

High-Temperature Coatings

Withstand thermal stress in furnaces, pipelines, and exhaust systems.

Industrial Painting and Coating Applications

Warehouses and storage facilities

Manufacturing and processing plants

Oil and gas equipment

Bridges, towers, and large steel structures

Marine vessels and offshore platforms

Food-grade and pharmaceutical plants

Each environment presents unique challenges, which is why tailored solutions are essential.

Why Choose Professional Industrial Coating Services?

While some might consider DIY or in-house painting options, professional application guarantees surface preparation, product compatibility, and environmental compliance. The right partner ensures coatings are applied correctly—enhancing performance and minimizing downtime.

Our Industrial Coating Services Include:

Surface cleaning and abrasive blasting

Epoxy and polyurethane coating systems

Corrosion control and zinc-rich priming

On-site or off-site application services

Project-specific consultations and maintenance planning

We work closely with clients to understand operational requirements and environmental conditions—delivering cost-effective solutions without compromising performance.

Final Thoughts

Choosing the right industrial painting and coating solution is not just a matter of appearance—it's a vital investment in safety, durability, and operational efficiency. Whether you're refurbishing aged equipment or starting a new build, professional coating services ensure your assets are built to last.

0 notes

Text

High-Temperature Coating Market Growth Explained: From Aerospace to Petrochemicals

Global High-Temperature Coating Market continues to demonstrate robust growth, with its valuation reaching USD 1.18 billion in 2023. According to industry analysis, the market is projected to grow at a CAGR of 5.5%, reaching approximately USD 1.91 billion by 2032. This growth is largely fueled by increasing applications in automotive, aerospace, and industrial sectors where heat-resistant solutions are critical for operational safety and efficiency.

High-temperature coatings are essential protective solutions designed to withstand extreme thermal conditions, typically ranging from 150°C to over 760°C. Their unique formulations using epoxy, silicone, or multi-polymeric matrices make them indispensable across industries transitioning toward more durable and sustainable material solutions.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/288620/high-temperature-coating-market

Market Overview & Regional Analysis

North America leads global demand with a USD 337.43 million market value in 2023, driven by advanced manufacturing sectors and strict industrial safety regulations. The region benefits from strong aerospace and automotive industries, where thermal protection is critical for engine components and exhaust systems.

Asia-Pacific shows the fastest growth trajectory, with China and Japan emerging as manufacturing hubs for industrial equipment requiring heat-resistant solutions. Europe maintains steady demand through its chemical processing sector, while the Middle East's oil & gas industry continues to drive specialized coating requirements.

Key Market Drivers and Opportunities

The market is primarily driven by escalating safety standards in manufacturing, expanding aerospace fleets, and automotive lightweighting trends that require advanced thermal protection. Industrial applications account for 42% of global demand, followed by automotive at 28% and aerospace at 18%.

Emerging opportunities include the development of eco-formulations to meet VOC regulations and nanotechnology applications that enhance thermal resistance properties. The renewable energy sector, particularly solar thermal plants, presents new avenues for high-performance coating solutions.

Challenges and Restraints

The industry faces hurdles including raw material price volatility, complex application processes requiring skilled labor, and competition from alternative thermal barrier technologies. Environmental regulations concerning solvent-based formulations continue to push manufacturers toward innovative, compliant solutions while maintaining performance standards.

Market Segmentation by Type

Liquid Resin and Polymer Coatings

Heat-Resistant Powder Coatings

Other Specialty Formulations

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/288620/high-temperature-coating-market

Market Segmentation by Application

Automotive Components

Aerospace Systems

Industrial Equipment

Energy Generation

Marine Applications

Construction Materials

Competitive Landscape

The market features established players and innovative specialists including:

AkzoNobel NV

PPG Industries

Sherwin-Williams

Axalta Coating Systems

Jotun Group

Hempel A/S

Belzona International

Aremco Products

Carboline Company

Nippon Paint

Report Scope

This comprehensive analysis covers the global high-temperature coating market from 2024 to 2032, providing detailed insights into:

Market size estimations and growth projections

Application-specific demand analysis

Technology and material advancements

Regional market dynamics

Regulatory landscape impacts

The report includes in-depth profiles of key players, examining their product portfolios, manufacturing capabilities, and strategic initiatives shaping the industry's competitive environment.

Get Full Report Here: https://www.24chemicalresearch.com/reports/288620/high-temperature-coating-market

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

Plant-level capacity tracking

Real-time price monitoring

Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

Other Related Reports:

0 notes

Text

Sealing Coatings Market Industry Competition Analysis, Size and Forecast Till 2025-2033

The Reports and Insights, a leading market research company, has recently releases report titled “Sealing Coatings Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033.” The study provides a detailed analysis of the industry, including the global Sealing Coatings Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Sealing Coatings Market?

The global sealing coatings market was valued at US$ 3.6 Billion in 2024 and is expected to register a CAGR of 5.2% over the forecast period and reach US$ 5.7 Billion in 2033.

What are Sealing Coatings?

Sealing coatings are substances applied to surfaces to form a protective layer that guards against moisture, chemicals, corrosion, and other environmental factors. They are utilized on various surfaces like concrete, metal, and wood to prevent harm and prolong the lifespan of the substrate. Commonly used in construction, automotive, and industrial sectors, these coatings enhance durability and preserve the aesthetic appeal of surfaces.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1788

What are the growth prospects and trends in the Sealing Coatings industry?

The sealing coatings market growth is driven by various factors. The sealing coatings market is experiencing consistent growth due to rising demand for protective coatings across industries like construction, automotive, and manufacturing. These coatings safeguard surfaces against corrosion, moisture, and environmental damage, boosting the longevity of materials. As technology advances and sustainability gains importance, the sealing coatings market is poised for further expansion, offering a variety of solutions to meet the diverse needs of various industries. Hence, all these factors contribute to sealing coatings market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

Resin Type:

Acrylic

Silicone

Polyurethane

Epoxy

Others

Substrate:

Metal

Concrete & Masonry

Wood

Plastic

Others

End-Use Industry:

Building & Construction

Automotive

Industrial

Marine

Aerospace

Electrical & Electronics

Others

Application:

Roofing

Flooring

Walls & Ceilings

Windows & Doors

Tank Linings

Others

Technology:

Water-based

Solvent-based

Radiation-cured

Powder-based

Others

Sales Channel:

Direct Sales

Distributor Sales

Online Sales

Price Range:

Economy

Mid-Range

Premium

Functionality:

Waterproofing

Corrosion Resistance

Thermal Resistance

Chemical Resistance

Others

Curing Type:

Air Cure

Heat Cure

Moisture Cure

Others

Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

3M Company

Akzo Nobel N.V.

Axalta Coating Systems

BASF SE

Dow Inc.

Henkel AG & Co. KGaA

Hempel A/S

Jotun Group

Nippon Paint Holdings Co., Ltd.

PPG Industries, Inc.

RPM International Inc.

Sherwin-Williams Company

Sika AG

Tikkurila Oyj

Wacker Chemie AG

View Full Report: https://www.reportsandinsights.com/report/Sealing Coatings-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Antimicrobial Glass Powder Market Sees Strong Growth Due to Rising Hygiene and Safety Standards

The Antimicrobial Glass Powder Market is gaining significant momentum as global industries increasingly prioritize hygiene and safety. The post-pandemic era has seen heightened awareness around cleanliness, especially in sectors where sterility and contamination control are paramount. As a result, antimicrobial materials, particularly glass-based powders, are seeing widespread adoption across healthcare, consumer goods, construction, and packaging industries.

Glass powder infused with antimicrobial agents offers a durable and long-lasting solution to mitigate microbial growth on surfaces. Its effectiveness, sustainability, and versatility make it a preferred choice for companies seeking to enhance product safety while maintaining regulatory compliance and brand reputation.

Rising Demand in Healthcare and Medical Applications

Healthcare remains the largest contributor to the expansion of the Antimicrobial Glass Powder Market, as hospitals and clinics urgently adopt materials that can limit the spread of infections. The need to maintain sterile environments in operating rooms, patient wards, and diagnostic labs has never been more pressing.

Antimicrobial glass powders are now widely used in:

Coatings for surgical tools and medical equipment

Hospital surface materials such as countertops and bed frames

Wall paints and floor tiles in high-contact zones

The inorganic nature of glass powder ensures long-term microbial resistance without degrading or requiring frequent reapplication. This is particularly important in healthcare settings, where safety and durability are equally vital. Regulatory agencies like the FDA and EPA are also encouraging the use of permanent antimicrobial solutions, further boosting market demand.

As healthcare infrastructure expands globally, especially in developing nations, demand for safe, infection-resistant materials is set to grow. This trend is propelling both domestic production and international trade of antimicrobial glass powders.

Expansion Across Consumer and Commercial Products

The Antimicrobial Glass Powder Market is also experiencing notable traction in the consumer electronics and home appliance segments. With increasing awareness about surface-transmitted bacteria and viruses, manufacturers are embedding antimicrobial properties into devices that are frequently touched, such as smartphones, tablets, remote controls, and kitchen appliances.

In consumer goods, glass powder coatings are being used to enhance the safety and longevity of everyday products. This includes:

Packaging for cosmetics and pharmaceuticals

Household fixtures such as faucets, handles, and tiles

High-touch electronics like ATM screens and kiosks

Not only do these innovations offer health benefits, but they also serve as valuable marketing features for brands looking to differentiate themselves in a competitive marketplace.

In retail and commercial buildings, antimicrobial coatings are becoming standard in public spaces such as malls, offices, and airports. These coatings, often enhanced with glass powders, reduce the microbial load on high-touch surfaces and help businesses align with post-COVID cleanliness standards.

Manufacturing and Construction Industry Adoption

Industrial sectors such as manufacturing and construction are integrating antimicrobial solutions to enhance safety in work environments. The Antimicrobial Glass Powder Market is playing a pivotal role in this transition by providing materials that combine antimicrobial protection with mechanical resilience.

Glass powders are being incorporated into:

Epoxy floor coatings in warehouses and production areas

Cement and paint formulations used in public infrastructure

HVAC components and insulation materials

These applications help prevent the buildup of harmful bacteria in industrial environments, thus ensuring cleaner and safer spaces for workers and customers alike. The durability of glass-based antimicrobial agents also ensures that these benefits are retained over long periods with minimal maintenance.

With growing emphasis on workplace hygiene and indoor air quality, particularly in shared facilities, the demand for antimicrobial building materials is on the rise globally.

Regulatory Standards Driving Market Growth

One of the most influential factors propelling the Antimicrobial Glass Powder Market forward is the increasingly stringent regulatory environment. Health and safety bodies worldwide are enforcing compliance with higher cleanliness and antimicrobial performance standards, especially in sectors dealing with food, medicine, and public health.

For example:

The EU’s Biocidal Products Regulation (BPR) supports the use of non-toxic, long-lasting antimicrobial technologies

U.S. Environmental Protection Agency (EPA) has approved several antimicrobial additives for industrial and consumer use

Asian markets, including China and India, are rapidly aligning with international standards to enhance export capabilities and public safety

These regulations are encouraging industries to adopt proven, low-risk antimicrobial solutions like glass powder, which not only pass compliance checks but also enhance consumer trust in the end product.

Innovation and Sustainability Driving Future Potential

Another key growth factor in the Antimicrobial Glass Powder Market is the ongoing innovation in product design and environmental responsibility. Manufacturers are developing powders with additional benefits such as:

UV resistance

Scratch resistance

Thermal insulation

Recyclability and low environmental impact

These multifunctional powders provide added value to industries aiming for both performance and sustainability. The ability to integrate these materials into existing manufacturing lines with minimal adjustment further enhances their appeal.

Sustainable and recyclable formulations are gaining traction, particularly among companies focused on ESG (Environmental, Social, and Governance) goals. As industries move toward greener production, antimicrobial glass powders that offer eco-friendly advantages are expected to lead the way.

Regional Insights and Market Outlook

The global Antimicrobial Glass Powder Market is seeing strong growth across key regions:

North America leads in innovation and healthcare usage

Europe focuses on sustainable, regulatory-compliant adoption

Asia-Pacific is rapidly scaling production due to infrastructure growth and export focus

Emerging economies in Latin America and the Middle East are also showing interest, especially in healthcare and urban development sectors. As awareness and demand rise, so will competition among manufacturers to provide cost-effective, customizable, and scalable antimicrobial solutions.

Conclusion

The Antimicrobial Glass Powder Market is expanding rapidly, driven by rising global hygiene standards and the need for safer, more durable materials across industries. From healthcare to consumer goods and construction, the versatility of antimicrobial glass powders is proving essential in the fight against harmful pathogens. With innovation, sustainability, and regulatory support shaping the market, its future outlook remains highly promising.

#AntimicrobialGlassPowder#HygieneStandards#WorkplaceSafety#HealthcareMaterials#SmartSurfaces#SurfaceProtection#ConsumerSafety#ConstructionTrends#SustainableMaterials#AntimicrobialCoatings

0 notes