#Ethylene Vinyl Acetate Industry

Link

Vinyl Acetate - Ethylene Copolymer Emulsion Market Report: 2023-2029 Vinyl Acetate - Ethylene Copolymer Emulsion Market (Newly published report) which covers Market Overview, Future Economic Impact, Competition by Manufacturers, Supply (Production), and Consumption Analysis Get

0 notes

Text

Understanding the Role of Pour Point Depressants in Oilfield Operations

Pour point depressants are chemical additives used to lower the freezing point or viscosity point of a fluid. They ensure that nothing gets stuck or frozen over, which is especially crucial in the winter. When it comes to controlling the pour point of oils and fuels, nobody will assist you better than a leading Pour Point Depressant manufacturer in India. By altering the crystal structure of waxy components in crude oils, lubricants, and diesel fuels, these additives reduce the pour points of these substances and enhance their flow properties at low temperatures.

They have a large range of pour point depressants available, and we are a distinguished Pour Point Depressant exporter in Syria, exporting quality PPDs to Oil and Gas industry in Syria as well as other countries. These additives lower the pour points and improve the low-temperature flow characteristics of crude oils, lubricants, and diesel fuels by modifying the crystal structure of waxy components in these substances.

What are Pour Point Depressants used for?

Depressants of the pour point are additives used to make lubricants and fuels more fluid at low temperatures. These chemicals are crucial in a wide variety of applications where it is necessary to maintain fluid flow despite freezing conditions. Imperial Oilfield Chemicals is your best option for locating a dependable pour point depressant producer in India or a supplier in Syria.

The waxes and paraffin present in oils and fuels tend to solidify when exposed to low temperatures, generating a network that impedes the free movement of the fluids. Pour point depressants function by changing the crystal structure of these ingredients, reducing the viscosity of the fluid. Even at low temperatures, the fluid is able to flow more freely because of this.

The oil and gas industry relies significantly on pour point depressants when transporting, storing, and managing petroleum products like crude oils, lubricants, diesel fuels, and more. The aerospace, automotive, maritime, and industrial industries all make use of them. They make it possible for car engines to start and function normally in freezing conditions. In the aviation sector, pour point depressants help keep fuel flowing freely and prevent fuel lines from clogging.

Types of Pour Point Depressants:

Pour point depressants (PPDs) are additives added to lubricants and fuels to increase their viscosity at low temperatures. For example:

Polymethacrylates

Ethylene Vinyl Acetate (EVA) Copolymers

Polyalkyl Methacrylates

Polyacrylates

Copolymers of Styrene and Esters

Polyalkylphenols

These pour point depressants are just a sampling of the numerous available options. Several factors, including the type of oil or fuel, the desired amount of pour point reduction, and the requirements of the application at hand, all play a role in determining which PPD to use.

How to choose the suitable Pour Point Depressant for your Oilfield application?

Several factors should be taken into account when deciding on a pour point depressant (PPD) for usage in the oil industry. Imperial Oilfield Chemicals, a renowned Pour Point Depressant manufacturer in India and Pour Point Depressant supplier in Syria offers helpful guidance during the selection procedure.

Compatibility

Performance Requirements

Environmental Considerations

Application Method

Field Conditions

Expertise and Support

The Role of Pour Point Depressants in Oilfield Operations:

Pour point depressants (PPDs) are crucial to oilfield operations because they improve the low-temperature flow properties of oils and fuels. The oil and gas sector relies heavily on Pour Point Depressants (PPDs), and Imperial Oilfield Chemicals is the well-known Pour Point Depressant exporter in Syria.

PPDs are used in oilfield operations to lower the pour point, or the temperature at which a fluid becomes too viscous to flow freely. This is especially important in climates where colder temperatures make it harder to transport lubricants and fuels. By disrupting the crystal structures of the waxy components, PPDs prevent the development of solid networks and reduce the viscosity of the fluids.

PPDs maintain efficiency by regulating the pour point, which guarantees continuous fluid flow. Shipping, storing, and managing lubricants, diesel fuels, and crude oils are all significant applications. PPDs allow operations to continue without interruption and decrease the probability of costly equipment failure because fluids may flow freely even when temperatures are low.

Final Thoughts:

PPDs are especially helpful in cold environments or throughout the winter since they regulate the pour point and prevent fluid flow disruptions. If you're looking for a reliable Pour Point Depressant supplier in Syria, or anywhere in the world, go no further than Imperial Oilfield Chemicals.

When oilfield operators have a strong grasp on the role performed by pour point depressants, they are better able to handle the dangers associated with low temperatures. With the assistance of manufacturers and suppliers like Imperial Oilfield Chemicals Pvt. Ltd., operators may select the optimal PPDs for their operations.

#Pour Point Depressant Supplier in Syria#Pour Point Depressant Manufacturer in India#Pour Point Depressant Exporter in Syria

6 notes

·

View notes

Text

Mulch Films Market Forecast 2024-2033

Overview and Scope

Mulch films refer a plastic film used to alter soil temperature, stop moisture growth, control weed growth, and increase crop production. It is used for large-scale fruit and vegetable farming to retain soil moisture, which controls soil temperature, and stops water from evaporating.

Sizing and Forecast

The mulch films market size has grown strongly in recent years. It will grow from $4.32 billion in 2023 to $4.67 billion in 2024 at a compound annual growth rate (CAGR) of 8.1%. The growth in the historic period can be attributed to aging population, minimally invasive procedures, increased awareness and diagnosis, healthcare infrastructure development, prevalence of aneurysms, fda approvals..

The mulch films market size is expected to see strong growth in the next few years. It will grow to $6.15 billion in 2028 at a compound annual growth rate (CAGR) of 7.1%. The growth in the forecast period can be attributed to rise in endovascular therapies, increased demand for medical products, focus on stroke prevention, growing healthcare expenditure, research and development investments.. Major trends in the forecast period include advancements in catheter technologies, ai enabled diagnosis and intervention, integration of imaging technologies, product innovations, collaborations and partnerships..

Segmentation & Regional Insights

The mulch films market covered in this report is segmented -

1) By Product Type: Non-Biodegradable, Biodegradable

2) By Material Type: Polyethylene, Polypropylene, Polyvinyl Chloride, Polylactic Acid /Polyhydroxyalkanoates, Polybutylene Succinate, Ethylene-Vinyl Acetate, Other Bio-Based Material

3) By Application: Agriculture, Horticulture

Asia-Pacific was the largest region in the mulch films market in 2023. The regions covered in the mulch films market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa

Major Driver Impacting Market Growth

Increasing demand for food is expected to propel the growth of the mulch films market going forward. Food refers to a material that is mostly made of protein, carbohydrates, and fat and is used by living things as fuel for crucial functions such as development and repair. Demand for food is met when the quantity and quality of crops are maintained. Mulch films for food production are extremely helpful, as these films modify the soil’s temperature, prevent moisture loss from the soil, conserve water, and minimize the spread of weeds. For instance, In July 2022, according to United Nations, a US-based intergovernmental organization, the global number of individuals experiencing hunger surged to approximately 828 million in 2021, marking a rise of about 46 million from 2020 and an alarming increase of 150 million since the onset of the COVID-19 pandemic. Therefore, the increasing demand for food is driving the growth of the mulch film market.

Key Industry Players

Major companies operating in the mulch films market report are The Dow Chemical Company, BASF SE, FKuR Kunststoff GmbH, Novamont S.p.A., Berry Global Inc., AEP Industries Inc., Trioplast Industrier AB, Tilak Polypack Private Limited, AB Rani Plast Oy, RKW Agri Gmbh & Co.KG, Armando Alvarez Group, BioBag International AS, Industrial Development Company Sal, ExxonMobil Corporation, Ginegar Plastic Products Ltd., Shandong Tianhe Plastic Co. Ltd., Kuraray Co. Ltd., Qingdao Huaxuyang Industrial Co. Ltd., Macro Plastic Sdn. Bhd., Plastika Kritis S.A., Organix AG, Al-Pack Enterprises Ltd., Barbier Group, British Polythene Industries, Cofco Tunhe Co. Ltd., Dubois Agrinovation Inc., Eiffel Trading Company, Pooja Plastic Industries, The Armando Alvarez Group, Guangdong Zhongxing Plastic Products Co. Ltd., Henan Yinfeng Plastic Co. Ltd., Hopewell Industries, Hyplast NV, Iris Polymers Industries Pvt. Ltd., Jindal Poly Films Ltd., Kung Hsing Plastic Machinery Co. Ltd., Laiwu Huaya Polymer Sci.& Tech. Co. Ltd.

The mulch films market report table of contents includes:

1. Executive Summary

2. Mulch Films Market Characteristics

3. Mulch Films Market Trends And Strategies

4. Mulch Films Market — Macro Economic Scenario

5. Global Mulch Films Market Size and Growth

.

.

.

31. Global Mulch Films Market Competitive Benchmarking

32. Global Mulch Films Market Competitive Dashboard

33. Key Mergers And Acquisitions In The Mulch Films Market

34. Mulch Films Market Future Outlook and Potential Analysis

35. Appendix

Explore the trending research reports from TBRC:

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

0 notes

Text

0 notes

Text

0 notes

Text

Foam Sheets: The Versatile Material You Didn't Know You Needed

Introduction

In the world of DIY projects, crafts, and construction, finding the right materials can make all the difference. Foam sheets are one such versatile material that often goes unnoticed. From cushioning delicate items to creating stunning art pieces, foam sheets offer endless possibilities. In this blog post, we'll explore the various types of foam sheets, their uses, and why they should be a staple in your material collection.

Types of Foam Sheets

Foam sheets come in various types, each with unique properties suited for different applications:

Polyethylene Foam Sheets: Known for their excellent shock absorption and insulation properties, these sheets are ideal for packaging and protecting delicate items.

Polyurethane Foam Sheets: These are highly flexible and can be used for cushioning, padding, and soundproofing. They are often found in furniture, mattresses, and automotive interiors.

EVA Foam Sheets: Ethylene Vinyl Acetate (EVA) foam sheets are lightweight, durable, and resistant to UV radiation. They are perfect for creating costumes, props, and craft projects.

PVC Foam Sheets: These sheets are rigid, lightweight, and resistant to moisture and chemicals, making them suitable for signage, displays, and outdoor applications.

Creative Uses for Foam Sheets

Foam sheets are incredibly versatile and can be used in a variety of creative and practical ways:

Craft Projects: EVA foam sheets are a favorite among crafters. They can be easily cut, shaped, and glued to create costumes, masks, decorations, and models.

Packaging and Protection: Polyethylene foam sheets provide excellent cushioning for fragile items during shipping. They can be custom-cut to fit around objects, preventing damage.

Soundproofing: Polyurethane foam sheets are widely used in studios, offices, and homes to reduce noise levels. They can be installed on walls, ceilings, and floors to absorb sound.

Home Décor: Foam sheets can be used to create custom wall art, headboards, and even furniture pieces. Their lightweight nature makes them easy to work with and install.

Education: Teachers and parents can use foam sheets for educational purposes, such as creating interactive learning tools, sensory boards, and puzzles.

Advantages of Using Foam Sheets

Foam sheets offer numerous benefits that make them a popular choice across various industries:

Lightweight: Foam sheets are easy to handle and transport, making them convenient for both DIY enthusiasts and professionals.

Durable: Despite their lightweight nature, foam sheets are durable and long-lasting, providing excellent value for money.

Versatile: Available in different densities, thicknesses, and types, foam sheets can be used for a wide range of applications.

Easy to Work With: Foam sheets can be cut, shaped, and glued with ease, allowing for creativity and customization.

Affordable: Foam sheets are cost-effective, making them accessible for various projects, from small crafts to large-scale constructions.

Tips for Working with Foam Sheets

To get the best results from your foam sheet projects, consider the following tips:

Choose the Right Type: Select the type of foam sheet that best suits your project needs. For example, use EVA foam for crafts and costumes, and polyethylene foam for packaging.

Use Sharp Tools: Ensure your cutting tools are sharp to achieve clean and precise cuts. Dull blades can tear the foam and result in uneven edges.

Experiment with Adhesives: Not all adhesives work well with foam. Test different types of glue to find the one that provides the best bond for your specific foam sheet and project.

Take Safety Precautions: When cutting or shaping foam sheets, work in a well-ventilated area and wear protective gear to avoid inhaling any dust or fumes.

Plan Your Design: Sketch your design and plan your cuts before starting to ensure efficient use of materials and minimize waste.

Conclusion

Foam sheets are a hidden gem in the world of materials, offering versatility, durability, and affordability. Whether you're a crafter, DIY enthusiast, or professional, foam sheets can enhance your projects and open up new creative possibilities. So next time you're planning a project, consider incorporating foam sheets – you might be surprised at what you can create!

0 notes

Text

Global Top 5 Companies Accounted for 85% of total PV Modules market (QYResearch, 2021)

An encapsulant is used to provide adhesion between the solar cells, the top surface and the rear surface of the PV module. The encapsulant should be stable at elevated temperatures and high UV exposure. It should also be optically transparent and should have a low thermal resistance. EVA (ethyl vinyl acetate) is the most commonly used encapsulant material. EVA comes in thin sheets which are inserted between the solar cells and the top surface and the rear surface. This sandwich is then heated to 150 °C to polymerize the EVA and bond the module together.

Encapsulant materials used in photovoltaic (PV) modules serve multiple purposes; it provides optical coupling of PV cells and protection against environmental stress. Polymers must perform these functions under prolonged periods of high temperature, humidity, and UV radiation. When PV panels were first developed in the 1960s and the 1970s, the dominant encapsulants were based on polydimethyl siloxane (PDMS). Ethylene-co-vinyl acetate (EVA) is currently the dominant encapsulant chosen for PV applications, not because it has the best combination of properties, but because it is an economical option with an established history of acceptable durability. Getting new products onto the market is challenging because there is no room for dramatic improvements, and one must balance the initial cost and performance with the unknowns of long-term service life. Recently, there has been renewed interest in using alternative encapsulant materials with some significant manufacturers switching from EVA to polyolefin elastomer-based (POE) alternatives.

According to the new market research report “Global PV Modules Market Report 2023-2029”, published by QYResearch, the global PV Modules market size is projected to reach USD 7.38 billion by 2029, at a CAGR of 11.2% during the forecast period.

Figure. Global PV Modules Market Size (US$ Million), 2018-2029

Figure. Global PV Modules Top 5 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of PV Modules include First, Sveck, HIUV, Bbetter, Cybrid Technologies, 3M, Hanwha, Lucent CleanEnergy, Vishakha Renewables, Tianyang, etc. In 2021, the global top five players had a share approximately 85.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

How EVA Cow / Buffalo Mats is useful in Modern Dairy Farm.

Cow mats or Buffalo mats also known as cow / buffalo mattresses. Today in modern dairy farm these type of mats serves a vital role. Most of the dairy farms mostly used sand, straw, or brick concrete as bedding or floor surface.

EVA cow / buffalo mats used in India more than 5-6 years. “The Supreme Industries Limited” recently introduce EVA (ethylene vinyl acetate) technology cow / buffalo mats…

View On WordPress

0 notes

Text

Guardian Glass: Exploring the World of Laminated Safety Glass

In the realm of architectural materials, safety and aesthetics often go hand in hand. Enter laminated safety glass, a remarkable innovation that not only enhances the visual appeal of buildings but also prioritizes the security and well-being of occupants. As we delve into the world of Guardian Glass, we uncover the fascinating journey of laminated safety glass and its transformative impact on architectural design and safety standards.

Guardian Glass: A Legacy of Innovation:

Guardian Glass stands as a beacon of innovation in the glass industry, renowned for its commitment to excellence and safety. With a legacy spanning decades, Guardian Glass has continually pushed the boundaries of technology to deliver cutting-edge solutions that meet the evolving needs of architects, designers, and building owners worldwide. At the heart of their portfolio lies laminated safety glass, a testament to their unwavering dedication to quality and performance.

The Science of Laminated Safety Glass:

At its core, laminated safety glass is a marvel of engineering, comprising multiple layers of glass bonded together with interlayers of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA) resin. This laminated construction imbues the glass with remarkable strength and durability, making it highly resistant to impact, breakage, and penetration. In the event of breakage, the interlayer holds the glass fragments together, preventing them from dispersing and minimizing the risk of injury—a crucial feature in safety-critical applications.

Enhancing Security and Protection:

Beyond its safety benefits, laminated glass also serves as a formidable barrier against forced entry, vandalism, and severe weather events. Its tough, shatter-resistant properties provide peace of mind to building occupants, safeguarding them against potential threats while maintaining transparency and visual clarity. From storefronts to curtain walls, from skylights to balustrades, Guardian laminated safety glass offers unparalleled protection without compromising on aesthetics.

Versatility in Design:

One of the most remarkable aspects of Guardian laminated safety glass is its versatility in design. Available in a wide range of thicknesses, tints, and finishes, laminated glass can be customized to suit virtually any architectural style or aesthetic preference. Whether it's creating striking facades with tinted glass panels or incorporating decorative interlayers for artistic flair, architects have the freedom to unleash their creativity and bring their vision to life with Guardian laminated safety glass.

Sustainable Solutions for a Safer Future:

In an era where sustainability is paramount, Guardian Glass remains committed to environmental stewardship, offering laminated safety glass solutions that prioritize energy efficiency and resource conservation. By optimizing glass compositions, manufacturing processes, and recycling initiatives, Guardian Glass strives to minimize its environmental footprint while delivering sustainable solutions that contribute to a safer, greener future for generations to come.

Conclusion:

As we conclude our exploration of Guardian Glass and the world of laminated safety glass, it's evident that this innovative material transcends mere functionality—it's a symbol of safety, security, and design excellence. From iconic skyscrapers to humble storefronts, Guardian laminated safety glass has become an indispensable element of modern architecture, enriching spaces with beauty, resilience, and peace of mind. As we look to the future, Guardian Glass continues to lead the way, pioneering new technologies and setting new standards for safety, sustainability, and innovation in the glass industry.

0 notes

Text

From Vinegar to Versatility: Unveiling Acetic Acid's Production Journey and Multifaceted Applications

Vinegar. That pantry staple we splash on salads and fries. But did you know this common household item packs a surprising scientific punch? The key ingredient in vinegar is Acetic Acid, a clear, colorless liquid with a powerful odor that's sure to clear your sinuses. Acetic Acid is much more than just a souring agent. It's a workhorse in the chemical world, playing a crucial role in the production of countless everyday items. From the plastics in your water bottle to the medicines in your cabinet, Acetic Acid might be lurking behind the scenes.

In this blog, we'll delve deeper into the fascinating world of Acetic Acid. We'll explore its surprising range of uses, from the industrial to the culinary, and uncover the science behind its unique properties. So, whether you're a curious cook or a science enthusiast, get ready to learn a whole new side to the humble vinegar you know and love!

Introduction

Acetic Acid, a clear organic compound with a strong odor and tart flavor, is industrially synthesized through methanol carbonylation or ethylene oxidation. Methanol carbonylation is the preferred method over ethylene oxidation. Key technology providers for Acetic Acid production include British Petroleum, Celanese, Eastman's acetyls technology, and LyondellBasell. Similar to ethanol, Acetic Acid is a water-friendly solvent, readily mixing with water, chloroform, and hexane, and dissolving substances such as oils, sulfur, and iodine.

It serves as a chemical precursor for various compounds like acetic anhydride, esters, vinyl acetate monomer (VAM), and various polymers. Acetic Acid is also utilized in vinegar production, where it constitutes 5 percent of the solution, finding applications in the food and beverage industry for marinades, pickling solutions, and salad dressings. Additionally, vinegar, containing Acetic Acid, can be added during food preparation to minimize contamination in meat and poultry products.

Manufacturing Process

Acetic Acid primarily undergoes production through chemical methods, utilizing both homogeneous and heterogeneous catalytic processes. The predominant method involves the carbonylation of methanol, a process initially established by Monsanto, which has since progressed into the Cavita process. This evolved approach offers flexibility in catalyst selection and incorporates advancements in process intensification techniques.

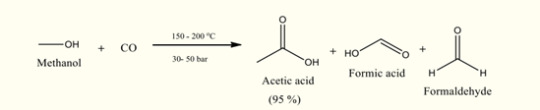

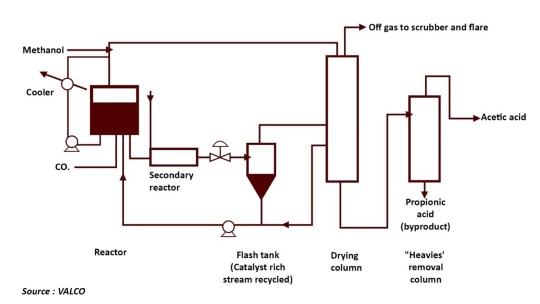

Methanol carbonylation process:

• The carbonylation process, commonly referred to as the Monsanto process, stands as the predominant commercial method for synthesizing Acetic Acid.

• Methanol and carbon monoxide undergo a liquid-phase reaction under the influence of a rhodium (Rh)-based catalyst at temperatures ranging between 150 to 200 degrees Celsius and pressures between 30 to 50 bar, yielding Acetic Acid with a selectivity of around 95% and minor side products including formic acid and formaldehyde.

• In this process, hydrogen iodide serves as an alkali promoter, with the reaction occurring in the liquid phase and methyl acetate acting as a solvent using a homogeneous catalyst. The controlled introduction of water is necessary for the reaction, which is generated in situ through the reaction of methanol with hydrogen iodide.

• The reaction rate in the Monsanto process is directly influenced by the concentration of water. Byproducts such as CO2, H2, and methanol are generated during the reaction, with the produced methanol being recycled. Over time, the process has undergone evolution, with various strategies implemented to separate pure Acetic Acid from a mixture of water and byproducts. BP Chemicals modified this process by substituting the rhodium-based catalyst with an Iridium (Ir) catalyst, resulting in what is known as the Cavita process.

• The selection of Ir as a coordination metal presents a relatively more economical approach compared to rhodium. The use of an iridium catalyst enhances the overall reaction rate.

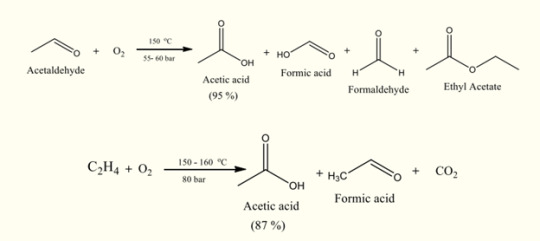

The following chemical reaction represents the same:

Acetaldehyde oxidation process

• The acetaldehyde oxidation method was one of the largely used method used for synthesizing Acetic Acid. Initially, acetaldehyde was prepared through the oxidation of ethylene, employing palladium and copper chloride catalysts, after which it underwent further oxidation to yield Acetic Acid.

• Alternatively, a similar procedure utilizing cobalt and chromium-based catalysts has been documented, operating at a pressure of 55 bar and a temperature of 150 degrees Celsius. Another variant of this process involves a one-step conversion of ethylene to Acetic Acid, employing lead and lead-platinum based catalysts at elevated pressures, in contrast to the acetaldehyde oxidation method, albeit with lower Acetic Acid yields.

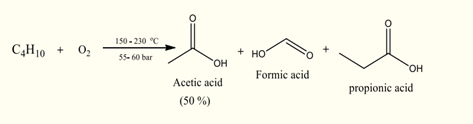

Hydrocarbon oxidation process

• Petroleum-derived hydrocarbons, including butane and naphtha, serve as the primary sources for producing Acetic Acid, a crucial chemical compound, through a reaction catalyzed by cobalt acetate and chromium acetate.

• This chemical transformation unfolds within a relatively elevated temperature range of 150-230°C and under pressures ranging from 50 to 60 bar. The utilization of petroleum feedstock, comprising a diverse hydrocarbon blend, initiates a multifaceted reaction pathway leading to the synthesis of not only Acetic Acid but also a spectrum of byproducts, notably acetone, formic acid, and propionic acid, alongside the target compound. Consequently, the resultant Acetic Acid may not exhibit a high degree of purity due to the coexistence of these impurities.

• However, this process's strength lies in its capability to generate a mixture of volatile fatty acids, rendering it more suitable for applications necessitating such a blend. Therefore, while it may not yield pristine Acetic Acid, this method finds relevance in industrial contexts where a mixture of volatile fatty acids is desirable. This underscores the importance of understanding the nuanced outcomes of chemical processes and tailoring them to meet specific industrial requirements.

Applications of Acetic Acid

1. Food & Beverages

Acetic Acid finds its primary application in the culinary sector, predominantly in the form of vinegar. Throughout history, it has served as a condiment, flavor enhancer, and preservative in pickling. Vinegar remains integral in various processed foods, including mayonnaise, due to its typical sour flavor and preserving properties. Acetic Acid finds application in preserving and pickling various food items such as vegetables and fruits, effectively thwarting spoilage and prolonging their shelf life. Its presence contributes to the characteristic tanginess observed in pickled foods.

2. Chemical Intermediates

Acetic Acid serves as a vital chemical reagent in the synthesis of various compounds. Its primary application lies in the production of vinyl acetate monomer, followed closely by acetic anhydride and ester production. While Acetic Acid is commonly associated with vinegar, its usage volume in this context is relatively minor compared to its extensive utilization in industrial processes for the production of essential chemical compounds. Acetic Acid serves as a foundational component in the production of various chemicals, including vinyl acetate, acetic anhydride, and acetate esters. Vinyl acetate is utilized in the synthesis of polyvinyl acetate, a versatile polymer applied in paints, adhesives, plastics, and textile finishes. Acetic anhydride finds application in the manufacturing of cellulose acetate fibers and plastics used in photographic film, clothing, and coatings. Furthermore, Acetic Acid plays a crucial role in the chemical process to produce purified terephthalic acid (PTA), essential for manufacturing PET plastic resin. PET resin is extensively employed in synthetic fibers, food containers, beverage bottles, and plastic films.

3. Cosmetics

Acetic Acid is a common component in many cosmetic items. It serves as an ingredient in hair conditioners, shampoos, and various other hair care products. Additionally, derivatives of Acetic Acid, such as alkyl acetates and acetate salts, contribute to the formulation of perfumes and skin conditioners. These derivatives play crucial roles in enhancing the effectiveness and sensory characteristics of cosmetic formulations, ensuring optimal performance and user satisfaction across a range of personal care applications.

4. Household Cleaners

Due to its acidic nature, Acetic Acid serves as a potent cleaning agent and disinfectant, commonly employed for sanitizing windows, countertops, and various surfaces in both residential and industrial environments. It presents a natural substitute for harsher chemicals and is particularly adept at removing limescale buildup in appliances like kettles and coffee makers. Its versatility extends to diverse cleaning tasks, offering an effective and eco-friendly solution for maintaining cleanliness and hygiene.

Market Outlook

The Acetic Acid market is influenced by the combination of industrial, economic, and regulatory factors. The main factors that drive the demand are the growing need in different industries like textiles, packaging, automotive, and construction, where Acetic Acid is a key component in the production of vinyl acetate monomer (VAM), purified terephthalic acid (PTA), acetate esters, and solvents. Besides, the chemical industry, which is growing especially in the developing countries such as China and India, is one of the factors that leads to the increase of the demand for Acetic Acid since it is a basic material for the production of many chemicals. Besides, the increase in the adhesive and sealant industry, caused by the rising construction activities and the demand for consumer goods, also brings the Acetic Acid demand up. The fast urbanization and the infrastructure development projects across the globe also are the reason behind the growth of the market, as Acetic Acid is a necessary component of the construction materials like paints, coatings, and adhesives.

Acetic Acid Major Global Players

Major players in the Global Acetic Acid market are Celanese Corporation, Eastman Chemical Company, LyondellBasell Industries N.V., Yangtze River Acetyls Co. Ltd (YARACO), The Saudi International Petrochemical Company (Sipchem), INEOS PCG ACETYLS SDN BHD (IPASB), Lotte BP Chemical, Gujarat Narmada Valley Fertilizer and Chemicals, Formosa BP Chemicals Corporation, British Petroleum, Formosa BP Chemicals Corporation, Formosa INEOS Chemicals Corporation (FBPCC), EuroChem Group AG, and Others.

Conclusion:

To sum up, the Acetic Acid market is set to keep on growing and changing due to a wide range of factors such as industrial demand, regulatory shifts and technological advancements. Acetic Acid is a very important chemical which has many applications in all the industries such as textiles, automotive, construction, and so on. Thus, it is the essential chemical for the processes and products. The growing chemical industry, especially in the developing economies, is the evidence of the growing demand of Acetic Acid as a basic chemical in chemical synthesis. Besides, the increasing of adhesive and sealant industry, the rapid urbanization and infrastructure development of the world and the need for Acetic Acid in the construction materials and consumer goods are also the reasons for the growth of the demand for Acetic Acid. Besides, the industry's transformation to the bio-based production methods and sustainability initiatives is proof of the shift towards the more eco-friendly practices. The market will keep on changing; hence it is important for the stakeholders to be up to date with these trends and developments so that they can take advantage of the emerging opportunities and at the same time avoid the possible problems. In a nutshell, the Acetic Acid market is expected to be a great one in the future, due to the innovation, diversification of demand, and sustainability imperatives.

0 notes

Text

In the heart of Delhi, amidst the hustle and bustle of urban life, lies a beacon of sustainable energy—the solar panel manufacturing plant. As the demand for renewable energy continues to soar, these facilities play a crucial role in driving the transition towards a cleaner and greener future. In this article with Sova Solar, we'll take a closer look at the operations of a solar panel manufacturing plant in Delhi, shedding light on the processes, technologies, and impact of this burgeoning industry.

Solar panel manufacturing plants in Delhi are at the forefront of the city's renewable energy revolution, producing the components essential for harnessing solar power. As a leading solar module manufacturing company in Delhi, these facilities are equipped with state-of-the-art machinery and a skilled workforce dedicated to producing high-quality solar panels and components. From photovoltaic cells to tempered glass, every aspect of the solar panel is meticulously crafted to ensure efficiency, durability, and performance.

The solar panel manufacturing industry in Delhi encompasses a wide range of activities, including the production of solar cells, modules, and other key components. Solar component manufacturers in Delhi specialize in manufacturing components such as silicon wafers, back sheets, and frames, which are integral to the assembly of solar panels. By leveraging advanced manufacturing techniques and quality control measures, these companies ensure that each component meets stringent standards for reliability and efficiency.

Now, let's explore the inner workings of a solar panel manufacturing plant in Delhi:

Raw Material Procurement: The production process begins with the procurement of raw materials, including silicon wafers, glass, aluminum frames, and various chemicals. Solar panel makers in Delhi source these materials from trusted suppliers, ensuring the highest quality and adherence to industry standards. By establishing strategic partnerships and streamlining supply chain operations, manufacturers optimize production efficiency and reduce costs.

Cell Production:

The heart of a solar panel is the photovoltaic cell, which converts sunlight into electricity. Solar panel manufacturing plants in Delhi utilize cutting-edge technology to produce high-efficiency solar cells with minimal energy loss. Through processes such as doping, texturing, and passivation, manufacturers enhance the performance and durability of the cells, maximizing energy output and longevity.

Module Assembly:

Once the cells are fabricated, they are assembled into solar modules, also known as solar panels. Solar module manufacturing companies in Delhi employ automated assembly lines to streamline the production process and ensure consistency in quality. The cells are interconnected, encapsulated, and sealed within a protective layer of tempered glass and ethylene vinyl acetate (EVA) to withstand harsh environmental conditions.

Quality Control:

Quality control is a critical aspect of solar panel manufacturing, ensuring that each panel meets the required specifications for efficiency, reliability, and safety. Solar panel makers in Delhi implement rigorous testing procedures at various stages of production, including visual inspection, performance testing, and reliability testing. Any defects or deviations from standards are promptly addressed to maintain product integrity and customer satisfaction.

Packaging and Distribution:

Once the solar panels are manufactured and tested, they are carefully packaged to protect them during transportation and storage. Solar panel manufacturers in Delhi work closely with logistics partners to coordinate timely delivery to customers across the city and beyond. By optimizing packaging and logistics processes, manufacturers minimize lead times and ensure prompt delivery of solar panels to meet the growing demand for renewable energy solutions.

In conclusion, solar panel manufacturing plants in Delhi play a pivotal role in driving the city's transition towards clean and sustainable energy. By producing high-quality solar panels and components, these facilities contribute to reducing greenhouse gas emissions, mitigating climate change, and promoting energy independence. As the demand for solar energy continues to rise, solar module manufacturing companies in Delhi are poised to lead the charge towards a brighter and more sustainable future for the city and beyond.

1 note

·

View note

Text

Vinyl Acetate Monomer Prices, Price Trend, News, Analysis & Forecast

Vinyl Acetate Monomer (VAM) Prices: During the first quarter of 2024

Vinyl acetate monomer (VAM) prices are a critical indicator within the chemical industry, impacting various sectors including adhesives, coatings, and polymers. Understanding the dynamics of VAM pricing involves delving into the intricate balance between supply and demand, as well as the broader economic landscape. VAM, a key raw material in the production of polyvinyl acetate (PVA) and other copolymers, experiences fluctuations influenced by multiple factors.

One significant determinant of VAM prices is the supply chain dynamics. VAM production is primarily carried out through the ethylene-based process or the acetylene-based process. Ethylene, a crucial feedstock, experiences its own price variations influenced by factors like crude oil prices, geopolitical tensions, and supply disruptions. Consequently, any fluctuations in ethylene availability can directly impact VAM prices. Additionally, factors affecting the production capacity and efficiency of VAM plants, such as maintenance shutdowns or technological advancements, contribute to supply-side fluctuations.

Get Real Time Prices of Vinyl Acetate Monomer (VAM): https://www.chemanalyst.com/Pricing-data/vinyl-acetate-monomer-34

Demand dynamics play an equally crucial role in shaping VAM prices. The demand for VAM is closely tied to downstream industries such as construction, automotive, and textiles. Economic indicators like GDP growth, consumer spending, and construction activity heavily influence the demand for VAM-based products. For instance, during periods of economic expansion, the demand for adhesives and coatings used in construction and manufacturing tends to rise, subsequently driving up the demand for VAM. Conversely, economic downturns can lead to reduced demand for VAM-based products, exerting downward pressure on prices.

Global market trends and trade dynamics also impact VAM prices. The chemical industry is inherently globalized, with producers and consumers spread across different regions. Changes in trade policies, tariffs, and currency exchange rates can affect the flow of VAM between countries, thereby influencing its pricing dynamics. Moreover, shifts in demand patterns or the emergence of new markets can lead to changes in trade flows, impacting regional supply-demand balances and ultimately, prices.

Environmental regulations and sustainability initiatives represent another significant factor affecting VAM prices. With increasing emphasis on environmental stewardship and sustainability, regulatory changes aimed at reducing emissions and promoting eco-friendly materials can impact the production processes and costs associated with VAM. Compliance with stringent environmental standards may require investments in cleaner technologies or alternative feedstocks, potentially leading to higher production costs and, consequently, higher prices for VAM.

Market sentiment and speculative activities also contribute to price volatility in the VAM market. Traders, investors, and speculators closely monitor market trends, news, and geopolitical developments to anticipate future price movements. Sentiment-driven factors, such as market rumors, supply concerns, or geopolitical tensions, can trigger speculative buying or selling, amplifying price fluctuations in the short term.

In conclusion, Vinyl acetate monomer (VAM) prices are influenced by a complex interplay of factors including supply chain dynamics, demand trends, global market conditions, regulatory environment, and market sentiment. Understanding these dynamics is essential for stakeholders in the chemical industry to make informed decisions regarding production, procurement, pricing, and risk management strategies. As the chemical industry continues to evolve in response to economic, environmental, and technological changes, monitoring and analyzing VAM prices will remain crucial for businesses to navigate the challenges and opportunities in the global marketplace.

Get Real Time Prices of Vinyl Acetate Monomer (VAM): https://www.chemanalyst.com/Pricing-data/vinyl-acetate-monomer-34

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

The Versatility of Foam Sheets: A Comprehensive Guide

Foam sheets have become a staple material in various industries and DIY projects due to their versatility, durability, and ease of use. Whether you're a professional craftsman, an enthusiastic hobbyist, or someone looking for practical solutions around the home, foam sheets offer endless possibilities. In this blog, we'll explore the different types of foam sheets, their uses, benefits, and some creative ideas to get you started.

Types of Foam Sheets

1. Polyurethane Foam

Polyurethane foam sheets are known for their flexibility and resilience. They are commonly used in upholstery, mattresses, and insulation. This type of foam is excellent for absorbing shock and providing cushioning, making it ideal for packaging delicate items.

2. Polystyrene Foam

Polystyrene foam, often referred to as Styrofoam, is lightweight and rigid. It's frequently used for insulation, craft projects, and packaging. Its excellent thermal insulation properties make it a popular choice in the construction industry.

3. Polyethylene Foam

Polyethylene foam sheets are highly durable and resistant to moisture, chemicals, and impact. They are commonly used for packaging, floor underlay, and as padding in sports equipment. This type of foam is also known for its excellent buoyancy, making it suitable for flotation devices.

4. EVA Foam

Ethylene-Vinyl Acetate (EVA) foam sheets are soft, flexible, and easy to mold. They are widely used in cosplay, footwear, yoga mats, and as protective padding in sports gear. EVA foam is also popular in the craft world for making custom shapes and designs.

Benefits of Using Foam Sheets

1. Versatility

Foam sheets come in various thicknesses, densities, and materials, making them suitable for a wide range of applications. Whether you need something flexible, rigid, or somewhere in between, there's a foam sheet for the job.

2. Durability

Many foam sheets are designed to withstand wear and tear, making them long-lasting and cost-effective. This durability is particularly important in applications like insulation, packaging, and protective gear.

3. Ease of Use

Foam sheets are easy to cut, shape, and glue, which makes them a favorite among DIY enthusiasts and professionals alike. With simple tools like a utility knife or scissors, you can create intricate designs and custom solutions.

4. Lightweight

Despite their durability, most foam sheets are lightweight, making them easy to handle and transport. This is especially beneficial in construction and packaging, where reducing weight can lead to cost savings and easier installation.

5. Insulation Properties

Foam sheets are excellent insulators, providing thermal, sound, and impact insulation. This makes them ideal for use in buildings, vehicles, and packaging fragile items.

Creative Uses for Foam Sheets

1. Craft Projects

Foam sheets are a crafter's dream. From school projects to home decor, the possibilities are endless. You can create costumes, masks, decorations, and even custom stamps. EVA foam, in particular, is popular in the cosplay community for making armor and props.

2. Home Improvement

Foam sheets can be used for various home improvement projects. Use them as padding under carpets, insulation in walls and roofs, or as soundproofing in music rooms. They can also be used to create custom cushions and upholstery.

3. Packaging

Protect your valuable items during shipping with foam sheets. Their cushioning properties make them ideal for wrapping delicate items and filling voids in boxes to prevent movement and damage.

4. Sports and Recreation

From yoga mats to protective padding in sports equipment, foam sheets are widely used in the sports industry. Their shock-absorbing properties help protect athletes from injury and provide comfort during exercise.

5. DIY Solutions

Foam sheets can be used to solve everyday problems around the house. Create custom drawer liners, tool organizers, or even insulation for your pet's house. The possibilities are only limited by your imagination.

Conclusion

Foam sheets are an incredibly versatile material with a wide range of applications. Whether you're working on a craft project, improving your home, or packaging delicate items, foam sheets provide a practical and cost-effective solution. With their durability, ease of use, and excellent insulation properties, foam sheets are a valuable addition to any project. So, the next time you embark on a new endeavor, consider incorporating foam sheets and explore the endless possibilities they offer.

0 notes

Text

Vinyl Acetate Monomer Market Report: Trends, Analysis, and Projections

Vinyl Acetate Monomer (VAM) is a key chemical intermediate used in the production of various polymers and resins, offering versatility in applications across industries. This blog explores the dynamics of the global VAM market, analyzing key drivers, applications, emerging trends, and future growth prospects.

Understanding the VAM Market:

Vinyl Acetate Monomer (VAM) Is an organic compound produced by the reaction of acetylene and acetic acid. It serves as a crucial building block in the synthesis of polyvinyl acetate (PVAc), ethylene-vinyl acetate (EVA) copolymers, and other vinyl acetate-based polymers and resins.

Market Dynamics:

Polymer Production: VAM is primarily used in the production of PVAc, a versatile polymer used in adhesives, paints, coatings, textiles, and packaging materials due to its adhesive properties, flexibility, and film-forming capabilities.

Adhesives and Sealants: PVAc-based adhesives and sealants find applications in woodworking, paper packaging, construction, and consumer goods industries, offering strong bonding, versatility, and ease of use.

Coatings and Emulsions: VAM-based polymers are used in paints, coatings, and emulsions for architectural, automotive, and industrial coatings, providing adhesion, durability, and weather resistance properties.

Textile and Nonwoven Applications: VAM polymers are utilized in textile finishes, nonwoven binders, and fiber treatments, enhancing fabric properties such as softness, water repellency, and strength.

Applications Across Industries:

Adhesives: Woodworking, paper packaging, construction.

Coatings: Paints, architectural coatings, industrial coatings.

Textiles: Finishes, nonwoven binders, fiber treatments.

Packaging: PVAc films, adhesives for flexible packaging.

Market Trends:

Green and Sustainable Solutions: Increasing demand for eco-friendly adhesives, coatings, and polymers drives the development of bio-based VAM and sustainable formulations using recycled materials, aligning with environmental regulations and market preferences.

High-Performance Applications: Innovations in VAM-based copolymers such as EVA copolymers and VAM-acrylic copolymers cater to specialized applications in automotive, electronics, and medical sectors requiring enhanced properties such as heat resistance, flexibility, and chemical resistance.

Technological Advancements: Advances in VAM production processes, catalyst technologies, and polymerization techniques improve efficiency, product quality, and cost-effectiveness, driving market competitiveness.

Future Prospects:

The global VAM market is poised for significant growth, driven by the expanding demand for polymers, adhesives, coatings, and specialty materials across industries. Investments in R&D, sustainability initiatives, and market diversification strategies will shape the market's evolution and unlock new opportunities for stakeholders.

Conclusion:

Vinyl Acetate Monomer (VAM) plays a vital role in the production of polymers, adhesives, coatings, and specialty materials essential for diverse industries. Understanding market trends, technological advancements, and sustainability imperatives is crucial for stakeholders in the VAM market to leverage growth opportunities and address evolving industry needs effectively. With a focus on innovation, sustainability, and customized solutions, the VAM market presents promising prospects for continued growth and development in the global chemical and materials industry landscape.

0 notes