#ExtremeEpoxyCoatings

Text

Sloped Flooring

Learn about slope flooring applications for Commercial Kitchens, Animal Housing, Running Tracks, Wheelchair Floors and Industrial Processing!

#https://www.extremeepoxycoatings.com/slope-flooring-applications/#sloped flooring#sloped floors#epoxy flooring installation#epoxy flooring#epoxy floor coatings#how to install epoxy floors#epoxy floor installation#epoxy flooring installation cost#what is epoxy flooring#epoxy flooring near me#general contractor#ExtremeEpoxyCoatings#Extreme Industrial Coatings#extremeepoxycoatings.com

0 notes

Text

Extreme Epoxy Coatings

Slope Flooring Applications

No one wants uneven floors – or do they? The fact is that sloped flooring has applications that few people realize. In some instances, uneven floors could actually serve the needs of certain industries!

Types of Sloped Floors

Sloped floors are basically uneven floors. In many instances, uneven flooring is unwanted and viewed as a structural defect. In some places, however, sloped floors are intended as part of the overall design of the building!

Currently, there are two major types of sloped floors. There are the anti-fatigue floors and the non-slip type. The anti-fatigue is typically made of foam or other material that helps cushion the feet. This is used in properties where people stand for long periods like the check-out counter. The foam helps reduce leg pain caused by standing for too long periods!

The non-slip flooring on the other hand is designed to create traction on the floor surface. They’re typically placed in high-traffic areas like hallways. This helps prevent slippage which can happen in areas with massive foot traffic!

Commercial Applications of Sloped Floors

In residential homes, sloped floors are mainly seen in bathrooms. The sloped floor leads to the drain, allowing water to naturally flow thanks to gravity. This way, there are zero chances of the water remaining stagnant on the bathroom floor!

In commercial properties, however, sloped floors are integrated due to a variety of reasons. Here’s where you can usually find these installations:

Commercial Kitchens

Sloped floors are installed in commercial kitchens for ease of cleaning. It’s necessary to keep the kitchen flooring clean since food is prepared in the space. With sloped floors, the cleaning process becomes easier, especially for incredibly busy kitchens. However, the reasoning is a bit more than that. The fact is that kitchens can experience spills of different liquid products from oil, vinegar, stock, and so on. A sloped floor helps the liquid pool into a particular area, therefore minimizing the chances of slipping on the surface!

Animal Housing

You will find that most dairy housings have sloped flooring. This is to help with cleaning, especially for certain animals. However, dairy housing has an added reason for the sloped surface. This is because cows develop weaker legs on flat surfaces. Remember – cows genetically evolved to walk on uneven ground. The uneven surface helps them grip the floor better and therefore develop stronger legs. With a completely flat surface, this becomes impossible. Good installers have the ability to create small grooves onto the surface, allowing it to get as close as possible to how the ground looks and feels. This minimizes slips and falls for the cows or other animals!

Running Tracks

This sounds counterproductive as running tracks are supposed to be flat in order to keep the surface safe for runners, right? However, studies have shown that slightly sloped floors can actually reduce the impact on the feet. This makes them ideal for runners who are training long distances and need to have a bit more cushioning for the joints. The sloped design can also help control overall speed so there’s less risk of falling or slipping!

Wheelchair Floors

This one’s a no-brainer as sloped floors actually make it easier for wheel-chair bound persons to move from one space to another. Gravity does most of the work as they move through space. But what about if they have to go uphill? Since the degree of the slope is very minimal and so it barely registers. Overall, however, sloped floors offer a net positive for wheelchair users!

Industrial Processing

The same with commercial kitchens, sloped floors in industrial buildings help reduce accidents resulting from slipping and sliding. Combined with the right materials, sloped floors can also withstand thermal shock, high-temperature changes, and certain chemicals!

Sloped or uneven floors have practical uses in both residential and commercial settings. However, it’s important to note that sloped flooring is as good as the people installing it. Extreme Epoxy Coatings are industry leaders who have ample experience in installing sloped floors that meet business needs without ruining the aesthetic appeal of the space. If you’re thinking about installing sloped floors, make sure to check them out and look through their offerings before placing an order!

#https://www.extremeepoxycoatings.com/slope-flooring-applications/#sloped flooring#sloped floors#epoxy flooring installation#epoxy flooring#epoxy floor coatings#how to install epoxy floors#epoxy floor installation#epoxy flooring installation cost#what is epoxy flooring#epoxy flooring near me#general contractor#ExtremeEpoxyCoatings#Extreme Industrial Coatings#extremeepoxycoatings.com

0 notes

Text

Keeping Up with the Weather with Insulated Metal Panels

Insulated metal panels are known for their superior thermal properties that can be used for walls and roofs. The finished products are not only attractive but also functional. Having insulated metal panels on the exterior of the roof or walls is a great choice for office buildings, arenas, airports, and even stadiums as they are cost-effective and energy-efficient.

They have a lower embodied carbon as compared to other building materials. Aside from their thermal superiority, insulated metal panels are easy to install and have a design flexibility that adds to their attractive finish and quality.

Using Extreme Epoxy Coatings in California for insulated metal panels can protect your structure from the elements like rain, wind, and moisture since it can act as a barrier to weather-tight your structure. This can be applied to traditional and non-standard building designs in the commercial, agricultural, and industrial, and post-frame markets.

Insulated metal panels come in a variety of colors that can be matched and customized to each client’s preferences. Since they are easy to install and require low maintenance, you can save not only on the construction cost but also on construction time.

In California, Extreme Epoxy Coatings offers the optimal choice for ceilings and interior partitions using our insulated wall panel. Using this product, we can provide customers with the following benefits:

Energy-efficient and cost-effective superior insulation

We use an advanced polyurethane core to lower heating which means less cooling cost.

Flexible design options and easy installation

Insulated metal panels are adaptable to any building material like stucco, brick, concrete tilt-up, etc. It comes in a variety of colors that can be customized to the client’s requirements. Has a clean and high-profile appearance with no visible attachments. Finishes can be done to resemble conventional construction materials like masonry, precast, or stucco.

Safe and Durable

Our materials meet the requirements of major building codes of many construction types. We utilized structurally strong yet lightweight panels that can support long spans that can help reduce frame cost support.

Sustainable

We use recyclable materials for our interior and exterior skins that also function as a continuous air barrier. The impermeable skin has unique self-sealing side joints.

Applications for Insulated Metal Panel

Institutional and Commercial Use

Insulated metal panels can be utilized in almost all types of commercial and industrial buildings. With its unique energy-efficient insulation, durability, lightweight installation and construction, and being cost-efficient, structures like schools, retail centers, and even power plants can benefit from these features. Aside from these attributes, insulated metal panels can also deal with climate considerations about humidity, temperature, air movements, and airborne particles, among others.

Architectural

Architectural application for insulated metal panels can be in the form of customization in shapes and width, colors and finishes, and fabrication. Custom fabrication can include curve panels, bent corners, and ends without trims among others.

Cold Storage

For climate-controlled facilities, Extreme Epoxy Coatings insulated metal panel wall is the answer. We can customize the specific thermal performance requirement needed by your structure. We also take into consideration the hygiene and safety requirements by using flat and ribbed-shaped panels with long spanning capacity, special joint designs, and high-performance coatings. Having insulated metal panel walls can make your manufacturing, processing, and distributing of perishable food or materials possible.

Insulated Roof

Using the insulated metal panel for your roof can help it last for decades. This roofing solution can provide your structures with superior insulation and the simplest maintenance. It requires only a two-step installation process which eliminates accidents and lots of material requirements that can straddle the budget. More low and high-rise commercial and industrial structures are benefiting from this application.

0 notes

Text

General Contractors

This article by Extreme Epoxy Coatings will highlight the top 5 things to look for in the best general contractor in Northern California!

#https://www.extremeepoxycoatings.com/top-5-things-look-northern-california-general-contractor/#general contractors#best general contractor in Northern California#epoxy flooring installation#epoxy flooring#epoxy floor coatings#how to install epoxy floors#epoxy floor installation#epoxy flooring installation cost#what is epoxy flooring#epoxy flooring near me#ExtremeEpoxyCoatings#Extreme Industrial Coatings#extremeepoxycoatings.com

0 notes

Text

extremeepoxycoatings.com

Top 5 Things to Look For in a Northern California General Contractor

For a construction project to be successful, it is essential to find the right contractor who can help turn a vision into reality. However, this can be challenging for businesses and homeowners considering there are a ton of general contractors available in both Northern and Southern California. Luckily, this article will highlight some of the key things that you should look for to find the best general contractor in Northern California!

What Should I Look For in a Good Contractor?

Building a new home or office space can be an exciting remodeling experience, but it is important to find someone whom you can trust and rely on throughout the entire process. When looking for a contractor, consider the following factors:

Licensed, Bonded, and Insured

Before you hire a contractor for your project, you need to make sure that they are licensed and insured. Having a license will prove that they are qualified to carry out the work while having worker’s compensation insurance ensures that you will be covered in case of an accident or any other unforeseen circumstances. Always read their contract carefully to ensure that their license and insurance are up-to-date before signing anything. Of course, we can never predict the future, but having this peace of mind for your building can help put you at ease!

Experience Is Key

Building construction projects can be complicated, which is why it is important to hire a professional who has the necessary experience and expertise to make the project run smoothly. If you plan to remodel your kitchen or bathroom, for example, make sure that your contractor has plenty of experience in these areas. They should be knowledgeable on what materials and techniques work best for each building project, as well as have a good understanding of proper safety procedures!

Ask For Referrals

You may ask for examples of building construction projects they have recently completed, as well as past customers that you can speak to. Doing so will give you an idea of how well they are in their profession. Additionally, do some research online and ask for referrals from your family, friends, and other trusted sources about the company!

Solid Team of Subcontractors

Whether you’re working on your house or business, you want to make sure that you’re hiring a reputable company that has a solid group of sub-contractors. Sub-contractors are the people who will actually carry out the physical labor, such as electricians, plumbers, painters, carpenters, and so on. The completion of a successful building construction project depends on the quality of your chosen team, as well as their availability to get the job done in a timely manner!

Transparent In All Things

When it comes to pricing, make sure that the professional is transparent and upfront with their rates. They should be able to provide you with a breakdown of the labor costs, including any fees or tax charges that may apply. San Francisco bay area, San Diego, and other major cities in northern California are home to a number of companies, but not all of them are reliable. Some may try to cut corners or lowball their estimates, which is why it is always important to do your research and get multiple quotes from different companies before hiring them for your home or business building!

Will Always Communicate

Lastly, make sure that your construction contractor is someone who will always keep you informed and in the loop on the progress of your building construction projects. If they take too long to reply or don’t respond to your text messages or calls, then it is probably time to look for a new team!

What questions should I ask a general contractor?

Questions you should ask include:

What is your experience in construction projects?

Do you have references I can follow up with?

Are you licensed and insured, and do you have any recent certifications or accreditations?

Can you create a detailed, itemized estimate of the costs for the projects?

What is your schedule for completing the job?

What documents should I ask for when hiring a contractor?

You must have three crucial documents prior to hiring an independent contractor:

A W-9 form that shows the person’s contact information as well as taxpayer ID number!

A resume to help verify the person’s qualifications!

A written contract outlining the terms of your agreement with the independent contractor!

Serving our clients in Northern California, Extreme Industrial Coatings provides numerous solutions and services to fit financial and environmental needs. We assist many clients across California, Extreme Industrial Coatings is your local specialist in durable, flawless epoxy coatings. Find out how Extreme Industrial Coatings can help protect your workplace, business, manufacturing, or industrial environment with our durable and customizable products and services by calling us for a free quote at 559-213-4731. For more information visit extremeepoxycoatings.com!

#https://www.extremeepoxycoatings.com/top-5-things-look-northern-california-general-contractor/#general contractors#best general contractor in Northern California#epoxy flooring installation#epoxy flooring#epoxy floor coatings#how to install epoxy floors#epoxy floor installation#epoxy flooring installation cost#What Is Epoxy Flooring#Epoxy Flooring Designs#Epoxy Flooring Near Me#ExtremeEpoxyCoatings#Extreme Industrial Coatings#extremeepoxycoatings.com

0 notes

Text

Drainage In Your Commercial Kitchen

What is a trench drain and how it works? Also, learn about the benefits & disadvantages of trench drains for commercial kitchens!

#https://www.extremeepoxycoatings.com/trench-drains-commercial-kitchens/#Drainage In Your Commercial Kitchen#Trench Drain System#Epoxy Flooring Installation#Epoxy Flooring#Epoxy Floor Coatings#How To Install Epoxy Floors#Epoxy Floor Installation#Epoxy Flooring Installation Cost#What Is Epoxy Flooring#Epoxy Flooring Designs#Epoxy Flooring Near Me#ExtremeEpoxyCoatings#Extreme Industrial Coatings#extremeepoxycoatings.com

0 notes

Text

Stop Water from Your Walls and Floors with Moisture Control System

The process of moisture control is given widespread attention in construction practices. The need to install a secure moisture control system is a must since there is a demand for better insulation and airtight envelope systems that can save energy.

Most new constructions have a higher demand for thermal comfort thus more heating and air conditioning systems are installed. With new construction being done this way, this imposed temperature and vapor pressure gradient can lead to condensation and mold growth. The need to install appropriate moisture control will ensure an energy-efficient system and damage-free building in the long run.

It is a challenging job to protect a residential, commercial, or industrial building from moisture. Moisture control is a very important aspect to keep the integrity of your structures.

In California, Extreme Epoxy Coatings can help protect your property surfaces from these harmful industrial challenges. We apply the best moisture control solution to address the need for impermeable membrane protection for your structures’ walls and floors. We locate the sources of these problems to have a proper assessment and application of solutions.

Importance of Maintaining a Moisture Control System

Relative humidity levels are important when it comes to the comfort and productivity of people working in office buildings. But moisture control system is not only for these structures but are also extremely important in other facilities like:

Pharmaceutical Manufacturing

The integrity of drug manufacturing can be compromised with the presence of just a trace of moisture in the area of production. Trace moisture can be absorbed during drug production and can affect its shelf life. Moreover, coated drugs are dried using a specific relative humidity. Any alterations from the specific requirement will affect the products’ quality.

Paper Manufacturing

Paper has a very specific relative humidity requirement that an increasing percentage from the normal can potentially damage the goods. It can cause irreversible damage once paper starts to expand and curl. Even cardboards are not spared from damage once unwanted moisture has seeped its way to them.

Stacking cardboard will be difficult and unsafe since it is already swelling from the presence of moisture. Printers can also be affected by unwanted moisture and it can present a poor print quality in magazines, banners, and other printed materials.

Understanding the Benefits of Quality Moisture Control Installation

There are a lot of structures that can benefit from having a good and properly installed moisture control system. Residences have the greatest need for this kind of protection since it is the one structure where people permanently dwell. The humidity in a given area can affect its thermal comfort and indoor air quality.

It can affect people’s health especially when damp air is always present. It can facilitate the growth of molds and bacteria that causes respiratory problems and also provides a haven for dust mites to multiply and affect asthmatic people. Aside from this, condensation can form on windows, floors, and ceilings that can potentially damage the building material.

The presence of moisture can practically result in unwanted repair costs and damage. Water molecules that are the source of this malady can be the outcome of poor construction practices done on the property. In most cases, the absence of a low permeable, tear, and puncture-resistant vapor barrier during construction can result in this moisture damage appearing later.

California-based Extreme Epoxy Coatings can help you re-establish control over your property to address and strengthen the areas of concern. Upon inspecting and assessing your area, we can give you recommendations that can prevent further damages.

We use duly tested and high-quality products to ensure your safety. Our product can create an impermeable membrane needed on the surface of your walls and floors that can prevent you from breathing air–filled spores and mildew.

This effective barrier will fortify your protection and increase the integrity of your wall and floor surfaces. We pattern our moisture solution based on the type of protection needed by the property. Our highly skilled technicians will be responsible for its installation to make sure it is done properly thus giving you the peace of mind that you need.

0 notes

Text

Polyurethane Cement

Learn about polyurethane or urethane cement, it's flooring system and why it is best in commercial and industrial flooring usages!

#https://www.extremeepoxycoatings.com/polyurethane-cement/#Polyurethane Cement#Polyurethane Flooring#Epoxy Flooring Installation#Epoxy Flooring#Epoxy Floor Coatings#How To Install Epoxy Floors#Epoxy Floor Installation#Epoxy Flooring Installation Cost#What Is Epoxy Flooring#Epoxy Flooring Designs#Epoxy Flooring Near Me#ExtremeEpoxyCoatings#Extreme Industrial Coatings#extremeepoxycoatings.com

0 notes

Text

Epoxy Flooring

Polyurethane Cement Floor

When searching for new, dependable flooring, most families place a high priority on durability. Along with picking a gorgeous style and a price range you can afford, it is also always important to be sure your new flooring will withstand the hectic lifestyle of your house and its daily activities. The good news is that there are plenty of flooring options available today that are both attractive and long-lasting. However, it may be challenging to know where to start given the wide variety of attractive and long-lasting flooring alternatives available. Fortunately, we, the experts, at your neighborhood ExtremeEpoxyCoatings are on hand to help you decide among the available alternatives and discover the ideal new floors for your house!

What is Polyurethane or Urethane Cement?

Polyurethane or urethane cement is a combination of polymer urethane technology with portland cement and other aggregates to create a smooth durable flooring system. Polyurethane cement, as its name implies, consists of layers of polymer binder, cement, and aggregates to resist floor and wall cracking and withstand heat, traffic, and heavy machinery, thus, it is very appropriate in industrial facilities and on industrial floors!

It is the toughest flooring system because it is safe, has a low maintenance cost, and has a lasting duration. It is non-slippery, resistant to moisture vapor, chemically resistant, and does not fade on exposure to ultraviolet sunlight. It is a solvent-based cement and also very elasticated. A polymer urethane resin technique that binds tailored cement powder aggregate to create high-performance and long-lasting flooring is known as urethane concrete. It is a sophisticated method of coating industrial concrete floors!

Polyurethane or Urethane Flooring System

The composition of the polyurethane cement gives a seamless flooring system – a smooth surface, which makes up for its strong flooring covering that is extremely resistant to thermal shock and protects the surface from humidity, high-temperature fluctuations, chemicals, and harmful microorganisms. A polyurethane floor is resistant to corrosion, chemical alkalis (both organic and inorganic), and other solvents, thus protecting the floor covering from stains or erosion. An especially unique characteristic of this flooring is its ability to withstand the extremes of temperature conditions!

It does not crack or even buckle under humid or extreme temperatures. It is in fact a very protective flooring system. Polyurethane flooring as a seamless flooring system can be modified to either extend or reduce its life span or durability span as well as the total curing time span. Polyurethane or urethane is considered a high-performance flooring coating. It is very flexible and elastic. It’s also softer and gives an abrasion-resistance factor, hence it is often applied over an epoxy floor as a protective non-scratch layer. It can also act as a protective waterproof surface for the safety of the cement!

It is also chemically reactive to moisture, both in the atmosphere and in the substrate. It is also very reactive to dust and other microorganisms. Cementitious polyurethane needs a strong anchorage before applying the floor coating to avoid troubles with the flooring system. It can also act in the capacity of a crack-bridging layer, providing no cracks in the floors. Polyurethane flooring is subdivided into either water-based or oil-based flooring. It can be used both for commercial and domestic purposes because of its absorption power, cushioning energy, noise reduction, and fast installation process!

Commercial and Industrial Use of Polyurethane Flooring

Polyurethanes have a variety of usages, including commercial and industrial facilities. Urethane concrete can be used in interior and exterior settings, especially aliphatic polyurethane because of its resistance to ultraviolet rays and its aesthetic quality. In food and beverage factories, polyurethane flooring is ideal because of its hygienic solutions to both wet and dry areas as well as in freezing chambers where it provides elastic properties to support the movement of heavy pallet trucks without cracking. It is suitable in gyms, schools, loading ramps, and other commercial spaces!

Epoxy Flooring

The most basic description of epoxy flooring refers to a flooring surface made up of several layers of epoxy that are put to a floor with a minimum two-millimeter depth. When correctly blended, epoxy glue and hardener react with one another, forming a chemical bond between each material and the floor itself. Epoxy flooring is composed of polymer resins and hardeners which react together to form a strong bond with each other and with the floor. This creates several layers of epoxy that are at least 2 millimeters thick which makes it durable, leveled, and shiny. It is a solution that is very feasible, highly resistant to impact, and customizable. It works well in commercial, industrial and residential areas where flooring systems must be at their best. There are types of epoxy flooring which include self-leveling epoxy floors, epoxy mortar floors, quartz-filled epoxy floors, epoxy flake floors, and even anti-static epoxy floors otherwise called the electrostatic charge (ESD) resistant floors which can be applied to reduce any static hazards in home spaces!

Polyurethane and Epoxy Flooring

Both polyurethane and epoxy are viable coating options, and they can be combined (polyurethane topcoat placed over epoxy) to offer the best resistance for industrial or commercial concrete floors that will be subjected to heavy traffic or persistent exposure to harsh, harmful chemicals. One significant distinction between polyurethane and epoxy is that the former is far thinner, only 2 or 3 miles thick, and contains roughly 60% or 70% solids. The substance transforms into a sturdy solid when heat is applied, producing a high-performance floor surface. Conversely, epoxy also effectively protects against hot tire pick-up, scratching, and wear from abrasion. Comparing the material to its floor coating equivalent, it is comparatively more affordable and easier to install!

Because installing flooring in a home is an expensive and time-consuming project, it is obvious that picking a material that will last for several years is better. Our company stays ahead of the pack when it comes to urethane flooring services in California. Our team of skilled and experienced technicians at ExtremeEpoxyCoatings is here to help you every step of the process, whether you are looking to replace the floors in your entire home or are only looking to renovate the flooring in your bathroom. We do not just give you a sterling flooring experience, but also offer advice on the best and most ideal flooring options available for your utility. This is why it is important and very necessary for you to work with us and in fact, refer friends and acquaintances to us!

#https://www.extremeepoxycoatings.com/polyurethane-cement/#Polyurethane Cement#Polyurethane Flooring#Epoxy Flooring Installation#Epoxy Flooring#Epoxy Floor Coatings#How To Install Epoxy Floors#Epoxy Floor Installation#Epoxy Flooring Installation Cost#What Is Epoxy Flooring#Epoxy Flooring Designs#Epoxy Flooring Near Me#ExtremeEpoxyCoatings#Extreme Industrial Coatings#extremeepoxycoatings.com

0 notes

Text

The Benefits of Spray Foam Roofing Installation for Commercial Properties

If you are looking into spray foam roofing, it is imperative to have a greater understanding of how the process works and the associated costs to determine whether it is a worthwhile investment or otherwise. Let us first enumerate the benefits of installing spray foam roofing for commercial application.

Exactly, what is spray foam roofing?

Foam roofing is made from spray polyurethane foam and is a popular solution for commercial properties with flat roofing systems. They are designed with ease of installation, energy efficiency, and durability in mind.

There are two types of spray foam being used for commercial establishments, namely the open-cell foam system and closed-cell foam system. The latter is considered a better solution due to its greater density and better insulation properties against external elements such as air and water penetration.

How is Spray Foam Roofing Installed?

The installation of spray foam roofing requires combining polyol chemicals and isocyanate on-site and spraying the resulting mixture on an underlayment or over a roof deck. Once sprayed over the surface, the mixture will then expand up to 30 times its original size. The dense foam layer can reach up to 1.5 inches and serves to protect your commercial establishment UV rays, fire, and other external stressors. To finish installation, contractors typically apply a single layer or two of elastomeric or silicone roof coatings.

The Advantages of Using Spray Foam Roofing for Commercial Properties

Energy Efficiency and Insulation

One of the biggest selling points of spray foam roofing is its ability of maintaining ideal indoor temperature while at the same time keeping out atmospheric temperature. With exemplary thermal resistance, commercial property owners enjoy savings on their electric bill simply by opting to install spray polyurethan foam on their flat roofing systems. Less air conditioning and heating requirements translate to significant savings in the long run.

When used in combination with a reflective coating, spray foam roofing becomes a cool roof. Lastly, spray foam roofing can greatly reduce energy costs and enhance the comfort inside your commercial establishment.

Waterproofing Properties

Spray foam roofing helps waterproof commercial structure in various ways. For one, spray form roofing ensures seamless application as the material is installed in one continuous layer. It creates an airtight and watertight seal as evidenced, so property owners do not have to worry about nooks and crannies where water can seep in, which can then compromise indoor spaces.

Secondly, spray foam roofing for commercial foundations utilizes closed-cell foam systems that are proven to resist water as well. Lastly, spray foam roofing when installed properly prevents water accumulation – a common concern in buildings with flat roofs. Due to this quality, spray foam roofing lasts longer as they are less likely to suffer from cracks, sagging, and other water-induced damages.

Easy Installation and Low Maintenance

As spray foam starts in liquid form, the material easily conforms to the irregularities of any roofing system. This makes it a great insulation roofing material not just for flat roofs, but for domed and pitched roofs as well. Due to its flexibility, spray foam can also be used for roofing systems with chimneys, skylights, and similar structures. In the case of damages, repairs are easily manageable and affordable, too.

Lifespan

Spray foam roofing, when installed correctly, can last up to 20 years. With proper care and maintenance, it can outperform traditional flat roofing materials. A spray foam roof can go beyond 20 years with simple and easy recoating every five years.

Given all of the qualities and benefits, spray foam roofing installation is well worth the investment. It’s one of the best low-pitched roofing options not only for commercial buildings, but residential properties as well. Accurate and efficient installation is key to reaping its full benefits. Make sure to obtain the services reputable Californian company Extreme Epoxy Coatings – specializing in spray foam roofing to get the most bang for your buck.

0 notes

Text

Urethane Flooring System

How to Apply Urethane Cement Floor Coating System!

#https://www.extremeepoxycoatings.com/urethane-cement-floor-coating/#Urethane Flooring System#Urethane Cement Flooring#Epoxy Flooring Installation#Epoxy Flooring#Epoxy Floor Coatings#How To Install Epoxy Floors#Epoxy Floor Installation#Epoxy Flooring Installation Cost#What Is Epoxy Flooring#Epoxy Flooring Designs#Epoxy Flooring Near Me#ExtremeEpoxyCoatings#Extreme Industrial Coatings#extremeepoxycoatings.com

0 notes

Text

extremeepoxycoatings.com

Urethane Cement Floor Coating

When it comes to flooring solutions for your office, resin-coated concrete floors are among the best possibilities, especially if you work in a strictly regulated industry like food production or pharmaceuticals. Using a material like urethane cement for a floor coating or epoxy to cover concrete floors creates a surface that is extremely durable, long-lasting, and easy to maintain and will satisfy your flooring needs with long-term durability. The important question is which type of coating is appropriate for your floor. Urethane cement and epoxy coatings are the two most popular and widely used alternatives for resinous flooring systems, and each has pros and cons and industrial applications of its own!

Urethane Cement – A Glimpse

Urethane cement comes into existence through the direct combination of polymer urethane with cement and aggregates concrete to create a mixture, therefore having the ability to create, and develop resistance to moisture, thermal shock, and chemicals. Also, it has a smooth surface for easy cleaning, has a coating for cement flooring, and can be directly or indirectly applied to the concrete floor!

Urethane Cement Floor Coating System

This urethane flooring system is with no spaces in its range and the thickness is 1/8″-1/4″ (3-6mm) depending on the way it was applied and the area of application. Urethane cement flooring was initially created specifically for the food and beverage sector, though it is now as common to find in commercial and industrial environments because of the heavy machinery used in these places. It can withstand excessive foot traffic. At the time, no other flooring option could stand up to the daily high-pressure, temperature-variable washdowns of this specific commercial establishment. It is created for heavy-duty environments and its the ideal solution to withstand thermal shocks, abrasion, and chemical exposure it is well suited for several places or areas including production spaces. And is used to create gum rubbers, rigid foams, and elastomers. This is primarily used to improve the floor’s functionality i. e durability, chemical resistance, longevity, etc, and to improve the floor’s aesthetics. Same benefits as epoxy flooring!

Industrial Application of the Urethane Cement Floor Coatings

It is used in mortar for plastering, masonry work, pointing, etc. It is also useful in making joints for drains and pipes. It is suitable for water fighting of a structure. Urethane is very efficient in concrete for layering floors, and roofs and constructing lintels, stairs, pillars, etc. It is also used as a hard surface for protection of exposed surfaces of structures against the destructive agents of the weather and certain organic and Inorganic chemicals and thermal cycling. It is also used for precast pipes manufacturing, piles, fencing, post, etc. Mostly used for the construction of important engineering structures. Such as bridges, culverts (dams), tunnels, lighthouses, etc. Also, it is mainly used in the preparation of foundations, watertight floors, footpaths, etc, and most importantly, it is employed for the construction of wells, water tanks, tennis courts, lamp posts, telephone cabins, roads, etc!

Benefits of Urethane Cement Floor Coating

Extreme temperatures can be withstood by urethane cement flooring

Chemical and Moisture Resistance of Urethane Cement

Flooring Made with Urethane Cement Offers Maximum Durability

Protection

Easy Maintenance and Cleaning

At extremeepoxycoatings.com, we have extensive knowledge in the installation of concrete coating, including urethane cement floors, having been in the business for many years. We provide our clients with the most modern floor covering systems. We constantly educate ourselves on the newest concrete flooring systems, and application techniques. Our reputation speaks for We will provide a suitable flooring system or Concrete floor that is resistant to moisture, thermal shock, and chemicals and is low maintenance. We take great pride in our dedication to providing top-notch goods, unrivaled craftsmanship, and unbeatable warranties!

#https://www.extremeepoxycoatings.com/urethane-cement-floor-coating/#https://www.extremeepoxycoatings.com/#Urethane Flooring System#Urethane Cement Flooring#Epoxy Flooring Installation#Epoxy Flooring#Epoxy Floor Coatings#How To Install Epoxy Floors#Epoxy Floor Installation#Epoxy Flooring Installation Cost#What Is Epoxy Flooring#Epoxy Flooring Designs#Epoxy Flooring Near Me#ExtremeEpoxyCoatings#Extreme Industrial Coatings#extremeepoxycoatings.com

1 note

·

View note

Text

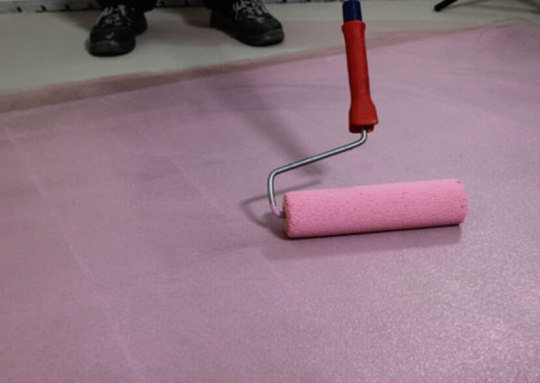

Is Epoxy Coating a Good Option for Sloped Floors?

Commercial establishments typically install sloped floors, especially in areas where water needs to efficiently flow out to prevent stagnant water from potentially causing accidents, injuries, health concerns and many more. For an even surface, many commercial property managers and business owners opt to use epoxy coatings on sloped floors. Given the uneven nature of sloped floors, is epoxy coating the ideal floor finishing solution?

Sloped Floor Installation Requirements

Whether you need liquid to run quickly and smoothly facilitated by a steep sloped flooring, or a more subtle incline, you need to install resin flooring systems to get the job done efficiently. If you plan on installing in a high-traffic area, you may also consider installing rapid cure polyurethane flooring resin systems to reduce downtime and ensure efficiency at your commercial site.

Before you can apply epoxy coating on a sloped floor, you need to start with a smooth surface. Obtain the professional services of Extreme Epoxy Coatings that can design and install a resin flooring solution that fits your business.

Typically, the installation starts with a base screed system to create the slope or falls that your commercial establishment needs. You can choose between acrylic polymer resin or bulk polyurethane resin. For small or short slopes, we usually install a single layer of epoxy resin or polyurethane system. After successful base installation, epoxy or polyurethan resin screed is applied to create a smooth and even finish to your floors.

There are a few factors to consider in determining which type of flooring is best for your business. Here are some of them:

Non-slip requirements of your commercial site

Requirements for existing Drainage Systems

Cleaning procedures and protocols

The amount of traffic that a sloped area experiences on a daily basis

Epoxy Coating Flooring Preparation

Simply put, epoxy coating always requires a clean and slightly porous surface to ensure proper adherence. One thing that you should remember is that epoxy coating does not bond properly to sealed or polished concrete. If you start off with concrete, make sure that it has completed its curing time before epoxy coating application.

Cracks, dents, and major chips on sloped floors needs to be patched or repaired to create an even surface. Cleaning is also a requirement to remove substrates and other debris that can compromise the smooth and even finish of your sloped floors.

If you are applying epoxy coating on old, sloped concrete floors, it is imperative to test the surface as to whether they have had previous layers of epoxy coating or other sealing products. To determine the presence of sealants, simply pour a small amount of water onto the floor. The water will immediately soak into a concrete floor without sealant. Water will not penetrate floors with old sealant and similar products, but instead will form water beads on the surface.

Check the temperature before applying epoxy coating onto the concrete floor. If you are doing this step all by yourself, it’s always best to follow manufacturer’s recommendations to ensure superior results.

If you choose to go ahead and apply epoxy coating on your sloped concrete floors, manage your expectations. In this case, epoxy coating on sloped floors will only deliver pleasing aesthetics and shine to your floor but will not level the floor altogether. Additionally, since epoxy coating adds shine to the surface, it will ultimately reveal the flaws of concrete underneath. If your aim is to level the surface, it’s best to use another finishing material instead.

If you need more information about epoxy coating installation, we highly recommend that you seek the guidance of Extreme Epoxy Coatings, a professional California company that specializes in the application of epoxy floors for commercial establishments.

#extremeepoxycoatings#california epoxy flooring#epoxy#epoxy floor coatings#epoxy floor installation#epoxy flooring#epoxy flooring designs#epoxy flooring installation#epoxy flooring installation cost#epoxy flooring near me

0 notes

Text

The Importance of Moisture Control Systems at Home

Water is life. It is absolutely necessary for human health. But not for your home’s structural foundation. Water can damage the physical structure of your home in many ways. This is why the amount of water, in the form of moisture, that enters your home must be controlled. Otherwise, you run the risk of suffering from several health and financial consequences. Moisture control systems at home must be put in place. Why? Read further to find out.

Why is Moisture Control Important for Your Home?

It prevents cracks on wooden structures

The wooden flooring and other fixtures at home will draw in more moisture during summer. This causes the wood to expand and warp. However, when winter comes, the opposite thing happens. This is because you will be using your heater a lot more often during the cold season. In turn, your air will dry out and then draw moisture out from the wooden structures that you have at home. This leads to wood flooring cracks, gaps and loose boards. You may also see cracks in your wooden furniture and other wooden items at home or contact an expert for analyzing floor and wall crack repair.

It prevents mold and mildew growth

Having too much moisture inside your home can make it conducive to mold and mildew growth. This leads indoor air to become polluted and more likely to cause allergens and other indoor pollution-related illnesses. It can also cause damage to your wooden flooring. Unfortunately, if the moisture doesn’t dry out, it creates a breeding ground for bacterial growth. But with moisture control systems at home, the growth of these mold and mildew can be prevented.

It protects the foundation of your home

When water gets absorbed into the ground where your foundation is built, it will lead the soil to swell thus putting pressure on your home’s foundation. The result would be hairline cracks, floods and the deterioration of your home’s foundation. Therefore, moisture has to be controlled before it starts to disrupt and compromise the integrity of your home’s physical structure.

What Should You Do to Control Moisture-Related Problems at Home?

If your home is having these issues then it is high time that you should consider calling the experts who will help you address your home’s moisture-related problems. Call on the professionals at Extreme Industrial Coatings who are known to be the best when it comes to applying effective barriers on walls and floors to avoid moisture from damaging your home.

Extreme Industrial Coatings employ epoxy products that have been proven effective in making your walls and floors highly impermeable. This will not only make the physical structure of your home less prone to damage. But a high-quality epoxy coating can also help you save thousands of dollars since you no longer have to think about repairing and replacing some parts of your home.

What are the Other Benefits of Hiring Moisture Control Experts?

When a moisture control system that is made by experts is in place, you can sleep with much peace of mind that no matter what the weather is, your home will be safe from any damage caused by too much moisture.

Not to mention the fact that when your home possesses an efficient moisture control system, it will also be free from any microbiological activity. This largely spares you from any allergens and diseases brought about by mold and mildew buildup.

A home is where your family’s heart is. Protect your family’s health. Protect your property’s integrity. Don’t let excessive moisture be a part of it. For any signs of cracks or too much moisture, call the experts right away. Call Extreme Epoxy Coatings.

0 notes

Text

Benefits Of Epoxy Flooring

A brief article about the top 13 benefits of epoxy flooring for commercial facilities and a comparison with traditional concrete flooring systems!

#https://www.extremeepoxycoatings.com/top-13-benefits-epoxy-flooring/#Benefits Of Epoxy Flooring#Epoxy Flooring Systems#Epoxy Flooring Installation#Epoxy Flooring#Epoxy Floor Coatings#How To Install Epoxy Floors#Epoxy Floor Installation#Epoxy Flooring Installation Cost#What Is Epoxy Flooring#Epoxy Flooring Designs#Epoxy Flooring Near Me#ExtremeEpoxyCoatings#Extreme Industrial Coatings#extremeepoxycoatings.com

0 notes