#Fadal CNC Machines

Text

Upgrades, Fadal Machine - Replacement Parts for Fadal

Upgrades your Fadal Machine at ITSCNC for high-quality replacement parts tailored for CNC machines. Enhance performance and longevity with our precision-engineered components, ensuring your machinery operates at peak efficiency. We offer Fadal amplifier, fadal electric parts, fadal ballscrew, fadal belts, fadal keyboard, and many more. Trust ITSCNC for reliable, durable, and cost-effective solutions to keep your Fadal machines running smoothly. Visit us today for premium Fadal parts and upgrades.

#fadal machine parts#fadal cnc parts#fadal parts online#fadal parts#fadal parts for cnc machine#fadal cnc replacement parts#fadal parts manual#fadal cnc machines#replacement parts for fadal#fadal machine and control technical documentation#Fadal Parts For CNC Machine#Fadal CNC Parts#Fadal Machine Parts#Fadal Parts Manual#Fadal Ballscrews#Fadal CNC Ballscrews#Fadal Parts#Fadal Spindle Drive#Fadal CNC Replacement Parts#Fadal CNC Machines

2 notes

·

View notes

Text

CNC Machining Orlando

The latest advancements in CNC milling and turning technologies

For over 15 years, Tychon, Inc., has been supplying precision CNC machined parts to customers nationwide. We operate a full-service machine shop and leverage the newest advancements in CNC milling and turning technologies to produce close tolerance parts in prototype to production volumes.

We operate a fleet of milling and turning centers with different work envelopes, automation features, and process capabilities. Our production assets include programmable 3- and 4-axis CNC equipment with live tooling, automated bar feeds, and other productivity features. Along with aluminum, alloy steels, bronze alloys, stainless, and many other metals, we manufacture parts from plastic polymers and other non-metals, such as composites.

Facility

Our state-of-the-industry equipment includes the following:

5 CNC vertical mills

4 CNC lathe

Bridgeport mill

Engine lathe

2004 FADAL VMC 15-XT CNC machining center – travel X-30″/ Y-16″/ Z-20″

1999 FADAL VMC-3016 HT CNC vertical machining center – travel X-30″/ Y-16″/ Z-20″

1995 FADAL VMC-3016 CNC vertical machining center – travel X-30″/ Y-16″/ Z-20″ w/ Fadal CNC 4th axis indexer

2011 Hardinge GX 1000 VMC w/OSP Control – travel X-40.16/Y-21.25/Z-21.25

2007 Okuma Heritage ES-L8 CNC lathe with tailstock – 8″ chuck, and 2″ bar through spindle

2008 Okuma Heritage ES-L8 II CNC lathe with tailstock – 8″ chuck, and 2″ bar through spindle

2010 Doosan Daewoo Lynx 220 LM CNC lathe with tailstock – C-axis milling capability, 6″ chuck and 2″ bar through spindle

2010 LNS Eco Load short magazine bar feed

2006 FADAL VH5C rotary head with servo control

2007 LNS Quick Load Servo 65 bar feeder – ¼”-2-5/8″ bar stock diameter

2004 VICTOR JF2VS knee mill with Newell digital readout and “X” axis power feed – travel X 49″ / Y 24″

2004 VICTOR 1440B Lathe with 5C collet closer and Newell digital readout- 8″ chuck, / 36″ between centers

VectraX gear drive saw

2018 Hardinge V480 APC CNC vertical machining center with pallet changer – travel X 18.9”/Y 15.75”/Z 16.93”

2019 Okuma Genos 125011-E CNC lathe with tailstock – 8” chuck, and 2” bar through spindle

1995 Fadal VH65 Indexable Rotary Head

Inspection Equipment:

2004 Tesa Micro-Hite 3D CMM

2020 Keyence IM-7501 Image Dimension Measuring System

INSPECTION EQUIPMENT:

36″ / 48″ Inspection grade surface plate

Electronic Micro Heights, Gauge Pins, Bore Mic, Rockwell Hardness Tester

0 notes

Video

undefined

tumblr

cnc special custom aluminum steel polishing machining milling spare parts frame China factory manufacturer price

KUNSHAN CARSAI AUTO PARTS INDUSTRY CO., LTD

https://www.carsai-precisionparts.com/

Whatsapp&WeChat: +8615212743691

email: [email protected]

---------------------

cnc special custom aluminum steel polishing machining milling spare parts frame China factory manufacturer price

polish aluminum motorcycle parts,polish aluminum engine parts,polish aluminum bike parts,how polish aluminum parts,polish aluminum car parts,mothers aluminum polish advance auto parts,how to polish aluminum parts,best way to polish aluminum engine parts,how do you polish aluminum engine parts,how to polish small aluminum parts,how to polish aluminum plate,how to polish dull aluminum,how polish aluminum parts,how to polish aluminum engine parts,how to polish aluminum motorcycle parts,how to polish aluminum bike parts,how to polish aluminum car parts,how to polish small aluminum parts,how do you polish aluminum engine parts,how to polish aluminum plate,spare parts cnc machine,spare parts for cnc router,spare parts for cnc lathe,car spare parts cnc,cnc spare parts online,cnc spare parts uk,cnc spare parts melbourne,cnc machine spare parts in bangalore,brother cnc spare parts,biesse cnc spare parts,cnc machine spare parts in chennai,cnc chuck spare parts,cnc machine spare parts hs code,cnc router spare parts hs code,cnc machine spare parts tariff code,cnc machine spare parts hs code zauba,cnc machine spare parts dubai,doosan cnc spare parts,daewoo cnc spare parts,spare parts for cnc machine,fanuc cnc spare parts in india,fanuc cnc spare parts,fadal cnc spare parts,haas cnc spare parts,cnc router machine spare parts hs code,cnc router spare parts india,jyoti cnc spare parts,cnc spare parts list,cnc laser spare parts,mitsubishi cnc spare parts,mazak cnc spare parts,okuma cnc spare parts,cnc router spare parts suppliers,cnc racing spare parts,cnc spare parts suppliers,siemens cnc spare parts,scm cnc spare parts,star cnc spare parts,bosch cncm30 spare parts,bosch cncm20 spare parts,cnc router spare parts,cnc tool spare parts,cnc 3018 spare parts,cnc 3040 spare parts,cnc special parts,cnc special parts eberswalde,custom cnc parts cost,custom cnc parts china,custom cnc parts near me,custom cnc parts online,custom cnc parts steering stabilizer,frame manufacturers,frame manufacturers near me,frame manufacturers in india,frame manufacturers uk,frame manufacturer malaysia,frame manufacturer in china,frame manufacturers in durban,frame manufacturer for bike,frame manufacturer,frame manufacturers machine,frame manufacturer bicycle,frame sentence of manufacture,manufacturer frame parts,photo frame manufacturer,bike frame manufacturer,steel frame manufacturer,manufacture frame the sentence,frame house manufacturer avis,frame molding manufacturer in ahmedabad,what is the frame sentence,a frame manufactured home,a frame manufacturers,a frame camper manufacturers,a frame towing manufacturers nz,a frame towing manufacturers,a frame house manufacturers,a frame cabin manufacturers,a frame trailer manufacturers,frame manufacturer business,frame manufacturers baroda,bmx frame manufacturer,vera bradley frame manufacturer,ted baker frame manufacturer,taiwan bicycle frame manufacturer,b-frame,frame manufacturer company,custom frame manufacturers,colnago frame manufacturer,bike frame manufacturer china,photo frame manufacturer china,eye frame manufacturers china,plastic photo frame manufacturers china,calvin klein frame manufacturer,c frame power press manufacturers,c frame hydraulic press manufacturers,d frame manufacturers,cote d'azur frame manufacturer,bicycle frame manufacturer europe,picture frame manufacturer europe,ernest hemingway frame manufacturer,elizabeth arden frame manufacturer,soho eyeglasses frame manufacturer,enhance frame manufacturer,elle frame manufacturer,largest eyeglass frame manufacturer,e bike frame manufacturers,e bike frame manufacturers in china,frame manufacturer factory,frame sentence for manufacture,free frame manufacturer,picture frame manufacturer for sale,bike frame manufacturer for sale,tom ford frame manufacturer,gucci frame manufacturer,guess frame manufacturer,grayson frame manufacturer,lulu guinness frame manufacturer,glasses frame manufacturer,largest glasses frame manufacturer,gant frames manufacturer,gwen stefani frame manufacturer,frame manufacturer home,steel frame house manufacture,harley frame manufacturer,heald frame manufacturer,carolina herrera frame manufacturer,scott harris frame manufacturer,van heusen frame manufacturer,h frame scaffolding manufacturer in ahmedabad,frame manufacturer in vietnam,frame manufacturers india,photo frame manufacturers in india,spectacle frame manufacturers in india,acrylic photo frame manufacturers in delhi,ring frame machine manufacturer in india,ibis frame manufacturer,i-frame,tres jolie frame manufacturer,john varvatos frame manufacturer,juicy couture frame manufacturer,betsey johnson frames manufacturer,jessica mcclintock frame manufacturer,jaguar frame manufacture

0 notes

Text

Fadal Customer Service

If you are looking for fadal customer service, simply check out our links below :

1. Fadal Support

https://www.fadal.com/support.html#:~:text=Fill%20out%20the%20form%20below,locate%20your%20local%20Fadal%20dealer.

2. Customer Support | Contact Us | FadalCNC.com

https://www.fadalcnc.com/contact-us

FadalCNC.com sells premium replacement and OEM Fadal CNC machine parts from ATC clips to…

View On WordPress

0 notes

Photo

https://www.bidspotter.com/en-us/auction-catalogues/timed/bscwint/catalogue-id-winter1-10011

FEATURED EQUIPMENT

• Mega 72 in. wide 200-Series PET Sheet Line, with 6 in. Extruder, Chill Roll Polishing Stand

• Brown 50 in. Model CS-5500 In-Line Thermoforming Machine (2009)

• (2) Una-Dyn XTLR-2000-GF Crystallizer Hopper Dryers

• (4) Armac In-Line Thermoforming Machines, each with 2-Roll Unwind Stands

• Brown SR-3036 In-Line Thermoforming Machine, with 2-Roll Unwind Stand

• Brown T-130L Trim Press (2009)

• Brown T-350L Trim Press, 30-Ton (2005)

• (2) Lyle Model 152PV Punch Presses, (1) 2009

• Cumberland 100-HP Model 50B Granulator

• AEC (Cumberland) 100-HP Model GP2439 (X1000) Granulator

• Econo Grind 75-KW Model ESS 560/1000 Grinder

• Cumberland 20-HP Model 36T Under Trimmer

• (4) Thiele & (1) Valley Automation Pressure Sensitive Labeling Lines

• Una-Dyn PCT2-2000 Pulse Cooling Tech Dehumidifying Hopper Dryer

• Una-Dyn 4/C Omni-1VWB Gravimetric Blender

• National Bulk 2,500 lb. Cap. Hyd. Tote Dumper, with Diverter

• (4) Una-Dyn 1,500-CFM & 600-CFM Gas Packs

• Over (10) Roots Rotary Lobe Blowers with Silencers, up to 30-HP, As New As 2019

• New York Blowers up to 40-HP and As New As 2020

• (5) Vertical Steel Day Silo's, 8 ft. x 8 ft. x 20 ft. high

• Fadal VMC 4020 CNC Vertical Machining Center

• (3) Fadal VMC 6030HT CNC Vertical Machining Centers

• Data Technology Model FT7260 Flatbed Laser

• Mater Model 5676 Empujador Lab Thermoforming Machine

• Promacut Model PMC 12-F Longitudinal Circular Cold Saw

• Fipi Prima Model FE25/A Clicker Die Press

• Harig 6 in. x 18 in. 618 Autostep Automatic Surface Grinder

• Dayton 9 in. x 16 in. Model 4YG31 Horizontal Band Saw

• Trane 200-Ton Air-Cooled Helical Rotary Liquid Chiller

• Kaeser 150-HP Model DSD-150 Rotary Screw Air Compressor

• Lantech Q300XT Semi-Auto Pallet Stretch Wrapper, with Ramp (2012)

• (3) Best Pack MSD 22-2 Adjustable T & B Carton Sealers

• Hyster 5,500 lb. Cap. Model S80XM-BCS LP Fork Lift Truck, with Bolzoni Auramo Roll Clamp

• Nissan 4,135 lb. Cap. Model MCU1F2A30LV LP Fork Lift Truck

• Toyota 2,500 lb. Cap. Model 7FGCU15 LP Fork Lift Truck

• Large Quantity of Plant Support Equipment

0 notes

Text

Fadal Spindle Air Kit, VLV-0006

Looking to enhance your Fadal CNC machine's performance? Order the Fadal Spindle Air Kit, VLV-0006, conveniently online at ITSCNC. Our comprehensive kit ensures optimal spindle function, promoting efficiency and precision in your machining operations. For detailed specifications and expert advice on our Fadal Valve products, don't hesitate to call us at 1-800-342-3475. Elevate your machining capabilities with ITSCNC today!

#VLV-0006#Fadal Valve#Fadal Spindle Air Seal#Fadal Valve Retrofit Kit#Fadal Valve for CNC Machine#Fadal Parts#Fadal CNC Parts#fadal machine#fadal parts for cnc machine#fadal cnc replacement parts#fadal parts manual#fadal cnc machines#fadal machine and control technical documentation#fadal parts online#fadal machine parts

2 notes

·

View notes

Link

Vertical machining relies on revolving cutters to eliminate metal from a work piece. It is also recognized as milling. Vertical machining occurs on the vertical machining center (VMC) that employs a shaft using a vertical orientation. With an upright oriented spindle, apparatuses stick straight down from tool holder, and cut across the top of a work piece. These machining is preferred where three-axis (3 axis) work is done on a single face as in mold and die work. 3-axis vertical machining works on the 3 axes, It is one of the most generally used techniques to form mechanical parts, and can be used for automatic & interactive operation for instance milling slots, drilling holes, and cutting sharp edges. 3-axis VMC have been leaders in machine tools in aerospace, medical, die mold and energy industries. The key benefits are included high efficiency, high spindle speed & rapid feed speed, increased productivity, stability completing heavy-duty cutting and high volume or low volume applications.

According to study, “Global 3-axis Vertical Machining Centers Market 2019 by Manufacturers, Regions, Type and Application, Forecast to 2024” the key companies operating in the global 3-axis vertical machining centers market are GFMS, Hermle, Chiron, DMG MORI Co. Ltd., SPINNER, Makino, Mazak, Alzmetall, Okuma Corp., JTEKT, Hardinge, MECAL, STAMA, FOM Industries, CB Ferrari, Emmegi, Fadal, Schaublin, Haas Automation Inc., Accuway, Hurco, SMTCL, AWEA, YCM, FIDIA, Hanland, DMTG, BYJC, JFMT, RIFA. The key vendors have been subjecting their products to considerable technological disruptions with an integration of modern technologies such as Non-Uniform Rational Basis Spline (NURBS) which can produce several shapes ranging from 2D line and curve or arc to complex 3D organic free-form surfaces & solids and provides better control over cutting and other operations in each axis.

Based on product type, 3-axis vertical machining centers market is segmented into low speed type and high speed type. In addition, based on end-use industry, market is segmented into aerospace manufacturing industry, machinery manufacturing industry, vehicle engineering industry and others. Vehicle engineering industry dominates the market owing to increase in need for high precision in the production process.

The 3-axis vertical machining centers market is driven by rise in demand for CNC-incorporated machine tools, followed by upgrade in emission standards, rise in vehicle sophistication, increase in demand for fabricated products and rise in investments in autonomous & electric vehicles manufacturing. However, stringent regulatory framework, refurbished vertical machining centers, and availability of horizontal machining centers may impact the market. Moreover, growth in adoption of advanced manufacturing technologies is a major opportunity for market.

Based on geography, the European and North-American regions hold major share in 3-axis vertical machining centers market owing to increase in investments in automotive manufacturing and presence of large manufacturers in the regions. The Asian-Pacific region is estimated to witness higher growth rate due to growth in economy, rise in population, and increase in disposable income of consumers over the forecast period. In upcoming years, it is expected that future of the market will be optimistic because of rise in development of advanced manufacturing processes during the forecast period. The global market is estimated to grow at a CAGR of approximately 1.0% over the next five years, will reach US $6200 million by 2024, from US $5830 million in 2019.

To know more, click on the link below:-

Global 3-axis Vertical Machining Centers Market

Related Reports:-

Global 3-axis Vertical Machining Centers Market Status (2015-2019) and Forecast (2020-2024) by Region, Product Type & End-Use

World 3-axis Vertical Machining Centers 2019 Market Research Report 2024(covering USA, EU, China, South East Asia, Japan and etc)

Contact Us:-

Ken Research

Ankur Gupta, Head Marketing & Communications

+91-9015378249

0 notes

Text

STC - Precision Machining graduates start a business

STC – Precision Machining graduates start a business

About a year ago I had heard that a couple of our graduates had started 2 different CNC machine shops. I contacted both of them and found it was true.

One of them was Keegan McDuffie and the other was Houston Miller.

Houston had bought a used Fadal CNC mill and I helped him find resources to get parts and repair. He was still working for a local CNC Job shop. I was at a local custom drag…

View On WordPress

#Brer Machine#CNC Machining#CNC Machinist#CNC Programmer#Fusion 360#Gene Haas Foundation#Haas CNC#HTEC#MasterCam#Miller precision Machine#Suncoast Technical College

0 notes

Text

5-axis Machining Centers Market Size, Growth, Trends, Industry Insights and COVID-19 Pandemic Presenting Future Opportunities 2027

"

This 5-axis Machining Centers Market research report has a complete overview of the market, covering various aspects such as product definition, segmentation based on various parameters, and the prevailing vendor landscape. The market report consists of explicit and up-to-date information about the consumer. demands, their inclinations, and their variable likings about a particular product. The report not only saves valuable time but also adds credibility to the work that has been done to grow the business. In this winning 5-axis Machining Centers Market business report, thorough investment analysis is offered which forecasts imminent opportunities for the market players and develops the strategies to grow return on investment (ROI).

The 5-axis Machining Centers market research report highlights the key trends and the factors driving the industry as well as those hindering it. Moreover, it boasts of accurate data pertaining the future growth model of this domain by referencing the past and present business landscape. Further, the document offers a broader perspective by defining the size and shares of the market and its segments, unveiling the top revenue prospects in the process.

Download Sample PDF+ All Related Graphs & Charts @: https://axelreports.com/request-sample/144708

(Note: The sample of this report is updated with COVID-19 impact analysis before delivery)

By Market Verdors:

Belotti Spa

Ellison Technologies

Pinnacle

OKUMA

DMG MORI

Jyoti CNC Automation

Mazak

SNK America

Hermle

Matsuura Machinery

Alzmetall

Chiron

Makino

Spinner

JTEKT

STAMA

Fadal

MECAL

Hardinge

Emmegi

FOM Industrie

CB Ferrari

FIDIA

Hurco

YCM

AWEA

Accuway

SMTCL

BYJC

Fives

By Types:

5-axis Horizontal Machining Centers

5-axis Vertical Machining Centers

By Applications:

Aviation

Military

Precision Equipment

High-precision Medical Equipment

Others

A detailed outline of the Global 5-axis Machining Centers Market includes a comprehensive analysis of different verticals of businesses. North America, Latin America, Asia-Pacific, Africa, and Europe have been considered for the studies on the basis of several terminologies.

Table of Content:

Market Overview: It includes six chapters, research scope, major manufacturers covered, market segments by type, Neutral and Extra Neutral Alcohol market segments by application, study objectives, and years considered.

Market Landscape: Here, the competition in the Worldwide Neutral and Extra Neutral Alcohol Market is analyzed, by price, revenue, sales, and market share by company, market rate, competitive situations Landscape, and latest trends, merger, expansion, acquisition, and market shares of top companies.

Profiles of Manufacturers: Here, leading players of the global Neutral and Extra Neutral Alcohol market are studied based on sales area, key products, gross margin, revenue, price, and production.

Market Status and Outlook by Region: In this section, the report discusses about gross margin, sales, revenue, production, market share, CAGR, and market size by region. Here, the global Neutral and Extra Neutral Alcohol Market is deeply analysed on the basis of regions and countries such as North America, Europe, China, India, Japan, and the MEA.

Application or End User: This section of the research study shows how different end-user/application segments contribute to the global Neutral and Extra Neutral Alcohol Market.

Market Forecast: Production Side: In this part of the report, the authors have focused on production and production value forecast, key producers forecast, and production and production value forecast by type.

Research Findings and Conclusion: This is one of the last sections of the report where the findings of the analysts and the conclusion of the research study are provided.

Key Questions Covered in the Report :

What is the total market value of the Global 5-axis Machining Centers Market report?

What would be the forecast period in the market report?

What is the market value of the Global 5-axis Machining Centers Market in 2021?

What is the Key Industry Leader’s opinion for the Global 5-axis Machining Centers?

Which is the base year calculated in the Global 5-axis Machining Centers Market Report?

What are the key trends in the Global 5-axis Machining Centers Market Report?

What are the market values/growth % of emerging countries?

Which market holds the maximum market share of the Global 5-axis Machining Centers Market?

Do You Have Any Query Or Specific Requirement? Ask to Our Industry Expert @ https://axelreports.com/enquiry-before-buying/144708

Note: This content doesn’t contain all the Information of the Report please fill the form (via link) and get all interesting information just one click in PDF with the latest update with chart and Table of Content.

Any special requirements about this report, please let us know and we can provide custom report.

ABOUT Axel Reports:

Axel Reports has the most comprehensive collection of market research products and services available on the web. We deliver reports from virtually all major publications and refresh our list regularly to provide you with immediate online access to the world’s most extensive and up-to-date archive of professional insights into global markets, companies, goods, and patterns.

Contact:

Axel Reports

Akansha G (Knowledge Partner)

Office No- B 201

Pune, Maharashtra 411060

Phone: US +18488639402

Email: [email protected]/

Web: https://axelreports.com/

"

0 notes

Text

CNC Machining Tolerances

CNC machine essentials ought to be called benefits. The benefits of a CNC machine are the same for every single machine because it is for each and every company who possesses one. Pc served engineering is a wonderful thing. A CNC machine presents that gain to its owners. Treatment by the staff is required less, as the device does most of the function after the software is programmed to the specifications desired. The machine may continue to run until the procedure is total, all entirely unmanned. That opens up the staff to do different projects if necessary.

Switching from the manufacturing of just one solution to a different really is easy and may save the business plenty of time. In the past it could have taken a day to several times to create a device up to help make the appropriate cuts which are necessary for the order. Now, with the CNC products, set up time is dramatically reduced. It's virtually as easy as loading a different application program.

CNC devices run not merely through a pc computer software, they're activity controlled and perform on many different axes depending upon the sort of the machine. The CNC lathe unit runs on the X and Ymca axis unlike the 5 axis models that are available these days on the market. The more axes that the device works on, the more delicate and accurate the cuts; the more creative you can become in your projects, and the more you can offer manufacture services. The CNC devices can more or less get it done all without individual treatment apart from through the use of the pc software. What is a CNC router machine

No more give wheels and joy stays causing the movement that many machining tools require. Now, the computer, through the software program, tells the equipment on what precisely to complete and the machine continues to execute before the specifications or directions have now been reached, upon which time it discontinues function for that page of material. The individual treatment that is needed with a CNC device may be the programming. Programming for the machines is written in phrase like structures which are in code. The signal shows different axes how to proceed and totally regulates all areas of the machine.

Fadal is among the leading CNC device makers. If you should be buying a top quality CNC device, then the Fadal CNC device is how you can go. Fadal offers many different makes and types of the CNC machine. These machines are made as vertical equipment centers and are generally known VMCs.

Performance Series VMCs are designed with major construction and large torque spindles. This helps to cut back the pattern time for the weightier metal operations. These products are so well made they are made from tough throw iron. They provide a variety of features such as for instance: automated mechanical spindle drive programs, fire hard field methods and a dual supply tool changer. They are the devices that you would want to use for those hard jobs as the Performance line VMCs can actually manage it.

Fadal presents other number of models for more standard operations. No matter which series that you decide to opt for, one thing is for many: a Fadal CNC machine will certainly endure the test of time and to the task at hand. They feature hard, well built construction with special functions that allows you to greatly help slice the machining time down, ultimately, helping you save time and money.

With the Fadal FX series, you can expect many characteristics that strike your competition away. These features contain: reduced pattern occasions, high machining performance, choice of controls, combined secured ball screws, improved rigidity, reduced friction, integral fire tough methods, increased shake dampening, and much more.

You are able to assume everywhere rpm for the Fadal X collection CNC machines. Machining today is becoming significantly better. Today, you can see why Fadal is one of the leaders in CNC products and CNC machining technology. The FX series is perfect for the die and mold industry. These machines are really firm with wonderful vibrant cutting power and ability.

To find out about the Fadal CNC machines either visit their web site or contact them. On the internet site you may find specific data regarding every one of their machines and the devices capabilities. When you yourself have further questions, they will have a way to solution them for you. Other merchants provide service for these machines, so you will do not have to be worried about maintaining your Fadal CNC unit operating for the business. They realize the models'abilities and how crucial they're to your business. This is the reason they produce excellent machines that are created to stand the test of time. You will surely be satisfied.

Parameters associated with the functionality of CNC models can vary greatly from one CNC kind to the other. CNC models are available in various forms. Almost anything beginning lathe systems to water jet designs, therefore the technicians for each differing device will undoubtedly be various; nevertheless, the basic principles perform the job mainly for the varied CNC unit varieties. CNC process methods should really be identified as positive aspects. The key benefits of a good CNC product is the exact same for every simple model since it is for each single company who includes one. Pc program assisted engineering is a superb thing. The CNC program presents that gain for their owners. Intervention from the workers is necessary less, while the equipment is going to do all the work the moment the applications are developed to the complex specs preferred. The device remains to operate before the task is finished, all entirely unmanned. This approach opens up the workers to hold out many other jobs if required.

CNC devices (like CNC Shark) work not merely via a applications, they're action manipulated and operated with many different axes dependant on the kind of the machine. The CNC lathe program works on the X plus Ymca axis nothing like the 5 axis products which you'll find now available in the marketplace. The higher number of axes that your device is run on, the more delicate and exact the cuts. More original you are able to become in your projects, and also the a lot more you are able to supply manufacture services. The CNC programs may more or less take action all with out persons engagement apart from through the use of the computer program.

0 notes

Text

Understanding Cnc Milling

The commonest CNC milling machines are the vertical machining middle and horizontal machining heart. Types of vertical and horizontal CNC machining centers range from three-axis benchtop CNC mills to 5 axis CNC mills, quick to lengthy travels, and fast to heavy-duty RPM spindle speeds. Some of the highest mill machine software manufacturers embrace Citizen, DMG Mori Seiki, Doosan, Daewoo, Fadal, Ganesh, Haas, Mori Seiki, Hurco, Makino, Mazak, Milltronics, Okuma, Samsung, OKK and other manufacturers.

Most CNC milling machines (also referred to as machining centers) are laptop managed vertical mills with the power to maneuver the spindle vertically alongside the Z-axis. This additional diploma of freedom permits their use in diesinking, engraving functions, and 2.5D surfaces corresponding to relief sculptures. CNC milling machines are great machines for custom manufacturing tasks. The difference between a CNC mill and a guide mill is that the CNC mill operates based mostly on an operator programming the cuts required to make the desired product. The CNC milling machine then cuts, drills, and tapers in accordance with the programmed operations.

A CNC milling machine lets you program your job offline or at the control utilizing a CAD – CAM software application and or G-Code. This permits you to save a job or part in the CNC milling machines management unit to use and reuse time and again. This reduces operator error and set up for manufacturers jobs and or components for production work or customized elements for a device room or job shop, allowing machinists to save lots of time and money. The CNC mill remains to be one of the common ways to fabricate metallic elements.

CNC mills are sooner than a regular handbook mill, as they have the potential of holding multiple instruments and shortly changing them, significantly lowering operation time. A vertical CNC mill or machining middle has a variable velocity spindle with a vertical axis orientation.

Raw material clamps on to the index table or with the help of a fixture. The spindle meeting moves alongside the travel columns in unison with the index desk to exactly maneuver the workpiece and chopping software to realize the right cutting path required for removing material. Vertical milling machines lend themselves to faster set-ups of single faceplate machining.

A knee sort CNC mill appears similar to a Bridgeport milling machine where the desk strikes up and down on the knee screw. Alternatively, on a mattress type CNC milling machine the head moves up and down.

The CNC milling process begins with the creation of a 2D or 3D CAD half design. When the machine is ready, the operator launches this system via the machine interface prompting the machine to execute the milling operation. The CNC milling machine or CNC mill are classified into two classes primarily based on the spindle orientation, both horizontal or vertical. They are also damaged down into knee sort CNC mills and mattress type CNC milling machines.

Our milling stock includes cutting-edge cutting tools for all of your vertical mill needs. The 3D CAD geometry modeled on a pc is translated into “device paths” and speeds by CAM software. A device path is the specific continuous chain of movements of the spinning slicing tool via the block of base material to be minimize. The CAM software selects tools and optimizes device paths for the shortest cutting time. The pc then interfaces with an automated CNC milling machine by sending it a stream of numerical information that determines the place of every axis at each second in time and other parameters for the cutting device.

0 notes

Text

Understanding Cnc Milling

The commonest CNC milling machines are the vertical machining middle and horizontal machining heart. Types of vertical and horizontal CNC machining centers range from three-axis benchtop CNC mills to 5 axis CNC mills, quick to lengthy travels, and fast to heavy-duty RPM spindle speeds. Some of the highest mill machine software manufacturers embrace Citizen, DMG Mori Seiki, Doosan, Daewoo, Fadal, Ganesh, Haas, Mori Seiki, Hurco, Makino, Mazak, Milltronics, Okuma, Samsung, OKK and other manufacturers.

Most CNC milling machines (also referred to as machining centers) are laptop managed vertical mills with the power to maneuver the spindle vertically alongside the Z-axis. This additional diploma of freedom permits their use in diesinking, engraving functions, and 2.5D surfaces corresponding to relief sculptures. CNC milling machines are great machines for custom manufacturing tasks. The difference between a CNC mill and a guide mill is that the CNC mill operates based mostly on an operator programming the cuts required to make the desired product. The CNC milling machine then cuts, drills, and tapers in accordance with the programmed operations.

A CNC milling machine lets you program your job offline or at the control utilizing a CAD – CAM software application and or G-Code. This permits you to save a job or part in the CNC milling machines management unit to use and reuse time and again. This reduces operator error and set up for manufacturers jobs and or components for production work or customized elements for a device room or job shop, allowing machinists to save lots of time and money. The CNC mill remains to be one of the common ways to fabricate metallic elements.

CNC mills are sooner than a regular handbook mill, as they have the potential of holding multiple instruments and shortly changing them, significantly lowering operation time. A vertical CNC mill or machining middle has a variable velocity spindle with a vertical axis orientation.

Raw material clamps on to the index table or with the help of a fixture. The spindle meeting moves alongside the travel columns in unison with the index desk to exactly maneuver the workpiece and chopping software to realize the right cutting path required for removing material. Vertical milling machines lend themselves to faster set-ups of single faceplate machining.

A knee sort CNC mill appears similar to a Bridgeport milling machine where the desk strikes up and down on the knee screw. Alternatively, on a mattress type CNC milling machine the head moves up and down.

The CNC milling process begins with the creation of a 2D or 3D CAD half design. When the machine is ready, the operator launches this system via the machine interface prompting the machine to execute the milling operation. The CNC milling machine or CNC mill are classified into two classes primarily based on the spindle orientation, both horizontal or vertical. They are also damaged down into knee sort CNC mills and mattress type CNC milling machines.

Our milling stock includes cutting-edge cutting tools for all of your vertical mill needs. The 3D CAD geometry modeled on a pc is translated into “device paths” and speeds by CAM software. A device path is the specific continuous chain of movements of the spinning slicing tool via the block of base material to be minimize. The CAM software selects tools and optimizes device paths for the shortest cutting time. The pc then interfaces with an automated CNC milling machine by sending it a stream of numerical information that determines the place of every axis at each second in time and other parameters for the cutting device.

0 notes

Text

Understanding Cnc Milling

The commonest CNC milling machines are the vertical machining middle and horizontal machining heart. Types of vertical and horizontal CNC machining centers range from three-axis benchtop CNC mills to 5 axis CNC mills, quick to lengthy travels, and fast to heavy-duty RPM spindle speeds. Some of the highest mill machine software manufacturers embrace Citizen, DMG Mori Seiki, Doosan, Daewoo, Fadal, Ganesh, Haas, Mori Seiki, Hurco, Makino, Mazak, Milltronics, Okuma, Samsung, OKK and other manufacturers.

Most CNC milling machines (also referred to as machining centers) are laptop managed vertical mills with the power to maneuver the spindle vertically alongside the Z-axis. This additional diploma of freedom permits their use in diesinking, engraving functions, and 2.5D surfaces corresponding to relief sculptures. CNC milling machines are great machines for custom manufacturing tasks. The difference between a CNC mill and a guide mill is that the CNC mill operates based mostly on an operator programming the cuts required to make the desired product. The CNC milling machine then cuts, drills, and tapers in accordance with the programmed operations.

A CNC milling machine lets you program your job offline or at the control utilizing a CAD – CAM software application and or G-Code. This permits you to save a job or part in the CNC milling machines management unit to use and reuse time and again. This reduces operator error and set up for manufacturers jobs and or components for production work or customized elements for a device room or job shop, allowing machinists to save lots of time and money. The CNC mill remains to be one of the common ways to fabricate metallic elements.

CNC mills are sooner than a regular handbook mill, as they have the potential of holding multiple instruments and shortly changing them, significantly lowering operation time. A vertical CNC mill or machining middle has a variable velocity spindle with a vertical axis orientation.

Raw material clamps on to the index table or with the help of a fixture. The spindle meeting moves alongside the travel columns in unison with the index desk to exactly maneuver the workpiece and chopping software to realize the right cutting path required for removing material. Vertical milling machines lend themselves to faster set-ups of single faceplate machining.

A knee sort CNC mill appears similar to a Bridgeport milling machine where the desk strikes up and down on the knee screw. Alternatively, on a mattress type CNC milling machine the head moves up and down.

The CNC milling process begins with the creation of a 2D or 3D CAD half design. When the machine is ready, the operator launches this system via the machine interface prompting the machine to execute the milling operation. The CNC milling machine or CNC mill are classified into two classes primarily based on the spindle orientation, both horizontal or vertical. They are also damaged down into knee sort CNC mills and mattress type CNC milling machines.

Our milling stock includes cutting-edge cutting tools for all of your vertical mill needs. The 3D CAD geometry modeled on a pc is translated into “device paths” and speeds by CAM software. A device path is the specific continuous chain of movements of the spinning slicing tool via the block of base material to be minimize. The CAM software selects tools and optimizes device paths for the shortest cutting time. The pc then interfaces with an automated CNC milling machine by sending it a stream of numerical information that determines the place of every axis at each second in time and other parameters for the cutting device.

0 notes

Text

Understanding Cnc Milling

The commonest CNC milling machines are the vertical machining middle and horizontal machining heart. Types of vertical and horizontal CNC machining centers range from three-axis benchtop CNC mills to 5 axis CNC mills, quick to lengthy travels, and fast to heavy-duty RPM spindle speeds. Some of the highest mill machine software manufacturers embrace Citizen, DMG Mori Seiki, Doosan, Daewoo, Fadal, Ganesh, Haas, Mori Seiki, Hurco, Makino, Mazak, Milltronics, Okuma, Samsung, OKK and other manufacturers.

Most CNC milling machines (also referred to as machining centers) are laptop managed vertical mills with the power to maneuver the spindle vertically alongside the Z-axis. This additional diploma of freedom permits their use in diesinking, engraving functions, and 2.5D surfaces corresponding to relief sculptures. CNC milling machines are great machines for custom manufacturing tasks. The difference between a CNC mill and a guide mill is that the CNC mill operates based mostly on an operator programming the cuts required to make the desired product. The CNC milling machine then cuts, drills, and tapers in accordance with the programmed operations.

A CNC milling machine lets you program your job offline or at the control utilizing a CAD – CAM software application and or G-Code. This permits you to save a job or part in the CNC milling machines management unit to use and reuse time and again. This reduces operator error and set up for manufacturers jobs and or components for production work or customized elements for a device room or job shop, allowing machinists to save lots of time and money. The CNC mill remains to be one of the common ways to fabricate metallic elements.

CNC mills are sooner than a regular handbook mill, as they have the potential of holding multiple instruments and shortly changing them, significantly lowering operation time. A vertical CNC mill or machining middle has a variable velocity spindle with a vertical axis orientation.

Raw material clamps on to the index table or with the help of a fixture. The spindle meeting moves alongside the travel columns in unison with the index desk to exactly maneuver the workpiece and chopping software to realize the right cutting path required for removing material. Vertical milling machines lend themselves to faster set-ups of single faceplate machining.

A knee sort CNC mill appears similar to a Bridgeport milling machine where the desk strikes up and down on the knee screw. Alternatively, on a mattress type CNC milling machine the head moves up and down.

The CNC milling process begins with the creation of a 2D or 3D CAD half design. When the machine is ready, the operator launches this system via the machine interface prompting the machine to execute the milling operation. The CNC milling machine or CNC mill are classified into two classes primarily based on the spindle orientation, both horizontal or vertical. They are also damaged down into knee sort CNC mills and mattress type CNC milling machines.

Our milling stock includes cutting-edge cutting tools for all of your vertical mill needs. The 3D CAD geometry modeled on a pc is translated into “device paths” and speeds by CAM software. A device path is the specific continuous chain of movements of the spinning slicing tool via the block of base material to be minimize. The CAM software selects tools and optimizes device paths for the shortest cutting time. The pc then interfaces with an automated CNC milling machine by sending it a stream of numerical information that determines the place of every axis at each second in time and other parameters for the cutting device.

0 notes

Text

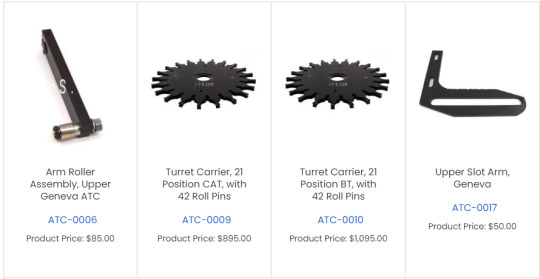

Fadal Tool Changer - Overview

About Fadal Tool Changer Parts

When it comes to Fadal tool changer parts, quality and reliability are paramount. At ITSCNC, we understand the importance of keeping your CNC machines operating at peak performance, which is why we offer a comprehensive selection of tool changer parts backed by a 90-day warranty. Whether you need carousel arms, grippers, or other components, we have you…

View On WordPress

#CNC Tool Changer Parts#Fadal Arbor Shim#Fadal Arm Roller Assembly#Fadal ATC Roller Assembly#Fadal ATC Slide Motor#Fadal ATC Tool Changer#Fadal BT Tool Clip#Fadal CAT40 Tool Clip#Fadal CNC Machines#Fadal cnc parts#Fadal Dual Arm Tool Changer#fadal machine parts#Fadal parts#Fadal Parts For CNC Machine#fadal parts online#Fadal Reman Servo Turret Amplifier#Fadal Roller Bearing#Fadal Servo Turret Power Supply#fadal tool changer#Fadal Tool Orientation Key#Fadal Turret Carrier#Fadal Turret Spindle#Fadal Turret Worm Gear

3 notes

·

View notes

Text

Understanding Cnc Milling

The commonest CNC milling machines are the vertical machining middle and horizontal machining heart. Types of vertical and horizontal CNC machining centers range from three-axis benchtop CNC mills to 5 axis CNC mills, quick to lengthy travels, and fast to heavy-duty RPM spindle speeds. Some of the highest mill machine software manufacturers embrace Citizen, DMG Mori Seiki, Doosan, Daewoo, Fadal, Ganesh, Haas, Mori Seiki, Hurco, Makino, Mazak, Milltronics, Okuma, Samsung, OKK and other manufacturers.

Most CNC milling machines (also referred to as machining centers) are laptop managed vertical mills with the power to maneuver the spindle vertically alongside the Z-axis. This additional diploma of freedom permits their use in diesinking, engraving functions, and 2.5D surfaces corresponding to relief sculptures. CNC milling machines are great machines for custom manufacturing tasks. The difference between a CNC mill and a guide mill is that the CNC mill operates based mostly on an operator programming the cuts required to make the desired product. The CNC milling machine then cuts, drills, and tapers in accordance with the programmed operations.

A CNC milling machine lets you program your job offline or at the control utilizing a CAD – CAM software application and or G-Code. This permits you to save a job or part in the CNC milling machines management unit to use and reuse time and again. This reduces operator error and set up for manufacturers jobs and or components for production work or customized elements for a device room or job shop, allowing machinists to save lots of time and money. The CNC mill remains to be one of the common ways to fabricate metallic elements.

CNC mills are sooner than a regular handbook mill, as they have the potential of holding multiple instruments and shortly changing them, significantly lowering operation time. A vertical CNC mill or machining middle has a variable velocity spindle with a vertical axis orientation.

Raw material clamps on to the index table or with the help of a fixture. The spindle meeting moves alongside the travel columns in unison with the index desk to exactly maneuver the workpiece and chopping software to realize the right cutting path required for removing material. Vertical milling machines lend themselves to faster set-ups of single faceplate machining.

A knee sort CNC mill appears similar to a Bridgeport milling machine where the desk strikes up and down on the knee screw. Alternatively, on a mattress type CNC milling machine the head moves up and down.

The CNC milling process begins with the creation of a 2D or 3D CAD half design. When the machine is ready, the operator launches this system via the machine interface prompting the machine to execute the milling operation. The CNC milling machine or CNC mill are classified into two classes primarily based on the spindle orientation, both horizontal or vertical. They are also damaged down into knee sort CNC mills and mattress type CNC milling machines.

Our milling stock includes cutting-edge cutting tools for all of your vertical mill needs. The 3D CAD geometry modeled on a pc is translated into “device paths” and speeds by CAM software. A device path is the specific continuous chain of movements of the spinning slicing tool via the block of base material to be minimize. The CAM software selects tools and optimizes device paths for the shortest cutting time. The pc then interfaces with an automated CNC milling machine by sending it a stream of numerical information that determines the place of every axis at each second in time and other parameters for the cutting device.

0 notes