#HVACcomponents

Explore tagged Tumblr posts

Text

DUCT MAT G.I CLEAT

The Duct Mat G.I. Cleat is a strong and reliable part used in heating, ventilation, and air conditioning (HVAC) systems. It is made from galvanized iron (G.I.), which means it won't rust easily and will last a long time.

*Main Features:*

- *Material:* Made from galvanized iron for strength and rust protection.

- *Design:* Holds duct mats or insulation securely in place.

- *Compatibility:* Can be used with many different duct sizes and insulation types.

- *Easy to Install:* Comes with pre-drilled holes for fast and secure attachment.

- *Durable:* Built to handle pressure and tough conditions.

- *Finish:* Has a smooth, shiny surface for extra protection and a clean look.

*Uses:*

The Duct Mat G.I. Cleat is perfect for both commercial and home HVAC systems. It helps keep insulation in place, making the system work better and use less energy. It also helps protect the duct system by preventing the insulation from moving out of place.

#alramiz#hvac#machines#wholesale#rewinding materials#thermostat#tools & safety#heater & element#acsparta#are#ARE#AL#RAMIZ#DuctMat#GICleat#HVACSolutions#DuctInstallation#GIMaterials#CleatFabrication#HVACComponents#Ductwork#MetalFabrication

2 notes

·

View notes

Text

Bhavya Machine Tools brings you the Hydraulic Shearing Machine – the perfect solution for precision sheet metal cutting. Ideal for aerospace engineering, HVAC components, and heavy manufacturing, our machine combines cutting-edge technology with reliable performance to deliver flawless results. Trust us for top-notch quality and efficiency in every cut.

For more details, visit - https://www.bhavyamachinetools.com/

#bhavyamachinetools#HydraulicShearingMachine#SheetMetalCutting#MetalFabrication#IndustrialMachinery#PrecisionEngineering#AerospaceManufacturing#HVACComponents#HeavyManufacturing

0 notes

Text

Air Cooled Condenser

Popular Condenser Manufacturers in Delhi at Concept Engineers. Our quality Air Cooled Condensing Units are typically used to cool down as well as condense refrigerant vapors into liquid form. The compressors equipped in our units efficiently raise the pressure from the refrigerant and transfers it outside with the help of quality fans. Call us: +91-9871130164 Visit our website: https://conceptengineers.co.in/

#aircooledcondenser#hvac#coolingsystem#condenserunit#aircooled#refrigeration#thermalmanagement#hvaccomponents#outdoorcondenser#heatremoval#heattransfer#finnedtubecoil#condensercoil#refrigerantflow#hvacengineering#energytransfer#forcedaircooling#fanassistedcooling#r410a#compressorsupport#commercialhvac#industrialcooling#buildingcooling#datacentercooling#manufacturinghvac#airconditioning

0 notes

Text

Refrigeration Copper Pipe Fittings Market, Global Outlook and Forecast 2025-2032

Refrigeration Copper Pipe Fittings Market Size, Demand & Supply, Regional and Competitive Analysis 2025-2031

Refrigeration copper pipe fittings are essential components in the HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration industries. They serve as connectors that direct and control the flow of refrigerants through copper pipes. These fittings come in various shapes and sizes, including elbows, tees, couplings, and valves. Designed to handle the high pressures and temperatures that are typical of refrigeration systems, these fittings are integral to ensuring a system’s efficiency and safety.

Copper is the material of choice for these fittings due to its excellent thermal conductivity, corrosion resistance, and ease of fabrication. These properties ensure reliable, leak-free connections, which in turn contribute to the longevity and performance of refrigeration and HVAC systems. Copper’s malleability also makes it easier to manufacture complex fittings that are essential for diverse applications, such as residential, commercial, and industrial refrigeration systems.

Market Size

The global refrigeration copper pipe fittings market was valued at USD 722 million in 2023 and is expected to grow to USD 943.73 million by 2032. This represents a compound annual growth rate (CAGR) of 3.90% over the forecast period. The market’s steady growth can be attributed to the rising demand for refrigeration systems, particularly in developing regions where industrialization and urbanization are on the rise.

Download a free Sample Report PDF

Historically, the refrigeration copper pipe fittings market has seen stable growth due to the increasing global demand for HVAC and refrigeration systems across various sectors, including food processing, pharmaceuticals, and automotive industries. The continued expansion of these industries, along with advancements in refrigeration technologies, is expected to drive the demand for copper pipe fittings in the coming years.

Global Refrigeration Copper Pipe Fittings Market: Market Segmentation Analysis

This report provides a deep insight into the global refrigeration copper pipe fittings market, covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trends, niche markets, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and assessing the position of the business organization. The report structure also focuses on the competitive landscape of the global refrigeration copper pipe fittings market, this report introduces in detail the market share, market performance, product situation, operation situation, etc., of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the refrigeration copper pipe fittings market in any manner.

Market Segmentation (by Application)

Refrigeration Copper Pipe

Heat Exchanger

Others

Market Segmentation (by Type)

90 Degree Elbow

45 Degree Elbow

Key Company

Conex Banninger (IBP)

Mueller Streamline

KME Copper

NIBCO

Viega

TSI Technologies

Parker

MM Kembla

Nippontube

Zhe JIANG HAI Liang

Ningbo Yongxiang Copper Pipeline

Qingdao HONGTAI COPPER

Ningbo Jintian Copper

Zhejiang Jiangxin COPPER Pipeline

Zhejiang Tongbu Pipe Industry

Linhai Hengye Tubing Equipment

Fuzhou Zhenxie PIPE

Access to full report

FAQ

What is the current market size of Refrigeration Copper Pipe Fittings?

➣ The global refrigeration copper pipe fittings market is valued at USD 722 million in 2023 and is expected to reach USD 943.73 million by 2032.

Which are the key companies operating in the Refrigeration Copper Pipe Fittings market?

➣ Key players in the market include Conex Banninger (IBP), Mueller Streamline, KME Copper, NIBCO, Viega, and Parker.

What are the key growth drivers in the Refrigeration Copper Pipe Fittings market?

➣ Key growth drivers include the increasing demand for refrigeration and HVAC systems, advances in refrigeration technology, and growing commercial and industrial applications.

Which regions dominate the Refrigeration Copper Pipe Fittings market?

➣ North America, Europe, and Asia-Pacific are the dominant regions in the refrigeration copper pipe fittings market.

What are the emerging trends in the Refrigeration Copper Pipe Fittings market?

➣ Emerging trends include the demand for eco-friendly and energy-efficient refrigeration systems and the growth of emerging markets such as Asia-Pacific and Latin America.

#RefrigerationCopperFittings#CopperPipeFittings#HVACMarket#MarketForecast#GlobalMarket#RefrigerationIndustry#PlumbingComponents#MarketTrends#IndustrialFittings#CoolingSystems#CopperMarket#MarketGrowth#HVACComponents#PipingSolutions#IndustryAnalysis#EnergyEfficiency

0 notes

Text

The Ultimate Guide to HVAC Duct Shop Drawings: Your Path to Accurate and Efficient Services

Are you ready to take your HVAC projects to new heights of precision and efficiency? Look no further than HVAC shop drawings! In this captivating exploration, we invite you to unlock the secrets behind these game-changing blueprints and witness their transformative impact on the world of heating, ventilation, and air conditioning systems.

Picture a world where every duct, every pipe, and every component fits seamlessly together, resulting in flawless installations and optimized performance. That’s the power of HVAC shop drawings. They are the unsung heroes behind successful HVAC projects, acting as a roadmap that ensures precision, coordination, and impeccable craftsmanship.

What are HVAC Shop Drawings?

HVAC shop drawings are the main base of its projects. They are detailed technical drawings that provide a comprehensive representation of HVAC systems within a building. These meticulously crafted blueprints serve as a guide for contractors, fabricators, and installers, enabling them to bring the HVAC design concepts to life with utmost accuracy and efficiency.

Key Benefits of HVAC Shop Drawings:

Pinpoint Accuracy: HVAC shop drawings leave no room for guesswork. They provide precise dimensions, equipment specifications, duct layouts, pipe routing, and electrical connections, ensuring that every element fits flawlessly into the designated space.

Streamlined Installations: By acting as a visual roadmap, HVAC shop drawings streamline the installation process. Contractors and installers can work with confidence, knowing exactly where each component should be placed and how they should be interconnected.

Coordination and Collaboration: HVAC shop drawings facilitatedrop us a line here effective coordination between different trades involved in the project. They ensure seamless integration with other building systems, such as electrical and plumbing, avoiding clashes and conflicts during construction.

Time and Cost Savings: With accurate shop drawings in hand, projects progress more smoothly, reducing the need for rework and costly delays. Fabricators can efficiently produce HVAC components based on the drawings, eliminating costly errors and wastage of materials.

KNOW MORE AVOUT OUR HVAC SHOP DRAWING SERVICES

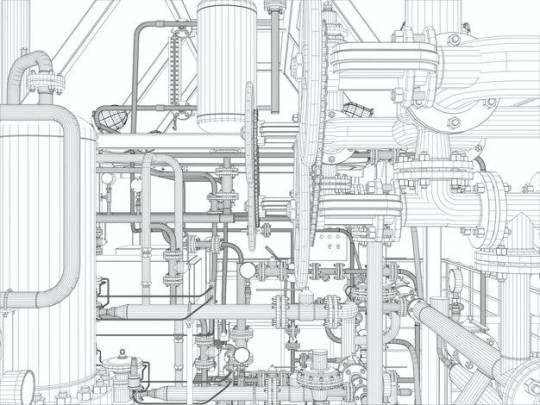

HVAC Duct Shop Drawings Services:

HVAC duct shop drawings play a crucial role in the successful implementation of its systems. They serve as a roadmap for the fabrication, installation, and coordination of ductwork within a building.

In this comprehensive guideline, we will walk you through the key steps and considerations involved in HVAC duct shop drawing services, from initial concepts to final execution.

1 . Understanding Project Requirements:

Before commencing HVAC duct shop drawings, it’s essential to gather all relevant project information. This includes architectural and structural drawings, mechanical specifications, equipment details, and any design considerations specific to the project.

2. Collaborating with the Design Team:

Effective collaboration with the design team is crucial for accurate drawings. Engage in discussions to understand the design intent, spatial constraints, and any specific requirements. Coordinate with architects, mechanical engineers, and other stakeholders to ensure a comprehensive understanding of the project.

3. Accurate Measurement and Layout:

Accurate measurement and layout are vital for creating precise HVAC duct shop drawings. Utilize laser measuring devices and digital tools to capture accurate dimensions of the building and existing systems. Document any obstructions or structural elements that may impact the ductwork layout.

4. Conceptualizing Ductwork Layout:

Based on the project requirements and design specifications, begin conceptualizing the ductwork layout. Consider factors such as airflow requirements, zoning, pressure drops, accessibility, and equipment locations. Utilize industry standards and guidelines to determine appropriate duct sizes, routing, and placement.

5. Creating Detailed Shop Drawings:

6. Coordinating with Other Trades:

Effective coordination with other trades is essential to avoid clashes and ensure seamless integration of ductwork within the building. Share and review shop drawings with electrical, plumbing, and structural teams to identify any conflicts and make necessary adjustments. Collaborate to create coordinated drawings that encompass all relevant systems

7. Adhering to Building Codes and Standards:

Ensure that your HVAC duct shop drawings comply with local building codes, industry standards, and regulatory requirements. Incorporate fire protection measures, clearance guidelines, and accessibility considerations into the drawings. Seek the expertise of code consultants or third-party reviewers, if necessary, to ensure compliance.

8. Reviewing and Approvals:

Thoroughly review it for accuracy, completeness, and compliance. Seek input and approvals from the design team, project managers, and other stakeholders. Address any comments or revisions promptly to expedite the approval process.

9. Fabrication and Installation Support:

Assist the fabrication team by providing clear and detailed instructions based on the approved shop drawings. Address any queries or clarifications during the fabrication process. Provide on-site support during the installation phase to ensure accurate implementation of the ductwork.

10. Documentation and As-Built Drawings:

Maintain comprehensive documentation of the HVAC duct shop drawings, including revisions and approvals. As the project progresses, update the drawings to reflect any changes made during construction. Upon project completion, compile accurate as-built drawings that represent the final installed ductwork.

HIRE HVAC SHOP DESIGNER

Why Choose Our HVAC Shop Drawing Services?

When it comes to HVAC shop drawings, precision and expertise matter. Our team of experienced professionals specializes in creating exceptional HVAC shop drawings tailored to your project’s unique requirements. With our meticulous attention to detail, cutting-edge software tools, and commitment to excellence, we ensure that our shop drawings exceed your expectations, helping you achieve extraordinary results.

So, if you’re looking for a Perfacet HVAC shop drawing service, then look no further! Get in touch with us at [email protected]. or simply drop us a line here to unlock the full potential of your interior design.

#HVAC #HVACshopdrawings #HVACdrawings #HVACdesign #HVACinstallation #HVACcommissioning #HVACdocumentation #HVACstandards #HVACregulations #HVACsystems #HVACcomponents #HVACmaterials #HVACsoftware

#HVAC#HVACshopdrawings#HVACdrawings#HVACdesign#HVACinstallation#HVACcommissioning#HVACdocumentation#HVACstandards#HVACregulations#HVACsystems#HVACcomponents#HVACmaterials#HVACsoftware

0 notes

Link

Read about the different components of your HVAC system here.

0 notes

Link

Learn the essential pieces that create warm or cool air in your property.

0 notes

Text

Solined Valve

The Castel solenoid valve is a reliable and efficient component designed for controlling the flow of refrigerant in air conditioning and refrigeration systems. It features screw connections compatible with 3/8" SAE fittings, ensuring easy installation and a secure seal. This valve operates as normally closed, providing precise control over refrigerant flow.

Specifications:

Screw Connections: 3/8" SAE Flow Rate: 0.23 m3/h Minimum Pressure Difference: 0 bar Voltage: 220/230 V Connection: ODS 3/8" Seat Diameter: 11.5 mm

Features:

High Performance: The Castel solenoid valve offers exceptional performance, maintaining precise control over refrigerant flow rates to ensure optimal system operation.

Durable Construction: Built with quality materials, this solenoid valve is designed to withstand demanding operating conditions, providing long-lasting reliability.

Easy Installation: Featuring screw connections compatible with 3/8" SAE fittings, installation of the Castel solenoid valve is quick and hassle-free, saving time and effort

#alramiz#hvac#machines#wholesale#rewinding materials#thermostat#tools & safety#heater & element#are#acsparta#CastelSolenoidValve#RefrigerantControl#HVACComponents#EfficientFlowControl#ReliablePerformance#EasyInstallation#SecureSeal#PreciseControl#RefrigerationSystems#QualityMaterials

1 note

·

View note