#Haitian Injection Machine

Explore tagged Tumblr posts

Text

Haitian 200T mars3 loading container

0 notes

Text

Haituo machines in Egypt!

#plasticchair #chairmold #furniture #plasticstool #molddesign #plasticinjectionmold #plasticmold #injectionmold #injectionmoldingmachine #injectionmolding #plasticmolding #toolmaker #moldmaker #chinamachine #chinamold #molder #plasticproduct

#haituo #haituomachinery #haituomachine

#injection machine#moldmaker#haituo#injectionmolding#plasticinjectionmold#haitian#injectionmoldingmachine#injectionmold#haitai#mould#plasticmachine

0 notes

Text

Global Plastic Injection Molding Machine Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2030

An Injection molding machine, also known as an injection press, is a machine for manufacturing plastic products by the injection molding process. It consists of two main parts, an injection unit and a clamping unit. Machines are classified primarily by the type of driving systems: hydraulic, electric, or hybrid. Instead of being driven by a hydraulic system, all-electric machines use digitally controlled, high speed and highly efficient servo motors to drive the whole process. Each axis is controlled by an independent motor for injection, extruder, clamping and ejection. According to our (Global Info Research) latest study, the global Plastic Injection Molding Machine market size was valued at USD 10370 million in 2022 and is forecast to a readjusted size of USD 12560 million by 2030 with a CAGR of 2.8% during review period. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes. From the analysis of product segment, small and medium-sized models (clamping force ≤ 650 tons) occupy more than 90% of the market. Injection molding machines are mainly used in general plastics industry, automotive industry and home appliance industry. Haitian International, ENGEL Holding GmbH, ARBURG GmbH, Sumitomo Heavy Industries, Milacron, Wittmann Battenfeld, Fanuc, Toshiba, Nissei Plastic, Husky, JSW Plastics Machinery, Toyo, Chenhsong, Yizumi, LK Technology, Cosmos Machinery, Tederic, UBE Machinery and Windsor are the key manufacturters of Plastic Injection Molding Machine. This report is a detailed and comprehensive analysis for global Plastic Injection Molding Machine market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Clamping Force and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2023, are provided.

Sample Request: https://www.reportsintellect.com/sample-request/2911740 Key Features Global Plastic Injection Molding Machine market size and forecasts, in consumption value ($ Million), sales quantity (Units), and average selling prices (USD/Unit), 2019-2030 Global Plastic Injection Molding Machine market size and forecasts by region and country, in consumption value ($ Million), sales quantity (Units), and average selling prices (USD/Unit), 2018-2029 Global Plastic Injection Molding Machine market size and forecasts, by Clamping Force and by Application, in consumption value ($ Million), sales quantity (Units), and average selling prices (USD/Unit), 2019-2030 Global Plastic Injection Molding Machine market shares of main players, shipments in revenue ($ Million), sales quantity (Units), and ASP (USD/Unit), 2019-2030

Inquire Request: https://www.reportsintellect.com/discount-request/2911740 The Primary Objectives in This Report Are: To determine the size of the total market opportunity of global and key countries To assess the growth potential for Plastic Injection Molding Machine To forecast future growth in each product and end-use market To assess competitive factors affecting the marketplace This report profiles key players in the global Plastic Injection Molding Machine market based on the following parameters - company overview, production, value, price, gross margin, product portfolio, geographical presence, and key developments. Key companies covered as a part of this study include Haitian International, ENGEL Holding GmbH, ARBURG GmbH, Sumitomo Heavy Industries and Milacron, etc. This report also provides key insights about market drivers, restraints, opportunities, new product launches or approvals, COVID-19 and Russia-Ukraine War Influence. Market Segmentation Plastic Injection Molding Machine market is split by Clamping Force and by Application. For the period 2018-2029, the growth among segments provides accurate calculations and forecasts for consumption value by Clamping Force, and by Application in terms of volume and value. This analysis can help you expand your business by targeting qualified niche markets. Market segment by Clamping Force Below 250T 250-650T Above 650T Market segment by Application Automotive Home Appliance General Plastic Others Major players covered Haitian International ENGEL Holding GmbH ARBURG GmbH Sumitomo Heavy Industries Milacron Wittmann Battenfeld Fanuc Toshiba Nissei Plastic Husky JSW Plastics Machinery Toyo Chenhsong Yizumi LK Technology Cosmos Machinery Tederic UBE Machinery Windsor Market segment by region, regional analysis covers North America (United States, Canada and Mexico) Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe) Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia) South America (Brazil, Argentina, Colombia, and Rest of South America) Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa)

0 notes

Text

Injection Moulding Machines Market

Injection Moulding Machines Market Size, Share, Trends: Engel Austria GmbH Leads

Shift Towards All-Electric Injection Moulding Machines Enhances Efficiency and Precision

Market Overview:

The Injection Moulding Machines Market is expected to develop at a 4.2% CAGR from 2024 to 2031. The market value is predicted to rise from XX USD in 2024 to YY USD in 2031. Asia-Pacific currently leads the industry, with key data suggesting robust manufacturing activity and technical breakthroughs. The market is growing steadily, owing to rising demand from numerous end-use sectors, technological advancements, and a growing trend towards automation in manufacturing processes.

The market is expanding rapidly due to the growing demand for plastic components, especially from the automotive industry. Technological advancements in injection moulding processes and equipment are further propelling market growth.

DOWNLOAD FREE SAMPLE

Market Trends:

The injection moulding machine market is experiencing a considerable shift towards all-electric equipment. Compared to hydraulic machines, these machines are more energy efficient, precise, and clean. All-electric machines offer greater control over the moulding process, resulting in higher quality products and lower scrap rates. Furthermore, they run more silently and require less maintenance, making them increasingly popular in a variety of industries. The trend is especially significant in areas that require very precise components, such as medical devices and electronics.

Market Segmentation:

All-electric injection moulding machines have emerged as the market's dominating category, accounting for a sizable market share. All-electric devices are popular because they offer several benefits such as energy savings, precision, and cleanliness. These machines consume up to 70% less energy than hydraulic machines, leading to significant long-term cost benefits for manufacturers.

All-electric machines' precision is especially valuable in industries that require high-accuracy components, such as medical devices and electronics. A renowned industry group discovered that all-electric machines may attain precision levels of up to 0.01mm, compared to 0.05mm for hydraulic machines. This level of accuracy is essential for making complex, high-quality parts with few flaws.

Recent technological developments have accelerated the introduction of all-electric injection moulding equipment. For example, the incorporation of Industry 4.0 technology like IoT sensors and improved control systems has increased the capability of these devices. A leading market research agency reported that the market share of all-electric machines climbed from 30% in 2019 to 45% in 2023, and this trend is projected to continue in the following years.

Market Key Players:

Engel Austria GmbH

Arburg GmbH + Co KG

Sumitomo (SHI) Demag Plastics Machinery GmbH

Haitian International Holdings Limited

KraussMaffei Group GmbH

Nissei Plastic Industrial Co., Ltd.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

7 Best Injection Molding Machine Manufacturer In Hyderabad

Certainly! Here’s a concise overview of seven top injection molding machine manufacturers:

Milacron India: Milacron is a renowned global leader in the injection molding machine industry, with a significant presence in India. Their machines are celebrated for precision, energy efficiency, and reliability. Milacron offers a broad range of machines, including hydraulic, electric, and hybrid models, catering to diverse industrial needs.

JSW Plastics Machinery: JSW, a major player in the Indian industrial sector, provides high-quality injection molding machine manufacturer under its JSW brand. Known for advanced technology and robust performance, JSW machines are designed to meet stringent quality standards and are suitable for various applications, from automotive to consumer goods.

L&T Machinery: Larsen & Toubro (L&T) is an established industrial conglomerate with a strong machinery division. Their injection molding machines are known for their durability and innovation. L&T focuses on delivering high-performance machines that enhance manufacturing efficiency across different sectors.

Haitian International: Haitian is a global leader with a strong foothold in India. They are recognized for their energy-efficient and high-performance injection molding machine manufacturer. Haitian’s machines are known for their advanced technology and ability to deliver consistent, high-quality results, making them a preferred choice for many manufacturers.

FCS Group: The FCS Group offers a diverse range of injection molding machines that stand out for their durability and technological advancements. With a focus on quality and efficiency, FCS provides solutions that cater to various industrial applications, from automotive parts to consumer products.

Santec Exim: Santec Exim is noted for its comprehensive range of injection molding machines that offer excellent performance and reliability. They provide customized solutions to meet specific manufacturing needs, emphasizing high-quality standards and customer satisfaction.

Toyo Machinery & Metal Co. Ltd.: Although a Japanese company, Toyo Machinery has a strong presence in India through its local partnerships and distributors. Toyo is known for its precision and innovation in injection molding technology, offering machines that are efficient, reliable, and designed to meet modern manufacturing demands.

1 note

·

View note

Text

𝙀𝙭𝙥𝙡𝙤𝙧𝙞𝙣𝙜 𝙩𝙝𝙚 𝙋𝙡𝙖𝙨𝙩𝙞𝙘 𝙋𝙧𝙤𝙘𝙚𝙨𝙨𝙞𝙣𝙜 𝙈𝙖𝙘𝙝𝙞𝙣𝙚𝙧𝙮 𝙈𝙖𝙧𝙠𝙚𝙩: 𝘼 𝙂𝙧𝙤𝙬𝙞𝙣𝙜 𝙄𝙣𝙙𝙪𝙨𝙩𝙧𝙮!

𝘿𝙤𝙬𝙣𝙡𝙤𝙖𝙙 𝙖 𝙁𝙍𝙀𝙀 𝙎𝙖𝙢𝙥𝙡𝙚: https://www.nextmsc.com/plastic-processing-machinery-market/request-sample

The 𝙋𝙡𝙖𝙨𝙩𝙞𝙘 𝙋𝙧𝙤𝙘𝙚𝙨𝙨𝙞𝙣𝙜 𝙈𝙖𝙘𝙝𝙞𝙣𝙚𝙧𝙮 𝙈𝙖𝙧𝙠𝙚𝙩 is experiencing significant growth and innovation. With increasing demand for plastic products across various industries such as packaging, automotive, healthcare, and consumer goods, the market is expected to expand substantially in the coming years.

𝙆𝙚𝙮 𝙏𝙧𝙚𝙣𝙙𝙨 𝘿𝙧𝙞𝙫𝙞𝙣𝙜 𝙩𝙝𝙚 𝙈𝙖𝙧𝙠𝙚𝙩:

𝙏𝙚𝙘𝙝𝙣𝙤𝙡𝙤𝙜𝙞𝙘𝙖𝙡 𝘼𝙙𝙫𝙖𝙣𝙘𝙚𝙢𝙚𝙣𝙩𝙨: Automation and IoT integration in plastic processing machinery are enhancing efficiency and productivity.

𝙎𝙪𝙨𝙩𝙖𝙞𝙣𝙖𝙗𝙞𝙡𝙞𝙩𝙮 𝙄𝙣𝙞𝙩𝙞𝙖𝙩𝙞𝙫𝙚𝙨: The push for eco-friendly and recyclable plastic products is fostering the development of advanced machinery designed for sustainable processing.

𝙀𝙢𝙚𝙧𝙜𝙞𝙣𝙜 𝙀𝙘𝙤𝙣𝙤𝙢𝙞𝙚𝙨: Rapid industrialization and urbanization in developing countries are boosting the demand for plastic processing machinery.

𝘾𝙪𝙨𝙩𝙤𝙢𝙞𝙯𝙖𝙩𝙞𝙤𝙣 𝙖𝙣𝙙 𝙁𝙡𝙚𝙭𝙞𝙗𝙞𝙡𝙞𝙩𝙮: Growing demand for customized plastic products is leading to the adoption of flexible machinery capable of handling diverse production requirements.

𝙈𝙖𝙧𝙠𝙚𝙩 𝙄𝙣𝙨𝙞𝙜𝙝𝙩𝙨:

Innovations in injection molding, extrusion, and blow molding technologies are expected to drive market growth.

Key players are investing heavily in R&D to introduce cutting-edge machinery with enhanced capabilities.

𝙆𝙚𝙮 𝙋𝙡𝙖𝙮𝙚𝙧𝙨: Various key market players operating in the plastic processing machinery industry includes Star Plastic Machinery, CMD Corporation, Arburg GmbH, ENGEL, Plustech Systems & Solutions, Sumitomo (SHI) Demag Plastics Machinery GmbH, FCS Group, Toshiba Machine Co. Ltd., Milacron Holdings Corporation, Haitian International Holdings Ltd., and others.

𝘼𝙘𝙘𝙚𝙨𝙨 𝙁𝙪𝙡𝙡 𝙍𝙚𝙥𝙤𝙧𝙩: https://www.nextmsc.com/report/plastic-processing-machinery-market

𝙇𝙤𝙤𝙠𝙞𝙣𝙜 𝘼𝙝𝙚𝙖𝙙: The future of the Plastic Processing Machinery Market looks promising, with continuous advancements and a strong focus on sustainability. As the industry evolves, staying updated with the latest trends and technologies will be crucial for businesses aiming to thrive in this dynamic market.

#plastic processing#manufacturing#industry trends#sustainability#innovation#market growth#market research#machinery#market analysis

0 notes

Text

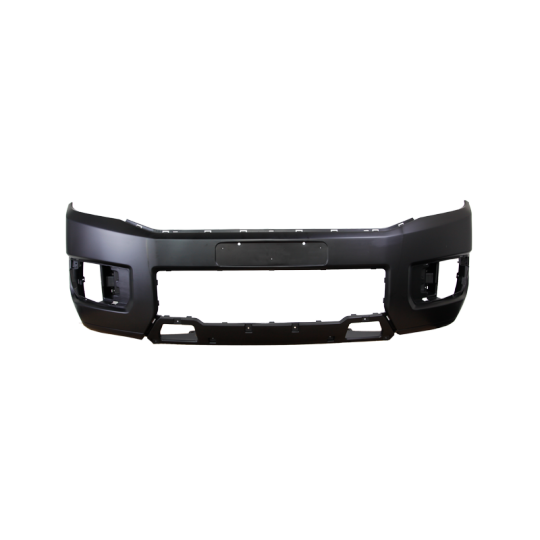

N3 FRONT BUMPER PP

Zhejiang Yongfeng Plastic Co., Ltd. was established in 1985, is a N3 Front Bumper PP Suppliers and N3 Front Bumper PP manufacturers. We have a completed system starts from design, DFM analysis, mold manufacture, to product processing, assembly, examination. The company takes over 50,000 square meters. It is professional in design, tooling and moulding automotive interior and exterior plastic parts. The company is fully equipped with design programs (UG, Catia etc.) and injection machines(mainly Haitian injection machine, from 160T to 21000T). Yongfeng cooperates with customers from design, mould tooling, and plastic parts moulding, assembling and quality checking. Company capacity is over 1 million sets plastic parts per year. Yongfeng’s high-standard quality products and professional service helps the company cooperate with customers like Beiqi, Guangqi and Huanghai.

0 notes

Text

Navigating the Landscape of Injection Molding: Unveiling the Leading Manufacturers and Machines

Injection molding stands as a cornerstone in modern manufacturing, offering a streamlined and efficient process for creating intricate plastic components. In this article, we delve into the world of injection molding companies and manufacturers, exploring the nuances of this industry, with a focus on the top players and cutting-edge machines.

Understanding Injection Molding:

Injection molding is a highly versatile manufacturing process that involves injecting molten plastic into a mold to produce a wide array of components, from simple to highly complex shapes. This method is favored for its efficiency, precision, and ability to produce high volumes of consistent parts.

Top Injection Molding Companies:

Cindre: Overview: Cindre is a standout player in the injection molding landscape, renowned for its commitment to precision engineering and material expertise. The company's injection molding prowess is exemplified by its state-of-the-art machinery and dedication to innovation.

Proto Labs: Overview: Proto Labs specializes in rapid prototyping and on-demand production through injection molding. With a focus on quick turnaround times and scalability, Proto Labs caters to a diverse range of industries, from automotive to healthcare.

Moldex3D: Overview: Moldex3D brings a unique angle to injection molding with its simulation software. This technology allows manufacturers to predict and optimize the molding process virtually, reducing the need for physical iterations and enhancing overall efficiency.

Key Considerations for Injection Molding Manufacturers:

Precision and Consistency: Top-tier injection molding manufacturers prioritize precision in their processes, ensuring that each molded piece meets exact specifications. Consistency is crucial for maintaining high-quality standards, especially in industries where tight tolerances are paramount.

Material Expertise: A deep understanding of plastic materials is a hallmark of successful injection molding manufacturers. This includes continuous research into new polymers, additives, and blends to optimize performance and meet specific application requirements.

Sustainability Initiatives: As the global focus on sustainability intensifies, leading injection molding manufacturers actively incorporate eco-friendly practices into their processes. This includes exploring recyclable materials, reducing waste, and implementing energy-efficient manufacturing practices.

Cutting-Edge Injection Molding Machines:

Arburg: Overview: Arburg is a prominent player in the injection molding machine market, offering a wide range of machines known for their precision and reliability. The company's machines cater to various industries, from automotive to medical.

Haitian International: Overview: Haitian International is a global leader in injection molding machines, with a focus on energy efficiency and cost-effectiveness. The company's offerings span a range of tonnages, making them suitable for diverse manufacturing needs.

Engel: Overview: Engel is renowned for its innovative injection molding machine technologies. The company's commitment to research and development has resulted in machines that prioritize efficiency, precision, and adaptability to different production requirements.

Future Trends in Injection Molding:

The injection molding landscape is continually evolving, with emerging trends such as the integration of Industry 4.0 technologies, the rise of sustainable materials, and advancements in automation and robotics shaping the future of this dynamic industry.

In conclusion, the world of injection molding is marked by the expertise of leading manufacturers and the cutting-edge technology of injection molding machines. As the demand for precision-manufactured plastic components continues to rise, these companies and machines play a pivotal role in shaping the landscape of modern manufacturing.

1 note

·

View note

Text

Plastic Injection Molding Machine Outlook, Geographical Segmentation, Industry Size & Share, Comprehensive Analysis to 2031

The global plastic injection molding machines market size was valued at $8,374.8 million in 2020, and is projected to reach $12,723.9 million in 2030, growing at a CAGR of 4.9%. Plastic injection molding machine is a mechanical equipment, which performs injection molding process. This process is used for mass production of injection molded plastic parts. In this report, various types of plastic injection molding machines have been considered. Plastic injection molding machines are used to manufacture items such as power tool housing, telephone handsets, electrical switches, car bumpers, disposable razors, closures, and dashboards. Injection molding machine is used in various end-user industries such as medical, automotive, home appliances, and consumer electronics industry.

Major players, such as Hillenbrand Inc, Husky Injection Molding Systems Ltd, Milacron Holding Corp, and others, offer injection molding machines with less than 200 tons clamping force. For instance, STM Inc based in Georgia, U.S. offers standard D700/I 5800 injection molding machines. It has clamping force of 7,000 KN and injection pressure capacity of 217 Mpa. In addition, these machines are equipped with five-point toggle mechanism, high-speed clamp options, either rigid platens, or others. They are widely used in automotive and packaging industries. Thus, all such factors are projected to fuel the plastic injection molding machines market growth.

The global plastic injection molding machines market is segmented based on material, application, clamping force, type, mode of operation, and region. Based on material, the market is divided into polypropylene, polyethylene, thermoplastic elastomer, cyclic olefin copolymer, acrylonitrile butadiene styrene, and others. The polyethylene segment is anticipated to dominate the global plastic injection molding machines market during the study period. Based on application, the market is classified into packaging, closures, medical, PET reforms, automotive, and others. The others segment is anticipated to dominate the global plastic injection molding machines market during the study period. The packaging segment is sub-segmented into personal care, thinwall containers, and others. The medical segment is sub-segmented into surgery, pharma, diagnostics, medical equipment, healthcare devices, and others. Based on clamping force, the market is divided into less than 200 tons force, 200 tons to 500 tons force, and more than 500 tons force. The more than 500 ton segment is anticipated to dominate the global plastic injection molding machines market. Based on type, the market is divided into standard injection molding machine, multi-component injection molding machine, and LSR injection molding machine. The standard injection molding machine segment is anticipated to dominate the global plastic injection molding machines market. Based on mode of operation, the market is fragmented into electric, hydraulic, and hybrid. The hydraulic segment is anticipated to dominate the global plastic injection molding machine market.

Competition Analysis

The key players profiled in this report include ARBURG GmbH + Co KG, ENGEL Austria GmbH, Haitian International Holding Ltd, Husky Injection Molding Systems, Krauss Maffei Group, Milacron Holdings Corp., Shibaura Machine Co Ltd., Sumitomo Heavy Industries, The Japan Steel Works, and Ube Industries, Ltd.

The major players operating in the global plastic injection molding machines market have adopted product launch and acquisition as key developmental strategies to improve the product portfolio of plastic injection molding machine products. For instance, in January 2021, Arburg GmbH + Co KG acquired AMK Arnold Muller GmbH & Co. KG with its automation division, and formed a new company AMKmotion GmbH + Co KG. The acquisition aimed to improve the product portfolio of its injection molding machines.

Full Report With TOC:-https://www.alliedmarketresearch.com/plastic-injection-molding-machines-market-A13698

0 notes

Photo

High Demand from Packaging Industry Expected to Drive World All-Electric Injection Molding Machine Market over the Forecast Period: Ken Research Buy Now An Injection molding machine is a machine for manufacturing plastic products by injection molding process, also known as an injection press.

#Arburg All-Electric Injection Molding Machine Market#Báo cáo nghiên cứu thị trường máy ép phun điện toàn thế giới#Borch All-Electric Injection Molding Machine Market#Chen De All-Electric Injection Molding Machine Market#China All-Electric Injection Molding Machine Market#Donghua All-Electric Injection Molding Machine Market#Отчет об исследовании мирового рынка обуви#Engel All-Electric Injection Molding Machine Market#Europe All-Electric Injection Molding Machine Market#Fanuc All-Electric Injection Molding Machine Market#GSK All-Electric Injection Molding Machine Market#Haitian All-Electric Injection Molding Machine Market#India All-Electric Injection Molding Machine Market#Japan All-Electric Injection Molding Machine Market#JSW All-Electric Injection Molding Machine Market#KraussMaffei All-Electric Injection Molding Machine Market#LS Mtron All-Electric Injection Molding Machine Market#Milacron All-Electric Injection Molding Machine Market#Mitsubishi All-Electric Injection Molding Machine Market#NegriBossi All-Electric Injection Molding Machine Market#Niigata All-Electric Injection Molding Machine Market#Nissei Plastic All-Electric Injection Molding Machine Market#Shuangma All-Electric Injection Molding Machine Market#South East Asia All-Electric Injection Molding Machine Market#Stork All-Electric Injection Molding Machine Market#Sumitomo (SHI) Demag All-Electric Injection Molding Machine Market#Toshiba All-Electric Injection Molding Machine Market#Toyo All-Electric Injection Molding Machine Market#UBE Machinery All-Electric Injection Molding Machine Market#USA All-Electric Injection Molding Machine Market

0 notes

Text

Injection molding machine original condition 99%new, if you are interested let me know

0 notes

Link

1 note

·

View note

Text

It also can serve as a breeding ground for insects

Patio furniture can be a sizable investment, one that you don't want to Haitian Injection Machine Screw Barrel have to make year in and year out. One of the best ways to keep your outdoor furniture looking like new for years are patio furniture covers.Patio furniture covers will keep the elements from taking their toll on your furniture.

From the harsh rays of the sun, the torrential rains of spring and fall and the cold weather and even snow of winter, your furniture can quickly fade, crack and weaken.Unfortunately, each piece of furniture doesn't come with its own cover. Still, there are plenty of choices out on the market, from patio furniture covers for single chairs to ones that cover an entire sofa or love seat.When selecting the right covers, there are some things you'll want to consider.

First, you want to select the smallest cover possible. You want it snug enough that it won't be prone to billowing in winds, which could rip the cover. But you don't want it to be so tight that a light breeze will cause it to strain to the point of tearing.Patio furniture covers that fit properly also won't form sags where water can collect. This standing water could potentially work its way into the furniture over time.

It also can serve as a breeding ground for insects, particularly mosquitoes.To measure your patio furniture covers you'll need a pad, pencil and tape measure.Start by measuring from the highest point on the back of the furniture to the ground. Then measure the width at the widest point. Finally measure from the front to the widest point on the back of the chair, sofa or love seat.This will give you the height, width and depth of the furniture.

If your piece of furniture has arms, you may want to measure them well as some patio furniture covers mirror the general shape of the chair.If you have a table with a set of chairs, push all the chairs in before you start to measure. First, measure from the ground to the top of the chair. Then measure the width and length of the table from the back of the chair to the back of the chair on the other side. Make sure the legs don't stick out farther than the back. If they do, factor that into your measurement.Now that you know the sizes you need, it's time to consider the type of weather you have. If you're in a rainy part of the country, you'll want to get covers that are of thick plastic or waterproof canvas.It if gets humid in the off-season, consider patio furniture covers that can breathe a bit so that your furniture doesn't become moldy.

Don't be tempted to go with the cheapest cover, especially if your furniture is high quality. You'll be very disappointed at the end of the season.It's highly recommended that you shop around for your covers. While there may be few choices in your local home improvement or outdoor furniture store, there are plenty of patio furniture covers to be found online. You'll find that the selection is better since online warehouses often offer better selection.If your furniture is going to be left out in the open, be sure you select patio furniture covers that are attractive.

Anyone who's had to stare at a bunch of blue tarps held down by bricks on an otherwise pristine snow covered day will understand the importance of getting covers that are nice to look at.Finally, be sure that you bring the cushions inside before covering your furniture for the season. The cushions can mold and mildew and if left out too long, can be ruined if they stay on the furniture. Clean them, dry them, then put them away in the garage or basement until the sun returns once again.

1 note

·

View note

Text

The Conscious Reaction to the Difficult Effort to Smoke

In part 1 and part 2 of this article series, we have discussed how the reasons a person started smoking at an early age helped to build the psychological smoking mechanism. This mechanism begins to operate beyond conscious control because the smoker has long since forgotten why they started smoking. The first part of the process to remove smoking is to use special techniques to recall these early reasons.

After that is done, it is time to look at the reasons a person continues to smoke.It's Hard to Smoke Each CigaretteSmokers don't consciously realize how hard it is to smoke. This is because the psychological smoking mechanism has faded into the Subconscious. It runs automatically each time a cigarette is smoked. The mind pushes all complex learned tasks into the subconscious. An example with which most people can relate is driving a car. When you first learn to drive, it is an almost overwhelming task. So many things to do, just to operate the automobile and then, you have to watch where you are going and what other drivers are doing! This is very stressful. However, eventually, all this fades into the Subconscious.

It's still just as hard, but it has become automatic so your consciousness isn't overwhelmed. The same thing happens to the complex psychological smoking mechanism.Still the difficulty of smoking is evident. Haitian Injection Machine Screw Barrel If you look at the face of a smoker, you can see the strain each time they take a drag. The face tenses and the eyes usually squint. It's the same facial expression a weight lifter has trying to lift a heavy weight. Yet, at the conscious level, the smoker has pushed this aside; it is ignored. However it is there with each cigarette and during the course of the day, the more cigarettes smoked, the more tired the smoker becomes. This is why, when a smoker manages to stop, they feel that they have so much more energy! It's not that they have more, it's that they're not wasting it fueling the psychological smoking mechanism.

The Conscious Reaction to the Difficult Effort to Smoke Each CigaretteAlthough the conscious mind ignores the extreme effort to smoke, it still registers at some level. This causes the smoker to feel the need to justify why they smoke. The next part of the process is to identify these reasons. Since these reasons are also faded into the Subconscious and not examined, special techniques have to be used to retrieve them. This is what The Unlearn Smoking Success System(tm) does in Part 2 of the program.Smokers Really Don't Like to SmokeIf you ask a smoker why they smoke, they will likely say, they like it. Yet, if you look at their behavior, it's clear they don't. For example, how many times have you seen a person smoking in their car in rainy weather, with the window rolled down to keep the cigarette away? With either the cigarette outside or the window cracked and the cigarette by the opening? If they liked it, why isn't it in the closed car with them?

The truth is, most smokers don't like smoking but the psychological mechanism they created years ago compels them to smoke. To justify doing what they don't really like, they rationalize benefits of smoking. How can they do this?By AssociationIt has been known since the early days of Psychology that by pairing things together, they become associated. The more emotion behind it, the stronger the association. For example, suppose your parents drive a particular model of car. Each time you see this car, you think of your parents. Even though it is not your parents and not their car; you have the association in your mind.

All these reasons, all these effects, are the result of you using your MIND to put a major calm on your body to tolerate the cigarette. You have given the cigarette benefits it didn't earn. Benefits caused by your MIND!While Having CoffeeAnother reason people give for smoking has to do with eating or drinking. This again is a typical association that has nothing to do with the effects of smoking a cigarette. Doing a pleasurable thing makes you feel good; adding a cigarette brings in the super MIND over BODY calm that you have developed and enhances the good feeling.

0 notes

Text

Fully Electric Injection Molding Machine Market Global Driving Factors & Technology Advancements Forecast 2024

Market.Biz focuses on providing the users or readers with a descriptive assessment of the industry and the valuable analyzed information of several markets. The latest research report on the global Fully Electric Injection Molding Machine market is completely concentrated on satisfying the requirements of the users by offering them with all insights into the industry. The Entire data Structured in the report is collected by Professional researchers and experts.

Market Scope of the Fully Electric Injection Molding Machine report:

Each segment included in the research report is detailed and well-examined based on various crucial factors such as market share, revenue, Production, Region, Usage of the Fully Electric Injection Molding Machine, Regional overview, Types, and Manufacturer. The report on Fully Electric Injection Molding Machine market supports the competitors to focus on key regions of the Industry. It also provides an independent assessment of each segment as per future opportunities.

"Global Fully Electric Injection Molding Machine Market 2019 Sample Pdf"

The Competitive Manufacturers of the Fully Electric Injection Molding Machine Market:

ARBURG Foxconn Chen Hson Holding Limited FCS Group Sumitomo Heavy Industries Taiwan Kinki Machinery Company Zhafir(Haitian International Holdings) Fanuc L.K. Group Demag Plastics Group

Some Advantages of the Global Fully Electric Injection Molding Machine Market Report:

1. This Report is a precise document that provides basic guidance to the User of the Fully Electric Injection Molding Machine market.

2. The information collected in the Report is derived for true sources such as Press releases, Personal Interviews, Industry expert reviews, Government documents, Financial Reports, and investor information.

3. The Evolution of market dynamics, market trends and also the changing supply and demand conditions are framed in the report.

4. It Quantifies market opportunities and threats with the help of market sizing and market forecasting.

5. Competitive insights included in this report helps in Tracking current trends which leads to a forecast of upcoming changes in current business ideas.

Key Type of Fully Electric Injection Molding Machine:

Horizontal Fully Electric Injection Molding Machine Vertical Fully Electric Injection Molding Machine

Main Applications of Fully Electric Injection Molding Machine:

Defense Electrical Industry Transportation Industry Construction Industry Packaging Industry Agriculture

Global Fully Electric Injection Molding Machine Market Key Geographical Segments:

North America Europe China Japan The Middle East & Africa India South America

"Ask Your Query Here"

In Addition, the Fully Electric Injection Molding Machine Market report gives a strong Foundation for gathering a bunch of insights that potential customers can refer to reduce costs and enhance the revenues. The Report is the outcome of various analyses such as Pestle analysis and Porter's 5 force analysis etc. The reference and facts in the report are put forth to give the reader a clear thought of the market.

Also, Visit this Interesting Article:

Global Vaseline Industry Market Research Report

1 note

·

View note

Text

V3 INSTRUMENT PANEL PP

Zhejiang Yongfeng Plastic Co., Ltd. was established in 1985, is a V3 instrument panel PP Suppliers and V3 instrument panel PP manufacturers. We have a completed system starts from design, DFM analysis, mold manufacture, to product processing, assembly, examination. The company takes over 50,000 square meters. It is professional in design, tooling and moulding automotive interior and exterior plastic parts. The company is fully equipped with design programs (UG, Catia etc.) and injection machines(mainly Haitian injection machine, from 160T to 21000T). Yongfeng cooperates with customers from design, mould tooling, and plastic parts moulding, assembling and quality checking. Company capacity is over 1 million sets plastic parts per year. Yongfeng’s high-standard quality products and professional service helps the company cooperate with customers like Beiqi, Guangqi and Huanghai.

0 notes