#High Heat Foams Market research

Text

06-07-23

Why Patagonia helped Samsung redesign the washing machine

Samsung is releasing a wash cycle and a new filter, which will dramatically shrink microfiber pollution.

Eight years ago, Patagonia started to study a little-known environmental problem: With every load of laundry, thousands (even millions) of microfibers, each less than 5 millimeters long, wash down the drain. Some are filtered out at water treatment plants, but others end up in the ocean, where fibers from synthetic fabric make up a surprisingly large amount of plastic pollution—35%, by one estimate. Fragments of your favorite sweatshirt might now be floating in the Arctic Ocean.

In a collaboration that began two years ago, the company helped inspire Samsung to tackle the problem by rethinking its washing machines. Today, Samsung unveiled its solution: A new filter that can be added to existing washers and used along with a “Less Microfiber” cycle that Samsung also designed. The combination makes it possible to shrink microfiber pollution by as much as 98%.

[…]

Patagonia’s team connected Samsung with Ocean Wise, a nonprofit that tests fiber shedding among its mission to protect and restore our oceans. Samsung shipped some of its machines to Ocean Wise’s lab in Vancouver, where researchers started to study how various parameters change the results. Cold water and less agitation helped—but both of those things can also make it harder to get clothing clean.

“There are maybe two ways of increasing the performance of your washing machine,” says Moohyung Lee, executive vice president and head of R&D at Samsung, through an interpreter. “Number one is to use heated water. That will obviously increase your energy consumption, which is a problem. The second way to increase the performance of your washing machine is to basically create stronger friction between your clothes . . . and this friction and abrasion of the fibers is what results in the output of microplastics.”

Samsung had already developed a technology called “EcoBubble” to improve the performance of cold-water cycles to help save energy, and it tweaked the technology to specifically tackle microfiber pollution. “It helps the detergent dissolve more easily in water so that it foams better, which means that you don’t need to heat up your water as much, and you don’t need as much mechanical friction, but you still have a high level of performance,” Lee says.

The new “Less Microfiber” cycle, which anyone with a Samsung washer can download as an update for their machine, can reduce microfiber pollution by as much as 54%. To tackle the remainder, the company designed a filter that can be added to existing washers at the drain pipe, with pores tiny enough to capture fibers.

They had to balance two conflicting needs: They wanted to make it as simple as possible to use, so consumers didn’t have to continually empty the filter, but it was also critical that the filter wouldn’t get clogged, potentially making water back up and the machine stop working. The final design compresses the microfibers, so it only has to be emptied once a month, and sends an alert via an app when it needs to be changed. Eventually, in theory, the fibers that are collected could potentially be recycled into new material rather than put in the trash. (Fittingly, the filter itself is also made from recycled plastic.)

When OceanWise tested the cycle and filter together, they confirmed that it nearly eliminated microfiber pollution. Now, Samsung’s challenge is to get consumers to use it. The filter, which is designed to be easily installed on existing machines, is launching now in Korea and will launch in the U.S. and Europe later this year. The cost will vary by market, but will be around $150 in the U.S. The cycle, which began to roll out last year, can be automatically installed on WiFi-connected machines.

#microplastics#textiles#laundry#environmental#science#patagonia#samsung#i'm. so excited.#also i HAD been silently judging patagonia a little for their heavy use of synthetics but. they ARE walking the walk actually.#(will say that ime the feel of natural fibers is just. better.)#(like. wool has an astonishing ability to keep you warm-but-not-sweaty at a bizarrely wide range of temps)#(whereas like. the synthetic fleece tops i still have are like. immediately cozy‚ sure‚ but you WILL get sweaty if you get warm)#(like being in‚ you know‚ a plastic bag!)#(so like. even if they Fix the Microplastics Problem i have no regrets abt switching my allegiance to woolens)#(but. still fucking THRILLED they might fix the microplastics problem.)#does make you feel like. i'm unavoidably a humanities person but. what are humanities ppl doing that matters this much.#like fundamentally if you really want to do good in the world you probably SHOULD become a scientist of some kind.#that said‚ science would almost certainly not be improved by my participating in it‚ so like. what can you do.#really hugely awed by & appreciative of scientists tho.#anyway. obvs this is really just a press release and we gotta see how this plays out but.#!

58 notes

·

View notes

Text

# LYNNS, ARLENE - AKA “ FIREFLY ” [ ... ] ARSENAL

training in pyrotechnics means lynns is skilled in the construction and use of incendiary devices, both handheld scale and large scale dem-olition level charges. SEE FEDERAL UPDATE, and obey all instructions with respect to federal notification protocols. engagement not recommended.

MILITARY GRADE FLAMETHROWER: a flamethrower capable of spewing flames upwards of 3,000 degrees fahrenheit / 1,648 degrees celsius.

CUSTOM FLIGHT ASSEMBLY: acquired from unknown source (possibly built by lynns herself), allowing lynns to fly up to of 250 miles per hour, and up to 360 mph with boosters engaged.

GAUNTLET LASER: both gauntlet's are equipped with lasers capable of cutting through most substances, including the most high end protective gear on the market. examination suggest this power comes from a customized gel of lynns' own design that allows a heat source to burn through almost anything.

INCENDIARY GRENADES: lynns is typically equipped with up to five of these incendiary grenades with a blast radius of about ten meters.

FLAMING SWORD: a modified wakizashi blade which emits a steady stream of flame from small nozzles mounted along the blade. flame is known to burn brighter and hotter when swung.

FLAME RETARDANT SUIT W/ COOLING UNIT: a high end flame retardant suit with built in cooling units that allow for extended presence in high temperatures. suit also acts as armor, allowing for resistance from ballistics and sharp objects.

HELMET W/ OPTOELECTRONICS: helmet is equpped with thermal imaging and night vision lenses that can be toggled remotely.

additionally, lynns has been known to steal chemicals in bulk -- aviation fuels, various chemical primers, and restricted reagents that suggest a specific chemical requirement for both her flight fuels and incendiary devices. the fire department and third party sources have noted that fires started by lynns cannot be extinguished through usual means (i.e water). recommended method is a specially developed foam developed by wayne industries' research and development division.

4 notes

·

View notes

Text

Men’s Comfortable Slippers Manufacturers and Suppliers in Saudi Arabia — Carbon Footwear

Finding comfortable slippers that blend style, quality, and affordability is essential, especially in a place like Saudi Arabia, where the climate demands footwear that can withstand heat and offer breathability. Carbon Footwear has emerged as one of the leading men’s comfortable slippers manufacturers and suppliers in the region, providing a perfect combination of comfort, durability, and elegance. In this comprehensive guide, we will explore why Carbon Footwear stands out in the competitive market and how our slippers are specially designed to meet the unique requirements of men in Saudi Arabia.

Why Carbon Footwear is the Best in the Market

Carbon Footwear, we believe that the foundation of a great slipper lies in its design, quality of materials, and the comfort it provides. Our manufacturing process is built upon these principles to ensure that every pair of slippers we produce exceeds customer expectations. We cater to a variety of needs, from casual wear to more formal, sleek designs for indoor and outdoor use.

Superior Craftsmanship and Materials

One of the key reasons behind the popularity of our slippers is the use of high-quality materials. We source the finest materials to ensure maximum comfort. The use of soft, breathable fabrics, high-quality rubber soles, and anti-slip technology ensures that our slippers are not only comfortable but also durable.

Premium Leather and Fabrics: We use top-grade leather and breathable fabrics that adapt to the foot’s shape, ensuring comfort for prolonged wear. The materials are resistant to wear and tear, making our slippers long-lasting even in extreme heat.

Ergonomic Design: Our slippers are designed with ergonomics in mind, ensuring the perfect fit for every foot type. The soft cushioning provides excellent support for your feet, reducing strain and making them ideal for daily wear.

Durability: Durability is a top priority for us. We understand the climate and lifestyle of our customers in Saudi Arabia, and our slippers are built to withstand high temperatures and daily wear without compromising on comfort or appearance.

Innovation in Comfort Technology

We have taken great care in incorporating advanced comfort technology into every pair of men’s slippers we produce. Our research and development team focuses on creating designs that promote foot health and provide maximum comfort throughout the day.

Arch Support: Our slippers are designed with added arch support to ensure better posture and reduce foot fatigue, especially during long hours of use. This is particularly beneficial in a hot climate, where comfort can make a big difference in daily activities.

Memory Foam Soles: The use of memory foam soles ensures a custom fit for every individual. The foam adapts to the shape of your foot, providing personalized comfort and preventing foot pain or discomfort.

Breathable Design: Our slippers feature a breathable design to ensure proper ventilation, keeping feet cool and dry, even in the scorching heat of Saudi Arabia.

A Wide Range of Styles and Designs

Carbon Footwear offers an extensive collection of men’s slippers that cater to various preferences and occasions. Whether you’re looking for something casual for daily wear or a more polished option for special occasions, we have something to suit your style.

Casual Slippers: Our range of casual slippers is perfect for daily wear, offering a combination of comfort and style that fits effortlessly into your lifestyle.

Formal Slippers: For those seeking a more refined look, our formal slippers provide a sleek and elegant design, suitable for office wear or special occasions. These slippers are made from premium materials, offering both durability and sophistication.

Outdoor Slippers: Designed for outdoor use, these slippers feature rugged soles and extra durability, making them ideal for various outdoor activities while maintaining the highest level of comfort.

Customizable Options for Bulk Orders

We cater to both individual customers and businesses looking for bulk orders. Our slippers are customizable based on specific preferences, including size, color, design, and branding. This makes Carbon Footwear an ideal partner for retailers and businesses looking to offer high-quality men’s slippers under their own brand.

We offer competitive pricing for bulk orders without compromising on quality, ensuring that our partners receive value for money with every purchase.

Sustainability and Ethical Manufacturing

As part of our commitment to the environment, Carbon Footwear places a strong emphasis on sustainable and ethical manufacturing processes. We source eco-friendly materials and ensure that our manufacturing processes have minimal environmental impact. Our factories maintain high standards of labor practices, ensuring a safe and fair working environment for all our employees.

Eco-friendly Materials: We use sustainable materials that are both durable and environmentally friendly, helping to reduce our carbon footprint.

Energy-efficient Manufacturing: Our production facilities incorporate energy-efficient technologies to minimize waste and emissions, aligning with global sustainability goals.

Availability and Distribution in Saudi Arabia

We have a well-established distribution network across Saudi Arabia, ensuring that our slippers are readily available in major cities, including Riyadh, Jeddah, and Dammam. Additionally, we offer fast and reliable shipping options for online orders, allowing customers to conveniently purchase their preferred slippers from the comfort of their homes.

Local Retailers and Distributors: Our partnerships with local retailers ensure that Carbon Footwear slippers are available in stores across the country, making it easy for customers to find and try on our products.

Online Availability: We also have a strong online presence, allowing customers to browse our collections and place orders directly through our website. Our user-friendly platform ensures a seamless shopping experience, complete with secure payment options and fast delivery services.

Read more - Men’s Comfortable Slippers Manufacturers and Suppliers in Saudi Arabia — Carbon Footwear

Customer Satisfaction and Support

At Carbon Footwear, customer satisfaction is at the core of our business. We strive to provide the best possible experience for our customers, from the moment they browse our products to after-sales support.

Easy Returns and Exchanges: We offer a hassle-free return and exchange policy, ensuring that our customers are completely satisfied with their purchases.

Customer Support: Our dedicated customer support team is available to assist with any queries, from product information to order tracking, ensuring a smooth and enjoyable shopping experience.

Conclusion

In the competitive market of men’s comfortable slippers in Saudi Arabia, Carbon Footwear stands out as a leader in innovation, comfort, and quality. Our commitment to superior craftsmanship, sustainable practices, and customer satisfaction sets us apart from other manufacturers and suppliers in the region. Whether you are looking for casual, formal, or outdoor slippers, our extensive collection ensures that you will find the perfect pair to suit your needs.

#pu footwear manufacturer in rajasthan#pu gents and ladies footwear in india#gent and ladies shoes manufacturer in india#stylish footwear for kids in rajasthan#best sandal for ladies in india#best quality gents and ladies shoes in india#school footwear for kids in jaipur#gents shoes manufacturer in india

0 notes

Text

Informative Report on PFAS Chemical Material Market | Bis Research

Per- and polyfluoroalkyl substances (PFAS) are a class of synthetic chemicals that have seen extensive global application across various industries and consumer products.

These substances are commonly found in items such as non-stick cookware, water-resistant clothing, stain-resistant carpets, certain cosmetics, firefighting foams, and products designed to repel grease, water, and oil.

The PFAS chemicals market is projected to reach $51,727.5 million by 2034 from $29,500.0 million in 2023, growing at a CAGR of 5.19% during the forecast period 2024-2034

Overview

Per- and polyfluoroalkyl substances (PFAS) are a group of synthetic chemicals that have been manufactured and used in various industries since the 1940s. These chemicals are characterized by their strong carbon-fluorine bonds, making them highly resistant to heat, water, and oil. PFAS are commonly referred to as "forever chemicals" due to their persistence in the environment and resistance to natural degradation.

Types of PFAS

Perfluoroalkyl substances: Fully fluorinated carbon chains.

Polyfluoroalkyl substances: Partially fluorinated carbon chains.

Properties and Uses

Non Stick Cookwares - PTFE (Teflon) coatings are made with PFAS chemicals.

Waterproofing- Used in clothing, furniture, and carpets to resist water and stains.

Firefighting Foam- Aqueous film-forming foams (AFFFs) containing PFAS are effective at suppressing fuel fires.

Electronics- PFAS are used in wiring and semiconductor manufacturing due to their insulating and heat-resistant properties.

Download our Report to know more !

Key Features and Benefits for PFAS Chemical Material

Key Features and Benefits

Key features are as follows

Chemical Stability

Hydrophobic and Lipophilic Stability

Thermal Resistance

Low Surface Energy

Electrical Insulation

Chemical Inertness

Key Benefits are as follows

Consumer Product Enhancement

Industrial Applications

Medical and Healthcare Uses

Electronics and Electrical Industry

Food Packaging

Visit our sample page click here !

Market Segmentation for PFAS Chemical Material

1 By Application

Blowing Agents, Refrigerants and Coolants, and Flame Retardants to Lead the Market - Blowing agents, refrigerants, coolants, and flame retardants are expected to dominate the PFAS chemicals market by application, given their essential roles in high-demand industries such as construction, electronics, and automotive. The unique properties of PFAS chemicals, such as thermal stability, non-flammability, and durability, make them critical in enhancing product performance. For instance, blowing agents are pivotal in creating insulating foams that boost energy efficiency, while refrigerants and coolants are vital for thermal regulation in various systems. Flame retardants contribute significantly to safety standards across numerous applications.

2 By Product - Others Segment to Lead the Market

The other segment is expected to lead the PFAS chemicals market by product due to its broad applicability and distinctive chemical properties. This category includes specialized PFAS compounds that do not fall under conventional classifications but are essential for industries requiring advanced performance and versatility.

By Region- Asia-Pacific Region to Lead the Market

The Asia-Pacific region is positioned to lead the PFAS chemicals market, driven by rapid industrialization, urbanization, and the growth of key sectors such as electronics, textiles, and automotive manufacturing. Countries such as China, Japan, and South Korea are significant consumers of PFAS chemicals, essential in applications such as water and stain repellents, firefighting foams, and semiconductor production

Visit our Advanced Materials Chemical Vertical Page here !

Key Players

3M

AGC Inc.

Archroma

Arkema

BASF

Bayer AG

BIONA JERSÍN s.r.o.

The Chemours Company

Market Drivers for PFAS Chemical Material

1 Growing demand for Non Stick and Strain Resistant Products

Consumer Goods: The increasing demand for non-stick cookware, water-resistant textiles, and stain-resistant fabrics is a significant driver for PFAS chemicals.

Home Furnishings: Carpets, upholstery, and other home textiles benefit from PFAS coatings, enhancing their durability and stain resistance.

2 Expanding Use in the Automotive and Aerospace Industries

High-Performance Materials: PFAS materials are used in automotive and aerospace sectors for seals, gaskets, hoses, and lightweight components.

Fuel Resistance: PFAS-based components that resist exposure to fuels, oils, and other chemicals are critical for engine performance and efficiency.

3. Increased Adoption in Electronics and Semiconductors

Electrical Insulation: PFAS materials are widely used in the electronics industry due to their excellent insulating properties, making them ideal for use in wiring, cables, and connectors.

Semiconductor Manufacturing: The semiconductor industry requires materials with high purity, chemical resistance, and stability, all of which PFAS provide, ensuring their continued use in the production of microchips and other components.

4 Growth in Food Packaging and Food Safety Concerns

Grease-Resistant Packaging: The food packaging industry continues to rely on PFAS materials for grease-proof and water-resistant packaging, which helps extend the shelf life of food products and maintain quality during transportation and storage.

Regulatory Compliance in Packaging: PFAS coatings in food packaging also provide a barrier against contaminants and help meet stringent food safety regulations.

Conclusion

The market for PFAS Chemical Material s is poised for significant growth, driven by a confluence of regulatory pressures, increasing consumer demand for sustainable practices, and the urgent global need to address climate change. As innovation in materials science and manufacturing processes continues to advance, low carbon materials are becoming more accessible and cost-effective, further accelerating their adoption.

0 notes

Text

Specialty Tapes Market: Current Analysis and Forecast (2021-2027)

A comprehensive overview of the global specialty tapes market is recently added by UnivDatos Market Insights to its humongous database. The report has been aggregated by collecting informative data from various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the specialty tapes markets globally. This report offers a detailed analysis of the latest industry developments and trending factors that are influencing market growth. Furthermore, this statistical market research repository examines and estimates the global specialty tapes market at regional and country levels. The global specialty tapes market is likely to showcase a growth of around 6% during the forecast period.

Market Overview

Specialty tapes are composed of a carrier film, foil, or other flexible material. These tapes are manufactured with high-performance adhesives using carrier materials and are designed for utilization in industries including electrical & electronics, automotive, building & construction, retail & graphics, and healthcare. Further, the trend toward using flatter and micro-electronic devices continues, increasing the application of specialty tapes in the electrical & electronics industry. In addition, the demand for in-vitro diagnostics, hydrophilic films, transdermal drug delivery patches, and oral dissolvable films are driving the specialty tapes market in the healthcare industry, globally. Furthermore, rising construction activities are rising the demand for specialty tapes for mounting window panels and sealing gaps in the window and door panels.

The global specialty tapes market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

By backing material, the market is primarily divided into:

Polyvinyl Chloride

Woven/Non-Woven

Paper

Foam

Polypropylene

Others

Among these, the paper held a prominent share in the global specialty tapes market. Paper tapes have excellent adhesion, heat insulation, temperature tolerance, and are environmentally safe, and come in various colors. Further, when compared to other adhesive tapes, these tapes offer more comfort. Moreover, they are thin, flexible, and smooth, making them ideal for vehicle and aviation manufacture, as well as appliance manufacturing, HVAC, and paper and printing applications.

By end-user, the market is primarily divided into:

Electrical & Electronics

Healthcare

Automotive

Paper & Printing

Building & Construction

Others

Among these, healthcare held a prominent share in the global specialty tapes market. The specialty tapes market is rising in healthcare due to the aging population, increased chronic illness incidence, and the high demand for in vitro diagnostics, hydrophilic films, transdermal patches, and oral dissolvable films. Also, the development of products such as disposable infant diapers, feminine hygiene products, and adult incontinence products all use specialty tapes.

Global Specialty Tapes Market Geographical Segmentation Includes:

North America (United States, Canada, Rest of North America)

Europe (Germany, France, United Kingdom, Italy, Spain, Rest of Europe)

Asia-Pacific (China, Japan, India, Australia, Rest of APAC)

Rest of the World

Asia-Pacific held a prominent share in the specialty tapes market owing to growing industries such as electric & electronics, healthcare, packaging, building and construction, and others. Also, the market growth can be attributed to the expanding automotive industry, in electric vehicles (Evs), specialty tapes are used for covering the gaps and for bonding purposes in the battery. Other prominent applications of such tapes in Evs are motor assembly, insulation, and wire harnessing. Moreover, increasing disposable income and rapid economic growth in the region are increasing the better-quality products, and improving the lifestyle is also fueling the market for specialty tapes.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=25092

Competitive Landscape

The degree of competition among prominent companies has been elaborated by analyzing several leading key players operating globally. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the global specialty tapes market. The major players have been analyzed by using research methodologies for getting insight views on market competition.

Key questions resolved through this analytical market research report include:

What are the latest trends, new patterns, and technological advancements in the global specialty tapes market?

Which factors are influencing the global specialty tapes market over the forecast period?

What are the global challenges, threats, and risks in the global specialty tapes market?

Which factors are propelling and restraining the global specialty tapes market?

What are the demanding global regions of the global specialty tapes market?

What will be the market size in the upcoming years?

What are the crucial market acquisition strategies and policies applied by the companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature. Please let us know if you have any custom needs.

Browse Related Newsletter from UnivDatos Market Insights

Autonomous Vehicle Sensor Compatible Coating Market: SWOT Analysis [2023-2028]

Glyphosate Market: SWOT Analysis [2023-2028]

About Us:

UnivDatos Market Insights: Your Partner in Data-Driven Market Strategies. Unlock growth opportunities and make smart decisions with our expert research and insights.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

Industrial Insulation 2023 Industry - Technologies, Applications, Verticals, Strategies & Forecast 2030

Industrial Insulation Industry Overview

The global industrial insulation market size was valued at USD 8.21 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.0% from 2023 to 2030.

Increasing product demand for boosting process efficiency, condensation control, noise reduction, freeze protection, and for reducing environmental pollution is expected to drive market growth over the forecast period. In addition, the rising awareness regarding the benefits of insulation in the industrial application and its related costs is expected to drive the market for industrial insulation in North America.

Gather more insights about the market drivers, restrains and growth of the Industrial Insulation Market

The market witnessed a severe downfall in the investments in the industrial sector owing to the pandemic, thereby impacting the market. In addition, dramatic fall in crude oil prices led to a drop in fiscal resources for oil-producing countries, which affected the product demand from oil & gas sector.

The market in the U.S. is expected to witness increased demand for insulation for industrial applications, such as, machinery, boilers, pipes, and storage tanks, and in linings of heat exchangers, cooling towers, and ventilation & air conditioning systems, among others. The demand outlook for the U.S. is favorable, with private investments in the industrial sector reaching the highest levels in 2018. The industrial sector is predicted to witness significant expansion owing to the rising GDP.

Many of the major manufacturers opt for independent distribution, in order to better serve their customers in case of customized products and to increase their profit margin. Manufacturers also establish a strategic relationship with distributors and provide solutions to the end-users through direct or third-party distribution.

The buyers in the market are essentially medium to large-scale businesses that exhibit limited sensitivity to the price of the product and lay higher emphasis on the product quality and the degree of insulation provided by the materials. In addition, key consumer industries have also exhibited a trend of adoption of the advanced products, which in turn is expected to drive the demand for niche product such as aerogel, perlite.

The market is exhibits high entry barriers, owing to the presence of large number of players. In addition, capital intensive nature of the market ensures the requirement of a substantial amount of time, planning, and resources for entry and sustenance. Achieving economies of scale remain a top priority in the market, which may discourage new market entrants.

Major industry participants are developing novel manufacturing processes for products in order to enhance its properties and make it suitable for several applications. Continuous investments in the R&D process by the companies for new product development and improvement in transparent technology for thermal insulation is expected to benefit the market.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

• The global copper pipes and tubes market size was estimated at USD 22.52 billion in 2023 and is estimated to grow at a CAGR of 5.9% from 2024 to 2030.

• The global automotive steel wheels market size was estimated at USD 14.94 billion in 2023 and is forecasted to grow at a CAGR of 2.5% from 2024 to 2030.

Global Industrial Insulation Market Report Segmentation

This report forecasts revenue growth at global, regional & country levels and provides an analysis on the industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global industrial insulation market on the basis of material, product, application, and region.

Material Outlook (Volume, Kilotons; Revenue, USD Billion; 2018 - 2030)

Stone Wool

Elastomeric Foam

Micro Silica

Glass Wool

Composites

CMS Fibers

Calcium Silicate

Cellular Glass

Foamed Plastic

Perlite

Aerogel

Cellulose

Others

Product Outlook (Volume, Kilotons; Revenue, USD Billion; 2018 - 2030)

Pipe

Board

Blanket

Others

Application Type Outlook (Volume, Kilotons; Revenue, USD Billion; 2018 - 2030)

Power Generation

Petrochemical & Refineries

EIP Industries

LNG/LPG

Others

Regional Outlook (Volume, Kilotons; Revenue; USD Billion; 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Poland

Spain

Italy

Benelux

Nordic

CIS

Asia Pacific

China

India

Japan

South Korea

Indonesia

Malaysia

Thailand

Vietnam

Central & South America

Brazil

Argentina

Colombia

Middle East & Africa

GCC

Turkey

Key Companies & Market Share Insights

The industry players are focused on increasing their market share through organic growth, rather than mergers and acquisitions. Companies in the market are focusing on expanding their product portfolio by developing cost-effective insulation products with enhanced properties. Manufacturers are also focusing on expanding their manufacturing capabilities in order to cater to the ascending product demand.

Large players, like Armacell have focused on international strategy, through which the company acquired Polipex Industria e Comercio Ltda, a Brazilian manufacturer of extruded polyethylene insulation products for technical equipment. The company also established a joint venture with JIOS Aerogel, South Korea to develop & manufacture high-tech silica aerogel blankets. Some prominent players in the global industrial insulation market include.

Rockwool Insulation A/S

Poroc Group Oy

Knauf Insulation

TechnoNICOL Corporation

Anco Products, Inc.

Aspen Aerogels, Inc.

Cabot Corporation

Morgan Advanced Materials plc

Unifrax LLC

RATH Group

IBIDEN Co., Ltd.

Armacell International

Order a free sample PDF of the Industrial Insulation Market Intelligence Study, published by Grand View Research.

0 notes

Text

Commercial Vehicle Accessories Market ruling majority of the Aftermarket Automotive Accessories Market

The Commercial Vehicle Accessories Market is a dominant force within the broader Aftermarket Automotive Accessories Market, driven by the increasing demand for enhanced vehicle functionality, safety and aesthetics. With the rising global fleet of commercial vehicles, particularly in emerging economies, the demand for specialized accessories such as telematics systems, cargo management solutions, lighting and safety features is rising. This market encompasses various products and services, including vehicle tracking systems, custom interiors, performance-enhancing parts and external accessories like mud flaps and roof racks.

The Commercial Vehicle Accessories Market has skyrocketed to a market cap of USD 94.88 Billion last year in 2023. This market is experiencing a CAGR of 6.30% which has driven its potential by the increase in demand for essential accessories such as interior upgrades, safety equipment and technological advancements in commercial vehicles.

Some of the Prominent Companies in the Commercial Vehicle Accessories Market are :-

Robert Bosch - Europe (Germany)

Denso - Asia (Japan)

Magna International - North America (Canada)

ZF Friedrichshafen - Europe (Germany)

Hyundai Mobis - Asia (South Korea)

Aisin Seiki - Asia (Japan)

Faurecia - Europe (France)

Lear - North America (USA)

Valeo - Europe (France)

Thyssenkrupp - Europe (Germany)

BASF - Europe (Germany)

Panasonic Automotive - Asia (Japan)

Gestamp - Europe (Spain)

Commercial Vehicle Accessories Market Segmentation

Product by Type Coverage (Includes Market Size, Products by Segment, its Type and Influence) :-

Driveline & Powertrain

Interiors & Exteriors, Electronics

Bodies & Chassis

Seating

Lighting

Wheel & Tires

Market Application in Commercial Vehicle Accessories Market:-

OEMs

Aftermarket

The Commercial Vehicle Accessories Market is segmented by Type and by Application, actors, stakeholders and the other members associated with the Commercial Vehicle Accessories Marketplace who can benefit from consuming the included content as a useful and powerful resource. The report consists of 162 pages of comprehensive data points that are segregated from different key regions around the world.

When it comes to commercial vehicles, the right accessories can make all the difference. Whether it's boosting performance, enhancing safety, or just making the ride more comfortable, the Commercial Vehicle Accessories Market offers a wide range of products designed to meet the unique needs of different industries.

Applications: OEMs vs. Aftermarket

Let’s start by breaking down where these accessories come from. There are two main sources:

OEMs (Original Equipment Manufacturers): These are the accessories that come directly from the vehicle’s manufacturer. They’re built to fit perfectly and work seamlessly with your vehicle. Think of these as the “official” parts that come pre-installed when you buy a new truck or van.

Aftermarket: This is where things get interesting. The aftermarket offers a huge variety of accessories that you can add or upgrade after you’ve bought your vehicle. Whether you’re looking for a better sound system, stronger tyres, or a high-tech navigation system, the aftermarket has it all. Plus, it often offers more options and better prices than OEMs.

Contact Us :

Report Prime - [email protected]

Browse more reports :

Automotive Heat Shields Market Overview

Automotive Parts Zinc Die Casting Market Growth and Restraints

Automotive Fuse Market Size

Sidewall Hovercraft Market and Military Hovercraft Market

Amphibious Hovercraft Market | Light Hovercraft Market

Automotive Hydraulic Systems Market Cap

Fire Block Foam Market Cap

Boron Phosphide Market Forecast [2023-2030]

Market Research by Report Prime.

#CommercialVehicleAccessoriesMarket #CommercialVehicles #CommercialVehicleAccessoriesMarketSize #CommercialVehicleAccessoriesMarketGrowth #VehicleAccessories #CommercialVehicleAccessoriesTrends #CommercialVehicleAccessoriesMarketOppportunities #OEM #Aftermarket #Denso #RobertBosch #MagnaInternational #Continental #ZFFriedrichshafen #AutomotiveIndustry #AutomobileIndustry #AutomotiveMarket #AutomobileMarket

0 notes

Text

Crosslinking Agent Market Share, Size, Future Demand, and Emerging Trends

Market Overview

The crosslinking agent market generated USD 10,207.3 million in 2023, which is projected to increase at a CAGR of 7.4% to attain USD 16,491.4 million by 2030. This is because crosslinking agents perform better, and there is a growing need for a variety of coatings.

The growing emphasis on sustainability and eco-friendly solutions is leading to the development of original cross-linking agents with a lower environmental impact.

Materials with enhanced qualities, such as strength, heat resistance, and durability, are required by industries including electronics, aerospace, and automation. Improved physical qualities are provided by these cross-linking, which are required for long-term heat resistance and durability in applications including medical devices, foam, pipes, cables, wires, and other PE applications.

These crosslinking agents do not produce any pollutants and release very low amounts of volatile organic chemicals. These agents are becoming common in a variety of applications, including wood finishing and automotive coatings.

These agents are used to improve the mechanical strength, chemical resistance, and thermal stability of polymers. In addition, the market's projected expansion is credited to the growing need for water-based crosslinking agents.

The production of bonds by condensation and free-radical polymerization eliminates most issues during usage, which is why the chemical crosslinking technique is mostly opted for.

Key Insights

The amino category held the largest market share, of 40%, in 2023.

This is due to the exceptional crosslinking capabilities and compatibility with a broad range of polymers offered by amino compounds, such as amino resins and amino silanes.

Specialized and advanced crosslinking agents, such as amino-based ones, have been introduced as a result of the ongoing research and development in amino chemistry.

The isocyanate category is expected to show the fastest growth in the market during the expected duration, owing to the growing application of these variants in a range of coating applications, including high-performance, ornamental, appliance, and automotive coatings.

Industrial coating is predicted to show the higher CAGR, of 8%, during the forecast period due to their wide usage in industries such as construction and automotive.

The industrial sector places a high priority on product quality and regulatory compliance, which propels the need for crosslinking agents to adhere to the strict specifications.

These agents increase the mechanical characteristics, chemical resistance, and lifespan of the materials used in various industries.

The decorative category holds the larger market share due to the usage of these coatings in in high volumes in commercial, residential, industrial, and institutional buildings.

The need for crosslinking agents in decorative coatings has increased as a result of the middle class's growing population and disposable income.

The APAC region is expected to grow at the fastest rate in the next few years, with China accounting for the largest share. This is attributed to its expanding economy and the growing automotive, electricals, and manufacturing sectors.

Governments’ encouragement programs for industry, increasing R&D spending, and a growing emphasis on environment-friendly solutions all contribute to the regional market's expansion.

Europe accounted for 20% of the revenue share in 2023 due to the growing construction industry, especially housing.

BASF, which has its headquarters and manufacturing plants in the region, announced in 2023 that it will increase the amount of isocyanate it now produces and increase its manufacturing capacity to approximately 600,000 metric tons annually.

Source: P&S Intelligence

#Crosslinking Agent Market Share#Crosslinking Agent Market Size#Crosslinking Agent Market Growth#Crosslinking Agent Market Applications#Crosslinking Agent Market Trends

1 note

·

View note

Text

The Ultimate Guide to Finding quality EPS Panel Manufacturer in India

Are you searching for the best EPS panel manufacturer in India? Look no further! In this ultimate guide, we will provide you with all the necessary information to make an informed decision. Whether you need EPS panels for your construction project or any other application, finding a reliable and high-quality manufacturer is crucial for success.

India is a bustling market with numerous manufacturers claiming to offer the best products and services. But how do you narrow down your options and choose the right one? That's where our guide comes in. We will walk you through the key factors to consider when selecting an EPS panel manufacturer in India, including quality standards, experience, pricing, delivery, and customer support.

By choosing the right manufacturer, you can ensure that your EPS panels are not only durable and energy-efficient but also meet your specific requirements. Don't settle for subpar products when you can have the best. Get started on your search for the top EPS panel manufacturer in India by diving into our comprehensive guide.

Understanding EPS panels and their uses

Expanded Polystyrene (EPS) panels are a versatile and widely-used building material that offer a range of benefits for various applications. These lightweight, yet durable panels are composed of expanded polystyrene foam, a material known for its excellent insulation properties, thermal efficiency, and structural strength.

EPS panels are commonly used in the construction industry for wall, roof, and floor insulation. They help regulate indoor temperatures, reducing the energy required for heating and cooling, thereby contributing to energy savings and a more sustainable built environment. Beyond construction, EPS panels find applications in packaging, automotive, and even the agricultural sector, where they are used for protecting and insulating sensitive products during transportation and storage.

Importance of choosing the right EPS panel manufacturer

Selecting the right EPS panel manufacturer in India is a critical decision that can have a significant impact on the success of your project. The quality, reliability, and performance of the EPS panels you choose can make or break your construction or application, affecting everything from the structural integrity to the overall energy efficiency of your building or product.

When you choose a reputable and experienced EPS panel manufacturer, you can be confident that you are investing in products that meet the highest standards of quality and safety. These manufacturers have the expertise, resources, and production capabilities to deliver EPS panels that consistently perform to your expectations, ensuring a smooth and successful project outcome.

Factors to consider when selecting an EPS panel manufacturer

When searching for the best EPS panel manufacturer in India, there are several key factors to consider to ensure you make an informed and strategic decision. These factors include quality standards, experience, pricing, delivery, and customer support, all of which play a crucial role in determining the success of your project.

Quality standards are of paramount importance when it comes to EPS panels. Look for manufacturers that adhere to strict quality control measures, use high-quality raw materials, and employ advanced production techniques to ensure the consistency and durability of their products. Certifications and accreditations from reputable industry organizations can provide valuable insights into a manufacturer's commitment to quality.

The experience and track record of an EPS panel manufacturer are also crucial factors to consider. Look for a company with a proven history of delivering successful projects, a deep understanding of the industry, and a reputation for reliable and responsive customer service.

Researching and shortlisting potential EPS panel manufacturers

The first step in finding the best EPS panel manufacturer in India is to conduct thorough research and create a shortlist of potential candidates. This process involves gathering information from various sources, including industry directories, online reviews, and personal referrals, to identify manufacturers that meet your specific requirements.

Begin by searching for EPS panel manufacturers in India that operate in your local or regional market. This will help you narrow down your options and focus on companies that are familiar with the local construction and building regulations, as well as the unique challenges and opportunities of your geographic area.

As you research potential manufacturers, pay close attention to their product offerings, manufacturing capabilities, and industry certifications. Look for companies that specialize in the type of EPS panels you require, whether it's for wall insulation, roof systems, or other applications. This level of specialization can indicate a deeper understanding of the specific needs and requirements of your project.

In addition to researching the manufacturers' technical capabilities, also consider their customer service and support. Look for companies that are responsive to inquiries, provide clear and transparent communication, and have a reputation for addressing customer concerns in a timely and effective manner. This can help ensure a smooth and stress-free experience throughout your project.

Evaluating the quality and reliability of EPS panel manufacturers

Once you have a shortlist of potential EPS panel manufacturers, it's time to delve deeper into evaluating their quality and reliability. This assessment process should involve a comprehensive review of the manufacturer's production processes, quality control measures, and overall track record.

Begin by examining the manufacturer's production facilities and equipment. Look for modern, well-maintained, and efficient production lines that demonstrate a commitment to quality and consistency. Observe the handling and storage of raw materials, as well as the manufacturing processes, to ensure that the EPS panels are produced in a clean, controlled, and safe environment.

Assess the manufacturer's quality control procedures, including their testing and inspection protocols. Reputable EPS panel manufacturers should have robust quality assurance systems in place, such as regular product testing, material analysis, and compliance with industry standards and regulations. This attention to quality can provide you with the confidence that the EPS panels you purchase will perform as expected.

Checking for certifications and accreditations

Certifications and accreditations are valuable indicators of an EPS panel manufacturer's commitment to quality, safety, and environmental responsibility. These third-party endorsements demonstrate that the manufacturer's products and processes meet or exceed industry standards and regulations.

When evaluating potential EPS panel manufacturers, look for certifications such as ISO (International Organization for Standardization) standards, which cover quality management systems, environmental management, and occupational health and safety. Manufacturers with these certifications have demonstrated their ability to consistently deliver high-quality products and adhere to best practices in their operations.

It's important to note that the presence of certifications and accreditations alone does not guarantee the quality or reliability of an EPS panel manufacturer. However, they do serve as a valuable starting point in your evaluation process and can help you narrow down your options to the most reputable and trustworthy manufacturers in the market.

Visiting the manufacturing facility and inspecting the products

To truly assess the quality and reliability of an EPS panel manufacturer, it's essential to visit their manufacturing facility and inspect the products firsthand. This hands-on approach allows you to gain a deeper understanding of the company's production processes, quality control measures, and overall commitment to excellence.

When visiting the manufacturing facility, pay close attention to the cleanliness, organization, and efficiency of the production lines. Look for modern equipment, well-trained personnel, and a clear focus on safety and environmental responsibility. This attention to detail can be a strong indicator of the manufacturer's dedication to quality and their ability to consistently deliver high-performance EPS panels.

During your visit, request to see samples of the EPS panels that are relevant to your project. Thoroughly inspect the panels for any signs of defects, such as uneven surfaces, inconsistent thickness, or structural imperfections. Additionally, ask the manufacturer to provide test reports or certifications that demonstrate the panels' compliance with industry standards and regulations.

Making the final decision and placing an order

After thoroughly researching and evaluating potential EPS panel manufacturers in India, it's time to make the final decision and place your order. This step requires careful consideration of all the factors you have evaluated, as well as a clear understanding of your project's specific requirements and budget.

Review the information you have gathered, including the manufacturers' quality standards, experience, pricing, delivery timelines, and customer feedback. Weigh the pros and cons of each option, and identify the manufacturer that best aligns with your project's needs and your overall goals.

Once you have selected the EPS panel manufacturer you believe is the best fit, it's time to initiate the ordering process. This may involve submitting a formal request for quotation, providing detailed specifications, and negotiating the terms of the agreement. Be sure to clarify any questions or concerns you may have, and ensure that the manufacturer is fully aware of your expectations and requirements.

During the ordering process, pay close attention to the manufacturer's communication, responsiveness, and attention to detail. A reliable and experienced EPS panel manufacturer should be able to guide you through the process, provide clear timelines, and address any issues or concerns that may arise promptly and effectively.

By making a well-informed decision and partnering with the right EPS panel manufacturer, you can be confident that your project will be completed successfully, with high-quality products that meet or exceed your expectations. This strategic approach can help you avoid costly mistakes, ensure the long-term performance of your EPS panels, and contribute to the overall success of your construction or application.

#3D EPS core panel#EPS 3D core Panels manufacturers#Insulated panels manufacturers#EPS core panel manufacturers#EPS core panels manufacturers and suppliers

0 notes

Text

Global Top 15 Companies Accounted for 57% of total Automotive Body Sealing Systems market (QYResearch, 2021)

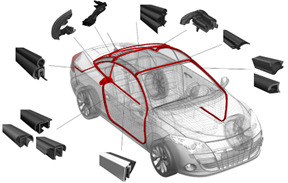

Body sealing system is commonly made of EPDM rubber and PVC, a thermoplastic elastomer (TPE) mix of plastic and rubber, and a thermoplastic olefin (TPO) polymer/filler blend. The goal of body sealing system is to prevent rain and water from entering entirely or partially and accomplishes this by either returning or rerouting water. A secondary goal of body sealing system is to keep interior air in, thus saving energy on heating and air conditioning.

The automotive body sealing system means the edges of a vehicle's windshield, windows, doors and trunk lid, etc. Automobile Sealing System strip is usually made into a hollow sponge foam tube.

According to the new market research report “Global Automotive Body Sealing Systems Market Report 2023-2029”, published by QYResearch, the global Automotive Body Sealing Systems market size is projected to reach USD 25.95 billion by 2029, at a CAGR of 13.3% during the forecast period.

Figure. Global Automotive Body Sealing Systems Market Size (US$ Million), 2018-2029

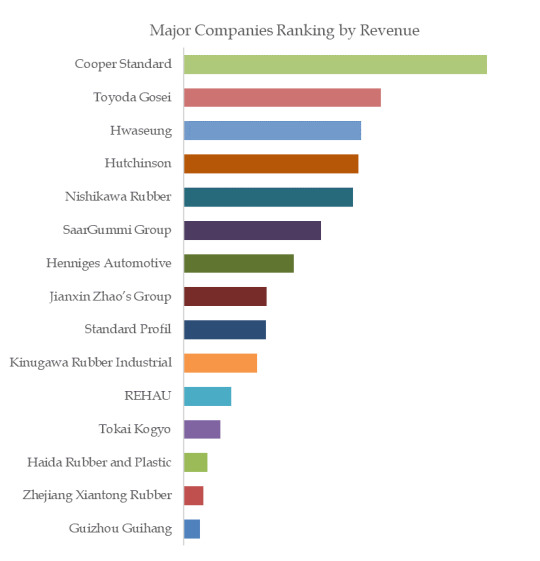

Figure. Global Automotive Body Sealing Systems Top 15 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Automotive Body Sealing Systems include Cooper Standard, Toyoda Gosei, Hwaseung, Hutchinson, Nishikawa Rubber, SaarGummi Group, Henniges Automotive, Jianxin Zhao’s Group, Standard Profil, Kinugawa Rubber Industrial, etc. In 2021, the global top five players had a share approximately 57.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

The Ultimate Guide to Finding an Affordable King Size Mattress

When it comes to ensuring a good night's sleep, the quality of your mattress plays a crucial role. However, finding the perfect balance between comfort, support, and affordability can be challenging. This guide will explore the key aspects of selecting an affordable king size mattress, with a special focus on the Beautyrest Mattress by Simmons, renowned for its exceptional quality and comfort.

Why Choose a King Size Mattress?

A king size mattress offers ample space for couples, families, or anyone who enjoys the luxury of extra room. The benefits include:

Enhanced Comfort: More space means less disturbance from a partner's movements, leading to a more restful sleep.

Versatility: Ideal for master bedrooms, a king size mattress can accommodate families with children or pets who like to join in for a cozy night's sleep.

Health Benefits: Sufficient space can help alleviate issues like back pain by allowing you to sleep in a more natural position.

However, the larger size often comes with a higher price tag. This is where the search for an affordable king size mattress becomes crucial.

Finding an Affordable King Size Mattress

The key to finding an affordable king size mattress without compromising on quality lies in understanding the different types of mattresses and their features. Here are some popular options:

Innerspring Mattresses: Known for their support and affordability, innerspring mattresses use a network of coils to provide a firm foundation.

Memory Foam Mattresses: These mattresses offer excellent pressure relief and contouring to your body shape, often at a slightly higher price.

Hybrid Mattresses: Combining the best of innerspring and memory foam, hybrid mattresses offer a balanced feel of support and comfort.

Latex Mattresses: Natural latex mattresses are durable and provide a firm, yet comfortable, sleeping surface, though they tend to be on the pricier side.

The Beautyrest Mattress by Simmons: A Premium Choice

The Beautyrest Mattress by Simmons stands out as a top contender in the market, known for its luxurious comfort and advanced sleep technology. Here’s why it’s worth considering:

1. Innovative Design: The Beautyrest Mattress by Simmons features advanced coil technology that provides targeted support and minimizes motion transfer. This means you can move freely without disturbing your partner.

2. Premium Materials: The use of high-quality materials such as memory foam and latex layers ensures a comfortable and supportive sleep experience. The plush top layer offers a cozy feel while the underlying support layers provide firmness where needed.

3. Temperature Regulation: One common issue with mattresses is heat retention. The Beautyrest Mattress by Simmons addresses this with breathable materials and cooling technologies that help regulate temperature, ensuring a cool and comfortable sleep environment.

4. Durability: Investing in a mattress is a long-term commitment. The Beautyrest Mattress by Simmons is designed to last, with reinforced edges and high-density foam that maintain the mattress's shape and support over time.

Balancing Affordability and Quality

While the Beautyrest Mattress by Simmons offers premium features, finding an affordable option within this range is possible. Here are some tips:

Sales and Discounts: Look for seasonal sales, discounts, and promotions. Retailers often offer significant reductions during events like Black Friday, Cyber Monday, or New Year sales.

Financing Options: Many retailers provide financing options, allowing you to spread the cost over several months. This can make a high-quality mattress more affordable.

Online Shopping: Online mattress retailers often have lower overhead costs than brick-and-mortar stores, which can translate to better prices for consumers. Additionally, many offer free shipping and returns, making it easier to try before committing.

Research and Reviews: Take the time to read reviews and compare prices across different platforms. Customer feedback can provide valuable insights into the comfort and durability of the mattress, helping you make an informed decision.

Conclusion

Finding an affordable king size mattress that doesn’t compromise on quality is entirely possible with the right approach. The Beautyrest Mattress by Simmons exemplifies how advanced sleep technology and premium materials can enhance your sleep experience. By exploring sales, financing options, and online deals, you can bring home a mattress that offers both luxury and affordability. Remember, investing in a high-quality mattress is an investment in your health and well-being, ensuring restful nights and energized days.

0 notes

Text

Building a Lighter, Stronger Future with AAC Blocks Project Report

The construction industry continually evolves, striving for materials that offer superior performance while promoting sustainability. Autoclaved Aerated Concrete (AAC) blocks have emerged as a revolutionary material in this quest. These lightweight, prefabricated blocks are transforming construction practices, offering numerous benefits for builders, architects, and homeowners. An AAC Blocks project report can provide comprehensive insights into their production, advantages, and applications for those interested in exploring this material further.

What are AAC Blocks?

AAC blocks, also known as autoclaved aerated concrete blocks, are a unique building material made from a mix of sand, cement, lime, water, and a foaming agent like aluminum powder. This mixture undergoes curing in an autoclave (a high-pressure steam chamber), creating lightweight, cellular concrete blocks with exceptional properties.

The Advantages of Building with AAC Blocks

There are several compelling reasons to consider AAC blocks for your next construction project:

Lightweight

AAC blocks are significantly lighter than traditional concrete blocks, weighing up to four times less, which translates to several advantages:

Reduced dead load on the structure: Lighter walls require less robust foundations, leading to cost savings.

Easier handling and installation: AAC blocks are easier to maneuver during construction, reducing labor costs and improving worker ergonomics.

Feasibility for high-rise buildings: The lighter weight makes AAC blocks suitable for multi-story constructions.

Superior Thermal Insulation

The air pockets within AAC blocks create an effective thermal barrier, resulting in:

Energy-efficient buildings: AAC structures require less heating and cooling, leading to lower energy bills for occupants.

Improved comfort: AAC walls help maintain a comfortable indoor temperature throughout the year.

Fire Resistance

AAC blocks are inherently fire-resistant, providing superior fire protection compared to traditional concrete blocks. They can withstand high temperatures for extended periods, offering valuable safety benefits.

Sound Insulation

The cellular structure of AAC blocks also contributes to excellent sound absorption, creating a quieter and more peaceful living environment.

Workability

AAC blocks can be easily cut, drilled, and shaped using standard woodworking tools, allowing for greater design flexibility and efficient on-site modifications.

Sustainability

AAC block production utilizes recycled materials like fly ash and requires less energy than traditional concrete production. Additionally, their energy-saving properties contribute to a more sustainable building environment.

Faster Construction

The lightweight nature and ease of working with AAC blocks facilitate faster construction times compared to traditional methods.

Applications of AAC Blocks

The versatility of AAC blocks makes them suitable for a wide range of construction projects, including:

Residential buildings: Ideal for constructing single-family homes, multi-unit dwellings, and interior walls.

Commercial buildings: Fire resistance and sound insulation properties make them well-suited for offices, retail spaces, and hotels.

Industrial buildings: Suitable for constructing warehouses, factories, and other industrial facilities.

Is Starting an AAC Block Manufacturing Business Right for You?

The growing demand for AAC blocks presents a profitable business opportunity for entrepreneurs. However, starting an AAC block manufacturing business requires careful planning and consideration. Key factors to explore include:

Market Research: Conduct thorough market research to assess the demand for AAC blocks in your region. Identify potential customers like construction companies and developers.

AAC Blocks Project Report: Develop a comprehensive AAC blocks project report detailing the feasibility of your business venture. This report should include market analysis, production process, financial projections, and equipment requirements. Consider seeking professional assistance from a business consultant or a company specializing in creating customized bankable project reports for AAC block manufacturing businesses.

Financial Investment: Setting up an AAC block manufacturing plant requires significant upfront investment for equipment, raw materials, and land.

Technical Expertise: Establishing a successful AAC block manufacturing business necessitates knowledge of the production process, quality control procedures, and relevant regulations.

How to Get a Project Report?

You can obtain a customized bankable project report with IID.

Conclusion

AAC blocks represent a significant advancement in building materials, offering a combination of lightweight construction, superior insulation, fire resistance, and ease of use. If you're looking for a sustainable and cost-effective building solution, AAC blocks are worth considering. For aspiring entrepreneurs, the growing demand for AAC blocks presents a promising business opportunity. However, careful planning, market research, and a well-defined AAC blocks project report are crucial for success.

0 notes

Text

Ethylene Industry: The Building Block of Our Modern World

Ethylene, often referred to as the world's most important chemical, plays a crucial role in our everyday lives. It's the foundation for countless products we rely on, from plastic packaging to clothing and building materials. This article delves into the fascinating world of ethylene, exploring its production, applications, and impact on various industries.

The Birth of Ethylene: Steam Cracking

Ethylene is primarily produced through a process called steam cracking. Here, hydrocarbons like ethane, propane, and naphtha are subjected to intense heat (750-950°C) along with steam. This high-temperature environment breaks down the larger hydrocarbon molecules, creating smaller ones, including ethylene. The resulting mixture then undergoes separation through processes like compression and distillation to isolate pure ethylene.

Ethylene: A Versatile Building Block

Ethylene's true strength lies in its versatility. It undergoes various chemical reactions to form a vast array of products. Here's a glimpse into some of its key applications:

Polyethylene (PE): The champion of ethylene derivatives, PE accounts for over half of global ethylene consumption. PE's flexibility, durability, and lightweight properties make it ideal for food packaging, bottles, bags, and various industrial applications.

Ethylene Oxide and Glycol: This duo paves the way for the creation of polyester, a prominent fiber used in textiles. Ethylene glycol also finds use as antifreeze, keeping our vehicles running smoothly.

Ethylene Dichloride (EDC): This vital intermediate transforms into PVC, a plastic extensively used in pipes, siding, medical devices, and even clothing.

Styrene: Ethylene's role in creating styrene is essential for the production of synthetic rubber, a key component in tires and foam insulation.

Beyond Industrial Applications: Ethylene in Agriculture

Interestingly, ethylene market plays a role beyond the realm of industry. It acts as a ripening agent for fruits and vegetables like citrus, tomatoes, and bananas. By mimicking the natural ripening process, ethylene helps regulate the shelf life and quality of these produce items.

The Ethylene Industry: A Global Powerhouse

The ethylene industry is a global giant, with a market size exceeding 150 million tonnes and a projected growth of over 4% annually. This growth is driven by the rising demand for plastics and other ethylene derivatives in developing economies. The industry leaders include major petrochemical companies across the globe.

Ethylene's Environmental Impact: A Cause for Consideration

The significant production and consumption of ethylene raise environmental concerns. The process of steam cracking generates greenhouse gases, and plastic waste from ethylene derivatives can pose challenges if not managed responsibly. The industry is constantly evolving, with research focused on cleaner production methods and improved plastic recycling technologies.

The Future of Ethylene: Innovation and Sustainability

As the world strives for a more sustainable future, the ethylene industry is embracing innovation. The exploration of alternative feedstocks like bio-based ethylene derived from renewable sources holds promise. Additionally, advancements in recycling technologies aim to create a more circular economy for ethylene-based plastics.

Buy the Full Report for More Insights into the Ethylene Industry Installed Capacity Forecast, Download A Free Report Sample

0 notes

Text

Sodium Hexametaphosphate Market Analysis: Trends and Forecasts

Introduction

Sodium hexametaphosphate, also known as SHMP, is an inorganic compound that has wide applications in the food and other industries. It is primarily used as a sequestrant, emulsifier and disintegrator.

Chemical Structure and Properties

Sodium hexametaphosphate has the chemical formula (NaPO3)6. It is a white, crystalline solid that is odorless and highly water-soluble. In water, it ionizes into sodium cations (Na+) and hexametaphosphate anions (P6O18)6-. Its sodium salt form enhances its water solubility. It is stable under normal conditions but decomposes when heated to high temperatures.

Usage in Food Industry

As a sequestrant, SHMP is commonly used in meat processing to prevent the binding or coagulation of proteins. This allows processed meats to retain moisture and texture. It is also used as an emulsifier in products like sausages and lunch meats.

In baked goods like bread, it improves volume, texture and shelf life by preventing staleness. As an additive, it has the E-number E452i. The FDA has approved its use at a maximum level of 0.5% by weight of food products.

Usage in Cleaning Products

Due to its ability to bind with molecules like calcium, magnesium and heavy metals, SHMP is a key ingredient in cleaning formulations. It helps remove tough stains by dissolving mineral deposits on surfaces. Many detergents, dishwasher tabs and stain removers contain it.

Usage in Water Treatment

SHMP functions as a water softener in industrial processes that require soft water. It forms soluble complexes with metal ions like calcium and magnesium, preventing the formation of scale. This keeps boilers, pipes, cooling towers and other equipment corrosion-free.

Polymer Industry Applications

The phosphorus content in SHMP makes it ideal for use as a flame retardant in polymers and plastics. It is often used as an additive in polyurethane foams, improving properties like tensile strength and durability. Its role in initiating polymerization also allows its use as a dispersing agent.

Regulations

As SHMP has potential health impacts if ingested in large amounts, certain regulations govern its safe usage:

The European Union classification is as an eye irritant.

Its use in food is regulated by the EC and FDA.

Safe levels have been specified for different products and industrial applications.

Workplace exposure and safety guidelines exist for manufacturers and handlers.

In conclusion, with its variety of functions, sodium hexametaphosphate finds diverse applications across industries. Strict adherence to safety guidelines ensure its continued responsible use in products that improve our lives. Further research also explores its potential in new areas.

0 notes

Text

Technical Insulation Market: Trends, Growth, and Forecast

Introduction

The Technical Insulation Market plays a vital role in various industries by providing thermal, acoustic, and fire protection solutions. From residential buildings to industrial facilities, technical insulation is essential for optimizing energy efficiency, enhancing occupant comfort, and ensuring the safety and longevity of infrastructure. In this comprehensive analysis, we delve into the key trends, growth drivers, and future forecasts shaping the Technical Insulation Market.

According to the study by Next Move Strategy Consulting, the global Technical Insulation Market size is predicted to reach USD 11.82 billion with a CAGR of 4.0% by 2030.

Request for a sample, here: https://www.nextmsc.com/technical-insulation-market/request-sample

Trends Shaping the Technical Insulation Market

Rising Demand for Energy Efficiency

The increasing emphasis on energy efficiency across industries is a primary driver fueling the demand for technical insulation solutions. As organizations strive to reduce energy consumption and minimize environmental impact, there is a growing preference for insulation materials that offer superior thermal performance. Technical insulation plays a crucial role in minimizing heat loss or gain in buildings, industrial equipment, and pipelines, thereby contributing to energy conservation efforts.

Advancements in insulation materials, such as aerogels, vacuum insulation panels, and eco-friendly foams, are enabling improved thermal insulation properties while ensuring sustainability. These innovative materials offer high thermal resistance and durability, making them ideal for applications where energy efficiency is paramount.

Advancements in Insulation Materials

Technological innovations have revolutionized the technical insulation industry, leading to the development of advanced materials with superior performance characteristics. Traditional insulation materials such as fiberglass and mineral wool are being augmented with newer options that offer enhanced thermal conductivity, moisture resistance, and fire retardancy.

Aerogels, for instance, are lightweight, highly porous materials with exceptional thermal insulating properties. These silica-based materials possess low thermal conductivity, making them effective insulators for a wide range of applications, including building envelopes, cryogenic systems, and aerospace components.

Vacuum insulation panels (VIPs) represent another breakthrough in insulation technology. Consisting of a rigid core encased in a gas-tight envelope, VIPs achieve extremely low thermal conductivity by minimizing convective and conductive heat transfer. These panels are increasingly being used in refrigeration, cold chain logistics, and building insulation applications.

Furthermore, eco-friendly insulation materials derived from renewable sources, such as soybean oil-based foams and cellulose insulation made from recycled paper, are gaining traction due to their sustainability credentials. These bio-based materials offer comparable thermal performance to traditional insulation options while reducing environmental impact.

Focus on Green Building Standards

The construction industry is undergoing a paradigm shift towards sustainable building practices, driven by increasing awareness of environmental conservation and energy efficiency. Green building standards and certifications, such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method), are becoming increasingly prevalent, influencing design and construction decisions worldwide.

Technical insulation plays a pivotal role in achieving green building certifications by enhancing energy efficiency and thermal comfort within buildings. By minimizing heat transfer through walls, roofs, and floors, insulation helps reduce heating and cooling loads, thereby lowering energy consumption and operational costs. Additionally, insulation materials with high recycled content and low embodied energy contribute to the overall sustainability of building projects.

Expansion in Industrial Infrastructure

The rapid expansion of industrial infrastructure, particularly in emerging economies, is driving significant demand for technical insulation solutions. Industries such as power generation, oil and gas, petrochemicals, and manufacturing rely heavily on insulation to maintain optimal operating temperatures, protect personnel and equipment, and ensure process efficiency.