#High Pressure Bellow manufacturer in India

Text

Safety Valves Manufacturer: A Comprehensive Guide to Pedlock's High Quality Products

In the industrial landscape, safety is a non negotiable priority, and one of the critical components ensuring this safety is the safety valve. From preventing accidents to ensuring the smooth functioning of various processes, safety valves play an indispensable role. This article delves into the world of safety valves, focusing on Pedlock, a renowned safety valves manufacturer in Mumbai, Chennai, Gujarat, Ahmedabad, Vadodara, Bangalore, Rajasthan, Delhi, Ghaziabad in India that known for its high quality products and customer centric approach.

What Are Safety Valves?

Safety valves are mechanical devices designed to control and limit pressure in a system by automatically releasing excess pressure. They serve as the last line of defense in preventing overpressure situations that can lead to catastrophic failures, equipment damage, and even loss of life.

Types of Safety Valves

There are several types of safety valves, each serving specific applications:

Pressure Relief Valves (PRVs): Open proportionally to pressure rise.

Pilot-Operated Safety Valves: Use system pressure to open and close the valve.

Spring-Loaded Safety Valves: Use a spring mechanism to control pressure.

Balanced Bellows Safety Valves: Designed to handle back pressure scenarios.

The Role of Safety Valves in Industrial Safety

Over pressure can occur due to various factors like process upsets, equipment malfunctions, or operator errors. Safety valves are critical in preventing overpressure by relieving excess pressure, thus protecting equipment and personnel from potential hazards.

Enhancing Operational Efficiency

Beyond safety, these valves also contribute to operational efficiency by maintaining optimal pressure levels. This helps in reducing downtime and maintenance costs, ensuring that industrial processes run smoothly and efficiently.

Why Choose Pedlock for Safety Valves?

Pedlock has established itself as a leader in the manufacturing of safety valves. With years of experience and a commitment to innovation, Pedlock has become synonymous with reliability and quality in the safety valve industry.

Pedlock's Commitment to Quality

Pedlock's dedication to quality is evident in every valve they manufacture. Each product undergoes rigorous testing to ensure it meets the highest industry standards. This commitment to quality ensures that Pedlock's safety valves perform reliably under the most demanding conditions.

Range of Safety Valves

Pedlock offers a diverse range of safety valves catering to various industrial needs. From simple pressure relief valves to sophisticated pilot-operated valves, we provide solutions for all types of pressure control requirements.

Features of Pedlock Safety Valves

High Precision: Pedlock valves are engineered to provide precise control over pressure, ensuring safety and efficiency.

Durability: Made from high-quality materials, these valves are built to last, even in harsh environments.

Easy Maintenance: Designed for ease of maintenance, our safety valves minimize downtime and reduce operational costs.

Types of Materials

Pedlock uses a variety of materials, including stainless steel, brass, and other alloys, to manufacture its safety valves. The choice of material depends on the application and the specific requirements of the customer.

Benefits of Using High Quality Materials

Using top grade materials ensures the durability and reliability of Pedlock safety valves. These materials provide resistance to corrosion, high temperatures, and pressure, making the valves suitable for various industrial environments.

Innovative Features of Safety Valves

Pedlock safety valves stand out due to their innovative design and features. They incorporate the latest technological advancements to provide superior performance and reliability.

Technological Innovations

Pedlock continually invests in research and development to enhance its product offerings. Innovations such as advanced sealing technologies and precision manufacturing techniques ensure that our safety valves are at the forefront of the industry.

Quality Assurance

Every safety valve from Pedlock undergoes stringent testing procedures. These tests ensure that the valves can withstand extreme conditions and perform reliably under all circumstances.

Certifications and Standards

Pedlock safety valves meet international standards and are certified by relevant industry bodies. This certification is a testament to the quality and reliability of Pedlock's products.

Custom Safety Valve Solutions

Pedlock understands that different industries have unique requirements. Therefore, they offer custom safety valve solutions to meet specific needs. Whether it's a particular pressure range or a specialized material requirement, Pedlock can provide a tailored solution.

Case Studies of Custom Solutions

Numerous industries have benefited from Pedlock's custom solutions. For example, a major chemical company needed a safety valve that could withstand highly corrosive materials. Pedlock provided a solution using specialized alloys, resulting in a successful and long-lasting application.

Installation and Maintenance of Safety Valves

Step-by-Step Installation Guide

Installing Pedlock safety valves is straightforward, thanks to their user-friendly design. Here’s a simple guide:

Ensure that the valve is compatible with the system.

Carefully follow the installation instructions provided by Pedlock.

Perform a system pressure test to verify the installation.

Maintenance Tips for Longevity

Regular maintenance is key to the longevity of safety valves manufacturers in Ahmedabad, Chennai, Mumbai, Delhi, Bangalore, Vadodara, Gujarat, Rajasthan, and Ghaziabad in India. Pedlock recommends periodic inspection and testing to ensure that the valves are functioning correctly. Regular maintenance helps in identifying potential issues before they become major problems.

Industries Benefiting from Pedlock Safety Valves

Oil and Gas Industry

Safety valves are crucial in the oil and gas sector to prevent overpressure in pipelines and storage tanks. Pedlock's robust valves ensure the safety and efficiency of these operations.

Chemical Industry

Handling hazardous chemicals requires precise pressure control. Pedlock safety valves provide reliable pressure management, ensuring the safety of chemical processing plants.

Power Generation

In power plants, safety valves are essential for protecting boilers and turbines from overpressure. Pedlock valves help maintain safe and efficient power generation operations.

Other Industries

Pedlock safety valves are also used in other industries, including pharmaceuticals, food and beverage, and water treatment, where pressure control is critical.

Eco-Friendly Manufacturing Processes

Pedlock is committed to sustainability. They employ eco-friendly manufacturing processes to minimize their environmental footprint, demonstrating their commitment to a greener future.

Sustainable Product Design

Pedlock designs its safety valves with sustainability in mind. This includes using recyclable materials and designing products that require minimal energy to operate.

How to Choose the Right Safety Valve Manufacturer

Choosing the right safety valve involves considering several factors, including:

Operating pressure

Temperature range

Type of media

Required flow rate

Matching Valves to Applications

Pedlock provides expert guidance to help customers match the right valve to their specific applications, ensuring optimal performance and safety.

Conclusion

Pedlock's safety valves manufacturer in Chennai, Mumbai, Vadodara, Ahmedabad, Gujarat, Delhi, Rajasthan, Ghaziabad, and Bangalore in India is synonymous with quality, reliability, and innovation. With a commitment to customer satisfaction and a focus on technological advancement, we continue to lead the industry. Whether you're looking for standard safety valves or custom solutions, Pedlock has the expertise and experience to meet your needs.

#safety valves manufacturer in Chennai#safety valves manufacturer in Mumbai#safety valves manufacturer in Ahmedabad#safety valves manufacturer in Gujarat#safety valves manufacturer in Vadodara#safety valves manufacturer in Bangalore#safety valves manufacturer in Delhi#safety valves manufacturer in Rajasthan#safety valves manufacturer in Ghaziabad

0 notes

Text

Elevating Home Efficiency with Mcneil Instruments - India's Top Hose Pipe Manufacturer

Introduction:

Hose pipes function as essential pipes that guarantee the smooth flow of water and other necessary liquids in every home. As the leading hose pipe manufacturer in India, Mcneil Instruments' dedication to quality is evident in the variety of goods we offer.

From hydraulic hoses to industrial hoses, SS corrugated hoses to PTFE hoses, and bellows, our offerings cater to diverse needs with uncompromising quality.

Types of Hose Pipes:

1. Hydraulic Hose: Hydraulic hoses are crucial in hydraulic systems and are designed for high-pressure applications offering flexibility and durability.

2. Industrial Hose: Industrial hoses are versatile and used in various industries for conveying fluids, chemicals, and gases.

3. SS Corrugated Hose: Made of stainless steel, SS corrugated hoses are flexible and resistant to pressure, ideal for conveying liquids and gases.

4. PTFE Hoses: PTFE hoses, made of Teflon, are chemical-resistant and can withstand extreme temperatures, enhancing the durability of piping systems.

5. Bellows: Bellows are used to absorb vibration and expansion in piping systems, ensuring smooth operation and longevity.

Pros and Cons of Hose Pipes:

Pros:

Versatility: Hose pipes can be used in various applications, from household to industrial settings.

Flexibility: Hose pipes offer flexibility, allowing for easy installation and maneuverability around obstacles.

Durability: High-quality hose pipes, like those manufactured by Mcneil Instruments, are durable and long-lasting, reducing the need for frequent replacements.

Safety: With features like anti-static and flame resistance, hose pipes ensure safety in various environments.

Cons:

Vulnerable to Damage: Hose pipes may be susceptible to damage from sharp objects or heavy loads, requiring regular inspection and maintenance.

Limited Temperature Range: Some hose pipes may have limitations in terms of temperature range, affecting their suitability for certain applications.

Uses of Hose Pipes:

1. Residential: Hose pipes are essential in homes for activities such as watering plants, washing cars, and filling swimming pools.

2. Industrial: In industries like manufacturing, construction, and agriculture, hose pipes are used for fluid transfer, ventilation, and equipment operation.

3. Commercial: Commercial establishments like restaurants, hotels, and hospitals utilize hose pipes for sanitation, food processing, and HVAC systems.

4. Automotive: In the automotive industry, hose pipes are used for coolant systems, fuel lines, and air conditioning.

Conclusion:

At Mcneil Instruments, we take pride in being India's premier hose pipe manufacturer, offering top-quality products tailored to meet diverse needs. Our range of hose pipes, including hydraulic hoses, industrial hoses, SS corrugated hoses, PTFE hoses, and bellows, are designed for durability, reliability, and safety. With our commitment to excellence and customer satisfaction, we aim to enhance home efficiency and productivity across industries. Trust in Mcneil Instruments for all your hose pipe needs and experience unparalleled quality and service.

0 notes

Text

Welcome to Omega Seals: Your Trusted Partner for Pump Seals

Welcome to the official blog of Omega Seals, a leading manufacturer of high-quality pump seals serving clients across India, UAE, Egypt, and South Africa. At Omega Seals, we take pride in our commitment to excellence, innovation, and customer satisfaction. With decades of experience in the industry, we have established ourselves as a trusted partner for businesses seeking reliable sealing solutions.

Our Products

Omega Seals specializes in the design and production of a wide range of pump seals tailored to meet the diverse needs of our clients. Our product offerings include:

1. Mechanical Shaft Seals: Engineered to prevent leakage and contamination in rotating equipment, our mechanical shaft seals provide robust sealing solutions for pumps, mixers, and other machinery.

2. Carbon Seals: Known for their exceptional durability and resistance to harsh operating conditions, our carbon seals offer reliable performance in high-temperature and high-pressure applications.

3. Pump Seals: Our pump seals are meticulously crafted to maintain fluid containment and prevent leakage in centrifugal, rotary, and reciprocating pumps, enhancing operational efficiency and safety.

4. Agitator Seals: Ideal for applications involving agitation and mixing, our agitator seals are designed to withstand dynamic forces and ensure leak-free operation in industrial processes.

5. Reactor Seals: Engineered for use in chemical reactors and process vessels, our reactor seals provide effective sealing solutions for corrosive and hazardous environments, safeguarding equipment and personnel.

6. Metal Bellow Seals: With their flexible metal bellows design, our metal bellow seals offer superior performance and longevity, making them suitable for a wide range of applications, including refineries, petrochemical plants, and pharmaceutical facilities.

7. Labyrinth Seals: Designed to control fluid leakage and minimize frictional losses, our labyrinth seals are widely used in turbomachinery, compressors, and gas turbines, ensuring efficient operation and prolonged service life.

8. Teflon Bellow Seals: Offering exceptional chemical resistance and low friction characteristics, our Teflon bellow seals are an ideal choice for handling corrosive fluids and abrasive particles in chemical processing, food, and pharmaceutical industries.

9. Blower Seals: Engineered for sealing blowers and fans, our blower seals deliver reliable performance under varying operating conditions, helping to maintain equipment integrity and efficiency.

10. Compressor Seals: Designed to withstand high pressures and temperatures, our compressor seals ensure gas-tight sealing in compressors and pneumatic systems, contributing to enhanced productivity and reduced maintenance costs.

Serving Global Markets

With a strong presence in India, UAE, Egypt, and South Africa, Omega Seals is dedicated to serving clients across diverse industries, including manufacturing, petrochemical, water treatment, and more. Our strategically located facilities enable us to efficiently cater to the needs of our customers while ensuring timely delivery and support.

Commitment to Quality

At Omega Seals, quality is at the forefront of everything we do. We adhere to stringent quality standards throughout the manufacturing process to ensure that our products meet the highest industry standards. From material selection to final inspection, every step is meticulously executed to guarantee the reliability and performance of our seals.

Innovation and Technology

Continuous innovation drives our commitment to excellence at Omega Seals. We invest in the latest technology and manufacturing processes to enhance product performance, efficiency, and longevity. By staying at the forefront of technological advancements, we empower our clients with cutting-edge sealing solutions that deliver superior results.

Customer Satisfaction

At Omega Seals, customer satisfaction is our top priority. We believe in building long-term relationships with our clients based on trust, integrity, and mutual respect. Our dedicated team of professionals is committed to providing exceptional service and support, ensuring that our clients receive personalized attention and solutions that exceed their expectations.

Stay Connected

Thank you for visiting the Omega Seals blog. We invite you to stay connected with us for the latest updates, industry insights, and news. Whether you’re looking for expert advice on pump sealing solutions or want to learn more about our products and services, we’re here to help. Contact us today to discover how Omega Seals can meet your sealing needs with precision and reliability.

Contact Us At: https://www.omegaseals.com/ | +91 9769499061 | [email protected]

#Mechanical Seal#Mechanical Shaft Seals#Carbon Seals#Pump Seals#Agitator Seals#Reactor Seals#Metal Bellow Seals#Labyrinth Seals#Teflon Bellow Seals#Mechanical Seals Manufacturers#Blower Seals#Compressor Seals

0 notes

Text

Best Mechanical Seals manufacturer and supplier in India

Mechanical seals are devices used to prevent fluid leakage in rotating equipment such as pumps, mixers, and agitators. There are various types of mechanical seals, each designed for specific applications and operating conditions. Here are some common types:

Single Spring Mechanical Seals:

Basic and widely used, these seals consist of a single spring to maintain contact between the seal faces.

2. Multiple Spring Mechanical Seals:

These seals use multiple springs arranged in a parallel or series configuration, providing enhanced flexibility and improved face conformity.

3. Cartridge Mechanical Seals:

Cartridge seals come pre-assembled and can be easily replaced as a single unit. They simplify installation and reduce the risk of errors during setup.

4. Mixer Seals:

Specifically designed for mixers and agitators, these seals accommodate axial and radial shaft movement to prevent leakage in dynamic applications.

5. Component Mechanical Seals:

These seals are assembled from individual components and are customizable for specific equipment and operating conditions.

6. Metal Bellow Seals:

Metal bellows provide a flexible, spring-like element that compensates for axial and angular shaft movement. They are often used in applications with high temperature or aggressive fluids.

7. Elastomer Bellows Seals:

Similar to metal bellows seals but using elastomeric materials, these seals are suitable for applications with less aggressive fluids and lower temperature requirements.

8. Pusher Seals:

Pusher seals use a dynamic secondary sealing element that moves axially along the shaft. This design accommodates shaft movement and is suitable for high-pressure applications.

9. Non-Pusher (Non-Contacting) Seals:

These seals operate without physical contact between the seal faces, reducing wear and friction. They are suitable for applications where minimal leakage is acceptable.

10. Dry Gas Seals:

Used in gas compressors and other high-pressure applications, dry gas seals use a non-contacting design to prevent the leakage of process gases.

11. Split Seals:

Split mechanical seals are designed for easy installation without the need to dismantle the equipment. They are particularly useful in retrofit situations.

12. Conical Spring Seals:

These seals use conical springs to maintain face contact, providing enhanced stability and resistance to face distortion.

#mechanical seals#manufacturer#qtseals#quantech#single coil#multi spring#cartridge#water pump#dry run#teflon bellow#wave spring#reversed balanced#pusher#non pusher#ceramic seal face

1 note

·

View note

Text

Understanding and Application's Guide: Bellows Manufacturers in India

Introduction

Metallic bellows are crucial parts utilized in a variety of industrial applications because they offer precision, dependability, and flexibility in changing situations. DMA Bellows, a leading Bellows Manufacturers in India in the industry, has been at the forefront of producing high-quality metallic bellows for a wide range of sectors.This in-depth manual will examine the concepts, components, production procedures, and uses of metallic bellows supplied by DMA Bellows.

What are Metallic Bellows?

Metallic bellows are flexible, accordion-like devices used to control the flow of fluids or gases or maintain a hermetic seal while accommodating mechanical motion. They are made up of a sequence of convolutions that alter in size in response to mechanical, thermal, or pressure stimuli. To ensure compatibility with varied locations and working situations, DMA Bellows offers metallic bellows built from a variety of materials, including stainless steel, nickel alloys, and other specialized metals.

Design and Manufacturing Process

Modern technical methods and cutting-edge production procedures are used by DMA Bellows to create premium metallic bellows. Application criteria, such as pressure range, temperature swings, chemical compatibility, and planned life cycle, are carefully taken into account during the design process. After the design is complete, the manufacturing process starts with the selection of suitable materials. Next, the intricate structure is created using precise shaping and welding procedures.

Materials

Modern technical methods and cutting-edge production procedures are used by DMA Bellows to create premium metallic bellows. Application criteria, such as pressure range, temperature swings, chemical compatibility, and planned life cycle, are carefully taken into account during the design process. After the design is complete, the manufacturing process starts with the selection of suitable materials. Next, the intricate structure is created using precise shaping and welding procedures.

Advantages of Metallic Bellows

Flexibility: Metallic bellows can accommodate axial, lateral, and angular movements, making them ideal for applications where traditional mechanical seals or joints may fail.

Hermetic Sealing: DMA Bellows' metallic bellows are designed to provide a leak-tight seal, preventing the ingress of contaminants and ensuring a controlled environment.

High Pressure and Temperature Resistance: With appropriate material selection, DMA Bellows' metallic bellows can withstand extreme pressures and temperatures, making them suitable for demanding applications.

Vibration Damping: Metallic bellows can absorb and dampen vibrations, reducing stress and wear on connected components.

Longevity: Properly designed and manufactured metallic bellows from DMA Bellows have a long service life, resulting in reduced maintenance costs and downtime.

Applications of Metallic Bellows

Aerospace: In aircraft and spacecraft, metallic bellows are used in fuel systems, engine thrust vector control, and environmental control systems.

Chemical Processing: Metallic bellows are employed in pumps, compressors, and expansion joints in chemical processing plants to handle corrosive and high-temperature fluids.

Medical Devices: DMA Bellows' metallic bellows find applications in medical devices such as ventilators, anaesthesia machines, and surgical equipment.

Nuclear and Power Generation: Metallic bellows are crucial components in nuclear reactors and power generation plants for reactor control systems, steam turbine connections, and exhaust systems.

Semiconductor Industry: Vacuum-sealed metallic bellows are utilized in semiconductor manufacturing equipment to control gas flows and maintain a clean environment.

Automotive: In automotive exhaust systems, metallic bellows help accommodate thermal expansion and reduce stress on exhaust components.

Conclusion

DMA Bellows, Bellows Supplier in India unmatched reliability and precision in diverse industrial applications. These bellows are essential to the smooth running of many systems because of their flexibility, hermetic sealing properties, and resilience to high pressure and temperature. Worldwide industries continue to benefit from DMA Bellows' experience in producing metallic bellows, which is used in everything from aerospace and chemical processing to medical equipment and power production.

In addition, they provide,

Rubber Expansion Bellows Manufacturer in India

Clamshell Bellows Manufacturer in India

Tank Farm Bellows Manufacturer in India

Instrument Bellows Manufacturer in India

Crossover Piping Bellows Manufacturer in India

Externally Pressurised Bellows Manufacturer in India

0 notes

Text

Pressure safety valve manufacturer in India

Specialityvalve is one of the top Pressure Safety Valve Manufacturer in India. A Pressure Safety Valve (PSV) is a safety device that is designed to protect equipment and personnel from the overpressure or overpressure build-up in a system. It is commonly used in industries such as oil and gas, petrochemicals, and chemical manufacturing, where high-pressure processes are involved.

A PSV automatically releases excess pressure in a system by opening at a pre-determined set pressure, and then closing again once the pressure has dropped below the set level. The valve typically consists of a spring-loaded disc that is held in place by a set pressure. When the pressure in the system exceeds the set pressure, the disc lifts, allowing the excess pressure to be released.

The main purpose of a PSV is to prevent catastrophic failure of equipment or piping due to overpressure, which can cause damage to equipment and pose a safety hazard to personnel. PSVs are typically designed, installed, and maintained in accordance with applicable codes and standards to ensure their proper operation and reliability.

Specialityvalve is the leading Pressure Safety Valve Manufacturer in India that ensures good quality valves in various materials and sizes.

Types of pressure safety valves

Spring-Loaded pressure safety valves

Pilot-Operated pressure safety valves

Bellows pressure safety valves

Deadweight pressure safety valves

Balanced Bellows pressure safety valves

Advantages of pressure safety valve

Safety

Reliability

Cost savings

Compliance

Flexibility

Industries of pressure safety valve

Oil and Gas

Chemicals and Petrochemicals

Power Generation

Materials: Cast iron, Ductile Iron, WCB, SS304, SS316, CF8, CF8M, WC6, WCC, LCB, LCC.

Class: 150 to 2500.

Nominal Pressure: PN10 to PN450.

Ends- Butt weld, socket weld, Flanged, Threaded

Size: ½” to 60”.

https://www.specialityvalve.com/product-category/pressure-safety-valve/

0 notes

Text

in Bangalore

Stainless Steel Hose Fittings - in Bangalore

INTRODUCTION:

Quality Flexibles is one of the leading Manufacturers, of Satainless Steel Hose , SS BELLOWS , P.T.F.E, Silicone, Rubber, Industrial, Thermoplastic Hose Assemblies & Accessories . We direct all our activities to cater the expectations of customers by providing them excellent quality products as per their gratifications. Moreover, we follow moral business policies and crystal pure transparency in all our transactions to keep healthy relations with the customers.

read also - https://www.qualityflexibles.com/stainless-steel-hoses/

STAINLESS STEEL HOSE SUPPLIER IN BANGALORE AND PAN INDIA - QUALITY FLEXIBLES

Stainless steel hose is a flexible metal hose made from stainless steel that is used to carry liquids or gases. It is often used in applications where a regular rubber or plastic hose would not be able to withstand the temperature or pressure of the liquid or gas being transported. Stainless steel hoses are also resistant to corrosion and can be used in many different industries, including automotive, industrial, and medical.

Stainless Steel Hose Fittings - in Bangalore

Sanipure Water Systems is one of the leading manufacturer, supplier and exporter of superior quality Stainless Steel Hoses in different types, various sizes, and grade qualities as we offer our products according to the client's requirements and specifications.

Stainless Steel Hoses are flexible and resistant tubes made of stainless steel which protects internal materials against corrosion, heat, wear and tear, and external pressure.

Sanipure Water Systems's Stainless Steel Hoses are made of superior grade stainless steel which is resistant to corrosion, chemical abrasion and is designed to withstand high pressure and compression.

Sanipure Water Systems's Stainless Steel Hoses's well-designed look gives elegant and aesthetic feel which goes well in enhancing with different styles of interior settings.

Sanipure Water Systems's Stainless Steel Hoses are 100% quality checked and tested since it is manufactured by the latest well-equipped CNC machinery and latest techniques like cutting and bending and for any other structural flaws by our highly qualified professional staff according to Indian and international industry standards guidelines.

Sanipure Water Systems's Stainless Steel Hoses are extensively used for diverse applications and in several industries like Pharma, Food, Dairy, Beverages, Chemical and other industries.

Since 2013 Sanipure Water Systems provides superior quality products that are functionally designed and precision manufactured to meet our esteem customer's requirements and specifications according to Indian and international industry standards at competitive and reasonable prices.

What is Stainless Steel Drainage System?

The purpose drainage system of any location such as commercial and industrial is to drain out all the impure or waste water and harmful substances from internal structure to the main sewage system of the area.

Through Drainage system, sewage or waste water is collected, transported through various drainage parts and components and dispose it through outlet connecting main sewer pipe or gutter in the vicinity.

0 notes

Text

A Bellow Mechanical Seal may be a ring-type seal

Aspects of a Bellow Mechanical Closure

A Bellow Mechanical Seal may be a ring-type seal which is used to prevent leaks within a mechanical pump. This China Rubber Bellows Mechanical Seal Factory type of seal has a group of advantages, including its easy installation and adjustment. It is designed with regard to medium-to-high viscosity fluids and is suitable for plenty of operating conditions, including higher and low-temperature contents.

Ashish Seals is a ISO-certified manufacturing company throughout Mumbai, India that offers a bunch of Bellow Mechanical Seals. They are designed to deliver rugged durability and are suitable for a large number of applications, including chemical process pumps, sewage pumps, as well as water pumps. Ashish Seals producers these seals using SS 304 plus SS 316 materials. On the other hand, they can also end up being manufactured using materials rather than these materials as each customer requirements.

These mechanical seals can be easily installed, and normally require no measurements and also set screws. They furthermore don't damage sleeve or maybe shaft components, as there is no relative movement between the actual seal's rubber boot along with shaft. As a result, they're mostly used within waste water treatment crops.

Another type of Bellow Mechanical Seal can be a metal Bellow Seal. These seals are ideal for corrosive and high-temperature applications. Their metal lugs give positive mechanical drive in addition to protect elastomer bellows. They're also popular in pulp in addition to paper mills, oil pumps, dewatering pumps, and sewage penis pumps.

The Rubber Bellow Mechanical Seal is usually an extremely versatile unit. Designed to contain fluid in the glass-lined vessel, this type of close up can protect top entry drives when it comes to a pump or machine. Its unique design makes it possible for it to compensate intended for abnormal shaft run-out along with protect against fretting. Additionally it is comfortable to use and carries a large variety of software.

Unlike a mechanical bellow, which will requires two o-rings, a metal bellow mechanical seal requires one. It's not dynamic, so it may not be suited for high pressure applications. However, a PTFE o-ring can even be used. A PTFE encapsulated o-ring comes into play most sizes.

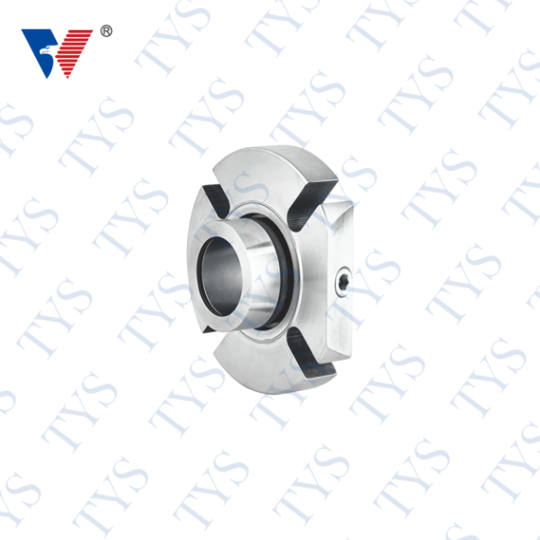

The BSIV(tm) series single cartridge Bellows are intended to provide excellent affordable sealing solutions. A bellow mechanical closure TYS T01 Cartridge Mechanical Seal double sealing depac 365 cartridge mechanical seal for agitator water pump is lightweight and includes a lower friction drag than the usual pusher seal. It also features superior face tracking as well as face loading. Furthermore, metal bellows mechanical seals reduce the chance of frictional heat.

0 notes

Text

Single Use Technology Welded Metal Bellow Market - Global Opportunity Analysis & Industry Forecast, 2020-2025

Single Use Technology Metal Welded Bellow Market

size was valued $320 million in 2019, estimated to grow at a CAGR of 5.7% during 2020-2025. The growing demand for edge welded bellows owing to the need for advanced instrumentation are highly accelerating the market growth. Moreover, the rising growth of the industrial sector leading to the need for

industrial automation

are highly boosting the Single Use Technology Welded Metal Bellow industry. The growing use of diaphragm bellows,

temperature sensor

and formed tube for monitoring the room temperature along with providing reliability and flexibility. These factors will further anticipate the growth of the Single Use Technology Welded Metal Bellow Market during the forecast period.

Report Coverage

The report:

“Single Use Technology Metal Welded Bellow Market Forecast (2020-2025)”

, by IndustryARC, covers an in-depth analysis of the following segments of the Single Use Technology Metal Welded Bellow Market.

Key Takeaways

In 2019, the Single Use Technology Welded Metal Bellow market was dominated by Asia Pacific region, due to the rising growth of the industrial sector in countries such as China, India and Japan.

The increasing of metal bellows with diameter range 51mm-100mm for high pressure applications including flight control and others are also highly proliferating the market’s growth.

The increasing demand for edge welded metal bellows in the oil and gas industries for advanced instrumentation and to endure high temperature are also fueling the growth of the Single use technology welded metal bellow market.

The formation process of welded metal bellows as it includes material such as stainless steel and so on requires high cost and skilled workforce which further hampers the growth of the market.

Diameter Range - Segment Analysis

51mm-100mm segment held the largest market share in the Single Use Technology Welded Metal Bellow market in 2019 and is anticipated to grow at CAGR of 6.30% during 2020-2025. Most of the metal bellows which are typically used for expansion joints or for piping systems and connections are of 51mm-100mm diameter range. The metal bellows under this range are highly versatile and have diverse tensile strengths that is achieved during the manufacturing process. Moreover, the metal bellows under this diameter range can also be used for high-pressure applications including flight control, firing mechanism and so on. This factors are leading to surge the 51mm-100mm diameter range of metal bellows further propelling the market growth.

Request Sample

Geography - Segment Analysis

In 2019, Asia Pacific dominated the Single use technology welded metal bellow market with a share of more than 38.7%, followed by North America and Europe. The rising growth of the industrialization in countries such as China, Japan, India and South Korea are highly fueling the market growth in this region. Furthermore, the transformation of infrastructure and industries for enhancing productivity are further influencing the development strategies in this region. Also, the rising of semiconductor, manufacturing and other industries are further boosting the Single Use Technology Welded Metal Bellow market in this region.

Drivers – Single Use Technology Welded Metal Bellow Market

Adoption of Single use Technology for Manufacturing Industries

The increasing need for automation in the manufacturing industries has driven the demand for single use technology welded metal bellow. The single use technologies include connection devices and sensors such as temperature sensors and pressure sensors which makes the metal bellow more efficient to be used in manufacturing. The rising use of single use technology welded metal bellow also lead to reduce processing times and other operational costs leading to provide reliability, flexibility and high productivity. Thus, this key drivers are proliferating the growth of the single use technology welded metal bellow market.

Inquiry Before Buying

Growing demand for Edge Welded Metal Bellows

The significantly rising demand for industries such as oil and gas along with renewable energy plants has enhanced the need for instrumentation for ensuring proper seating, containment and movement of the components. This has also led to the deployment of edge welded metal bellow technology that can be used for the proper maintenance and resist high temperature, pressure, and corrosive environments. Additionally, edge welded metal bellows are manufactured using material such as stainless steel, Inconel, and titanium and so on which can withstand during any chemical reaction in the oil and gas industry. Thus, the growing demand for edge welded metal bellow technology will enhance the growth of the market.

Challenges – Single Use Technology Metal Bellow Market

Formation Process of the Metal Bellows

The formation process of the metal bellows are highly sensitive and also requires high cost and efficient workforce to form the high quality metal bellows with enhanced thickness and dimensions. Thus, the cost for providing advanced formation of the metal bellows is specifically high which hinders the use of this bellows in certain industries including aerospace. Thus, this major challenge hampers the growth of the single use technology metal bellow market

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the Single Use Technology Welded Metal Bellow market. In 2019, the market of Single Use Technology Welded Metal Bellow market has been consolidated by the top ten players – KSM USA, BOA Group, Technetics, AESSEAL, Senior Aerospace Metal Bellows, Metalflex, Duraflex, MIRAPRO, Flex-A-Seal, Hyspan, Weldmac, Bellows Tech

Buy Now

Acquisitions/Technology Launches

In August 2018, MW Industries announced the acquisition of Ameriflex Inc. MW Industries is amongst the major provider of highly engineered springs, specialty fasteners, machined parts, and other precision components which also includes metal bellows. Moreover, the acquisition has led to the expansion and formation of formed metal bellows and bellows assemblies which are used in the semiconductor, microelectronics, and aerospace industries.

For more Automation and Instrumentation Market reports - Please click here

#Single Use Technology Metal Bellow Market size#Single Use Technology Metal Bellow Market share#Single Use Technology Metal Bellow Market price

0 notes

Text

What Are The Grade 904L Stainless Steel Valves?

Stainless steel Grade 904L Valves are available with a variety of customization options, including size and thickness. There are several uses for these stainless steel 904L butterfly valves, including gas cleaning facilities and devices for ocean water cooling.

The Grade 904L Stainless Steel Valves sometimes referred to as a super austenitic alloy, are intended for use in circumstances where resistance to corrosion and pitting is recognized as a crucial quality. Compared to other types of valves, High Temp 904l UNS N08904 Ball Valves have greater contamination resistance.

Applications Of 904L Stainless Steel Valves

Buy High Quality of SS 904L Cryogenic Valves, Alloy 904L Compression Ball Valves, Stainless Steel 904L Check Valves, DIN 1.4539 SS Port Conduit Valves, and ASTM A494 Stainless Steel 904L Pressure Reducing Valve, Offer the Best Price on a range of SS 904L Pinch Valve, 904L SS Sluice Valves Dealers. Grade 904L Stainless Steel Bellow Seal Valve Distributors in India

Characteristics Of 904L Stainless Steel Valves

Stainless Steel 904L Piston Valves, Stainless Steel 904L Non-Return Valve, Stainless Steel 904L Severe Service Control Valves, SS 904L Valve Lockouts, SS 904L Process Interface Valves, SS 904L Gauge Valve, SS 904L Float Valves Manufacturers, SS 904L Trunnion-Style Ball Valves Exporters, UNS N08904 SS 904L Double Locking Check

Ball valves made of stainless steel 904l are some of the least often used valves. The stainless steel 904l ball valves, sometimes referred to as a super austenitic alloy, are intended for usage in situations where corrosion and pitting resistance are crucial.

Reverse osmosis saltwater desalination, cleaning and decontamination cycling processes, etc. are only a few uses for 904L stainless steel valves.

0 notes

Photo

PTFE Bellow Provide safe passage of pipeline from the main glass equipment reduce the transfer of vibration from the rotation equipment connected to the glass assembly, Available in two, three and five convolution construction.

0 notes

Text

What are the industrial applications of Metal Belows?

Metal bellows:

Metal bellows expansion joints are available with a diverse collection of chemical and physical properties, in addition to a high level of tensile strength. When using a bellows machine to make metal bellows, one has the option of selecting from a number of different types of materials. Because of their varied uses, metal bellows can be made from a variety of materials, each of which brings its own set of benefits and features to the table.

No matter the sector, the bellows is an indispensable component that ensures the efficient functioning of a wide variety of apparatuses and systems. They are praised throughout an extremely diverse variety of industries for being the most malleable of tools. These spherical tubes will not expand or compress even when subjected to high pressure. Due to the fact that they are able to absorb a great deal of heat, they are able to tolerate a great deal of heat and continue to be in better condition than they were before for a considerable amount of time. Bellows can be made of a variety of materials, including plastic, rubber, steel, or fibre, depending on their intended application. Noble Glass Works is an excellent PTFE high pressure bellows supplier in India.

Metal bellows can expand to dampen vibration and movement while high-temperature materials, such as exhaust gases or electricity, are transported through them. This allows the bellows to withstand higher temperatures. Additionally, they have a wide variety of other applications, such as. Regulation, in addition to the movement of earthquakes. Bellows are an indispensable component of any operation that requires great performance as well as high pressure. They are also wonderful for reducing the amount of garbage and by-products produced. You will require components such as liners, covers, particle barriers, and perimeter bars in order to extract the most amount of value from your bellows.

Industrial Applications:

Metal bellows are frequently used in the mechanical and hydraulic fields of engineering. Because the bellows are filled with known liquid, the liquid is either compressed or expanded as temperatures rise and fall. The expansion of the liquid will take place in a manner that can be reasonably anticipated. A machine assembly's precise positioning can be accomplished with the assistance of bellows and the response percentage, both of which can be adjusted. In a mechanical activity, a pressure change that is equal to thermal activation can be used to achieve the same results as compressing or adjusting the extension of the bellows. If you are looking for the best quality bellows, Noble Glass Works - one of the most reputed as well as noteworthy PTFE high pressure bellows manufacturers in India can fulfill all of your requirements.

The use of bellows in the rotating display is a creative and unique application. Because their primary axis is flexible, the bellows that are attached to the ends of the waves, along with the waves that are not precisely aligned or linear, as well as variations in radial or angle, can be used as a coupling or an indicator of rotation.

The bellows design is ideal since it solves the claw problem while still allowing for the transmission of rotational energy. Be sure that these bellows are encoded before using them because the accuracy of the rotation is of the utmost importance.

Metal bellows are required for all electrical applications, including valve seals, positive displacement pumps, volume and fluid compensation, and volumetric control. It is well knowledge that metal bellows can prevent leakage without the need of seal rings, which are superfluous.

There are hydropneumatic accumulators installed along with the metal bellows helping to separate the compressible gas cushion from the working fluid in oil and gas sector metal bellows accumulators. Bellows or metal bellows are used as the separating element.

Metal Compensators (MEJs), often known as metal bellows, are a type of mechanical device. Expansion joints / bellows elements are made up of many folds in a series to sustain internal pressures in a piping system. Equipment like pumps, traction fans and compressors can all experience thermal expansion and mechanical vibration; yet the materials used must be flexible enough to allow for these deflections as well as other types of motion.

Compression movements as well as Axial expansion are absorbed by axial compensators. If you use axial displacement in both extension as well as compression directions, it will provide the longest life.

1 note

·

View note

Text

PTFE high pressure bellows manufacturers in india | Nobleglassworks

Noble Glass Works is an excellent PTFE high pressure bellows supplier in India. Our continuous interaction with customers have benefited and helped us to upgrade in our inhouse engineering infrastructure to cater to their requirements and to provide state-of-art facilities and human resources. The growing use of borosilicate glass as a material of construction is a direct result of the following properties when compared to other materials of construction.

If you are looking for one of the distinct PTFE high pressure bellows manufacturers in India, Noble Glass Works is the best pick for you.

Address:

E-52/1, Sardar Industrial Estate,

Ajwa Road, Vadodara.

Pincode - 390019, Gujarat, India.

Email_ID - [email protected]

Mo: +91 9904406603

Website URL: https://www.nobleglass.in/

[All Social Media Platform With Link]:

Youtube : https://www.youtube.com/channel/UC1_x0uenwaKqLYuISbVn8CQ

Facebook : https://www.facebook.com/nobleglass.in/

Twitter : https://twitter.com/nobleglass_in

Instagram : https://www.instagram.com/nobleglass.in/

1 note

·

View note

Text

The Metals Factory

The Metals Factory is an ISO certified and PED approved professional and international manufacturer, supplier and exporter of stainless steel, aluminium, nickel alloys, carbon steel and alloy steel products. With a collective experience of over 30 years, we have emerged as one of the largest just in time exporter of steel and aluminum products. Our range of products includes steel plates, rods, bars, angle, channels, steel pipe and tube, forged flange and fittings, elbow, tee, reducer, stub end, gaskets, fasteners, valves etc. We are devoted to provide the best solutions for steel materials and industrial equipment for our respected customers. We have manufacturing set up, sales and export offices in both India and China to meet the immediate and long term steel and aluminium product requirements across the globe.

Our stainless steel pipe and carbon steel pipe products are designed and manufactured in compliance with international standards and are appreciated for their sturdiness, precise dimensions, durability, finish and corrosion resistance. They are available in distinguished sizes, dimensions and thicknesses to cover the requirements of various industries like power plants, automobile, heavy engineering, offshore and chemical.

In addition to being a manufacturer of seamless pipes and welded steel pipes, we are also one of the biggest stainless steel plate and aluminum plate processing center in India. We are a leading stockholder, processor and supplier of high quality stainless steel plates, stainless steel sheets, stainless steel coils, stainless steel strips, alloy steel plates, special alloy plates, mild steel plates, mild steel coils, hot rolled coils, hot rolled plates, cold rolled coils.

We supply not only commonly used carbon steel and stainless steel materials (SS304/L, SS316/L, SS321), but also duplex and super duplex steel 1.4547, 1.4462, 1.4410 (S31254, S31803, S32750, S32760), and special austenite stainless steel such as 310S, 347H, 317L, 904L.

Some of our important & key products include the following:

1) Aluminium sheets, plates and coils in size range of 0.2mm to 350mm in Alloys 1050, 1060, 1070, 1080, 1100, 1200, 3003, 3105 and 8011. We are also one of the leading suppliers of 5052, 5083, 5086, 6061, 6082 and 7075 plate, and sheet products. Other products available in Aluminium alloys include bar and rods, seamless tubes, buttweld fittings, flanges and aluminium blocks for CNC machining.

2) Stainless steel sheets, plates and coils in size range of 0.2mm to 80mm in SS 304/L, SS316/L, SS321, duplex and super duplex steel, 310S, 347H, 317L, 904L. We offer stainless steel products in various forms including stainless steel pipes, stainless steel rods, stainless steel forgings, stainless steel large diameter pipes, stainless steel pipe fittings and flanges.

3) Carbon steel plates are available for sale in size range of 6mm to 200mm in custom widths and lengths, especially boiler quality plates, pressure vessel steel plates, abrasion resistant steel plates, and high tensile plates.

4) Stainless steel flexible hose pipes and bellows in sizes from 1/4” to 12” in custom lengths with various types of end connections such as flanges, female or male nuts, nipples, adaptors, camlock couplings, quick release couplings etc.

5) Carbon steel seamless pipes available in size range of 1/2’’~24’’NB, carbon steel ERW pipes available in sizes 1/2’’~40’’NB, while LSAW and Spiral welded steel pipes are available in size range of 18’’~72’’NB

6) Stainless steel pipes are available in various grades such as SS 304/L, SS316/L, SS321, duplex and super duplex steel, 310S, 347H, 317L, 904L, Stainless steel seamless pipes are available in size range of 1/2’’~24’’NB, while stainless steel ERW and Fabricated pipes are available in sizes 1/2’’~40’’NB.

Various piping system related pipes fittings, fasteners, gaskets and flanges are available in carbon steel, stainless steel, nickel alloys and alloy steel grades. We manufacture and supply buttweld pipe fittings, forged fittings and flanges in size ½” to 60”.

1 note

·

View note

Text

A Guide to Understanding and Applications: Bellows Manufacturers in India

Introduction

Metallic bellows are essential components used in various industrial applications, providing flexibility, reliability, and precision in dynamic environments. DMA Bellows, a leading Bellows Manufacturers in India in the industry, has been at the forefront of producing high-quality metallic bellows for a wide range of sectors. In this comprehensive guide, we will explore the principles, materials, manufacturing processes, and applications of metallic bellows offered by DMA Bellows.

What are Metallic Bellows?

Metallic bellows are flexible, accordion-like structures designed to accommodate mechanical motion while maintaining a hermetic seal or controlling the flow of fluids or gases. They consist of a series of convolutions that expand and contract with the application of pressure, thermal changes, or mechanical forces. DMA Bellows offers metallic bellows made from various materials, including stainless steel, nickel alloys, and other specialised metals, ensuring compatibility with different environments and operating conditions.

Design and Manufacturing Process

DMA Bellows employs cutting-edge engineering techniques and state-of-the-art manufacturing processes to produce high-quality metallic bellows. The design process involves careful consideration of the application requirements, such as pressure range, temperature fluctuations, chemical compatibility, and desired life cycle. Once the design is finalised, the manufacturing process begins with the selection of suitable materials, followed by precision forming and welding techniques to create the convoluted structure.

Materials

DMA Bellows offers a wide selection of materials to cater to diverse applications. Stainless steel bellows are commonly used in general industrial applications due to their excellent corrosion resistance and durability. For extreme temperature or corrosive environments, nickel alloys like Inconel or Hastelloy are preferred. Additionally, specialised coatings can be applied to further enhance the bellows' performance and extend their lifespan.

Advantages of Metallic Bellows

Flexibility: Metallic bellows can accommodate axial, lateral, and angular movements, making them ideal for applications where traditional mechanical seals or joints may fail.

Hermetic Sealing: DMA Bellows' metallic bellows are designed to provide a leak-tight seal, preventing the ingress of contaminants and ensuring a controlled environment.

High Pressure and Temperature Resistance: With appropriate material selection, DMA Bellows' metallic bellows can withstand extreme pressures and temperatures, making them suitable for demanding applications.

Vibration Damping: Metallic bellows can absorb and dampen vibrations, reducing stress and wear on connected components.

Longevity: Properly designed and manufactured metallic bellows from DMA Bellows have a long service life, resulting in reduced maintenance costs and downtime.

Applications of Metallic Bellows

Aerospace: In aircraft and spacecraft, metallic bellows are used in fuel systems, engine thrust vector control, and environmental control systems.

Chemical Processing: Metallic bellows are employed in pumps, compressors, and expansion joints in chemical processing plants to handle corrosive and high-temperature fluids.

Medical Devices: DMA Bellows' metallic bellows find applications in medical devices such as ventilators, anaesthesia machines, and surgical equipment.

Nuclear and Power Generation: Metallic bellows are crucial components in nuclear reactors and power generation plants for reactor control systems, steam turbine connections, and exhaust systems.

Semiconductor Industry: Vacuum-sealed metallic bellows are utilized in semiconductor manufacturing equipment to control gas flows and maintain a clean environment.

Automotive: In automotive exhaust systems, metallic bellows help accommodate thermal expansion and reduce stress on exhaust components.

Conclusion

DMA Bellows, Bellows Supplier in India unmatched reliability and precision in diverse industrial applications. With their flexibility, hermetic sealing capabilities, and resistance to high pressure and temperature, these bellows play a critical role in ensuring the efficient operation of various systems. From aerospace and chemical processing to medical devices and power generation, DMA Bellows' expertise in manufacturing metallic bellows continues to drive innovation and enhance performance in industries worldwide.

In addition, they provide,

Rubber Expansion Bellows Manufacturer in India

Clamshell Bellows Manufacturer in India

Tank Farm Bellows Manufacturer in India

Instrument Bellows Manufacturer in India

Crossover Piping Bellows Manufacturer in India

Externally Pressurised Bellows Manufacturer in India

1 note

·

View note

Text

Stainless Steel Hose Fittings - in Bangalore

Stainless Steel Hose Fittings - in Bangalore

INTRODUCTION:

Quality Flexibles is one of the leading Manufacturers, of Satainless Steel Hose , SS BELLOWS , P.T.F.E, Silicone, Rubber, Industrial, Thermoplastic Hose Assemblies & Accessories . We direct all our activities to cater the expectations of customers by providing them excellent quality products as per their gratifications. Moreover, we follow moral business policies and crystal pure transparency in all our transactions to keep healthy relations with the customers.

read also - https://www.qualityflexibles.com/stainless-steel-hoses/

STAINLESS STEEL HOSE SUPPLIER IN BANGALORE AND PAN INDIA - QUALITY FLEXIBLES:

Stainless steel hose is a flexible metal hose made from stainless steel that is used to carry liquids or gases. It is often used in applications where a regular rubber or plastic hose would not be able to withstand the temperature or pressure of the liquid or gas being transported. Stainless steel hoses are also resistant to corrosion and can be used in many different industries, including automotive, industrial, and medical.

Stainless Steel Hose Fittings - in Bangalore :

Stainless Steel Hoses are flexible and resistant tubes made of stainless steel which protects internal materials against corrosion, heat, wear and tear, and external pressure.

What is Stainless Steel Drainage System?

The purpose drainage system of any location such as commercial and industrial is to drain out all the impure or waste water and harmful substances from internal structure to the main sewage system of the area.

Through Drainage system, sewage or waste water is collected, transported through various drainage parts and components and dispose it through outlet connecting main sewer pipe or gutter in the vicinity.

Are flexible plumbing hoses any good?

Flexible hoses are very versatile and significantly reduce the time it takes to hook-up hot and cold water pipe appliances, such as taps, dishwashers and water heaters.

It generally works with the help of gravity from downward slope of the structure through large diameter pipes and sewage gutters.

What is stainless steel hose for?

It is ideal for attaching pipes for instant water heaters, washbasins, low tanks, solar water heaters, etc. Non-weld general-purpose union type braided flexible hose. General purpose: Features a union fitting for absorbing displacement. A non-weld all-stainless steel union type flexible hose.

KIND OF STAINLESS STEEL HOSES AND THERE USE

There are multiple kinds of categories that come in the market when we talk about stainless steel hoses/Flexible metal hoses/Flexible steel pipes. Even sometimes there are names of a single flexible that are different in different sectors. Here are some main classification that we also manufacture and supply.

SS HOSES:

SS hose, or stainless steel hose, is a flexible metal hose made from stainless steel. It is used in a variety of applications where a strong, durable and heat–resistant hose is needed. Common uses for SS hose include hot water and steam lines, exhaust systems, and industrial vacuum cleaners.

CORRUGATED HOSES:

Corrugated hoses are flexible tubes that are made from a variety of materials such as rubber, plastic, metal, and fabric. They are used in a variety of applications including automotive, industrial, and medical. Corrugated hoses are designed to be flexible and resistant to kinking or collapsing when pressure is applied. They can also be used to protect wires and cables from abrasion or damage.

BRAIDED HOSES:

Braided hoses are flexible hoses that consist of multiple layers of reinforced material, such as rubber, metal, or synthetic fibers. They are typically used in applications where high pressure and temperature are present. Braided hoses are often used in plumbing and automotive applications, as well as for industrial machinery.

STEAM HOSES:

Steam hoses are specialized hoses designed to handle the extreme temperatures and pressures found in steam applications. They are typically made from reinforced rubber or thermoplastic and are designed to withstand high temperatures, abrasion, corrosion, and other harsh conditions. Steam hoses are used in a variety of industries including food processing, chemical processing, and power generation.

SS BELLOW HOSES:

Ss bellow hoses are flexible metal hoses that are used to absorb vibration, misalignment, and thermal expansion or contraction in piping systems. They are made of stainless steel and are often used in applications where corrosion resistance is important. There is a specific section for SS bellow hoses. Kindly click the link from the products section or click here for SS bellows. It is one of most selling section.

METAL HOSES:

Metal hoses are flexible tubes made of metal that are used to transport liquids and gases. They are often used in applications where a high degree of flexibility is required, such as in plumbing, automotive, and industrial applications. Metal hoses can be made from a variety of metals, including stainless steel, aluminum, copper, and bronze. Check this page for complete info on metal hoses and types.

read more for more info - https://www.qualityflexibles.com/stainless-steel-hoses/

0 notes