#PTFE high pressure bellows manufacturers in India

Text

Elevating Home Efficiency with Mcneil Instruments - India's Top Hose Pipe Manufacturer

Introduction:

Hose pipes function as essential pipes that guarantee the smooth flow of water and other necessary liquids in every home. As the leading hose pipe manufacturer in India, Mcneil Instruments' dedication to quality is evident in the variety of goods we offer.

From hydraulic hoses to industrial hoses, SS corrugated hoses to PTFE hoses, and bellows, our offerings cater to diverse needs with uncompromising quality.

Types of Hose Pipes:

1. Hydraulic Hose: Hydraulic hoses are crucial in hydraulic systems and are designed for high-pressure applications offering flexibility and durability.

2. Industrial Hose: Industrial hoses are versatile and used in various industries for conveying fluids, chemicals, and gases.

3. SS Corrugated Hose: Made of stainless steel, SS corrugated hoses are flexible and resistant to pressure, ideal for conveying liquids and gases.

4. PTFE Hoses: PTFE hoses, made of Teflon, are chemical-resistant and can withstand extreme temperatures, enhancing the durability of piping systems.

5. Bellows: Bellows are used to absorb vibration and expansion in piping systems, ensuring smooth operation and longevity.

Pros and Cons of Hose Pipes:

Pros:

Versatility: Hose pipes can be used in various applications, from household to industrial settings.

Flexibility: Hose pipes offer flexibility, allowing for easy installation and maneuverability around obstacles.

Durability: High-quality hose pipes, like those manufactured by Mcneil Instruments, are durable and long-lasting, reducing the need for frequent replacements.

Safety: With features like anti-static and flame resistance, hose pipes ensure safety in various environments.

Cons:

Vulnerable to Damage: Hose pipes may be susceptible to damage from sharp objects or heavy loads, requiring regular inspection and maintenance.

Limited Temperature Range: Some hose pipes may have limitations in terms of temperature range, affecting their suitability for certain applications.

Uses of Hose Pipes:

1. Residential: Hose pipes are essential in homes for activities such as watering plants, washing cars, and filling swimming pools.

2. Industrial: In industries like manufacturing, construction, and agriculture, hose pipes are used for fluid transfer, ventilation, and equipment operation.

3. Commercial: Commercial establishments like restaurants, hotels, and hospitals utilize hose pipes for sanitation, food processing, and HVAC systems.

4. Automotive: In the automotive industry, hose pipes are used for coolant systems, fuel lines, and air conditioning.

Conclusion:

At Mcneil Instruments, we take pride in being India's premier hose pipe manufacturer, offering top-quality products tailored to meet diverse needs. Our range of hose pipes, including hydraulic hoses, industrial hoses, SS corrugated hoses, PTFE hoses, and bellows, are designed for durability, reliability, and safety. With our commitment to excellence and customer satisfaction, we aim to enhance home efficiency and productivity across industries. Trust in Mcneil Instruments for all your hose pipe needs and experience unparalleled quality and service.

0 notes

Text

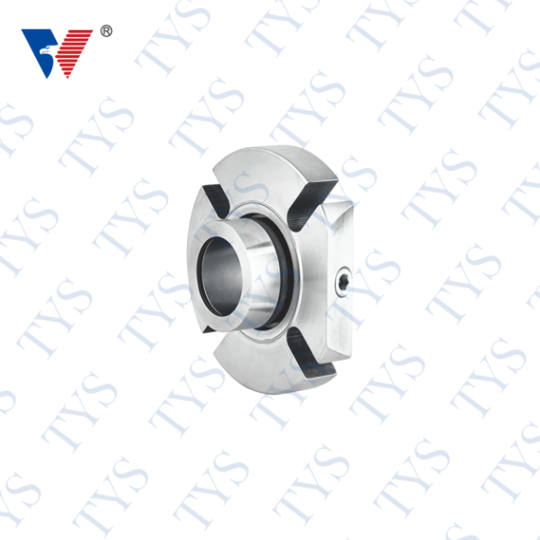

A Bellow Mechanical Seal may be a ring-type seal

Aspects of a Bellow Mechanical Closure

A Bellow Mechanical Seal may be a ring-type seal which is used to prevent leaks within a mechanical pump. This China Rubber Bellows Mechanical Seal Factory type of seal has a group of advantages, including its easy installation and adjustment. It is designed with regard to medium-to-high viscosity fluids and is suitable for plenty of operating conditions, including higher and low-temperature contents.

Ashish Seals is a ISO-certified manufacturing company throughout Mumbai, India that offers a bunch of Bellow Mechanical Seals. They are designed to deliver rugged durability and are suitable for a large number of applications, including chemical process pumps, sewage pumps, as well as water pumps. Ashish Seals producers these seals using SS 304 plus SS 316 materials. On the other hand, they can also end up being manufactured using materials rather than these materials as each customer requirements.

These mechanical seals can be easily installed, and normally require no measurements and also set screws. They furthermore don't damage sleeve or maybe shaft components, as there is no relative movement between the actual seal's rubber boot along with shaft. As a result, they're mostly used within waste water treatment crops.

Another type of Bellow Mechanical Seal can be a metal Bellow Seal. These seals are ideal for corrosive and high-temperature applications. Their metal lugs give positive mechanical drive in addition to protect elastomer bellows. They're also popular in pulp in addition to paper mills, oil pumps, dewatering pumps, and sewage penis pumps.

The Rubber Bellow Mechanical Seal is usually an extremely versatile unit. Designed to contain fluid in the glass-lined vessel, this type of close up can protect top entry drives when it comes to a pump or machine. Its unique design makes it possible for it to compensate intended for abnormal shaft run-out along with protect against fretting. Additionally it is comfortable to use and carries a large variety of software.

Unlike a mechanical bellow, which will requires two o-rings, a metal bellow mechanical seal requires one. It's not dynamic, so it may not be suited for high pressure applications. However, a PTFE o-ring can even be used. A PTFE encapsulated o-ring comes into play most sizes.

The BSIV(tm) series single cartridge Bellows are intended to provide excellent affordable sealing solutions. A bellow mechanical closure TYS T01 Cartridge Mechanical Seal double sealing depac 365 cartridge mechanical seal for agitator water pump is lightweight and includes a lower friction drag than the usual pusher seal. It also features superior face tracking as well as face loading. Furthermore, metal bellows mechanical seals reduce the chance of frictional heat.

0 notes

Text

What are the industrial applications of Metal Belows?

Metal bellows:

Metal bellows expansion joints are available with a diverse collection of chemical and physical properties, in addition to a high level of tensile strength. When using a bellows machine to make metal bellows, one has the option of selecting from a number of different types of materials. Because of their varied uses, metal bellows can be made from a variety of materials, each of which brings its own set of benefits and features to the table.

No matter the sector, the bellows is an indispensable component that ensures the efficient functioning of a wide variety of apparatuses and systems. They are praised throughout an extremely diverse variety of industries for being the most malleable of tools. These spherical tubes will not expand or compress even when subjected to high pressure. Due to the fact that they are able to absorb a great deal of heat, they are able to tolerate a great deal of heat and continue to be in better condition than they were before for a considerable amount of time. Bellows can be made of a variety of materials, including plastic, rubber, steel, or fibre, depending on their intended application. Noble Glass Works is an excellent PTFE high pressure bellows supplier in India.

Metal bellows can expand to dampen vibration and movement while high-temperature materials, such as exhaust gases or electricity, are transported through them. This allows the bellows to withstand higher temperatures. Additionally, they have a wide variety of other applications, such as. Regulation, in addition to the movement of earthquakes. Bellows are an indispensable component of any operation that requires great performance as well as high pressure. They are also wonderful for reducing the amount of garbage and by-products produced. You will require components such as liners, covers, particle barriers, and perimeter bars in order to extract the most amount of value from your bellows.

Industrial Applications:

Metal bellows are frequently used in the mechanical and hydraulic fields of engineering. Because the bellows are filled with known liquid, the liquid is either compressed or expanded as temperatures rise and fall. The expansion of the liquid will take place in a manner that can be reasonably anticipated. A machine assembly's precise positioning can be accomplished with the assistance of bellows and the response percentage, both of which can be adjusted. In a mechanical activity, a pressure change that is equal to thermal activation can be used to achieve the same results as compressing or adjusting the extension of the bellows. If you are looking for the best quality bellows, Noble Glass Works - one of the most reputed as well as noteworthy PTFE high pressure bellows manufacturers in India can fulfill all of your requirements.

The use of bellows in the rotating display is a creative and unique application. Because their primary axis is flexible, the bellows that are attached to the ends of the waves, along with the waves that are not precisely aligned or linear, as well as variations in radial or angle, can be used as a coupling or an indicator of rotation.

The bellows design is ideal since it solves the claw problem while still allowing for the transmission of rotational energy. Be sure that these bellows are encoded before using them because the accuracy of the rotation is of the utmost importance.

Metal bellows are required for all electrical applications, including valve seals, positive displacement pumps, volume and fluid compensation, and volumetric control. It is well knowledge that metal bellows can prevent leakage without the need of seal rings, which are superfluous.

There are hydropneumatic accumulators installed along with the metal bellows helping to separate the compressible gas cushion from the working fluid in oil and gas sector metal bellows accumulators. Bellows or metal bellows are used as the separating element.

Metal Compensators (MEJs), often known as metal bellows, are a type of mechanical device. Expansion joints / bellows elements are made up of many folds in a series to sustain internal pressures in a piping system. Equipment like pumps, traction fans and compressors can all experience thermal expansion and mechanical vibration; yet the materials used must be flexible enough to allow for these deflections as well as other types of motion.

Compression movements as well as Axial expansion are absorbed by axial compensators. If you use axial displacement in both extension as well as compression directions, it will provide the longest life.

1 note

·

View note

Text

PTFE high pressure bellows manufacturers in india | Nobleglassworks

Noble Glass Works is an excellent PTFE high pressure bellows supplier in India. Our continuous interaction with customers have benefited and helped us to upgrade in our inhouse engineering infrastructure to cater to their requirements and to provide state-of-art facilities and human resources. The growing use of borosilicate glass as a material of construction is a direct result of the following properties when compared to other materials of construction.

If you are looking for one of the distinct PTFE high pressure bellows manufacturers in India, Noble Glass Works is the best pick for you.

Address:

E-52/1, Sardar Industrial Estate,

Ajwa Road, Vadodara.

Pincode - 390019, Gujarat, India.

Email_ID - [email protected]

Mo: +91 9904406603

Website URL: https://www.nobleglass.in/

[All Social Media Platform With Link]:

Youtube : https://www.youtube.com/channel/UC1_x0uenwaKqLYuISbVn8CQ

Facebook : https://www.facebook.com/nobleglass.in/

Twitter : https://twitter.com/nobleglass_in

Instagram : https://www.instagram.com/nobleglass.in/

1 note

·

View note

Photo

PTFE Bellow Provide safe passage of pipeline from the main glass equipment reduce the transfer of vibration from the rotation equipment connected to the glass assembly, Available in two, three and five convolution construction.

0 notes

Text

Everything you need to know about Expansion Joints

Importance of pipeline expansion joints

Expansion joints are an essential component of a pipe system and are extensively used in industries where thermal expansion in pipe systems occurs. According to major expansion joints manufacturers, another of these units is in reducing stresses in pipe systems which are generated due to thermal expansion and reduce the pipe loads at joints to sensitive equipment such as steam turbines and pumps. All this helps in prolonging the life of pipe systems and decreases the chances of downtime that happens for extra maintenance and repair. Engineers always include expansion joints in the pipe systems because expansion joints bring additional flexibility into the design and decrease the costs by eliminating the complexity of fixpoints, hence reducing the overall space requirement for the pipe system. Moreover, expansion joints are much more efficient than alternatives like pipe loops and pipe bends because of their extra ability to conserve space, enhanced economic efficiency and efficient performance in absorbing movements. Expansion joints are also called an expansion bellows, flexible joints, and compensators.

A standard expansion joint consists of one or more metal bellows that are usually made up of stainless steel or from other materials such as rubber or plastic like PTFE. While materials like rubber and plastic have their limitations, metals are the most versatile of all materials. They can be utilized at high temperatures and have much greater strength.

Metallic expansion joints are designed to absorb the changes in sizes of steel pipe systems adequately. The changes can be expansion and contraction induced by heat, vibrations due to rotating machinery, pressure deformations or due to misalignment during installation.

The main part of the expansion joints is the bellow which is made up of a series of convolutions. They are designed to endure the internal pressure of the system but have enough flexibility to stand lateral, axial and angular deflections.

Uses of expansion joints

According to fasteners manufacturers in India, expansion joints are a vital component in many industries and are used extensively in industries like:

• The energy sector (power plants, district heating pipe systems, etc.)

• Steel manufacturing plants

• Petrochemical industry (oil refineries, oil rigs, pumping stations, etc.)

• Chemical industries

• Food processing plants

• Exhaust systems and engines

• Paper and pulp industries

• LNG/LPG/CNG tankers, carriers, etc.

Expansion joints are usually installed near boilers, heat exchangers, condensers, engines, pumps, turbines, and in long pipe systems.

0 notes

Text

Types of Borosilicate Glass Process Equipment in India

Looking for high quality borosilicate glass process equipment in India? Here is your answer! Ablaze Glass Works is a well-known borosilicate glass manufacturer in India offering glass process equipment for three decades now. For mass industrial supply to single piece, every order is catered with 100% commitment at Ablaze Glass Works. In this blog post, lets learn about Borosilicate Glass Process Equipment by Ablaze Glass Works that are ranked best in the market:

Valves

Ablaze Glass Works manufactures and delivers valves made of Borosilicate glass 3.3. Valves are available with PTFE bellow. These borosilicate valves are widely used in the chemical and pharmaceutical industries. Valves are further categorized based on overflow, monitor line flow and so on.

Vessels and Stirrers

Vessels by Ablaze Glass Works can be used as borosilicate glass reactors, glass vessel chemical reactors, receivers, separators and re-boilers. Vessels can also be used for measurement, storage and feed. They also manufacture many kinds of stirrers that usually comprise two parts namely a drive unit and stirrer shaft.

Pipeline and Column Component

Borosilicate glass pipeline components of Ablaze Glass Works have smooth surfaces, universal resistance, and transparency permit and can be easily cleaned. There is no risk of contamination in these pipeline column components among process equipment. Ablaze Glass Works also manufactures column components and its accessories in its process equipment segment.

Pressure Relief Valve

Pressure Relief Valves aim to protect reactors and thereby prevent accidents. These open automatically when system pressure exceeds pre-set value without any electrical power or control from outside. Pressure relief valves by Ablaze Glass Works are heat and corrosion resistant. Glass Pressure Relief Valves are part of process equipment in India.

If you need any or mass supply for borosilicate glass process equipment in India, contact Ablaze Glass Works now. Ablaze Glass Works has many more kinds of borosilicate glass process equipment listed on their website.

0 notes

Text

What is the difference between PTFE, FEP and PFA?

PTFE, FEP, and PFA are the most well-known and commonly utilised fluoroplastics. But what are the differences between them? Learn why fluoropolymers are unique and which fluoroplastic is suitable for your application.

The properties of fluoroplastics:

Fluoropolymers offer a number of unique characteristics that make them suited for a wide range of applications, including residential, medical, automotive as well as electrical.

Noble Glass Works is the most prominent and noted PTFE Lined Ball Valves manufacturer in India.

The properties:

● They can withstand extremely high temperatures,

● They have non-stick qualities,

● They are known to have a low friction surface,

● They have extreme resistance to solvents, chemicals, as well as electricity.

Different fluoroplastics have small differences, such as different working temperatures, and are suitable for different applications. When used effectively, fluoropolymers can give significant cost and performance benefits.

Noble Glass Works is a respected PTFE Lined Ball Valves manufacturer in Gujarat.

1. PTFE (Polytetrafluoroethylene):

The forefather of all fluoroplastics is polytetrafluoroethylene or PTFE. The most prevalent fluoropolymer is PTFE, which was discovered by chemist Roy J. Plunkett in 1938 and has the best temperature, chemical resistance, and non-stick properties.

Aside from the unique properties of fluoroplastics, PTFE stands out by providing the following benefits:

● It has the best price-performance ratio of any fluoroplastic, and it can work continuously at 260°C + temperature, which is the highest of any other fluoroplastic.

● It is chemically resistant, has strong non-stick characteristics, and is translucent in colour.

The fact that PTFE does not dissolve when heated is its primary disadvantage, making it difficult to process. Very uncommon methods are required to mould, extrude, and fuse this fluoropolymer.

PTFE is ideal for electronic component protection as well as electrical insulation due to its unique properties.

Noble Glass Works is one of the excellent as well as most reliable PTFE High Pressure Bellows manufacturers in India.

2. FEP (Fluoroethylenepropylene):

FEP is the melt-processable version of PTFE (Fluoroethylenepropylene). FEP is similar to PTFE in terms of properties, although it has a lower maximum operating temperature of +200°C. FEP, on the other hand, is easier to work with and can be welded and re-moulded into complex shapes.

In addition to the unique properties of fluoroplastics, FEP has the following advantages:

● It has a great potential for welding and re-moulding, and it can act without hesitation at temperatures ranging from -200°C to +200°C and cryogenic temperatures. FEP is highly resistant to chemicals and ultraviolet rays, and it is bio-compatible and clear in colour.

The low shrink temperature of FEP heat shrink allows it to be safely shrunk over objects that are temperature-sensitive without causing any kind of injury. As a result, FEP is a fantastic material for encasing sensitive electrical components and equipment.

If you are looking for the renowned and most prevalent PTFE Lined Ball valve manufacturer in India, Noble Glass Works is the right choice for you.

3. PFA (Perfluoralkoxy):

PFA, or perfluoralkoxy, is a high-temperature FEP derivative. PFA has similar properties to FEP, but because of its lower melt viscosity than PTFE, it can be used at temperatures up to +260°C and still be melt-processed.

In addition to the distinctive characteristics of fluoropolymers, PFA stands out by providing the following benefits:

● It has the same ability to work at 260°C+ as PTFE, and it has a high potential for welding and re-moulding.

● It has good permeability resistance, is chemically resistant even when working at high temperatures, is biocompatible, and has a clear colour.

The main disadvantage of PFA is that it is more costly than PTFE and FEP.

PFA is used in applications that require a higher purity grade, better chemical resistance, and a higher working temperature. Medical tubing, valve liners, pumps and fittings, semi-conductor baskets, as well as heat exchangers all use this fluoroplastic.

#PTFE Lined Ball Valves manufacturer in India#PTFE Lined Ball Valves manufacturer in Gujarat#PTFE High Pressure Bellows manufacturers in India#Nobleglasswork

1 note

·

View note

Text

5 common types of PTFE products

At room temperature, PTFE is a fluorocarbon (solid-state) because it is a high molecular weight polymer comprised entirely of carbon and fluorine. PTFE is used to treat pans and other equipment with a nonstick coating. Because of the strength of the carbon-fluorine bonds, it is often employed in containers and pipelines for reactive and corrosive chemicals. PTFE reduces friction, wear, and energy consumption in equipment when used as a lubricant. It's commonly used as a graft material in surgical procedures. It's also used as a catheter coating to prevent bacteria and other infectious agents from adhering to catheters and causing hospital-acquired infections.

Noble Glass Works is the most popular as well as distinct PTFE Lined Ball Valves manufacturer in Gujarat, India.

PTFE is made by polymerizing tetrafluoroethylene with free radicals. The formula is

n F2C=CF2 → −(F2C−CF2)n−

Because tetrafluoroethylene can disintegrate explosively into tetrafluoromethane and carbon, specific polymerization equipment is needed to minimise hot spots that could induce this harmful side reaction. The process is usually started with persulfate, which homolyzes to create sulphate radicals:

[O3SO−OSO3]2− ⇌ 2 SO4•−

Sulphate ester groups in the resultant polymer can be hydrolyzed to yield OH end-groups.

Noble Glass Works is an excellent and the most renowned PTFE lined ball valve manufacturer in India.

As a medium-sized international active firm, Noble Glass Works is recognised as a trusted and competent partner to all industrial groups. PTFE Bellows, PTFE Lined Sightflow Indicators, PTFE Bushes, PTFE O Rings, and PTFE Lined Ball Valves are among the products available.

Types of PTFE products:

1. PTFE O Ring:

Due to its low moisture absorption capabilities and wide temperature operating range, PTFE O Rings are utilised as gaskets in different applications where various chemical processes are required or in the glass fittings and also to seal the joints between Glass – Glass, Metal – Glass, or Metal – Metal connectors.

2. PTFE Bush:

PTFE is a widely used substance having a number of applications in a wide range of industries. The raw materials used to make these brushes are of the highest quality. T Bush made up of PTFE is also available.

3. PTFE Bellow:

In expansion joints, bellows, and compensators made from PTFE, the exceptional corrosion resistance of PTFE is paired with its remarkable flexing capabilities.

Because of the two PTFE qualities listed above, PTFE materials are acceptable for use with all chemical products and compensate for recurrent thermal expansion in pipes.

If you are looking for one of the most prevalent and trustworthy PTFE high pressure bellows manufacturers in India, Noble Glass Works is a reliable name that you can trust with your PTFE line product needs.

4. PTFE Lined Sight Flow Indicators:

Sight Flow Indicators are widely used in a variety of industries to measure pipe flow. Despite the fact that traditional Sight Flow indicators are beneficial in most sectors, metal bodies are incompatible with the process medium in specific applications.

5. PTFE Lined Ball Valves:

Various stainless-steel or Cast Ductile Iron grades are commonly used to manufacture the valve body. Corrosion-resistant polymers like PFA or FEP are used to completely line the wetted parts.

The self-adjusting packing in PTFE coated ball valves allows for maintenance-free spindle sealing. Even after extended usage, there are almost no backlashes in the stem and ball. The valve's performance is improved by the PTFE lining. To ensure that the liner is securely in place, slots are machined into the body, making it suitable for high vacuum operation.

#PTFE Lined Ball Valves manufacturer in Gujarat#PTFE lined ball valve manufacturer in India#PTFE high pressure bellows manufacturers in India#Nobleglasswork

1 note

·

View note

Text

What are the various Types of Sight Glass used in Industries?

A sight glass is an instrument used to see the oil inside a reservoir tank or machine. They are available in two basic types: bullseye and columnar, and may be used to monitor both oil levels and pollutants. Because all of these approaches allow air, moisture, and other impurities to enter closed systems, sight glasses offer an alternative to using a dipstick or simply opening a tank to look inside.

It's also important to think about the dangers of installing them. Outside tanks, columnar sight glasses are mounted, making them vulnerable to damage. This isn't a problem with Bullseye sight glasses, but you must be able to put them exactly or they'll give you erroneous readings.

Noble Glass Works is the most preferred and distinguished Tank sight glass manufacturer in India.

Types of Sight Glass:

Although almost every sight glass may be classed as either bullseye or columnar, there are a few differences to be aware of before determining which is best for your needs.

● Bullseye:

Drilling a hole in a tank at the top of the ideal oil level is used to attach a bullseye sight glass. After that, the sight glass is threaded into the hole, resembling a bolt with a glass head. When the machine is running, some have a line in the glass that displays where the oil level should be. One of the advantages of employing a bullseye sight glass is that it might aid in the detection of foam in your system. This normally occurs when there is water or other impurities present, so you can discover problems before they become serious.

If you are looking for the excellent and the most popular PTFE high pressure bellows manufacturers in India, Noble Glass Works is one of the most reliable names you’ll come across in the market.

● Columnar:

These are clear, vertical tubes that are positioned outside of tanks and allow you to see a greater sample of oil than bullseye sight glasses allow. They are, however, more difficult to install and are frequently put near the bottom of tanks, where they are vulnerable to damage. Another issue is that they tend to draw from the bottom of tanks, so when foaming is there, they don't usually show it. When compared to bullseye sight glasses, columnar sight glasses have the advantage of allowing you to indicate the correct oil levels for a machine while it is operating and idling. Bullseye glasses only show one of the two options.

● BS&W Bowls:

Bowls for bottom sediment and water (BS&W) are placed to the bottom of tanks and often include a magnet that attracts metallic impurities. Many of them also have a release valve for collecting oil samples. It's possible that these will be destroyed because they're positioned on the bottom of tanks, but most are much smaller than columnar choices.

Noble Glass Works is the most trustworthy and distinct glass flow indicator manufacturer in India.

● 3D:

This is a bullseye sight glass with a difference: instead of being flat, it expands outward from a tank. This allows you to examine the oil from different angles and allows light to pass through it, making it easier to see pollutants. The majority of these are composed of glass, acrylic, or polyamide and are designed to withstand high temperatures as well as pressures.

● Multifunctional:

These devices have a combination of functions seen in the preceding alternatives, as well as additional capabilities such as sight glass removal for cleaning and examination.

#Tank sight glass manufacturer in India#PTFE high pressure bellows manufacturers in India#glass flow indicator manufacturer in India.

1 note

·

View note

Text

Chemical Structure, Properties and Applications of PTFE Products

Polytetrafluoroethylene (PTFE) is a flexible, high-performance fluoropolymer made consisting of carbon and fluorine atoms that are widely utilised. The non-stick coating in kitchen cookware (pans, baking trays, etc.) is one of the most popular applications of this polymer, therefore you may easily find it in your kitchen.

PTFE is employed as a cost-effective solution in a variety of industries including chemical processing, oil and gas, electrical/electronic, industrial, as well as construction.

Noble Glass Works is the most popular and well-known PTFE Lined Ball Valves manufacturer in Gujarat.

PTFE (polytetrafluoroethylene) is a high-performance engineering plastic with the following characteristics:

● Chemically Inert & Non-Reactive to almost all chemicals

● Can resist upto 260°C temperature

● Non-adhesive and non-stick properties

● The exceptionally low friction coefficient

● Excellent Electrical Insulation properties

● Weather Resistant

Chemical processes, railways and defence sectors, thermal and automatic power plants, electrical and electronic industries, pharmaceuticals, and almost all industries employ PTFE Products due to their unique features.

Chemical Structure:

Poly Tetra Fluoro Ethylene is a non-branched linear polymer with the following chemical structure:

Because of the big fluorine atom, the PTFE molecule twists into a zigzag shape, with the fluorine atoms packed closely in a spiral around the carbon-carbon backbone. The dense interlocking of fluorine atoms produces a stiff PTFE molecule with a high crystalline melting point of 327°C, thermal stability, and electrical insulating qualities. The chemical inertness of the PTFE molecule is due to the strong and stable link between carbon and fluorine atoms.

Noble Glass Works is an excellent and trustworthy PTFE lined ball valve manufacturer in India.

Properties:

PTFE is available in both virgin and filled compounds to improve the basic qualities for a wide range of applications and end-uses.

Based on the required property for specified service conditions/applications, the grade of PTFE is chosen from the Virgin and Filled grades of PTFE. The handbook explains the different grades of PTFE and Filled PTFE, the filler content in PTFE, basic qualities, and important service conditions/end uses.

If you are looking for one of the most reliable PTFE High Pressure bellows manufacturers in India, Noble Glass Works is the name you can count on.

Applications:

PTFE goods are utilised in a variety of the sectors mentioned below as sealing and gasketing materials, electrical insulation products, antifriction components, anti-corrosive articles, anti-stick barriers, radiation barriers, inert and hygienic items, weathering-proof & non-water absorption materials.

● Chemical

● Adhesives Manufacturing

● Computer Hardware

● Valve Manufacturing

● Paper & Pulp

● Railways

● Pharmaceuticals

● Aviation & Aeronautical

● Petroleum

● Atomic Power Station

● Thermal Power Station

● Petrochemicals

● Electronics

● Fertilizers

● Space Station

● Electrical

● Pump Manufacturing

#PTFE Lined Ball Valves manufacturer in Gujarat#PTFE lined ball valve manufacturer in India#PTFE High Pressure bellows manufacturers in India

1 note

·

View note

Text

What are the applications of PTFE Products?

Because it is a high molecular weight polymer made completely of carbon and fluorine, PTFE is a fluorocarbon (solid-state) at room temperature. The nonstick coating on pans and other equipment is made of PTFE. It is commonly used in containers and piping for reactive and corrosive chemicals because of the strength of the carbon-fluorine bonds. When used as a lubricant, PTFE minimises friction, wear, and energy consumption in equipment. It's widely utilized in surgical treatments as a graft material. It's also commonly used as a catheter coating to keep bacteria and other infectious agents from sticking to catheters and triggering hospital-acquired infections.

Noble Glass Works is an excellent and noted PTFE Lined Ball Valves manufacturer in Vadodara.

As a medium-sized international active firm, Noble Glass Works is recognized as a trusted and competent partner to all industrial groups. PTFE O Rings, PTFE Bushes, PTFE Bellows, PTFE Lined Sight flow Indicators, and PTFE Lined Ball Valves are among the products available.

Types of PTFE products:

1. PTFE O Ring:

Due to its low moisture absorption capabilities and wide temperature operating range, PTFE O Rings are utilised as gaskets in different chemical process applications or in glass fittings and for sealing joints between Metal – Metal, Metal – Glass, or Glass – Glass connectors.

2. PTFE Bush:

PTFE is a versatile substance with several applications in a wide range of industries. For such bespoke applications, we offer the whole spectrum of PTFE Bush in a variety of Dimensions. The typical length is 100mm, but custom lengths are available on request. The raw materials used to make these PTFE bushes are made of the highest quality. Our production process assures great material uniformity in the finished PTFE Bush, assuring structural integrity. T Bush made of PTFE is also available.

3. PTFE Bellow:

In PTFE bellows, PTFE expansion joints, and PTFE compensators, the exceptional corrosion resistance of PTFE is paired with its remarkable flexing capabilities.

Noble Glassworks is one of the dominant and well-known PTFE High Pressure Bellows manufacturers in India.

4. PTFE Lined Sight Flow Indicators:

Sight Flow indicators are extensively used to monitor flow in pipes throughout industries. Metal bodies are incompatible with the process medium in some applications, despite the fact that classic Sight Flow indicators are useful in most industries.

Cast Ductile Iron or a range of stainless steel grades are commonly used for the body of a Flow Indicator. To thoroughly line the wetted parts, corrosion-resistant polymers such as FEP or PFA are utilised.

5. PTFE Lined Ball Valves:

Cast Ductile Iron or various stainless-steel grades are commonly used for the valve body. To thoroughly line the wetted parts, corrosion-resistant polymers such as FEP or PFA are utilised.

In PTFE coated ball valves, the self-adjusting packing enables maintenance-free spindle sealing. It has nearly no backlashes in the stem and ball, even after extended use. The PTFE liner improves the valve's performance. Slots are machined into the body to guarantee that the lining is securely in place, making it suited for high vacuum operation.

If you are looking for a distinct PTFE Lined Ball Valve manufacturer in India, Noble Glass Works is the right place for you.

Applications of PTFE Products:

● It's widely utilised in ski bindings as a non-mechanical AFD (anti-friction device).

● It can be stretched to contain microscopic pores of varied sizes, then sandwiched between fabric layers to make a waterproof, breathable fabric for outdoor wear.

● It's widely used as a stain-repellent fabric protector on formal schoolwear like uniform blazers.

● It's usually used to keep trapped insects and other arthropods from escaping.

● It's meant to provide strength and heat resistance to surgical instruments and other medical equipment, and it's utilised as a coating for medical and healthcare applications.

● It is utilised in high-friction sections of footwear, insoles, ankle-foot orthoses, and other sports and medical applications as a pressure-sensitive adhesive-backed film interface patch.

● PTFE is often found in lubricants for musical instruments, particularly valve oil.

● PTFE is found in some aerosol lubricant sprays, including micronized and polarised forms. It's known for its low coefficient of friction, hydrophobia (which prevents corrosion), and the dry coating that forms after application, which prevents particles from gathering and forming an abrasive paste.

● PTFE is well known for coating nonstick frying pans and other cookware since it is hydrophobic and has high heat resistance.

#PTFE Lined Ball Valves manufacturer#PTFE High Pressure Bellows manufacturers in India#PTFE Lined Ball Valve manufacturer in India#Nobleglasswork

0 notes

Text

How PTFE, FEP and PFA are different from one another?

The most well-known and widely used fluoroplastics are PTFE, FEP, and PFA. But what exactly are their distinctions? Learn why fluoropolymers are so special, and which fluoroplastic is best suited to your purpose.

The properties of fluoroplastics:

Fluoropolymers have various distinct features that make them suitable for usage in a variety of applications, including medical, residential, electrical, & automotive.

Noble Glass Works is the leading manufacturer & supplier of PTFE Lined Sight Flow Indicators in Gujarat, India.

The properties of Fluoroplastics are as follows:

● They can work at significantly high temperatures,

● They have non-stick properties,

● They have a low friction surface,

● They are highly resistant to chemicals, solvents as well as electricity.

Different fluoroplastics have subtle variances, such as varied working temperatures, and are appropriate for various purposes. Fluoropolymers, when used correctly, can provide good economic and performance benefits.

Noble Glass Works is a respected PTFE Lined Ball Valves manufacturer in Gujarat.

1. PTFE (Polytetrafluoroethylene):

Polytetrafluoroethylene, or PTFE, is the forefather of all fluoroplastics. PTFE, discovered by chemist Roy J. Plunkett in 1938, is the most uncommon fluoropolymer and has the best temperature, chemical resistance, and non-stick qualities.

In addition to the unique features of fluoroplastics, PTFE distinguishes itself by offering the following advantages:

● It gives the best price-performance ratio,

● It can work continuously at 260°C + temperature which is considered to be the highest among any other fluoroplastics,

● It is resistant to almost all chemicals,

● It has significantly high non-stick properties that even if a gecko tries to get on, it would slip),

● It is translucent in colour.

The fundamental disadvantage of PTFE is that it does not melt when heated, making it difficult to process. To mould, extrude, and fuse this fluoropolymer, very unusual procedures are required.

Because of its particular qualities, PTFE is perfect for electrical insulation and electronic component protection.

Noble Glass Works is an excellent and well-known PTFE lined ball valve manufacturer in India.

2. FEP (Fluoroethylenepropylene):

The melt-processable form of PTFE is FEP (Fluoroethylenepropylene). FEP has qualities that are quite similar to PTFE, but it has a lower maximum operating temperature of +200°C. FEP, on the other hand, is more easily processed and may be welded and re-moulded into intricate profiles.

FEP has the following advantages in addition to the special features of fluoroplastics:

● It has a high potential for welding as well as re-moulding,

● It can nonchalantly operate under temperatures ranging from -200°C to +200°C and under cryogenic temperatures, FEP remains super flexible,

● It is highly resistant to chemicals and Ultra-violet rays,

● It is bio-compatible and clear in colour.

Because FEP heat shrink has a low shrink temperature, it can be safely shrunk over temperature-sensitive objects without causing injury. As a result, FEP is an excellent material for encapsulating delicate electrical components and instruments.

Noble Glass Works is one of the most popular and distinguished PTFE high pressure bellows manufacturers in India.

3. PFA (Perfluoralkoxy):

Perfluoralkoxy, or PFA, is a high-temperature variant of FEP. PFA has similar qualities to FEP but, due to its lower melt viscosity than PTFE, may be employed at working temperatures of up to +260°C while remaining melt-processable.

In addition to the unique features of fluoropolymers, PFA distinguishes itself by offering the following advantages:

● It can continuously work at 260°C+ temperature just as PTFE,

● It has a high potential for welding as well as re-moulding,

● It has good resistance to permeability,

● It is highly resistant to chemicals even while working at high temperatures,

● It is bio-compatible and has a clear colour.

PFA's primary disadvantage is that it is more expensive than PTFE and FEP.

PFA is appropriate for applications requiring a higher purity grade, superior chemical resistance, and a high working temperature. This fluoroplastic is commonly utilised in medical tubing, heat exchangers, semi-conductor baskets, pumps and fittings, valve liners, and valve liners.

#PTFE Lined Sight Flow Indicators in Gujarat India#PTFE Lined Ball Valves manufacturer#PTFE lined ball valve manufacturer in India#PTFE high pressure bellows manufacturers in India#Nobleglass

0 notes

Text

Difference between Lined Ball Valves & an Unlined Ball Valves

Lined Ball Valves are a type of ball valve that consists of a body, stem, ball, seat, and lining.

The interior is totally lined with a high-quality PTFE or PFA lining material, and because of its thickness, it completely protects the valves from any chemical corrosion, making it a perfect choice for any harsh applications.

They are also called Shut Off valves because some manufacturers feature a free-floating ball design that facilitates Positive shut–off over the pressure range.

Noble Glass is the leading manufacturer of Sight flow indicator in India.

Difference between a Lined Ball Valve & an Unlined Ball Valve:

Lined ball valves perform the same duties as unlined valves but are a more cost-effective choice for chemical and severe corrosive applications that require long-term sealing and durability. They are long-lasting and dependable, even after numerous cycles, making them an excellent choice for shutdown and control applications.

Noble Glass is one of the most distinguished PTFE Lined Ball Valves manufacturers in India.

They may be installed without regard for flow direction and are suitable for automation since they have an ISO 5211 universal mounting pad that enables easy automation even with the valve in the pipeline. The stem design has an anti-blow out function to increase safety, and each lined ball valve has its own anti-static mechanism to defend against potentially deadly electrostatic discharges.

If you are looking for the best PTFE high pressure bellows manufacturers in India, Noble Glass is the name you can count on.

Some additional key benefits include;

● You can factory-assemble the Pneumatic actuators.

● Provides superior resistance for chemicals.

● Highly durable and thermal resistant.

Industry Sectors:

● Basic (Organic & Inorganic)

● Specialty (Fine & Consumer)

● Petrochemicals

● Downstream Processing

#Sight flow indicator in India#PTFE Lined Ball Valves manufacturers in India#PTFE high pressure bellows manufacturers in India#Nobleglass

0 notes

Text

Features of PTFE Lined Products

Noble Glass Works Pvt. Ltd. is one of the best industrial Glass equipment manufacturers in India, whose PTFE range has highest demand. PTFE products by Noble Glass Works Pvt. Ltd. include PTFE Lined Sight Flow Indicators, PTFE High Pressure Expansion Bellow, PTFE Lined Ball Valve, PTFE Lined Piping Components and more. In this blog post, we will be learning about the features of two of Noble Glass Works Pvt. Ltd. products - PTFE Lined ball valves and PTFE high pressure bellows.

Features of PTFE Lined ball valves

Noble Glass Works Pvt. Ltd is a PTFE lined ball valve manufacturer in India.

PTFE Lined Ball Valves

PTFE lined ball valves by Noble Glass Works Pvt. Ltd. has PFA or FEP lining including the wet parts. The body of the PTFE lined ball valve is made of cast ductile iron or various stainless-steel grades. Use of iron and steel makes the PTFE lined ball valves corrosion resistant. Popular industries that use PTFE lined ball valves are oil and gas, pharma, petrochemical, water treatment, pesticide, fertilizer, dyes, paper and pulp processing. Before delivery, every PTFE lined ball valve is tested BS EN 12266-1&2 (2003) – for best efficiency.

Noble Glass Works Pvt. Ltd. is a PTFE Lined ball valves manufacturer.

PTFE High Pressure Bellows

There are different types of PTFE High Pressure Bellows available at Noble Glass Works Pvt. Ltd. Used for managing misalignment in pipe structures, PTFE High Pressure Bellows are designed to reduce system stress. Noble Glass Works Pvt. Ltd. also offers heavy duty expansion bellow with reinforcement rings. Depending on requirement, you can also choose heavy duty expansion bellow with PTFE lining on wetted part only. PTFE High Pressure Bellows are widely used in pharmaceutical, chemical, petrochemical, agrochemical, food & beverages, petroleum, refinery process equipment, dyes and pigments industry.

For all kinds of requirements of PTFE lined products such as PTFE High Pressure Bellows, PTFE Lined Ball Valves and more, please contact at Noble Glass Works Pvt. Ltd. Noble Glass Works Pvt. Ltd is one of the best PTFE high pressure bellows manufacturers in India.

#ptfe lined ball valves manufacturer#PTFE lined ball valve manufacturer in India#PTFE high pressure bellows manufacturers in India

0 notes

Text

A Premier Supplier of PTFE Lined Products

When it comes to industrial operations, if you switch to the crappy gadgets or appliances, things won’t work the way they are expected.

That’s how managing every aspect makes sure you are aligning with what is highly sought in place.

Thus, have you been in any situation wherein you required the tool to get started any industrial operation?

In fact, are you a business owner who has to do a lot with a wide range of Lined Pipes, Fittings, Valves and other such customized products?

If this is what you are considering, this is the right guide for you.

We will do the best to ensure you have the best information available.

Do ensure to stick with the guide and let’s get started.

When it comes to manufacturing and supplying a wide range of Lined Pipes, Fittings, Valves and other such customized products, all you have got to look just at Ablaze Lining since they are a thought-leader, expert, including a leading manufacturer and supplier of Fluoropolymer Lined Pipes, Fittings and Valves. The amazing thing you will note is – They have been a successful partner with leading companies across the world. They know what it takes to working in corrosion resistant company. Therefore, whatever requirement you have got, just make sure to visit the website and fill in the contact form. This will make things a lot easier and advantageous.

Products they offer are:

Lined Pipe

Lined Elbow 45

Lined Elbow 90

Lined Equal TEE

Solid Spacer

Lined Spacer

Ball Valve

Ball Check Valve

Plug Valve

Full View Sight Glass

Thus, were you looking for the products that are designed in a way that can be used in highly corrosive applications?

If yes, the recommendation will do the best.

Final Thoughts

No matter if you need High Pressure Bellow Manufacturer in India or something, the thing that separates the recommendation than the others is the level of quality product they deliver.

On a sweeter note – Thanks for the read, though!

0 notes